1200W VARIABLE SPEED ROUTER

MODEL NO: CR1C

PART NO: 6462072

OPERATION & MAINTENANCE

INSTRUCTIONS

01/11

INTRODUCTION

Thank you for purchasing this CLARKE 1200W Variable Speed Router.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

IN THE BOX

• 1 x 1200 Watt Variable Speed Router

• 2 x Collet 8mm and 6.35mm (1/4") (one of which may be supplied

fitted in the router).

• 1 x Collet Nut

• 1 x Collet Spring

• 1 x Parallel Fence

• 2 x Parallel Fence Rods; 300mm x 8mm (Supplied with two M4.5mm x

10.0mm screws and washers for mounting the fence See page 9.)

• 1 x 18mm Guide Bush (Template Guide)

• 1 x Trammel Attachment

• 2 x M4.5 Plain Nuts

• 1 Collet Spanner

• 1 Reusable Cable Tie

2

TABLE OF CONTENTS

INTRODUCTION .....................................................................2

GUARANTEE ..........................................................................2

IN THE BOX ............................................................................2

TABLE OF CONTENTS ............................................................3

GENERAL SAFETY RULES .......................................................4

ELECTRICAL CONNECTIONS ................................................6

OVERVIEW ............................................................................7

BEFORE USE ...........................................................................8

FITTING THE GUIDES ..............................................................9

USING YOUR ROUTER ...........................................................10

ADJUSTMENTS .......................................................................11

ROUTER TIPS ..........................................................................13

TROUBLESHOOTING ..............................................................13

FITTING YOUR ROUTER TO A ROUTER TABLE ........................14

MAINTENANCE .....................................................................15

ENVIRONMENTAL PROTECTION ...........................................15

SPECIFICATIONS ...................................................................16

PARTS AND SERVICING ........................................................16

VIBRATION EMMISIONS .......................................................17

DECLARATION OF CONFORMITY ........................................19

3

GENERAL SAFETY RULES

WORK AREA

1. Keep the work area clean and well lit. Cluttered and dark areas invite

accidents.

2.

Do not operate power tools in explosive atmospheres, such as in the

presence of

may ignite the dust or fumes.

3.

Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce the risk of electric shock.

2.

Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

3.

Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep the cord away from heat, oil, sharp edges

or moving parts.

4. When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

flammable liquids, gases or dust. Power tools create sparks which

Damaged or entangled cords increase the risk of electric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when

operating a power tool.

influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in personal injury.

2.

Use safety equipment. Always wear eye protection. Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

3.

Avoid accidental starting. Ensure the switch is in the off position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A

4.

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

5.

Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

Do not use a power tool while you are tired or under the

4

6. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate which it was designed.

2.

Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

3.

Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing power tools.

safety measures reduce the risk of starting the power tool accidentally.

4.

Store idle tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

Power tools are dangerous in the hands of untrained users.

tool.

5. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

6.

Keep cutting tools sharp and clean. Poorly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

7.

Use the power tool, accessories and tool bits etc., in accordance with

these instructions. Use of the power tool for operations different from intended

could result in a hazardous situation.

Such preventive

SERVICE

1. Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

5

ELECTRICAL CONNECTIONS

Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply

through an approved 13 amp BS 1363 plug, or a suitably fused isolator switch.

THIS APPLIANCE IS DOUBLE INSULATED

The wires in the mains lead are coloured in accordance with the following

code:

Blue - Neutral

Brown - Live

As the colours of the flexible lead of this appliance may not correspond with

the coloured markings identifying terminals in your plug proceed as follows:

• No connection should be made to the earth terminal .

• Connect BROWN cord to terminal marked with a letter “L” or

coloured RED.

• Connect BLUE cord to terminal marked with a letter “N” or coloured

BLACK.

If this appliance is fitted with a plug which is moulded onto the electric cable

(i.e. non-rewireable) please note:

1. The plug must be thrown away if it is cut from the electric cable. There is a

danger of electric shock if it is subsequently inserted into a socket outlet.

