Clarity Wildcat WN-4030-S, Wildcat WN-4030-SE Service Manual

Wildcat Series

WN-4030-S

WN-4030-SE

GuideService

WN-4030-S

WN-4030-SE

Wildcat Series

40" Display Wall Unit

Service Guide

070-0050-01

18 April 2003

© 2003 by Clarity Visual Systems™, Inc.

All Rights Reserved.

Contents of this publication may not be reproduced in any form without permission of Clarity Visual Systems,

Inc.

Trademark Credits

Windows™ is a trademark of Microsoft Corp.

Clarity's Big Picture™ is a trademark of Clarity Visual Systems, Inc.

All other names are trademarks or registered trademarks of their respective companies.

Disclaimer:

The information contained in this document is subject to change without notice.

Clarity Visual Systems Company makes no warranty of any kind with regard to this material. While every precaution has been taken in the preparation of this manual, Clarity V isual Syst ems shall not be liable for errors or

omissions contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

ii

iii

iv

Table of Contents

1Some Basic Information… 1

1.1 About the WN-4030 … 2

1.2 Your Safety Is Important … 4

1.3 Removing the Screen … 6

1.4 ESD Can Kill Equipment … 8

2 Troubleshooting the Problem … 11

2.1 What Kind of Problem Is It? … 12

2.1.1 Normal Startup Sequence … 14

2.1.2 Startup Problems … 16

2.1.2.1 Using the Remote Control and LEDs … 18

2.1.2.2 How to the Use Menu Chains … 20

2.1.2.3 How to Read On-Screen Status Code … 22

2.1.2.4 How to Read the Inside LEDs … 24

2.1.2.5 How to Read the Status Menu … 26

2.1.2.6 How to Get to the Service Menu … 28

2.1.3 Image Problems … 30

2.1.3.1 Loop-Thru Has Limits … 32

2.1.3.2 How Mode Detect Works … 34

2.1.4 Cooling Problems and Solutions … 36

2.2 Functional Tests in the Field … 38

2.2.1 Is the Picture Acceptable? … 40

2.3 How To Get Technical Support … 42

3 Regular Maintenance … 45

3.1 Changing the Lamp from the Rear … 46

3.2 Replacing the Lamp from the Front … 48

3.2.1 Removing the Optical Engine … 50

3.2.2 Replacing the Optical Engine … 52

3.3 Changing the Air Filter … 54

3.4 Cleaning the Screen and Mirror … 56

4 Taking Apart a Wall … 59

4.1 Removing a Floor-Mounted Display … 60

4.2 Removing a Wall-Mounted Display … 62

5 Replacing Parts … 65

5.1 Where Everything Is … 66

5.2 Replacing the Power Supply … 68

5.3 Replacing the Electronics Module … 70

5.3.1 Installing the Big Picture Key … 72

5.3.2 Installing a Video Decoder Card … 76

5.4 Replacing Parts under the Light Shield … 80

5.4.1 Removing the Optical Engine … 82

5.4.1.1 Replacing the Thermal Cutoff Switch … 84

5.4.1.2 Replacing the Intake Fan … 86

5.4.1.3 Removing the LCD in Optical Engine 750-0605-00 … 88

5.4.1.4 Replacing the LCD in Optical Engine 750-0605-00 … 90

5.4.1.5 Removing the LCD in Optical Engine 750-0605-01 … 92

5.4.1.6 Replacing the LCD in Optical Engine 750-0605-01 … 94

5.4.2 Installing the Optical Engine … 96

5.4.3 Changing the Lamp Ballast … 98

5.4.4 Replacing the Exhaust Fan … 100

5.5 AC Power Entry Repair … 102

6 Reference Section … 105

6.1 Menu Structures, Wildcat S … 106

6.2 Menu Structures, Wildcat SE … 114

6.3 On-Screen Status Codes, Both Wildcats … 124

6.4 LEDs, Wildcat S … 126

6.5 LEDs, Wildcat SE … 128

6.6 Connector Diagrams … 130

6.7 Wiring Diagrams … 132

6.8 Specifications for the WN-4030 … 134

