Clark ESX Series, ESX15, ESX12, ESX17, ESX20 Operator's Manual

...

65702

8

Operator's Manual

ESX Stand-Up Counterbalanced Trucks

Book No. 2827061

OM-718

Do not remove this manual

from the truck.

Record the following information pertaining to your truck.

Model No. __________________________________________

Serial No. ___________________________________________

Customer Truck Identifi cation No. ________________________

Truck Weight, Empty __________________________________

Truck Rated Capacity _________________________________

Truck Gross Weight ___________________________________

Truck Gross Weight, Loaded w/ Rated Load ________________

Special Equipment or Attachments _______________________

IMPORTANT

Do not expose this manual to hot water or steam.

©2007 Clark Material Handling Company

Operator's Manual

8

You must be trained and authorized to operate a lift truck.

YOU can prevent accidents

First: Learn safe operating rules and your company rules.

Next: Read your Operator's Manual. If you do not

understand it, ask your supervisor for help.

Learn about the unit you operate.

KNOW YOUR TRUCK

Then: Practice operating your

truck safely.

And: Keep your truck in safe

operating condition with

correct and timely

maintenance.

65702

Breaking these rules will cause serious or fatal injury to

yourself and others

i

A Message to CLARK Lift Truck Operators

Lift trucks are specialized machines with unique operating characteristics, designed to perform a specifi c job. Their function and operation

is not like a car or ordinary truck. They require specifi c instructions and

rules for safe operation and maintenance.

Safe operation of lift trucks is of primary importance to CLARK. Our

experience with lift truck accidents has shown that when accidents

happen and people are killed or injured, the causes are:

• Operator not properly trained

• Operator not experienced with lift truck operation

• Basic safety rules not followed

• Lift truck not maintained in safe operating condition

For these reasons, CLARK wants you to know about the safe operation

and correct maintenance of your lift truck.

This manual is designed to help you operate your lift truck safely . This

manual shows and tells you about safety inspections and the important

general safety rules and hazards of lift truck operation. It describes

the special components and features of the truck and explains their

functions. The correct operating procedures are shown and explained.

Illustrations and important safety messages are included for clear understanding. A section on maintenance and lubrication is included for

the lift truck mechanic.

ii

A Message to CLARK Lift Truck Operators

The operator’s manual is not a training manual. It is a guide to help trained

and authorized operators safely operate their lift truck by emphasizing

and illustrating the correct procedures. However, it cannot cover every

possible situation that may result in an accident. You must watch for

hazards in your work areas and avoid or correct them. It is important that

you know and understand the information in this manual and that you

know and follow your company safety rules! Be sure that your equipment is maintained in a safe condition. Do not operate a damaged or

malfunctioning truck. Practice safe operation every time you use your

lift truck. Let's join together to set high standards in safety.

Remember, before you start operating this lift truck, be sure you understand all driving procedures. It is your responsibility , and it is important

to you and your family, to operate your lift truck safely and effi ciently .

Be aware that the Federal Occupational Safety and Health Act (OSHA)

and state laws require that operators be completely trained in the safe

operation of lift trucks; it is also an OSHA requirement that a machine

inspection be performed before every shift. If you think you need training

in operating or inspecting your lift truck, ask your supervisor.

CLARK lift trucks are built to take hard work, but not abuse. They are

built to be dependable, but they are only as safe and effi cient as the

operator and the persons responsible for maintaining them. Do not

make any repairs to this truck unless you have been trained in safe lift

truck repair procedures and are authorized by your employer.

A Message To CLARK Lift Truck Operators

iii

iv

Contents of this Manual

A Message to CLARK Lift Truck Operators ................ii

Introduction ..................................................................vi

How to Use this Manual ........................................viii

Safety Signs and Safety Messages .........................x

Section 1. General Safety Rules ...............................1-1

Section 2. Operating Hazards ...................................2-1

Section 3. Common Truck .........................................3-1

Section 4. Operator Maintenance and Care ............4-1

Section 5. Operating Procedures .............................5-1

Section 6. Planned Maintenance ..............................6-1

Section 7. Specifi cations ......................................... 7-1

Index ................................................................... Index-1

Contents of this Manual

v

Introduction

CLARK welcomes you to the growing group of professionals who

own, operate, and maintain CLARK lift trucks. We take pride in the

long tradition of quality products and superior value the CLARK name

represents. This manual familiarizes you with safety, operating, and

maintenance information about your new lift truck. It has been specially

prepared to help you use and maintain your CLARK lift truck in a safe

and correct manner.

Your CLARK lift truck has been designed and built to be as safe and

effi cient as today’s technology can make it. As manufactured, it meets all

the applicable mandatory requirements of ANSI B56.1 Safety Standard

for Powered Industrial Trucks. Each truck is also furnished with equipment to help you operate safely; for example, load back rest, parking

brake and horn are standard equipment.

Safe, productive operation of a lift truck requires both skill and knowledge

on the part of the operator. The operator must know, understand, and

practice the safety rules and safe driving and load handling techniques

described in this manual. T o develop the skill required, the operator must

become familiar with the construction and features of the lift truck and

how they function. The operator must understand its capabilities and

limitations, and see that it is kept in a safe condition.

Routine Servicing and Maintenance

Regular maintenance and care of your lift truck is not only important

for economy and utilization reasons; it is essential for your safety. A

faulty lift truck is a potential source of danger to the operator, and to

other personnel working near it. As with all quality equipment, keep your

lift truck in good operating condition by following the recommended

schedule of maintenance.

vi

Introduction

Operator Daily Inspection — Safety and Operating Checks

A lift truck should always be examined by the operator, before driving, to be sure it is safe to operate. The importance of this procedure

is emphasized in this manual with a brief illustrated review and later

with more detailed instructions. CLARK dealers can supply copies of

a helpful “Drivers Daily Checklist.”

Planned Maintenance

In addition to the daily operator inspection, CLARK recommends that a

planned maintenance and safety inspection program (PM) be performed

by a trained and authorized mechanic on a regular basis. The PM will

provide an opportunity to make a thorough inspection of the safety and

operating condition of your lift truck. Necessary adjustments and repairs

can be done during the PM, which will increase the life of components

and reduce unscheduled downtime and increase safety. The PM can

be scheduled to meet your particular application and lift truck usage.

The procedures for a periodic planned maintenance program that

covers inspections, operational checks, cleaning, lubrication, and

minor adjustments are outlined in this manual. Your CLARK dealer is

prepared to help you with a Planned Maintenance Program by trained

service personnel who know your lift truck and can keep it operating

safely and effi ciently.

Introduction

vii

How to Use this Manual

This manual is a digest of essential information about the safe operation, the features and functions and explains how to maintain your lift

truck. This manual is organized into eight major parts:

Section 1, General Safety Rules, reviews and illustrates accepted

practices for safe operation of a lift truck.

Section 2, Operating Hazards, warns of conditions that could cause

damage to the truck or injury to the operator or other personnel.

Section 3, Common Truck, describes the most common operating

components, systems, controls, and other features of your truck and

tells how they function.

Section 4, Operator Maintenance and Care, presents details on how to

perform the operator's daily safety inspection and refuel the lift truck.

Section 5, Operating Procedures, discusses more specifi c instruction

on the safe, effi cient operation of your lift truck.

Section 6, Planned Maintenance, describes the PM program.

Section 7, Specifi cations, provides reference information and data

on features, components, and maintenance items.

Also, the Index helps you locate information about various topics.

NOTICE: The descriptions and specifi cations included in this manual

were in effect at the time of printing. CLARK Material Handling Company

reserves the right to make improvements and changes in specifi ca-

tions or design, without notice and without incurring obligation. Please

check with your authorized CLARK dealer for information on possible

updates or revisions.

