BELT & DISC SANDER

MODEL NO: CS69D

PART NO: 6500421

OPERATION & MAINTENANCE

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC 0420 - ISS 1

INTRODUCTION

Thank you for purchasing this CLARKE Belt and Disc Sander. The CS69D is

designed for workshop use and comprises a 9” diameter sanding disc and a

6” wide sanding belt.

This machine is designed for sanding WOOD ONLY. DO NOT USE for sanding

asbestos or materials containing asbestos, painted surfaces, or materials

which produce toxic dust. Do not use for sanding magnesium as this produces

a highly flammable dust.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL RECYCLING POLICY

By purchasing this product, the customer is taking on the obligation

to deal with its safe disposal in accordance with the Waste Electrical

and Electronic Equipment (WEEE).

In effect, this means that this product must not be disposed of with general

household waste. It must be disposed of according to the laws governing

Waste Electrical and Electronic Equipment (WEEE) at a recognised disposal

facility.

If disposing of this product or any damaged components, do not dispose of

with general waste. This product contains valuable raw materials. Metal

products should be taken to your local civic amenity site for recycling of metal

products.

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SPECIFICATIONS

Model no CS69D

Part no 6500421

Rated Voltage 230V ~ 50Hz

Power output 1.5 HP/1.1kW

Rated input wattage 1100W

Rated input ampere 4.8 A

Duty cycle S1 (continuous)

IP rating IPX0

Electrical insulation class Class 1

Fuse rating 13A

Disc Speed 1500 rpm

Sanding belt speed 5.8 m/s

Sound Pressure Level LpA 78.4 dB(A), Uncertainty Factor (K) 3 dB(A)

Sound Power Level LWA 91.4 dB(A), Uncertainty Factor (K) 3 dB(A)

Vibration

Less than 2.5 m/s

1.5m/s2

Dimensions (L x W x H) Sander - 720 mm x 520 mm x 980 mm

2

Uncertainty Factor (K)

Dimensions (L x W x H) Stand - 425 mm x 385 mm x 575 mm

Weight 40 kg

Dust extract port size 50.8 mm (2”)

Sanding belt size 152 mm x 1219 mm

Sanding disc size 228 mm dia (9”)

Sanding table size 300 x 150 mm

Tilt angle

Mitre gauge adjustment

0-45

-60

o

o

- +60

o

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

POWER TOOL SAFETY WARNINGS

WORK AREA

1. Keep the work area clean and well lit. Cluttered and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids or gases. Power tools create sparks which

may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use adaptor plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce the risk of electric shock.

2. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

3. Do not abuse the cable. Never use it for carrying, pulling or unplugging the

power tool. Keep the cable away from heat, oil, sharp edges or moving

parts. Damaged or entangled cables increase the risk of electric shock.

4. When operating a power tool outdoors, use an extension cable suitable for

outdoor use. Use of a cable suitable for outdoor use reduces the risk of

electric shock.

5. If operating the power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in personal injury.

2. Use safety equipment. Always wear eye protection. Safety equipment such

as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

3. Avoid accidental starting. Ensure the switch is in the off position before

plugging in. Carrying power tools with your finger on the switch or plugging

in power tools that have the switch on invites accidents.

4. Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct accessories for your

application. The correct power tool will do the job better and safer at the

rate which it was designed for.

2. Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

3. Disconnect the plug from the power source before changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

4. Store idle tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate it. Power tools

are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power

tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

6. Use the power tool and accessories in accordance with these instructions

and in the manner intended, taking into account the working conditions

and the work to be performed. Use of the power tool for operations

different from intended could result in a hazardous situation.

7. The performance of this tool may vary, depending upon variations in line

voltage. Extension cable usage may also affect performance.

SERVICING

1. Have your power tool serviced by qualified service personnel using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

ADDITIONAL SAFETY WARNINGS FOR SANDERS

1. Dust arising from sanding may endanger the health of the operator and

possible bystanders. Wear a dust mask and ensure that persons entering

the work area are also protected.

