STAIR JIG

STAIR JIG

Model No: CSJ100

Part No: 6462120

OPERATION & MAINTENANCE

INSTRUCTIONS

0405

Please note that the details and specifications contained herein, are correct at the time of going

to print. However, CLARKE International reserve the right to change specifications at any time

without prior notice.

-1-

Thank you for purchasing this CLARKE Stair Jig.

Before attempting to use the jig, please read this manual thoroughly and follow the

instructions carefully. In doing so you will ensure the safety of yourself and that of others

around you, and you can look forward to the jig giving you long and satisfactory service.

CLARKE GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt as proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered

with in any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee does not effect your statutory rights.

Introduction

Easy to follow step by step instructions.

The all in one jig accommodates open and closed staircases.

Producing a stair case is a fairly complicated task, even for the experienced carpenter.

Understanding the various technical terms and conforming to BS585 (1989 Wood Stairs)

and building regulations requirement (Approved document K of the buildings regulations

1985) can seem very daunting. However, once you have familiarised yourself with the

terminology for the various parts of the staircase, you will make the job quicker and easier

to do than you may have first thought. This jig is certainly simpler and more user friendly

than anything else currently on the market.

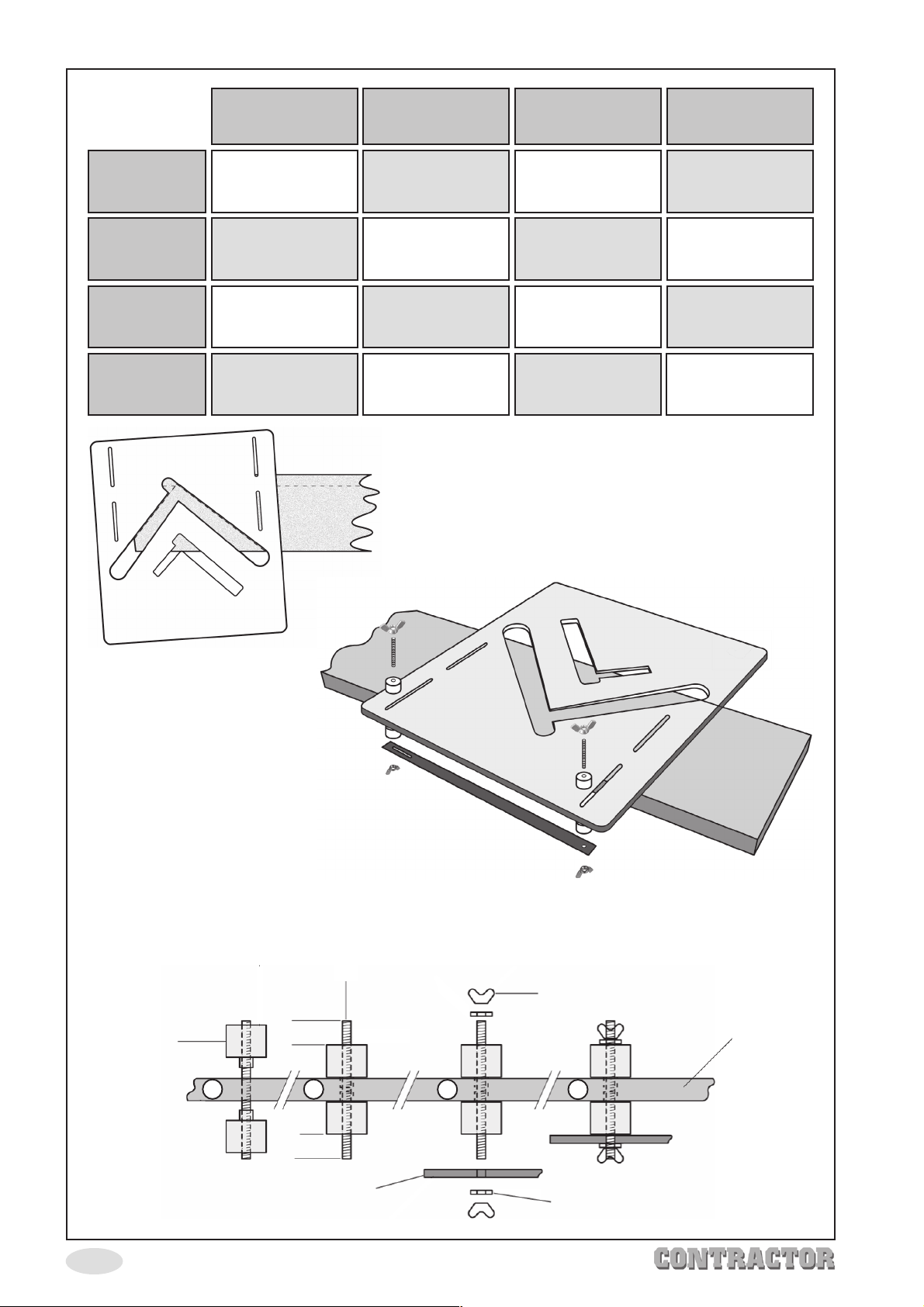

Check List

4 x Wing nuts.

4 x Washers.

4 x Aluminium spacers.

1 x Adapter Plate.

2 x Threaded studs.

2 Guide bushes.

(1 Pair)

1 x Template.

1 x Sliding bar.

NOTE: The guide bushes are universal and fit the majority of routers on the market.

An adapter plate is supplied, to enable the use on routers that do not support these guide

bushes.

IMPORTANT When using the adapter plate, always ensure the guide bushes are firmly

secured and sit flat. Always refer to the router manufacturers instructions.

-2-

Other equipment required for use with this jig

Hand Router capable of taking a 22mm dovetail cutter

+ standard 30mm guide bush.

Minimum of 2 ‘G’ clamps.

For closed staircase:-

16mm cutter for 22mm & 25.4mm treads.

22mm cutter for 28.1mm & 32mm treads.

(only use 95º dovetail cutters - see diag opposite).

Added option to use a 30mm template

guide to produce 38mm nose.

For open staircase:-

30mm guide bush.

16mm straight cutter.

Closed Staircase Cutter

D = 16mm or 22mm

C = 25mm

C

95º

D

Before commencing, 3 key features that need assessing.

1. The number of steps and pitch of the staircase.

2. Projectional length of the nosing.

3. The thickness of the staircase tread.

It is recommended you start by understanding these terms before commencing. Once

