Page 1

VARIABLE SPEED

JIG SAW

ELECTRIC SANDER

ELECTRIC SANDER

MODEL No. CON300

OPERATING & MAINTENANCE

Part No. 6460200

Part No. 6462052

INSTRUCTIONS

1

LS0610

Page 2

2

Page 3

Thank you for purchasing this CLARKE Sander.

Before attempting to use the sander, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to the sander giving you

long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Please keep your receipt which will be required as

proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered

with in any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee does not effect your statutory rights.

PACK CONTENTS

• CON300 Electric sander • 4 x 60 Grit Sanding Sheets

• 3 x 120 Grit Sanding Sheets • 3 x 240 Grit Sanding Sheets

SPECIFICATIONS

Model ........................................................ CON300

Part No ....................................................... 6462052

Electrical Supply .......................................230V 50Hz 1 ph

Wattage .................................................... 330 W

No Load Speed ........................................ 6000 - 11000 Orbits per minutes

Sanding pad size ...................................... 230 mm x 115 mm

Weight (unpacked) ................................. 2.62 kg

Dimensions ................................................ 340 x 120 x 195 mm

Sound Pressure Level L

Sound Power Level L

Please note that the details and specifications contained herein, are correct at the time of going to print. However,

CLARKE International reserve the right to change specifications at any time without prior notice.

.............................................

PA

.................................................

WA

3

84.5 dB(A)

95.5 dB(A)

Page 4

SAFETY PRECAUTIONS

WARNING!

As with all machinery, there are certain hazards involved with their

operation and use. Exercising respect and caution will considerably

lessen the risk of personal injury. However, if normal safety precautions

are overlooked or ignored, personal injury to the operator or damage

to property, may result.

1. ALWAY S Learn the machines’ applications, limitations and the specific

potential hazards peculiar to it. Read and become familiar with the entire

operating manual.

2. ALWAY S use a face or dust mask if sanding operation is particularly dusty.

3. ALWAY S check for damage. before using the machine, any damaged

part, should be checked to ensure that it will operate properly, and

perform its intended function. Check for alignment of moving parts,

breakage of parts, mountings, and any other condition that may affect

the machines’ operation. Any damage should be properly repaired or the

part replaced. If in doubt, DO NOT use the machine. Consult your local

dealer.

4. ALWAY S disconnect the tool/machine from the power supply before

servicing and when changing accessories.

5. ALWAY S wear safety goggles, manufactured to the latest European Safety

Standards. Everyday eyeglasses do not have impact resistant lenses, they

are not safety glasses.

6. ALWAY S keep work area clean. Cluttered areas and benches invite

accidents.

7. ALWAY S ensure that adequate lighting is available. A minimum intensity of

300 lux should be provided. Ensure that lighting is positioned so that you

will not be working in your own shadow.

8. ALWAY S keep children away. All visitors should be kept a safe distance from

the work area, especially whilst operating the machine.

9. ALWAY S maintain machine in top condition. Keep tools/machines clean for

the best and safest performance, follow maintenance instructions.

10. ALWAY S handle with extreme care do not carry the tool/machine by its’

electric cable, or yank the cable to disconnect it from the power supply .

11. ALWAY S ensure the switch is off before plugging in to mains. Avoid

accidental starting.

12. ALWAY S concentrate on the job in hand, no matter how trivial it may seem.

Be aware that accidents are often caused by carelessness due to

familiarity.

13. ALWAY S keep your proper footing and balance at all times - don’t

overreach. For best footing, wear rubber soled footwear. Keep floor clear

of oil, scrap wood, etc.

14. ALWAY S wear proper apparel. Loose clothing or jewellery may get caught

in moving parts. Wear protective hair covering to contain long hair.

4

Page 5

15. ALWAYS use recommended accessories. The use of improper accessories

could be hazardous.

16. ALWAY S remove plug from electrical outlet when adjusting, changing parts,

or working on the machine.

17. NEVER operate machine while under the influence of drugs, alcohol or

medication.

18. NEVER leave machine running unattended. Turn power off. Do not leave

the machine until it comes to a complete stop.

19. NEVER force the machine. It will do a better and safer job at the rate for

which it was designed.

20. NEVER use power tools in damp or wet locations or expose them to rain.

Keep your work area well illuminated. do not use in explosive atmosphere

(around paint fumes, flammable liquids etc.). Avoid dangerous

environment.

