Page 1

VARIABLE SPEED

JIG SAW

DEMOLITION HAMMER

DEMOLITION HAMMER

MODEL No. CON2100 / CON2300

OPERATING & MAINTENANCE

Part No. 6460200

Part No. 6462076 / 6462078

INSTRUCTIONS

LS0209

Page 2

Thank you for purchasing this CLARKE demolition hammer.

Before attempting to use the demolition hammer please read this manual

thoroughly and follow the instructions carefully. In doing so you will ensure the

safety of yourself and that of others around you, and you can look forward to

the demolition hammer giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Please keep your receipt which will be required as

proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered

with in any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be

returned to us without prior permission.

This guarantee does not effect your statutory rights.

SPECIFICATIONS

ledoM0012NOC0032NOC

rebmuNtraP67026468702646

egatloVzH05@V011zH05@V032

rewoPW0012W0012

)nimrepsekorts(etartcapmI05

ygrenetcapmIseluoJ72-7seluoJ72-7

redloHlooTxeH12xeH12

etercnocniyticapaCmumixaMmm05mm05

oisnemiD052x031x547052x031x547

)HxWxL(sn

thgieWgk71gk71

derusaeMrewoPdnuoSwL)A(Bd201

)SMR(noitarbiVs/m79.9

91-0570591-057

A

2

wL)A(Bd201

A

2

s/m79.9

PACK CONTENTS

• Demolition hammer • Side handle

• 1 x Chisel • 1 x Drill bit

Please note that the details and specifications contained herein, are correct at the time of going to print.

However, CLARKE International reserve the right to change specifications at any time without prior notice.

2

Page 3

SAFETY PRECAUTIONS

WARNING!

As with all machinery, there are certain hazards involved with their

operation and use. Exercising respect and caution will considerably

lessen the risk of personal injury. However, if normal safety precautions

are overlooked or ignored, personal injury to the operator or damage

to property, may result.

1. ALWAYS Learn the machines applications, limitations and the specific

potential hazards peculiar to it. Read and become familiar with the entire

operating manual.

2. ALWAYS use a face or dust mask if the operation is particularly dusty.

3. ALWAYS check for damage. before using the machine, any damaged part,

should be checked to ensure that it will operate properly, and perform its

intended function. Check for alignment of moving parts, breakage of parts,

mountings, and any other condition that may affect the machines’

operation. Any damage should be properly repaired or the part replaced.

If in doubt, DO NOT use the machine. Consult your local dealer.

4. ALWAYS disconnect the tool/machine from the power supply before

servicing and when changing accessories.

5. ALWAYS wear safety goggles, manufactured to the latest European Safety

Standards. Everyday eyeglasses do not have impact resistant lenses, they

are not safety glasses.

6. ALWAYS keep work area clean. Cluttered areas and benches invite

accidents.

7. ALWAYS ensure that adequate lighting is available. A minimum intensity of

300 lux should be provided. Ensure that lighting is positioned so that you will

not be working in your own shadow.

8. ALWAYS keep children away. All visitors should be kept a safe distance from

the work area, especially whilst operating the machine.

9. ALWAYS maintain machine in top condition. Keep tools/machines clean for

the best and safest performance, follow maintenance instructions.

10. ALWAYS handle with extreme care do not carry the tool/machine by its’

electric cable, or yank the cable to disconnect it from the power supply .

11. ALWAYS ensure the switch is off before plugging in to mains. Avoid

accidental starting.

12. ALWAYS concentrate on the job in hand, no matter how trivial it may seem.

Be aware that accidents are often caused by carelessness due to

familiarity.

3

Page 4

13. ALWAYS keep your proper footing and balance at all times - don’t

overreach. For best footing, wear rubber soled footwear. Keep floor clear

of oil, scrap wood, etc.

14. ALWAYS wear proper apparel. Loose clothing or jewellery may get caught in

moving parts. Wear protective hair covering to contain long hair.

15. ALWAYS use recommended accessories. The use of improper accessories

could be hazardous.

16. ALWAYS remove plug from electrical outlet when adjusting, changing parts,

or working on the machine.

17. NEVER operate machine while under the influence of drugs, alcohol or

medication.

18. NEVER leave machine running unattended. Turn power off. Do not leave the

machine until it comes to a complete stop.

19. NEVER force the machine. It will do a better and safer job at the rate for

which it was designed.

