Page 1

HYDRAULIC MOTOR CYCLE LIFT

Model: CML2

Part No: 7610142

OPERATING & MAINTENANCE

INSTRUCTIONS

1000

Page 2

2

11

Page 3

Thank you for purchasing this CLARKE Strongarm hydraulically operated Motor Cycle Lift.

Before attempting to use the lift, please read this leaflet thoroughly and follow the instructions

carefully. In doing so you will ensure the safety of yourself and that of others around you,

and you can also look forward to the lift giving you long and satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Please keep your receipt which will be required as proof of

purchase.

This guarantee is invalid if the product is found to have been abused or tampered with in

any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be returned to

CLARKE International without prior permission.

This guarantee does not effect your statutory rights.

SAFETY PRECAUTIONS

✘ NEVER exceed the lift’s capacity of 500kg, and use it ONLY for the purpose for which it

was intended.

IMPORTANT: If the load capacity decal becomes worn or illegible, contact Clarke

International Spare Parts Department, on 0208 988 7400 for replacement.

✘ NEVER use the lift if it has been subjected to an abnormal load or shock. It should be

removed from service immediately and fully inspected by qualified personnel, and

passed as serviceable, before being used again.

✘ NEVER rely upon the Hydraulic Ram (item 1), to support the Table. Always use the

Locking Bars (see Fig. 1) to secure the table in one of the positions provided.

✔ ALWAYS use the Lift on a solid, flat, level surface only.

✔ ALWAYS screw down the Stabilisers (see Fig. 6), before putting the platform under load.

NOTE: The castors are not designed to take the weight of a fully loaded platform, but are

used merely to move the lift quickly and easily around the workshop. On no account must

you raise a loaded platform unless the stabilisers are screwed down, and NEVER transport a

load using the lift.

✔ ALWAYS use appropriate safety equipment, such as protective footwear, when using

this lift.

✔ ALWAYS inspect the lift before use to ensure it is in good condition, and replace any

damaged or worn parts.

✔ ALWAYS use spare parts supplied by Clarke International. Using non-standard parts

could be extremely dangerous.

✔ ENSURE that the lift is properly maintained, and lubricated at all times, and that no rust

or other forms of corrosion is allowed to weaken any part of it.

✔ ENSURE the operator is skilled and trained in both operation and safety aspects.