you do understand these terms, and the measurement and planning of your staircase,

the actual time to produce the stair strings could take less than an hour.

Terminology and standards - Parts of a staircase(GLOSSARY)

String

The string is the wooden side support, which holds the tread. It is either positioned on one

or both sides. All machining with the router takes place on the string.

Tread

The tread is the wooden part on which you stand on a staircase.

Riser

The riser is the part between each tread (See diagram). This effects the rise which is

measured from the top of the tread to the top of the next tread and every step or landing

must have an equal amount of risers. British standards insist that the rise of a step must be

no more than 220mm for a private stairway and not more than 190mm for a common

stairway. Approved Document K states that the number of risers in a flight should be

limited to 16 if a stairway serves an area used for shop or assembly purposes.

Nosing

The nosing is the length of material which overlaps the riser. we reccomend that this should

project by no less than 22mm and is the size of nosing that can be routed by the smallest

guide bush provided with this jig. However BS585 (Wood stairs) states the minimum should

be no less than 16mm

-3-

Going

The going of a step is the space between the nosing of one step and the nosing of the

step above - or as British Standards state, face of a riser to face of a riser. Like the riser,

British Standards state strict regulations. These are - The going should not be less than

220mm for a private stairway and not less than 250mm for a common stairway.

Pitch line

The pitch line is an imaginary line, which is drawn from the edge of each tread. It stretches

from the floor to the landing.

Pitch

The pitch is the angle between the imaginary pitch line and the horizontal of the tread.

(See diagram). Regulations state that this should not exceed 42º for a private stairway

and 38º

for a common stairway. The pitch should never be less than 25º because a stairway

with a shallow angle takes up more room than those with a deeper angle.

Margin

The margin is the distance between the imaginary pitch line and the edge of the string.

Going

String

Rise

Riser

Pitch Xº

Margin

Pitch Line

Nosing

Tread

Planning your staircase

The first information that you will need to find out is the total rise of the flight and the

total going of the flight, if this is restricted. The normal rise of a step is between 170mm

and 200mm. Therefore, divide the total rise by say 180.

For example, If the total rise of a flight is 2405mm and we have assumed that 180mm is

your chosen rise, calculate the exact size as follows;

2405 = 13.36

180

Round off to the nearest decimal point, this example = 13.

You will therefore need 13 steps (13 risers)

2405 = the size (185mm) of each rise.