2. Never use the plug without the fuse cover fitted.

3. When replacing a detachable fuse carrier, ensure the correct replacement

is used (as indicated by marking or colour code).

4. Replacement fuse covers can be obtained from your local dealer or most

electrical stockists.

FUSE RATING

• The fuse in the plug must be replaced with one of the same rating

and this replacement must be ASTA approved to BS1362.

• We strongly recommend that this machine is connected to the

mains supply via a Residual Current Device (RCD)

If in any doubt, consult a qualified electrician. DO NOT attempt any repairs

yourself.

6

OVERVIEW

1

2

3

4

5

6

7

8

9

10

11

NO. DESCRIPTION PART NUMBER NO. DESCRIPTION PART NUMBER

1 Speed Dial KPCR1C01 7 Multi-stop Turret KPCR1C07

2 Safety Button KPCR1C02 8 Depth Stop KPCR1C08

3 Trigger Switch (Rear) KPCR1C03 9 Depth Stop Lock KPCR1C09

4 Spindle Lock KPCR1C04 10 Plunge Lock Lever

5

Parallel Guide

Locking Screws

6 Collet Nut KPCR1C06

KPCR1C05 11 Micro Adjustment

(Rear)

Dial

7

KPCR1C10

KPCR1C11

BEFORE USE

WARNING: MAKE SURE THAT THE ROUTER IS SWITCHED OFF AND

UNPLUGGED FROM THE MAINS SUPPLY BEFORE FITTING OR REMOVING

ANY ACCESSORIES.

INSTALLING AND CHANGING ROUTER BITS

1. Rotate spindle whilst pushing the

spindle lock inwards until spindle is

locked, (hold the spindle lock on).

2. Using the wrench supplied, loosen

the collet nut a few turns and

remove bit if fitted.

3. Insert new bit and tighten collet

nut, release spindle lock.

IMPORTANT: At least two thirds of the

bit shank should be located inside the collet.

WARNING: NEVER TIGHTEN THE COLLET NUT WITHOUT A ROUTER BIT

INSERTED

FITTING THE DUST EXTRACTION COVER

1. Fit the dust extraction cover to the

router as shown.

2. Use the screws provided to secure

the dust extraction cover.

8

FITTING THE GUIDES

The tool is supplied with three guides,

• Parallel fence guide: primarily used for straight cuts, when

chamfering or grooving.

• Template guide: Fitted when the tool is used in conjunction with

templates.

• Trammel attachment: Used to move the router in an arc around a

selected pivot point.

