PROFESSIONAL DIGITAL CLAMPMETER

- 6 FUNCTION

MODEL No: CDM90

Part No: 4500097

OPERATING & MAINTENANCE

INSTRUCTIONS

GC0111

INTRODUCTION

Thank you for purchasing this CLARKE CDM90 Digital Clampmeter.

Please read this manual thoroughly and follow the instructions carefully, in

doing so you will ensure that operations are carried out in complete safety

and you can look forward to the product giving you long and satisfactory

service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period

of 12 months from the date of purchase. Please keep your receipt as proof

of purchase. This guarantee is invalid if the product is found to have been

abused or tampered with in any way, or not used for its intended purpose.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

Specification

SNOITACIFICEPS09MDC

htrae&slanimretneewtebegatlovxaM CDV006IIITACdnaV0001IITAC

edutitlagnitarepoxaM)teef0

yalpsiDces3-2setadpu,DCL

yalpsideulavmumixaM9991

rewoPgnitarepO)3PP(,yrettabV9x1

iciffeoCerutarepmeT

pmeTgnitarepO0

pmeTegarotS01-

)HxWxL(snoisnemiDmm34x99x052

)sdaelcxe(thgieWyrettabcnig064

gninepOwaJ )ezisrotcudnocxam(mm24

O

)C/ycaruccadeificepsx1.0<

82>ot81<(tne

O

O

007(sertem0002

O

C

O

O

04otC

O

05otC

O

23(C

401otF

)F

O

O

01(C

221otF

)F

2

CONTENTS

SAFETY INFORMATION ................................................ 4

Preliminary ........................................................................................................ 4

During Use ......................................................................................................... 4

Symbols .............................................................................................................. 5

DESCRIPTION .............................................................. 6

Components of the Meter ........................................................................ 7

The LCD (Liquid Crystal Display) .............................................................. 8

OPERATION INSTRUCTIONS ........................................... 9

Holding Readings ........................................................................................... 9

Backlight ............................................................................................................ 9

Measuring AC Current ................................................................................. 10

Measuring AC Voltage ............................................................................ ... 10

Measuring DC Voltage ................................................................................ 11

Measuring Resistance ................................................................................... 1 2

Testing Diodes .................................................................................................. 1 2

Continuity Testing ........................................................................................... 13

MAINTENANCE ............................................................ 14

General Care ................................................................................................... 14

Replacing the Battery .................................................................................. 1 4

Replacing Test Leads ...................................................................................... 14

Calibration ......................................................................................................... 14

DECLARATION OF CONFORMITY ..................................... 15

3

SAFETY INFORMATION

WARNING

Take care when using this meter. Improper use can result in electric shock

or damage to the meter. Take all normal safety precautions and follow the

safeguards suggested in this manual.

PRELIMINARY

1. When using the meter, the user must observe all normal safety rules

concerning:

General protection against electric shock

Protection of the meter against misuse.

2. When the meter is delivered, confirm it has not been damaged in

transit.

3. Before using, check that the insulation on the test leads has not been

damaged or any wire exposed.

4. Use only the test leads supplied to ensure operational safety. If

necessary, they must be replaced with test leads of the same model or

class.

DURING USE

1. Do not take measurements that exceed the maximum values for this

meter.

2 . Do not touch the metal probes of the test leads when the meter is

connected to the circuit being measured.

3. Keep your fingers behind the probe barriers when taking

measurements.

4. Do not take voltage measurements if you suspect the value exceeds

1000V.

5. If the appropriate value range is unknown select the highest range on

the scale.

6. Disconnect the test leads from the circuit under test before turning the

rotary function selector.

7. Do not measure the resistance, diode or continuity of live circuits.

8. Never touch exposed wiring, connections or any live circuit while

taking any measurements.

9. Do not use the meter near explosive gases or steam.

4

10. Stop using the meter if any abnormalities or faults are observed.

11. Do not use the meter unless its rear case and battery cover are

correctly and securely fastened.

12. Do not store or use the meter in areas exposed to direct sunlight, at

high temperature or with high relative humidity.

13. To avoid false readings, replace the battery as soon as the Low

Battery indicator appears.

14. Before use, verify the meter operation by measuring a known voltage.

15. Keep your body isolated from ground by using dry clothing, rubber

shoes, rubber mats or any approved insulating material.

SYMBOLS

Caution, risk of danger.

Beware electrical hazards.

Double insulation ( Protection class II).

Conforms to the European Union Directive

Earth (ground) terminal

5

DESCRIPTION

This meter is a portable, professional, measuring instrument with a Liquid

Crystal Display (LCD) and back light for easily reading.