ADDITIONAL PRECAUTIONS FOR ORBITAL SANDERS

1. Always wear ear protectors/defenders, as the noise level of this machine

can exceed 85dB (A).

2. Do not use the machine if the electric cable, plug or the motor, is in poor

condition.

3. Keep the mains cable well away from the sander, and ensure an

adequate electrical supply is close at hand so that the operation is not

restricted by the length of the cable.

4. Switch the machine OFF immediately the task is completed.

5. Never allow the ventilation slots in the machine to become blocked.

6. Always use the appropriate sanding medium for the material being

worked. Both metal and wood sanding sheets of various grades are

available from all good hardware stores.

7. Do not attempt any electrical repair yourself. Consult a qualified

electrician, or our Service Department on 020 8988 7400

Additionally, please keep these instructions in a safe place for future reference.

DUST EXTRACTION

The sander is provided with a dust extraction facility, Please note however, that

this does not preclude the user from wearing a face mask to prevent the

inhalation of dust particles.

It is an EEC requirement that a dust extraction facility be provided on power tools,

however, due to the nature of the tool, some of the dust produced will be forced

into the surrounding atmosphere, and will not be collected.

5

Page 6

ELECTRICAL CONNECTIONS

This product is provided with a standard 13 amp, 230 volt (50Hz), BS 1363 plug, for

connection to a standard, domestic electrical supply. Should the plug need

changing at any time, ensure that a plug of identical specification is used.

WARNING!

This appliance is double insulated, and the two wires in the mains lead should

be wired in accordance with the following colour code:

BLUE - NEUTRAL

BROWN - LIVE

•

Connect the BLUE coloured wire to the plug terminal marked with a letter “N”

• Connect the BROWN coloured wire to the plug terminal marked with a letter “L”

If this appliance is fitted with a plug which is moulded on to the electric cable (i.e.

non-rewireable) please note:

1. The plug must be thrown away if it is cut from the electric cable. There is a

danger of electric shock if it is subsequently inserted into a socket outlet.

2. Never use the plug without the fuse cover fitted.

3. Should you wish to replace a detachable fuse carrier, ensure that the

correct replacement is used (as indicated by marking or colour code).

4. Replacement fuse covers can be obtained from your local Clarke dealer

or most electrical stockists.

FUSE RATING

The fuse in the plug must be replaced with one of the same rating (5 amps) and

this replacement must be ASTA approved to BS1362.

If in doubt, consult a qualified electrician. Do not attempt any electrical repairs

yourself.

CABLE EXTENSION

Always use an approved cable extension suitable for the power rating of this tool

(see specifications), the conductor size should also be at least the same size as

that on the machine, or larger. When using a cable reel, always unwind the cable

completely. If using tool outdoors, only use extension cables intended for outdoor

use.

Page 7

PREPARATION

WARNING!

Disconnect the plug from the power source before fitting/changing the

sandpaper.

FITTING THE SANDPAPER

To fit the sandpaper, proceed as follows:

