Page 1

52” VideoWall Display

WN-5220-S

User’s

Guide

Page 2

1999 by Clarity Visual Systems™, Inc.

All Rights Reserved.

Contents of this publication may not be reproduced in any form without permission of Clarity Visual

Systems, Inc.

Trademark Credits

Macintosh is a registered trademark of Apple Computer Corp.

IBM is a registered trademark of International Business Machines, Inc.

Windows is a trademark of Microsoft Corp.

All other names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this document is subject to change without notice.

Clarity Visual Systems Company makes no warranty of any kind with regard to this material. While every

precaution has been taken in the preparation of this manual, Clarity Visual Systems shall not be liable for

errors or omissions contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

ii

Page 3

52” VideoWall Display

WN-5220-S

User’s

Guide

070-0026-02

Page 4

June 1999

iv

Page 5

LIMITED WARRANTY

properly used and serviced, will perform substantially in accordance with the product data sheet

and users manual, and will be free from defects in material and workmanship for 1 year following

date of shipment. This warranty does not apply to lamps (see following section for lamp warranty)

and other consumable parts.

The main illumination lamp is considered a consumable, and is warranted against failure for the

first 3000 hours of usage, or 125 calendar days, whichever occurs first. The replacement of other

consumable parts are the Buyer's responsibility.

If any Product fails to conform to the written warranty, Clarity's exclusive liability and Buyer's

exclusive remedy will be, at Clarity's option, to repair, replace or credit Buyer's account with an

amount equal to the price paid for any such defective Product returned by Buyer during the

warranty period, provided that: (a) Buyer promptly notifies Clarity in writing that such Product

failed to conform, furnishes an explanation of any alleged deficiency and obtains from Clarity a

return authorization; and (b) Clarity is satisfied that claimed deficiencies actually exist and were

not caused by accident, misuse, neglect, alteration, improper installation, repair or improper

testing. Clarity will have a reasonable time to make repairs, to replace Products or to credit

Buyer's account.

LIMITATIONS.

OTHER WARRANTIES, EXPRESS OR IMPLIED. CLARITY NEITHER ASSUMES NOR

AUTHORIZES ANY OTHER PERSON TO ASSUME ANY OTHER LIABILITIES IN

CONNECTION WITH THE SALES OR USE OF ANY PRODUCT WITHOUT LIMITATION.

CLARITY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR.

IN NO EVENT WILL CLARITY BE LIABLE TO BUYER OR ANY OTHER PARTY FOR

PROCUREMENT COSTS, LOSS OF PROFITS, LOSS OF USE, OR FOR ANY OTHER

INCIDENTAL, CONSEQUENTIAL, INDIRECT OR SPECIAL DAMAGES OR FOR

CONTRIBUTION OR INDEMNITY CLAIMS, HOWEVER CAUSED. CLARITY'S LIABILITY SHALL

BE LIMITED TO ACTUAL DIRECT DAMAGES NOT IN EXCESS OF THE AMOUNTS PAID TO

CLARITY BY BUYER FOR THE PRODUCT. THESE LIMITATIONS WILL APPLY TO ALL

CLAIMS, INCLUDING, WITHOUT LIMITATION, WARRANTY, CONTRACT, INDEMNITY, TORT

(INCLUDING NEGLIGENCE), STRICT LIABILITY OR OTHERWISE.

ANY WRITTEN WARRANTY OFFERED BY CLARITY IS IN LIEU OF ALL

. Clarity warrants to Buyer that the WN-5220-S (the “Product”), if

v

Page 6

June 1999

vi

Page 7

Table of Contents

Product Introduction.....................................................................................................................1

Introduction....................................................................................................................1

Features .........................................................................................................................1

Options and Accessories ..................................................................................................2

Safety.............................................................................................................................................5

Mechanical Installation.................................................................................................................9

Site Requirements ......................................................................................................... 10

Power.....................................................................................................................10

Temperature and Humidity ......................................................................................11

Flooring .................................................................................................................. 11

Clearance ...............................................................................................................12

Cooling ...................................................................................................................12

Mechanical Setup, Standard Screen ................................................................................13

Mechanical Setup, Ultra-Thin Mullion Screen ...................................................................14

Basic Steps for Alignment ........................................................................................15

Alignment Procedure in Detail ..................................................................................16

Cables ..........................................................................................................................21

Initial Setup.................................................................................................................................23

Step 1 – Power-Up ........................................................................................................23

Step 2 - Adjust the Input Signal Settings......................................................................... 25

Select the Source ....................................................................................................25

Adjust the Black Input Level - PC, MAC or RGBS Video............................................... 27

Adjust the White Input Level – PC, MAC or RGBS Video .............................................28

Comp Video/S-Video Level Adjustment .....................................................................30

Adjust the Frequency...............................................................................................33

Adjust the Phase .....................................................................................................34

Set the Sharpness ...................................................................................................35

Position the Image ..................................................................................................36

Scale the Image ......................................................................................................38

Step 3 - Adjust the Colors .............................................................................................. 39

Step 4 – Save, Recall, or Reset the Settings ....................................................................43

Turning off the System ..................................................................................................45

Turn off the Lamp, Enter Standby Mode....................................................................45

Turn off Main Power Switch .....................................................................................46

Clarity’s Big Picture™ ..................................................................................................................47

Loop-Thru of Source Video.............................................................................................50

Installing Big Picture Option Key.....................................................................................52

Other Features and Adjustments................................................................................................ 53

Curtain ...................................................................................................................53

vii

Page 8

Monitor Select .........................................................................................................54

ID ..........................................................................................................................54

Miscellaneous Controls...................................................................................................54

Set the Number of Colors.........................................................................................55

Remote Control Tone............................................................................................... 56

Flip the Image Horizontally ......................................................................................56

Flip the Image Vertically ..........................................................................................56

Auto Lamp On.........................................................................................................57

Reset Lamp Hours .........................................................................................................57

About ...........................................................................................................................59

Cleaning and Maintenance..........................................................................................................61

Lamp............................................................................................................................61

Lamp Replacement, Front, Standard Mullion Screens .......................................................62

Removing a Standard Screen Using the Screen Removal Tool..................................... 63

Lamp Replacement, Rear Access, Either Screen Type ......................................................64

Air Filter Replacement, Front or Rear Access ...................................................................64

Cleaning the Screen and Mirrors ..................................................................................... 65

Troubleshooting ..........................................................................................................................67

Power and Start-Up Problems ........................................................................................67

Common Problems and Answers.....................................................................................70

Image Problems ............................................................................................................71

Connector Pinouts.......................................................................................................................72

RGBS............................................................................................................................72

MAC .............................................................................................................................73

PC & LOOP-THRU.......................................................................................................... 73

RS-232 IN.....................................................................................................................75

RS-232 OUT..................................................................................................................75

S-VIDEO ....................................................................................................................... 76

Interface and Controls ................................................................................................................77

Rear Panel Indicators, Connectors and Controls............................................................... 77

Rear Panel Indicators ..............................................................................................77

Rear Panel Connectors.............................................................................................78

Rear Panel Controls .................................................................................................79

Remote Control .............................................................................................................80

Remote Control Functions ........................................................................................ 80

Menus ..........................................................................................................................82

RS-232 Control ............................................................................................................................89

RS-232 Control Items ....................................................................................................92

Specifications ..............................................................................................................................97

Environmental............................................................................................................... 97

Picture Control ..............................................................................................................97

Optical..........................................................................................................................98

Mechanical....................................................................................................................99

Electrical..................................................................................................................... 100

Regulatory Information ............................................................................................................103

Declaration of Conformity ............................................................................................ 103

FCC Regulations .......................................................................................................... 104

Other Certifications...................................................................................................... 104

Index..........................................................................................................................................105

June 1999

viii

Page 9

Introduction

The WN- 5220-S VideoWall is a mult i- frequency, multi-source display capable

of displaying a wide range of video sources. The clear, bright image is a

product of careful engineering and optical innovation. Setup is easy because of

light weight and simple mechanical connections. And it is fast because there

are only a few adjustments necessary to configure the image.

Product Introduction

The optional Ultra-Thin Mullion screen gives the display additional flexibility in

meeting the most demanding image quality applications. By eliminating t he

front-surf ace frame, this screen nearly eliminates the visible seam between the

displays. (Mullion: the metal edge around the screen.)

Clarity’s Big Picture™ option is a built-in data/videowall processor. Without the

need for an external processor, Big Pict ur e can scale t he source video to

accommodate any display wall size up to four high and four wide.

Features

Clarity’s products are designed and developed by experts in LCD projection

technology and offer sig nificant advantages over conventional cathode ray

tube (CRT) based systems including:

optical resolution of 800x600 pixels

•

ability to scale lower resolution sources up to 800x600

•

supports a wide variety of computer and video formats

•

superior image quality (even in high ambient light conditions)

•

substantially lighter weight – 120 lbs (55 kg)

•

significantly reduced depth (reduced footprint)

•

lack of image flicker

•

improved brightness uniformity (no “ hot spots”)

•

no convergence requirements

•

no color drifting

•

easy to service

•

fast and easy setup

•

1

Page 10

Additional Features

direct compatibility with a wide range of video and computer data

•

sources: 800x600 and 640x480 for PC and MAC; 31.5 kHz line

doubled RGBS video

with the optional S/300 electronics, 15.75 kHz RGBS video and the

•

ability to decode and display NTSC, PAL and SECAM directly

Options and Accesso r i es

Clarity’s display products can be enhanced with several accessories.

Ultra-Thin Mullion Screen

!"

The standard screen has a mullion 1/8” (3 mm ) wide.

•

– The options are:

The mullion is a strip of sheet met a l sur r ounding the

screen which holds it in place.

The Ultra-Thin Mullion Screen, or mullionless screen,

•

does not have the 1/8” (3 mm) strip of sheet metal

around the screen. The edge of t he scr een goes to

within 0.025” (0.64 mm) of the edge of the display unit,

which makes the lines between display units almost

invisible in the finished video wall.

