Page 1

AIR PRESSURISED PAINT FEED

AIR PRESSURISED PAINT FEED

CONTAINER

CONTAINER

Model Nos:

CPP5 • CPP11 • CPP30 • CPP40

OPERATING & MAINTENANCE

INSTRUCTIONS

1106

Page 2

Parts List - CPP 30 & 40

Please read these instructions carefully before using the Paint Pot

Thank you for purchasing this CLARKE Air Pressurised Paint Feed Container.

Before using the device, please read this manual thoroughly and carefully

follow all instructions given. This is for your own safety and that of others around

you, and is also to help you achieve long and trouble free service from your

new product.

CLARKE GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period

of 12 months from the date of purchase. Please keep your receipt as proof

of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product

can be returned to us without prior permission.

This guarantee does not affect your statutory rights.

SPECIFICATIONS

CPP5 CPP12 CPP30 CPP40

Inner Container capacity 3.25L 9.25L 24.5L 34L

Outer Container capacity 4.2L 11.7L 31.2L 43.4L

Fluid Type Oil/Solvent based paints

Maximum Operating Pressure 3bar 3bar 3bar 3bar

Absolute Maximum Pressure 5.5bar 5.5bar 5.5bar 5.5bar

Air Hose Connection 1/4”BSP 1/4”BSP 1/4”BSP 1/4”BSP

Liquid Hose Connection 3/8” BSP 3/8” BSP 3/8” BSP 3/8” BSP

Weight unpacked 5.85kg 14.5kg 24kg 26kg

No. Description Part No:

1 Container CPP30 1 KLCPP3001

1 Container CPP40 1 KLCPP4001

2 Lid assembly 1 KLCPP3002

3 Inner Container CPP30 1 KLCPP3003

3 Inner Container CPP40 1 KLCPP4003

4 Gasket 1 KLCPP3004

5 Guard 1 KLCPP3005

6 Hex. Nut 2 KLCPP3006

7 Air Exhaust Valve 1 KLCPP3007

8 O-ring 1 KLCPP3008

9 Adapter 1 KLCPP3009

10 Air inlet adapter 2 KLCPP3010

10a Air adapter 2 KLCPP3010A

11 Tee Piece 1 KLCPP3011

12 Air Outlet Cock 1 KLCPP3012

13 Nut 1 KLCPP3013

14 Air Outlet 1 KLCPP3014

15 Air inlet Cock 1 KLCPP3015

16 Pressure Regulator 1 KLCPP3016

17 Bolt 1 KLCPP3017

18 Handle 1 KLCPP3018

19 Hex. Nut 5 KLCPP3019

20 Handle Lever 1 KLCPP3020

21 Bolt 1 KLCPP3021

22 Bolt 1 KLCPP3022

23 Cap Screw 1 KLCPP3023

24 Sealing Ring 1 KLCPP3024

No. Description Part No:

25 Connecting ring 1 KLCPP3025

26 O-ring 2 KLCPP3026

27 Guide Bush 1 KLCPP3027

28 Seal Ring 1 KLCPP3028

29 Pressure Relief valve 1 KLCPP3029

35 Fluid outlet Cock 2 KLCPP3035

36 Fluid Outlet Adapter 1 KLCPP3036

37 Pressure Gauge 1 KLCPP3037

38 Agitator Rod CPP30 1 KLCPP3038

38 Agitator Rod CPP40 1 KLCPP4038

39 Hex. Nut 1 KLCPP3039

40 Agitator 1 KLCPP3040

41 Swing Bolt 4 KLCPP3041

42 Washer 4 KLCPP3042

43 Wing Nut 4 KLCPP3043

44 Washer 4 KLCPP3044

45 Caster 4 KLCPP3045

46 C-Snap Ring 8 KLCPP3046

47 Cotter Pin 4 KLCPP3047

48 Fluid tube CPP30 1 KLCPP3048

48 Fluid Tube CPP40 1 KLCPP4048

49 Fluid Pick-Up 1 KLCPP3049

50 Filter Support 1 KLCPP3050

51 Filter 1 KLCPP3051

52 Snap Ring 1 KLCPP3052

53 Spanner 1 KLCPP3053

54 Air flow guide 1 KLCPP3054

2

11

Page 3

Parts Diagram - CPP 30 & 40

SAFETY PRECAUTIONS

1. ALWAYS keep the unit perfectly clean. This will not only prolong its life, but will

also ensure you get the best results.