20. NEVER use power tools in damp or wet locations or expose them to rain.

Keep your work area well illuminated. Do not use in explosive atmosphere

(around paint fumes, flammable liquids etc.). Avoid dangerous environment.

ADDITIONAL PRECAUTIONS FOR DEMOLITION HAMMER

1. Always wear ear protectors/defenders, as the noise level of this machine

can exceed 85dB (A).

2. In cold-weather conditions or when the tool has not been used for a longer

period of time, let the tool run with no load for several minutes before use.

3. Always hold the tool firmly with both hands and ensure a secure stance.

4. Always operate the tool with the side handle properly mounted.

5. When working above ground level ensure the area below is clear.

6. To prevent electric shock, check the working area for live wires before

operation.

7. Do not touch the bit/chisel or the parts close to the bit/chisel immediately

after operation, as they maybe extremely hot and cause burns to the skin.

8. Always direct the power cable to the rear, away from the tool.

9. Do not attempt any electrical repair yourself. Consult a qualified electrician,

or our Service Department on 020 8988 7400

Additionally, please keep these instructions in a safe place for future reference.

4

Page 5

ELECTRICAL CONNECTIONS

230 VOLT MODELS

Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through

an approved 13 amp BS 1363 plug, or a suitably fused isolator switch.

WARNING! THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in the mains lead are coloured in accordance with the

following code:

As the colours of the flexible lead of this appliance may not correspond with the

coloured markings identifying terminals in your plug, or your mains supply,

proceed as follows:

• No connection should be made to the plug terminal marked with a letter “E” or

Earth symbol “ ” or coloured GREEN or GREEN & YELLOW.

• Connect BROWN cord to terminal marked with a letter “L” or coloured RED.

• Connect BLUE cord to terminal marked with a letter “N” or coloured BLACK.

FUSE RATING

The fuse in the plug must be replaced with one of the same rating and this replacement

must be ASTA approved to BS1362.

Blue ....................................................Neutral

Brown ................................................ Live

110 VOLT MODELS

These models must be connected to a protected 110V supply, through a suitably approved

connector. On no account must a 230V, 13amp (BS1363) plug be used.

NOTE: If a portable 110V transformer is used, make sure it has a rated capacity sufficient to

take the load of the machine.

CABLE EXTENSION

Always use an approved cable extension suitable for the power rating of this tool (see

specifications), the conductor size should also be at least the same size as that on the

machine, or larger. When using a cable reel, always unwind the cable completely.

WARNING!

IF YOU ARE IN ANY DOUBT ABOUT ELECTRICAL CONNECTIONS, CONSULT A

QUALIFIED ELECTRICIAN.

NEVER ATTEMPT ELECTRICAL REPAIRS YOURSELF.

