Page 1

Cll

C

arriitt

a

y

y

U

U

s

s

err

e

G

G

uii

u

d

d

e

e

March 1, 2011 Part 87392-11, Rev. 1.06

Page 2

Warnings, Cautions and Notes as used in this Guide

WARNING

This publication uses Warning notices to emphasize situations in which

hazardous voltages, temperatures, or other conditions associated with the use of

this equipment could cause personal injury or serious damage to the equipment.

In situations where inattention or misuse could cause either personal

injury or serious damage to the equipment, a Warning notice is used.

CAUTION

operating instructions are not followed.

Caution notices are used where equipment might be damaged if proper

NOTE

Notes call attention to information that is especially significant for proper

understanding and operation of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details of the

hardware or software, or to provide for every possible contingency in connection with installation,

operation or maintenance.

Safety Reminders

• DO NOT operate this equipment until you have read and understood this manual. If operating

for the first time, ask your supervisor or a qualified operator for assistance.

Plug the power supply into a grounded receptacle ONLY. Do not cut off the grounding prong

•

or use any power cord or adapter without a grounding prong.

Always assume the power is ON. Do not attempt any maintenance until you have verified that

•

the power is OFF by unplugging the power supply from the Clarity.

Never turn the machine on while someone is performing maintenance or repair.

•

Keep your hair, hands, and clothing clear of the machine while it is in operation.

•

This product is not intended to be used in an explosive environment.

•

•

Unit should be positioned so that it can easily be disconnected from the power source.

THINK SAFETY FIRST – ALWAYS PRACTICE SAFE WORK HABITS.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 2

Page 3

TABLE OF CONTENTS

Page

Chapter 1 - Getting Started............................................................................................................. 5

Unpacking the Clarity ........................................................................................................... 5

Foam Shipping Blocks in the Blocking Chamber................................................................. 6

Block #1 - #33593 - Bottom Shipping Block........................................................... 6

Block #2 - #33592 - Rear Shipping Block............................................................... 7

Shipping Bracket Used in the Blocking Chamber................................................................. 7

Shipping Bracket Assembly, #33648....................................................................... 7

Installed Shipping Bracket Assembly ...................................................................... 8

Clarity Front View - User Items............................................................................................ 9

Clarity Rear Connector Bulkhead .........................................................................................10

Accessory Kit........................................................................................................................10

Installing the Glass Plate.......................................................................................................11

Installing Light Shielding......................................................................................................11

Chapter 2 - Basic Operation............................................................................................................13

Powering on the Clarity.........................................................................................................13

Establishing Communications...............................................................................................13

The Touch Screen Display and Job Screen...........................................................................14

The Processing Screen ..........................................................................................................15

The Analysis Screen..............................................................................................................16

The Teach Function...............................................................................................................17

The Teach Screen.....................................................................................................18

Chapter 3 - Setup Screens................................................................................................................21

Main Menu Screen................................................................................................................21

Preferences Screen ................................................................................................................22

Key Features of the Preferences Screen................................................................................22

Batch Blocking.........................................................................................................22

Auto Blocking Mode................................................................................................22

Add Verification.......................................................................................................22

User Interface...........................................................................................................22

Tolerances Screen .................................................................................................................23

Interface Screen.....................................................................................................................24

Key Features of the Interface Screen ....................................................................................24

Display of Communication Events on the Main Menu............................................24

Hide Patient Name Received From Host for Privacy...............................................24

Run 30-Second Loopback Test................................................................................24

Communications Log...............................................................................................24

Blocking Screen ....................................................................................................................25

Key Features of the Blocking Screen.......................................................................25

Standard Finish Block Size, Small Finish Block Size (Half Eye),

Extra Small Block Size ...............................................................................25

PD, Seg Height, Axis ...............................................................................................25

Block Size Safety Margin ........................................................................................25

Blocker Arm Load Position......................................................................................26

Calibration Screen.................................................................................................................26

Advanced Screen...................................................................................................................27

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 3

Page 4

Key Features of the Advanced Screen ..................................................................................27

Home........................................................................................................................27

Burn In .....................................................................................................................27

Distance, Near and Prism Power Checks.................................................................27

Technician Screen .................................................................................................................28

Statistics Screen.....................................................................................................................29

Chapter 4 - Calibration....................................................................................................................31

Calibration Screen.................................................................................................................31

Step 1: Preliminary Camera Focus.......................................................................................31

Step 2: Camera.....................................................................................................................31

Step 3: Screen Calibration....................................................................................................31

Step 4: Block Position Offsets..............................................................................................32

Step 5: Power Calibration ....................................................................................................32

Touch Screen Calibration......................................................................................................34

Chapter 5 - The Advanced Screen in the Setup Menu..................................................................37

Distance Power......................................................................................................................37

Near Power............................................................................................................................38

Prism Power ..........................................................................................................................38

Lens Feature Detection..........................................................................................................38

Auto-Run at Windows Startup..............................................................................................38

Warm-Up Time.....................................................................................................................38

Image ..................................................................................................................................38

Display Options.....................................................................................................................38

Setup Password ..................................................................................................................... 39

Job Data Log .........................................................................................................................39

Burn In 39

Home ..................................................................................................................................39

Chapter 6 - Maintenance.................................................................................................................41

Cleaning the Glass Plate........................................................................................................41

Cleaning the LCD.................................................................................................................. 41

Cleaning the Touch Screen ...................................................................................................41

Replacement of the Main Fuse Located on the Rear Bulkhead ............................................41

Maintenance Tips..................................................................................................................41

Intended Use & Limitations ............................................................................................................43

Glossary of Terms ............................................................................................................................45

Appendix A .....................................................................................................................................47

General Specifications...........................................................................................................47

Technical Specifications .......................................................................................................48

Appendix B - Certifications & Standards......................................................................................49

FCC Class A Device Compliance .........................................................................................49

Appendix C - Electrical Diagram...................................................................................................51

Appendix D - Certificate of Compliance........................................................................................53

Declaration of Conformity ....................................................................................................53

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 4

Page 5

Chapter 1 – Getting Started

The Clarity Automated Lens Analyzer/Blocker is designed to verify all prescription

parameters including sphere power, cylinder power, axis, optical center location, prism, and

all add powers as well as thickness and front curve information. It will also affix a finish

block to the lens on axis at the geometric center of the frame shape. It is shipped in an almost

ready-to-run condition. This guide will allow you to put the Clarity into service quickly. We

will cover the following topics:

• Unpacking the Clarity

• Applying power and turning on the unit

• Connecting the unit to your lab’s computer system

• Using the touch-panel display and examining some of the operator screens

• Operation including lens insertion and blocking

• Calibration

• Advanced screen functions

The Clarity has many features and settings to allow you to optimize it for your specific lab

environment. It also has diagnostic capabilities and adjustments to fine tune its operation.

This guide does not describe all of the features or adjustments. Once you have become

familiar with operation as described in this guide and want more information, call Technical

Support.

Unpacking the Clarity

The Clarity is shipped in molded foam blocks within a cardboard carton. These blocks need to

be removed prior to removing the machine from the carton. An accessory kit is shipped in

two small cardboard inserts. The shipping carton and shipping materials should be retained in

the event that the unit must be shipped again.

Before removing the Clarity from the packing box and setting it up, please read this guide and

familiarize yourself with the accessories, features and terms used throughout the guide. There

is a glossary of terms in the back of this guide. Once the carton is opened, remove the two

inserts containing the power supply, power cord, and accessory kit. Remove the two side

panels and lift the unit out of the carton. Be careful to use the appropriate lift points. (See

Fig. 1.2) Place the unit in the desired location, but out of direct sunlight.

Inspect the contents to ensure you have all the items listed below. (See Fig. 1.4). There

should be 14 items in the two inserts. They are:

1. Power supply

2. Power cord

3. 70mm Plano CR39

4. 70mm -6.00 CR39

5. 65mm +6.00 CR39

6. 58mm calibration disc

7. White marking pen for progressives

8. Oval calibration template with permanent block attached

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 5

Page 6

9. Main fuse (located on rear bulkhead)

10. Glass plate (See Fig. 1.5) Remove and install in the blocking chamber as described

later in this chapter.

11. Light shield (blocking arm)

12. Light shield (left gripper)

13. Light shield (right gripper)

14. Bag of screws for the light shielding

15. Clarity User Guide (not shown in Fig. 1.4)

When the Clarity is prepared for shipment (by the factory or the user), its mechanism must be

secured against movement caused by jarring or shocks to the shipping carton. Units may use

one of two means for doing this: (1) molded foam blocks within the blocking chamber, or (2)

a clamping device attached to the blocking mechanism. In either case, the shipping restraints

must be removed prior to using the Clarity, and must be re-installed prior to shipping the unit,

should that prove necessary.

CAUTION

Shipping the unit without properly re-installing the factory shipping

restraints may cause severe damage to the equipment.