2. Remove all dust after sanding.

3. Avoid sanding lead based paint, wood or metal which may produce toxic

dust, - do not let children or pregnant women enter the work area.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

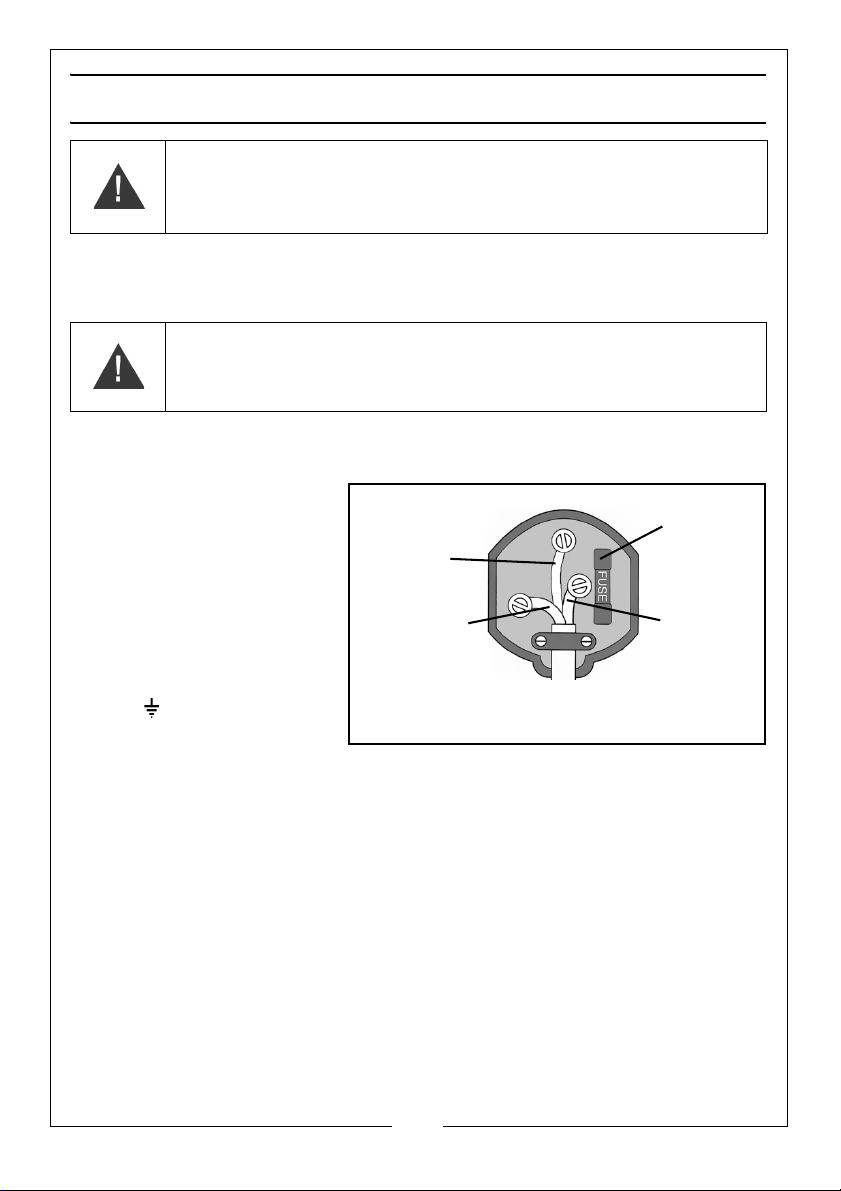

ELECTRICAL CONNECTIONS

Plug must be BS1363/A approved.

Always fit

Ensure that the outer sheath of

Neutral

(Blue)

Live

(Brown)

Earth

(Green and

a 13 Amp

the cable is firmly held by the clamp

fuse.

Yel low)

WARNING: READ THESE ELECTRICAL SAFETY INSTRUCTIONS FULLY

BEFORE CONNECTING THE PRODUCT TO THE MAINS SUPPLY.

This product is provided with a standard, 230 volt (50Hz), BS 1363 plug, for

connection to a standard, domestic electrical supply. Should the plug need

changing, make sure that a plug of identical specification is used.

WARNING: THE WIRES IN THE CABLE ARE COLOURED AS FOLLOWS:

BLUE = NEUTRAL BROWN = LIVE YELLOW AND GREEN = EARTH

If the colours of the wires in the power cable do not correspond with the

markings on the terminals of your plug, proceed as follows.

• Connect the blue wire

to the terminal

marked N.

• Connect the brown

wire to the terminal

marked L.

• Connect the yellow

and green wire to the

terminal marked E or

.

