CONCRETE MIXER

Models CCM125C & CCM126

Part Nos: 3400840 & 3400842

ASSEMBLY & MAINTENANCE

INSTRUCTIONS

GC514

INTRODUCTION

Thank you for purchasing this CLARKE Concrete Mixer.

Before attempting to operate the machine, it is essential that you read this

manual thoroughly and carefully follow all instructions given. In doing so you

will ensure the safety of yourself and that of others around you, and you can

also look forward to the product giving you long and satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of

12 months from the date of purchase. Please keep your receipt as proof of

purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for its intended purpose.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL PROTECTION

Through purchase of this product, the customer is taking on the

obligation to deal with the WEEE in accordance with the WEEE

regulations in relation to the treatment, recycling & recovery and

environmentally sound disposal of the WEEE.

In effect, this means that this product must not be disposed of with general

household waste. It must be disposed of according to the laws governing

Waste Electrical and Electronic Equipment (WEEE) at a recognised disposal

facility.

2

CONTENTS

INTRODUCTION .................................................................................. 2

GUARANTEE ........................................................................................ 2

ENVIRONMENTAL PROTECTION ......................................................... 2

PARTS & SERVICE CONTACTS .............................................................2

TECHNICAL SPECIFICATION ...............................................................3

GENERAL SAFETY PRECAUTIONS .......................................................4

ELECTRICAL CONNECTIONS .............................................................. 5

UNPACKING & PRE-ASSEMBLY CHECK ..............................................6

ASSEMBLY ........................................................................................... 7

MAINTENANCE ...................................................................................12

COMPONENT PARTS LIST AND DIAGRAM ......................................... 13

DECLARATION OF CONFORMITY....................................................... 15

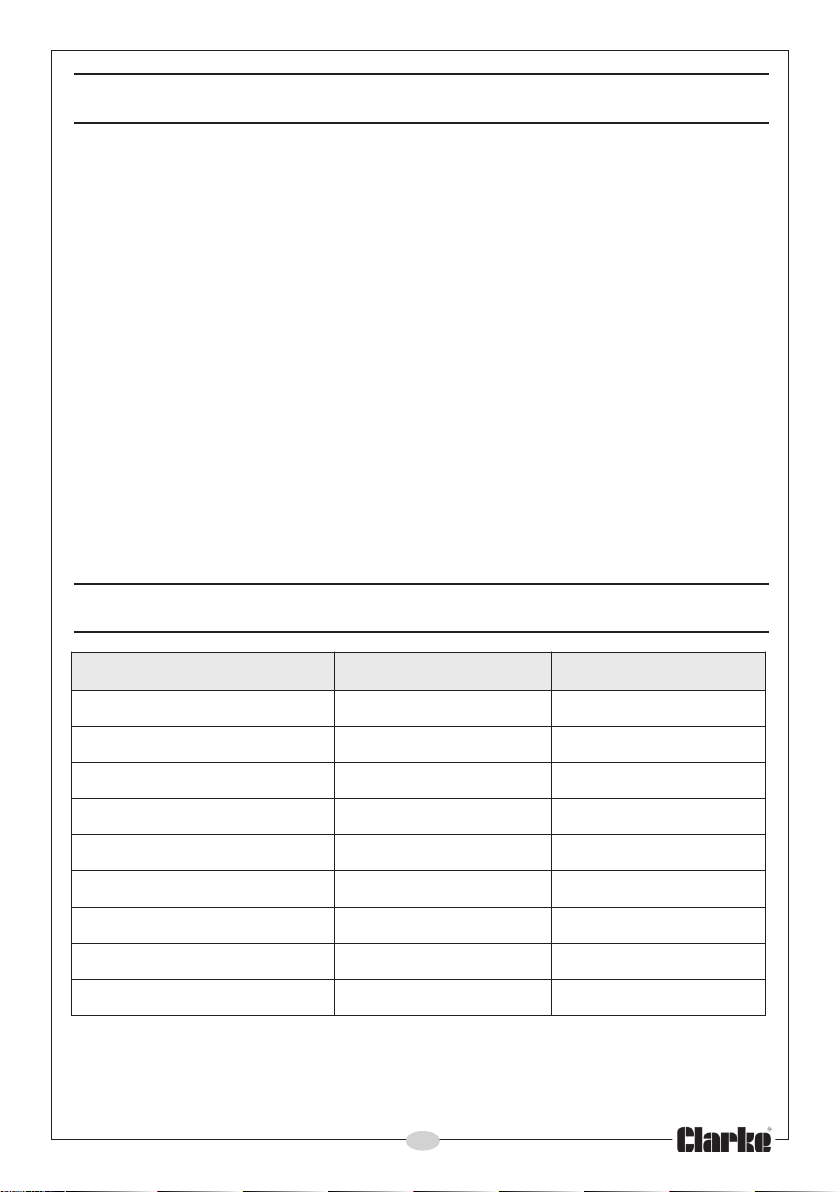

TECHNICAL SPECIFICATION

erutaeF C521MCC 621MCC

rebmuNtraP04800432480043

thgieWgk36gk36

mm)hxwxl(snoisnemiD0421x017x08110621x017x0221

rotoMesahp1,zh05,v0

gnitarrewoprotoMPH3/1PH3/1

tnerruCdaoLlluFspma46.1spma2.4

yticapacgnixiMsertil521sertil521

deepSmurDmpr13mpr13

levelrewopdnuoSAWLBd0.19AWLBd2.29