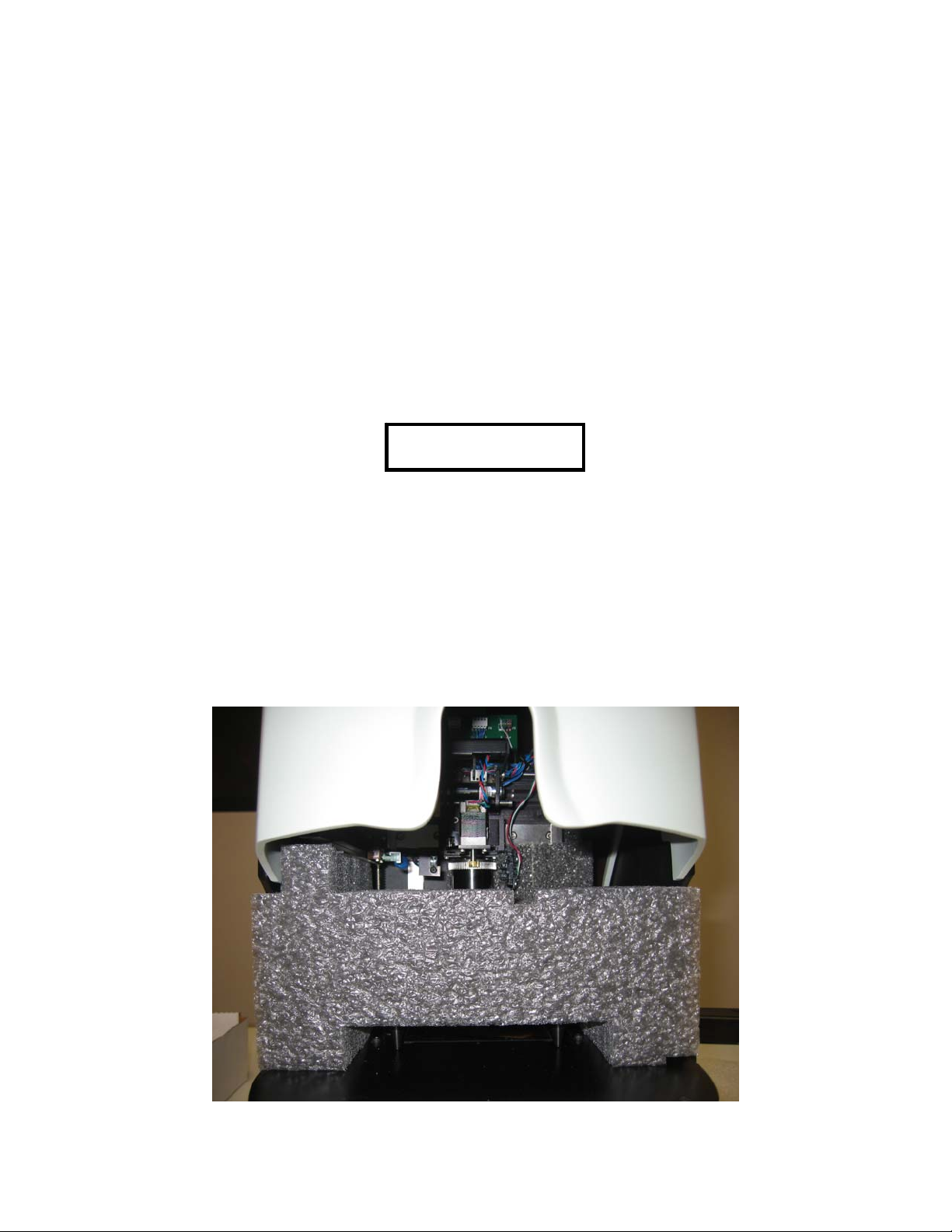

Foam Shipping Blocks in the Blocking Chamber

Remove the two foam blocks that hold the mechanism in place during shipment. Note how

they are installed in the event that the Clarity needs to be shipped from your location. Call

Technical Support for help in packing the machine for shipment. Figures 1.1a and 1.1b show

how the foam shipping blocks are installed.

Figure 1.1a - Block #1 (P/N 33593 - Bottom Shipping Block)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 6

Page 7

Figure 1.1b – Block #2 (P/N 33592 - Rear Shipping Block)

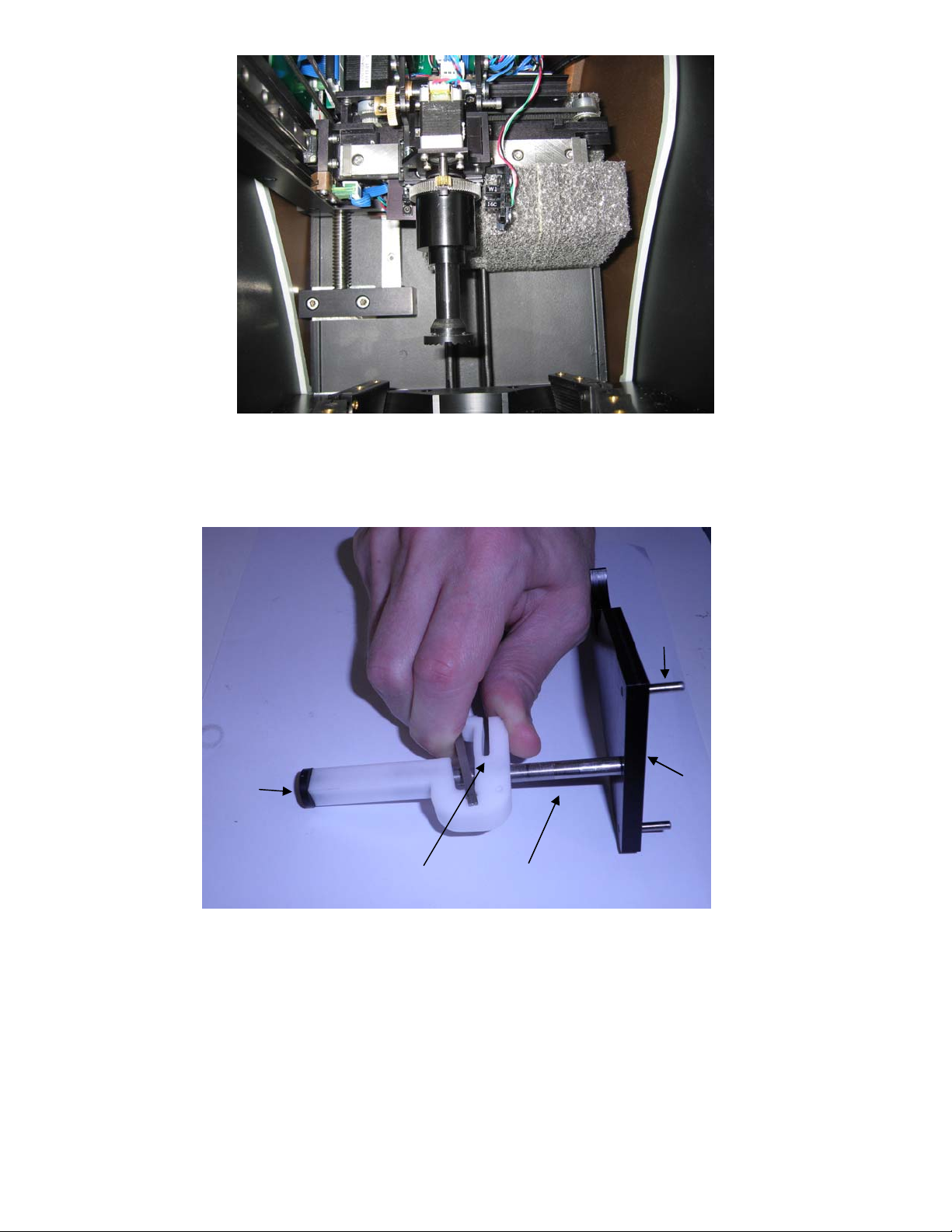

Shipping Bracket Used in the Blocking Chamber:

Foot

Foot

Locating

Locating

Plate

Plate

Pinch Lock

Pinch Rod

Figure 1.1c – Shipping Bracket Assembly, Clarity (P/N 33648 )

The Shipping Bracket assembly is shown in Figure 1.1c. The Foot is placed on the base of

the blocking chamber. By squeezing the Pinch Lock, the Pinch Rod may be moved up or

down so that the cutout in the Plate engages the chuck and the Locating Pins engage the

bottom of the blocking mechanism. When installing the assembly, the Pinch Lock mechanism

should be moved downward so that the rubber Foot is slightly compressed. Figure 1.1d shows

the shipping bracket in its installed aspect.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 7

