Clarkson Knife Gate Valves Figure 955/956 Storage/Installation Instructions, Clarkson-EN Manuals & Guides

CLARKSON KNIFE GATE VALVES

FIGURE 955/956

Storage and installation instructions for F955 ported slide gate valves and F956 dual gland ported slide gate valves

STORAGE

IMPORTANT

Do not remove any identification or instruction

tags from the valve assembly.

For optimum protection, undercover storage is

desirable.

Valves

Flange faces should be protected at all times

with wooden, or heavy cardboard shields.

Valves should be handled carefully to prevent

damage to exterior protective coating. Flange

bolt holes should be coated with a suitable

rust inhibitor for prolonged or exterior storage.

Careshould be taken in the placement of valves

in storage to assure excessive pressure is not

placed on polymer body shrouds or spindle

covers so as to cause component damage.

F955 valves should be stored in the closed

position.

F956 valves should be stored in the open

position.

Handwheel spindle thread should NOT be

lubricated as dirt will accumulate in threads.

Actuators

All air line and electrical cable entries should

be plugged to prevent the ingress of foreign

material. Actuator cylinders, where not fitted

to a valve, should be stored with the piston rod

fully retracted. Internal cylinder components

should not require any corrosion inhibitor as

they are assembled with a light coating of

grease.

INSTALLATION INSTRUCTIONS

Heavy valves will require a chain block

or crane to assist in the installation.

Indifficultinstallations, large actuator

cylinders may be removed from the valve

andre-fitted after installation. When re-fitting

the actuator cylinder care must be taken

to ensure the cylinder/valve alignment is

maintained (refercylinder fitting instruction

sheet). Largeractuated valves installed in

vertical pipework will require structural

support to takethe weight of the actuator.

Thissupportmay also be desirable in larger

valves installed in non-vertical positions.