10

3

Page 4

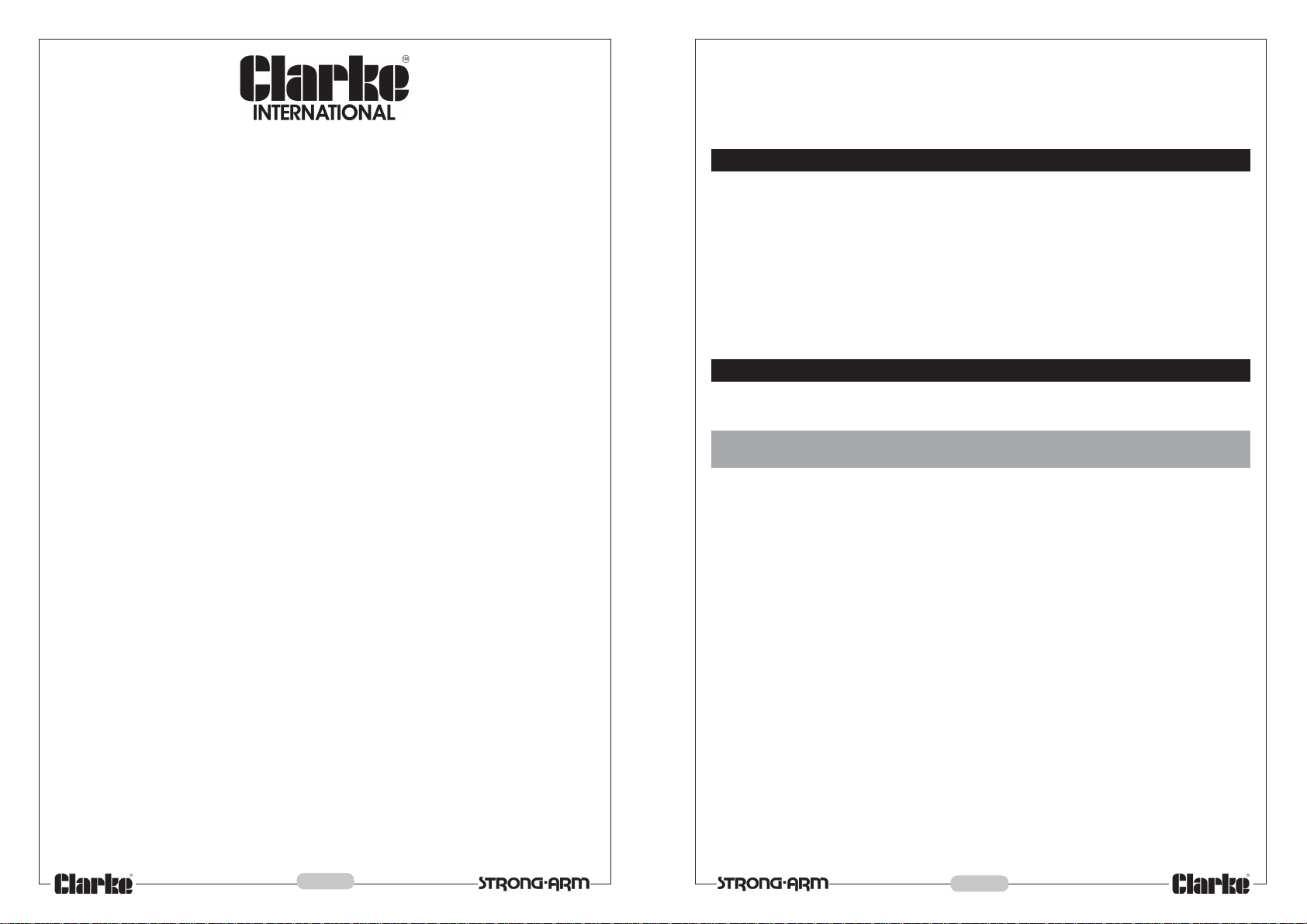

UNPACKING

Lay out the components carefully, and check to ensure that no damage has

occurred during transit. Any damage should be reported to your Clarke dealer

immediately.