The examples, illustrations, and explanations in this manual should

help you improve your skill and knowledge as a professional lift truck

operator and take full advantage of the capabilities and safety features

of your new lift truck.

The fi rst Section of the manual is devoted to a review, with illustrations

and brief messages, of general safety rules and the major operating

hazards you can encounter while operating a lift truck. Next, you will

fi nd descriptions of the components of your specifi c lift truck model and

how the instruments, gauges, and controls operate. Then, you will fi nd

a discussion of safe and effi cient operating procedures, followed by

viii

How to Use this Manual

instructions on how to tow a disabled lift truck. The later sections of the

manual are devoted to maintenance and truck specifi cations.

T ake time to carefully read the “Know Your Truck” section. By acquiring

a good basic understanding of your truck's features, and how they function, you are better prepared to operate it both effi ciently and safely.

In “Planned Maintenance,” you will fi nd essential information for cor-

rect servicing and periodic maintenance of your truck, including charts

with recommended maintenance intervals and component capacities.

Carefully follow these instructions and procedures.

Each major Section has its own table of contents, so that you can fi nd

the various topics more easily . If you cannot fi nd a topic in the table of

contents, check the index at the back of the manual.

We urge you to fi rst carefully read the manual from cover to cover.

Take time to read and understand the information on general safety

rules and operating hazards. Acquaint yourself with the various procedures in this manual. Understand how all gauges, indicator lights,

and controls function. Please contact your authorized CLARK dealer

for the answers to any questions you may have about your lift truck’s

features, operation, or manuals.

Operate your lift truck safely; careful driving is your responsibility . Drive

defensively and think about the safety of people who are working nearby .

Know your truck’s capabilities and limitations. Follow all instructions

in this manual, including all IMPORTANT, CAUTION, WARNING, and

DANGER messages to avoid damage to your lift truck or the possibility

of any harm to yourself or others.

This manual is intended to be a permanently attached part of your lift

truck. Keep it on the truck as a ready reference for anyone who may

drive or service it. If the truck you operate is not equipped with a manual,

ask your supervisor to obtain one and have it attached to the truck.

And, remember, your CLARK dealer is pleased to answer any questions

about the operation and maintenance of your lift truck and will provide

you with additional information should you require it.

How to Use this Manual

ix

Safety Signs and Safety Messages

Improper operation can cause accidents. Don’t take chances with incorrect or damaged equipment. Read and understand the procedures for

safe driving and maintenance outlined in this manual. Don't hesitate to

ask for help. Stay alert! Follow safety rules, regulations, and procedures.

Avoid accidents by recognizing dangerous procedures or situations

before they occur. Drive and work safely and follow the safety signs

and their messages on the truck and in this manual.

Safety signs and messages are placed in this manual and on the truck

to provide instructions and identify specifi c areas where potential hazards

exist and special precautions should be taken. Know and understand

the meaning of these instructions, signs, and messages. Damage to

the truck, death, or serious injury to you or other persons may result if

these messages are not followed. If warning decals are damaged, they

must be replaced. Contact your CLARK dealer for replacements.

NOTICE

This message is used when special information, instructions or identifi cation are required relating to procedures,

equipment, tools, pressures, capacities and other special

data.

IMPORTANT

This message is used when special precautions should

be taken to ensure a correct action or to avoid damage to

or malfunction of the truck or a component.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or injury

x

Safety Signs and Safety Messages

CAUTION

WARNING

DANGER

Section 1. General Safety Rules

General Safety Rules

Contents

Daily Inspection .........................................................1.2

Do's and Don'ts ..........................................................1.3

No Riders ....................................................................1.4

Pedestrians ................................................................1.5

Operator Protection ...................................................1.6

Fork Safety .................................................................1.7

Pinch Points ...............................................................1.8

Travel ..........................................................................1.9

Surface and Capacity ..............................................1.10

Grades, Ramps, Slopes, and Inclines ....................1.11

Tip Over ....................................................................1.12

What to do in Case of a Tip-Over ..........................1.13

Parking ......................................................................1.14

Contents

1.1

Daily Inspection

At the beginning of each shift, inspect your truck and fi ll out a daily

inspection sheet.

Check for damage and maintenance problems.

Have repairs made before you operate the truck.

CAUTION

DO NOT MAKE REP AIRS YOURSELF . Lift truck mechanics

are trained professionals. They know how to make repairs

safely. (See Section 4)

1.2

Daily Inspection

XXX

Section 1. General Safety Rules

Do's and Don'ts

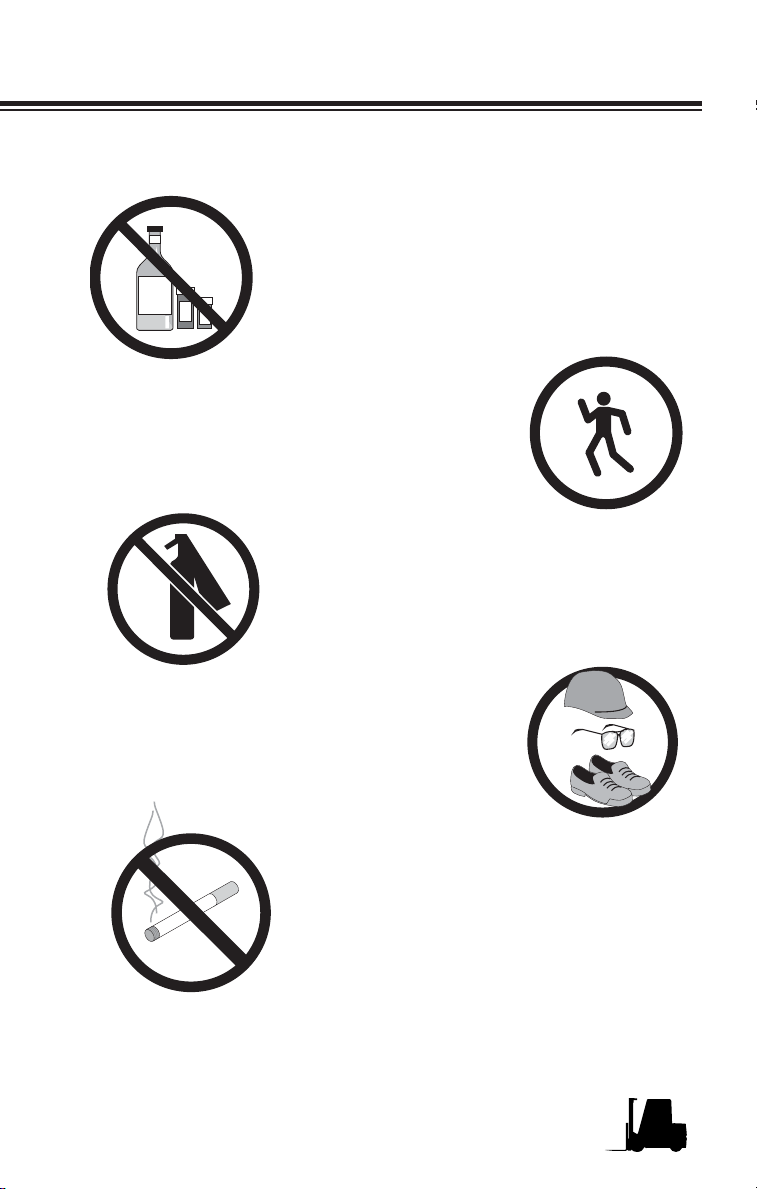

Don't mix drugs or alcohol with your job.

OM0001

Do watch for pedestrians.

OM0002

Don't block safety or emergency

equipment.

OM0003

Do wear safety equipment when

required.

Don't smoke in "NO SMOKING" areas

or when refueling.