S/300 Option - Video Input M odul e

!"

This option adds the ability to scale up the image on each

edge of the display for a better image fit when working with

multiple displays. It also adds three new source inputs:

15.75 kHz RGBS video, and composite and S-video in

both NTSC, PAL and SECAM.

Clarity’s Big Picture™

!"

This option allows a single video source to be expanded

over a video wall up to 4x4 displays, eliminating the need

for an external processor. (

display units in the video

All

wall must have this option.) Scaling and moving of t he

individual images facilitates exact matching at the borders.

June 1999

2

SRT-100 Screen Removal Tool

!"

This tool makes it easy to rem ove the nor mal mullion

screens when the displays are used in video walls, where

units are placed directly adjacent to each other. The

SRT-100 minimizes the chance of damaging the screen

and the screen’s latches. (It cannot be used with Ultra- Thin

Mullion Screens.)

SAT-500 Screen Alignment Tool

!"

This tool is essential to properly position the display units

with the Ultra-Thin Mullion Screen in a video wall. It helps

assure the correct spacing between adjacent screens in

the assembled video wall. (Cannot be used with standard

mullion screens.)

Page 11

BAS-520 Base for the WN-5220-S

!"

The BAS-520 provides a permanent attachment to

flooring.

Please contact your reseller for a current listing of available options or visit

Clarity’s website at

www.ClarityVisual.com

3

Page 12

June 1999

4

Page 13

WN-5220-S VideoWall User’s Guide

Safety

Please read this chapter carefully bef or e at tempting to install, use,

service, or repair the WN-5220-S VideoWall. There are a number of

potentially dangerous areas inside the unit. T hese ar e ident ified with

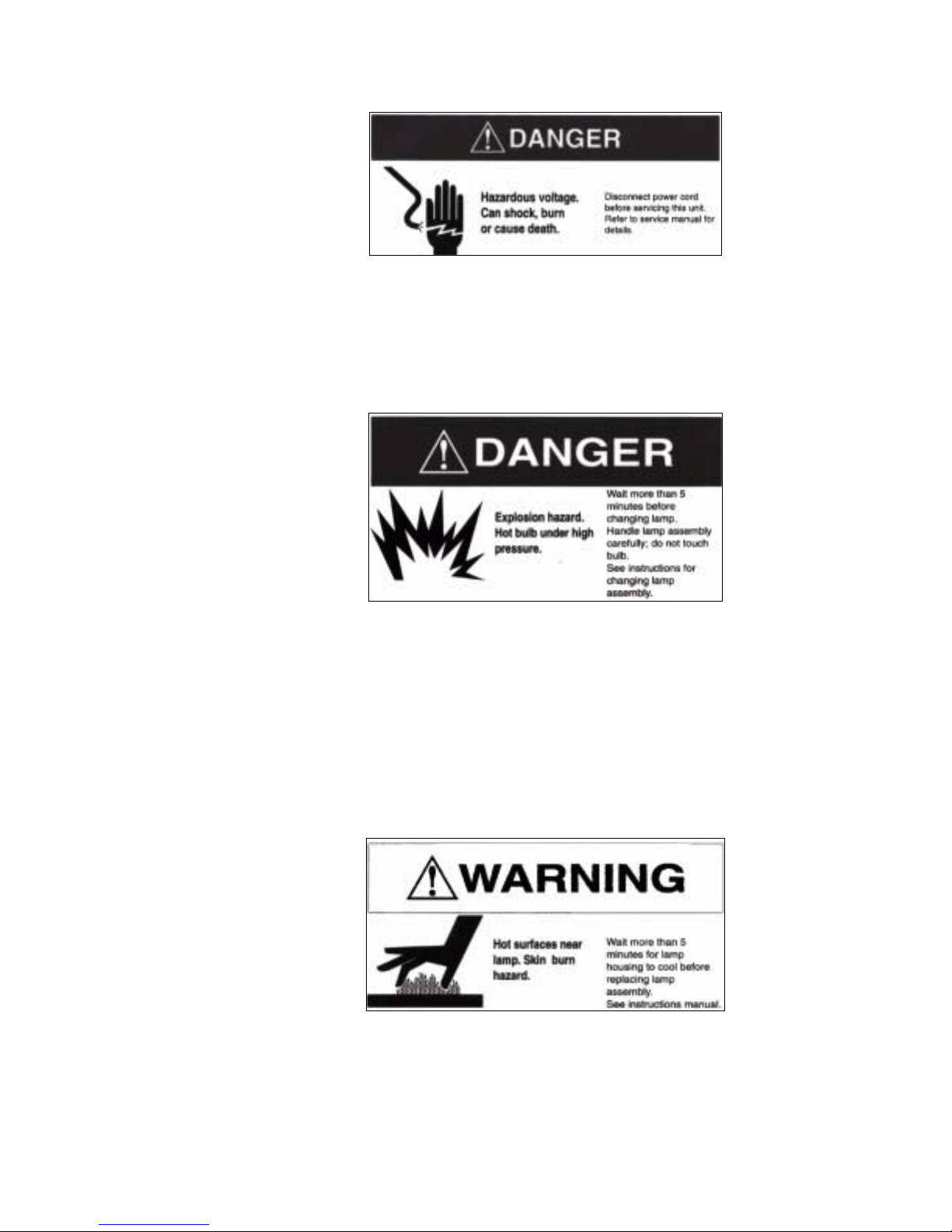

the following warning labels.

Hazardous voltage inside. Can shock, burn, or cause

death. No user serviceable parts inside. Refer all

service to qualified serviceman.

5

Page 14

Clarity Visual Systems

Hazardous voltage. Can shock, burn or cause death.

Disconnect power cord before servicing this unit . Refer

to service manual for details.

Explosion hazard. Hot bulb under high pressure. Wait

more than 5 minutes before changing lamp. Handle

lamp assembly carefully; do not touch bulb. See

instructions for changing lamp assembly.

Hot surface near lamp. Skin burn hazard. Wait mor e

than 5 minutes for lamp housing to cool before

replacing lamp assembly. See instruction manual.

June 1999

6

Page 15

WN-5220-S VideoWall User’s Guide

UV radiation from unprotected, operating bulb. Eye

damage injury. Do not disturb light path shielding f r om

the bulb.

WARNING

Only the WN-5220- S lamp, air filter, and fuse are user

serviceable. Always turn off and disconnect power before

servicing these items. Refer all ot her service to a qualified

service center. Failure to do so could result in electrical shock,

ultraviolet radiation burns, contact heat bur ns, serious injury, or

irreparable damage to the WN-5220-S and may void your

factory warranty.

WARNING

WARNING

WARNING

The area around the projection lamp and the pr ojection lamp

assembly become extremely hot during and after use. Use

extreme caution and let the WN-5220-S’s lamp assembly cool

for 5 minutes before t ouching or replacing the lamp assembly.

The WN- 5220- S cont ains electrical interlocks that prevent

operation of the display when the front screen is r em oved. Do

not bypass these interlocks, except for servicing . Never

operate the WN-5220-S with any access panels or the front

screen removed from the unit, except for servicing. Operating

the WN-5220- S with access panels or the front screen

removed can expose service or operating personnel to

ultraviolet burns and high electrical voltages. Always wear

ultraviolet-blocking eyewear with side guards when servicing

the WN-5220- S.

The WN- 5220- S uses a high-intensity projection-lamp module.

Do not attempt to replace the projection lamp module with any

alternative light source. Doing so can cause overheating or

unacceptable image quality. Replacement lam p m odules m ay

7

Page 16

Clarity Visual Systems

WARNING

CAUTION

CAUTION

be ordered from Clarity Visual Systems, Inc. Use only the

projection lamp module specified by Clarity Visual Systems,

Inc. or an authorized Clarity Visual Systems, Inc. Service

center. Use of any other lamp voids the warranty.

Do not block the WN-5220-S cooling fan or free air movement

under, over, or around the WN-5220-S. Loose papers or other

objects should not be nearer to the WN-5220-S than 6 inches

on any side.

Air handling ducts can discharge unwanted dust or hightemperature air directly on the display. Do not oper at e t he

WN-5220-S in dust y or high-temperature conditions.

Where several WN-5220-S displays are combined vertically,

installation of the top level requir es a m inim um of 12 inches of

clearance in order to position and fasten t he display in place.

CAUTION

CAUTION

CAUTION

Some types of environmental lighting , such as incandescent, or

high-intensity discharge lamps such as metal halide or m ercury

vapor lamps create high temperatures. This can cause

excessive heating of the display. The unit should be positioned

away from lighting to prevent heat buildup.

The front screen of the WN-5220-S display can be easily

scratched and the optical quality degraded by f ing erprints.

Install the WN-5220-S in such a way that it is not exposed to

touching or possible scratching by hard objects.

Display units with Ultra-Thin Mullion screens are not

serviceable from the front .

June 1999

8

Page 17

Read the chapter on safety precautions bef ore installing and

operating the WN-5220-S VideoWall.

WARNING

WN-5220-S VideoWall User’s Guide

Mechanical Installation

Use help. The WN-5220-S weighs approximately 120 lbs

(55 kg). Do not attempt to lift or m ove the WN-5220-S without

help. Always use all four lifting handles to move or lift the WN5220-S.

The WN- 5220- S com es with either a st andar d scr een or an Ultra-Thin

Mullion Screen:

standard screen

The

•

has a mullion about 1/8

th

inch (3 mm) wide.

The mullion is a strip of sheet met al sur r ounding the screen and

holds it in place.

Ultra-Thin Mullion Screen

The

•

have the 1/8

th

inch strip of sheet metal around the scr een. The

, or mullionless screen, does not

viewing area of the screen goes right to t he edge of the display

unit. This makes the lines between display units much less

apparent in the finished video wall.