6.10 Technical Support Forms … 140

Index … 143

1 Some Basic Information

1.1 About the WN-4030 … 2

1.2 Your Safety Is Important … 4

1.3 Removing the Screen … 6

1.4 ESD Can Kill Equipment … 8

1

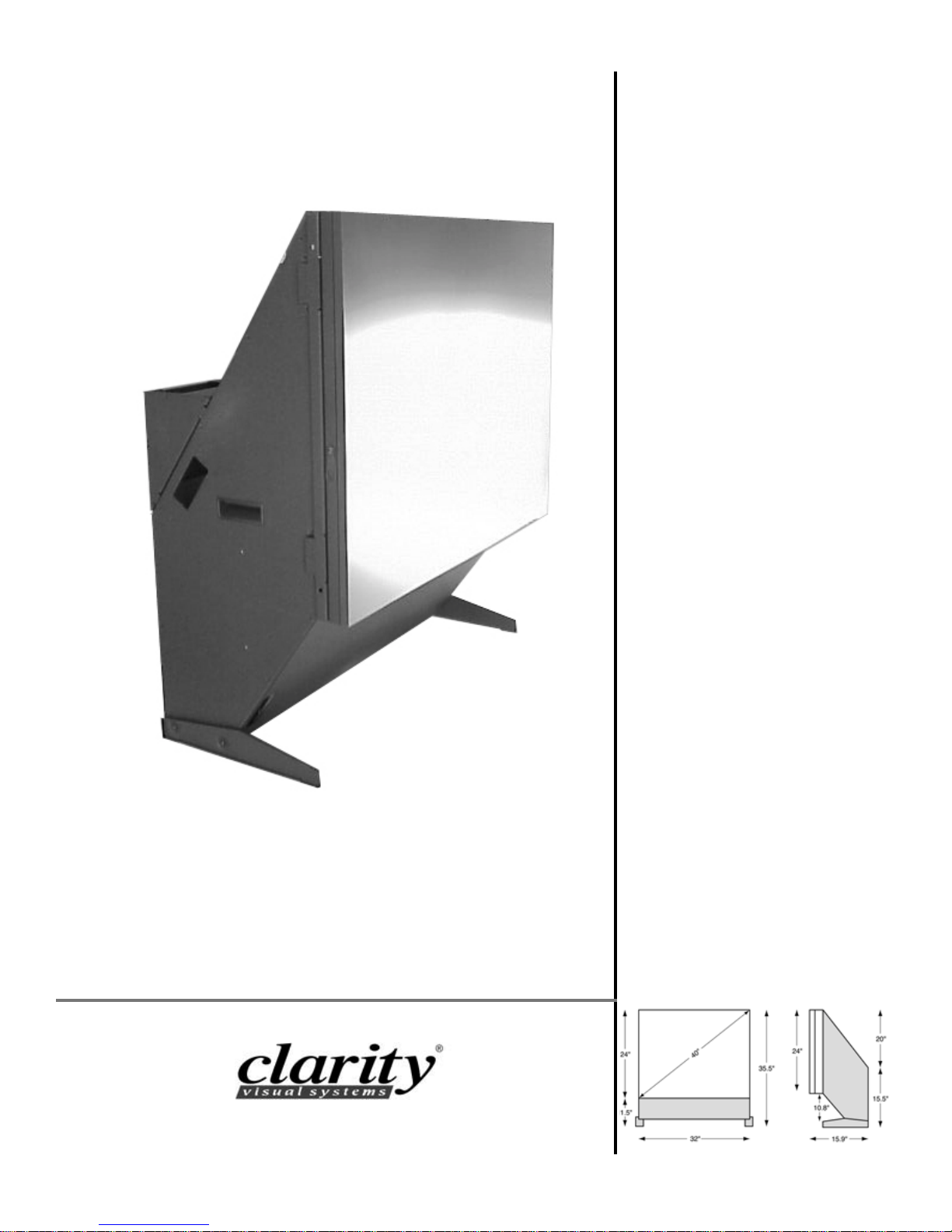

1.1 About the WN-4030

This manual covers both models of the Clarity Wildcat display for troubleshooting and parts replacement. Parts are replaced at the module or “black box” level; there are no component level repairs

required.

The Clarity Wildcat comes in two types:

• WN-4030-S is the standard version. It uses an

800 × 600 LCD, but it also accepts 640 × 480

computer pictures. Optional inputs for C-Video

and S-Video are available, and these connectors

may be in the unit you are servicing. Clarity’s Big

Picture™ is an option that spreads one image over

a wall of displays.

• WN-4030-SE also uses an 800 × 600 LCD, but it

accepts inputs up to 1600 × 1200 and down converts them to 800 × 600.

The two models, called Wildcat S and Wildcat SE,

have somewhat different menus, but in most other

respects they are the same.

Tools required

Fortunately, not many tools are required.

• a #2 Phillips screwdriver

• a flat-blade screwdriver – sometimes even a coin

will do the job for this

• 3/8" socket for the bolts that hold displays

together

•5/16" socket for the nuts that hold cable hole cov-

ers and brackets

Some general information about the WN-4030

• There is no electrical interlock on the screen.

Removing the screen does not turn off the high

voltage, and the lamp stays lit.

• There is an interlock on the lamp access door at

the rear. Opening this door turns off the high voltage and the lamp goes out.

• There is an electrical interlock on the light shield

that covers the optical engine. Removing this

shield turns off the high voltage, and the lamp

goes out.

• There is no electrical interlock on the other rear

access door, the one behind the electronics module.

• The power supply is self-adjusting to 115V or

230V.

not last this long. Median means “middle.” If you

could line up a bunch of lamps in the order they were

going to fail (assuming you could know this in

advance), the lamp in the middle would last 8000

hours.

For the lamps in a WN-4030-SH, the median lamp

life is 4000 hours.

A guide to this manual

This manual is divided into sections and subsections. In general, it is as good idea to read the parent

sections before trying to do something described in a

subsection. For instance, if you want to remove the

“gizmo-thingy,” as described in section 3.2.1.2, first

read sections 3.2 and 3.2.1.

Information about operations and RS232 commands are found in the separate Wildcat S and Wildcat SE manuals, part numbers 070-0046-xx and

070-0082-xx.

Terms used in this manual

The words

•cube

•display

• unit

all mean a single WN-4030 display.

• WN-4030 or “Wildcat” means either type of Wild-

cat.

Lamp Life

The median life of the lamp in a WN-4030-S is

8000 hours. Half of any sample of lamps will last at

least this long. Some lamps, maybe half of them, will

2

Tools You Will Need

#2 Phillips screwdriver

flat-blade screwdriver

3/8" socket wrench

5/16" socket wrench

In this Service

Guide,

the words, “display,”

“unit,” and “cube”

all mean a WN-4030,

one of these

!