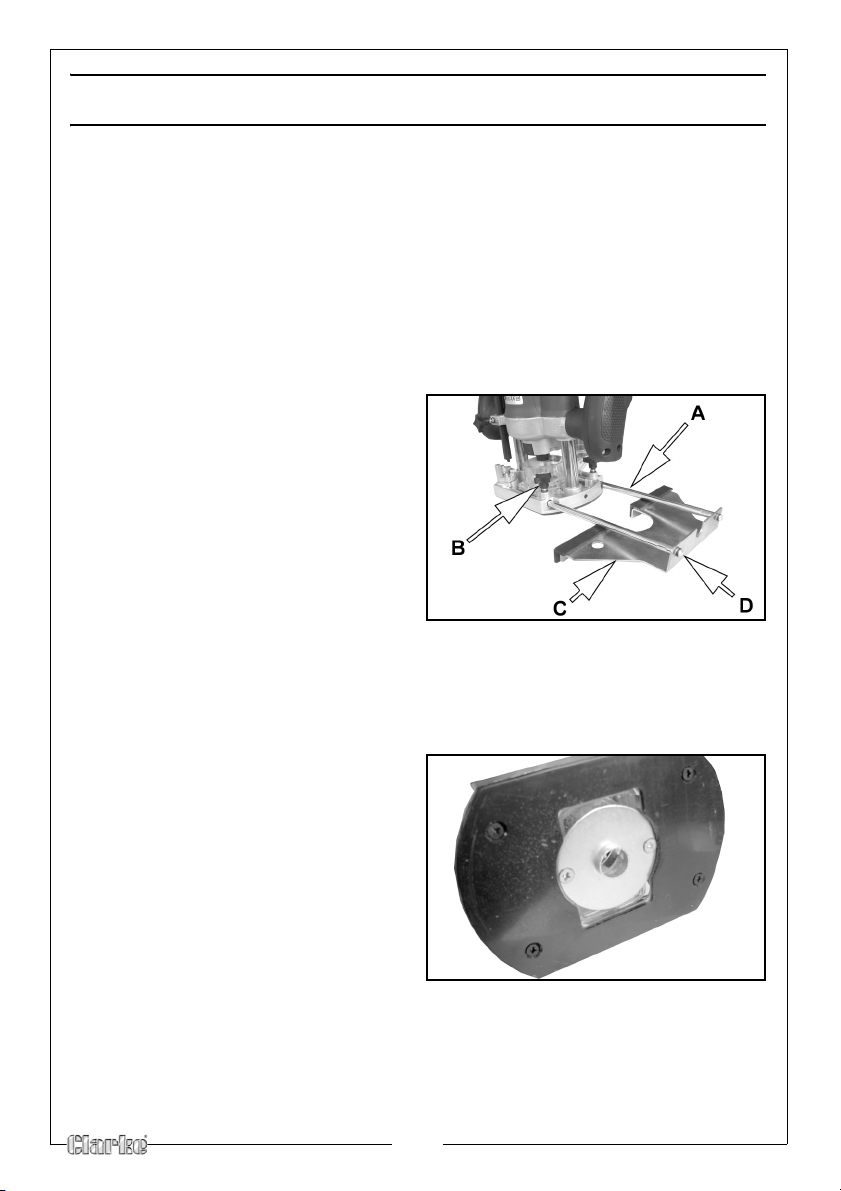

FITTING THE PARALLEL GUIDE FENCE

1. Connect the rods (A) to the guide

body (C), securing with the screws

(D) provided.

2. Fit the assembled guide to the

router as shown on the right.

3. Secure using the parallel guide

locking screws (B).

The parallel guide allows the user to

follow a straight edge with accuracy.

It is always advisable to make a trial

cut in a piece similar to that to be worked where possible.