5

Page 6

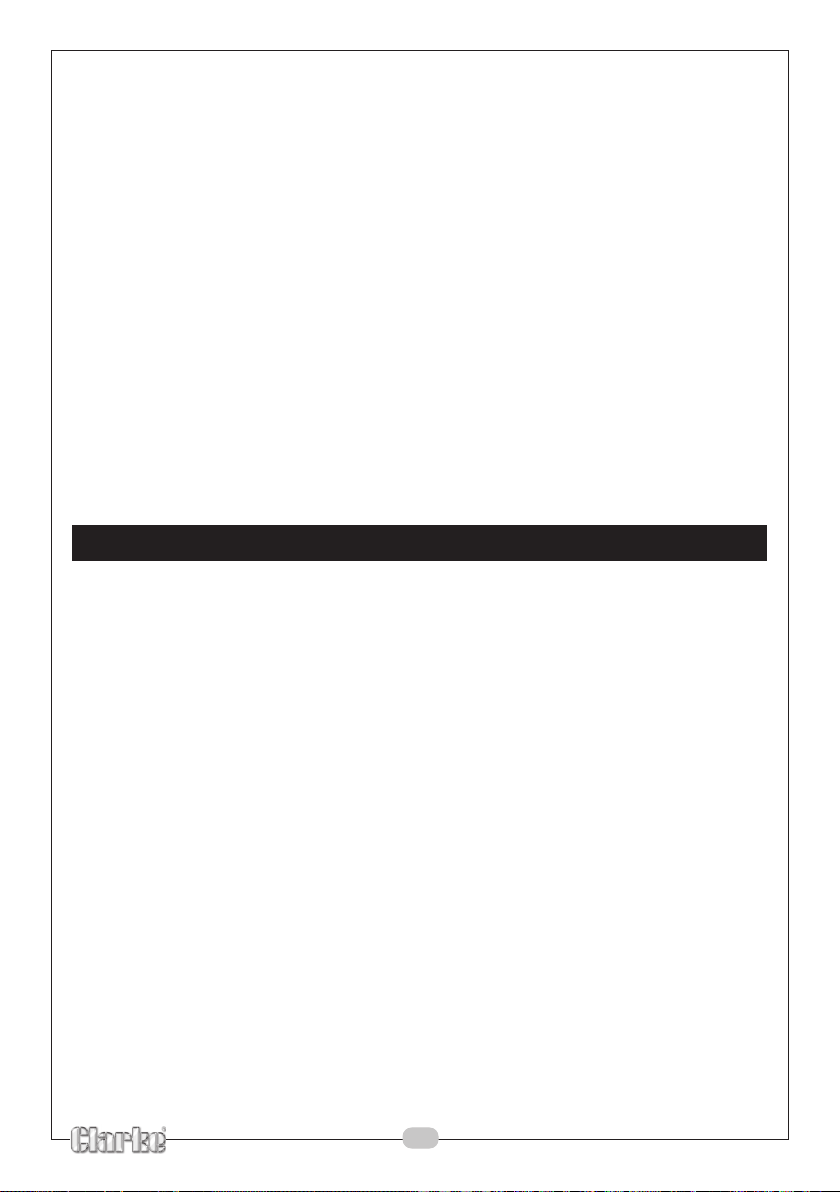

PREPARATION

ADJUSTING D SHAPED HANDLE

1. Turn the clamp knob

anticlockwise to loosen the D

shaped handle.

2. Adjust the D shaped handle to

the required angle and position.

3. Rotate the clamp knob

clockwise to lock the D shaped

handle into position.

FITTING THE SIDE HANDLES

1. The side handle can be fitted to

one of 3 points on the demolition

hammer shown on figure 2.