AN APPROVED RESIDUAL CURRENT DEVICE (RCD) WHICH HAS A TRIPPING

CURRENT OF LESS THAN 30MA MUST BE USED.

If you are not sure, consult a qualified electrician. DO NOT try to do any

repairs.

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

6

EXPLANATION OF SYMBOLS & PICTOGRAMS

Read instruction manual before use.

Wear safety glasses or goggles when using the tool.

Wear ear protection when using this tool.

Wear a dust mask.

Wear protective gloves.

For indoor use only

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

INVENTORY

The CS69D sander is supplied with the following items which will require

assembly.

• Stand assembly kit, comprising: - 2 x side panels, 2 x short cross members,

2 x long cross members, 4 x rubber feet with flat washers & nuts, 12 x M8

coach bolts /12 x M8 plain washers/12 x M8 nuts.

• 1 x Hex wrench (long)

• 1 x Spanner (10-13mm)

•1 x Workstop

• 1 x Drive housing

• 1 x Sanding face plate

• 1 x Drive cover c/w fixing screws

• 1 x Small (motor) pulley

• 1 x Large (driven) pulley

• 1 x Drive belt

• 1 x Work table assembly

• 1 x Table support rod

• 1 x Mitre fence assembly

• 1 Fixing kit containing, grubscrews, parallel keys, 4 x bolts,4 x spring

washers, 4 x large washers (sander to stand fixings), workstop retaining

bolt/washer.

• 1 x Abrasive disc

• 1 x Abrasive belt

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

BEFORE USE

ASSEMBLING THE STAND

Assemble the stand as shown. The upper and lower beams are secured with

the 12 x M8 coachbolts with flat washers & nuts. Add the rubber feet securing

them with flat washers & nuts.

Do not tighten the nuts until all bolts are in place and the stand is rocked to

ensure it is stable and evenly assembled. When satisfied, tighten securely.

WITH ASSISTANCE, considering its weight, place the sander on top of the stand.

Position it so that the bolt holes, viewed from below, line up. Enter the 13mm

bolts fitted with flat and lock washers and tighten securely from below.