OM0005

Do's and Don'ts

OM0004

1.3

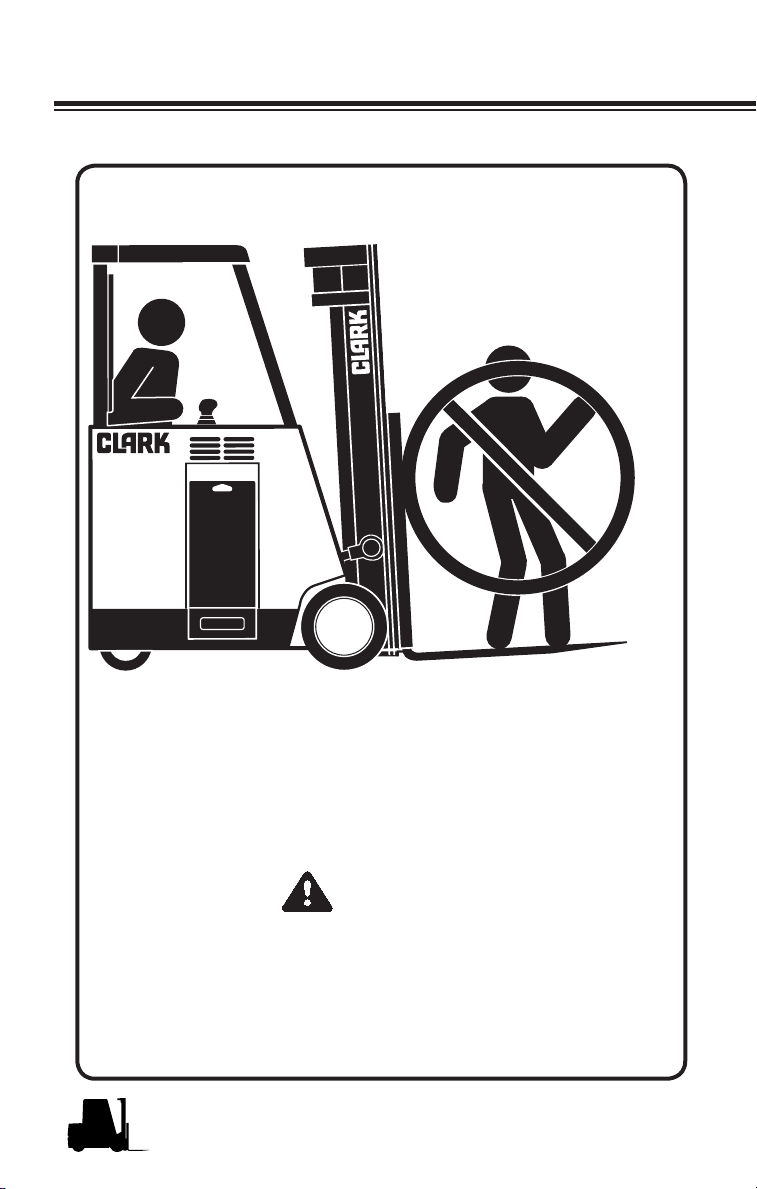

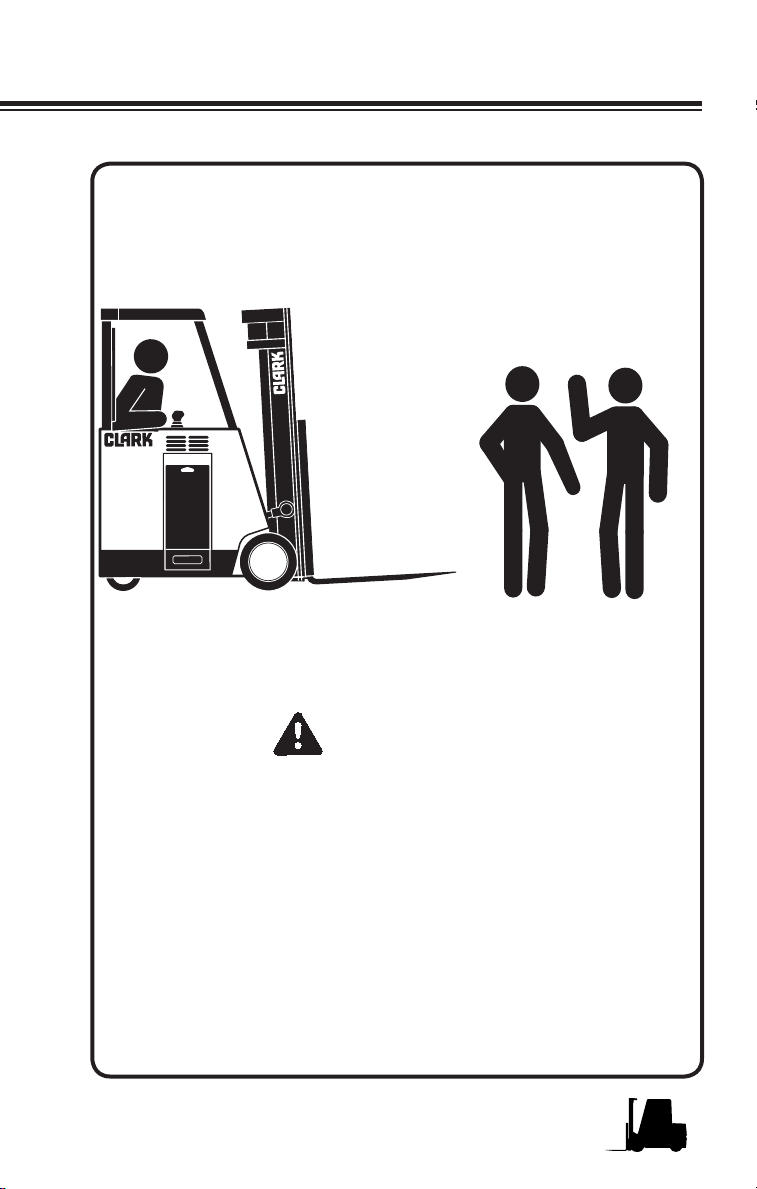

No R iders

718001

657028

The operator is the only one who should be on a truck.

WARNING

Never transport personnel on the forks of a lift truck.

1.4

No Riders

Pedestrians

718002

Section 1. General Safety Rules

IMPORTANT

• Watch where you are going.

• Look in the direction of travel.

• Pedestrians may use the same roadway you do.

• Sound your horn at all intersections or blind spots.

• Watch for people in your work area even if your truck

has warning lights or alarms. People may not watch for

you.

• Make people stand back, even when you are parked.