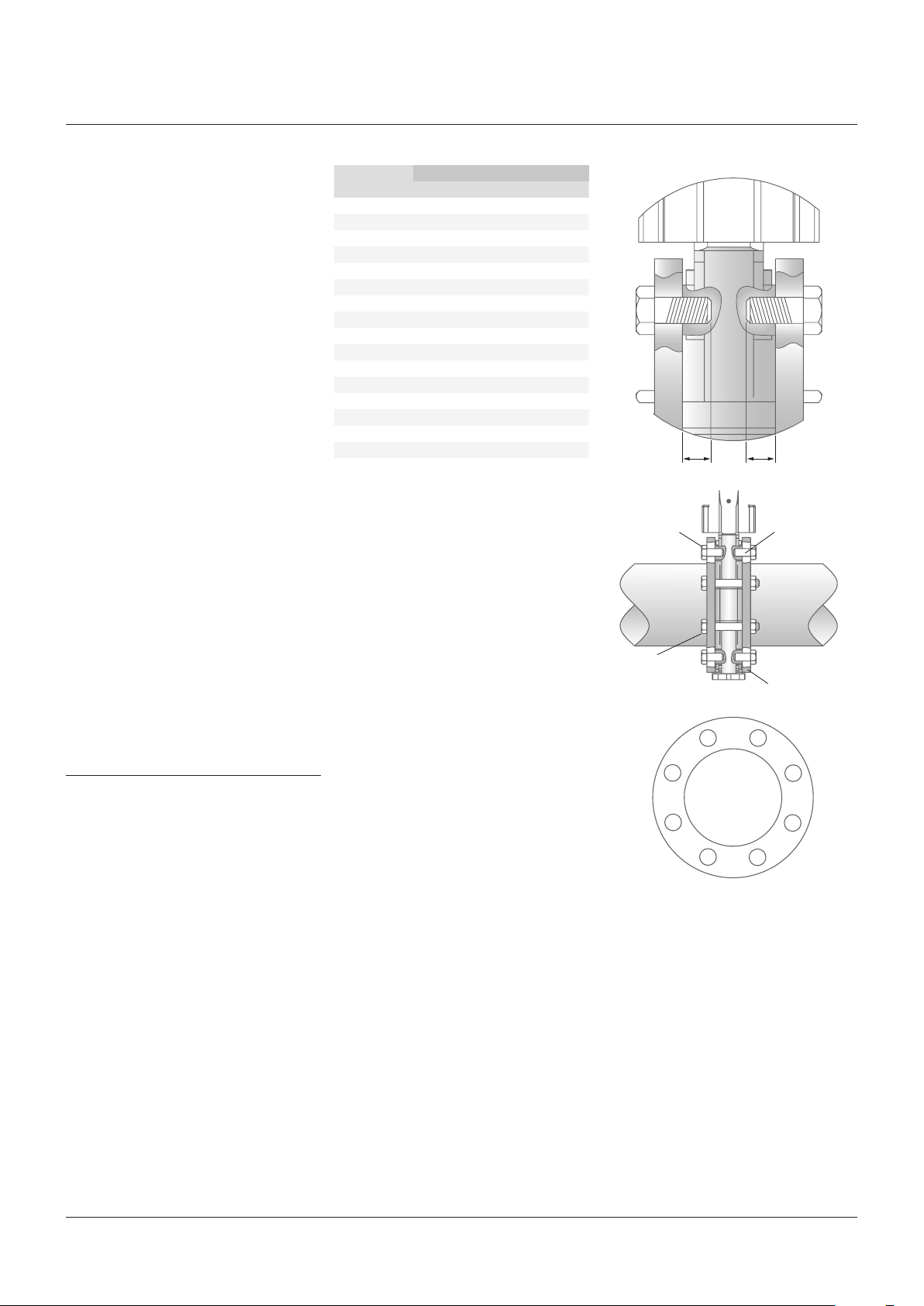

The F955/F956 is configured for installation

in conventional bolted flange connections.

Flanges are required to support the seat by

presenting a flat surface across the seat. If

the flange does not present a flat surface

then companion flanges can be used. The

companion flanges should be raised or flat

face type to ensure full sleeve support and a

continuous, unvarying I.D. If slip-on flanges

are used without companion flanges, the pipe

should be cut square and welded in position

with the pipe end matched evenly with the

flange face. (see below diagram)

A B

SAFETY PRECAUTIONS

Actuated valves are generally operated from

aremote location.

Caution should be exercised when working in

close proximity to these valves. The F955/F956

valves are supplied with upper body shrouds

and spindle covers for environmental and safety

purposes.

To ensure the long term operation and safety

of the valves, the covers and shrouds must be

maintained at all times.

CAUTION

Care must be taken with the installation of the

F955/F956 valve to resilient faced companion

flanges. Excessive tightening of the flange bolts

will result in severe valve seat damage on valve

actuation. Companion flange bolts must only be

tightened asnoted below.

1. Close valve.

2. Check the valve size is correct and there

isadequate clearance to install the valve.

3. Check valve and pipe flange faces are clean

and smooth, and that the valve bolt pattern

is the same as the flange.

4. Check flange bolt sizing and ensure the bolt

threads are clean (separate technical data is

available).

5. Check the alignment of the upstream and

downstream pipes and the squareness

ofthe pipe flanges.

Spare parts

Seats, cord and packing should be carefully

stored and protected from sharp edges or

heavy objects which could damage sealing

faces.

TYPICAL VALVE INSTALLATION WITH

SCHEDULE 40 PIPE SHOWN.

A) Example of incorrect installation:

Void area of pipe flange/pipe connection

does not support seat sufficiently. Fillet weld

between pipe and flange shown creates this

void area. Thin walled pipes can also fail to

support seats.

B) Example of correct installation:

The inside diameter of the pipe/flange is

Schedule 40 pipe inside diameter or less. The

pipe/flange presents a flat face to the seat.

© 2017 Emerson. All Rights Reserved.valves.emerson.com VCIOM-02872-EN 19/09

CLARKSON KNIFE GATE VALVES

FIGURE 955/956

NOTE

If rubber coated pipe flanges are being used, the steel

flange rings (minimum thickness of valve DN 50 - 200

(NPS 2 - 8) of 3 mm (0.12 inches) and DN 250 - 750

(NPS 10 - 30) of 5 mm (0.20 inches)) must be fitted on

both sides of the valve and ensure correct opperation

of seats.

6. Do not use flange gaskets with these valves

as the seats form the seals.

7. Spread pipe flanges to clear valve, lower

valve into position taking care to prevent

damage to the valve seat flange as the valve

is being lowered.

8. Liberally coat all flange bolt threads with an

effective rust inhibitor/anti-seize compound,

and install all flange bolts. Tighten bolts

in a diagonally opposed sequence (see

Figure2) to assure even tightening of the

flange faces. Ensure bolts in the chest

area of the valve is not bottoming out in the

blind holes. If the valve is being installed to

resilient faced flange(s) care must be taken

to assure the flange bolts are only tightened

sufficiently to allow the resilient facing to

contact the machined valve body face.