FITTING THE DRIVE COMPONENTS

1. Fit the drive housing to the frame

using 4 x M8 x12 retaining bolts

and flat washers.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

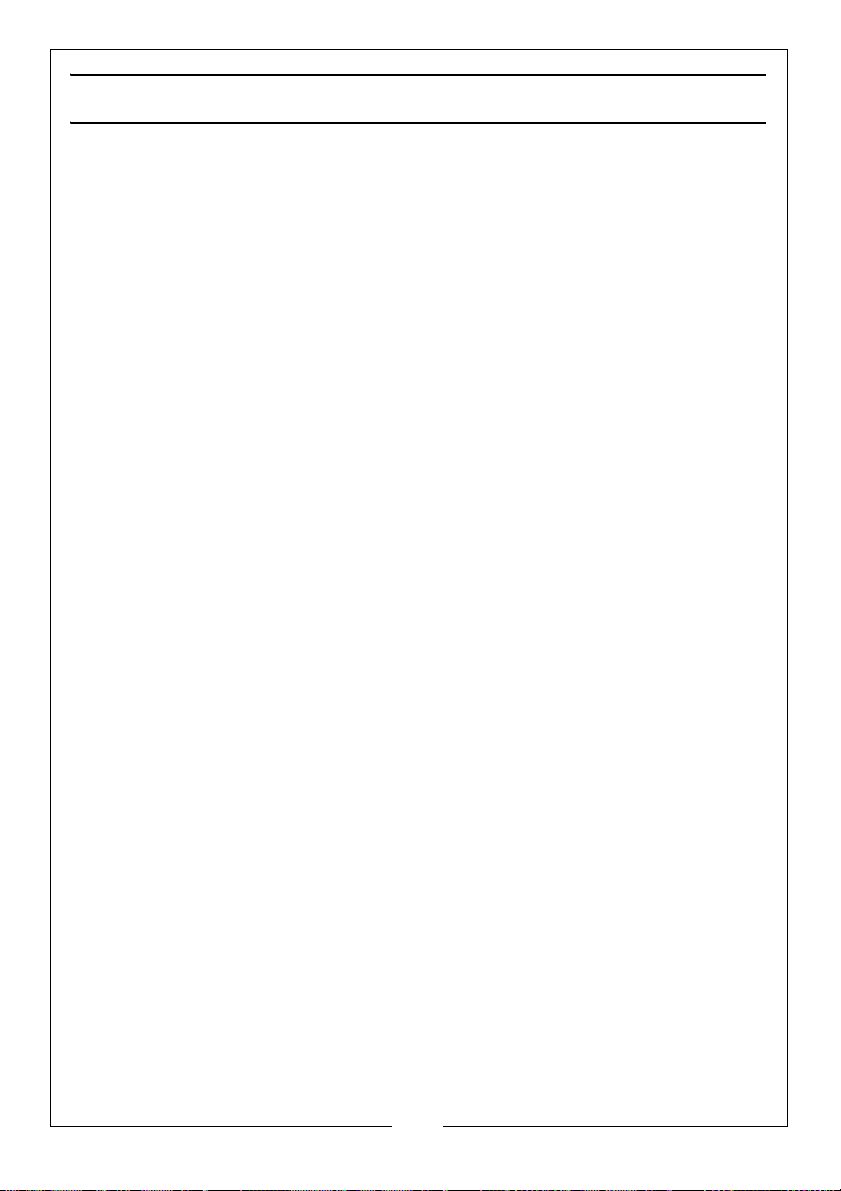

2. Slide the 5 x 55 mm parallel key

into the groove in the shaft and

slide driven pulley onto the end of

the driven shaft, engaging with

the key.

3. Pass the drive belt over both

pulleys and slide the motor pulley

onto the motor shaft complete

with the 5 x 25 mm parallel key.

4. Press both pulleys onto the shafts

as far as they will go. This will ensure that they are correctly aligned.

5. Using the hex wrench supplied,

tighten the M8 x 10 setscrews to

secure the both pulleys.

6. Tension the drive belt as necessary

by adjusting the position of the

motor on the bedplate using the 4

adjusting bolts.

• As a rough guide, aim for

approx 12mm deflection at the

mid-point of the drive belt and

confirm there is no slippage of

the belt on the pulleys.

7. Slide the face plate onto the

driven shaft, engaging with the

parallel key already in postion.

8. Use the hex wrench supplied to

tighten the setscrew and secure

the face plate to the driven shaft,

inserting the wrench through the

access slot in the drive cover.

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

9. Check that the surface of the

face plate is clean and attach

the abrasive disc after peeling off

the backing material. Take great

care to position it centrally.

10. Fit the drive cover using the selftapping screws.

Fit the work stop to the frame using

the M8 x 20 bolt and flat washer.

CHECKS BEFORE USE

As with all machinery, it is important to ensure that the various components are

properly secure and in good order before use.

The sander is designed so that when switched ON, both the belt AND the disc

will rotate. It is also important therefore, to ensure that the belt runs true on the

rollers, referred to as ‘Tracking’. Although the necessary adjustments have

been carried out at the factory, it is nevertheless prudent to perform this

check when first setting up your machine in the event it has been disturbed

during transit.

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHECKING THE BELT TRACKING

The rollers must run parallel, otherwise

the belt will be driven off to one side.

1. Plug in to the mains supply and

press the GREEN ON button,

marked ‘I’ to start the machine.

keeping well away from the belt.

2. Observe the belt for a short period

as it passes over the front

roller....there should be no creep

to one side. If it does creep, switch

OFF by pressing the RED OFF button, marked ‘O’.

To perform the adjustment, release the locking knob on each side of the

machine and turn the adjusting wheel to either slacken or tension one side of

the abrasive belt. Note that only small adjustments should be required.

3. Restart the machine and screw the adjusting wheels very gently in or out to

compensate for the creep. When the belt is running true, switch off and

tighten the locking knobs. When satisfied, restart and check the tracking is

now correct. If necessary, repeat until the belt runs true.

FITTING THE WORK TABLE FOR USE WITH THE DISC

The mounting of the work table will depend upon the job in hand, i.e. either

adjacent to the disc or to the belt.

The table is mounted on a support bar which is inserted into the housing on the

machine base and secured with 2 x M8x20 setscrews.

1. Tighten the securing setscrews to secure the support bar in the base.

2. Slide the table assembly on to the

support bar and bring the table to

within 2mm of the sanding disc.