Pedestrians

1.5

718003

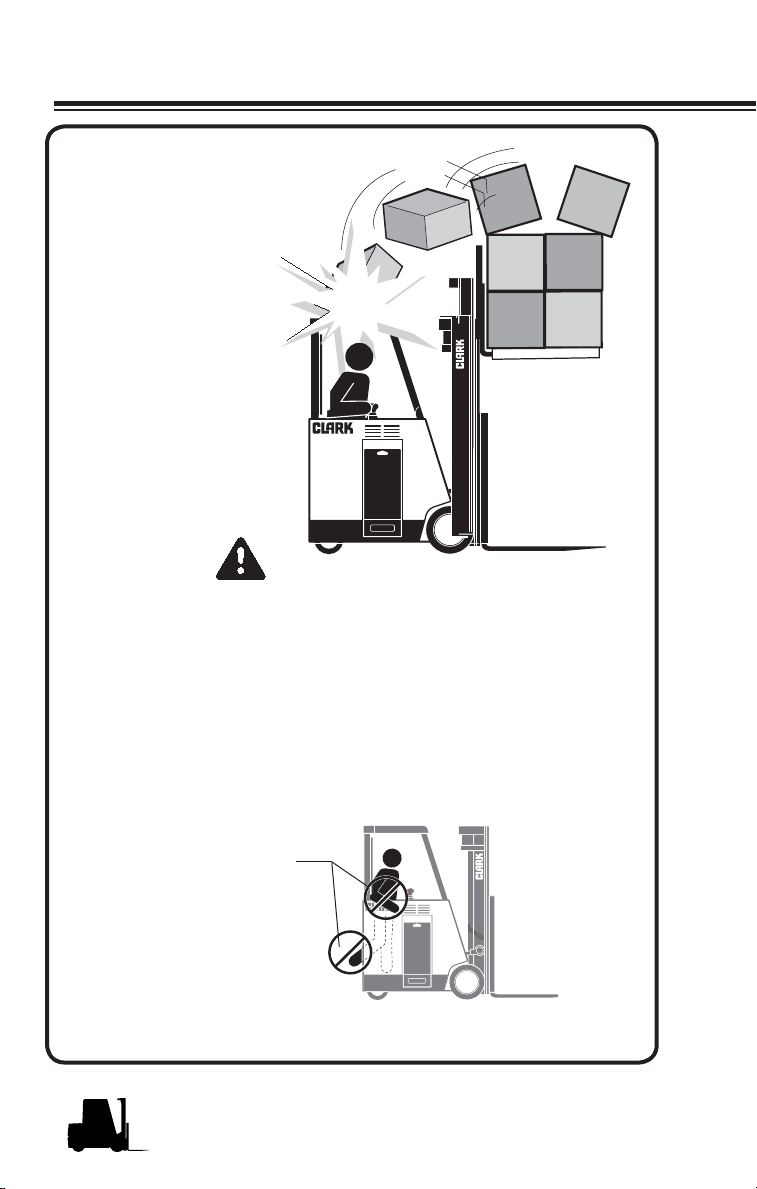

Operator Protection

IMPORTANT

• Keep under the overhead guard.

• Always keep your body within the confi nes of the

truck.

• Be especially careful when traveling in reverse and maneuvering in tight areas.

Keep arms and legs in the

operator compartment

1.6

Operator Protection

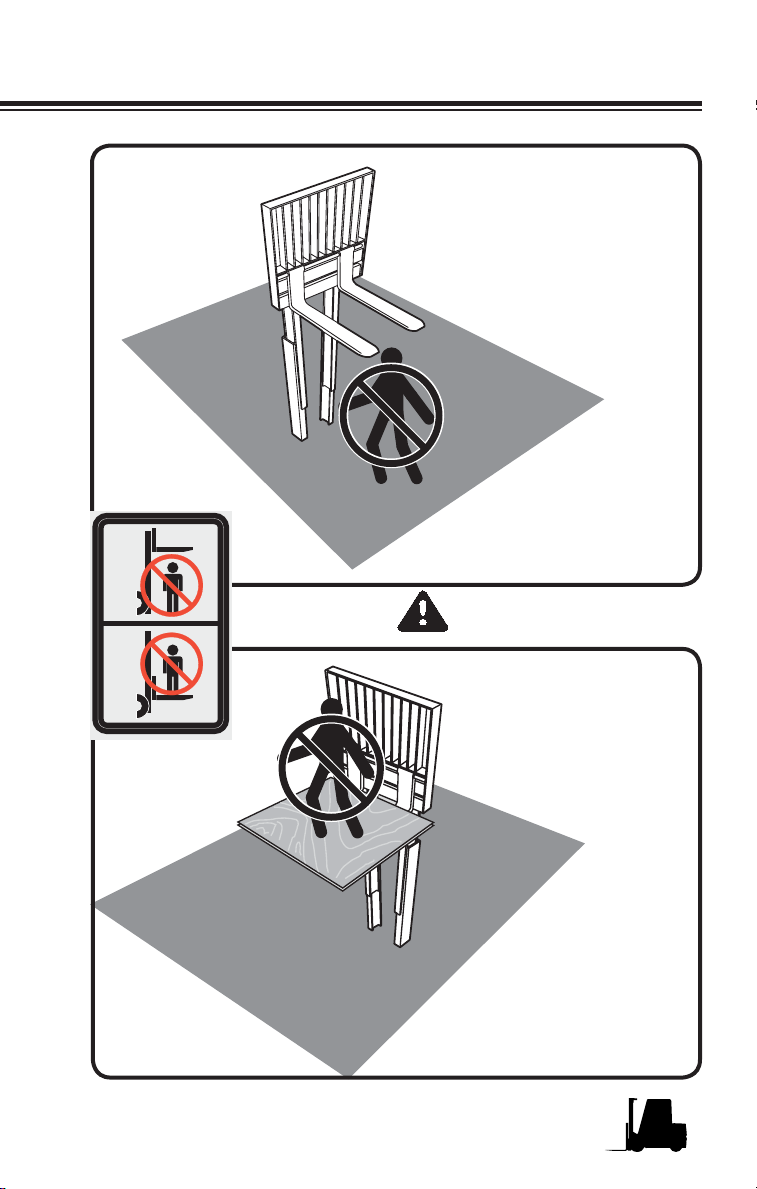

Fork Safety

Section 1. General Safety Rules

Never allow anyone

to walk under raised

forks.

657005

DANGER

There is special equip-

2372604

ment to raise people for

overhead work. DO NOT

USE LIFT TRUCKS.

657006

Fork Safety

1.7

718007

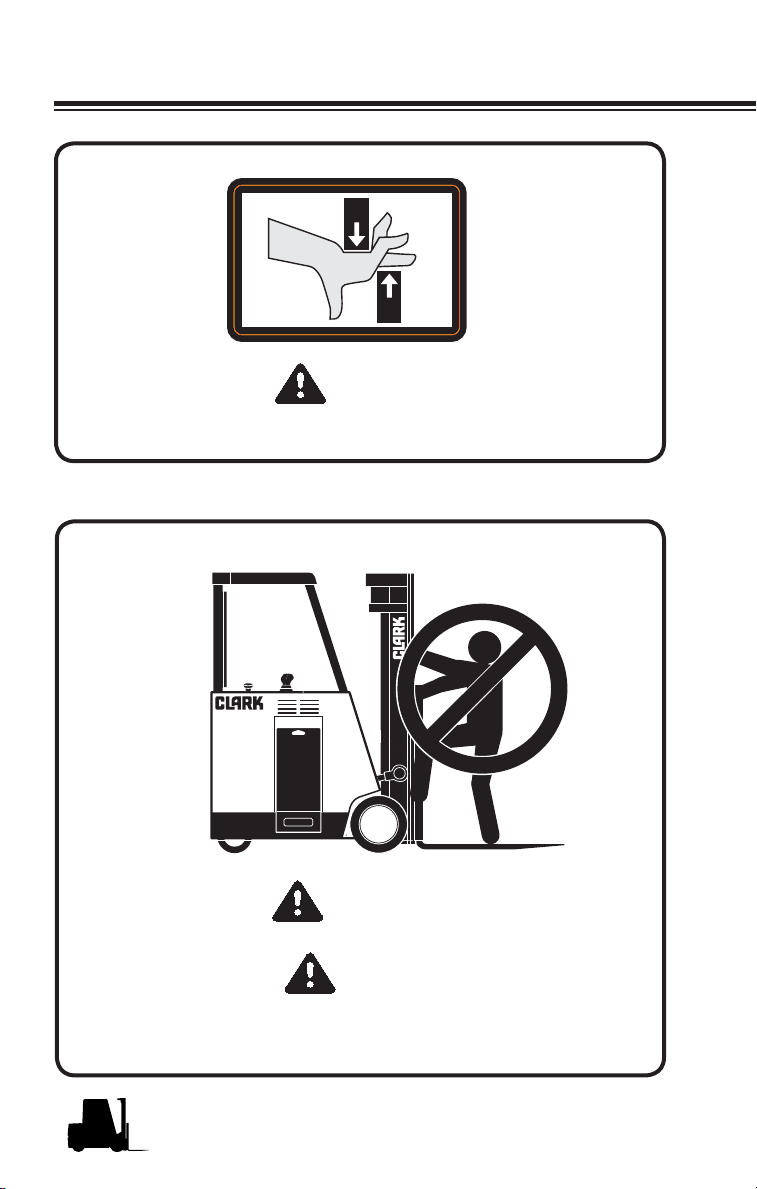

Pinch Points

2791862

WARNING

Keep hands, feet and legs out of the upright.