Fig 1

Fig 2

2

1

6

Page 7

PREPARATION

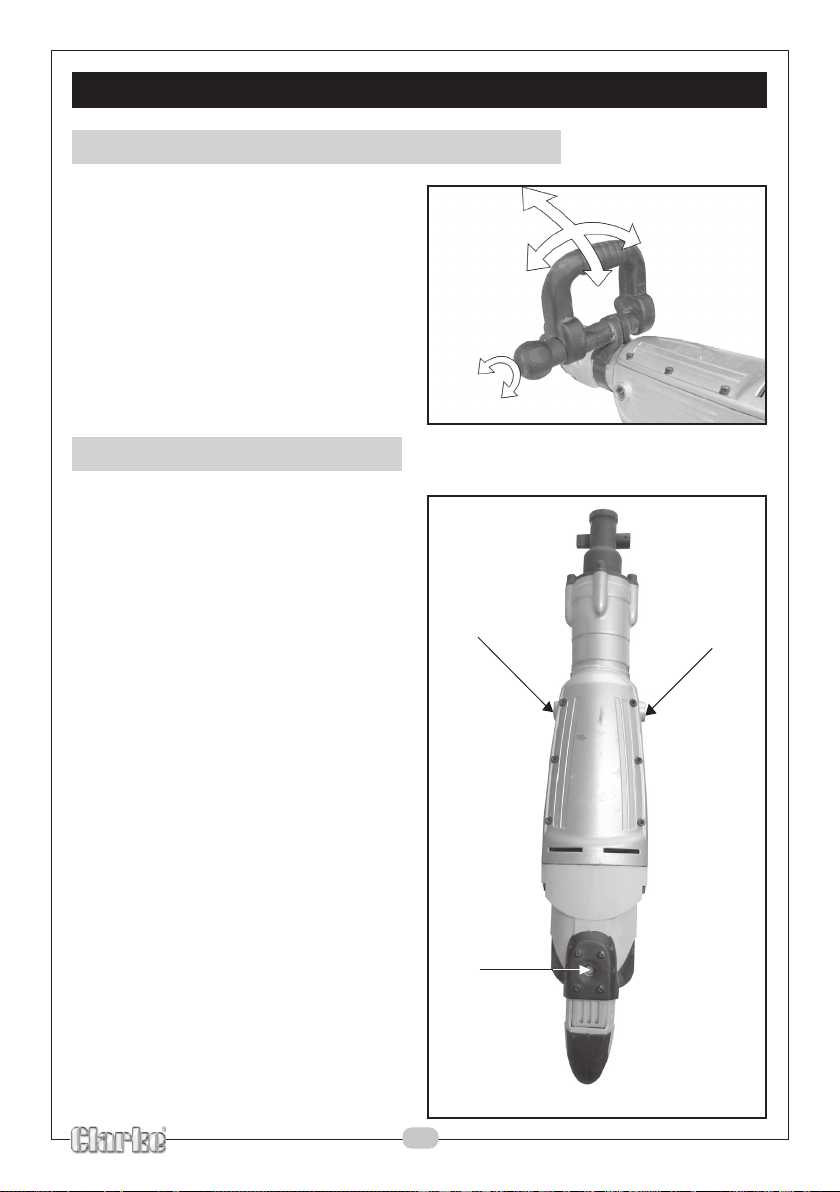

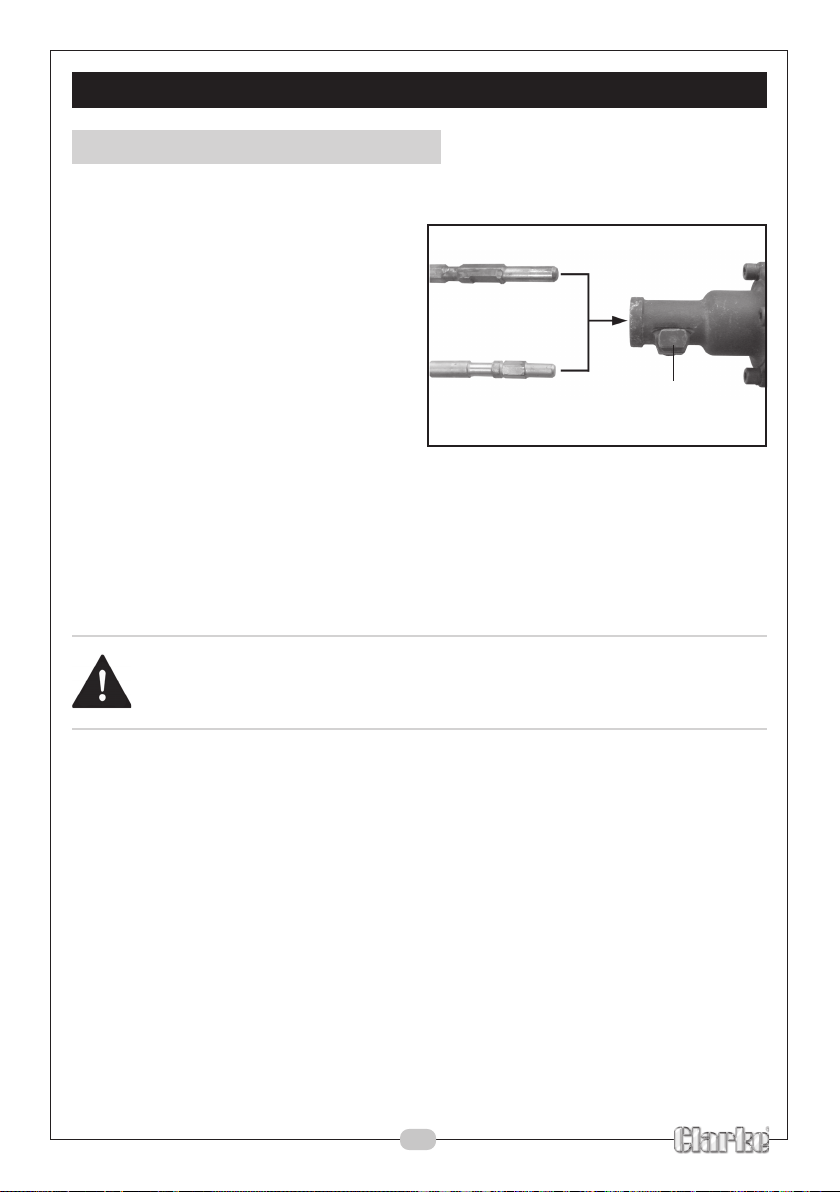

FITTING THE CHISEL/BIT

To fit the chisel/bit, proceed as follows:

1. Clean and grease the chisel

shank. Do NOT lubricate the

machine.

2. Pull out and rotate the locking

pin.