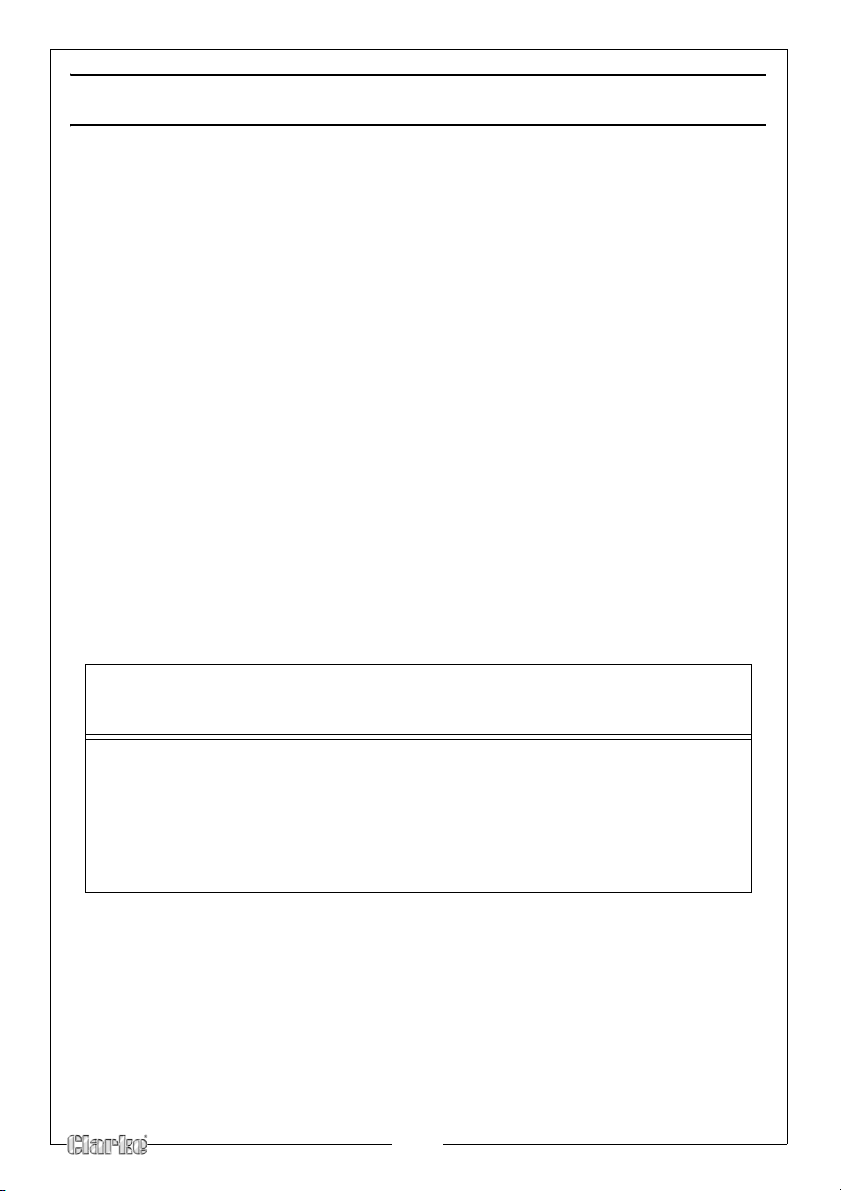

FITTING THE TEMPLATE GUIDE

The template guide allows the user to

duplicate a particular shape, that

shape being used as a template.

NOTE: The template guide can only

be used if the dust extraction

cover is fitted.

1. With the tool upside down,

remove the two screws securing

the dust extraction collar in place.

2. Fit the template guide with the

raised boss facing the workpiece.

3. Secure using the two screws.

9

FITTING THE TRAMMEL ATTACHMENT

Screw

Wing Nut

Piviot Point

Rod

1. Remove one of the rods from the parallel guide and insert it into position on

the router. Secure in place using the parallel guide locking screws.

2. Loosen the wing nut on the

trammel attachment and slide

the attachment on to the parallel

guide rod as shown.

3. Adjust the height of the pivot

point by turning the screw.

4. Tighten the wing nut to lock the

pivot point in place and the

trammel attachment to the rod.

USING YOUR ROUTER

When using the router, there are some points to bear in mind which will ensure

that the best results are achieved.

SWITCHING THE ROUTER ON/OFF

1. Grip the tool with both hands,

ensuring the power on/off switch

is in the right hand.

2. Push and hold the safety button,

and pull the trigger switch.

• Allow the motor to reach full

speed before use.

3. To stop the router, simply release

the trigger.

TO PLUNGE THE ROUTER

1. Place router on the workpiece with the cutter in the position to be cut.

10

2. Press down on both handles to

the required depth, pushing the

bit into the work piece.

• The depth stop should be pre-

set (See “Setting The Depth Of

Cut” on page 11.)

3. Pull the plunge lock lever towards

the handle to lock the body in

position.

4. To raise the tool, push the plunge

lock lever away from the handle and allow the body to rise out of the

workpiece.

WARNING: ENSURE THAT THE TOOL HAS REACHED OPERATING SPEED

BEFORE BEGINNING ANY CUTTING OPERATIONS.

ADJUSTING THE SPEED

The tool speed can be adjusted to

suit the bit diameter and the type of

material being cut.

Generally, the larger the diameter of

the bit, the slower the tool speed

should be.

• Rotate the speed selector

wheel to adjust the speed

setting from 1 to 7.

It is advisableto make practice cuts

on a piece of scrap timber to determine the best speed.