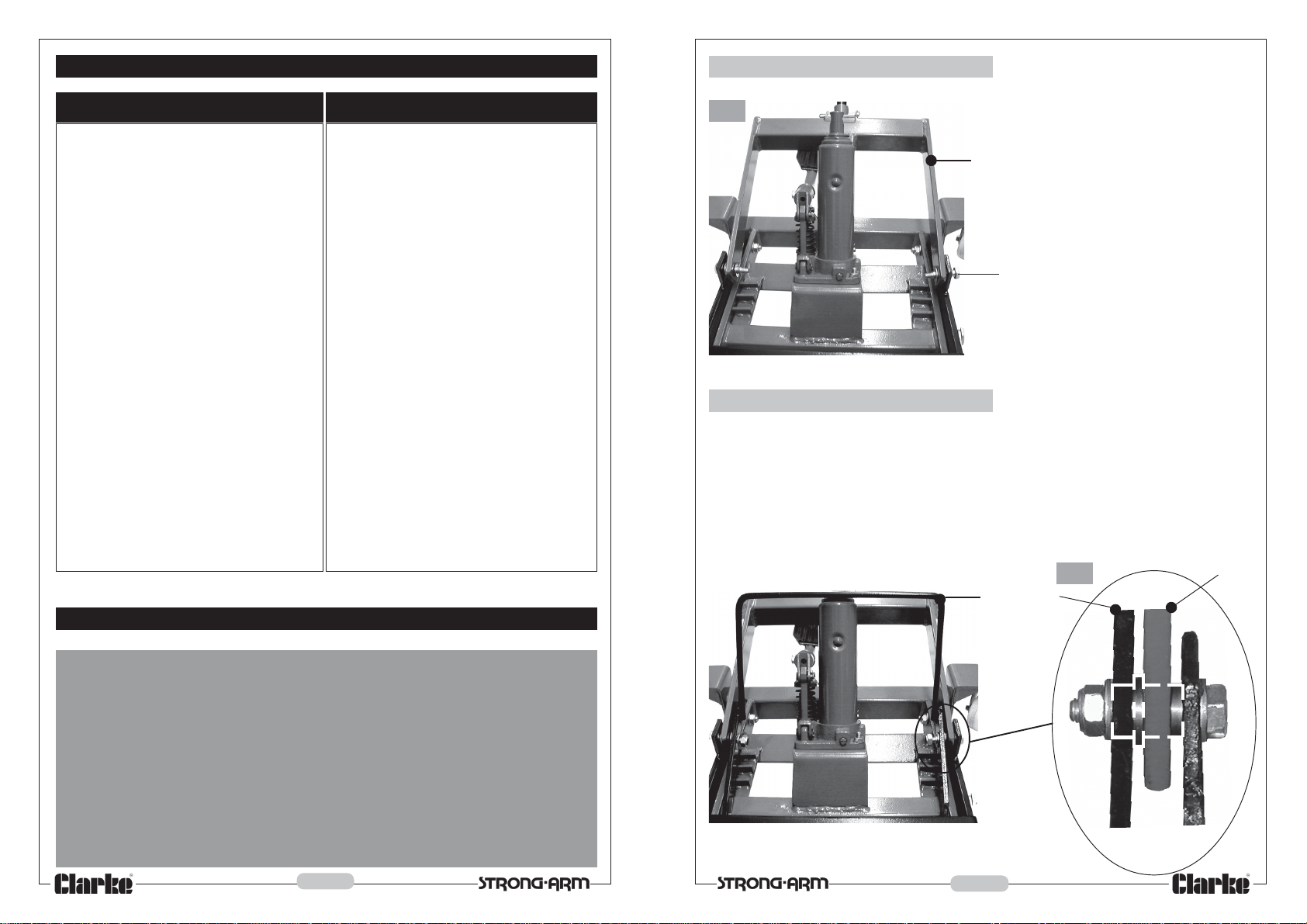

Fig.1

Loose components comprise:

a. Base Assembly

b. Ram Assembly

c. Locking Bar

d. Frame

e. Handle

f. Loose Support

PARTS DIAGRAM

ASSEMBLY

1. The Ram Assembly.

First, secure the ram assembly to its

platform using the two bolts with nuts and

washers supplied, as shown in Fig. 1.