Page 8

Plate

Pinch Rod

Pinch Lock

Foot

Figure 1.1d – Installed Shipping Bracket Assembly

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 8

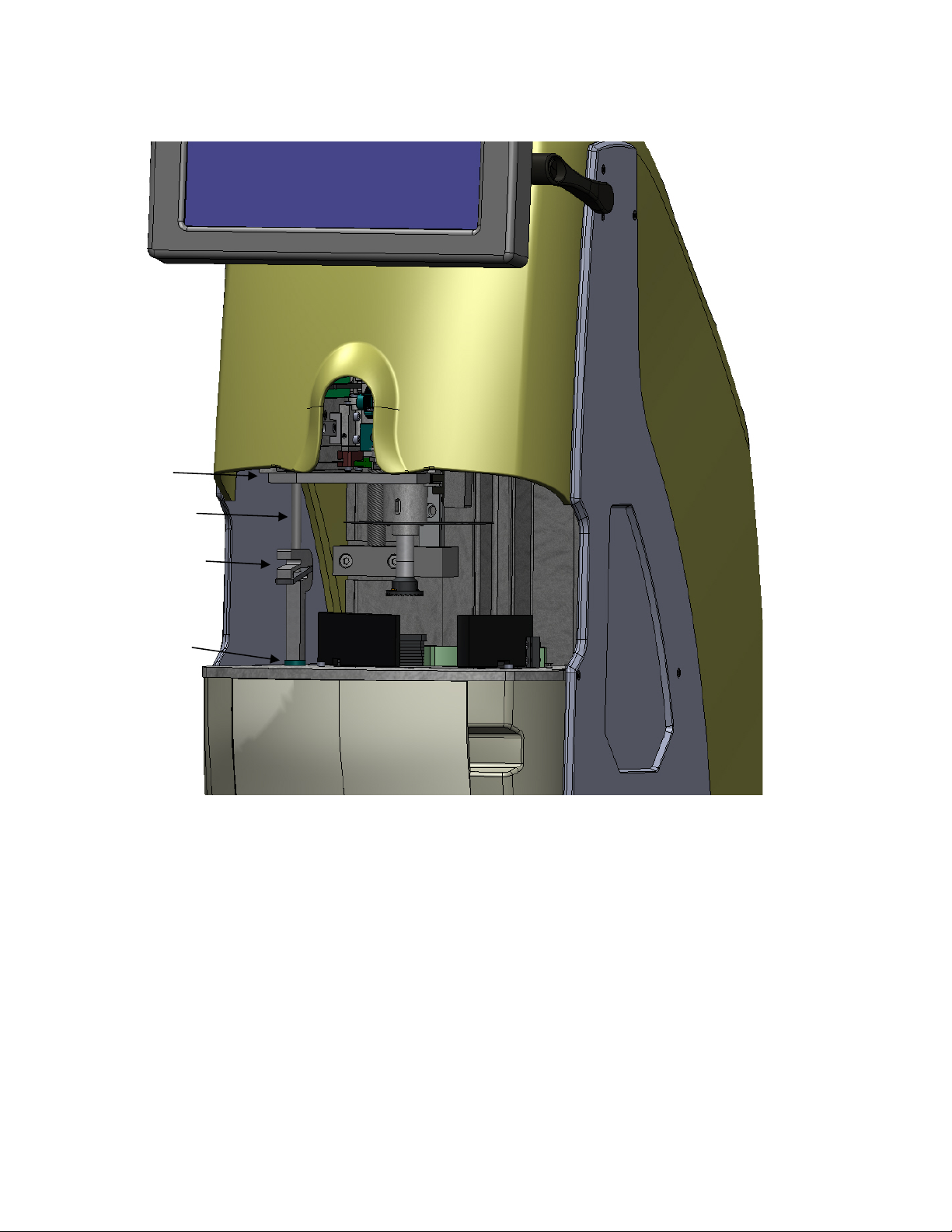

Page 9

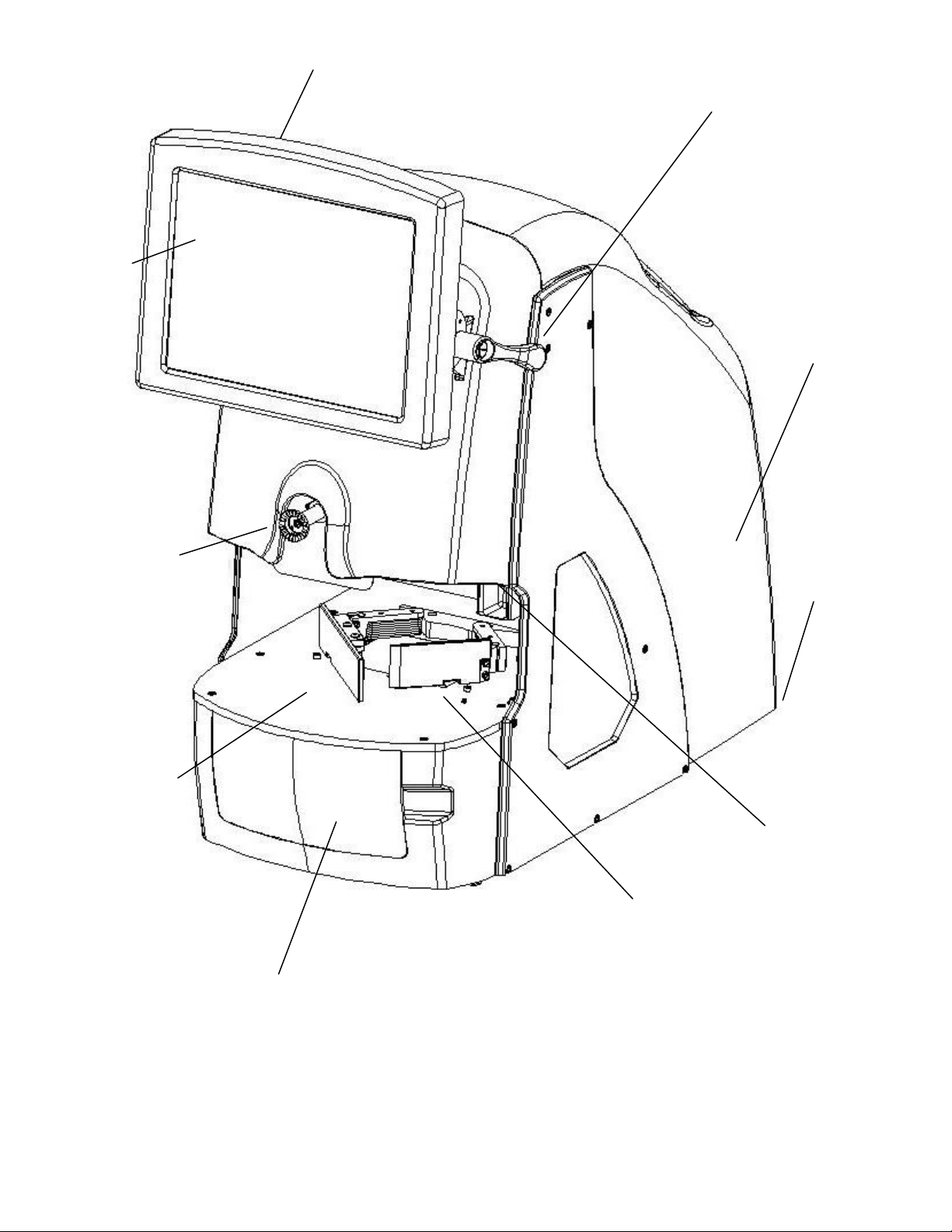

Touch

Screen

Display

Display Frame

Display Tilt Handle

Rear

Cover

Block Arm

(Extended or

Retracted)