ADJUSTMENTS

SETTING THE DEPTH OF CUT

With the appropriate bit installed, proceed as follows:

1. Fit a suitable router bit and place the tool on a flat surface.

11

2. Release the plunge lock lever and

Depth Stop

Depth Stop

Micro

Adjustment

Dial

Lock

lower the tool body until the bit just

touches the flat surface, then apply

the plunge lock.

3. Slacken the depth stop lock and

lower the depth stop rod, until the

rod touches the multi-stop turret at its

lowest setting.

4. Make a note of the position

indicated on the scale.

5. Raise the height of the depth stop

rod by the depth you want to cut

into the wood. Each mark on the

scale is equal to 1mm.

6. Tighten the depth stop lock.

7. Fine adjustment can be made by

turning the micro adjustment dial. A

full turn is equal to 1mm.

CAUTION: TO PREVENT DAMAGE TO THE MOTOR OR DIFFICULTY

CONTROLLING THE TOOL, THE DEPTH OF CUT SHOULD BE LIMITED TO

10MM AT ONE PASS. IF YOU REQUIRE MORE THAN 10MM MAKE SEVERAL

PASSES WITH PROGRESSIVELY DEEPER SETTINGS.

USING THE MULTI-STOP TURRET

The multi-stop turret can be used to assist in making multiple passes. Using the

turret in this manner removes the necessity for resetting the adjuster rod for

each pass. Each stop on the turret is approx. 3mm.

1. With the total depth set and the

router raised fully, turn the turret to

a higher step to restrict the depth

of cut.

2. Make the first pass on the wood.

3. Rotate the turret to a lower setting

and make the second pass.

4. Repeat this until the final cut is

made.

12

ROUTER TIPS

DIRECTION OF FEED

Remember that the direction the

cutter is fed into the wood must

always be against the direction of

rotation as shown in the diagram on

the right.

This ensures a quality finish and also

ensures that the cutting action pulls

the side fence or guide bearing into

the wood.

FEED RATE

The optimum speed at which the bit is fed into the workpiece will come with

experience.

• Feeding too fast may cause a poor quality cut or damage the

motor.

• Move too slowly and the bit may leave burn marks on the face of

the wood.

The proper feed rate to use depends on the bit size, the material being cut,

the depth of the cut and the speed selected.

It is advisable to make practice cuts on a piece of scrap timber to determine

the best feed rate.

TROUBLESHOOTING

Problem Reason Solution

Router is overheating. Ventilation holes are

blocked / Machine is dirty.

Router is overloading. Do not use put excessive pres-

Excessive sparking. Worn Brushes. Contact you nearest Clarke

Router does not operate

when switched on.

Fuse has blown. Replace fuse.

13

Make sure the ventilation

holes are clear.

sure on the cutter.

dealer for repair.

FITTING YOUR ROUTER TO A ROUTER TABLE

This unit shown fitted to the Clarke CRT1 Router Table

A router table allows the work to be passed over the router, rather than

passing the router over the work. This makes working with smaller objects

easier. A router table may be fitted with a fence, fingerboards and other workguiding accessories to make the operation safer and more accurate.

• We recommend the Clarke CRT1 available from your local Clarke

dealer.

1. With the router unplugged, fit the

router to the router table as

shown in the router table user

guide.

2. Push and hold the safety button,

and pull the trigger switch on the

router.

3. Lock the trigger switch in the ON

postion using the re-useable

cable tie supplied.

CAUTION: ONLY USE THE CABLE TIE IF THE ROUTER IS FITTED TO THE

ROUTER TABLE.

4. Plug the router into the router table switch and follow the instructions in the

router table user guide.

14

MAINTENANCE

There are no user serviceable parts in this router, all servicing should be carried

out by your nearest Clarke dealer.

CLEANING

• To ensure the best performance from the router, it must be kept

clean.

• To reduce fire hazard, keep the cooling vents free of debris.

GENERAL MAINTENANCE

• Make sure that all nuts, bolts and screws are tight and secure.