Please note that the details and specifications contained herein, are correct at the

time of going to print. However, CLARKE International reserve the right to change

specifications at any time without prior notice.

32esahp1,zh05,v011

3

GENERAL SAFETY PRECAUTIONS

1. ALWAYS Keep the work area clean and well lit. Floors should always be kept

clear. Cluttered or dark areas invite accidents.

2. ALWAYS keep children and bystanders away while operating a power tool.

Distractions can cause loss of control.

3. ALWAYS stay alert & do not use a machine while you are tired or under the

influence of medication or alcohol.

4. ALWAYS wear suitable protective clothing and eye protection including

industrial gloves, ear defenders & approved impact resistant safety glasses.

(Eye glasses are NOT safety glasses)

5. NEVER over-reach. Keep your proper footing and balance at all times to

enable better control of the machine in unexpected situations.

6. NEVER stand on the machine. Injury could occur from a fall.

7. ALWAYS store machines out of reach of children.

8. ALWAYS read and become familiar with the entire operating manual.

9. NEVER allow persons unfamiliar with this manual to operate this machine.

10. ALWAYS maintain the machine with care and keep it clean for best / safest

performance.

11. NEVER use this machine if any part is damaged. Have it inspected and

repaired by a competent technician.

12. NEVER modify this machine in any way. Use it ONLY for the purpose for which

it is designed.

13. ALWAYS keep guards in place when the machine is in operation.

14. ALWAYS ensure the electrical cable is fully protected and there is no danger

of damage from equipment or materials. Always Inspect the cable before

use and replace if any damage is apparent.

15. ALWAYS disconnect the machine from the power supply when not in use,

and before carrying out any maintenance.

16. NEVER leave the machine running unattended or leave machine until it

comes to a complete stop.

17. ALWAYS keep your hands well clear of the rotating drum at all times. NEVER

put your hands inside the drum when the machine is switched ON.

18. NEVER wear jewellery or loose clothing that could be snagged by any part

of the rotating drum.

19. NEVER load the drum when the machine is switched off. Always switch on

and ensure the drum is rotating.

20. ALWAYS have power tools serviced by your CLARKE dealer, using only identical

replacement parts. This will ensure the safety of the machine is maintained.

4

ELECTRICAL CONNECTIONS

CCM125C

Connect the power lead to a standard 230 Volt (50Hz) electrical supply

through an approved BS1363, 13amp plug or a suitably fused isolator switch.