3

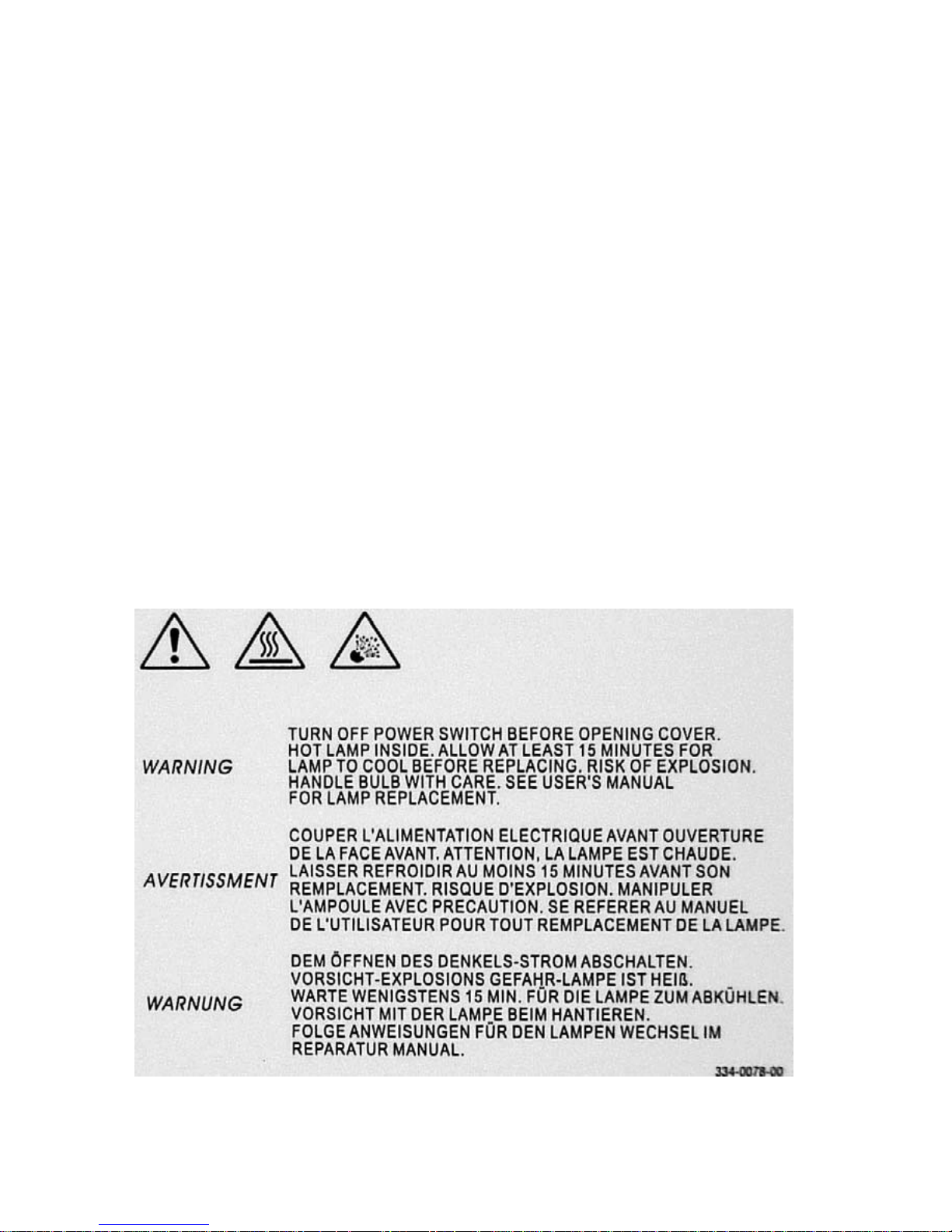

1.2 Your Safety Is Important

This list of safety warning and caution notes isn’t very long. Reading it could save you from getting an

electric shock, a UV radiation burn, or a heat burn.

These display units were designed with safety in

mind. However, if you don’t heed the safety warning

and cautions, you could get hurt. The safety warning

are on stickers in various places in and on the display.

they are reproduced on these pages so you can see

them all at once.

There are some other times you should be aware of

that relate to safety, things to keep in mind while

installing and using the displays:

• There is no electrical interlock for the screen.

Removing the screen does not turn off the AC

power or the lamp.

• There is a switch under the light shield.

Removing the light shield turns off high voltage

to the lamp. Do not bypass this switch.

• There is another switch behind the lamp access

door in the rear. Opening this door turns off

high voltage to the lamp. Do not bypass this

switch.

• If the displays are hung on a wall, the wall must

be strong enough to hold them. Each unit

weighs about 68 lbs (31 k g). S imply mounti ng

them into wallboard or wall paneling won’t be

adequate or safe.

• If the displays are standing on the floor, use the

optional base. Secure the bases to the floor and

to each other before stacking displays on them.

Then secure the displays to the base. the base is

not very deep, front to back, and a high stack

could tip over , injuring or even killing someone.

You may not need a base for one row of displays

on the floor, but if the displays will be stacked

two high, use the base. Very high stacks – over

four high – should be tied back to a supporting

wall.

4

FRONT

!

WARNING

HOT SURFACES NEAR

LAMP. SKIN BURN

HAZARD

Lamp housing label, seen from the rear.

When you see it, this label will appear upside down,

and the arrow will point down.

5

1.3 Removing the Screen

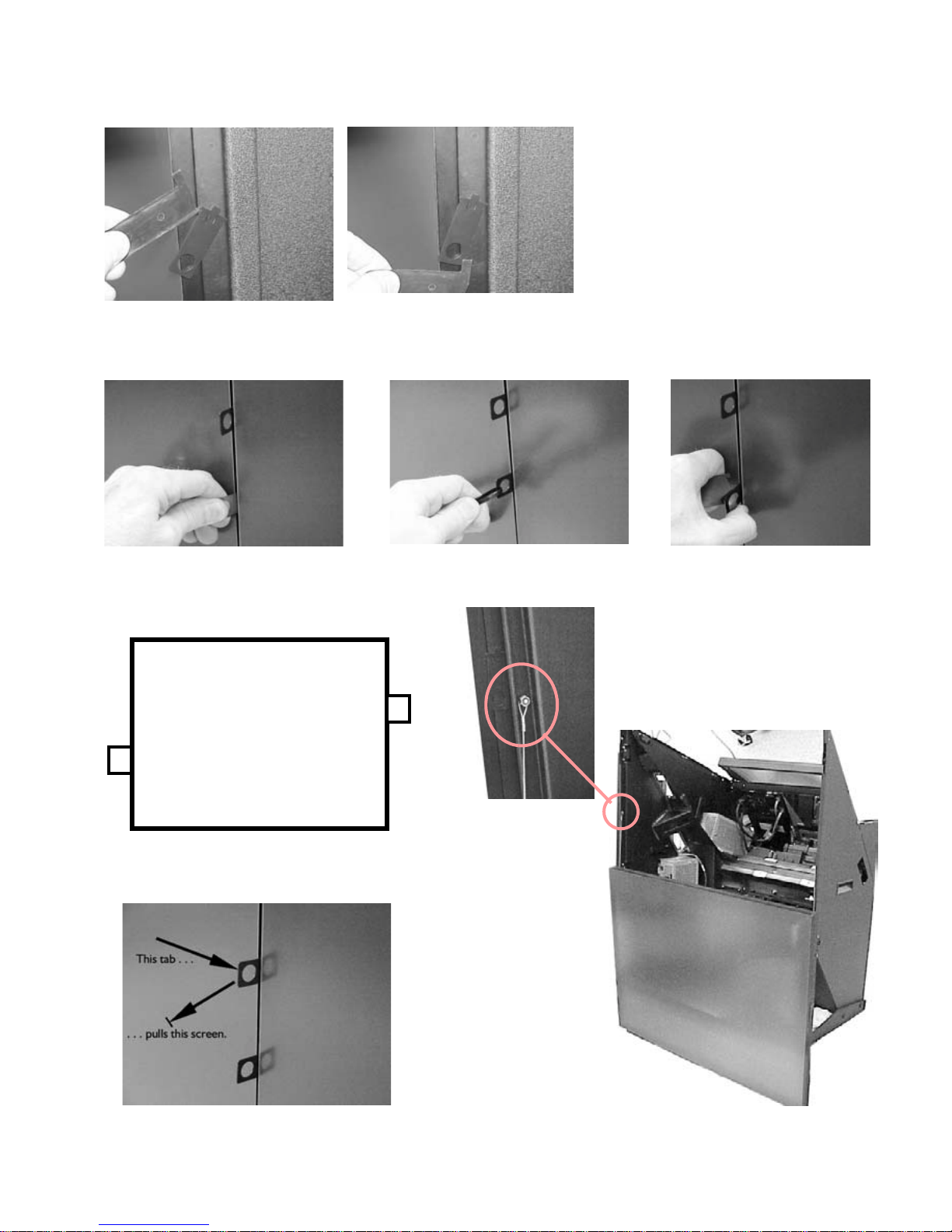

The screen is held on by four spring-loaded clips. When the display is in a wall, insert a thin object

between the screens to bring out the built-in scr een handles. Don't lift the display by the screen. When

you place the displays in a wall, use the external hand grips or the internal struts for lifting.