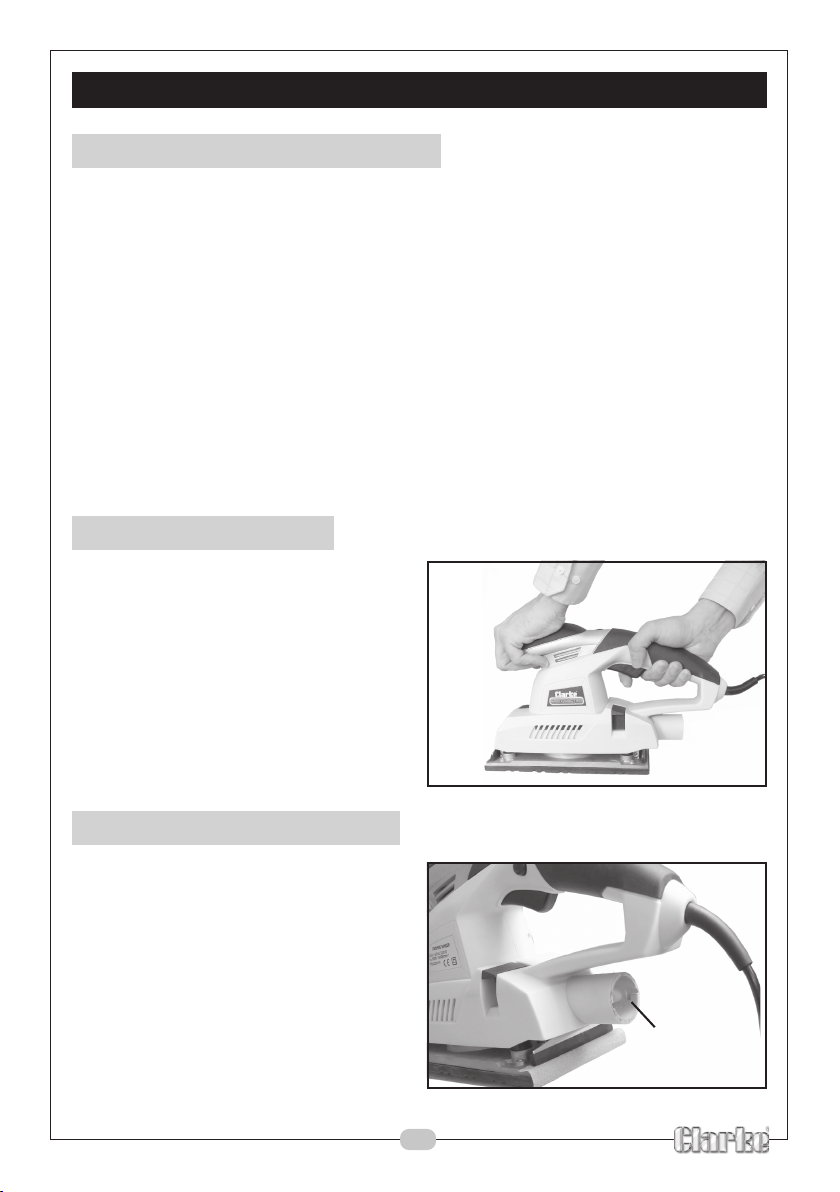

1. Lift the clamp lever, see figure 1.

2. Insert the end of the sandpaper

and push the clamp lever down.

3. Fold the sandpaper around the

vibrating plate, ensuring the

holes on the sandpaper are

aligned with the holes on the

vibrating plate, see figure 2.

4. Insert and clamp the other end

of the sandpaper to the other

end of the sander.

WARNING!

When using the orbital sander, certain materials will generate harmful

or toxic dusts and grit. Contact with or inhalation of these dusts can

endanger the health of the operator and bystanders, see general

safety rules for appropriate personal protective equipment.