Lens

Table

Drawer

Figure 1.2 – Clarity Front View - User Items

Gripper Arm

Lift Point

Lift Point

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 9

Page 10

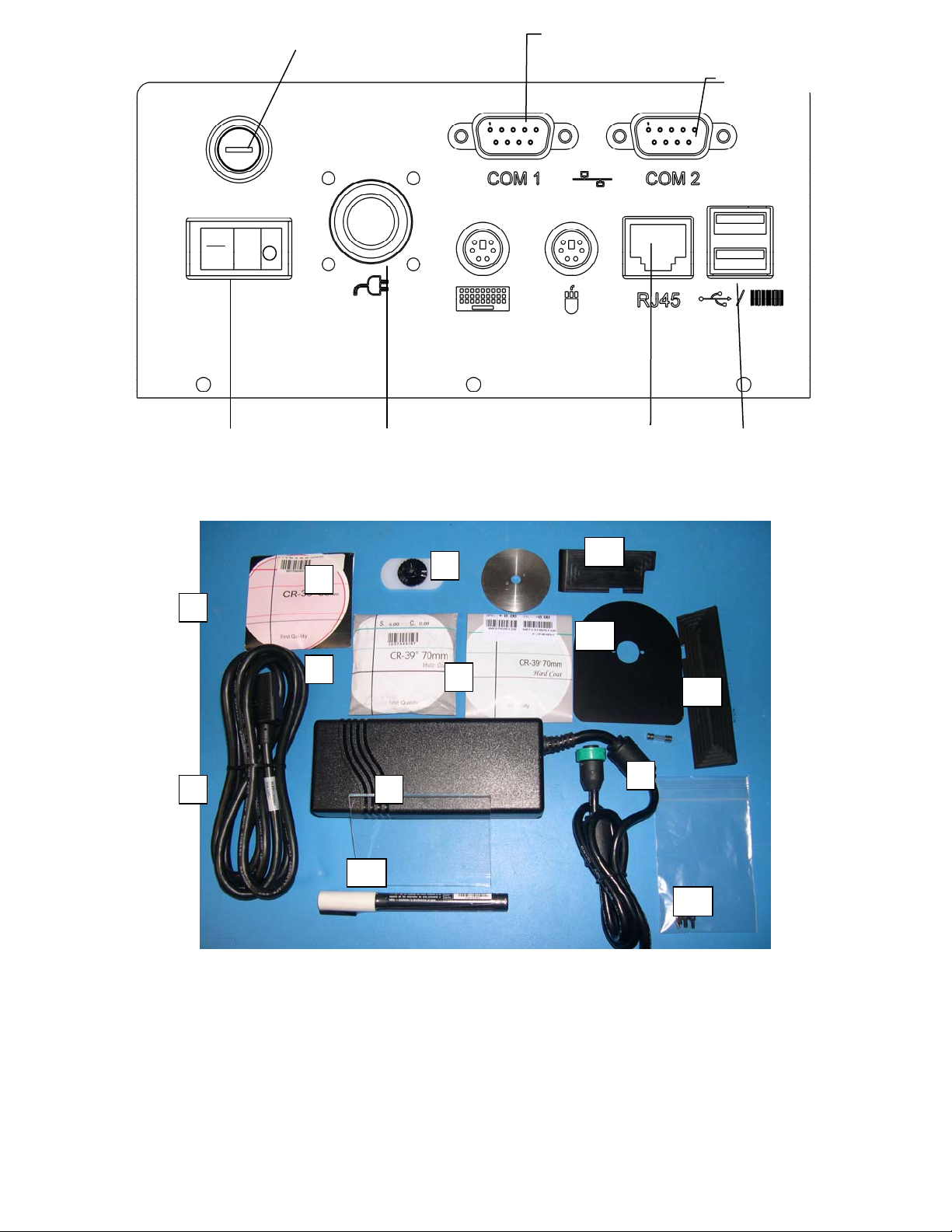

Fuse 5A, 250V

,

r

r

5x20mm

T5.0

Serial Port COM1

Serial Port COM2

Power

Switch

Power Supply

Connecto

Ethernet

Connector

USB

Connecto

Figure 1.3 - Clarity Rear Connector Bulkhead

8

5

4

6

3

13

11

12

2

1

9

10

14

Figure 1.4 – Accessory Kit

1. Power supply 8. Oval calibration template with permanent block attached

2. Power cord 9. Fuse (in the bag of screws)

3. 70mm Plano CR39 10. Glass plate

4. 70mm -6.00 CR39 11. Light shield (Blocking Arm)

5. 65mm +6.00 CR39 12. Light shield (Left Gripper)

6. 58mm calibration disc 13. Light shield (Right Gripper)

7. White marking pen

14. Bag of screws for the light shielding

s

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 10

Page 11

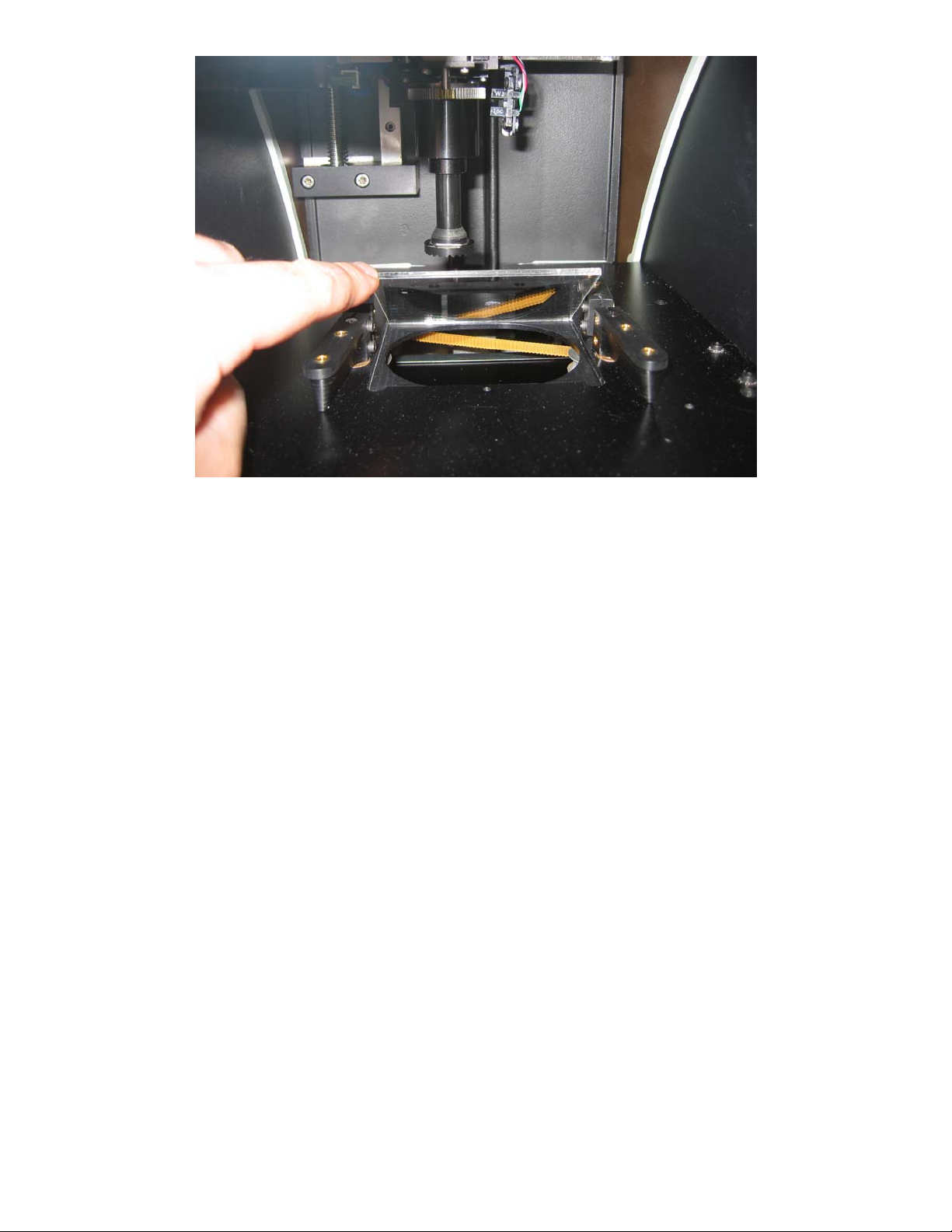

Figure 1.5 – Installing the Glass Plate

Installing the Glass Plate – The glass plate is placed over the opening in the base plate of the

blocking chamber. Clean the glass plate and then slide it into the pocket. It should fit and

seat down in the pocket fully. (The glass plate is shipped in the accessory box.)

Installing Light Shielding – This shielding is designed to reduce or eliminate light coming in

to the blocking chamber causing inconsistent lens analysis. The shields are not necessary in

all lab environments. Only if you see white or clear areas on the lens image (on screen)

during processing should the shields be needed. They are in the accessory box in the event

that there is too much light entering the chamber. There are three separate parts to the light

shielding including the left gripper shield, the right gripper shield and the blocking arm shield.

The left and right gripper shields can be installed using the screws in the accessory box to

secure them to the tops of the front gripper arms. There are two threaded holes for the screws

to attach the shields to the tops of each gripper arm.

The blocking arm shield requires that you remove the center screw of the blocking arm,

thereby removing the chuck. Place the shield over the arm with the flat side facing down.

Replace the chuck (align small hole on the back of the chuck with the locator pin) and insert

and tighten the center screw.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 11

Page 12

(This page intentionally left blank for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 12

Page 13

Chapter 2 – Basic Operation

WARNING

Use only a grounded outlet. Do not defeat the grounding by cutting off the

grounding prong on the power cord, or by using a non-grounding adapter.

NOTE

The power supply module is designed to work with both 115 VAC (60 Hz) and with

230 VAC (50 Hz). A separate power cord is available for each application. In the

U.S., units will be shipped with 115 VAC power cord unless otherwise specified.

WARNING

The back case top should not be removed while the machine is powered ON. Power

the machine OFF and unplug from the wall.

Powering on the Clarity

• Make sure that the Clarity main power switch is in the OFF position. The side of the

switch with the symbol 0 should be depressed.

• Plug one end of the AC power cord into the power supply module. (Fig. 1.3)

• Plug the other end of the AC power supply cord into a grounded outlet.

• Plug the power supply module into the power socket on the rear connector bulkhead

shown in Fig. 1.3.

• At this time you can connect a serial cable for communications from the host computer to

COM 1 or COM 2, 9-pin serial port on the rear bulkhead. This method will require the

use of a null modem at either end of the serial cable.

• Once the unit is properly plugged in, both at the machine and the wall, press the left side

of the power switch (with the symbol l) to apply power to the Clarity. Within 6 to10

seconds, the display should become active and the mechanism should move to locate its

home position.

• Either of the two 9-pin serial ports on the rear bulkhead labeled COM 1 and COM 2 (may

show up in the Interface tab as COM 5 and COM 6 respectively) can be used to set up

serial communications.

Establishing Communications

At this time, you will want to set the communications to your lab software. From the Job

Screen, press EXIT, then select Setup, and then select the Interface tab. Choose the VC

Connection Method, and then set the Baud Rate and COM Port if you are using a serial

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 13

Page 14

connection. If you are using an Ethernet connection, then you must set the two ports in the

TCP/IP Network Auto-Connect Settings box.