Tighten the securing setscrew in

the table frame to secure it to the

support rod.

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. To ensure the table is at exactly

o

to the sanding disc, position a

90

small engineers set square on the

table so that it touches the disc.

Slacken off the table angle

adjustment knob, shown and

adjust accordingly so that the

table sits level.

4. Tighten the adjustment knob and

if necessary, zero the pointer

adjacent to the scale by

slackening the securing screw and repositioning.

FITTING THE WORK TABLE FOR USE WITH THE BELT

1. When using the work table with

the sanding belt in the upright

position, remove the work stop

from the belt frame by removing

the workstop securing bolt.

2. Before attaching the table to the

mounting, raise the sanding belt

arm and secure in position using

the locking bolt shown. An open

spanner is provided for this.

3. Slide the table support rod into

the mounting as shown and

tighten the two securing

setscrews.

4. Mount the table on the support

bar, bring to within 2 mm of the

belt and tighten the securing

setscrew. Ensure the table is level.

5. To ensure the belt is perpendicular

to the table, use an engineers

square as described above, adjusting the angle of the sanding belt arm

using the arm locking bolt shown.

6. Ensure the work stop is replaced correctly when returning the belt to the

horizontal position.

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

METHOD OF USE

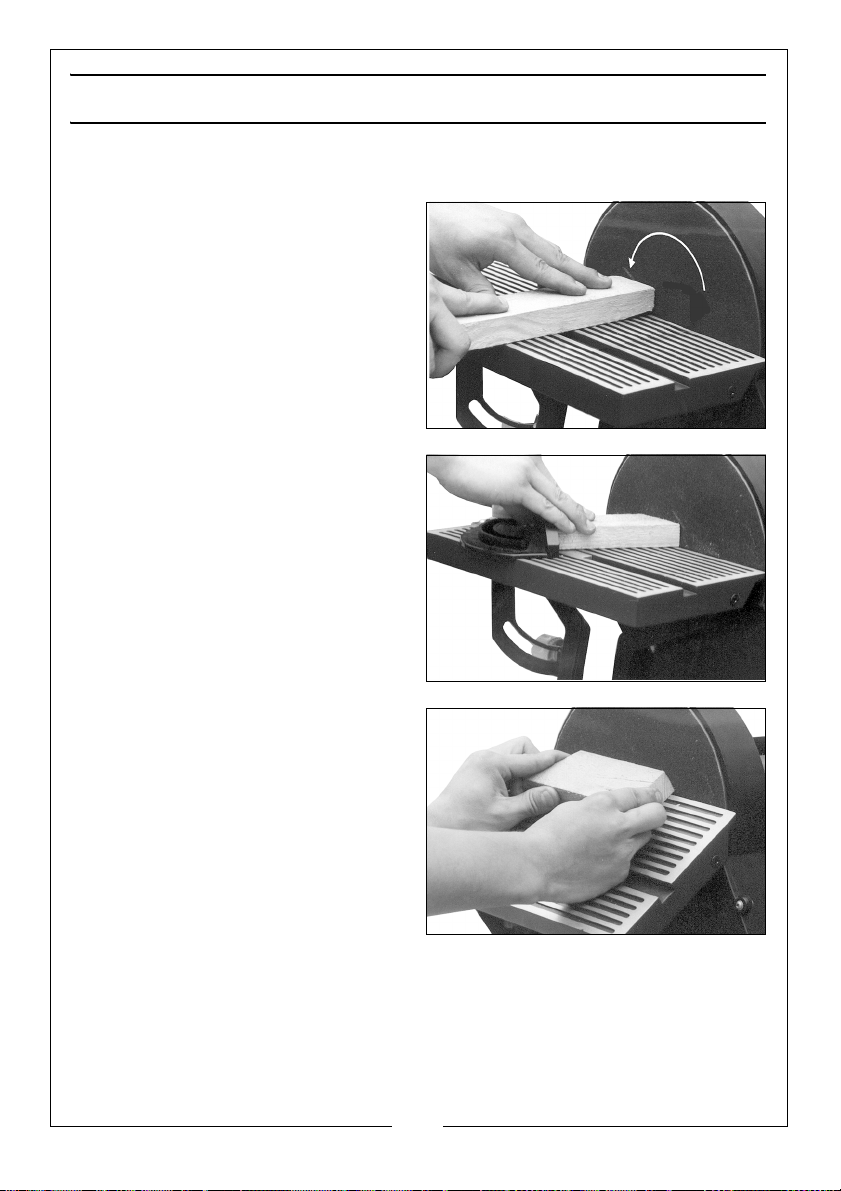

USING THE DISC

1. Check that the table is

approximately 2mm from the

sanding disc before switching on.

