Clark SM-619, G127, GP127, Gl27E, GPl27E Service Manual

...

SM-619

G127, GP127

Gl27E, GPl27E

CUIRK

CONTENTS

SERVICE MANUAL

SM619

GCSl2-15-17s

GCXl2-15E

GPSl2-15-17

GPXl5-17E

CONTENTS

GROUP

PAGE

FOREWORD

HOW TO USE THIS MANUAL

SAFETY SIGNS AND SAFETY MESSAGES

USER SAFE MAINTENANCE PRACTICES

PICTORIAL INDEX

PLANNED MAINTENANCE INTERVALS

SAFETY AND OPERATIONAL CHECKS

RECOMMENDED PLANNED MAINTENANCE AND

LUBRICATION SCHEDULE

PM

00

00

00

01

01

02

02

06

11

12

12

22

22

23

25

26

29

30

32

34

38

38

40

40

40

Planned Maintenance Program

4G32 Engine - 1.6 Liter

4652 Engine - 2.0 Liter

4663 Engine - 2.0 Liter

Cooling System - Troubleshooting

Cooling System

Fuel System - Gas

Fuel System - LPG

Transaxle (Transmission)

Electrical - Distributor

Electrical - Alternator

Electrical - Starter

Wheels and Tires - Cushion

Wheels and Tires - Pneumatic

Hydraulic Brakes & Inching

Steering Gear

Power Steering System - Steer Axle

Hydraulic System, Main Pump

Main Hydraulic Valve

Tilt Cylinder

Upright

Counterweight

Machine Jacking & Blocking

Truck Data Plate and Decals

Specifications

Hydraulic and Electrical Diagrams

ii

ii

III

iv

vi

vi

vii

. . .

VIII

PM-l

00-l -1

00-2-l

00-3-l

01-1-l

01-2-l

02-l -1

02-2-l

06-l -1

11-1-l

12-1-1

12-2-l

22-l -1

22-2-l

23-l -1

25-1-l

26-l -1

29-l -1

30-l -1

32-l -1

34-l -1

38-l -1

38-2-l

40-l -1

40-2-l

40-3-l

Index - Provides help for locating information about various topics.