CAUTION

Keep hands away from unit during the blocking function.

The Touch Screen Display and Job Screen

CAUTION

Do not use a sharp object (pencil or pen point, paper clip, etc.) on the touch screen as it may

scratch or tear the screen. Clean the screen with a microfiber cloth such as is used to clean

eyeglasses. A soft cloth slightly dampened with clear water may be used for hard-to-remove

spots. Turn the Clarity off before cleaning the screen.

The Clarity is equipped with a touch screen display. A mouse and keyboard can be installed

on the rear bulkhead if desired. A mouse is recommended to have at all times for manual

alignment of progressives, bifocals and trifocals. There are two USB ports that can be used as

well as two PS-2 connectors at the rear of the machine. (See Fig. 1.3) If you install a PS-2

mouse or keyboard while the machine is ON, you will have to reboot the machine (cycle the

power OFF and then ON) for the machine to recognize

there is a device connected.

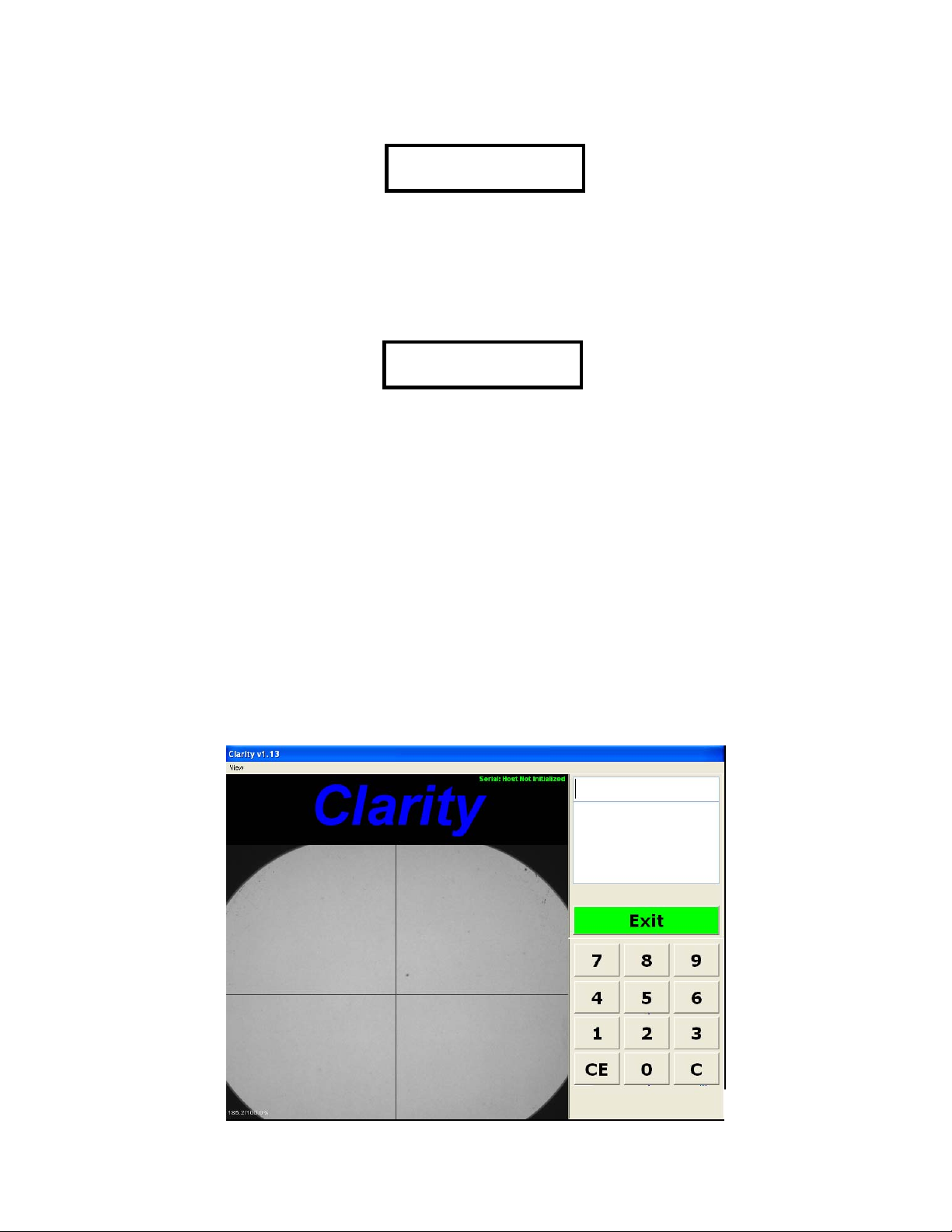

Once the unit is powered ON, it will boot to the main Job screen. (See Fig. 2.1.) The

program will open, initialize communications, and the camera will go through several checks.

Fig. 2.1 - Job Screen

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 14

Page 15

When a Job Number has been entered, the EXIT label on the control button changes to

PROCESS. Jobs are processed in one of the following three ways:

1. You may enter the job number manually with the touch screen keypad or keyboard

and then select PROCESS.

2. You may use USB barcode reader and scan a job number into the machine and then

select PROCESS.

3. You may enter multiple job numbers either manually or with the barcode reader by

going to the Preferences tab in the Setup menu and checking the box labeled Enable

Batch Blocking and activating Last in First Out, or First in First Out.

NOTE

Selection 3 above allows the operator to enter a large group of jobs (like a stack of trays) for

efficiency. The Clarity will then bring up each job in the order that was specified in the setup.

(See batch blocking in the glossary.)

The Processing Screen

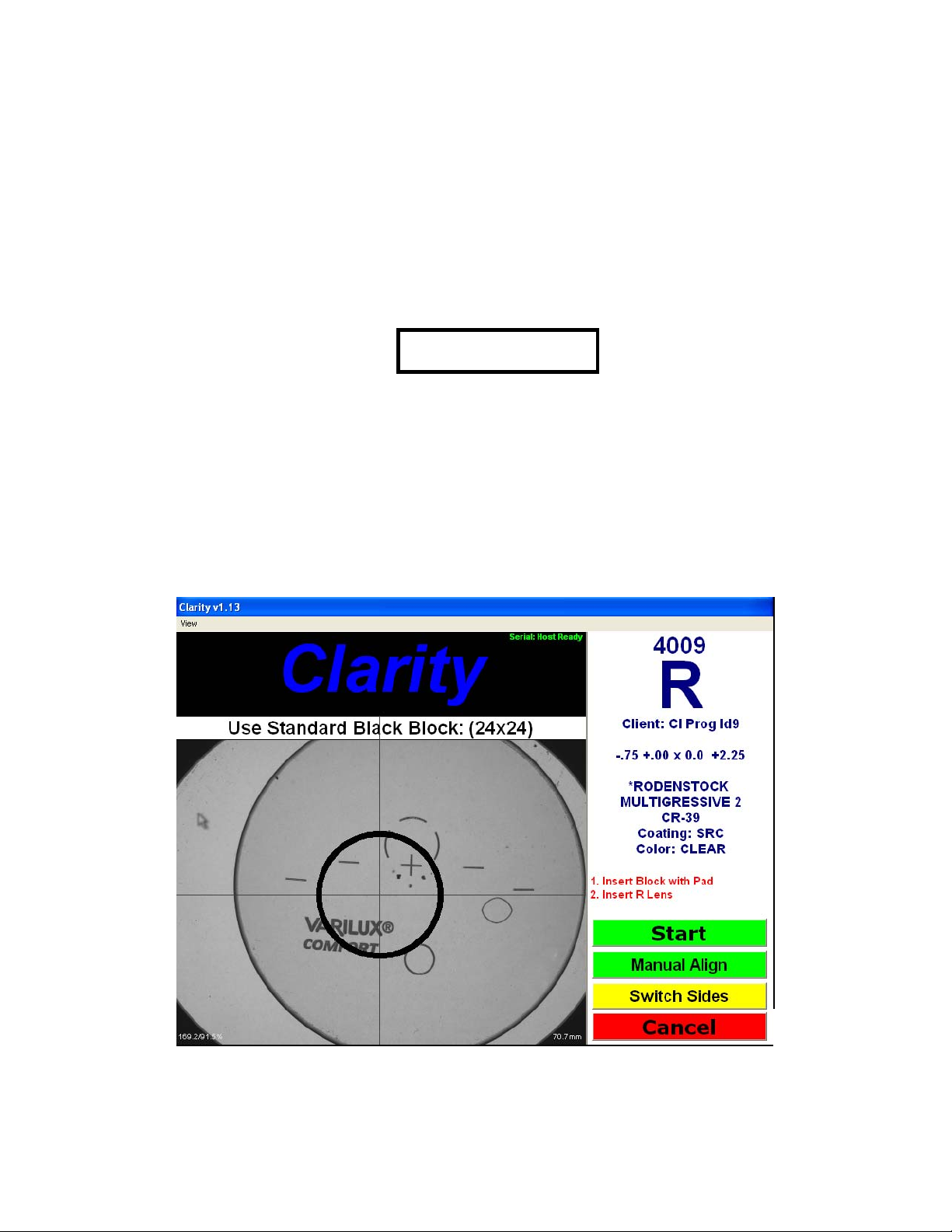

From the Job Screen, press the PROCESS control button to gain access to the Processing

Screen (Figure 2.2).