WARNING

Don't use the upright as a ladder.

CAUTION

Never try to repair the upright, carriage, chain, or attachment yourself! Always get a trained mechanic.

1.8

Pinch Points

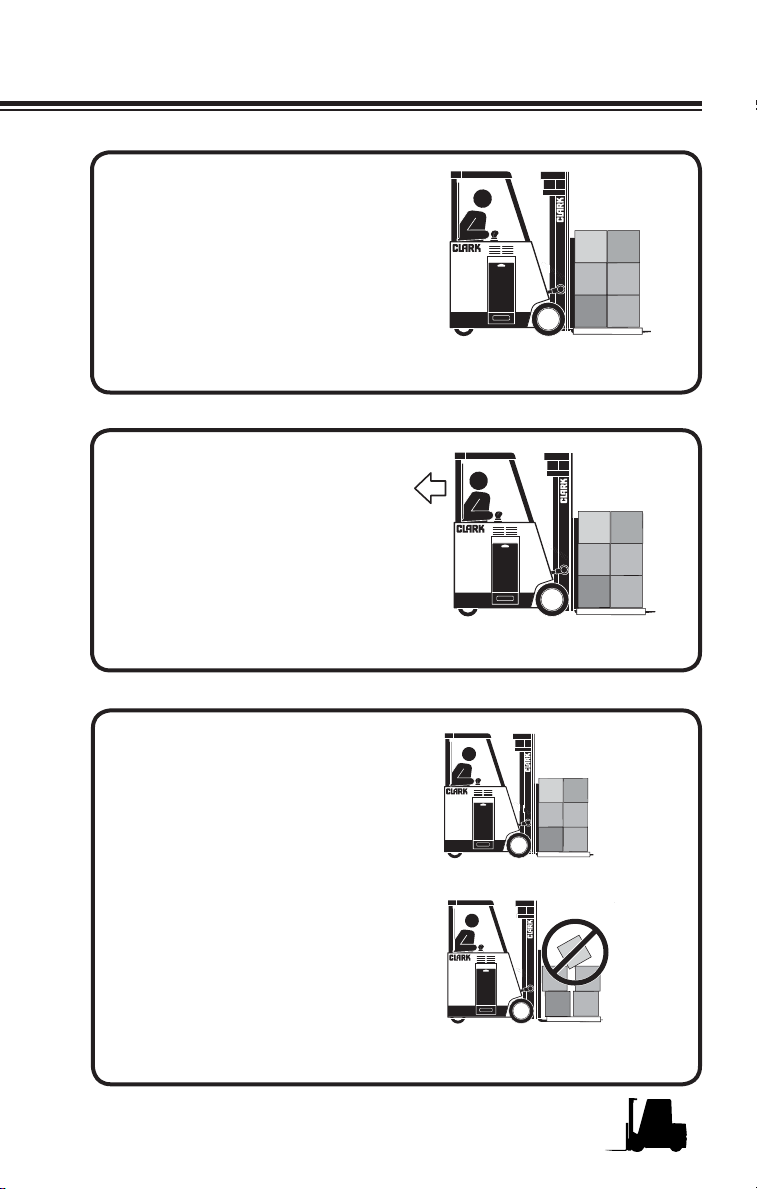

Travel with the load near

the fl oor/ground with forks

tilted back to cradle the load

whenever possible.

Never lift or lower the

load when the truck is in

motion.

When handling bulky

loads that restrict your

vision operate your truck

in reverse to improve visibility.

Be sure to pivot in the

operator compartment to

give maximum visibility.

Section 1. General Safety Rules

Travel

718008

718009

Unstable loads are a

hazard to you and to your

fellow workers.

Always make certain that

the load is well stacked

and evenly positioned

across both forks.

Never attempt to lift a

load with only one fork.

718008

718010

Travel

Right

Wrong

1.9

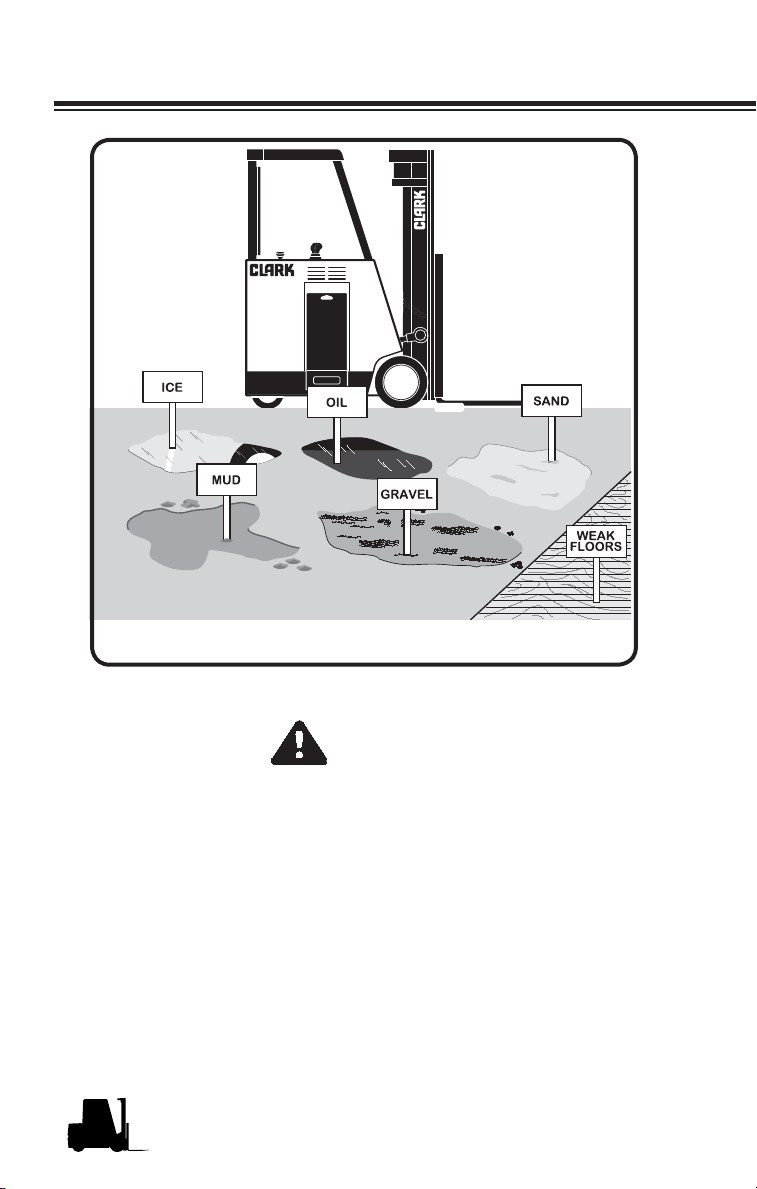

Surface and Capacity

657011

Avoid these conditions. They can cause a truck to tip over or lose traction for braking or driving.

WARNING

Know the weight of your truck and load. Especially when

using elevators. Know the capacity of the elevator you

intend to use. Do not overload.