SM 619, Jan ‘98

Contents-l

Grow PS, Periodic Service

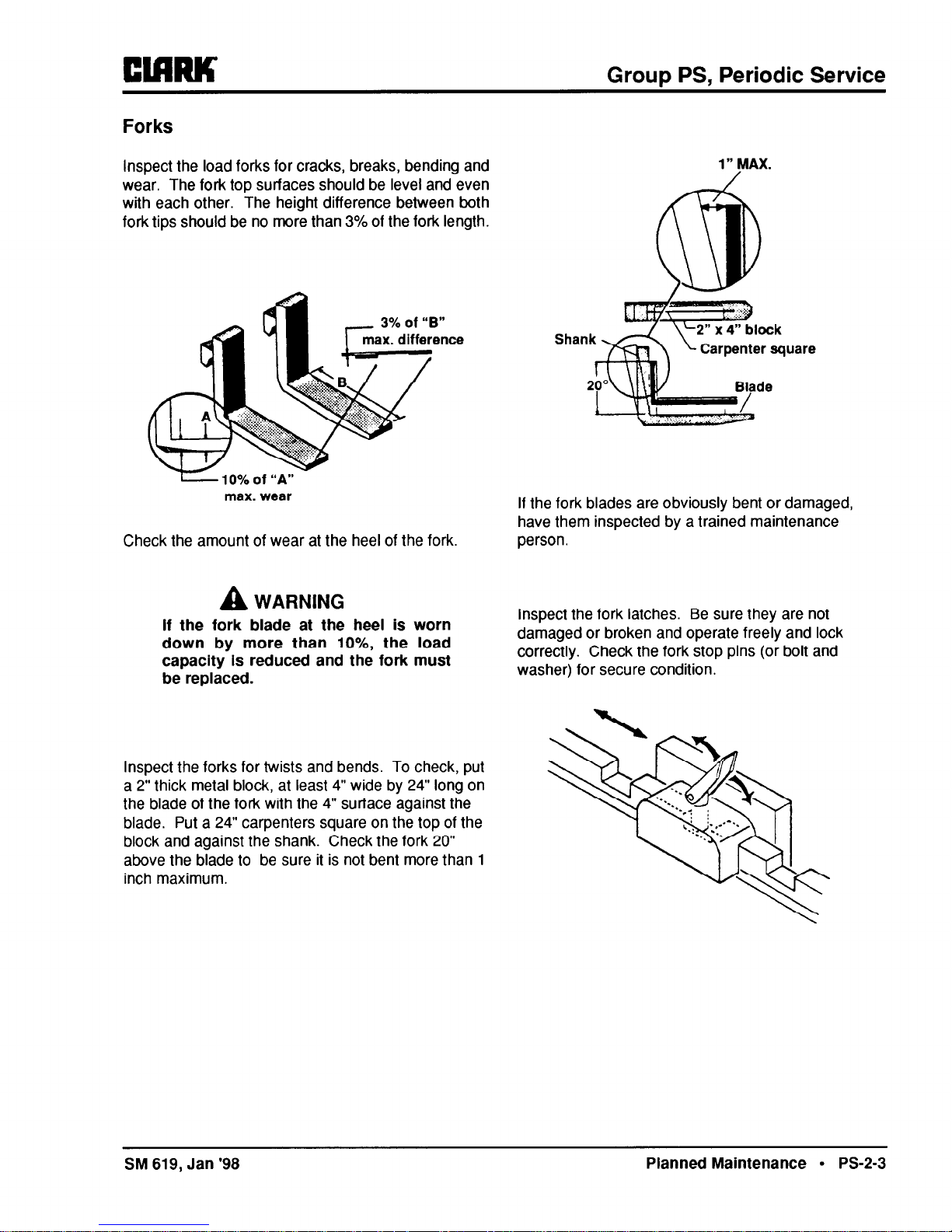

Forks

inspect the load forks for cracks, breaks, bending and

wear. The fork top surfaces should be level and even

with each other. The height difference between both

fork tips should be no more than 3% of the fork length.

max. wear

Check the amount of wear at the heel of the fork.

1" MAX.

If the fork blades are obviously bent or damaged,

have them inspected by a trained maintenance

person.

A

WARNING

If the fork blade at the heel is worn

down by more than lo%, the load

capacity Is reduced and the fork must

be replaced.

Inspect the fork latches. Be sure they are not

damaged or broken and operate freely and lock

correctly. Check the fork stop pins (or bolt and

washer) for secure condition.

Inspect the forks for twists and bends. To check, put

a 2” thick metal block, at least 4” wide by 24” long on

the blade of the fork with the 4” surface against the

blade. Put a 24” carpenters square on the top of the

block and against the shank. Check the fork 20”

above the blade to be sure it is not bent more than 1

inch maximum.