Fig 1

Clamp

Lever

Fig 2

Clamp

Lever

Page 8

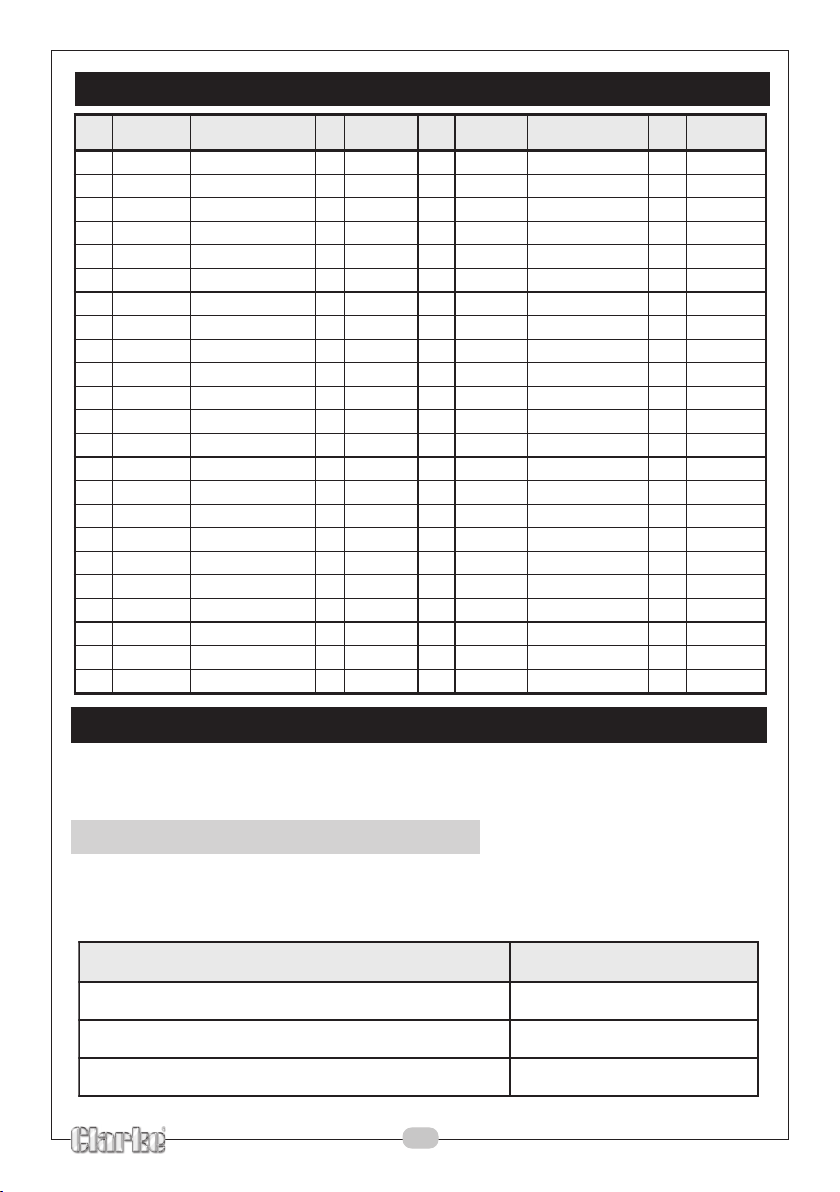

OPERATION

1. Connect the plug to the mains supply socket and switch on.

2. Hold the sander firmly with both hands.

OPERATING THE TRIGGER SWITCH

WARNING!

Never start the sander when it is in contact with the work piece.

1. Hold the sander in mid air and

squeeze the trigger, the sander

will start.

2. Release the trigger to stop the

sander.

3. If continuous operation is

required, squeeze the trigger,

and depress the lock-on button

and release the trigger.

4. To stop the sander, squeeze the

trigger to release the lock-on button, then release the trigger.

Fig 3

Handle

WARNING!

After Use, ensure that the sander has stopped before putting the tool

down.

Lock-on

button

Trigger

8

Page 9

OPERATION

USING THE SANDER

1. Make sure that there are no nails or other objects in the area to be sanded.

2. Let the sander reach full speed before applying it to the work surface.

3. Do not apply pressure to the sander during use. The weight of the sander

alone is sufficient for normal use.

4. Move the sander evenly over the work area. Do not allow the sander to stay

in one place for too long.

5. Replace worn sanding sheets. The performance of your sander is dependant

on the quality of the sanding sheets being used. Replacement sanding

sheets are available from your CLARKE dealer (see page 13).

6. Remove the sander from the work area before releasing the trigger.

SANDING HINTS

• Always use both hands to hold

the sander

• Clamp the workpiece for

added stability and safety.

DUST EXTRACTION PORT

You can connect a vacuum cleaner

directly to the dust extraction port.

• The extraction port has an

internal diameter of 30mm and

an external diameter of 37mm

Fig 4

Fig 5

Dust

Extraction

Port

9

Page 10

MAINTENANCE

WARNING!

Make sure that the sander is switched off and disconnected from the

mains supply before starting any cleaning or maintenance procedures.

• Keep the cooling vents clear.

• Clean the housing with a soft cloth.

• Any worn or damaged parts should be replaced by qualified personnel.

• Keep the handles clean and free from oil and grease.

• There are no user serviceable parts inside this sander.

TROUBLE SHOOTING

SANDER IS OVERHEATING

• Clean the ventilation holes, and blow out with compressed air or clean

with a dry cloth.

• Overloading the machine could cause overheating. Do not apply

excessive pressure.

SANDER DOES NOT OPERATE WHEN SWITCHED ON

• Check to make sure that the fuse has not blown, if it has, replace the

fuse. If the fuse blows repeatedly, consult your CLARKE dealer.

• If the fuse is OK and the machine still does not work, consult your CLARKE

dealer.

THE DUST IS NOT EXTRACTED

• Dust extractor port is blocked.