The screen is held on with four spring-loaded latches,

one near each corner.

To remove the screen from a single display

When it is standing alone, pull out sharply at the

four corners. Y ou only need to pull out about one inch

to release the latch. The display is relatively light (68

lbs.), and four latches together are strong. It may be

necessary to have someone hold the back of the display as you pull forward.

CAUTION

Do not twist the screen as you remove it.

Twisting the screen may break the springloaded latches. Pull straight forward. If one of

the latches still holds a corner, do not twist

the screen to get it loose.fio

To remove the screen from display in a wall

On Wildcats with glass screens, use a suction cup

to pull at the four corners of the glass, one corner at a

time. Pull out sharply just enough to release the

spring latch, about one inch or 25 mm.

On some Wildcats, you can use the built-in tabs.

The tabs are small nylon handles, one on each side of

the screen.

Use the screen puller tool, shown here. Slide the

tool between the screens and hook the tab to retrieve

it. The tab has points to hook or push to get it to turn

out. If you don't have the screen pullers, you can use

anything thin and plastic, such as a credit card.

tool, through the hole in the tab to get a good grip on

it. Be careful not to scratch the screen.

Do not twist the screen as you remove it. If one of

the latches still holds a corner , do not tw ist the screen

to get it loose.

To replace the screen

, line up the screen with the four corners of the

chassis. Use the heel of your hand to press sharply at

each corner, snapping the latches in place.

Screen tethers

Some installations use wire tethers on the screen

for safety. The wires hold the screen on both sides.

You can still remo ve the screen and lower it to work

inside, and usually that is enough.

If you have to remove the screen completely,

remove the tethers from the chassis end and leave the

tethers attached the screens. The tethers loop around

a threaded stud on the chassis. The stud has a nylock

nut. The loop at this end of the tether is large enough

to come off over the nut.

When you replace screens like this, loop the wire

over the stud again, and do not tighten the nut.

Handling the displays

The display has two hand grips, one on each side.

Do not lift the display by the screen.

When the screen is off, you can use the two braces

inside, near the upper corners. These are handy when

lifting displays into a wall.

You need to pull on the correct tabs. There will be

two tabs between each pair of screens. To pull a

screen, use the upper tab on the right side and the

lower tab on the left. Remember: High-right, Lowleft.

Pull sharply forward on the tabs. You may have to

put something, such as a tie-wrap or the screen puller

6

1a. Use screen puller tool to push

the hooks on the tab …

2a. Pull the tab, resting hand against

next screen …

High Right

1b … or hook the tab and pull it out.

b … or pull the tab with a tie-wrap …

2c … or pull the tab with the

screen puller tool.

Screen tethers are looped over a stud on

the inside of the chassis frame.

Do not tighten this nut.

Low Left

When you remove a screen from a wall, use

the High tab on the Right

and the Low tab on the Left.

7

1.4 ESD Can Kill Equipment

ESD – electro-static discharge – can literally kill electronic equipment. The components in the

WN-4030, particularly the electronics module, are very susceptible to ESD. Take precautions by using

an approved grounding strap when handling these parts.

MOS-FETs and J-FETs (two types of field-effect tran-

sistors) are wonderful components in circuits. They

provide high amplification with very little power consumption, but they are extremely vulnerable to static

discharge. These components are used in the modules (electronic boxes) in this product.

Static electricity can easily build up in your body,

and you won’t even know it. Rubber-soled shoes on

vinyl floors, walking across carpet or rugs, even swiveling in your chair can build up enough static electricity to zap (kill) a FET. If you kill the FET, you kill the

module it is in.

To prevent electro-static discharge (ESD)

, use a wrist ground strap whenever you remove

and handle any of these modules:

•the electronics module

•the lamp ballast

•the power supply

Before you remove any module listed above, connect

your wrist strap to the main chassis.

Before you install a new module, connect your wrist

strap to the main chassis.

If you carry the module, connect the wrist strap to a

ground point on the module.

When you pack a module for shipping

, use an anti-static bag, if possible. If you don’t

have an anti-static bag, wrap the module in aluminum foil before packing it.

Never, never

pack the bare module in loose, styrofoam "peanuts." When these styrofoam pieces touch the connectors, they can easily zap a FET.

8

ESD Precautions

for handling electronics modules,

power supplies

and ballasts:

• When you remove an electronic "box," connect a wrist strap

to the main chassis before you start.

• When you walk with an electronic part, always connect a

wrist strap to a ground point (the case) on the part.

• When you ship a part separately, put it in an anti-static bag,

or wrap it in aluminum foil, before packing it in a carton.

• Never put the bare, unwrapped device in an ordinary plastic

bag or styrofoam of any kind.

9

10

2 Troubleshooting the Problem

2.1 What Kind of Problem Is It … 12

2.1.1 Normal Startup Sequence … 14

2.1.2 Startup Problems … 16

2.1.2.1 Using the Remote Control and LEDs … 18

2.1.2.2 How to the Use Menu Chains … 20

2.1.2.3 How to Read On-Screen Status Code … 22

2.1.2.4 How to Read the Inside LEDs … 24

2.1.2.5 How to Read the Status Menu … 26

2.1.2.6 How to Get to the Service Menu … 28

2.1.3 Image Problems … 30

2.1.3.1 Loop-Thru Has Limits … 32

2.1.3.2 How Mode Detect Works … 34

2.1.4 Cooling Problems and Solutions … 36

2.2 Functional Tests in the Field … 38

2.2.1 Is the Picture Acceptable? … 40

2.3 How To Get Technical Support … 42

11

2.1 What Kind of Problem Is It?

Is this a startup problem or an image problem? Usually a black screen means its a startup problem. If

you can see anything at all, it is probably an image problem. This whole chapter divides the types of

problems into smaller and smaller groups, eventually leading you to another section of this manual.

Types of startup problems

Look through this list. If any of these things apply

to your situation, the problem is a startup problem.

• The lamp will not light.

• You can’t display any menus.

• When you press the

gives a triple beep, a very rapid beep-beep-beep.

• When you press the

pens.

• When you press the

flashing, out-of-focus, colored light.

If you see any of the problems above, turn to “Startup

Problems” on page 16.

LAMP ON button, the display

MONITOR button, nothing hap-

MONITOR button, you see a

Types of image problems

If any of these things apply to your situation, the

problem is an image problem.