SM 619, Jan ‘98

Planned Maintenance l PS-2-3

Group 00, Engine

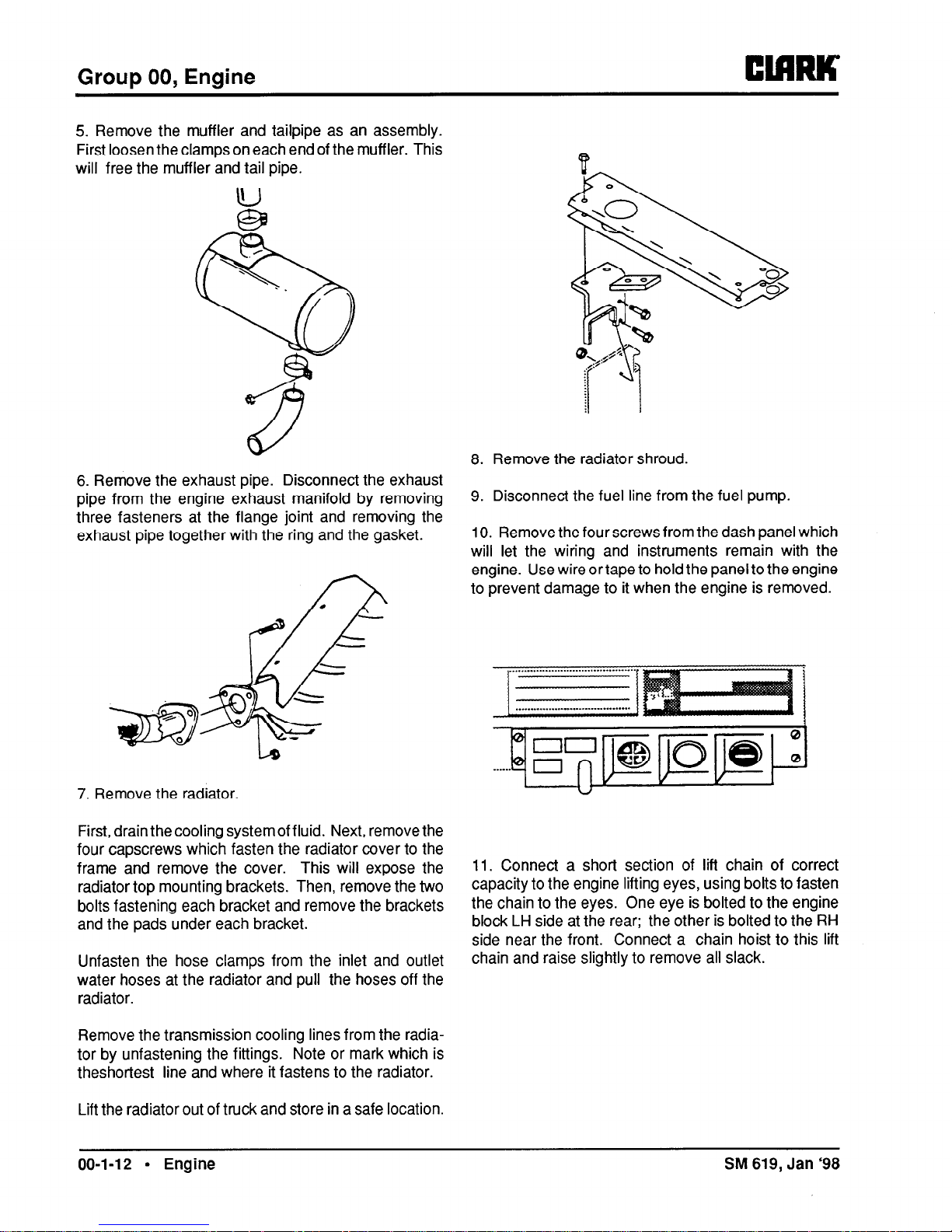

5. Remove the muffler and tailpipe as an assembly.

First loosen the clamps on each end of the muffler. This

will free the muffler and tail pipe.

6. Remove the exhaust pipe. Disconnect the exhaust

pipe from the engine exhaust manifold by removing

three fasteners at the flange joint and removing the

exhaust pipe together with the ring and the gasket.

7. Remove the radiator.

First, drain thecooling systemof fluid. Next, remove the

four capscrews which fasten the radiator cover to the

frame and remove the cover. This will expose the

radiator top mounting brackets. Then, remove the two

bolts fastening each bracket and remove the brackets

and the pads under each bracket.

Unfasten the hose clamps from the inlet and outlet

water hoses at the radiator and pull the hoses off the

radiator.

Remove the transmission cooling lines from the radiator by unfastening the fittings. Note or mark which is

theshortest line and where it fastens to the radiator.

Lift the radiator out of truck and store in a safe location.

8. Remove the radiator shroud.

9. Disconnect the fuel line from the fuel pump.

10. Remove the four screws from the dash panel which

will let the wiring and instruments remain with the

engine. Use wire ortape to hold the panel to the engine

to prevent damage to it when the engine is removed.

11. Connect a short section of lift chain of correct

capacity to the engine lifting eyes, using bolts to fasten

the chain to the eyes. One eye is bolted to the engine

block LH side at the rear; the other is bolted to the RH

side near the front. Connect a chain hoist to this lift

chain and raise slightly to remove all slack.

00-l-12 l Engine

SM 619, Jan ‘98

Loading...

Loading...