Tighten the nuts securely

Fig.2

4

9

Page 5

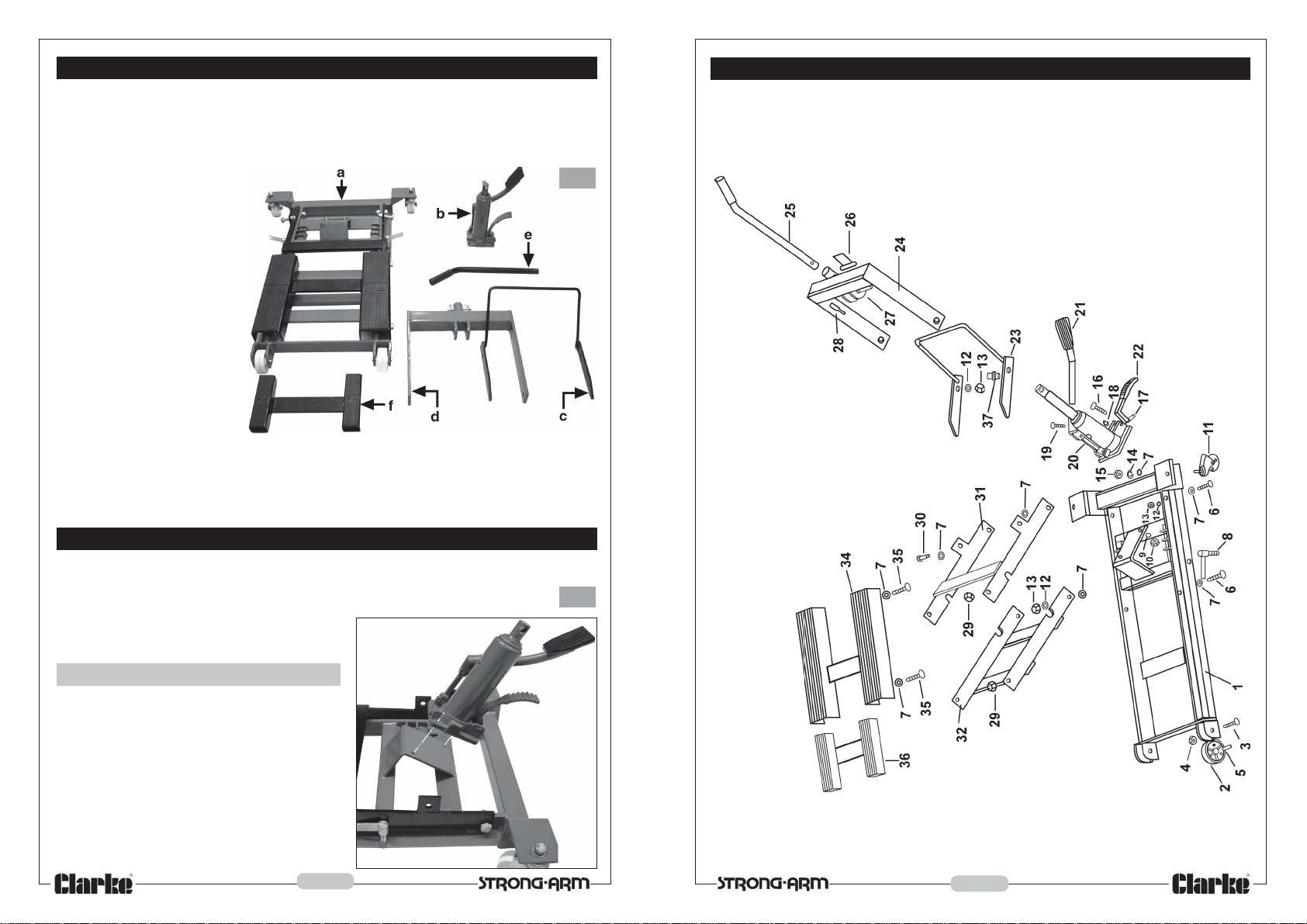

PARTS LIST

2. The Frame: Ref: Fig.3

No. Description Part No.

1. Base HTCML201

2. Wheel HTCML202

3. Bolt M8x65 HTCML203

4. Lock Nut M8 HTCML204

5. Bush HTCML205

6. Bolt Ml0x40 HTCML206

7. Washer HTCML207

8. Screw Ml2 HTCML208

9. Washer HTCML209

10. Nut M8 HTCML210

11. Caster Assembly HTCML211

12. Washer HTCML212

13. Lock Nut M10 HTCML213

14. Spring Washer HTCML214

15. Nut M12 HTCML215

16. Bolt M8x25 HTCML216

17. Pin HTCML217

18. Circlip HTCML218

19. Bolt M8xl0 HTCML219

No. Description Part No.