Figure 2.2 - Processing Screen

When the screen is first displayed, only two control buttons are shown in the lower right:

Switch Sides – Change displayed eye to the opposite side. OD is displayed initially.

Cancel – Return to Job Screen.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 15

Page 16

As instructed by the screen prompts, load a block and pad onto the blocking arm chuck and place the

lens to be blocked on the glass plate in the blocking chamber. The Clarity automatically detects that a

lens has been loaded and displays two additional control buttons at the lower right:

START – Initiate the lens analysis/verification and blocking process.

Manual Alignment – Perform the lens alignment manually prior to blocking.

Select START to identify features of the lens and perform lens analysis.

The Manual Alignment button can be used instead of the Start button when a progressive is

known not to align properly. You can choose Manual Alignment and not have to wait for

analysis to proceed.

The Analysis Screen

The Analysis screen will appear and show the prescribed Rx information on the left side of

the screen and the measured information on the right side of the screen. Once the analysis is

complete, the measured information will be checked against the prescription to determine if

the lens meets ANSI standards. If the lens does not meet the tolerances, the individual

parameter(s) that are out of tolerance will be displayed in red. Those that fall within the

standards will display in black. (See Fig. 2.3.)

Figure 2.3 – Analysis Screen

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 16

Page 17

After the lens has been analyzed, the bottom of the screen will display eight buttons and five

arrows. (See Fig. 2.3.) The eight buttons are:

1. Turn Off – Exit the program and shut the power off.

2. Setup – Access the main Setup screen with tabs at the top of the screen for other setup

options.

3. Teach – “Teach” the Clarity how to analyze a problem lens. Described later in this

chapter.

4. Manual Alignment - Use this button whenever the camera misaligns a lens after

analysis. Proper alignment may be drawn on the screen using a mouse.

5. Block – Activate the blocking sequence. Typically this is the most used button after

the lens is analyzed. (See Figure 3.2 for automatic blocking.)

6. Open – Open the lens clamps to remove the lens from the chamber.

7. Recheck – Recheck the lens that is in the chamber.

8. Next – Exit the Analysis screen and return to the Process screen to enter a new job

number.

The arrows have two functions:

1. The lowest arrow that has either an R or an L in it allows you to switch to the other

eye for the job you are blocking on screen.

2. The four arrows (up, down, in, and out) allow you to change the block position in case

of cutout issues for the frame.

Once you have blocked the lens, the screen will prompt you to remove lens. The display will

then change to the left lens, or if this was the left lens, then it will return to the Process screen

to start the next job.

NOTE

If the information about the lens coming from the host program is inaccurate on any of

the following items, then the power measured could be inaccurate and out of tolerance.

1. Front Curve

2. Back Curve

3. Lens center thickness

4. Lens diameter

If you see power problems, check data coming from the host for that particular lens.

The Teach Function -- In some cases, the Clarity is unable to recognize the fitting cross on

progressive lenses. When this occurs, the user may use the teach function to “draw” the

fitting cross on the screen to “teach” the Clarity what it looks like. The teach function is

accessed from the Analysis screen via a button at the bottom of the screen. A mouse and

keyboard should be attached to the Clarity to effectively use the teach function. Upon pressing

the Teach button, a screen similar to that shown in Figure 2.4 will appear.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 17

Page 18

Figure 2.4 – The Teach Screen

At the lower left of the screen, there may appear one or more images that the Clarity has

identified as candidates for the fitting cross. If one of these matches the actual fitting cross

and is on axis, left-click the image; it will move to the Image Box at the left top of the screen.

NOTE

Do not select a candidate image from the lower-left unless if is aligned. In Figure 2.4,

the image is not aligned so should not have been copied to the Image Box at upper left.

If there is no suitable candidate image at the lower-left, two alternatives re main for creating

an image:

1. Use the image cleanup tools and the mouse to draw an image in the image box. The

width of drawn pixels may be selected by clicking on one of the tool-width squares.

Select the black draw color to actually draw, and the white draw color to clear or

erase.

2. Click the Feature From Camera control. A screen shot of the lens will appear.

Rotate the lens if necessary to align it. Then use the mouse to draw a rectangle around

the fitting cross. The pixels enclosed in the rectangle will be copied to the Image Box.

The rectangle should be as small as possible but still include the complete image of the

fitting cross.

Once an image has been acquired (from among the candidates, or drawn, or copied from the

camera image) it may need to be “cleaned up” by removing stray pixels or adding pixels to fill

gaps. Use the Image Cleanup tools for this purpose. (Cleanup is especially important for

camera captures.) The result should be a clean image that nearly spans the width and height of

the Image Box.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 18

Page 19

The image should be saved in the Clarity database. Images in the database are listed in the

upper-right of the Teach screen. Each image has a unique name that may be derived from the

lens type name, or entered via a keyboard. The first character of each name in the database

must be either a “+” or “ T ” to indicate whether the image is a cross or T-shape. T-shapes

may be upright or inverted. Once the name has been assigned, use the SAVE control to make

the database entry.

NOTE

The teach function cannot be used with fitting crosses that include gaps (white space).

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 19

Page 20

(This page intentionally left blank for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 20

Page 21

Chapter 3 – Setup Screens

Figure 3.1 – Main Menu Screen

The Setup screens are accessed by pressing the Setup button at the lower left of the Main

Menu screen. (See figure 3.1.) Specific setup functions are selected by using the tabs across

the top of the Setup screen. The tabs are:

Preferences

Tolerances

Interface

Blocking

Calibration

Advanced

Technician

Statistics

The screens associated with each tab are shown below. The meanings of most of the setup

options should be apparent to the operator. The descriptions provided in this chapter only

include highlights of features that may not be obvious. Complete guidance on using all of the

Setup screens may be obtained by phoning the Technical Support group.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 21

Page 22

The Preferences Screen

Figure 3.2 - Preferences Screen

Key Features of the Preferences Screen

Batch Blocking: If enabled, the user may enter a series of job numbers. As each job

completes, the next job is automatically started. Use the check boxes to specify the order in

which the jobs are processed.

Auto Blocking Mode: In auto-blocking mode, the Clarity will block a lens that has been

successfully analyzed without operator intervention. Use the check boxes to select which

types of lenses may be auto blocked.

Add Verification: Many labs find it unnecessary to verify the add power once the distance

Rx has been verified. Leaving the boxes unchecked will reduce analysis time and improve

system throughput.

User Interface: Select either or both of these somewhat advanced features if desired. They

are most useful in processing “difficult” lenses in which the Clarity may not be able to find

alignment marks or the fitting cross.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 22

Page 23

Tolerances Screen

Figure 3.3 – Tolerances Screen

The values on this screen indicate how closely a measured lens characteristic must match the

Rx in order for the verification to pass. The values are preset prior to shipment to ANSI

standards. You can customize the tolerances by selecting Custom and then changing any or

all of the parameters using the touch screen keypad. (If you switch to Custom and make any

changes to any or all of the tolerances, you can easily return to the ANSI standards by

selecting ANSI.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 23

Page 24

The Interface Screen

Figure 3.4 – Interface Screen

Key Features of the Interface Screen - This screen allows you to set the serial

communication baud rate for the port used. It also allows for the use of Ethernet, which

includes UDP and TCP/IP port setup.

Display of Communication Events on the Main Menu – Check this box to view

communication events on the Main Menu screen.

Hide Patient Name Received From Host for Privacy – If this box is checked, the patient’s

name will not be shown during processing.

Run 30 Second Loopback Test – Check this box to run a loopback test on the serial port.

This test verifies that the port can send and receive data. You must insert a loopback plug in

the port to perform this test. Press the test button. In the box below the button, you will see a

string of letters and numbers if the port is working. You will not see any characters in the box

if the port is not functioning.

Communications Log – This button is a diagnostic tool that may be used by Technical

Support.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 24

Page 25

NOTE

Communication Events include packet requests, download a job, received packet,

timeouts, etc. If you place a checkmark in the box under Communications Display, you

will see communication errors on the screen. This can be a useful diagnostic tool.

The Blocking Screen

Figure 3.5 – Blocking Screen

Key Features of the Blocking Screen

Standard Finish Block Size, Small Finish Block Size (Half Eye), Extra Small Block Size

– Enter the dimensions for the finishing blocks used in your lab. Use the dropdown menu to

enter the color of each block.

PD, Seg Height, Axis – Enter values to correct any observed offset in these parameters across

all jobs.

Block Size Safety Margin – Specifies tolerance to ensure that the correct block size is used

under close tolerances between block B-size and frame B-size.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 25

Page 26

Blocker Arm Load Position - Values are used to position the blocker arm so that it does not

collide with the slot in the case top.

The Calibration Screen

Figure 3.6 – Calibration Screen

This screen contains the calibration values obtained in performing the five calibrations

necessary for best performance of the Clarity:

Preliminary Camera Focus (described in the Technician Screen)

Camera Calibration

Screen Calibration

Block Position Offsets Calibration

Power and Prism Calibration

The preliminary camera focus calibration is performed via the Technician screen. The other

calibrations are described in Chapter 4: Calibration.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 26

Page 27

The Advanced Screen

Figure 3.7 – Advanced Screen

This screen is discussed in detail in the last chapter of this guide. Please call Technical

Support before making any changes to this screen.