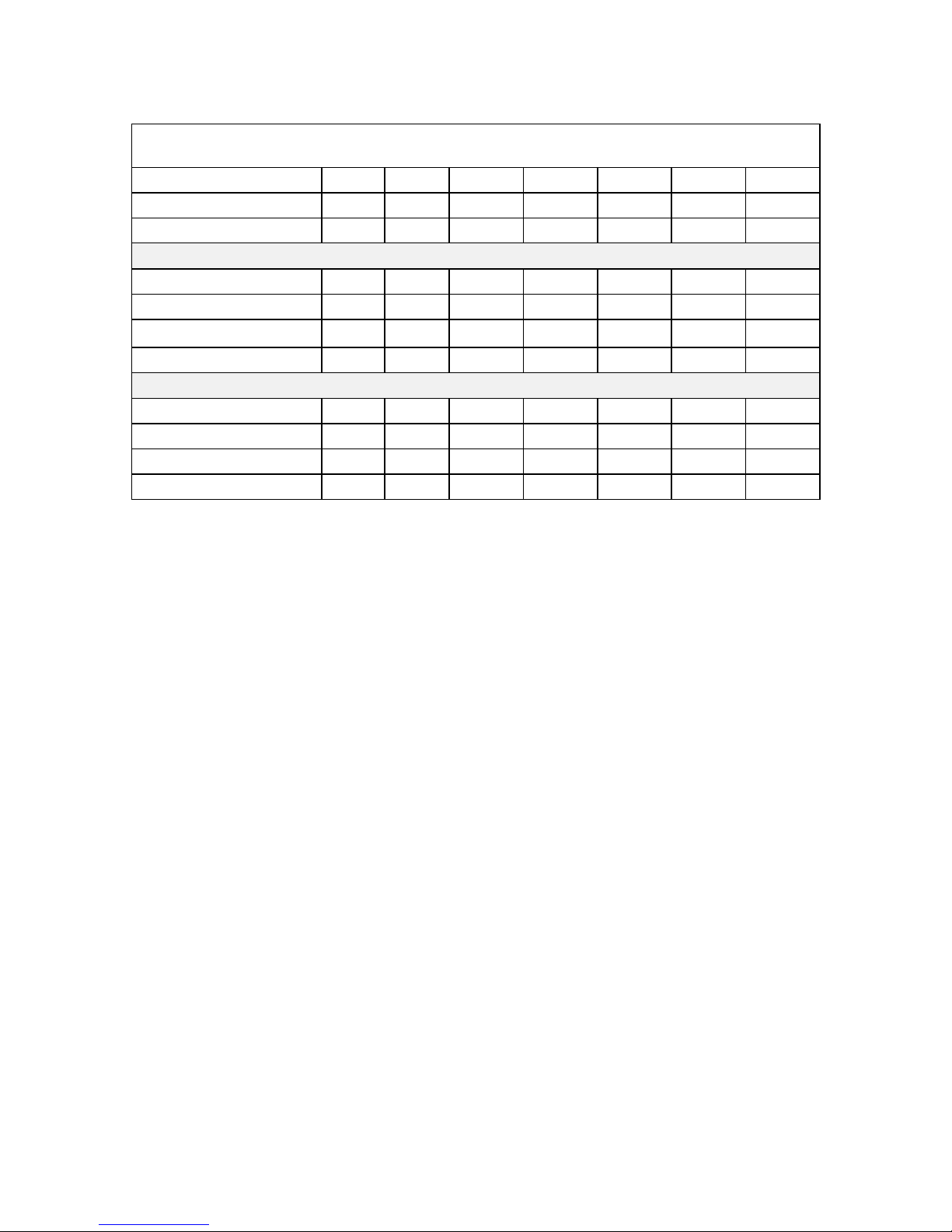

The following table shows installation specifications for common

display configurations. (The t able applies t o both the standard screen

and the Ultra-Thin Mullion Screen.)

9

Page 18

Clarity Visual Systems

Height x Width

Number of display units

1x1

Single

1x2

2 displays

2x2

4 displays

2x3

6 displays

3x3

9 displays

3x4

12 displays

4x4

16 displays

Screen Height, inches 31.3 31.3 62.6 62.6 93.3 93.9 125.2

Screen Width, inches 41.7 83.4 83.4 125.1 125.1 166.8 166.8

Weight, pounds 120 240 480 720 1080 1440 1920

115 Volts A/C Input

Current, amps 8 16 32 48 72 96 128

Power, watts 920 1840 3680 5520 8280 11,040 14,720

Heat, BTU/hr 2827 5655 11,310 16,965 25,448 33,931 45,241

Air Cond., tons .24 .47 .94 1.41 2.12 2.83 3.77

230 Volts A/C Input

Current, amps 4 8 16 24 27 48 64

Power, watts 920 1840 3680 5520 8280 11,040 14,720

Heat, BTU/hr 2827 5655 11,310 16,965 25,448 33,931 45,241

Air Cond., tons .24 .47 .94 1.41 2.12 2.83 3.77

Site Requirements

Power

Table 1

Make sure the power cord is compatible with the nominal power

source used with the WN-5220-S display.

Power Consumption

Power consumption of the WN-5220-S is 920 Watts, or approximately

8 Amps current draw at 115 VAC (4 Amps at 230 VAC). The

WN-5220-S can be configured to operate on either 90-130 VAC or

180-260 VAC nominal power sources at 50/60 Hz.

Voltage Range

The operating voltage rang e of the W N- 5220- S is set via a switch on

the power supply near the AC power plug and on/off switch.

Operation of the display at the incorr ect voltage level can cause

damage to the unit which is not covered by the warranty.

!"Select the setting labeled 115V if your power source is

between 100 and 120 Volts AC.

!"Select the setting labeled 230V if your power source is

between 200 and 240 Volts AC.

If the input voltage drops below approximately 90V (175V if the

WN-5220-S is set to the 230V setting) the display will automatically

shut down to protect itself.

June 1999

10

Page 19

WN-5220-S VideoWall User’s Guide

On a typical 20A, 115V circuit, no more than t wo WN-5220-S displays

may be installed. This allows an extra current marg in. If any circuit

used to power one or more W N- 5220- S displays is not a dedicated

circuit, the additional electrical load placed on the cir cuit by other

equipment must be considered.

WARNING

Displays that are intended for 240V configuration must have a

properly rated power supply cord and attachment plug supplied

by the installer.

WARNING

If extension cords are used for power, use only 3-prong

grounded cords sized to handle system power requirements.

Using the wrong-size extension cord can cause a fire-safety

hazard and can reduce the voltage available to the

WN-5220-S. If the extension cord is warm to the touch it is t oo

small and should be immediately removed from operation.

Temperature and Humidity

The WN- 5220- S is designed to operate over an ambient temperatur e

range of 0° to 35° C (32° to 95° F) and a humidity of 20 to 80 % R.H.

non-condensing.

Some types of environmental lighting , such as incandescent, or high

intensity discharge lamps such as metal halide or mer cur y vapor

lamps, create high temperatur es and t his can cause excessive

heating of the WN-5220-S. Displays should be positioned far enough

away from high-temperature lights to prevent heat buildup.

Nearby heat sources can cause high operating temper at ur es in the

WN-5220-S display. Minimize the display’s exposure to heating ducts,

radiators, or other external heat sources.

Flooring

A single WN- 5220- S display unit weighs appr oximat ely 120 lbs (55

kg). Befor e inst alling the WN- 5220- S, determine the structural

integrity of the flooring where it will be used. The floor should be level

and strong enough to support the combined weight of the number of

displays and other equipment used in the installation. Take special

care when installing a WN- 5220-S in a wall configuration on a

temporary structure such as a stage floor, where the flooring could

bend or collapse under the weight of the installat ion. Never st ack

more than four (4) WN-5220-S displays vertically on a tempor ar y

floor.

11

Page 20

Clarity Visual Systems

Clearance

Normal maintenance, such as lamp module and air filter replacement,

can be performed from the front or rear of the WN-5220-S. Maintain

sufficient clearance to allow easy access from t he front. A minimum of

4 feet is recommended. For full maintenance from the r ear , the

minimum recommended clearance is 3 feet .

To allow proper cooling, the minimum required clearance to the rear

of the display should be 6 inches. The minimum required clearance to

the top at the front of the unit is 6 inches. See Environmental

Specifications on page 97 for cooling requirements.

If installed in a video wall configuration, a m inim um of 12 inches to

the ceiling from the t op of the highest display is needed if the unit s

are installed from the front.

Cooling

Regardless of clearances and the gener al am bient temperature, the

most important fact or t hat affects reliable operat ion is t he temperature

and quantity of air coming int o the display. The intake air temperature

at the air filter must not exceed 95° F (35° C). If there is any doubt

about this temperature in an installat ion, r un t he displays for several

hours before taking t em per at ure measurements. Prevent problems by

replacing dirty air filters and keeping the air path clear.

June 1999

12

Page 21

WN-5220-S VideoWall User’s Guide

Mechanical Setup, Standard Screen

Install the WN-5220-S in the desired position and connect the power

and signal cables. See the following section f or an explanation of the

cabling configuration.