20. Jack HTCML220

21. Release Pedal HTCML221

22. Foot Pedal HTCML222

23. Locking Bar HTCML223

24. Frame HTCML224

25. Handle HTCML225

26. Clevis Pin HTCML226

27. Lock Pin HTCML227

28. Split Pin HTCML228

29. Lock Nut M12 HTCML229

30. Bolt Ml0x50 HTCML230

31. Back Strut HTCML231

32. Front Strut HTCML232

33. Bolt Ml2x60 HTCML233

34. Saddle HTCML234

35. Bolt Ml2 HTCML235

36. Loose Support HTCML236

37. Bush (1) HTCML237

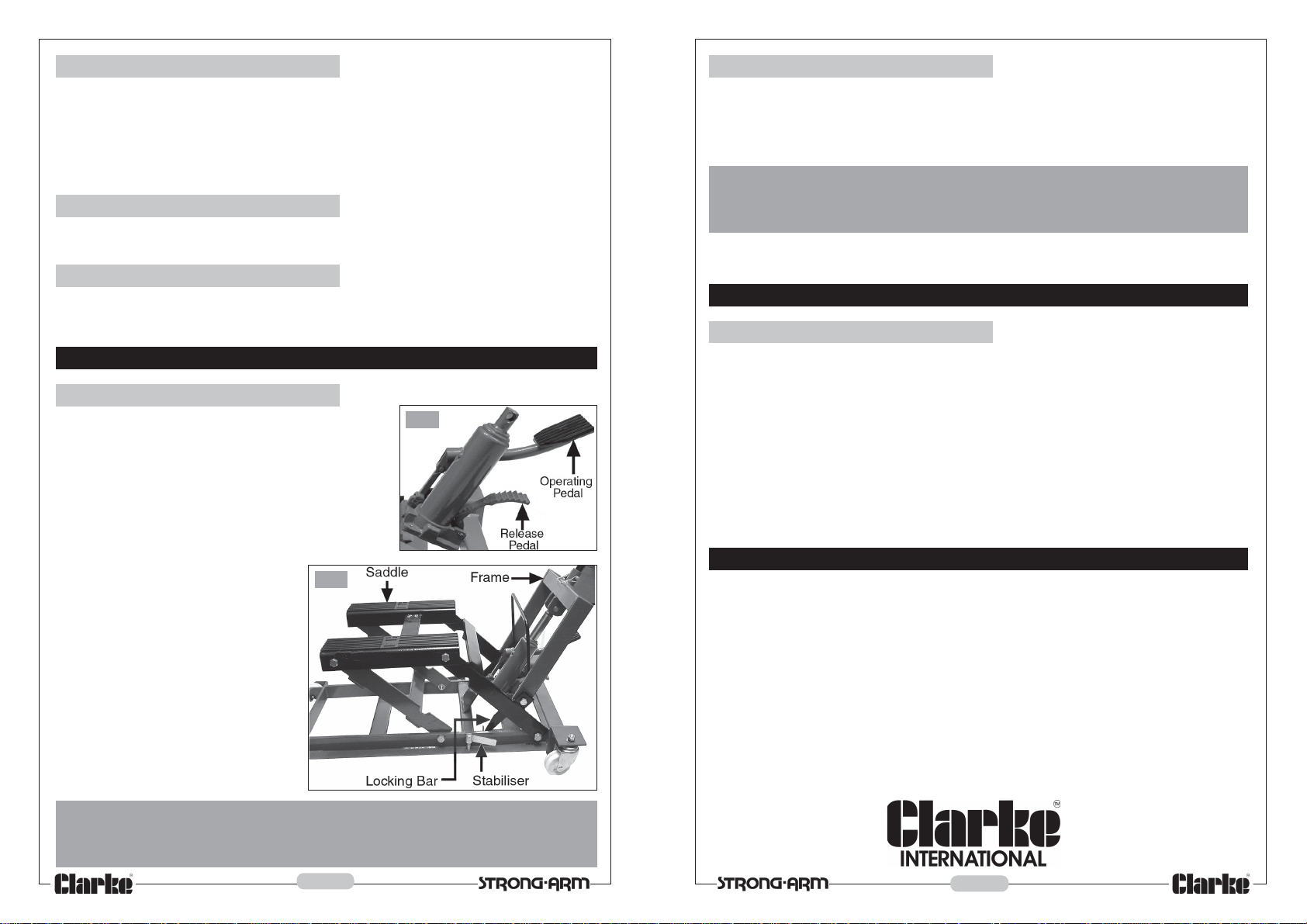

Fig.3

Frame

Remove the pin, securing the

ram to the frame, if fitted.