13

-4-

As stated earlier in the

terminology, the going should

be no less than 220 for a private

stairway or 250mm for a

common stairway. Let us

presume that the going (G) is

240mm. Calculate your total

going for the flight and ensure

that this falls within your

permissible space. This is

calculated by multiplying the

number of steps ie 13 x 240=

3120 (This is your total going of

flight). If this is not permissible,

adjust accordingly.

To ensure your sizes comply with

both the building regulation

requirements and BS585, you

need to calculate the following

2R +G (R=Rise and G=Going)

For example: 2 x 185 + 240 =

6 10mm.

If this number falls between

550mm

and 700mm, it fits all requirements.

Rise of

flight

Rise of step

Example - 185mm

Going of

step

Example - 240mm

Pitch

Line

Going of

flight

Example -

3120mm

Closed Stair Jig

Procedure for finding start point

1. Prepare string for marking out and keep best

face upper most. It is best to keep any bow in

the string towards the top of the stairs.

2. A line has to be drawn for a metre or so, a

certain distance away from the edge of the

string. The distance is governed by the nose

length which will be used. To obtain the right

distance, refer to the table below.

Nose Projection

Distance

22.0mm 51mm

25.4mm 53mm

28.1mm 55mm

32.0mm 57mm

38mm (achievable only using 61mm

standard 30mm guide bush)

Margin

Gap

Margin

3. To create the pitch (Angle of

slope) on the string. First of all,

mark a right angled line across

the string, on the end from which

you will start (i.e. the botom of the

string).

Important: check that the line is at

right angles to the edge of the

string as well as the margin line.

17 mm (open staircase 51mm

-5-

Right Angled Line

4. Measure from the right angled line

along the side of the string, the going

length and mark this point. From the

same corner point intersection, measure

across the end along the right angled

line, the rise, and mark this point. Now

draw a line between these two points.

This line creates your pitch angle.

(Measure pitch line and note for point

15 - page 8).

Rise

FIRST RISER

AT BASE OF

STAIRS

6. Finally, mark a line (The first tread line) at right

angles to the first riser line from the

intersection point with the riser and the pitch

line.

Pitch Angle Line

Going

5.To find your start point along the

margin, you need to draw a line at

right angles to this pitch angle line.

This line must be no less than the

length of the rise and

right angles with the pitch line

angles. The intersection of this line

(The first riser line) with the margin

will be your start point and the angle

at which this line is drawn will be the

angle to set the jig.

must be at

Setting Up the Jig

Offset Value

10. Mark the offset value against the first riser and the first tread line as shown in the

diagram above.

NOTE: If a 30mm guide bush is going to be used instead of the supplied guide bushes,

then refer to table below.

7. The final thing to calculate is the offset value

between the edge of the cutter and the

edge of the jig cut out.

8. This offset value varies according to which

tread thickness you require.

9. Select from the table (page 7) the tread

thickness and nose projection you require. As

a general rule the nose projection equals the

tread thickness. This will tell you which cutter

size to use and the resultant offset value

required to set the jig. Refer back to the table

to determine which guide bush and cutter

to use, before cutting.

38mm Fixed Nose

Ø16mm Cutter 25.4mm tread - 8mm offset

Ø22mm Cutter 32mm tread - 5mm offset

-6-

NOSE

TREAD

22.0mm

22.0mm 25.4mm 28.1mm 32.0mm

Ø16mm Cutter

10mm Offset

Bush 2

Ø16mm Cutter

10mm Offset

Bush 1

25.4mm

28.1mm

32.0mm

12. Attach the aluminium

spacers, (steps 1 to 4

below) to the relevant

slots in the jig, push

spacers firmly against the

edge of the string. Ensure an

equal amout of the stud is

visible on both sides when the

spacers are tightened (‘A’ = ‘B’).

Tighten the spacers by turning them in

opposing directions until tight (hand tight only).

Fit washer and wingnut on the top two studs and

gently tighten.

Attach the sliding bar to the bottom studs and secure with washers and wingnuts.

The jig is now fully assembled, and does not require dissasembling for storage etc.

To use agin, simply loosen wingnuts and spacers, adjust the jig accordingly.

Ø22mm Cutter

7mm Offset

Bush 2

Ø16mm Cutter

8mm Offset

Bush 3

Ø22mm Cutter

7mm Offset

Bush 1

Ø22mm Cutter

5mm Offset

Bush 3

11. Line up The jig perfectly with the two offset lines,

as per diagram Clamp the jig firmly to the string

in this position.