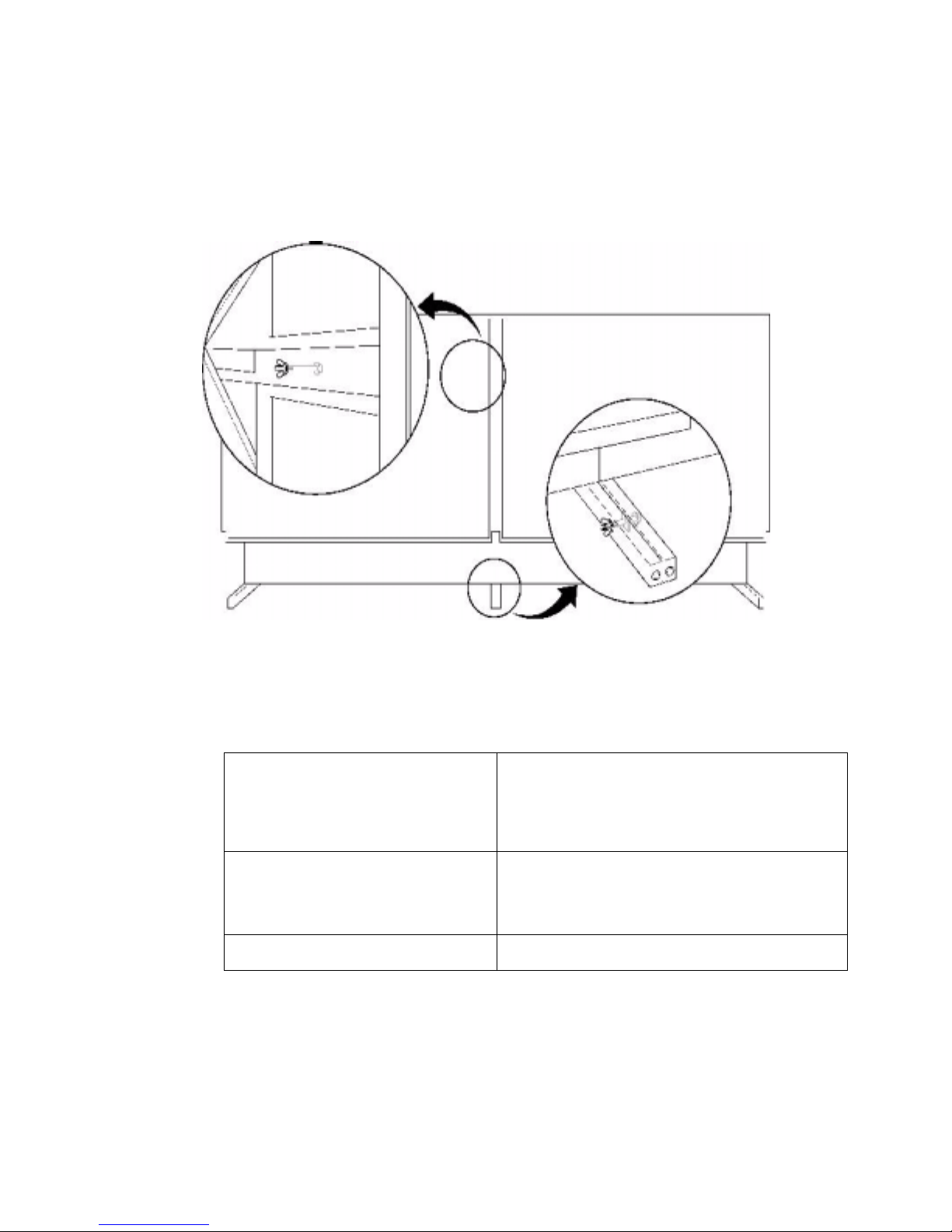

Figure 1 Connecting display units

To setup the WN-5220-S display in a video wall configuration, follow

these steps:

1. Grasp the screen on each side

at the bottom

2. Slip fingers between the screen

frame

3. Using both hands…

The “screen” you are removing is 2 or 3 inches thick.

Pull out at the bottom first, to separate the latchhooks from the latches. It comes out with a “pop.”

The screen should now be loose at the bottom, but

still attached at the top.

Slip fingers between the screen frame and the

display chassis, as close to the top latches as

possible and pull the top of the screen from the

latches.

Carefully remove the screen and set it aside.

13

Page 22

Clarity Visual Systems

4. Assemble the lower row first.

5. Stack the next higher row.

6. Insert a supplied fastener.

Line up the legs for the bottom row as straight as

possible.

Insert a ¼” X 2 ½” bolt through the holes as shown

in Figure 1. Tighten a nut securely on this bolt.

Secure the legs to the floor. Use the tapped 5/16-18

holes in the front and rear of the legs. You can put an

eye-bolt in this hole and secure it to the floor with a

lag screw. Or use angle bracket, screwed to the floor

and bolted to this hole in front and rear. Or use the

optional

putting the lower row of displays on it.

Before going to the next higher rows, see that the

bottom row is straight. From one end of the line, look

along the front of the displays. The line should be

straight and flat. Level is not as important as straight

and flat.

Slide the legs of each display into the mating sockets

of the display in the first (lower) row. Check it for

“straight and flat.”

Insert a bolt through the hole in side wall of the lower

unit into each leg of the unit above.

Tighten a nut on this bolt to lock the units together.

See

BAS-520

Figure 1 above

base, securing it to the floor and

7. Continue with subsequent rows

of displays

8. For added stability…

9. Check

10. Reinstall screens

Lock each display to the adjacent displays after the

row above it (if any) has been installed.

Use the rear-tapped holes in the legs of the upper

units to fasten to a solid support, such as a structural

wall.

The threaded inserts in each leg are female 5/16-18

UNC.

Check that all displays in the video wall are locked

together.

Reinstall each display’s screen.

Mechanical Setup, Ultra-Thin Mullion Screen

CAUTION

You will need these tools:

Displays with the Ultra-Thin Mullion Screens are not

serviceable from the front . Service should be performed

through the rear access cover.

a large, flat blade screwdriver

•

an SAT-500 Screen Alignment Tool ( two of these tools makes

•

installing a video wall even easier.)

black cloth tape

•

a tape measure (inches or centimeters)