Key Features of the Advanced Screen

Home - To return all of the axes to their home position, press this button.

Burn In - Is used to exercise the axes, especially when the machine is cold.

Distance, Near and Prism Power Checks – Specifies both the number of power checks and

the number of power targets. Higher values improve accuracy but take longer. The Clarity is

set at the factory for the combination that provides optimum function balancing speed and

accuracy.

Other features:

• Update Software (Install new versions of software.)

• Set Date and Time

• Restore Data (If a backup was made, which is recommended.)

• Backup Data (Copy setup data to a USB thumb drive.)

• Import Lens Data (Used to import finished lens data for accurate power reading of stock

finished lenses.)

• Save Tech Data Save screen images of all the Setup screen tabs.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 27

Page 28

There are two other buttons that will allow you to check and save job log data for analysis of

VC labels:

• View Log

• Copy Logs to Flash Drive

To copy or look at the log, you must have the Activate Job Log Data box checked. This

screen also includes a box to allow the machine to boot up completely past Windows and

open into the Clarity software. There is a Brightness Image Level that is set at the factory to

185. There is also a box called Display Options. These parameters should only be changed

with input from Technical Support. Advanced screen functions are discussed in detail in

Chapter 5.

The Technician Screen

Figure 3.8 – Technician Screen

When you select the Technician tab, a number keypad appears. Enter the password (082379)

to allow entry into the screen. This screen contains a wide variety of features that will be

useful in diagnostics. Contact Technical Support before making any changes to this screen.

This screen also contains a Focus Camera button that is used as a preliminary calibration of

the camera focus to optimize the camera's ability to recognize clearly the edge of the lens.

This, in turn, optimizes diameter checks and affects power readings.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 28

Page 29

The Statistics Screen

Figure 3.9 - Statistics Screen

The box labeled Job Count shows the number of Single Vision, Bifocals, Trifocals and

Progressives that have been processed. There is a CLEAR button that will reset the counter

for all of the lens types.

The area labeled Stepper Motor Cycle Count has four boxes for the four motors the Clarity

uses. The X, Y and Z Axis Motors and the Block Axis Motor each have their own CLEAR

button so that you can keep track of the individual motor counts and clear the data when a

motor is replaced.

In the upper-left and center of the screen are a number of indicators related to LCD operation

and showing axis home switch status.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 29

Page 30

(This page left blank intentionally for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 30

Page 31

Chapter 4 – Calibration

Figure 4.1 – Calibration Screen

A full calibration of the Clarity involves the following five steps:

Step 1: Preliminary Camera Focus: This step is performed from the Technician screen.

There you will find a button labeled Camera Focus. Select this button and follow the

instructions on the right side of the screen. This calibration will require the use of the 58mm

round pattern found in the accessory kit.

Step 2: Camera - This calibration sets the Brightness, Shutter and Gain of the camera.

Select the Calibrate button and a box will appear that is titled Remove Lens. Select OK and

in a couple of seconds another box will appear that will say The camera calibration is

completed. Select OK to complete this step.

Step 3: Screen Calibration – This calibration requires the use of the 58mm round pattern

found in the accessory kit. (See Fig. 1.4) Select the Calibrate button and a box will appear

titled Graphics Scale Calibration. It prompts you to put the 58mm round pattern in the

chamber and select OK. Within a couple of seconds another box will appear with the same

title saying that the screen graphics have been calibrated. Select OK to complete this step.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 31

Page 32

Step 4: Block Position Offsets – The oval calibration template with a Vario block

permanently mounted and the 70mm plano CR39 lens are required for this calibration. This

process places the oval calibration template on the plano lens and takes a snapshot of the

position eight separate times to complete this operation. This will set the horizontal, vertical

and axis position. Select the Calibrate button and, after a few seconds, you will be

prompted to clean the glass plate and make sure no lens is in the chamber. (See Fig. 1.5.)

NOTE

Clean the glass plate using an A/R microfiber cleaning cloth. The glass plate is

removable and it may be necessary to clean the lower LCD under the glass plate. Refer

to the Maintenance chapter for details.

Select OK and the screen will change to the Block Position and Axis Calibration screen.

Select the Calibrate button and the first of eight boxes will appear. The box will direct you

through the operation.

1. Place the plano 70 mm lens (found in the accessory kit) in the blocking chamber.

2. Place a blocking pad on the alignment block. (See Fig. 4.2) The pad must have a hole

in the center to allow the camera to see through the hole on the center of the finishing

block.

3. Mount the alignment block on the blocking arm.

4. Select OK.

At this time, the machine will place the block on the lens and analyze the data to set the 0, 0

Coordinate Origin position (See Glossary) for X and Y and also set the axis. This calibration

will ask you to perform 1-4 above eight separate times. The software rotates the block 45

degrees each cycle.

Follow the on-screen direction until the calibration is complete. At the end of this calibration

three numbers will appear in the box for:

1. Horizontal offset (X)

2. Vertical offset (Y)

3. Axis (A)

NOTE

Look closely as the block is being placed on the lens. If you believe each of the eight steps were

completed with no block slippage or any irregular motion, then select OK to accept the new

offsets and continue to the power calibration. If you feel that any of the eight steps were

compromised, select Cancel and start the process over.

Step 5: Power Calibration – This calibration requires the use of the 70mm CR39 -6.00 and

the 65mm CR39 +6.00 lenses found in the accessory kit. This process will set the power

throughout the range of powers this device is able to verify.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 32

Page 33

On the Calibration screen under Step 4 (See Fig. 4.1), there are six parameters that describe

the lens that will be analyzed:

1. Diameter

2. Index of Refraction

3. Power

4. Front Curve

5. Back Curve

6. Center Thickness

These parameters are for both the plus and the minus lenses.

NOTE

If these lenses are misplaced or compromised in any way, please call the factory and

order a new calibration lens. Once the new lens arrives, check these parameters and

make any necessary changes.

To perform this calibration, select the Calibrate button. You will be prompted to remove the

lens. Make sure there is no lens in the chamber and select OK. After 25 seconds, you will be

prompted to insert the calibration lens. Put the -6.00 lens in the chamber and select OK. The

Clarity will analyze the lens and will instruct you to place the +6.00 lens in the chamber.

Select OK.

After both lenses are analyzed, the plus and minus slope adjustments will be displayed. Select

YES to accept these changes. The calibration wizard will appear telling you that the power

calibration is complete. Select OK. To exit back to the Job screen, select OK at the bottom

of the screen and then on the next screen select Next.

NOTE

On this screen, there is also a Power Offset box. This can be used if you see a consistent

power error. For example, powers are showing 0.25 weak across the board. Enter a

+.25 and all analyzed powers will have 0.25 added to the final reading. This functions

like the manual eyepiece adjustment for power on a conventional lensometer.

This screen includes two parameters labeled Minus Prism Bias and Plus Prism Bias.

They are constants and should not be changed unless directed by the factory.

To verify power calibration, there is an internal job (Job Number 999999999) which will

allow you to use the two calibration lenses (+6 and -6). From the main Job screen enter the

Job Number 999999999 and follow the directions. Each lens will show the measured power

in the upper right hand corner of the screen. If they are within acceptable limits, you can

move on. If they are out of tolerance, recalibrate.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 33

Page 34

Touch Screen Calibration

Fig 4.2 Touch Screen Calibration Screen

Touch Screen Calibration – In the upper right corner of the calibration screen there is a box

titled Touch Screen Calibration.

NOTE

This calibration is done at the factory and does not need to be done on a regular basis,

only if the touch screen fails.

Select the box labeled Touch Screen Calibration. After a second, the touch target will move

and a new screen will appear. In the center of the screen it will read Press the blinking X

symbol until stop blinking.

• In the lower left corner of the screen a blinking X will appear and there will be a

yellow to blue progress bar at the bottom of the screen.

• Hold your finger over the blinking X.

• When the X stops blinking, remove your finger and the X will move to the lower right

hand corner.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 34

Page 35

• Hold your finger over the blinking X and when it stops blinking, remove your finger

and the X will move to the upper right hand corner.

• Hold your finger over the blinking X and when it stops blinking, remove your finger

and the X will move to the upper left hand corner.

• Hold your finger over the blinking X and when it stops blinking, remove your finger.

• The screen will then change to a blank screen with a progress bar box in the center.

• When the progress bar fills completely, the screen will return to the Calibration tab in

the setup.

To exit back to the Job screen, select OK at the bottom of the screen and then on the next

screen select Next.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 35

Page 36

(This page intentionally left blank for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 36

Page 37

Chapter 5

– The Advanced Screen in the Setup Menu

Figure 5.1 - Advanced Screen

The Advanced screen has software adjustments for power, lens edge detection, lens diameter,

prism, brightness of the camera image, as well as updating software and data import, restore

and backup.

To enter the Advanced screen from the Job screen select Exit. When the next screen

appears, select Setup. In the Setup screen select the Advanced tab.