2. NEVER exceed an air pressure supply of 80psi to the product.

3. NEVER attempt to adjust the safety valve

4. NEVER tamper with the product or modify in any way, as this could prove to

be dangerous and will invalidate the guarantee.

5. ONLY use the product for the purpose for which it is intended,

6. ALWAYS wear approved impact resistant SAFETY GOGGLES. (Eye glasses are

NOT safety glasses), and a FACE MASK

7. DO NOT remove any labels. Damaged labels should be replaced.

AIR SUPPLY

WARNING

Compressed air can be dangerous.

Ensure that you are thoroughly

familiar with all precautions relating

to the use of compressors and

compressed air supply.

Air pressure supply to the container should not be greater than 80psi. Higher pressure and

unclean air, will shorten the tools’ life because of faster wear, and could be a safety hazard.

Water in the air line will also cause damage. Ensure it is properly maintained at all times.

The recommended procedure to connect this product to an air supply, is shown below. A

filter/regulator should always be placed in line with the supply and the paint pot.

The air inlet used for connecting air supply, has a standard ¼” BSP thread.

Line pressure, or hose inside diameter, should be increased to compensate for unusually

long air hoses (over 10m). Minimum hose diameter should be 6mm (¼") ID., and fittings

should have the same inside dimensions.

10

3

Page 4

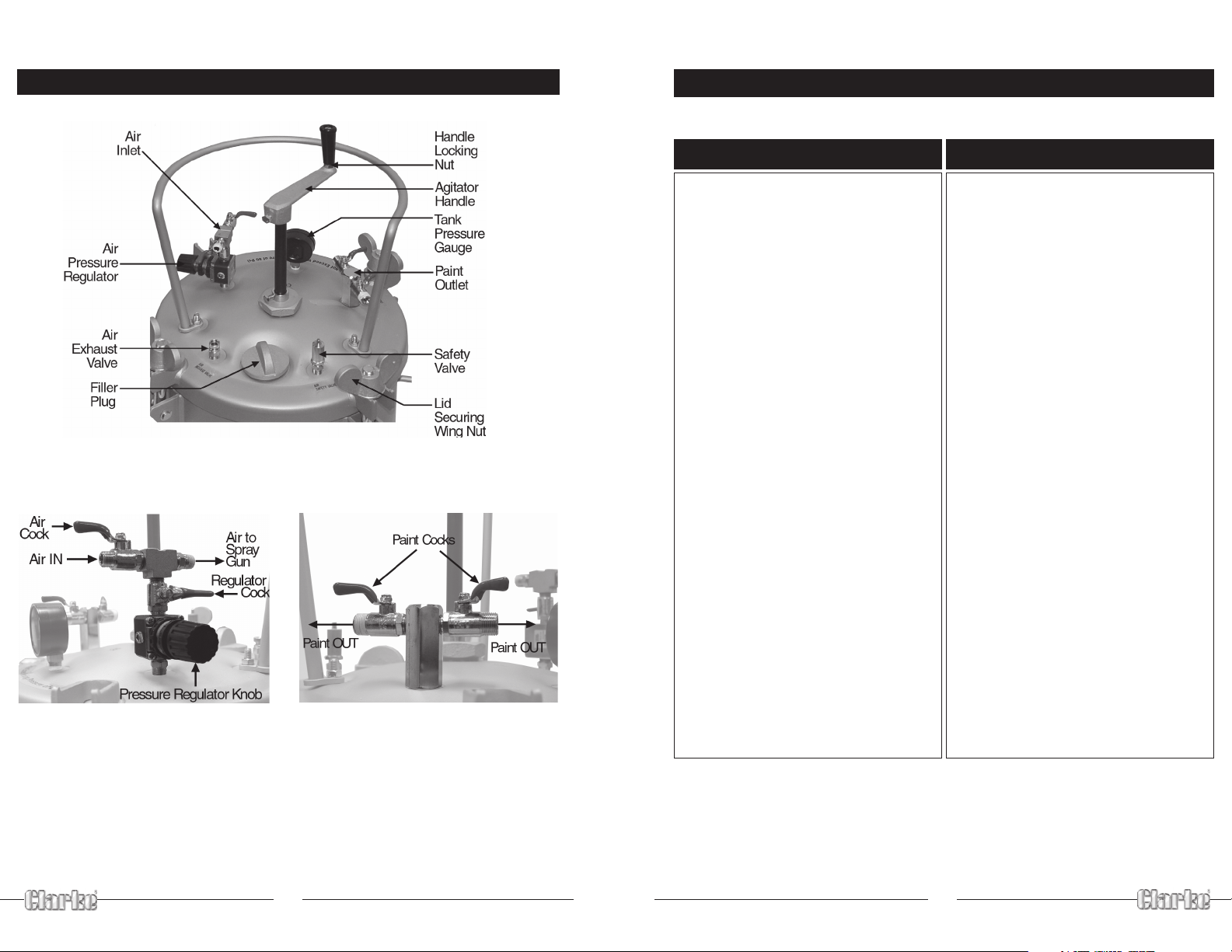

FEATURES

Parts List - CPP 11

Fig.1

Fig.2 Fig.3

The illustration above is of a CPP30, but components of other models are similar.

No. Description Part No:

1 Container 1 KLCPP1101

1a Inner Container 1 KLCPP1101a

2 Lid Assy 1 KLCPP1102

3 Gasket 1 KLCPP1103

4 Bolt 1 KLCPP1104

5 Handle 1 KLCPP1105

6 Nut Hex 1 KLCPP1106