•

June 1999

14

Page 23

•

•

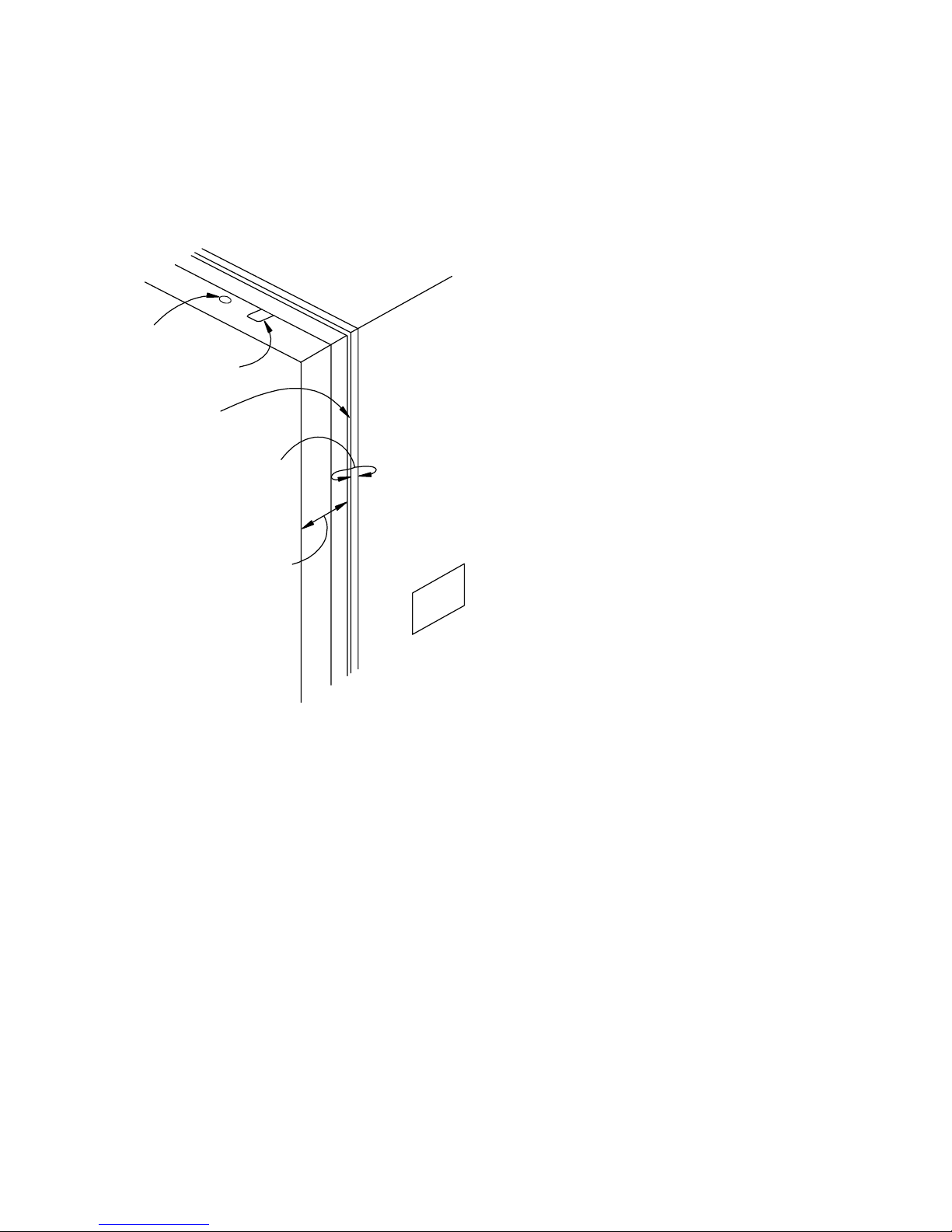

The thin mullion display screens consist of two basic parts. There is

the screen itself and the f r ame it is held in, an assembly which is

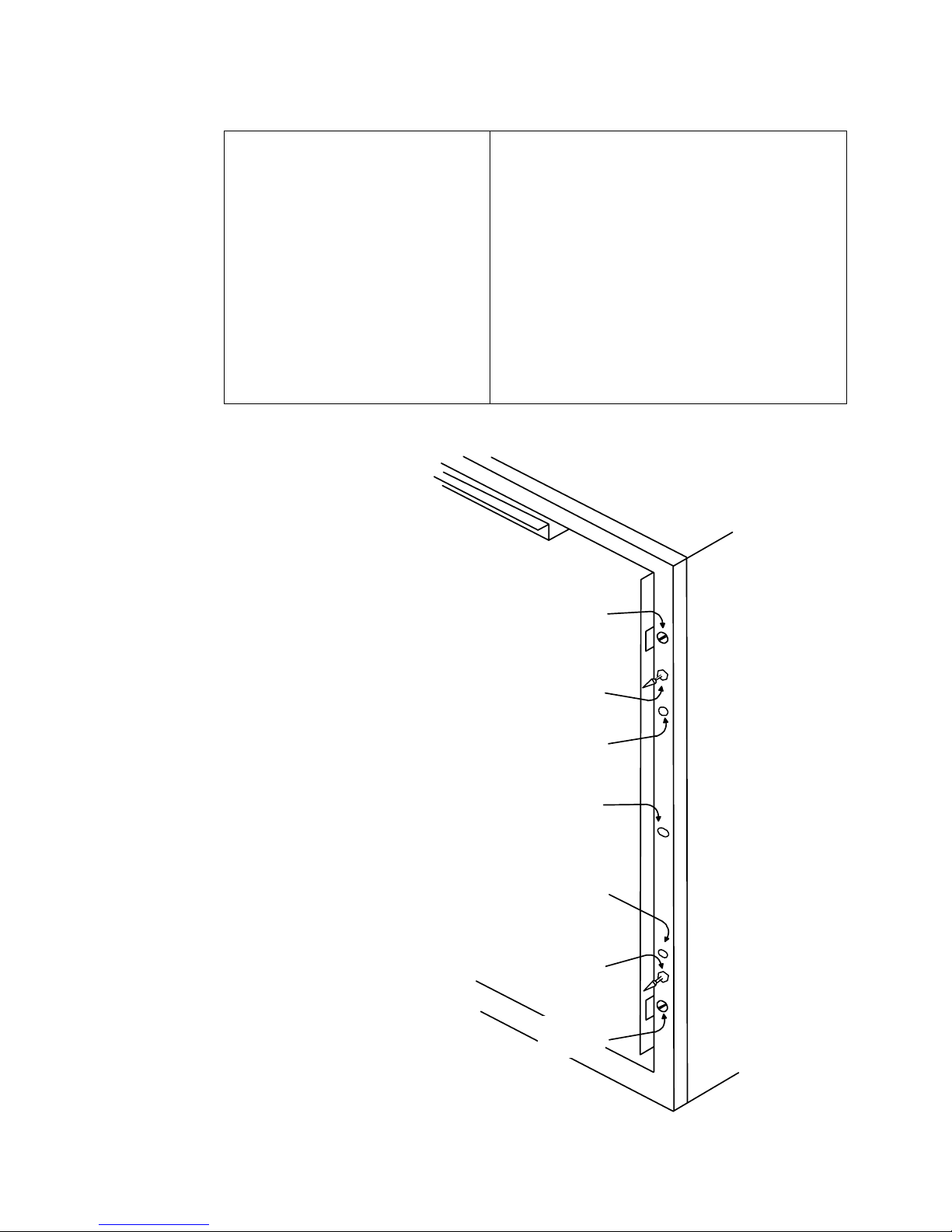

Reta ining scre w

Finger hole

Space

Adapter Plate

Thin Mullion Screen

Figure 2 Ultra-Thin Mullion Screen

WN-5220-S VideoWall User’s Guide

1/2” open end wrench, deep-well socket, or an adjustable

wrench

5/64” Allen hex wrench

about 3” (7 cm) thick. T he scr een

attaches to the second part, an adapter

plate which is about 1/4” (6 mm) thick.

The adapter plate is mounted on the front

of the display unit.

During the alignment process, you

remove the screen from the adapter

plate, then adjust the adapter plat e t o

make its corners square and alig n

correctly with its neighbors. Then the

screen is re-installed and adjusted in or

out.

Installing a video wall with Ultra-Thin

Mullion Screens is a little more complex

than installing the wall with standard

mullion screens. Mechanical alignment is

more critical, and the larger the video

wall, the more precisely each unit must

be aligned to produce a good looking

image. The outcome of this alignment

process is partly dependent on how flat

the floor is, but it is most ly dependent on

how tightly the displays are fitted to each

other.

Basic Steps for Alignment

This is a summary of the steps necessary to build a video wall thin mullion

displays and align their screens. This is a

perform each step follow the summ ar y.

1. Remove the screens from all the display units.

2. Build the video wall.

3. Start with the display unit in the center of t he bot tom row. Square its

adapter plate.

4. Using the Alignment Tool, working along the bottom row in both

directions from the squared adapter plate and align each of the ot her

Adapter Plates to its neighbor.

summary

only. The details on how to

15

Page 24

Clarity Visual Systems

5. Align the adapter plates on the rest of the rows, working upward, to the

adapter plates in the bottom row.

6. Hang the screens on the bottom row and adjust them in or out so the

front surfaces (t he scr een faces) are flat with each other. Then do t he

rows above.

7. Put retaining screws in the top row and cover any holes and seams with

black tape to prevent light leak s.

Alignment Procedure in Detail

Read through all the detailed parts of each numbered step before starting it.

1. Remove the screens from all

the display units

2. Build the video wall.

.

A. Look down on the top of the screen and locate

the two retaining screws. Remove these screws,

using the 5/64-inch Allen hex wrench, and set

them aside.

B. Grab the sides of the screen, or use the finger

holes, and lift it up about half an inch (1 cm), and

remove it from the adapter plate. Set it aside.

A. Assemble the lower row first. Line up the legs for

the bottom row as straight as possible. Insert a

¼” x 2½” bolt through the holes as shown in

Figure 1. Tighten a nut securely on this bolt, but

not so tight as to bend the legs. From one end of

the bottom row, look down the row. See that all

the units are aligned, that the line of the front of

the display units does not curve forward or

backward, up or down. The straighter the first

row, the better the finished wall will be. And the

easier it will be to get in right.

B. Secure the legs to the floor. Use the tapped 5/16-

18 holes in the front and rear of the legs. You can

put an eye-bolt in this hole and secure it to the

floor with a lag screw. Or use angle bracket,

screwed to the floor and bolted to this hole in front

and rear. Or use the optional

securing it to the floor and putting the lower row of

displays on it. Stack the next higher row. Sliding

the legs of each display into the mating sockets of

the display in the first (lower) row.

C. Insert a bolt (supplied). Insert a bolt through the

hole in side wall of the lower unit and into each

leg of the unit above. Tighten a nut on this bolt to

lock the units together. See Figure 1 above.

Tighten all the bolts after you have checked for

straightness, as in Step A above.

D. Continue with higher rows of displays. Lock each

display to the adjacent displays after the row

above it (if any) has been installed. Check for

straightness on each row.

E. For added stability, use the tapped holes in the

rear of the legs of the upper units to fasten to a

solid support, such as a structural wall. The

threaded inserts in each leg are female 5/16-18

UNC.

BAS-520

base,

June 1999

16

Page 25

WN-5220-S VideoWall User’s Guide

F. Check that all displays in the video wall are

locked together. And straight.

3. Start with the display unit in the

center of the bottom row. This

will be the Base Unit. Align the

Base Unit’s adapter plate.

(If the

bottom row has an even number of

display units, choose either middle

one. This step can be done before

the wall is built, if necessary.)

A. Look at the sides of the Adapter Frame. (See

Figure 3, below.) Starting at the top edge and

moving down you will see a large Locking Screw,

a pointed Alignment Bolt, and an Alignment Hole.

Near the middle of each side is a threaded hole

for the Alignment Tool’s spring-loaded screws.

(Do not attach the Alignment Tool yet.) At the

bottom of the side notice the Alignment Hole, the

Alignment Bolt, and the Locking Screw.

B. Look at all the Alignment Bolts of all units. They

should all be the same distance out. The factory

standard is 3/32

nd

of an inch, measured to the

base of the hex nut, or three full revolutions of the

bolt from when it is completely down against the

frame.

C. Check to see that the Adapter Frame of the Base

Unit is centered on the chassis. If the frame is not

centered on the chassis opening, for instance, if it

is offset to the left, then all the other frames will

have to be offset in this same direction. It is best if

this first frame is nicely centered on its chassis

opening.

D. Check to see that all the Locking Screws are

tight.

E. Measure the opening diagonally, from corner to

corner in both directions, and compare the

results. Be sure to measure from exactly the

same points each time. An accuracy of 1/32

inch (0.8 mm) is necessary for most applications,

but the more accurately you can do this,

particularly in the bottom center unit, the better

the video wall will be aligned and the better the

picture will look.

F. If the two measurements are the same, you have

a rectangle with perfectly square corners,

nd

4. Working along the bottom row

in both directions, align each of

the adapter plates, using the

Alignment Tool.

and you may go on to Step 4.

G. If the two measurements are not the same, within

nd

1/32

inch (0.8 mm), the frame is not a rectangle

with perfectly square corners, it is a

parallelogram.

Loosen the top Locking

Screws on each side. Move the adapter plate left

or right a bit and tighten the screws. Measure the

diagonals again. Repeat this process until you are

satisfied that the two diagonals are the same.

This means the adapter plate is a perfect

rectangle with square corners.

A. Now that the center unit adapter plate is squared,

align one of its neighbors in the bottom row.