2. Hold the work firmly as shown and

ALWAYS hold the workpiece

against the left half of the disc. i.e.

that half moving downwards

towards the sanding table.

3. DO NOT exert too much pressure.

A light touch is all that is required.

• The photo shows the table

being used in conjunction with

the mitre gauge.

4. Set the gauge to the angle you

require and hold the workpiece

firmly against the gauge, feeding

it gently against the sanding disc.

5. Keep the workpiece in contact

with the left side of the disc as far

as possible.

• The illustration shows the

sanding table set to an angle.

The mitre gauge may also be

used with this setup.

• Angles up to 45o may be set.

6. If accuracy is required, check the

angle using a suitable square or

template.

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

USING THE BELT

The work stop must be in place when

using the belt horizontally.

1. Secure using the bolt and flat

washer as shown.

2. Ensure a gap of no more than

2mm exists between the belt and

the work stop.

3. The belt can be used in the

vertical position as shown. In this

case, the work stop should be

removed. Lock the belt frame in

the upright position using the arm

locking bolt shown on page 13.

The belt is used for long workpieces,

as shown. The workpiece is driven

against the work stop by the action

of the belt.

• DO NOT exert too much

pressure - a light touch is all that

is required.

• Curves may be sanded as

shown.

4. Let the sander do the work and

ensure the workpiece is flat on the

table surface. Never apply heavy

pressure as this will not only

produce an uneven finish but will

overload the motor causing it to

burn out.

5. On very uneven surfaces or when removing layers of paint, start with a

coarse grit. On other surfaces, start with a medium grit. In both cases,

gradually change to a fine grit for a smooth finish. Regularly check the

condition of the sanding belt or disc and replace it when necessary.

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DUST EXTRACTION

WARNING: HARMFUL OR TOXIC DUST MAY BE PRODUCED WHEN

SANDING LEAD PAINTED SURFACES, WOODS OR METAL. CONTACT WITH,

OR INHALATION OF THESE DUSTS CAN ENDANGER THE HEALTH OF THE

OPERATOR OR BYSTANDERS. CERTAIN DUSTS LIKE OAK AND BEECH ARE

CONSIDERED TO BE CANCEROUS IN CONJUNCTION WITH ADDITIVES IN

WOOD TREATMENTS (CHROMATE, WOOD PRESERVATIVES). ASBESTOSCONTAINING MATERIALS MAY ONLY BE HANDLED BY EXPERTS.

WARNING: - USE A DUST EXTRACTION DEVICE OR A VACUUM CLEANER.

WARNING: - WORK IN A WELL VENTILATED ROOM.

WARNING: -THE USE OF A DUST MASK FILTER CLASS P2 IS RECOMMENDED.

- OBSERVE LOCAL REGULATIONS REGARDING THE HANDLING OF

CERTAIN MATERIALS.

Provision is made for dust extraction

from both the disc and belt.

The dust extraction outlets are shown

and have a diameter of 51mm (2”).

Connect a suitable hose to a

vacuum cleaner via a reducer if

required, or dust extraction device

(see your CLARKE dealer).

NOTE: The user should still wear a

face mask to prevent the

inhalation of dust particles.

Due to the nature of the sander some of the dust produced will be forced into

the surrounding atmosphere and will not be collected.

16

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

MAINTENANCE

WARNING: BEFORE PERFORMING ANY MAINTENANCE, SWITCH OFF AND

UNPLUG THE SANDER.

Your sander will operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends upon proper care.

Regularly clean the motor ventilation slots using a soft dry brush, cloth or

vacuum cleaner and remove undue buildup of dust from the sander. Do not

use any abrasive or solvent-based cleaner.

A damaged power cable should be replaced by your CLARKE dealer or

qualified electrician.

The bearings in this sander are sealed for life and require no maintenance.

CHANGING THE BELT

1. Disconnect any dust extract hoses

connected to the machine.

2. Remove the lower belt cover by

slackening the six securing screws

sufficiently for the cover to be

slipped off the frame.