• The picture is noisy .

• There is a black area on the side or top or bottom

of the screen, and you can’t move the image into

this space with the Position control.

• There is a sign on the screen that says S

A

BSENT.

•You are displaying a computer screen, and you

can’t see enough of the edges.

• The colors seem wrong.

• This display has different colors than the other

display in the wall.

• This display is darker or brighter than the others.

• When you press

of-focus, showing at the bottom of the screen. (No

problem. This is normal.)

• Image is distorted.

• Image is out of focus.

• Lamp is on, but you have no image.

• Image isn’t positioned on the screen properly.

• The lamp lights, but the screen is all white. You

can’t see any picture. When you press the

button on the remote control, no menu appears.

MONITOR, there is a red light, out-

OURCE

MONITOR

12

If you see any of these problems, turn to “Image Problems” on page 30.

13

2.1 What Kind of Problem Is It?

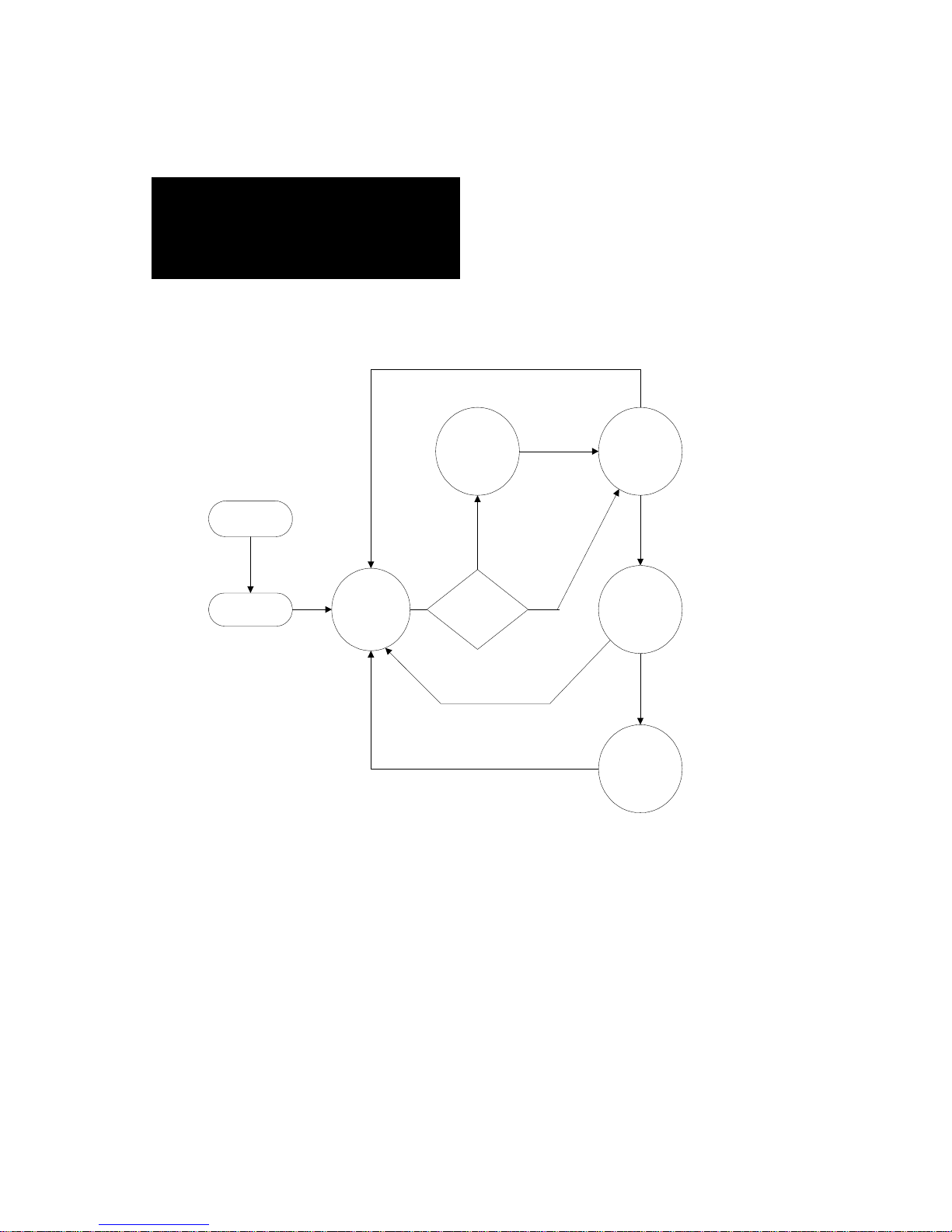

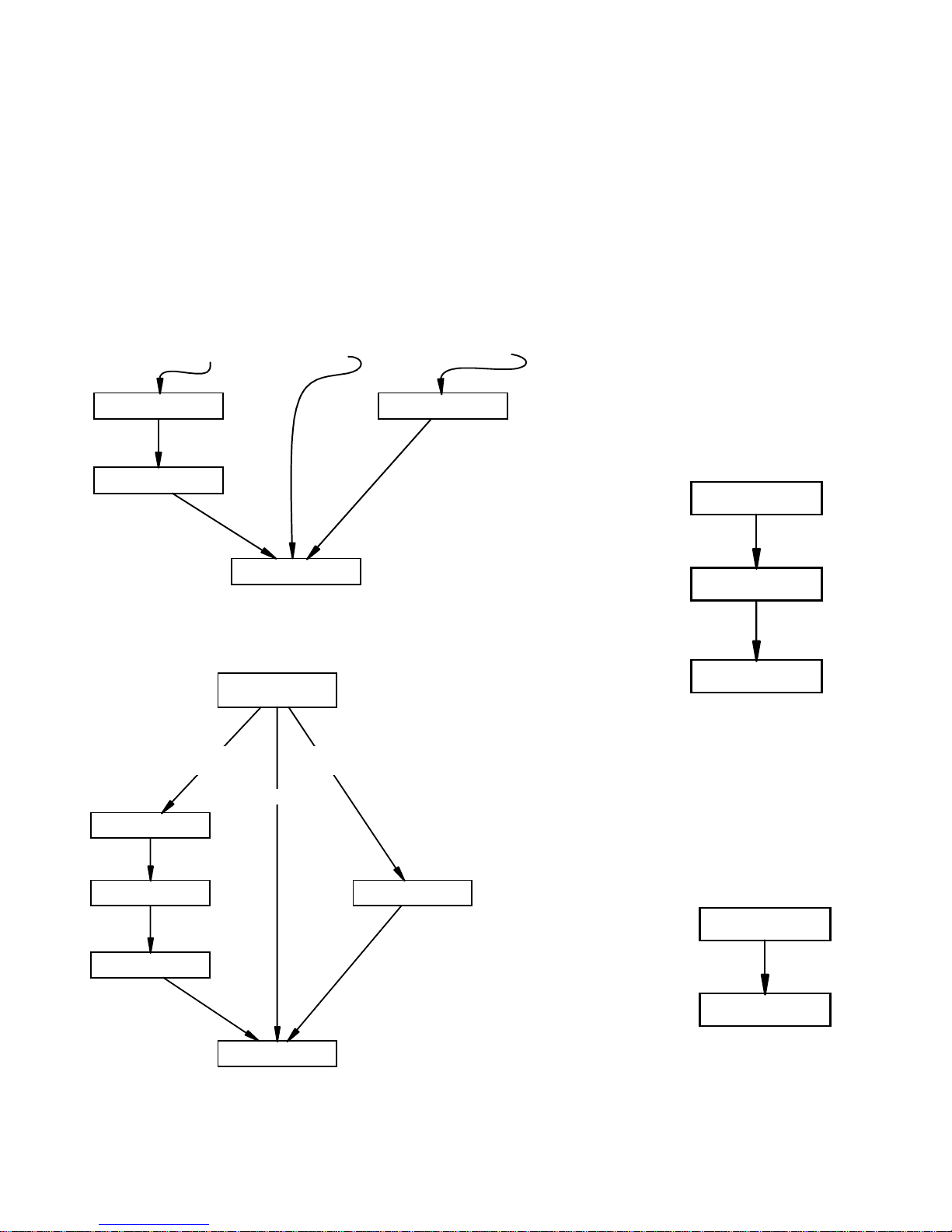

2.1.1 Normal Startup Sequence

If Auto Lamp On is enabled, the lamp should turn on about one minute after AC power is applied. If

Auto Lamp On is not enabled, about one minute after AC power is applied you can manually turn on

the lamp.

You can observe the startup sequence from the front

or rear . R emove the screen to see it from the fron t and

watch the LEDs on the electronics module. From the

rear, open the right (larger) access door to see the

LEDs.

What happens in the WN-4030:

1. Plug AC power into the power entry box.

2. Turn on the AC switch, which lights up. This

sends AC to the power supply.

3. The power supply sends +5v, –5v and +12v to

the electronics module, the optical engine, and

350V to the lamp ballast.

4. When the electronics module first has voltage, it

goes through an initialization period and takes

care of some housekeeping tasks. It checks the

RS232 port to see if there is any data there. LEDs

turn on and off during initialization.

5. The electronics module turns on the two fans and

goes into a lockout period, for 30 seconds. The

Standby LED flashes. During lockout, you cannot

turn on the lamp. You should see these LEDs:

electronics module is waiting for a lamp on command. This is the standby mode. The fans stop.:

LAMP ON

EXHT FAN

INTK FAN

STANDBY

TEMP

INTRLOCK

SOURCE

RS232 ACT

RS232 CMD

REMOTE

CPU ACT

!!!"""$$$$#

! If Auto Lamp On is checked in the Misc Control menu,

the display goes directly from lockout (Step Step 5.) to

the lamp ignition stage (Step Step 1.). Step Step 1. is

bypassed, and the Standby is never on steady.

1. When the electronics module receives an On

command, or Auto Lamp On is enabled, it enters

the ignition stage.

a) The fans start.

b) The interlock system is monitored to see that

all interlocks are closed.

c) The LCD is energized.