3. Insert the chisel shank into the

tool holder. Pull out and rotate

the locking pin again to secure

the chisel.

If the chisel bit you are using has a flat area on the shank, this should be

facing downwards.

4. Pull on the chisel to ensure it is locked into the tool holder, be aware that

the hammer action requires the chisel to be able to move axially by 2-3

cm.

WARNING!

Chisels/bits may be hot after use, take care when removing them from

the machine.

Fig 3

Locking

Pin

7

Page 8

INSTRUCTIONS FOR USE

WARNING!

Always check the location of pipes and wiring before starting the

machine.

Do not apply excessive pressure to the machine.

THE TRIGGER SWITCH

1. Pull the trigger switch up and back to start the machine.

2. Release the trigger to stop the machine.

Fig 4

Trigger

Speed

control

ADJUSTING THE SPEED

1. Adjust the speed control to the required setting.

MAINTENANCE

WARNING!

Make sure that the demolition hammer is switched off and disconnected

from the power supply before starting any cleaning or maintenance

procedures.

• Keep the cooling vents clear.

• Regularly clean the housing with a soft cloth.

• Any worn or damaged parts should be replaced by qualified personnel.

• Keep the handles clean and free from oil and grease.

8

Page 9

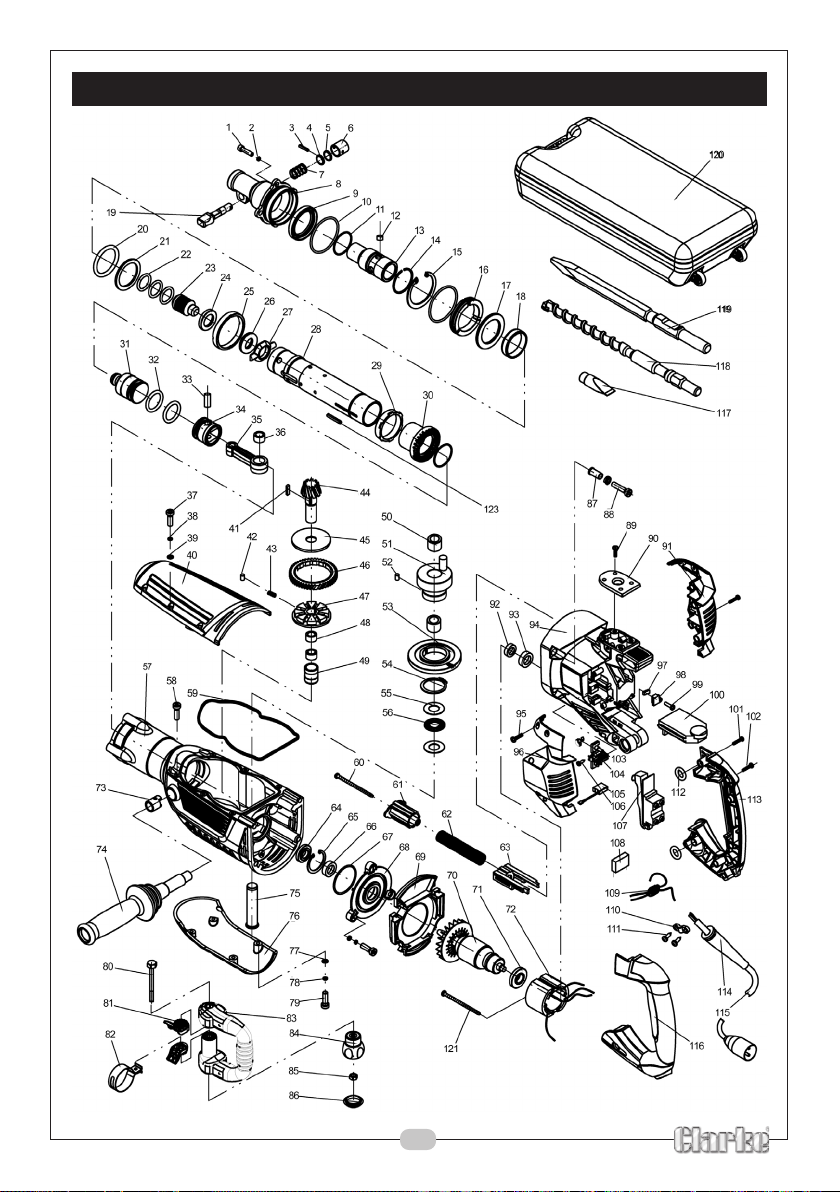

PARTS DIAGRAM

9

Page 10

PARTS LIST

metI rebmuNtraP noitpircseD ytQ metI rebmuNtraP noitpircseD ytQ

11000012NOCPK53X8MwercS4141400012NOCPKyeKrehtaeF1

22000012NOCPK8rehsaWgnirpS4242400012NOCPKetalPhctulC8

33000012NOCPK71

44000012NOCPK1X21X81rehsaW2444400012NOCPKraeGhtfiF1

55000012NOCPKtaeSgnirpS1545400012NOCPKtee

66000012NOCPKAgniR1646400012NOCPKraeGhtruoF1

77000012NOCPKgnirpS1747400012NOCPKetalPpilS1

88000012NOCPKteuoC18484

99000012NOCPKlaeSliO1949400012NOCPKrevoCeldeeN1

010100012NOCPKgniRO2050500012NOCPK6181KHgniraeB

111100012NOCPKgniRO2151500012NOCPKtfahSknarCdrihT1

212100012NOCPKeloPlletS4252500012NOCPK8X4BniP1

313100012NOCPKe

414100012NOCPKgniRpilC1454500012NOCPK04gniRpilC1

515100012NOCPK86gniRpi

616100012NOCPKgniraeBliO1656500012NOCPKetalPeldeeN1

717100012NOCPKelffaBgniraeBliO175750

818100012NOCPKgniRleetS1858500012NOCPK53X5MwercS2

919100012NOCPKdoR1959500012NOCPKgniR1M1

CPKgniRO1060600012NOCPK53X4TSwercS2

020200012NO

121200012NOCPKrehsaW1161600012NOCPKtaeSgnipmaD1

222200012NOCPKgnIRO3262600012NOCPKgnir

323200012NOCPKmaR1363600012NOCPKliaRerusolCgnipmaD1

424200012NOCPKelffaBmaR1464600012NOCPKrehsaW1

CPKelffaBliOtnorF1565600012NOCPKgniRpilC1

525200012NO

626200012NOCPKkcolBdaeD1666600012NOCPK2006gniraeBllaB1

727200012NOCPKkcolBde

828200012NOCPKrednilyC1868600012NOCPKrevoCraeG1

929200012NOCPKgniraeBliOkcalB1969600012NOCPKe

030300012NOCPKraeGxiS1070700012NOCPKrotoR1

131300012NOCPKmaR1171700012NOCPKrehsaW1