1.10

Surface and Capacity

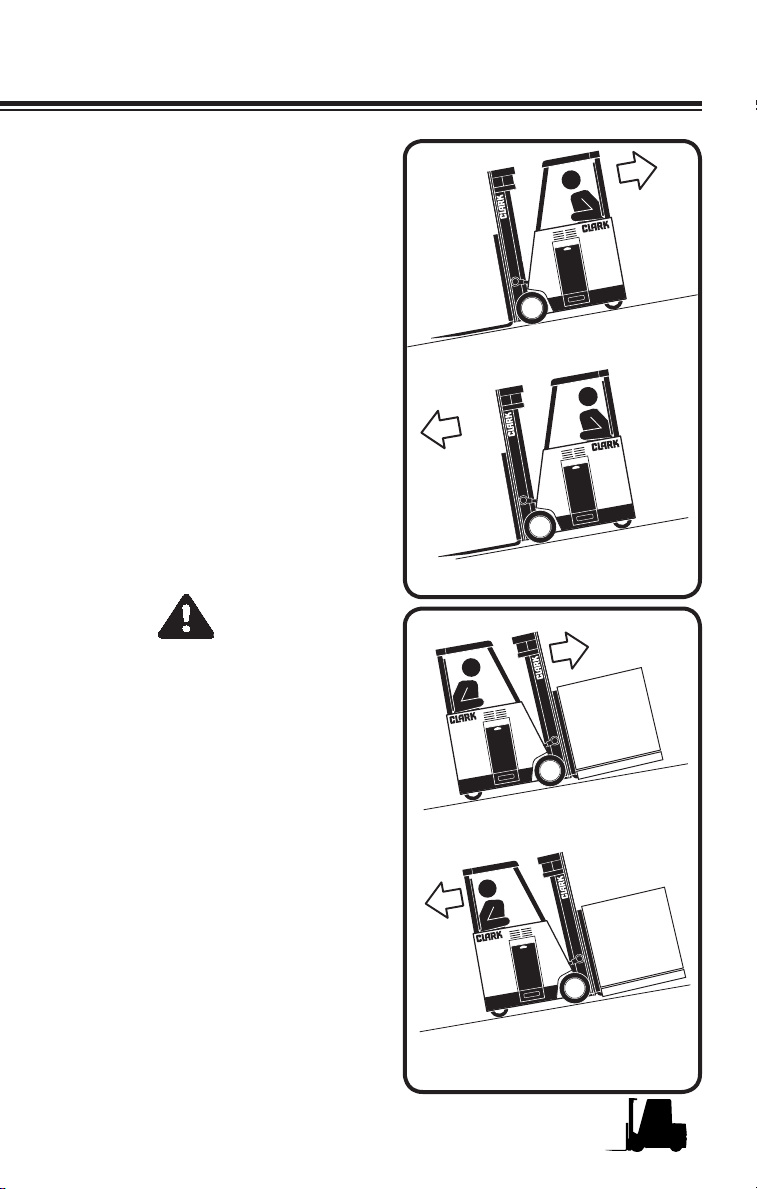

Grade, Ramps, Slopes and Inclines

There are fi ve basic points you

should practice when operating on

grades:

1. Travel up and down grades

slowly.

2. Travel straight up and straight

down.

3. Without a load, travel up or

down with the forks pointing

downgrade. (see illustration)

Section 1. General Safety Rules

657012

657013

Without Load

WARNING

Never turn on grades, ramps,

slopes or inclines; wait until

you are back on level surface.

4. With a load travel up or

down with the load pointing

upgrade. (see illustration)

5. The load should be tilted back

and raised only high as necessary to clear the surface.

Grade, Ramps, Slopes and Inclines

657014

657015

With Load

1.11

657017

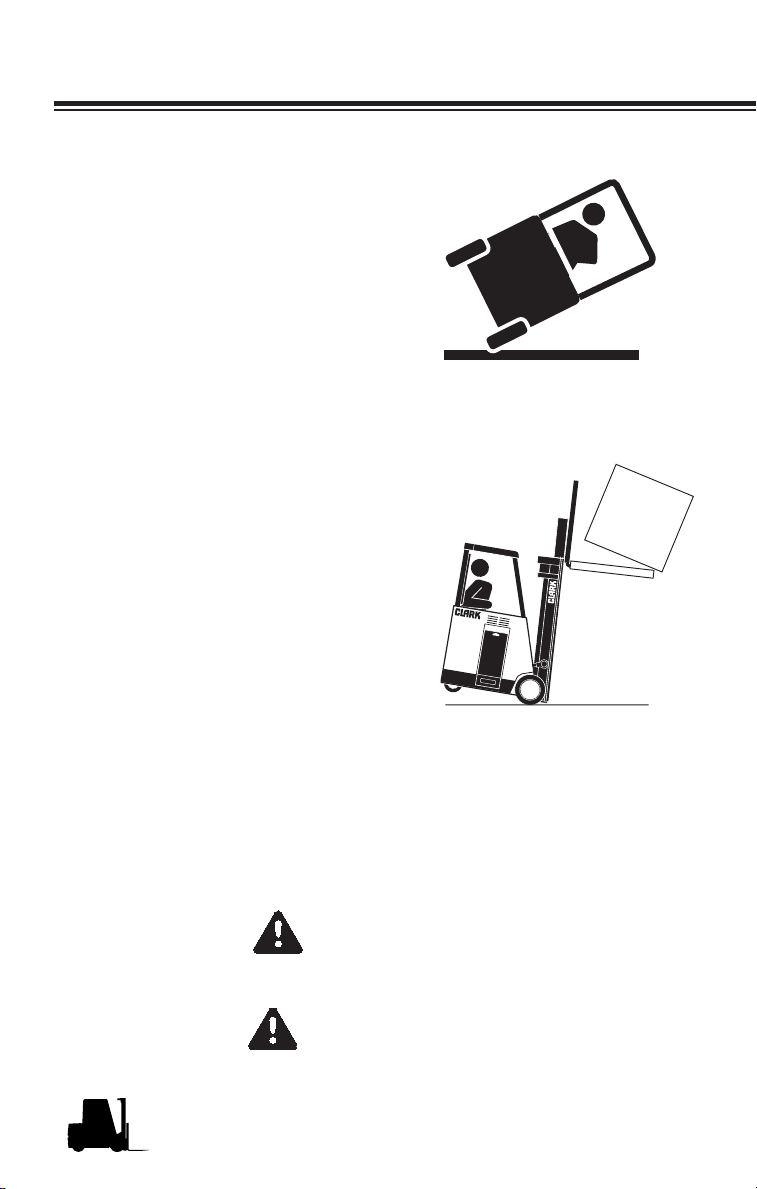

Tip-over

Lateral Tip-over

• Lateral tip-over can occur with a combination of travel speed and sharpness

of turn. This combination may exceed

the stability of the truck. This condition

is even more likely with an unloaded

truck.

• While traveling with the load or upright

raised, lateral tip-over can occur while

turning and/or braking when in reverse

or accelerating and turning while traveling forward.

• Lateral tip-over can occur loaded or

unloaded by turning on an incline or

ramp.

Longitudinal Tip-over

• Longitudinal tip-over can occur with a

combination of overloading and load

elevated also with capacity load and

elevated. Traveling with this combination may exceed the stability of the truck.

This condition is even more likely with

excessive forward tilt, braking in forward

travel or accelerating rearward.

• Longitudinal tip-over can occur by driving with the load down slope on a steep

grade.

Lateral and longitudinal tip-over can occur if the truck is driven over objects

on the fl oor or ground, off the edge of improved surfaces, or into potholes

in the road surface, or by running into overhead objects or collisions.