17

Page 26

Clarity Visual Systems

g

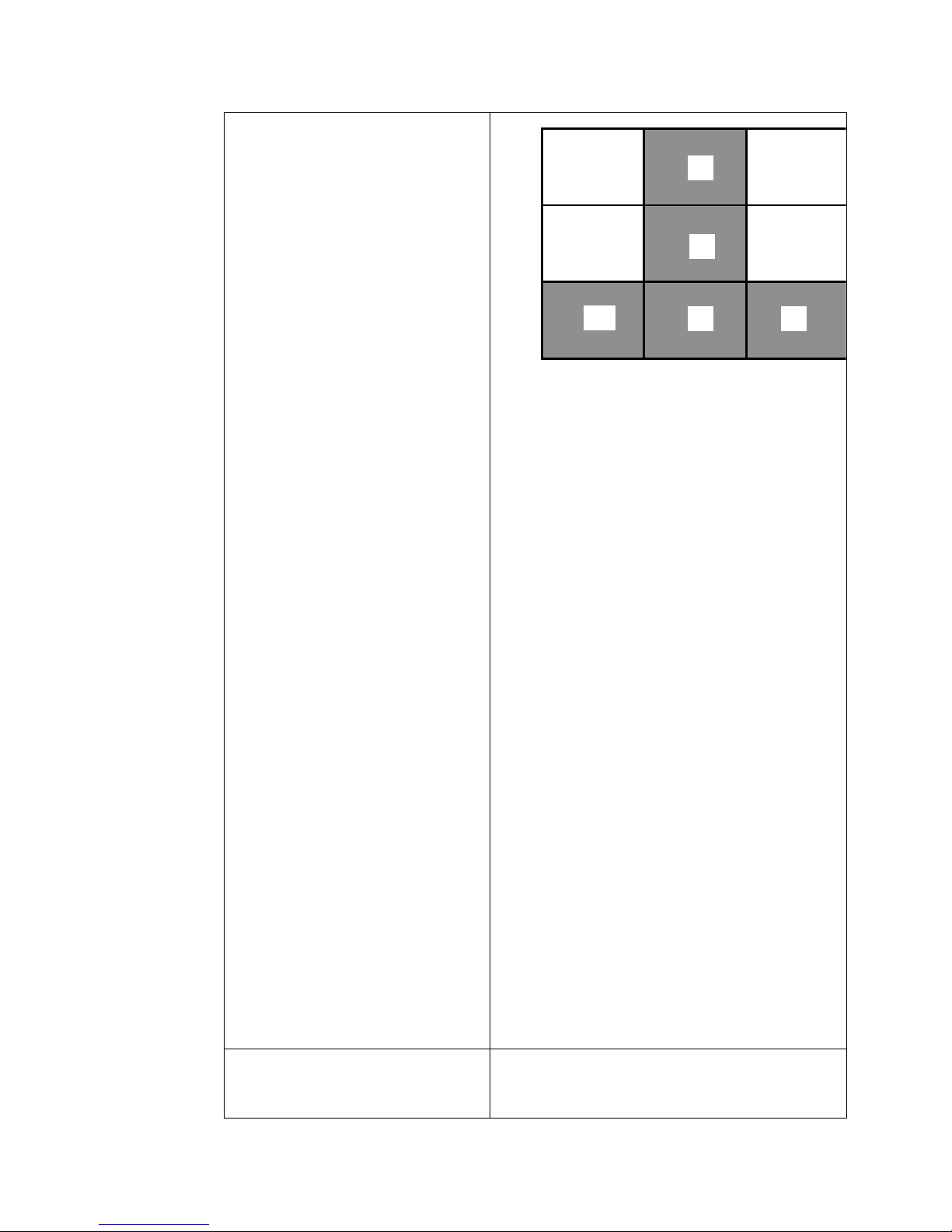

5. Align the adapter plates on the

units above the Base Unit,

working upward.

8

6

2

B. The diagram above shows the order in which you

should align the displays in a typical video wall.

(Note: This is not the same as the Unit ID

address of the display units.)

C. The Alignment Tool fits over the seam of two

adjacent adapter plates. The Tool has six guide

pins, three on each side, and four spring-loaded

screws, two on each side. (Only two of the springloaded screws, one on each side, will be used at

a time.)

D. Position the Alignment Tool between the two

displays. One of these (#1) is already square and

the other (#2) is about to be aligned. Fit the tool

into display #1 first and attach it with the lower

spring-loaded screw. The guide pins should go

into the Alignment Holes in display #1.

E. Loosen the two Locking Screws in #2 on its right

side under the Alignment Tool and move the

adapter plate of display #2 until the guide pins go

in the Alignment Holes. Secure the Alignment

Tool to #2 with the spring-loaded screw. Tighten

the two Locking Screws on #2 under the

Alignment Tool. (Do not be concerned about the

units in the row above at this time.)

F. With the Alignment Tool still in place, check

display #2 for squareness by measuring the

diagonals. Loosen the Locking Screws on #2 that

are on the other side from the Alignment Tool,

and adjust adapter plate #2 until it is squarecornered rectangle.

G. When you are satisfied that display #2 is aligned

to display #1 and it has perfectly square corners,

remove the Alignment Tool. (If you have two

Alignment Tools, leave this first one in place, and

put the second on the other side.)

H. Go to the display on the other side of the center

display (#3) and align it to the center display,

following the steps 4.C through 4.G.

A. Start with the display above the Base Unit. Align

display #4 to display #1. Put the Alignment Tools

on either side of the Base Unit, #1. The upper

uide pin should now fit the bottom Alignment

5

4

1

9

7

3

June 1999

18

Page 27

WN-5220-S VideoWall User’s Guide

6. Hang the screens on the

bottom row and adjust them in

or out so their front surfaces

are flat with each other.

Hole of #4. Loosen the bottom Locking Screw in

#4 and make it fit. Do the same on the other side,

moving the Alignment Tool, if you have only one.

B. Measure the diagonals of #4. Loosen the top two

Locking Screws and make its corners square,

then tighten the screws.

C. Continue with display #5, working your way up the

video wall to the top.

D. When you have completed the inverted-T, use

these as a frame and align the other units to it,

working from the lower rows upward. For each

display, you should be sure it is the correct

distance vertically and horizontally from all its

neighbors and that each unit’s diagonals are

equal.

A. Hang the screens on the bottom row. Be sure the

finger holes are on the top of each screen. When

each screen is seated, pull on it slightly to make

sure it is secure at both the top and bottom.

B. Notice the seams. Are the two screens flush at

each seam? If not, note how much you will have

to adjust one of the screens to make it flat and

flush with its neighbor. Measure this amount, but

be careful not to scratch the screens. Also, sight

along the row from the end. Look down the groove

on the top of the screens. This helps to prevent

where the corners match,

but the screens are not flat. Make a diagram of

the video wall and note how far to move each

corner of each unit in or out. Try to get the wall flat

within 1/32” inch (0.8 mm)

C. Remove the screens again.

D. Working from your notes, adjust the pointed

Alignment Bolts with the ½-inch wrench. Looking

at the display from the front, each complete turn

of the bolt CW (clockwise) pulls the corner of the

screen IN (away from you) by 1/32nd of an inch

(0.8 mm).

E. Hang the screens again and check your work.

F. With the screens in place on the bottom row, put

the screens on the next row above. “Flatten” this

row in the same way, paying attention to how

these fit with the bottom row as well as with their

neighbors to the left and right.

19

Page 28

Clarity Visual Systems

7. Put retaining screws in the top

row and cover holes and seams

with black tape to prevent light

leaks.

A. When all the screens are aligned with each other

to make a flat, square video wall, put the screws

in the top row of screens to hold them in place.

B. The finger holes and the space between the

screen and the adapter plate can be a source of

light leaks, allowing stray light to hit the back of

the screen and wash out some of the picture. To

prevent this, cover the finger holes in the top row

of displays with black cloth tape. “Gaffer” tape

does a nice job of this. Masking tape is

sometimes difficult to remove cleanly. You can

check for light leaks during the video setup

process. Select “Curtain” from the main menu and

verify that the whole screen is black. It is best to

do this in the actual lighting that will be on when

the wall is used.

Figure 3 Adapter Plate Parts

Lock i n g

Screw

Alignment

Bolt

Alignment

Hole

Hole for Spri ng-

Loaded screw

Alignment

Hole

Alignment

Bolt

Lock i n g

Screw

June 1999

20

Page 29

WN-5220-S VideoWall User’s Guide

Cables

Video connections from the signal source t o the WN-5220-S depend

on the type of signal supplied by the source. The com pat ible video

inputs are; PC 800x600 (SVGA), PC 640x480 (VGA), MAC 800X600

or 640X480, and 31.5 kHz (progr essive scan) RG BS Video. The VIM300 option recognizes 15.75 kHz (interlaced) RGBS video, composit e

video, and S-Video for NTSC, PAL and SECAM. These will be

processed and displayed.

The Loop-thru video output uses a standard 15-pin VGA t ype

connector for output to an external com puter monitor or another

display. The format of t he Loop- t hru video is same as the source

video. VGA and MAC will have RGB with separate H-Sync and

V-Sync. RGBS video will come out RGBS with the composite sync on

the connector’s H-Sync pin. RGB Sync on Green sources will loopthru RGBS-Sync on Green. Displays with the VIM-300 option also

have a Composite Video and S-Video loop-thru connectors.

The video cables used should be high quality and shielded to insure

the best image quality when displayed.

Using poor quality cables can lead to picture noi se, jitter and

crosstalk.

Control data enters the display via the RS-232 In connection, and is

supplied to an adjacent display (if used) via the RS-232 Out

connector. High quality shielded cables designed for RS-232

communication should be used to ensure proper data transm ission

and control.

21

Page 30

Clarity Visual Systems

June 1999

22

Page 31

WN-5220-S VideoWall User’s Guide

Initial Setup

After the displays are installed, follow these steps for

unit:

Step 1 - Power-Up

Step 2 - Adjust the Input Signal Settings

Step 3 - Adjust the Colors

Step 4 - Save the Settings

Step 1 – Power-Up

CAUTION

CAUTION

100 Volt Users –

plug on the power supply to 115V.

115

plug on the power supply to 115V.