232300012NOCPK5X04gniRO227270001

333300012NOCPKniPnotsiP1373700012NOCPKtuN2

434300012NOCPKnotsiP1474700012NOCPKeldnaHediS1

535300012NOCPKdoRg

636300012NOCPKgniraeBeldeeN1676700012NOCPKrevoCliaT1

737300012NOCPK52x5MwercS477770

838300012NOCPK5rehsawgnirpS6878700012NOCPK5rehsaWgnirpS7

939300012NOCPK5rehsaW6979700012NOCPK61X5Mwe

040400012NOCPKrevoCesaCknarC1080800012NOCPK071X8MwercS1

X4niP1343400012NOCPKgnirpS8

hScitsalP1

00012NOCPKetalPeldeeN2

eldeeN2

veelSreniateR1353500012NOCPKraeGhtruoFdnoceS1

lC1555500012NOCPK1X81X53rehsaW2

0012NOCPKesaCknarC1

pSgnipmaD1

liforP1767600012NOCPKgniRO1

diuGnaF1

2NOCPKrotatS1

nitcennoC1575700012NOCPKklatStsujdA1

0012NOCPK5rehsaW7

rcS7

10

Page 11

PARTS LIST

metI rebmuNtraP noitpircseD ytQ metI rebmuNtraP noitpircseD ytQ

180800012NOCPKredloHeldnaHediS22012010012NOCPK81X4TSwercS7

281800012NOCPKpmalC13013010012NOCPKgnirpS2

382800012NOCPKeld

484800012NOCPKtuN15015010012NOCPKhsurBnobraC2

585800012NOCPK8MtuN616016010012NOCPK01X

686800012NOCPKrevoCtuN17017010012NOCPKhctiwS1

787800012NOCPKtuNtsujdA18018010012NOCPKFU22.0roticapaC1

88880001

989800012NOCPKF-61X6TSwercS40110110012NOCPKpilCdroC1

090900012NOCPKknalPtu

191900012NOCPKtloBthgiRtfiL12112110012NOCPK5X42gniRO4

292900012NOCPK0006gniraeBllaB1311311

393900012NOCPKteSgniraeBllaB14114110012NOCPKtekcaJdroC1

494900012NOCPKgnisuoH15115110012NOCPKdro

595900012NOCPK41X4TSwercS86116110012NOCPKeldnahtfiL1

696900012NOCPKrevoCliaTtfiL17117110012NOCPKxoBliO+esaerG1

797900

898900012NOCPKpilCdrawroFhctertS19119110012NOCPKelsihC1

999900012NOCPK01X

0010010012NOCPKscinortcelE11211210012NOCPK07X8.4TSwercS2

1011010012NOCPK03X8.4TSwercS12212

2NOCPK04X8MwercS49019010012NOCPKecnatcudnI1

012NOCPKdrawroFhctertS18118110012NOCPKreguA1

naHediSD14014010012NOCPKesuoHhsurB2

4TSwercS2

N11111110012NOCPK61X4TSwercS2

0012NOCPKeldnaHthgiR1

C1

4TSwercS10210210012NOCPKesaC1

210012NOCPKyeKrehtaeF2

PARTS & SERVICE

For Spare Parts and Service, please contact your nearest dealer, or CLARKE International,

PARTS & SERVICE TEL: 020 8988 7400

PARTS: parts@clarkeinternational.com

SERVICE: service@clarkeinternational.com

When disposing of this product, ensure it is disposed of according to all

local ordinances. It must not be disposed of with general household waste.

on one of the following numbers.

or e-mail as follows:

11

Page 12

VIBRATION EMISSIONS

HAND-ARM VIBRATION

Employers are advised to refer to the HSE publication “Guide for Employers”.

All hand held power tools vibrate to some extent, and this vibration is transmitted

to the operator via the handle, or hand used to steady the tool. Vibration from

about 2 to 1500 hertz is potentially damaging and is most hazardous in the range

from about 5 to 20 hertz.