657016

An off dock type of tip-over can occur if the truck is steered too close to the

dock edge, driven off the edge of the dock or ramp, or if the highway truck

or trailer rolls away from the dock or is driven away during loading.

WARNING

The conditions listed above can be further aggravated by

overloading, excessive tilt, or off center loads.

DANGER

Lift truck tip-over can cause serious injury or death if the

operator is trapped between the truck and the ground.

1.12

Tip Over

Section 1. General Safety Rules

What to do in Case of a Tip-over

If your truck starts to tip over,

DANGER

If your electric stand-up lift truck starts to tip over in

any direction, CLARK recommends stepping off and

away from the rear of the truck.

657018

IMPORTANT

If you tip an electric stand-up lift truck over, you can

be seriously injured, or killed, no matter what you do!

Y our best chance of surviving a tip over is to get away

from the falling truck and load. You must step out and

away from the driver's compartment.

NOTE: This only applies to a stand-up rider type truck

with a large rear opening in the drivers compartment.

Tip-over

1.13

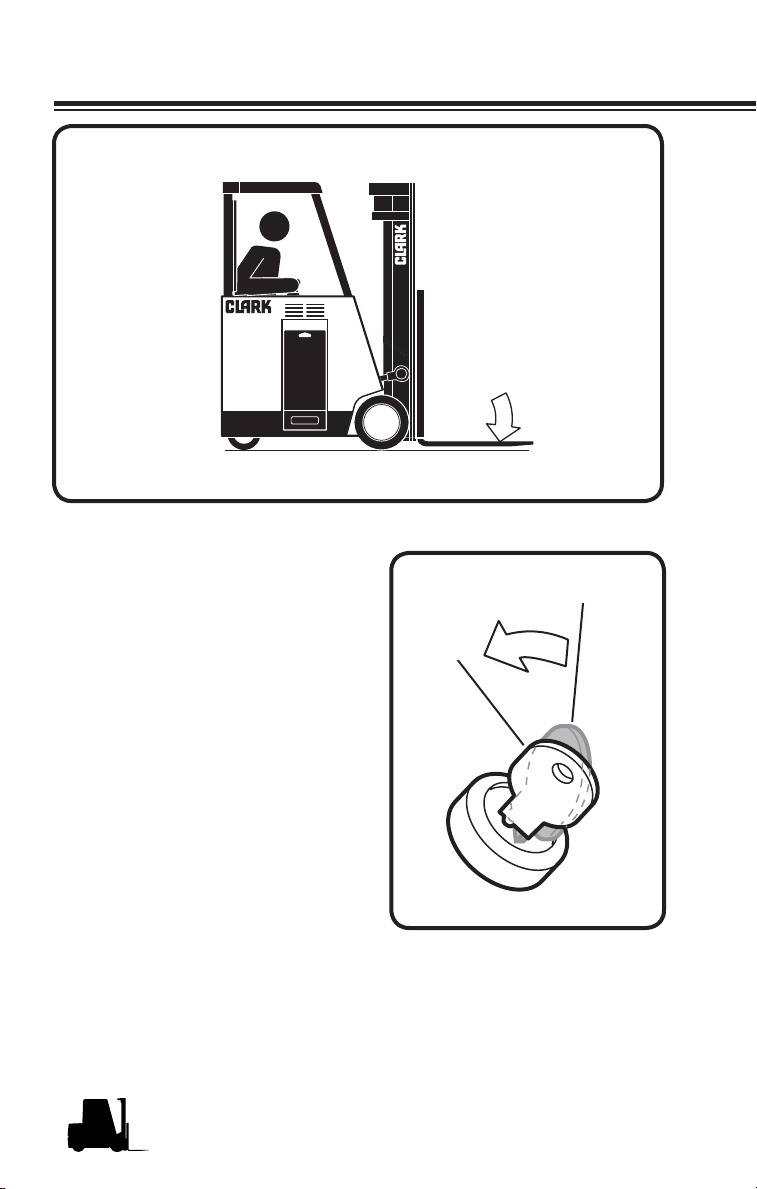

Parking

• Always come to a complete

stop.

Tilt

718019

• Park only in authorized locations.

• Never park on a grade.

• Be sure travel control is in NEUTRAL.

• Lower forks fully to fl oor and tilt

forward.

• Turn key to OFF position.

• When you step from the truck or

turn the key switch to OFF, the

brake will set itself.

• Never step from the truck while

it is motion. Always come to a

complete stop before leaving

the truck. Doing so is not only

dangerous, but will cause accelerated wear of the brake

components.

1.14

Parking

RUN

OFF

657020

Section 2. Operating Hazards

Operating Hazards

Contents

Loose Loads ...............................................................2.2

Long and Wide Loads ...............................................2.3

Rear Swing .................................................................2.3

Low Overhead Clearance ..........................................2.4

Fast Turns and High Loads .......................................2.4

Docks / Drop-offs .......................................................2.5

Right-Angle Stacking ................................................2.6

Chain Slack ................................................................2.7

Pallets and Skids .......................................................2.8

This Section shows some of the hazards that may cause you, or someone around you, to be killed or badly hurt. As the operator, you must

look for other hazards. Get your supervisor to help you identify and

avoid those hazards.

Contents

2.1

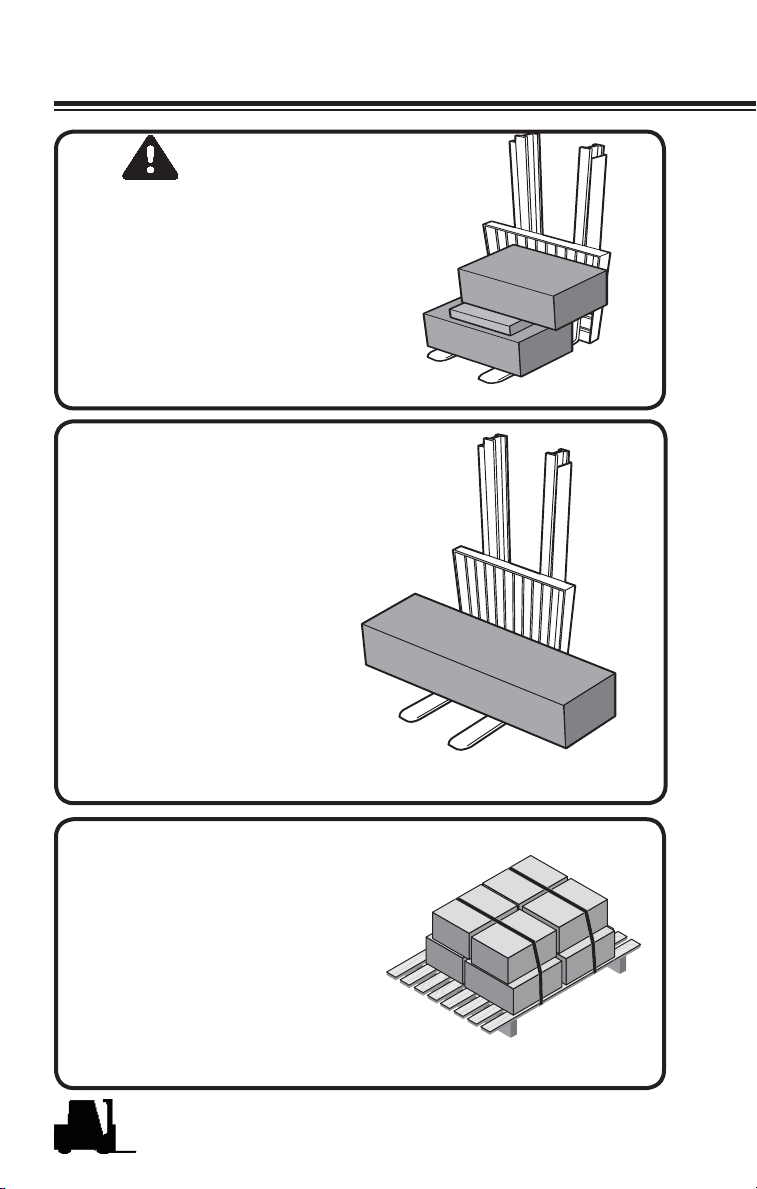

Loose Loads

WARNING

Loose or unbalanced loads

are dangerous. Observe

these precautions.