• Always have any damaged or worn parts repaired, or replaced.

• Always have your router inspected and maintained by qualified

service personnel. Do not attempt to repair the router unless you are

qualified to do so.

STORAGE

• Make sure that the router has been thoroughly cleaned before

storing it in a clean, dry place out of the reach of children.

ENVIRONMENTAL PROTECTION

Do not dispose of this product with general household waste. All

tools, accessories and packaging should be sorted, taken to a

recycling centre and disposed of according to the laws governing

Waste Electrical and Electronic Equipment.

15

SPECIFICATIONS

For Parts & Servicing, please contact your nearest dealer, or

CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

Electric Supply 230V 50Hz

Motor Power Rating 1200W

No Load Speed 13700/30000 RPM

Maximum Plunge Depth 50mm (Without Extraction Spout)

42mm (Extraction Spout Fitted)

Collet Size 2 Supplied (8mm & 6.35mm)

Dust extraction Adaptor Port Size 32 mm

Net Weight 4 kg

Guaranteed Sound Power (L

Vibration Levels

Specifications are correct at the time of going to print. However, CLARKE International reserve the

right to change specifications at any time without prior notice.

wa dB) 97 dB

6.23m/s

2

Uncertanty value K (1.5)

PARTS AND SERVICING

There are no user serviceable parts, all servicing and repairs should be carried

out by your nearest Clarke dealer.

16

VIBRATION EMMISIONS

Employers are advised to refer to the HSE publication “Guide for Employers”.

All hand held power tools vibrate to some extent, and this vibration is

transmitted to the operator via the handle, or hand used to steady the tool.

Vibration from about 2 to 1500 herz is potentially damaging and is most

hazardous in the range from about 5 to 20 hertz.

Operators who are regularly exposed to vibration may suffer from Hand Arm

Vibration Syndrome (HAVS), which includes ‘dead hand’, ‘dead finger’, and

‘white finger’. These are painful conditions and are widespread in industries

where vibrating tools are used.

The health risk depends upon the vibration level and the length of time of

exposure to it……in effect, a daily vibration dose.

Tools are tested using specialised equipment, to approximate the vibration

level generated under normal, acceptable operating conditions for the tool in

question. For example, a grinder used at 45° on mild steel plate, or a sander

on soft wood in a horizontal plane etc.

These tests produce a value ‘a’, expressed in metres per second per second,

which represents the average vibration level of all tests taken, in three axes

where necessary, and a second figure ‘K’, which represents the uncertainty

factor, i.e. a value in excess of ‘a’, to which the tool could vibrate under

normal conditions. These values appear in the specification panel below.

Model Number CR1C

Description Router

Declared vibration emission value in accordance with EN12096

Measured vibration emission value - a:

Uncertainty Value - k.

Value determined according to EN28622-1

2

‘a’ values in excess of 2.5 m/s

are considered hazardous when used for

6.23 m/s

1.5

prolonged periods. A tool with a vibration value of 2.8 m/s

2

2

may be used for

up to 8 hours (cumulative) per day, whereas a tool with a value of 11.2 m/s

may be used for ½ hour per day only.

17

2

The graph on the right shows the

vibration value against the maximum

time the respective tool may be

used, per day.

The uncertainty factor should also be

taken into account when assessing a

risk. The two figures ‘a’ and ‘K’ may

be added together and the resultant

value used to assess the risk.

It should be noted that if a tool is

used under abnormal, or unusual

conditions, then the vibration level

could possibly increase significantly. Users must always take this into account

and make their own risk assessment, using the graph above as a reference.

Some tools with a high vibration value, such as impact wrenches, are

generally used for a few seconds at a time, therefore the cumulative time

may only be in the order of a few minutes per day. Nevertheless, the

cumulative effect, particularly when added to that of other hand held power

tools that may be used, must always be taken into account when the total

daily dose rate is determined.

18

DECLARATION OF CONFORMITY

19

Loading...

Loading...