Volt Users -

display

each

Set the red voltage switch at t he power

Set the red voltage switch at t he power

CAUTION

1. Turn the main power

switch (next to the

power cord) to the ON

(1) position

230 Volt Users -

Set the red voltage switch at t he power

plug on the power supply to 230V.

The STBY LED flashes, indicating the power up cycle has

begun. Wait approximately three minutes until the STBY

LED is on continuously.

23

Page 32

Clarity Visual Systems

2. Press the remote

control ON button to

power up each Display

3. Check for normal

operation

You will hear a ‘beep,” and the sound of the internal fans.

The lamp will come on, but will require approximately 5

minutes to fully warm up. There is a built-in delay from

when you press the remote’s ON button to when the lamp

lights. The extent of the delay depends on the Monitor ID

Unit setting. The two switches have a total number of 256

individual Monitor ID settings.

GROUP ID numbers are 0-9 and A-F for a total of 16

different settings. Each number is equal to that

number times 16. A setting of 3 is equal to 48.

UNIT ID numbers are 0-9 and A-F for a total of 16

different settings. Each number is equal to that

number times one. A setting of C equals 12.

The Monitor ID number is the combination of the Group ID

plus the Unit ID. A Group ID number of 2 and a Unit ID

number of 5 equals a Monitor ID of 37.

The delay the time between an “on” command to the

display and the ignition of the lamp is approximately 2

seconds times the Monitor Unit ID number.

Observe the LED on the rear of each unit. When proper

power is on, the STBY LED is off, and the fan and lamp

LEDs are on. A faint glow from the lamp exhaust vent in

the rear of the unit indicates the lamp is on.

June 1999

24

Page 33

Step 2 - Adjust the Input Signal Settings

Select the Source

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

WN-5220-S VideoWall User’s Guide

Source Select Source

#

$

PC

#

$

800x600 MAC

PC

••••

[ ] Auto 9-PIN

[ ] Sync On Green BNC

[ ] Interlace C-Video

S-Video

H Freq: 00000

Lines: 000

V Rate: 00

Source Select Mode

#

$

PC

#

$

800x600

640x480

800x600

••••

[ ] Auto

[ ] Sync On Green

[ ] Interlace

H Freq: 00000

Lines: 000

V Freq: 00

(The menu with the VIM-300 option installed is pictured here.)

25

Page 34

Clarity Visual Systems

After all the displays are turned on, use t his procedure to select the

correct source. This must be done with

unit in a video wall.

each

1. On the remote

control, press

SOURCE

2. Press the

Up/Down arrow

keys and

highlight the

upper

pair of

arrows

3. Auto

#### $$$$

The Source Select menu is displayed.

Notice the menu choices of “Source” on the right side of

the menu. The current selection in shown next to the

arrows and is marked with a bullet in the right hand list.

Use the left/right keys to make this selection. (Depending

on the options installed, the unit you have may not display

all these choices.)

If you have selected a good Source in Step 2, “Auto” can

set Mode automatically. Highlight the [ ] next to Auto and

press ENTER. Auto takes information from H Freq, Lines,

and V Freq, shown at the bottom of the menu, and sets

the image size and refresh rate. Auto does this just once.

The X will appear in Auto for a very brief moment.

computer sources, always use Auto rather than

selecting the Mode manually.

Note: PCs sometimes produce a 400 line video signal.

This happens when Windows boots up or when the PC

has a fault and shows a fault message. During this time,

the display will roll, because it does not recognize 400-line

video and can’t sync to it. If this happens, and you have

no other way to see the video output of the computer,

press Source on the remote control. Then highlight Auto

and press Enter. The display will now recognize and show

the 400-line video image. (This mode cannot be saved in

memory.) After the PC’s problem is fixed, use Auto again

to reset the input mode.

For

June 1999

26

4. Sync on Green

5. Interlace

H Freq:

Lines:

V Freq:

If the Source is RGBS or MAC and the source has sync

on the green channel, press ENTER to put an X in this

box. However, Auto (See Auto above) takes care of this,

and much more, for you.

This displays whether or not Interlace is present in the

signal; you can’t change it.

Shows the horizontal frequency of the displayed signal.

You can’t change this value.

Shows the number of horizontal lines in the displayed

signal. You can’t change this value.

Shows the frame rate in Hertz of the displayed signal. You

can’t change this value.

Page 35

WN-5220-S VideoWall User’s Guide

Adjust the Black Input Level - PC, MAC or RGBS Video

(This does not apply to Composite or S-Video sources – see Comp

Video/S-Video Level Adjustment on page 30.

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Input Level

Black Level

White Level

Black Level

(Requires black field)

Auto [ ]

#### $$$$

All

Level Sample

Red 126 000

Green 125 001

Blue 129 000

Adjusting the input levels allows the unit to display the f ull color range

of the video source. If the input levels are not pr oper ly adjust ed the

image may look washed-out or posterized.

The Black Level must be adjusted

White Level.

Note:

to color balance the displays. Matching the displays so they all

produce the same colors is done in a later step called Color Balance.

Color Balance and Level Adjust are entirely independent of each

other. Level Adjust must be done with external video signals. Color

Balance may be done with internally generated patterns.

before

adjusting the

Black Level Adjust and White Level Adjust should

be used

not

27

Page 36

Clarity Visual Systems

1. Display a black screen image from

the signal source (

built-in test patterns)

2. Press the Level button, or

highlight Level in the main menu

and press ENTER.

3. Use the up/down arrows to

highlight Black Level and press

ENTER.

4. Move the cursor to Auto and press

ENTER.

not

from the

Examples of all-black sources are a black PC Paint

screen or frame 50882 on Reference Recordings, “A

Video Standard” test disk. Note: It is not necessary

for the entire screen to be black. The area of interest

is within 100 pixels of the upper left corner of the

Black Level menu.

The Input Level menu is displayed.

The Black Level menu is displayed

The display will automatically seek the black level of

the input signal and adjust the A/D converter to it.

Adjust the White Input Level – PC, MAC or RGBS Video

(This does not apply to Composite or S-Video sources – see Comp Video/SVideo Level Adjustment on page 30.)

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Input Level

Black Level

White Level

White Level

(Requires white field)

Auto [ ]

All

Level Sample

Red 128 255

Green 128 255

Blue 128 255

#### $$$$

June 1999

28

Page 37

WN-5220-S VideoWall User’s Guide

Adjusting the input levels allows the unit to display the f ull color range

of the video source. If the input levels are not pr oper ly adjust ed the

image may look washed-out or posterized.

The input black level must be adjusted to match the source

before adjusting the input white level!

1. Display an all-white image from

the signal source (

built-in test patterns)

2. Press the Level button, or

highlight Level in the main

menu and press ENTER.

3. Use the up/down arrows to

highlight White Level and press

ENTER.

4. Move the cursor to Auto and

press ENTER.

not

from the

Examples of all-white sources are a white PC Paint

screen or frame 50823 on Reference Recordings, “A

Video Standard” test disk. It is not necessary for the

entire screen to be white. The area of interest is

within 100 pixels of the upper left corner of the White

Level menu.

The Input Level menu is displayed.

The White Level menu is displayed

The display will automatically seek the white level of

the input signal and adjust the A/D converter to it.

29

Page 38

Clarity Visual Systems

Comp Video/S-Video Level Ad justment

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Video Controls

Brightness 128

Contrast 128

Saturation 128

Hue 128

Blue Only [ ]

Sample

R:010 G:008 B:149

This menu selection is only available when the source selected is

Comp Video or S-Video in units with the VIM-300 option installed. It is

not available when PC, MAC or RGBS sources are selected.

Brightness:

This adjusts the overall lightness and darkness of the

image.

Contrast:

Increases the difference between light and dark parts of

the image.

Saturation:

Hue:

Changes the tint of images to be more gr een or m ore

Adjusts the am ount of color the image has.

magenta colored.

1. Press the remote control LEVEL

button

2. Display an all-black image from

not

the source (

test patterns)

from the built-in

Brings up the Video Controls menu (must have Comp

Video or S-Video selected as a source).

Frame 50882 on Reference Recordings, “A Video

Standard” test disk is an all-black image.

June 1999

30

Page 39

WN-5220-S VideoWall User’s Guide

3. Adjust Brightness

4. Display an all-white image from

the source

5. Adjust Contrast

Set the Sample values for R, G and B as close to 001

as possible while keeping the Brightness number as

high as possible.

If all the initial Sample values (R, G, & B) are greater

than 001, then reduce the Brightness number until

the first Sample value reaches 001.

If the initial Sample values are showing 001, then

increase the Brightness number until all Sample

values are 002 or greater. Stop adjusting when the

last Sample value goes from 001 to 002.

If Brightness is decreased while the Sample values

are at 001, the color range for the displayed image

will be decreased.

Frame 50823 on Reference Recordings, “A Video

Standard” test disk is an all-white image.

Set the Sample values for R, G and B as close to 254

as possible while keeping the Contrast number as

low as possible.

If all the initial Sample values are less than 254 then

increase the Contrast number until the first Sample

value reaches 254.

If the initial Sample values are showing 254 then

decrease the Contrast number until all Sample

values are 253 or less. Stop adjusting when the last

Sample value goes from 254 to 253.

If Contrast is increased while the Sample values are

at 254, the color range for the displayed image will be

decreased.

6. Display a standard SMPTE Color

Bar pattern

7. Enable the Blue Only function

8. Adjust Saturation

A SMPTE Color Bar pattern is available at frame

17177 on Reference Recordings, “A Video Standard”

test disk.

Select the Blue Only option with the up/down arrows

and press ENTER to enable it. At this point the

screen will show only shades of blue.

Adjust Saturation up or down until the large color

bars at the each end of the pattern match the smaller

color bars beneath them.

31

Page 40

Clarity Visual Systems

9. Adjust Hue

10. Exit the Video Controls m enu

Adjust Hue up or down until the two central color bars

match the smaller color bars beneath them.

Press the PREV MENU button on the remote. This

will exit the menu and de-select Blue Only at the

same time.