Place a flat washer on the

securing bolt (A), then thread

the bolt through the hole in the

base assembly bracket, and

have an assistant hold it in place.

Insert the collar (Shown in dotted

line in the insert, Fig.4), through

A

the hole in the end of the Frame,

long boss first, then thread the

collar, with frame, over the bolt.

Repeat this procedure on the

opposite side.

3. The Locking Bar: Ref: Fig.4

Locate the locking bar on to the collar at each side ( It will be necessary to ‘spring’

the bar in order to do so), then place a flat washer on to the threads of the bolt

and screw on the locknut. Tighten securely.

Ensure the Locking Bar is free to rotate under its own weight. It may be necessary

to manipulate the bar, or bend it, by hand slightly, in order to accomplish this.

The locking bar should rotate so that the ends engage in one of the slots in the

base, when the frame is raised.

Fig.4

Locking Bar

Frame

PARTS AND SERVICE CONTACTS

For Spare Parts and Service, please contact your nearest dealer, or CLARKE

International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

8

Collar shown

in dotted line

5

Page 6

4. The Ram to Frame.

b. Lowering a Load

Line up the holes in the mounting bracket and ram, then locate the ram using the

pin previously removed and secure using the split pin provided.

NOTE: It may be necessary to push the ram into the cylinder, in order to line up the holes. To

do this, press down on the Release Pedal, (see Fig. 5), whilst levering the ram down using a

screwdriver, or similar tool.

5. The Handle

The handle is secured to the frame using the pin provided

6. The Loose Support

The loose support may be used at any time to provide stability for a load, and

simply rests in a convenient location on the saddle.

OPERATION

a. Raising a Load

Position the Lift so that the saddle is at right angles

to, and between the wheels of, the motor cycle,

and as near to the centre of gravity as possible.

Pump the Operating Pedal so that the saddle

makes light contact with the motor cycle frame,

then assess where packing is required in order

to raise the load in a fully stabilised manner . The

loose support may also be used for this purpose.

When satisfactorily supported,

screw down the two stabilisers (see

Fig. 6), to remove any load from

the castors, then raise the load by

pumping the Operating Pedal.

Once you have attained the

desired height, ensure the Locking

Bar is engaged with one of the pair

of slots in the base, then press the

Release Pedal gently, allowing the

saddle to lower until the load is

taken by the Locking Bar.

It is now safe for you to commence

work.

1. UNDER NO CIRCUMSTANCES must you rely upon the ram to support the load.

2. Ensure the Motor cycle is fully stabilised before commencing work

Fig.6

WARNING!

Fig.5

When work is complete, pump the Operating Pedal in order to raise the load

slightly and release the Locking Bar. Once the bar is released, hold it, to pr event

it dropping back into one of the slots, then very gently press down on the Release

Pedal and allow the load to descend.

WARNING!

Take great care when lowering. A light touch ONLY is required. Too heavy a

touch will result in the load descending too rapidly which could be hazardous

MAINTENANCE

Before each use

Visually inspect the lift for distortion of parts, cracked welds, damaged wheels or

castors, excessive oil leak from ram, or any other sign of damage. Should any of

these be apparent, remove the Lift from service, and have it inspected and

repaired by a qualified technician before putting back into use. If necessary,

consult your Clarke dealer.

If the Warning label becomes worn or illegible, have it replaced. Contact your

Clarke dealer.

SPECIFICATIONS

Model Number ..........................................................CML2

Part Number ..............................................................7610142

Maximum Load .........................................................500kg

Minimum Height ........................................................ 105mm

Maximum Height .......................................................472mm

Weight ........................................................................45kg

6

7

Loading...

Loading...