Ø16mm Cutter

8mm Offset

Bush 4

Ø22mm Cutter

5mm Offset

Bush 4

Aluminium

Spacer X 4

-7-

Threaded Stud X 2

‘A’

1 2

‘B’

Sliding Bar

Wing Nut X 4

Jig

3 4

Washer X 4

13. Attach the correct nosing bush and cutter size to the router, set the plunge depth

to 12mm (refer to tabIe on page 7 for correct guide bush and Cutter).

The edge of bush has to be flat with inside edge of jig

to ensure correct nosing and gap thickness for tread.

Ensure the long side of the guide

bush is flat against the side of the aperture to ensure a

correct size nose and width of cut for the tread to fit

comfortably.

14. Proceed to cut out the tread and riser

housing using the sequence shown in

diagram (right). Always refer to router

manufacturers instructions before

commencing.

Pitch Angle Line

Next jig position

15. You should now have completed the

first going and riser recess on the first

string. To complete the succession of

goings and risers along this string, the jig

must be moved sequentially along the

string. The distance between each movement of the Jig is equal to the length of the

pitch angle line (See diagram above), refer back to page 6 when steps were followed

to calculate the pitch angle line and the length measured. The angle of the pitch is

maintained by the sliding bar mechanism.

The procedure to follow is to mark a line along the margin where the right hand side of

the stair jig crosses. From this point, measure the length of the pitch angle line along the

margin and mark this point. This is the place at which to position the right hand side of the

stair jig for the next succession. Please ensure before re-clamping the jig, the sliding bar is

pushed firmly against the top edge of the string.

Repeat this procedure until the required number of rise and going recesses have been

cut.

IMPORTANT: whenever repositioning the jig, always ensure the spacers are pushed up

firmly against the edge of the string before clamping in position.

-8-

NOTE:

Enough room has to be left on the string before the first

riser is cut to ensure there is no break-out. It is better to

have more material, than not enough as the strings can

be cut to size afterwards.

16. All you need to do now is complete your “mirror image” string. The jig makes this very

simple. Remove the sliding bar from the spacers taking care not to move or loosen

them whilst doing so. Refit sliding bar on opposite side of the jig and secure in position

with the wingnuts, again taking care not to loosen or allow the spacers to move. The

jig is now prepared for the opposing string.

17. Draw the margin along the second string to the same distance as on the first. Next,

position the jig on the string, utilising the sliding bar to achieve the pitch angle and

ensuring that the first riser will not break out through the end of the string. See

diagram above. No measuring or calculating is required as the jig transfers all the

required datum information to the second string.

18. Repeat the succession of risers and treads along the second string in the same

).

way as the first string, (see point 15

Please note, you must, of course, use the same

pitch angle line distance as on the first string.