June 1999

32

Page 41

WN-5220-S VideoWall User’s Guide

Adjust the Frequency

(This control has different effects with computer and video sources.)

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Frequency Select

096

For RGBS, Composite and S-video sources –

Use the FREQ function to adjust the image’s horizontal width.

1. Press the remote control FREQ

button

2. Press the Left/Right arrow keys

Displays the Frequency Select menu. Observe the

horizontal width of the image.

Expand or contract the image horizontally.

For Computer (PC or MAC) sources –

Use the FREQ function to match the internal sampling clock of the

display to the incoming video data.

1. Turn Sharpness on

In the main menu, highlight Misc Control and press

Enter. If there is

Sharpness and press Enter.

an X for Sharpness, highlight

not

33

Page 42

Clarity Visual Systems

2. Display an image containing

many on/off (black/white)

transitions

3. Press the remote control FREQ

button

4. Press the left/right arrow keys

5. Press PREV MENU

A checkerboard pattern works best. One of the “fill”

patterns in Windows 95 Paint has this. Start Paint

program found under Accessories. Select Image,

Attributes, Black and White, OK, Yes. Select View

and see that Color Box is checked. Choose the Fill

tool (paint jar spilling over). In the bottom row of

black/white shades, click the 9

Click in the drawing area. Choose View, View Bitmap

to fill the computer screen with this pattern.

With MAC OS 8.0, look for a checkerboard pattern in

File, Control Panel, Desktop Patterns.

With Sharpness

correct and does not match the input source, you will

see large vertical bands in the pattern.

The FREQ adjustment menu is displayed.

The vertical bands will disappear when the frequency

matches the incoming signal.

Exit the FREQ menu.

enabled

th

box from the left.

, if the FREQ setting is not

Adjust the Phase

This setting is important for computer input. It has no effect with

Composite or S-Video sources.

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Phase Select

028

June 1999

34

Page 43

WN-5220-S VideoWall User’s Guide

Use the PHASE button to adjust the phase of the internal sampling

clock relative to the incoming data. This adjustment is usually not

necessary for most applications, but can be used to eliminate some

types of video noise.

1. Press the remote

control PHASE

button

2. Press the

Left/Right arrow

keys

3. Press PREV

MENU

The PHASE adjustment menu is displayed.

Adjust to produce the best image quality. For computer

applications, use the same large area checkerboard as for

the FREQ adjustment. Incorrect Phase will show up as

horizontal streaks of random noise. This shows most

clearly with Sharpness ON.

Exit the PHASE menu.

Note: If the display unit is part of a video wall which is being fed by an

external multiplexer, a potential problem exists for Frequency and

Phase settings. The default vert ical r at e is 60Hz, which is correct for

normal computer sources.

Set the Sharpness

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Misc Control

[X] Sharpness

[X] 16M Colors

[X] Buzzer Enable

[ ] Flip Horz

[ ] Flip Vert

[ ] Auto Lamp On

[ ] Test Patterns

35

Page 44

Clarity Visual Systems

Use the Sharpness menu to toggle Sharpness O n/ O ff. In general, the

sharpness should be off (no X) for composite and S-video sources,

and on (with X) for PC, MAC, or RGBS sources. Shar pness controls

an internal filter that r educes som e t ypes of video noise and softens

the edges.

1. Press the remote

control MENU

button

2. Press the up/down

arrow keys

3. Press ENTER

4. Press the up/down

arrow keys

5. Press ENTER

6. Press PREV MENU

Displays the main menu.

Move the cursor to the Misc Control selection.

The Misc Control menu is displayed.

Move the cursor to the Sharpness Selection.

Use the ENTER key to toggle sharpness on or off.

On

for PC, MAC, RGBS; of f for Comp and S-video.

Exit the Misc Control menu.

Position the Image

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Position

%

"#" "$

&

Use the arrow keys to adjust the position of the image on each

display unit.

June 1999

36

Page 45

WN-5220-S VideoWall User’s Guide

1. Press the MENU

button on the

remote control

2. Press the

Up/Down arrow

keys

3. Press ENTER

4. Press the remote

control arrow

keys

Displays the main menu.

Move the cursor to the Position selection.

Displays the Video Position menu.

Position the image. It is easiest to see the effect of

Position when the image is a some form of geometry

pattern, one that exactly defines the edges of the image.

Note: W hen t he image is expanded with Zoom, as it is when Wall Mode is on, the

Position control has two movement speeds, fine and coarse. At first, the

movement is in fine steps, the smallest st eps possible. After 8 fine steps, the

movement is coarse, moving faster in lar ger steps. If the direct ion of movement is

changed, Position goes back to fine steps for the next 8 steps. This means you

may have to pass the position you want, then back up.

Detailed explanation: W hen using Big Picture for a 2x2 wall, each pixel in the

original picture (the

For the first 8 clicks of the Position control, the image moves 1

picture) is displayed with four

input

output

pixels in a 2x2 block.

output

pixel at each

click, the smallest amount t he im age can move electronically. After 8 clicks, the

image moves by

pixels or 2 screen pixels per click, which moves the image

input

faster. When you move the image in a new direction, the Position contr ol r evert s t o

the 1-output-pixel rate, the slowest rate .

For Composite or S-Video displays, Position speed works a little differently. For the

first 8 clicks of t he remote control, Position moves the imag e one

before. After 8 clicks

horizontally

expansion. So, for a 2x2 wall, the 9

pixels instead of two. For this 2x2 wall, the 9

, the image moves by two times the Big Picture

th

horizontal click moves the image four output

th

vertical

click moves the image two

output

pixel, as

output pixels.

37

Page 46

Clarity Visual Systems

Scale the Image

Use the arrow keys to adjust the size of the im age on each display.

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Zoom Factor

Left

Right

Top

Bottom

- +

"#" "$

"#" "$

"#" "$

"#" "$

[ ] Lock

[ ] Default

W:0640

H:0480

June 1999

38

1. Press the MENU

button on the

remote control

2. Press the Up/Down

arrow keys

3. Press ENTER

Displays the main menu.

Move the cursor to the Zoom selection.

Displays the Zoom Factor menu.

Page 47

WN-5220-S VideoWall User’s Guide

4. Scale the image

Step 3 - Adjust the Colors

Source Select

Frequency

Phase

Input Level

Position

Zoom

Wall Processor

Color Balance

Curtain

Hours

Save Config

Recall Config

Reset Config

Misc Control

About

Color balancing is essentially balancing the brightness and color of all

the lamps in the video wall, so you do not need to color balance the

displays for each source. The color balance inf ormation is saved in

memory in only one location, not for each source.

The goal of color balancing t he displays is to match the luminance

and white color of all the displays in video wall, and then match the

intermediate gray shades. Therefore, color balancing is accomplished

with all displays on in the finished video wall. (If you have only one

unit, color balancing is not very important. )

Select an edge of the image that needs to be expanded or

compressed (Left, Right, Up or Down). It is easiest to see

the effect of Zoom when the image is a some form of

geometry pattern, one that exactly defines the edges of the

image.

Selecting the Lock feature causes the image to scale the

same amount in the opposite direction. If you scale the

Right, the Left will scale by the same amount. Similarly, Up

and Down

The Default feature scales the image back to 800x600 or

640x480 pixels, depending on the source.

Note: Resetting the Scale to default settings will also clear

any Position changes that have been made.

Color Balance

Wht Gry

All

####$$$$ ####$$$$

Red 031 007

Green 031 007

Blue 031 007

39

Page 48

Clarity Visual Systems

The color balance menu provides control over the individual RED,

GREEN, and BLUE settings to balance the white color, as well as an

ALL adjustment to control the overall lum inance. I n addition, similar

control for the RED, G REEN, and BLUE set tings is provided to adjust

the balance of the gray shades without affecting the white balance.

For white balancing

selections have a number associated with them between 0 and 31.

Zero is the darkest and 031 the brig htest. The ALL selection allows all

of the balance settings to be adj ust ed sim ultaneously. The up/down

arrow keys moves the cursor from All t o Red, Green, Blue in the

White colum n, then All, Red, Green, and Blue in the Gr ay column,

then back to All in the White column again. The left/right arrow keys

increment and decrement the brightness number.

For gray balancing

settings have a number associated with them between 0 and 7. Zero

is the darkest and 007 the bright est .

The following chart shows the relationship of t he m enu item

adjustments.

, the individual RED, GREEN, and BLUE color

, the individual RED, GREEN, and BLUE balance

1. Display an all-white

image

2. Open the Color

menu

3. Maximize all settings

4. Identify the leastbright display in the

system

5. Luminance match

the displays

6. Color balance the

displays – white

mode

On each display in the video wall, open the Misc Control

menu, select Test Pattern and choose White.

Press the Color button on the remote control, or choose

Color Balance from the main menu and press Enter.

Adjust the WHT setting of

and the GRY setting of ALL displays to 007.

The darkest display is already as bright as it will ever be. This

display will serve as a baseline to which the other displays

will be adjusted, since it cannot be adjusted to be brighter.

Note: The baseline display does not have to be the middle

one. It should be the darkest one, wherever it is in the wall.

Beginning with the display next to the baseline display, adjust

the ALL settings on the white levels to approximately match

the luminance (brightness) of the baseline unit.

Adjust the relative amounts of RED, GREEN, and BLUE in

the white (WHT) column to achieve the best match in color

and luminance to the baseline display.

If a color appears to need to be increased, but that color is

already up as high as it can go, then the other two colors can

be reduced. For instance, if you need the white to be have

more red, but red is already at 031, reduce the green and

blue. This will make the display look more red.

ALL

displays so they are at 031

7. Adjust the next

display

June 1999

40

Adjust each of the displays for white balance, working

outward from the baseline unit. Do not go to the next step of

adjusting for Gray until you are satisfied that all the displays

look the same for a white image.

Page 49