CCM126

Connect the power lead to a suitable 110 Volt (50Hz) electrical supply

through an approved plug or a suitably fused isolator switch. If using a

portable 110 Volt transformer make sure it has a rated capacity sufficient to

take the load of the motor - See Data Plate.

Both models:

We recommend that this machine is connected to the mains supply through

a Residual Current Device (RCD).

WARNING! THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in the mains lead are coloured in accordance with the

following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the flexible cord of this appliance may not correspond with

the coloured markings identifying terminals in your plug proceed as follows:

• Connect GREEN & YELLOW wire to terminal marked with a letter “E” or

Earth symbol “ ” or coloured GREEN or GREEN & YELLOW.

• Connect BROWN wire to terminal marked with a letter ‘L’ or coloured RED.

• Connect BLUE wire to terminal marked with a letter ’N’ or coloured BLACK.

CCM125C

If this appliance is fitted with a plug which is moulded onto the electric cable (i.e.

non- rewirable) please note:

1. The plug must be thrown away if cut from the electric cable. There is a

danger of electric shock if it is subsequently inserted into a socket.

2. Never use the plug without the fuse cover fitted.

3. Should you wish to replace a detachable fuse carrier, ensure that the

correct replacement is used (as indicated by marking or colour code).

Replacement fuse covers can be obtained from your local dealer or most

electrical stockists.

4. The fuse in the plug must be replaced with one of the same rating

(13amps) and this replacement must be ASTA approved to BS1362.

If in doubt, consult a qualified electrician....DO NOT attempt repairs yourself.

5

UNPACKING & PRE-ASSEMBLY CHECK

Remove all components from the packing case and lay them out neatly so

that they can be identified and checked for any possible damage during

transit. Should any component be found to be damaged, please contact

your CLARKE dealer immediately.

Check the components against the following list, referring to Fig 1.

A. Rubber Sealing Ring

B. Upper Drum

C. Lower Drum Assembly

D. Locking Plate

E. Axle Assembly

F. Motor Support Plate

G. Drum Collar (2 pcs)

H. Clamp Plate

I. Spacer Plate

J. Fixings Pack(nuts,bolts washers)

ACD

K. Pulley Alignment Rod

L. Front Leg

M. Wheels (pair)

N. Mixing Blades (2 pcs)

O. Hand Wheel

P. Frame

Q. Drive Pulley

R. Drive Belt

S. Inner Motor Cover

T. Motor c/w End Cove

r

Fig. 1

E

M

B

F

G H I J K L

N

O P

Q

RST

6

ASSEMBLY

N

otes:1. The letters in brackets refer to Fig.1

2. Unless otherwise stated, all nuts, bolts, washers and fixings are

supplied in the fixings pack (J). This also contains the Clamp

Plate (H) and Spacer Plate (I).

3. Tools required will include a X-headed screwdriver and

spanners / sockets of 6,10,12,13,14 & 17mm sizes.

IMPORTANT

F

or maximum safety and to ensure the adjustments are carried out correctly,

assistance should be employed during the assembly operation.

THE STAND

1. With the frame (P) lying on its

side, attach the axle assembly (E)

as shown in fig 2, using two M8 x

60 bolts, together with nut, spring

and flat washers.

2. Turn the frame over and attach

the front leg (L) as shown.

3. Stand the assembly upright and

slide a wheel on to each stub

axle, followed by a large flat

washer and secure them using

the split pins.

Fig. 2

THE LOWER DRUM

1. With the help of an assistant if

required, lower the lower drum

assembly (C), onto the side

supports of the stand as shown in

fig 3, so that the bearing blocks at

each end, slot into the channels

provided by the side supports.

• The larger diameter shaft should

be at the Leg end of the stand.

2. Use an M8 x 60 bolt with flat

washer at each fixing position,

and secure using a nut and spring

washer.

Fig 3

7

3. Slide the circular locking plate (D), over

the large diameter shaft, at the leg end of

the frame, with the rim facing inwards, as

shown in Fig.4. (Note that the centre hole

in the plate is cut away to allow the plate

to pass over the circlip on the shaft).