d)The lamp ballast is enabled

LAMP ON

EXHT FAN

INTK FAN

STANDBY

TEMP

INTRLOCK

SOURCE

RS232 ACT

RS232 CMD

REMOTE

!""#""$$$$#

! off

" on

# 1 flash per second

% 2 flashes per second

$ don’t care

1. At the end of lockout, the Standby LED turns on

steady, without flashing, which shows that the

14

! If the either fan is not turning, or if any interlock is open,

the electronics module goes back into the lockout

CPU ACT

period, Step Step 5. above. If a fan is connected but it

isn’t turning, that fan’s LED will flash. If the fan is

completely disconnected, its LED will be off.

2. The lamp ballast applies 25 kV to the lamp which

produces an arc in the lamp. As the gas in the

lamp heats up, it becomes more conductive,

which causes the ballast to decrease the voltage

and increase the current. During this ignition

stage, the Standby LED flashes quickly (2 flashes

per second).

LAMP ON

EXHT FAN

INTK FAN

STANDBY

TEMP

INTRLOCK

SOURCE

RS232 ACT

RS232 CMD

REMOTE

CPU ACT

%""%""$$$$#

1. When the lamp is lit, the ballast sends a signal to

the electronics module, and the Standby LED goes

out. The Lamp LED turns on.

LAMP ON

EXHT FAN

INTK FAN

STANDBY

TEMP

INTRLOCK

SOURCE

RS232 ACT

RS232 CMD

REMOTE

CPU ACT

"""!""$$$$#

Interlock opens

Standby state: Standby

LED is on steadily, no

flashing

AC Power Up

Electronics

initializes itself

Lockout state: Standby LED

is flashing slowily, one flash

per second

Lockout:

30 seconds

Standby

No

Auto Lamp On

Enabled?

Interlock opens

Remote Lamp Off

RS232 POF

Interlock opens

Remote Lamp Off

RS232 POF

RS232 PON

Remote Lamp On

Yes

Lamp Delay, if

any, from Misc

Control menu

Lamp Ignition

Lamp On

Ignition state: Standby LED

is flashing quickly, two

flashes per second

Lamp On state: Standby

LED is off

15

2.1 What Kind of Problem Is It?

2.1.2 Startup Problems

Startup problems usually mean the screen is black – no image, no menus. If the display has power and

the electronics are working, you can learn a lot by watching the LEDs (inside the cube, viewed with

the screen off) or the On-Screen Status Codes (viewed with the screen on).

Follow these steps to determine what the problem is:

1. Press the

Do you see a Monitor Status menu?

a) Yes – This is not a startup problem. Turn to

section “Image Problems” on page 30.

b)No – Go to Step 2..

2. Do you see a colored light in the lower right part

of the screen? It may be flashing or steady. It may

have two colors. It will be out of focus and look

strange.

a) Y es – This light is flashing in a non-secret code.

See “How to Read On-Screen Status Code” on

page 22 to learn how to read the code.

b) No – The electronics module is not operating.

Go to Step 3..

3. Remove the screen. Is the circuit breaker inside

the unit lit?

a) Yes – Go to Step 4..

b) No – Power problems: Check line cord, source

AC power, circuit breaker switch.