The meter can perform measurements of AC current, AC/DC voltage, as

well as resistance, continuity and diode testing.

6

COMPONENTS OF THE METER

1. Moving Jaw Measures AC current flowing through the

2. HOLD Button When this button is pressed, the display will keep

3. Rotary Selector

4. Light Button Press this and the backlight display will come on.

5. (LCD) Liquid Crystal Display.

6. ‘V’ Jack This is the positive input terminal for measuring

7. COM Jack This is the negative (ground) input terminal for all

8. Ω Jack This is the positive input terminal for ohms and

9. On/Off Button

10. Trigger Used to open the jaws.

conductor

the last reading and “H” symbol will appear on

the LCD until the button is pressed again.

Used to select functions and ranges.

After approx 4-6 seconds the light will

automatically turn off.

Voltage. Connection is made using the red lead.

measurement modes except current.

Connection is made to it using the black lead.

diode measurement. Connection is made using

the red lead.

Used to turn the meter on/off.

7

THE LCD (Liquid Crystal Display)

AC Alternating current

DC Direct current

Diode test

Continuity buzzer

Battery low

H This indicates that the display data is being held.

V Voltage

A Amperes (Current)

Ω, kΩ, M Ω Ohms, Kilo-ohms, Mega-ohms (Resistance)

O

C Outside recommended working temperature range

Voltage or current should not exceed the specified value

kHz Kilohertz (Frequency)

8

OPERATION INSTRUCTIONS

1. Switch on the power by pressing the ON/OFF button.

2. Turn the rotary selector to the required function and range to be

measured. Choose the highest range when the value of the voltage or

current to be measured is unknown.

3. Connect the black earth test lead before the red positive test lead

when making the connection. Remove the positive test lead first when

disconnecting.

HOLDING READINGS

1. Press the HOLD button while taking measurements.

• The value on the display will be held.

2. Press the HOLD button again to release the function.

THE BACK LIGHT

1. Press the LIGHT button to switch on the back light if the natural light in

the environment is too dim for taking readings.

• The backlight will turn off automatically after 6 seconds.

NOTE:

Frequent use of the back light will shorten the life of the battery

•

and therefore should not be used unnecessarily.

Low Battery Indicator

When the battery voltage falls too low, the Low Battery symbol, will

appear on the LCD. The accuracy of measurement cannot be assured

when the symbol appears.

NOTE:

• When the back light is on, the low battery symbol may appear

due to the greater working current causing the voltage to drop. In

this case, there is no need to replace the battery until the Low

Battery symbol appears when the back light is not being used.

9

MEASURING AC CURRENT

Ensure the test leads are disconnected from the meter before making

current clamp measurements.

1. Set the rotary selector to the A range position.

2. Squeeze the trigger to open the jaw. Fully enclose only one

conductor.

3. Take the reading showing on the LCD.

NOTE:

• If the figure “1” is displayed, this indicates the current has

exceeded the maximum value allowed in the range, and a higher

range should be selected.

• For accurate results, only enclose one conductor in the jaws.

• For optimum results, centre the conductor in the jaws.

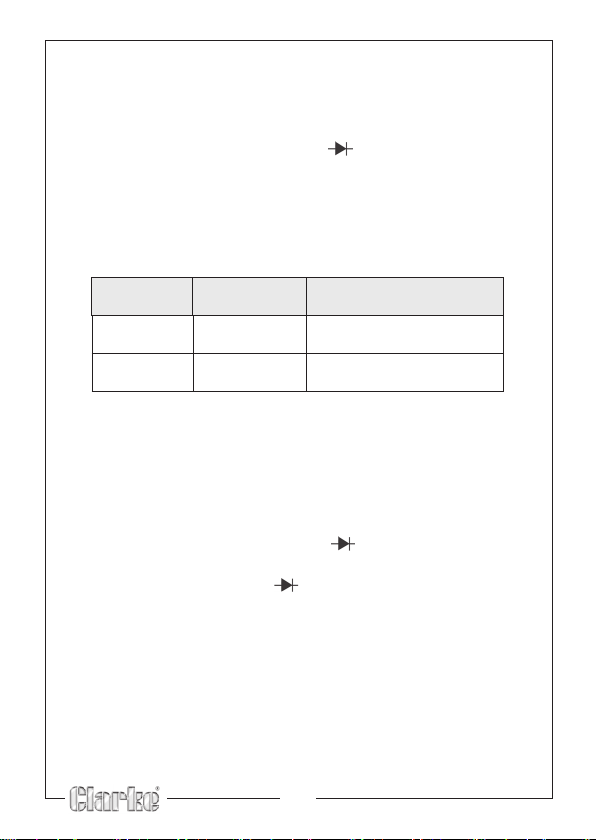

egnaR noituloseR ycaruccA

A02A10.0stigid5±gdrfo%0.2±

A002A1.0stigid5±gdrfo%0.2±

A0001A1stigid7±gdrfo%0.2±

• Overload protection: 1200A for 60 seconds maximum

• Frequency range: 50 to 60Hz

MEASURING AC VOLTAGE

Pay special attention to avoid electric shock if measuring high voltages.