10

Page 11

PARTS DIAGRAM

11

Page 12

PARTS LIST

saelbaliavA

metI rebmuNtraP noitpircseD ytQ

1202061PKdaeLsniaM1seY42820413PKnaFrotoM1oN

2600223PKdrauGdroC1seY52320025PKZ926gniraeBrelloR1oN

3000513PKpmalCdroC1seY62400413

4102005PK41x9.3TSwercSgnippaT2oN72813422PKrevoCyaWriA1oN

5405323PKraBtroppuS4oN82602005PK9x9.3TSwercSgnippaT3oN

6746361PKhctiwS1seY92104322PKpmalCrepaP2seY

7005161PKroticapaC1oN03400123PKtooFpmalCrepaP2oN

8000123PKpaCrebbuR2oN13200142PKgnir

9613422PKetalPpmalC4oN23600512PKniP2oN

01000005PK9x9.2TSwercSgnippaT5oN33000532PKetalPesaB1seY

11460512PKniP2oN43930025PKZ200

21300142PKgnirpS2oN53008432PKecnalabretnuoC1oN

31268213PK1reveLpmalCrepaP1seY63200305PKrehsaWnialP1oN

41002

005PK91x9.3TSwercSgnippaT41oN73400405PKrehsaWgnirpS1oN

51530003PK2gnisuoH1seY83505105PK61x5MwercS1oN

61128261PKBCP1oN93938513P

71005413PKredloHhsurB2oN04200023PKgniRO1oN

81008222PKtroppuSredloHhsurB2oN14018005PK01x4MwercS6oN

91004261PKylbmes

02307161PKrotcudnI1oN34400143PKdaP1seY

12840011PKrotatS1oN44368213PK2reveLpmalCrepaP1s

22210025PKZ706gniraeBrelloR1oN54530003PK1gnisuoH1seY

32840001PKrotoR1oN

sAhsurBnobraC2oN24300405PKrehsaWgnirpS6oN

traperapSa

metI rebmuNtraP noitpircseD ytQ

PKnaFtsuD1oN

pS2oN

6gniraeBrelloR1oN

KtroPtsuD1oN

saelbaliavA

traperapSa

eY

ACCESSORIES

Accessories are available from your nearest CLARKE dealer, or via the CLARKE

International Sales department on 01992 565 300.

REPLACEMENT SANDING SHEETS

Replacement sanding sheets are available from your CLARKE dealer. Please

quote the following part numbers:

epyT rebmuNtraP

)kp01(06#steehsgnidnastnemecalpeR6902646

)kp01(021#steehsgnidnastnemecalpeR8902646

teehsgnidnastnemecalpeR9902646

)kp01(042#,s

12

Page 13

DECLARATION OF CONFORMITY

When disposing of this product, ensure it is disposed of according to all

local ordinances. It must not be disposed of with general household waste.