Secure with two M8 x 25 bolts, each with a

nut, flat washer and spring washer.

THE HANDWHEEL

1. Insert the spring into its holder in the centre

of the wheel spar. Hold it in place, and

slide the handwheel over the shaft so that

the shaft retains the spring, and the holes

in the bracket Y, (Fig 4), line up with the

drilled hole in the shaft.

2. Insert the M10 x 65mm bolt with flat

washer at the bolt head, and screw on

two nuts. Screw the first nut up against the bracket firmly, but not so tightly

so as to prevent the handwheel from pivoting about the bolt. Lock the

nut in this position by screwing up the second nut tightly.

Fig. 4

NOTE: The handwheel must be allowed to pivot about the bolt so that

the lugs on the bracket (Y) can be engaged or disengaged from

the slots in the locking plate.

THE MIXING BLADES

1. Bolt the mixing blades in place loosely as

shown in Fig 5.

• Two holes are provided at the base of

the drum into which an M8 x 20 bolt may

be inserted from the inside the drum.

These bolts are supplied attached to the

blades and are provided with a flat and

leather washer. The leather washer

should contact the drum.

2. A spring washer and a nut should be

threaded on loosely onto the bolt from

the outside. Do not tighten these yet.

Fig. 5

THE UPPER DRUM

1. Position the rubber sealing ring on to the rim of the lower drum, ensuring

the holes in the seal and those of the drum line up.

2. Push an M6 x 16 cross headed screw through the rim from below and twist

through the corresponding hole in the sealing ring.

• The screws will hold the sealing ring loosely in position and not drop out.

8

3. With assistance if required, rest the upper drum so that it sits on the rim of

the lower drum. Rotate it so that the screws enter the fixing holes from

below. Look to see that the holes for the upper mountings of the mixing

blades also line up with those in the upper drum.

4. When all fixings are correctly lined up, use the screws, nuts and flat

washers to gently pull the upper and lower drum halves together, gripping

the seal between them. Look inside the drum to check that the seal is

sitting correctly in position.

NOTE: It is desirable practice for the screws to be fitted from above,

therefore, remove them one at a time and re-fit the correct way,

adding a spring washer at each position.

5. Finally, tighten all the fastenings progressively.

6. Secure the mixing blades to the upper drum by inserting the dome

headed coachbolt, through the hole in the drum from the outside,

ensuring the square portion of the bolt seats in the square hole in the

drum. The leather washer should bear against the drum.

7. Secure the mixing blade on the inside using a flat washer, spring washer

and nut.

8. Finally, ensure top and bottom mixing blade mountings are tight.

THE MOTOR COVER, MOTOR SUPPORT & DRIVE PULLEY

Note: To restrain it in transit, the

motor will be found bolted

to the inner cover with

suitable packing materials.

Remove the bolts which are

used for this.

1. Bolt the inner motor cover (S) to

the bearing block using two M8 x

25mm bolts with flat washers at

the bolt heads, from within the

inner cover, and spring washers

with nuts to the rear of the

bearing block. Leave the nuts

loose at this stage.

2. Attach the motor support plate

(F), as shown in Fig. 6, by inserting

four M6 x 65mm bolts, through

the holes in the support plate (F),

the slotted holes in the inner

cover (S), and the spacer, which

is inserted between the back of

the inner cover, and the frame

(see fig 6).

9

Fig. 6

The bolts extend through the securing plate which locates behind the

frame, each bolt being secured using a spring washer and nut. The nuts

should be left loose at this stage.

NOTE: The spacer and securing plate are of similar construction,

however, the LARGER of the two should be used as the SPACER.

3. When all four bolts are fitted, centralise the inner cover (S) on the support,

then fully tighten the two bolts securing it to the bearing block.

4. Remove any adhesive tape used to secure the key to the drive shaft

during transit and slide the drive pulley (Q) on to the shaft, having lined up

the key and keyway. Ensure the grub screw in the hub of the pulley faces

outwards (see Fig 7).