Do not connect to a voltage of more than 750V rms AC.

1. Plug the black test lead into the COM jack and red test lead into the

V~ jack.

2. Set the rotary selector to the 750V~ position.

3. Connect the test leads to the voltage source being measured.

4. Note the reading on the LCD.

10

egnaR noituloseR ycaruccA

V057V1stigid5±gdrfo%0.1±

• Input impedance 10MΩ

• Frequency range: 40 to 400Hz

• Response average, calibrated in rms of sine wave

NOTE:

• At the low voltage range, unsteady readings may appear before

the test leads touch the circuit due to the sensitivity of the meter.

When the test leads touch the circuit, the true reading will be

shown.

MEASURING DC VOLTAGE

Pay special attention to avoid electric shock if measuring high voltages.

Do not connect to a voltage greater than 1000V DC.

1. Plug the black test lead into the COM jack & the red lead into the V

jack.

2. Set the rotary selector to the 1000V position.

3. Connect the leads to the voltage source or load terminals for

measurement.

4. Take the reading on the LCD noting the polarity of the red/black lead

connections.

egnaR noituloseR ycaruccA

V0001V1stigid2+gdrfo%0.1±

• Input impedance 10MΩ

NOTE:

• At the lower voltage range, unsteady readings will appear before

the test leads touch the circuit due to the sensitivity of the meter.

When the test leads touch the circuit, the true reading will be

shown.

11

MEASURING RESISTANCE

When measuring in-circuit resistance, make sure that the circuit under

test has been turned off and that all capacitors have been fully

discharged.

1. Connect the red test lead into the Ω

the COM jack.

2. Set the rotary selector to the W range position.

3. Connect the leads to the ends of the resistor or circuit for

measurement.

4. Note the reading on the LCD.

egnaR noituloseR ycaruccA

mho002mho1.0stigid3±gdrfo%0.1±

mho0002mho0.1stigid3±gdrfo%0.1±

NOTE:

• If the figure “1” is displayed, this indicates the resistance has

exceeded the maximum value allowed in the range, and a higher

range should be selected.

jack & the black lead into

TESTING DIODES

1. Connect the red test lead into the Ω jack & the black lead into

the COM jack.

2. Set the rotary selector to the

3. Connect the red test lead to the anode and the black test lead to the

cathode of the diode for testing.

4. Take the reading on the LCD. The approx. forward voltage drop of the

diode will be displayed. If the connection is reversed, only figure “1”

will be shown.

position.

12

CONTINUITY TESTING

1. Plug the black test lead into the COM jack & the red lead into the

Ω

jack.

2. Set the range switch to the position.

3. Connect the test leads to the two ends of the circuit for measurement.

4. If continuity exists, the built-in buzzer will sound.

13

MAINTENANCE

GENERAL CARE

1. Switch off the power when the meter is not in use.

2. If the meter will remain unused for a long time, remove the battery

and store it in the carry case to avoid possible damage.

3. Do not attempt to remove the rear case to adjust or repair the meter.

Such actions should only be performed by a technician who fully

understands the meter and the dangers involved.

4. Use a damp cloth and mild detergent to clean the meter. Do not use

abrasives or solvents.

BATTERY REPLACEMENT

The battery required is a single 9V type PP3.

If the

1. Disconnect the test leads from live equipment before opening the

2. Replace the exhausted battery with a new one. Take care that the

3. Replace the battery cover and secure with the fixing screw.

4. Dispose of your old battery in accordance with local regulations.

REPLACING THE TEST LEADS

A test lead must be replaced if the insulation layer has been damaged. The

replacement leads must be in good condition with the same rating as the

originals i.e. 1000V.

CALIBRATION

Calibration should be carried out once a year. This task should be assigned

to a qualified service technician. Accuracy is specified for period of one

year after calibration and at 18OC to 28OC (64OF to 82OF).

sign appears, it indicates that the battery should be replaced.

battery cover. Loosen the fixing screw on the battery cover and

remove it.

polarity of the battery is correct, as marked on the inside of the

housing.

14

DECLARATION OF CONFORMITY

15

Loading...

Loading...