7 Hand Lever 1 KLCPP1107

8 Bolt 1 KLCPP1108

9 Connecting Ring 2 KLCPP1109

10 O-Ring 2 KLCPP1110

11 Guide Bush 1 KLCPP1111

12 Seal Ring 1 KLCPP1112

13 Screw bolt 2 KLCPP11013

14 Guard 1 KLCPP1114

15 Hexagon nut 2 KLCPP1115

16 Adapter 1 KLCPP1116

17 Fluid Outlet adapter 1 KLCPP1117

18 Air Inlet Adapter 2 KLCPP1118

18a Adapter 1 KLCPP1118a

19 Air Cock 1 KLCPP1119

20 Pressure Regulator 1 KLCPP1120

21 Tee Piece 1 KLCPP1121

No. Description Part No:

22 Pressure gauge 1 KLCPP1122

29 Pressure Relief Valve 1 KLCPP1129

30 Adapter 1 KLCPP1130

31 O-ring 1 KLCPP1131

32 Air Exhaust Valve 1 KLCPP1132

33 Agitating rod 1 KLCPP1133

34 Hex. Nut 1 KLCPP1134

35 Agitator 1 KLCPP1135

36 Screw 1 KLCPP11036

37 Fluid Tube 1 KLCPP1137

38 Pick-Up 1 KLCPP1138

39 Filter Support 1 KLCPP1139

40 Filter 1 KLCPP1140

41 Snap ring 1 KLCPP1141

42 Swing bolt 4 KLCPP1142

43 Washer 4 KLCPP1143

44 Wing Nut 4 KLCPP1144

45 Nut 4 KLCPP1145

46 Washer 4 KLCPP1146

47 Caster 4 KLCPP1147

48 Spanner 4 KLCPP1148

49 C-Snap Ring 8 KLCPP1149

This Paint Feed Container is designed primarily for use in spraying oil and solvent

based paint.

Clarke International provides a range of Spray Guns which may be used with

these Feed Containers. Please see your local dealer for the HVLP and PRO Ranges.

4

9

Page 5

Parts Diagram - CPP 11

8

METHOD OF OPERATION

Prior to use, ensure the casters are properly screwed to their housings where appropriate

WARNING!

ALWAYS check to ensure the container is NOT under pressure, by checking the

pressure gauge and opening the air exhaust valve - turn the knurled ring nut

anticlockwise. Tighten the ring nut once again once all air is exhausted.

1. Fill the container with paint as follows:

• Undo each lid securing wing nut and swing the bolts out of the way.