Never carry loose or uneven material.

Center wide loads.

OM0006

Stack and band loose material.

2.2

Loose Loads

OM0007

OM0008

Section 2. Operating Hazards

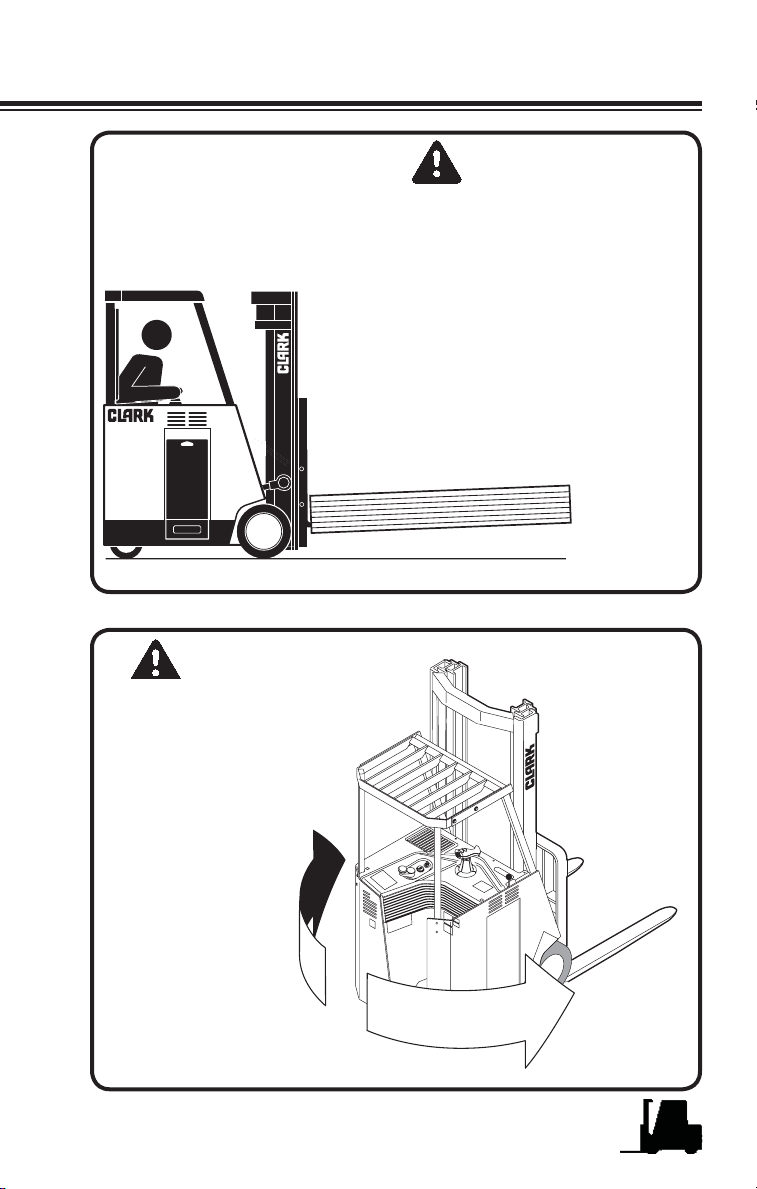

718066

Long and Wide Loads / Rear Swing

WARNING

With long or wide loads, you

need more room. So slow down

and watch your clearance.

A long load reduces the capacity of the truck. Know and

understand your truck load

rating.

When extra-long material makes it necessary to travel with the load elevated, do

so with extreme care and be alert to load

end-swing when turning.

718022

WARNING

When turning, be

sure the rear end

of the truck does

not swing into

racks, posts, etc.

Watch for pedestrians beside the

truck.

Long and Wide Loads • Rear Swing

2.3

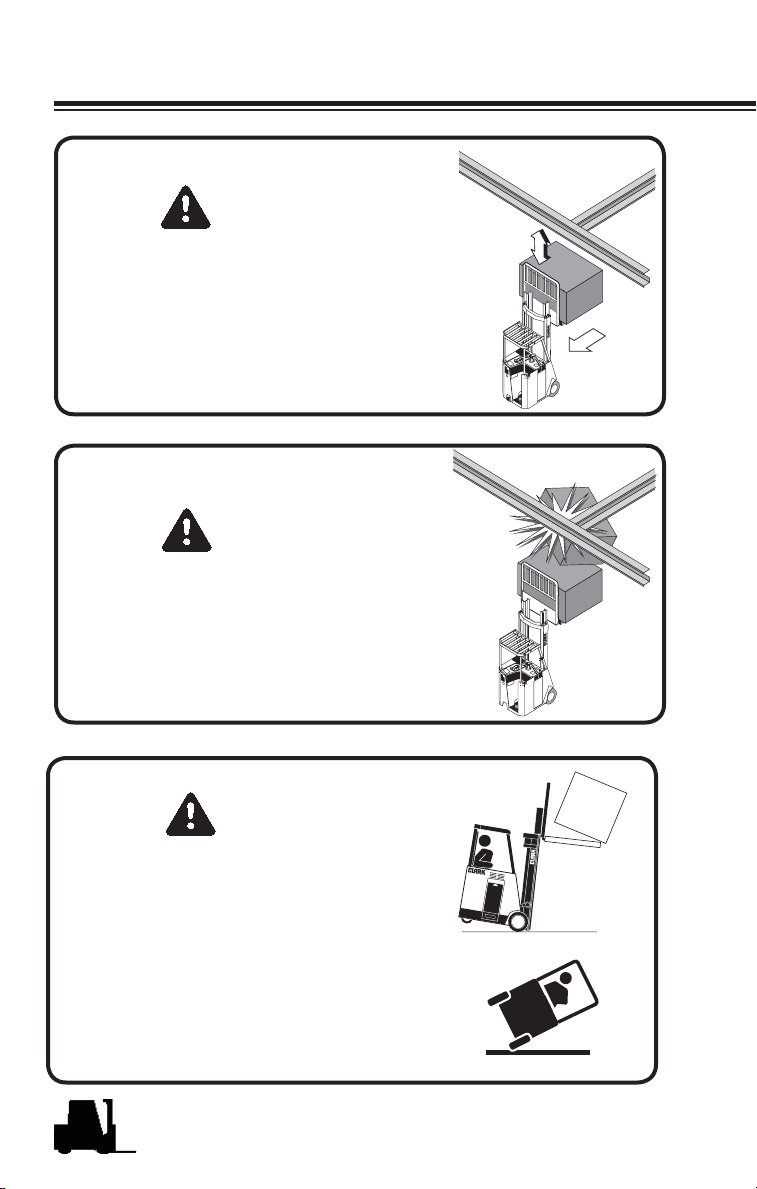

Low Overhead Clearance

718064

718065

Fast Turns and High Loads

WARNING

Know the height of your truck, with

and without a load.

Check your clearances.

Keep the load low and tilted back.

WARNING

Watch overhead clearance.

WARNING

Slow down before turning. The truck

can tip over.

Turn too sharp with a raised load

and your truck can tip even at slow

speeds.

Travel with a load raised only when

removing or depositing a load.

2.4

Low Overhead Clearance • Fast Turns

657017

657016

Loading...

Loading...