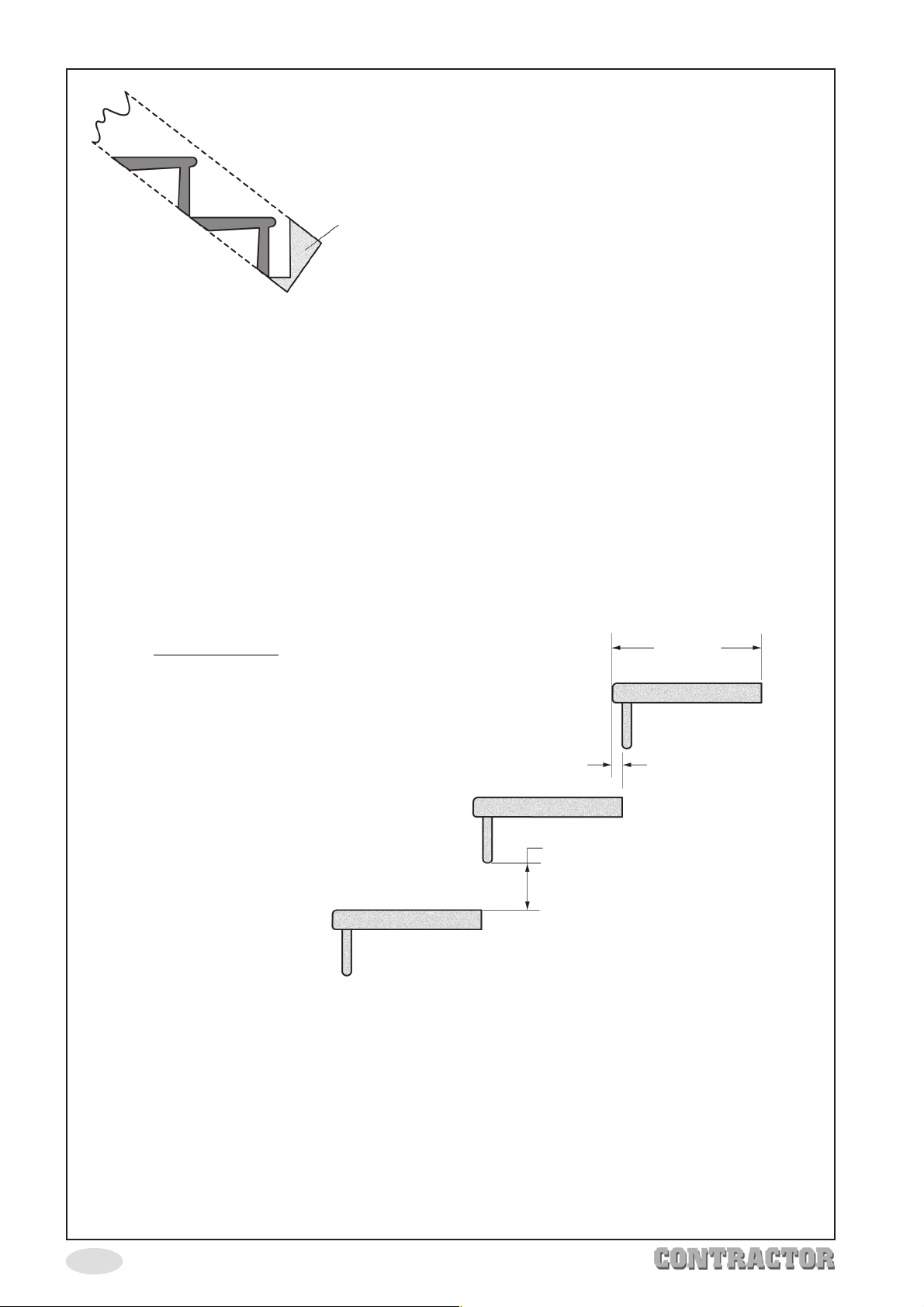

Open Stair Jig

260mm

The open stair jig works very much

in the same way as the closed

staircase, but the risers are left open.

Setting up follows the same

procedure as the closed staircase,

15mm Overlap

but there are a number of factors,

which the user will have to follow,

to ensure right construction, and to

comply with approved document K

Building Regulations 1985.

♦ A 30mm guide bush is used with a 16mm straight cutter, producing the correct gap

Gap MUST NOT Exceed 100mm

for the riser and tread.

♦ The tread has a fixed length of 260mm, with a thickness of 33mm.

♦ The radius of the base of the riser and the nosing of the tread is set at 8mm.

♦ The nosing on the tread has a fixed projection of 17mm.

♦ The tread should overlap each other by 15mm (see diagram above).

♦ The gap between the base of the riser and the upper face of the tread below should

not exceed 100mm. This is to ensure that a 100mm diameter sphere, the equivalent

of a child’s head, will not pass through the riser (see diagram above).

-9-

1. Follow the same procedure as in points 1 — 3 on page 5, making sure that the margin

is set at 44mm.

2. Calculate the rise with the going to make sure it complies with approved

document K. As there is an overlap of 15mm on the tread, the going is set at 245mm

as opposed to 260mm. Use this figure to calculate the relationship between the rise

and going making sure the final figure using the formula 2R + 6 falls between 550mm

and 700m.

3. Mark out your going and rise as in point 4, page 6, to calculate the pitch angle line,

and continue to follow steps 5 to 6 on page 6.

4. Follow point 10, marking an offset value of 7mm (page 6).

5. Follow procedure as for the closed stair jig, but remembering that the gap

between base of riser and upper face of lower tread does not exceed 100mm (see

diagram above). A block spacer can be put in the base of riser aperture on the jig

to decrease the length of the riser altering the gap accordingly.

6. Continue to slide the jig up the string sequentially following the procedure on

page 8 remembering to cut in the direction shown in the diagram.

7. The stair jig is flipped to opposite face on the opposing string in the same manner

as the construction of the closed staircase.

-10-

Loading...

Loading...