3. Tilt the frame assembly up in order

that the belt cover remains away

from the belt.

4. Lock the bed in the upright

position using the locking nut.

5. Release the belt tension locking

knobs and unscrew the belt

adjusting wheels until the belt

goes slack.

The belt may now be slipped off and

replaced by a new one. Drop the

frame back to the horizontal position

and refit the belt guard/cover.

6. Tension the belt by the belt

tension adjusting wheels.

7. Check the belt tracking as previously described on page 12.

17

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

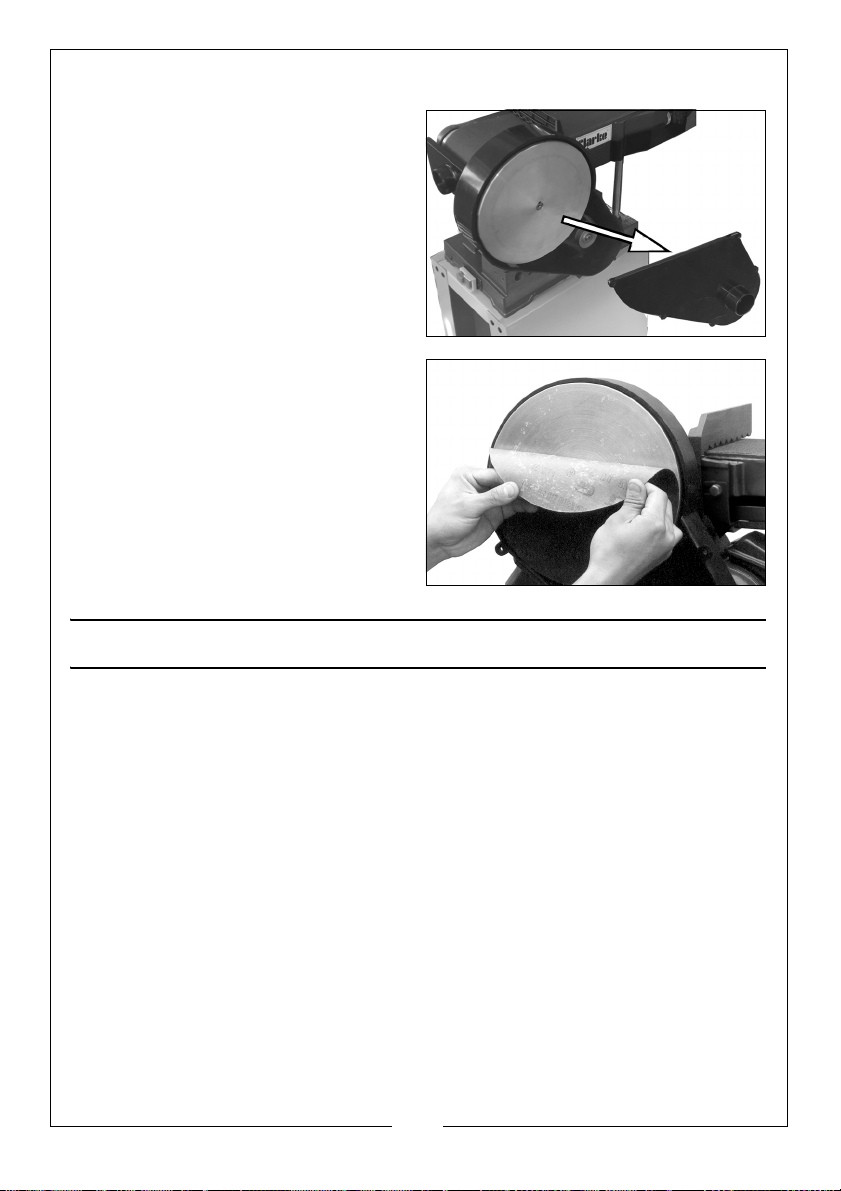

CHANGING THE DISC

1. Remove the screws and lift away

the drive cover as shown then

peel the abrasive disc from the

faceplate.

2. Clean any residual adhesive from

the faceplate and refit a new

abrasive disc, taking great care

that it is central. Ensure it is evenly

attached across its surface.

3. When satisfied, replace the drive

cover.