13

Page 14

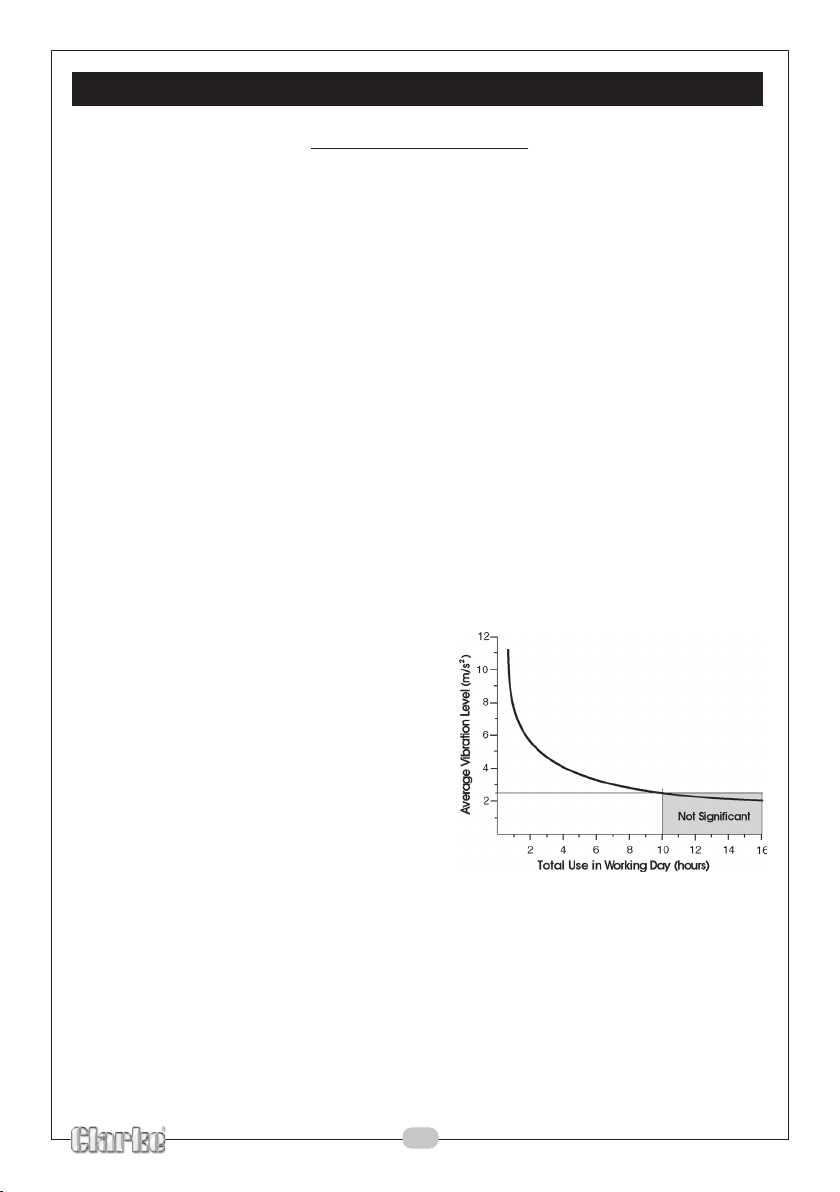

VIBRATION EMISSIONS

HAND-ARM VIBRATION

Employers are advised to refer to the HSE publication “Guide for Employers”.

All hand held power tools vibrate to some extent, and this vibration is transmitted

to the operator via the handle, or hand used to steady the tool. Vibration from

about 2 to 1500 hertz is potentially damaging and is most hazardous in the range

from about 5 to 20 hertz.

Operators who are regularly exposed to vibration may suffer from Hand Arm

Vibration Syndrome (HAVS), which includes ‘dead hand’, ‘dead finger’, and

‘white finger’. These are painful conditions and are widespread in industries

where vibrating tools are used.

The health risk depends upon the vibration level and the length of time of

exposure to it……in effect, a daily vibration dose.

Tools are tested using specialised equipment, to approximate the vibration level

generated under normal, acceptable operating conditions for the tool in question.

For example, a grinder used at 45° on mild steel plate, or a sander on softwood

in a horizontal plane etc.

These tests produce a value ‘a

which represents the average vibration level of all tests taken, in three axes where

necessary, and a second figure ‘K’, which

represents the uncertainty factor, i.e. a value

in excess of ‘a’, to which the tool could

vibrate under normal conditions. These

values appear in the specification panel

below.

You will note that a third value is given in the

specification - the highest measured

reading in a single plane. This is the maximum

level of vibration measured during testing in

one of the axes, and this should also be

taken into account when making a risk

assessment.

‘

a

’ values in excess of 2.5 m/s2 are considered hazardous when used for prolonged

periods. A tool with a vibration value of 2.8 m/s2 may be used for up to 8 hours

(cumulative) per day, whereas a tool with a value of 11.2 m/s2 may be used for

½ hour per day only.

The graph shows the vibration value against the maximum time the respective

tool may be used, per day.

’

, expressed in metres per second per second,

14

Page 15

VIBRATION EMISSIONS

The uncertainty factor should also be taken into account when assessing a risk.

The two figures ‘a’ and ‘K’may be added together and the resultant value used

to assess the risk.

It should be noted that if a tool is used under abnormal, or unusual conditions, then

the vibration level could possibly increase significantly. Users must always take this

into account and make their own risk assessment, using the graph above as a

reference.

Some tools with a high vibration value, such as impact wrenches, are generally

used for a few seconds at a time, therefore the cumulative time may only be in

the order of a few minutes per day. Nevertheless, the cumulative effect,

particularly when added to that of other hand held power tools that may be

used, must always be taken into account when the total daily dose rate is

determined.

Declared vibration emission value in accordance with EN12096

Measured vibration emission value -

Values determined according to EN28622-1

a:

< 2.5 m/s

2

15

Page 16

16

Loading...

Loading...