• Lift off the lid.

• Fill the inner container with paint.

NOTE: It is permissible to fill the container itself, but we strongly recommend the

inner container be used at all times, as it is easier to clean.

• Replace the lid, ensuring the wing nuts are tightened progressively.

NOTE: Models CPP 30 and CPP40 are provided with filler plugs in the lid. These may

be used if preferred, but take care to comply with all precautions before undoing

2. Connect the air supply hose to the air inlet.

NOTE: See notes on Air Supply on page 4.

3. Connect the air hose from the spray gun, to the air outlet.

4. Connect the paint hose from the spray gun to the paint outlet.

5. Ensure the pressure regulator knob is turned fully anticlockwise, then turn ON

the air supply from compressor/air supply to the paint pot.

Where necessary, turn ON the air inlet cock at the cylinder, followed by the

pressure regulator cock.

6. Turn the pressure regulator knob slowly clockwise to pressurise the container.

Working pressure will depend upon the consistency of the medium, but must

NEVER exceed 3bar. If the medium is sluggish at this pressure, then it is of too

thick consistancy, and should not be sprayed.

7. Turn ON the air outlet cock.

8. Turn ON the paint outlet cock.

9. Finally, make adjustment

to the spray pattern

according to the spray

gun manufacturers

instructions.

The paint should be agitated

at regular intervals during use

to ensure consistancy and

avoid colour difference due

to the paint settling.The CPP5

may be shaken gently.

A typical configuration is shown in Fig.4.

Fig.4

5

Page 6

MAINTENANCE

It is important to clean the complete unit thoroughly at the end of any operation.

1. Turn OFF air to the container.

2. Turn the air exhaust valve knurled ring nut anticlockwise and allow the

container to completely depressurise.

3. Loosen all lid wing nut securing nuts, swing back the bolts and move the lid so

that it rests at one side of the container.

4. Hold the spray gun and hose above the level of the unit and pull the spray

gun trigger to allow paint in the hose to drain back into the container. The

paint cock should be open (where fitted).

5. Empty the container of paint, then clean it thoroughly with solvent or white

spirits etc., depending upon the type of paint being sprayed.

Clean and dry all components that have come into contact with paint agitator etc.

6. With the container and other components cleaned thoroughly, pour clean

solvent or other cleaner, into the container.

7. Replace the lid and tighten the wing nuts - progressively.

8. Turn ON the air to the container and pull the spray gun trigger. Keep it pressed

until only clean solvent or other cleaner is ejected from the spray gun.

9. Repeat steps 1 - 4 to allow solvent or other cleaner to drain back into the

container.

10 Finally empty the container and dry all components thoroughly,

Store in a clean dry place, with all cocks closed, and the lid loose.

Periodically, pressurise the container to 5.5bar in order to test the safety valve.

If it does not blow off at this pressure, do not use the appliance...have the Pressure

Relief Valve replaced.

Parts List & Diagram - CPP 5

PARTS & SERVICE CONTACTS

For Spare Parts and Service, please contact your nearest dealer,

or CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

6

No. Description Part No:

1 Container 1 KLCPP501

1a Inner Container 1 KLCPP501a

2 Lid Assy. 1 KLCPP502

3 Handle 1 KLCPP503

4 Gasket 1 KLCPP504

5 Fluid Tube 1 KLCPP505

6 Swing Bolt 1 KLCPP506

7 Washer 4 KLCPP507

8 Wing Nut 4 KLCPP508

9 Pressure Regulator 4 KLCPP509

10 Pressure Gauge 1 KLCPP510

11 Adapter - Air Inlet 1 KLCPP511

No. Description Part No:

12 Fluid Outlet 2 KLCPP512

13 Fluid Outlet Adapter 1 KLCPP513

14 Air Exhaust Valve 1 KLCPP514

15 O-Ring 1 KLCPP515

16 Adapter 1 KLCPP516

22 Pressure Relief Vlv 1 KLCPP522

23 Air Flow Guide 1 KLCPP523

24 Nut 1 KLCPP524

25 Cotter Pin 4 KLCPP525

26 Snap Ring 8 KLCPP526

27 Adapter Post 1 KLCPP527

7

Loading...

Loading...