9. Ensure the valve flushing system is

operational prior to cycling the valve with

process pipeline media's.

10. Cycle the valve several times, checking for

correct valve operation.

11. After pressurisation of the pipeline, check

flanges and gate gland packing for leaks.

Adjust if necessary.

12. Ensure upper body shrouds and spindle

covers are in place.

FLANGE BOLTS

CAUTION

It is critical that flange bolts do not bottom out in

the valve body tapped holes, as this could cause

damage to the valve chest area. Stud bolts can be

used in blind holes to alleviate the risk of flange

bolts bottoming out.

BODY FLANGE TAPPING DEPTH

Valve size Dimensions 'R'

DN (NPS) mm inches

50 (2) 12 ½

65 (2½) 12 ½

80 (3) 12 ½

100 (4) 12 ½

125 (5) 15

150 (6) 15

200 (8) 18 ¾

250 (10) 12 ½

300 (12) 16 ⅝

350 (14) 16 ⅝

400 (16) 22 ⅞

450 (18) 35 1⅜

500 (20) 32 1¼

600 (24) 30 1⅛

700 (28) 27 1

750 (30) 32 1¼

FIGURE 1

9

/

16

9

/

16

Flange

Flange

Valve

1

/

16

R

R

Blind holes

Bolt

in chest area

Bolts for

waferflanges

1

8

6

4

Pipe flange

3

5

7

2

To determine the bolt length for the blind holes

in the flange bolting , add the width of the mating

flange, + any washers to dimension 'R'.

Coating the flange bolt threads with an anti-seize

compound (e.g. Loctite 729) is recommended to

prevent bolt seizure.

2

CLARKSON KNIFE GATE VALVES

FIGURE 955/956

FLUSHING PORTS

CAUTION

Valves should be isolated prior to flushing, as valve

operation during flushing,

cause the discharge of pipeline media through the

flushing ports at full pipeline pressure.

Valves are provided with flushing ports

to enable the valve body to be cleared of

sedimentation or debris which could impair

valve operation. The provision of a suitable

flushing system to each valve is imperative to

assure proper valve operation.

The type of flushing system employed will need

to be decided by site/project personnel with

due regard to such factors as, services

available, pipeline media, solids content,

service duty, and individual site considerations.

Please contact our Emerson sales/engineering

centres for recommendations on suitable

systems.

NOTE

It should be noted that the use of 'positive flushing' is

mandatory for valves used for line media’s containing

hard gravel like solids.

Manual flushing

With the valve in either the open or closed

position, the flushing port plugs may be

carefully removed (see caution note above).

Apply a strong pressurized stream of fluid to

each port

the opposing port. When body is cleared, refit

port plugs.

Waste flushing

Flushing plugs may be removed from the

ports and permanent pipework installed to

each port to direct pipeline media, lost during

valve cycling, to a collection point or to waste.

Additional valving may be installed in this

pipework to limit the velocity and/or duration

ofthe media discharge.

allowing the discharge of debris from

or defective seats, may

Positive flushing

Pipework may be attached to the flushing

ports to supply the lower valve body with line

compatible fluid at a pressure significantly

above that of the pipeline.The flushing

supply system must also be capable of a

volumetric delivery suitable for this application.

Theflowofflushing media into the main

pipeline during valve actuation both minimizes

the amount of debris and sedimentation in the

lower bucket, and also clears larger pipeline

solids from the seat area for valve re-opening.

Someperiodic flushing of the lower bucket will

still berequired to clear sedimentary solids.

Automatic flushing

Additional valving and pipework may be

installed to the flushing ports to supply flushing

media to one of the flushing ports and a drain

facility to the other. The flushing system may

then be activated by a control system during

valve cycling.

Gland adjustment

Gate gland adjustment on new or rebuilt valves

should be checked on valve installation to the

pressurized pipeline. If leakage occurs, tighten

each adjustment nut evenly until the leak

subsides. If leakage persists check that the

valve is not being subjected to line pressures

above that of its pressure rating, orthat

the packing may be damaged, incorrectly

installed or contaminated with foreign matter

(refergland packing instruction sheet).

CAUTION

Do NOT over tighten gland packing as this will

impede valve operation and cause premature

gate/packing wear.

3

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Clarkson is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

Loading...

Loading...