Operators who are regularly exposed to vibration may suffer from Hand Arm

Vibration Syndrome (HAVS), which includes ‘dead hand’, ‘dead finger’, and

‘white finger’. These are painful conditions and are widespread in industries

where vibrating tools are used.

The health risk depends upon the vibration level and the length of time of

exposure to it……in effect, a daily vibration dose.

Tools are tested using specialised equipment, to approximate the vibration level

generated under normal, acceptable operating conditions for the tool in question.

For example, a grinder used at 45° on mild steel plate, or a sander on softwood

in a horizontal plane etc.

These tests produce a value ‘a

which represents the average vibration level of all tests taken, in three axes where

necessary, and a second figure ‘K’, which

represents the uncertainty factor, i.e. a value

in excess of ‘a’, to which the tool could

vibrate under normal conditions. These

values appear in the specification panel

below.

You will note that a third value is given in the

specification - the highest measured

reading in a single plane. This is the maximum

level of vibration measured during testing in

one of the axes, and this should also be

taken into account when making a risk

assessment.

‘

a

’ values in excess of 2.5 m/s2 are considered hazardous when used for prolonged

periods. A tool with a vibration value of 2.8 m/s2 may be used for up to 8 hours

(cumulative) per day, whereas a tool with a value of 11.2 m/s2 may be used for

½ hour per day only.

The graph shows the vibration value against the maximum time the respective

tool may be used, per day.

’

, expressed in metres per second per second,

12

Page 13

VIBRATION EMISSIONS

The uncertainty factor should also be taken into account when assessing a risk.

The two figures ‘a’ and ‘K’may be added together and the resultant value used

to assess the risk.

It should be noted that if a tool is used under abnormal, or unusual conditions, then

the vibration level could possibly increase significantly. Users must always take this

into account and make their own risk assessment, using the graph above as a

reference.

Some tools with a high vibration value, such as impact wrenches, are generally

used for a few seconds at a time, therefore the cumulative time may only be in

the order of a few minutes per day. Nevertheless, the cumulative effect,

particularly when added to that of other hand held power tools that may be

used, must always be taken into account when the total daily dose rate is

determined.

Declared vibration emission value in accordance with EN12096

Measured vibration emission value -

Values determined according to EN28622-1

a:

9.97 m/s

2

13

Page 14

14

Page 15

15

Page 16

Loading...

Loading...