• If the fit is unduly tight, check that the hole in the pulley is smooth and

clear of any excess paint and clean up if necessary using a round file. It

may be necessary to drive the pulley on to the shaft using a soft faced

hammer, until the central boss is roughly flush with the end of the shaft.

Lock the pulley in this position by tightening the grub screw.

THE DRIVE BELT & MOTOR

1. Wrap the drive belt around the drive pulley, seating it into the groove.

2. Place the motor on the support plate with the motor pulley resting on the

drive belt. Fit four M8 x 25mm bolts through the slotted holes in the motor

mounting bracket and through those in the motor support plate, ensuring

flat washers are in place against the bolt head. Fit a flat washer, followed

by a spring washer and nut to each of the bolts from below, leaving the

nuts loose at this stage.

NOTE: During this operation, take care not to

strain the power cable which is

attached to the motor cover.

3. Slide the motor support plate (F) upwards

until the motor and support plate are sitting

level and secure in this position temporarily,

by nipping up two of the four nuts securing

the support plate to the frame, (do not fully

tighten them). The motor, belt and support

plate should be as shown in Fig 7.

4. Hold the steel guide rod so that it rests

across the face of the upper pulley as

shown in Fig 7, as near to the centre of the

pulley as possible. Gently adjust the position

of the motor and motor support plate until

the back of the motor pulley just comes into

contact with the rod.

5. Check the distance between the back of

the motor mounting bracket and the back

10

Fig. 7

edge of the motor support plate as

shown in fig 8, to ensure the motor is

square to the support and frame. Secure

Fig. 8

the motor in this position by fully

tightening the four mounting bolt/nuts.

• This adjustment ensures that the two

pulleys are in alignment and it is

important that time is taken to ensure it is

correct, otherwise premature failure of

the drive belt could occur.

6. Slacken the two nuts, previously nipped

up, which secure the motor mounting

plate to the frame, then push down on the motor so that tension is applied

to the belt. The tension is correct when there is approximately ½"

movement at the centre of the belt when using moderate thumb

pressure. When satisfied, secure the motor support plate by evenly

tightening the nuts behind the securing plate.

NOTE: It is important that the belt tension and pulley alignment are

correct, to ensure satisfactory operation of the machine and to

prevent excessive wear and premature failure of the drive belt.

7. To attach the outer cover to the inner cover it is first necessary to attach

the support chain, using the cross headed screws attached with washers

and nuts, to the holes provided in the inner and outer cover. The outer

cover is then secured to the inner cover using similar cross headed screws

with nuts and washers.

NOTE: The chain is a safety feature to prevent undue strain on the power

cable when the outer cover is removed, and it is important that it

is attached at all times.

DRUM COLLAR

NOTE: The drum collar is a safety feature, and must ALWAYS be in place.

DO NOT operate the machine with the collar removed.

1. Before the collar is attached, it is recommended that a layer of grease

(not supplied) is applied to the drive teeth under of the rim of the drum.

2. Attach the drum collar as shown in Fig 9. The two halves must bolted

together using three M6 x 20mm

bolts with a flat washer, spring

washer and nut, and each half is

secured to a bracket at either

side with a single M6 x 10mm

bolt with a flat and spring

washer. (Bolts may be supplied

already fitted to the collar).

11

Fig. 9

CARE AND MAINTENANCE

STARTING WORK

Inspect the power cable and ensure it is completely free from damage and

is not in danger of being damaged by vehicles, equipment or other

operations taking place on the work site.

Important: Do not load the drum when the machine is switched off. Always

set the machine running before filling.

AFTER USE

It is essential that the machine is hosed down thoroughly with clean water,

being sure to remove all traces of cement mix especially from around the

mixing blades, Take care to prevent water from entering the motor housing

and if necessary, wrap a polythene sheet or bag over it during cleaning.

PERIODICALLY

It is recommended that the collar occasionally be removed and grease

smeared on the drive teeth underside of the lower rim. Ensure the collar is

replaced correctly.