FAULTFINDING

SANDER IS OVERHEATING

Overloading the machine will cause overheating. do not apply excessive

pressure when working. The motor may over heat if covered in dust which can

be blown out with compressed air. Always wear eye protection and a dust

mask when using compressed air.

EXCESSIVE MOTOR SPARKING OCCURS

This indicates worn brushes. This problem is quickly remedied but you should

consult your CLARKE dealer for parts and advice.

SANDER DOES NOT OPERATE WHEN SWITCHED ON

Check to ensure the fuse is sound and replace if necessary. If the fuse is sound

or blows repeatedly, consult your CLARKE dealer.

POOR ABRASION

If the sander is not removing material efficiently, check the sanding sheet. If

the abrasive is worn down replace the sheet. The sanding sheet must always

18

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

be stored in a dry place as if it allowed to become damp, the abrasive

particles will detach from the sheet and will not abrade.

POOR DRIVE

If the sander does not reach full speed or slows down during hard sanding, the

main drive belt may be slipping. Tension the belt by means of the adjsuting

bolts shown on page 10.

ACCESSORIES

Replacement discs and belts are available in packs of 5 from your CLARKE

dealer.

Please quote the part numbers below.

6” Replacement belts (150 x 1219mm) Part Number

Fine 6502098

Medium 6501164

Coarse 6502103

Replacement 9”discs Part Number

Fine 6502099

Medium 6501076

Coarse 6502100

19

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PAR T S DI AGR AM

20

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PAR TS L IST

No Description No Description

1 Abrasive belt 31 M8 x 10 set screw

2 Bearing cover 32 Abrasive disc

3 Circlip 33 Disc cover

4 Bearing 34 Pointer

5 M8 nut 35 4mm flat washer

6 Lock washer 36 4mm lock washer

7 Drum cover 37 M4 x 5 pan head screw

8 M8x10 set screw 38 Lock knob

9 Connecting rod 39 Mitre gauge

10 Abrasive belt guard 40 Guide bar

11 Drive drum 41 Table

12 5 x 55 mm key 42 Angle plate

13 Drive shaft 43 8mm washer

14 Bearing 44 M8 x 12 bolt

15 Washer 45 Locking knob

16 Circlip 46 8mm flat washer

17 M8 x bolt 47 M5 x 40 flat head bolt

18 8mm flat washer 48 M5 hex nut

19 Bracket 49 Pointer

20 Spacer plate 50 M8 x 10 set screw

21 M8 x 40 carriage bolt 51 Table support

22 Belt housing 52 Nut

23 M8 x 10 set screw 53 M5 x 40 flat head bolt

24 Driven pulley 54 M5 hex nut

25 M8 x 10 set screw 55 Self tapping screw

26 Motor pulley 56 Support bar

27 8mm washer 57 M5 x 16 pan head screw

28 M8 x 12 bolt 58 Washer

29 V-belt 59 Power cable

30 Aluminium disc 60 Terminal

21

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

61 5mm flat washer 90 M6 nut

62 5mm lock washer 91 M8 nut

63 M5 hex nut 92 8mm lock washer

64 Switch 93 8mm flat washer

65 Self tapping screw 94 Strain relief 1

66 Switch plate 95 Strain relief 2

67 M8 x 20 set screw 96 M8 x 20 bolt

68 Base 97 M8 x 10 setscrew

69 Cable clamp plate 98 5mm flat washer

70 5mm flat washer 99 M5 x 20 pan head screw

71 M5 hex nut 100 5 x 25 key

72 5mm lock washer 101 Motor

73 Switch box 102 Support rod

74 Top frame 103 M8x20 bolt

75 M6 x 12 carriage bolt 104 8mm flat washer

76 Brace 105 Work stop

77 M6 x 12 carriage bolt 106 Belt frame

78 Rubber foot 107 Lock knob

79 M8 x 25 socket head bolt 108 Tracking nut

80 8mm flat washer 109 Drum cover

81 8mm flat washer 110 Circlip

82 M8 nut 111 Bearing

83 6mm flat washer 112 Shaft

84 M6 nut 113 M5 x 6 setscrew

85 Leg 114 Adjusting nut

86 M8 x 16 bolt 115 Idler drum

87 8mm lock washer 116 6mm flat washer

88 8mm flat washer 117 M6 x 10 pan head screw

89 6mm flat washer

22

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATION OF CONFORMITY

23

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...