4. Are any LEDs lit on the electronics module?

a) Yes – These LEDs will tell you the state of the

display. See section “How to Read the Inside

LEDs” on page 24 to learn w hat th e se LED s

mean.

b)No – Go to Step 5..

5. Is the power supply on the left wall of the cube

connected to the left side of the electronics module?

a) Yes – Either the power supply is dead or the

electronics module is dead. Or both. Swap the

power supply with a known good supply. (See

section “Replacing the Power Supply” on

page 68.) If that does not help, then swap the

electronics module with a known good one. See

section “Replacing the Electronics Module” on

page 70.)

b) No – Turn off AC power. Connect the power

supply to the electronics module. Turn on AC

power again.

MONITOR button on the remote control.

16

17

2.1 What Kind of Problem Is It?

2.1.2 Startup Problems

2.1.2.1 Using the Remote Control and LEDs

The LEDs are inside, but they are duplicated in the Status Menu. If you can’t see the inside LEDs,

there are two bright LEDs that flash a code on the scr een. The r emote control has special buttons that

start menu chains, a series of menus presented in the order you normally use them.

The remote control opens menus on the screen and

gives you control of the electronics. The remote has

many “hot key” buttons that go directly to the control

you want.

Many of the hot keys lead you through a menu

chain, a series of menus presented in a natural order.

Each press of a hot key moves you to the next menu

in the chain.

The menu chains are slightly intelligent;: they take

you through different paths depending on what

choices you make in the menus. These chains are

listed on the facing page and shown as diagrams in

“How to the Use Menu Chains” on page 20.

Menu button

Press the

open the Main Menu. The up and down arrow buttons move the selection arrow through the various

items. Press

Many of the Main Menu items have hot keys, so

you can initiate these functions without using the

Main Menu. This is a little faster and more convenient.

The

selection or it moves you to the next menu.

Menu symbols

MENU button on the remote control to

ENTER to choose an item.

ENTER button either activates the current

" is the selection arrow. Move this symbol with

the up and down arrow keys on the remote

control to choose a function. Press

activate the function.

ENTER to

#$ means you can change this item with the + and

– arrow keys.

$ at the right end of a menu item means that

when you press

another menu.

ENTER for this item, it leads to

! is a radio button. Only one of these buttons in a

group can be selected at a time. Use the

button to select one of these radio buttons,

which deselects all the others.

ENTER

" is the currently selected radio button.

& is a check box that is not checked. Select it with

ENTER button. Several check boxes can be

the

selected at one time.

' is a check box that is selected. Its feature is cur-

rently active. Deselect it with the

ENTER key.

# is a selector dot in the Source Select menu

(only). It indicates the current selection.

" is a momentary push button. Press

push it when the selection arrow points to it.

When this button is pushed, it changes shape a

little.

LEDs and Status menu

The WN-4030 has three ways to find out what is

happening: Status menu, inside LEDs, and

On-Screen Status Codes.

Press

MONITOR on the remote control to see the

Status menu. Part of this menu repeats the state of

the inside LEDs. Turn the page to see an explanation

of all the items in this menu.

You can see the inside LEDs if you remove the

screen. You can also see them through the rear access

door. See “How to Read the Inside LEDs” on page 24.

The On-Screen Status Codes help you when the

lamp does not light and you can’t see the inside

LEDs. Press

Codes operate. They flash a simple code in the lower

left part of the screen. See “How to Read On-Screen

Status Code” on page 22.

MONITOR to make the On-Screen Status

ENTER to

18

SETUP button menu chain goes to menu:

Source Select, then

if Source1 or Source2 is selected, then

Frequency/Phase

Black Level

White Level

Color Balance

Position

Save Config

or if Digital is selected, then

Color Balance

Position

Save Config

or if C-Video or is S-Video selected, then

Video Controls

Color Balance

Position

Save Config

LEVEL button menu chain goes to menu:

if the currently selected source is Source1

or Source2, then

Black Level

White Level

Color Balance

or if the currently select source is Digital, then

“Input level controls do not apply to digital

sources”, then

Color Balance

or if the currently selected source is C-Video or

S-Video, then

Video Controls

Color Balance

SOURCE button menu chain goes to menu:

Source Select, then

if Source1 or Source2 is selected, then

Frequency/Phase

Black Level

White Level

Mode Detect

or if Digital is selected, then

Mode Detect

or if C-Video or is S-Video selected, then

Video Controls

Mode Detect

SAVE button menu chain goes to menu:

Save Config

Recall Config

Reset Config

SIZE/POS button menu chain goes to menu:

Position

Zoom Control

19

2.1 What Kind of Problem Is It?

2.1.2 Startup Problems

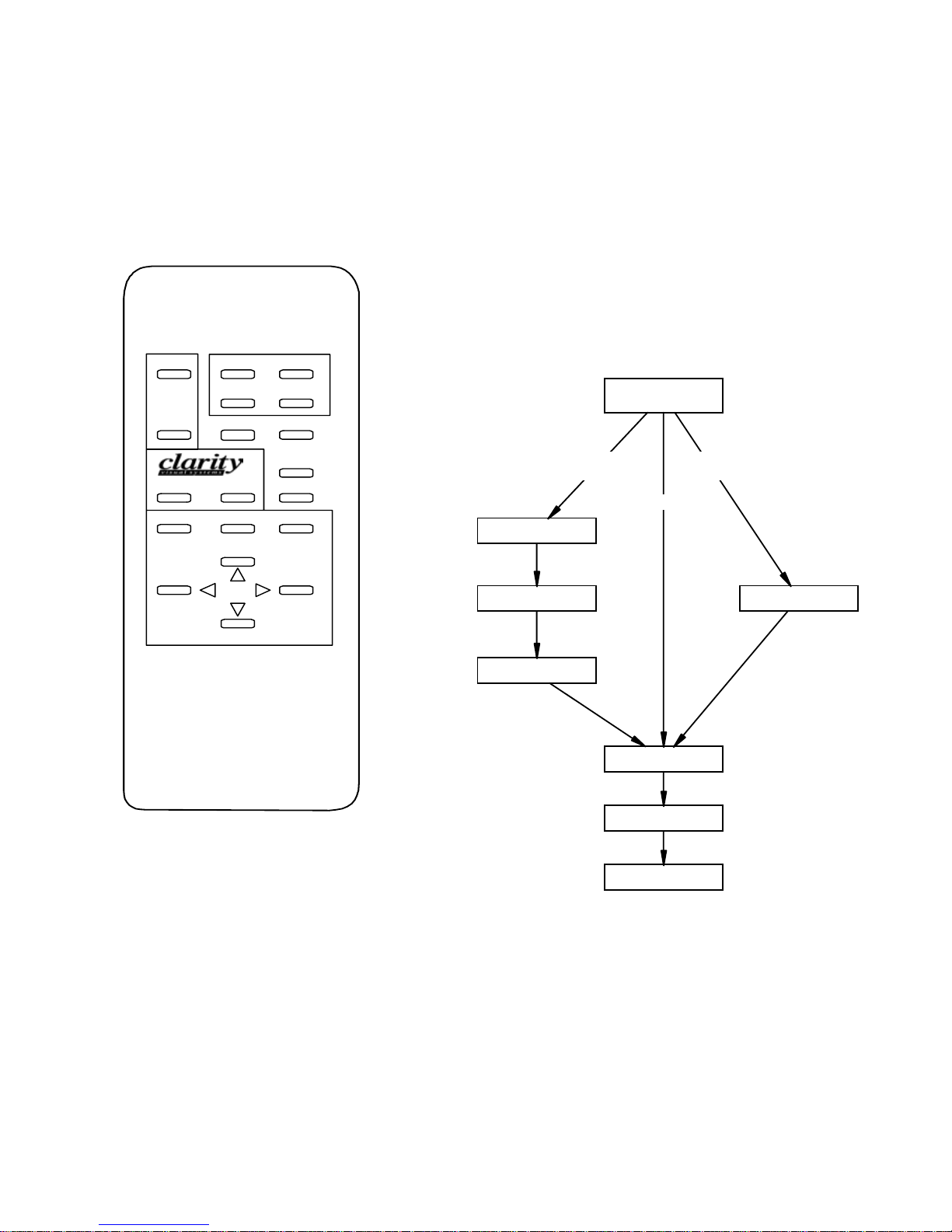

2.1.2.2 How to the Use Menu Chains

The menu chains go through a string of related menus. The diagrams on these pages show how these

strings connect one menu to another . Each push of the designated button steps to the next menu. The

last push exits all menus.

LEVEL button menu chain

If the current source

is Source1 or Source2

Black Level

White Level

OURCE button menu chain

If Source1 or Source2

is selected. . .

If the current

source is Digital

Color Balance

Source Select

If C-Video or S-Video

is selected. . .

If the current source

is C-Video or S-Video

Video Controls

SAVE button menu chain

Save Config

Recall Config

Reset Config

If Digital is selected. . .

Frequency / Phase

Black Level

White Level

Mode Detect

20

SIZE/POS button menu chain

Video Controls

Position

Zoom Control

SETUP button menu chain

LAMP

OFF

+

SOURCEON

CURTAIN

SAVE

WALLMONITOR

PREV M ENUMENU ENTER

LEVE L

FREQ/

PHAS E

SETUP

SIZE/POS

MISC

–

If Source1 or Source2

is selected. . .

Frequency / Phase

Black Level

White Level

Source Select

If C-Video or S-Video

is selected. . .

If Digital is selected. . .

Video Controls

Color Ba lan ce

Remote control

Position

Save Config

21

2.1 What Kind of Problem Is It?

2.1.2 Startup Problems

2.1.2.3 How to Read On-Screen Status Code

If the lamp is not lit, you can still get important information from the display by watching the

On-Screen Status Code. Two, bright LEDs flash behind the screen in a simple code.

The Status Menu is the best place to get information

about the display, and the inside LEDs are next best.

But if the lamp won't light and you don't want to (or

can't) take the screen off, the On-Screen Status Code

will tell you what you need to know.

The On-Screen Status Code are two very bright

LEDs (one red and one green or some other color)

that flash on the back of the screen at the lower right

corner. The flashes form a coded pattern , whic h can

tell you about the system.

To start the On-Screen Status Code

Aim the remote control at the screen and press

monitor. If the lamp is on, this will also display the

Status menu. You should immediately see the LEDs

in the lower right corner of the screen. (If you do not

see these LEDs

This is not a secret code. The table on the facing

page shows the patterns. Read the pattern, then look

in the following list for an explanation.

Exhaust Fan locked—The rotor on the exhaust fan

has stopped. Either some object has stopped it

from rotating, the fan is disconnected, or it has

failed. The lamp will not light until this problem is

fixed.

Intake Fan locked—The rotor on the intake fan has

stopped. Either some object has stopped it from

rotating, the fan is disconnected, or it has failed.

The lamp will not light until this problem is fixed.

Thermal interlock open—The lamp has overheated,

tripping the thermal interlock. This interlock can

be reset, but you should first determine why it

tripped. The lamp will not light until this problem

is fixed.

Lamp door switch open—The lamp door at the rear

is open or not securely closed. The lamp will not

light until this door is closed.

Light shield switch open —The light shield is not

properly in place and not closing the switch. The

lamp will not light until the light shield is properly

in its place.

One or more temps went beyond limit—A t least one

of the three temperature sensors has detected a

temperature over its limit. The lamp may still

light.

Unit is in lockout period—The lockout period is

about 30 seconds long. Every time the lamp goes

off the system goes into this lockout state while

the fans cool the lamp so it can be lit again. This

lockout state also occurs during AC power up. At

this end of this period the display should go into

Standby, below, or the lamp will turn on automatically.

Unit is in Standby—After the lockout state, the sys-

tem goes into Standby and waits for an On command from the remote or from RS232. If the Auto

Lamp On feature in Misc Control is enabled with

an ×, the display goes from Lockout to Lamp On

immediately, unless there is an Interlock open.

Lamp is on—If you see this pattern and you do not

see the Status menu, something is seriously

wrong. The electronics module thinks the lamp is

on, but it isn't. Call a qualified service person.

The Priority rating in the table shows which problems are most important. If there are two problems,

only the pattern with the lower number will show up

in the code. When this problem is fixed, the next

problem will show in the code.

To stop the On-Screen Status Code

Press the monitor button again. The Status menu

goes away.

How the On-Screen Status Code works

The pattern is designed so you can look at the colors or the long-short pattern of the lights. Or both.

The pattern repeats continuously .

The pattern does not change when the status

changes. For instance, if the unit were in Lockout (7)

and you turned on the On-Screen Status Code with

the

MONITOR button, you would see the Red-Amber-

Red code. At the end of the Lockout Period, the unit

would go into Standby Mode (8), but the code would

not change.

If you turn off the codes with the

then turned them back on again, you would see the

Standby Mode pattern of Red-Red Amber.

In other words, when you display the codes, the

electronics module asks just once about the current

status of the unit. This one code is displayed until the

codes are turned off.

MONITOR button,

22

Loading...

Loading...