After extensive use, inspect the paintwork and remove any rust that may be

apparent before touching up where necessary with a rust resistant paint.

It may be benificial to inject a few drops of light oil into the lubrication points

located on top of the bearing blocks and rotate the drum to ensure

distribution of oil around the bearing surface.

STORAGE

By removing the higher of the two

bolts connecting the legs to the frame,

the leg/axle assemblies can be

hinged, so as to collapse the machine

to low level as shown in Fig 10. The

lower bolts will need to be slackened

off for this.

The wheels can still be used for

mobility in this position. Always replace

the bolts loosely in their normal

positions during storage.

CAUTION; OWING TO THE WEIGHT OF THE MACHINE, TWO PEOPLE WILL

BE REQUIRED TO UNBOLT THE SUPPORTING COMPONENTS AND SAFELY

LOWER THE MIXER TO THIS POSITION.

Fig 10

12

COMPONENT PARTS DIAGRAM

13

COMPONENT PARTS LIST

No. Description Qty Part No.

1 Frame 1 SD0001

2 Axle Assembly 1 SD0002

3 Leg 1 SD0003

4 Wheel 4 SD0004

5 Large Washer 2 SD0005

6 Split Pin 2 SD0006

7 Motor Support Plate 1 SD0007

8 Spacer/Plate 6mm 2 SD0008

9 Motor Assy - 230V 1 SD0009

9 Motor Assy - 110V 1 SD0009A

10 Motor Pulley 1 SD0010

11 Key 1 SD0010

12 Switch Assembly 1 SD0012

13 Outer Cover 1 SD0013

14 Cable Grommet 1 SD0014

15 Drive Pulley 1 SD0015

16 Grub Screw 1 SD0016

17 Inner Cover 1 SD0017

18 Circlip 4 SD0018

19 Flat Bearing Washer 4 SD0019

20 Bearing Block 2 SD0020

21 Drive Shaft 1 SD0021

The following items are the nuts, bolts, and washers packed separately and which

may be locally procured from any hardware or DIY store, or from your CLARKE

dealer quoting the part numbers given.

No. Description Qty Part No.

22 Parallel Key 1 SD0022

23 Circlip 1 SD0023

24 End Cap 1 SD0024

25 Bearing Set 1 SD0025

26 Pinion 1 SD0026

27 Yoke Assembly 1 SD0027

28 Lower Bearing Plate 1 SD0028

29 Bearing Set 1 SD0029

30 Bearing Plate Upper 1 SD0030

31

Locking Plate 1 SD0031

32 Hand Wheel 1 SD0032

33 Spring 1 SD0033

34 Lower Drum 1 SD0034

35 Sealing Ring 1 SD0035

36 Upper Drum 1 SD0036

37 Collar Assembly 1 SD0037

38 Drive Belt 1 SD0038

39 Mushroom Head Bolt 2 SD0039

40 Leather Washer 4 SD0040

41 Mixing Blade 2 SD0041

42 Support Chain 1 SD0042

43 Steel Guide Rod 1 SD0043

a. M5 x 10 Slot Rd Hd 4 3044701

b. M6 x 20 Hex Bolt 6 3044501

c. M6 x 16 Cross Hd 6 3044705

d. M6 x 65 Hex Bolt 4 3044702

e. M8 x 25 Hex Bolt 8 7101107

f. M8 x 60 Hex Bolt 6 3044703

g. M10 x 65 Hex Bolt 1 3044704

h. M5 Nut 4 3040608

i. M6 Nut 16 3040600

j. M8 Nut 14 3040601

k. M10 Nut 1 3040602

l. 5mm Flat Washer 4 3040574

m. 6mm Flat Washer 24 3040575

n. 8mm Flat Washer 18 3040576

o. 10mm Flat Washer 1 3044577

p. 5mm Spr. Washer 4 3040595

q. 6mm Spr. Washer 22 3040581

r. 8mm Spr. Washer 14 3040582

14

DECLARATION OF CONFORMITY

15

Loading...

Loading...