These parameters are set at the factory to achieve a balance between speed and accuracy.

Note that different values may be set for single vision and other lenses.

Distance Power:

1. Number of Power Checks – How many times the Clarity will analyze the power.

2. Number of Power Targets – There are several different sized power targets that the

Clarity uses to determine the power in different areas of the lens.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 37

Page 38

Near Power:

1. Number of Power Checks – How many times the Clarity will analyze the power.

2. Number of Power Targets – There are several different sized power targets that the

Clarity uses to determine the power in different areas of the lens.

Prism Power:

Number of Power Checks – The number of times the software analyzes prism.

Lens Feature Detection:

This box contains thresholds for accurate diameter measurement and identifying ink

dots for progressives.

1. Edge Detection Threshold (10-40) -- Generally this number will be between 15 and

25. This parameter allows maximum sensitivity in detecting and measuring the

diameter of a lens. It is a critical component of calculating power.

2. Minimum and Maximum Ink Dot Diameters -- These two parameters relate to the

minimum and maximum size of progressive ink dots put on after A/R coating prior to

edging. The camera identifies features like these dots for proper lens alignment prior

to blocking.

Auto-Run at Windows Startup:

This box will be checked as a default at the factory. The machine will boot up to the

main job screen of the Clarity software. If the box is unchecked, the Clarity will boot

up to the Windows Desktop screen.

Warm-Up Time:

A non-zero value causes a burn-in cycle upon power-up. This may improve accuracy

in situations where overnight lab temperature is low.

Image:

Brightness Level – This is the brightness level of the camera image. 185 is the

factory setting. Call Technical Support before changing this parameter.

Display Options:

1. Briefly Display Filtered Lens Image During Operation – Check this box if you

want to see a quick image of the lens during processing. This can be used as a

diagnostic tool to see what the camera is picking up.

2. Display Detected Pixels in Red – Check this box if you want to see the pixel that the

camera is going to use displayed in red.

3. Seconds to Display – This feature should be set to 0 during normal operation, just to

get a glimpse of the image. A service technician may change this to two seconds for

diagnostic purposes.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 38

Page 39

Setup Password:

The Setup Password is set at the factory to 082379. This feature allows you to

change the password if you choose. If you forget the password, call Technical

Support.

Job Data Log:

Activate Job Data Log – Place a check in this box if you would like to begin

maintaining a job log.

View Log – Select this button if you would like to view the log. (The log must have

been previously activated.) This can be useful in diagnosing issues.

View Blocked Job Log – Select this button if you want to view only those jobs that

were successfully blocked.

There are six buttons in the upper center of this screen (See Fig. 5.1):

1. Update Software - Select this button to download new software versions. Follow the

on-screen instructions to complete the update.

2. Set Date/Time – Use this function to set the time if you are not in the eastern U.S.A.

time zone. The date and U.S. Eastern Time are entered at the factory.

3. Restore – If you have made a backup of the system data, you can restore the data if

need be.

4. Backup – Follow the on-screen instruction to back up the system data onto a USB

thumb drive.

5. Import Lens Data – This function can be used when periodic updates are available to

update and import new lens data. This is finished lens data that the Clarity uses to

verify power.

6. Save Tech Data – This function causes all of the Setup screens to be saved. Saved

screen images may be useful for error recovery.

NOTE

We recommend backing up your system prior to and immediately after making any

significant changes in the Setup Menu. The USB thumb drive needs to be 256 megabyte

or higher.

Burn In:

In the lower left corner of the screen there is a Burn In button. This button is used to exercise

a cold machine or to diagnose axis movement issues. A box will appear with a default number

of cycles set for operation. You can change this number or accept it and select OK. Select the

Stop button to abort the burn in cycles.

Home:

This button causes the axes to move to their home positions. The Home function is also

available from the Technician screen.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 39

Page 40

(This screen intentionally left blank for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 40

Page 41

Chapter 6 – Maintenance

NOTE

Always unplug unit before performing any maintenance.

Cleaning the Glass Plate:

Lift the glass plate out (See Fig. 1.5) and clean it using a microfiber cloth as used in cleaning

A/R coated lenses. You can also clean the glass plate with glass cleaner or warm soapy water

and a clean water rinse. Make sure that the plate is completely dry before replacing into the

chamber. Replace the glass plate and resume using the Clarity.

Cleaning the LCD:

Remove the glass plate (See Fig. 1.5) and reach down into the opening that the glass plate

covered. Using a microfiber cloth, clean the LCD gently and thoroughly.

Cleaning the Touch Screen:

The touch screen can be cleaned using a microfiber cloth. Wipe the screen gently until

fingerprints and smudges are eliminated.

Replacement of the Main Fuse Located on the Rear Bulkhead (Fig. 1.3):

Using a flat head screw driver, insert it into the slot on the cover and push in while rotating to

remove the cover/holder. Remove the bad fuse and replace it with the proper 250v 5amp 5x20

mm slow blow fuse. Re-install the fuse holder using the flat head screwdriver to push in and

rotate to lock in place.

Maintenance Tips

• Do not attempt to lubricate any part of the mechanism except under supervision of

factory service personnel.

• Do not interfere with the motion of the lens grippers or the blocking mechanism.

• Operate the equipment in an environment free from dust or debris.

• Use the burn-in function to warm the machine if its temperature is estimated to be 5

• Do not ship the equipment unless you have re-installed the factory shipping restraints

o

or 9

F below the final stable operating temperature.

and foam packing-box inserts.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 41

o

C

Page 42

(This page left blank intentionally for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 42

Page 43

INTENDED USE & LIMITATIONS

• This machine is designed to measure power, axis and prism of ophthalmic lenses of all

materials, and to place a block on axis at the geometric center of the frame shape in a

commercial laboratory environment. For operational and safety reasons, this machine

should only be used with parts supplied by the manufacturer listed in the Technical

Specifications section of this manual. Any use of this machine in a manner not

specified in this manual may unintentionally bypass machine safeguards.

• This unit is capable of inspection and blocking of all materials in single vision,

bifocals, trifocals, progressives and polarized lenses. It cannot process round segs,

ultex or curve tops.

• It cannot do automatic alignment of single vision lenses with prescribed prism;

although, it can process them manually if the lensometer dots are present and the

Setup menu on the Preferences tab has Look For Lensometer Dots checked.

• For best analysis results, insert the lens into the inspection chamber at a 45-degree

angle.

• If alignment or power checks fail, rotate the lens 5 degrees and recheck.

• Single vision polarized lenses must be placed in the chamber with the polarization

within +/- 10 degrees to eliminate the image being blacked out due to the polarization

being off axis too far.

• When straight top or progressive polarized lenses are inserted into the chamber close

to the 180 +/- 10 degrees and the image is blacked out, then the polarization is off axis

from the lens manufacturer. (This is a rare occurrence.)

• On progressive lenses with factory ink marks, if the markings are worn or broken, the

chance of misalignment increases. Remove all factory markings and dot the two

watermarks on the lens with the white marking pen provided in the accessory box.

This will also decrease the cycle time.

• Progressives with no markings visible cannot be processed. There must be either

factory markings or white dots on the watermarks. If the factory markings are used,

there must be a clearly marked fitting cross.

• Progressive add power accuracy is inconsistent. They will still be aligned and

blocked accurately.

• Progressive cylinder axis on powers < 1.00 diopter can be inconsistent depending on

the design of the lens. They will still be aligned and blocked accurately.

• Cylinder axis accuracy on 0.25 cylinder and below for single vision lenses is not

guaranteed to block within ANSI.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 43

Page 44

• Manual alignment of lenticular and occupational lenses is recommended.

Occupationals could be aligned upside down in automatic mode.

• In the case of extreme prism >6 diopters, the prism accuracy is good, but the lens may

be tilted to such a degree that cylinder accuracy decreases and spheres may show some

cylinder. This can be eliminated by holding the lens so that the front curve is parallel

to the glass plate when you insert it into the chamber and then select START and let

the clamps close on the lens in that position. It will then process normally.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 44

Page 45

GLOSSARY OF TERMS

Batch Blocking: Method of entering jobs. For example, with a stack of ten or more trays,

you can enter or scan all jobs in succession and then start to process them either by first in/

first out or last in/ first out.

Blocking Chamber: Where the lens is placed for analysis and blocking. Four grippers will

center and hold the lens in place until the blocking is complete.

Coordinate Origin: Position 0,0 for X and Y; it is the starting point for the placement of the

finished block on the lens.

Edge Detection Threshold: Refers to the sensitivity of the camera image to detect the edge

of a lens for diameter measurement. This is found on the Technician screen and is generally

numbered between 15 and 20.

Grippers: Four paddles that clamp and center the lens in the blocking chamber once Start is

selected.

Gain: Intensity of the brightness of the camera.

Glass Plate: Found in the accessory kit during shipping; it covers the opening in the blocking

chamber.

LCD: Stands for Liquid Crystal Display. It is found under the glass plate in the blocking

chamber.

Measured: On the Analysis screen (on the right side of the screen), the measured results of

the lens being analyzed and compared to the Tolerances screen for accuracy (generally

ANSI).

Oval Calibration Template: This is a pattern attached to a Vario block found in the

accessory kit. It is used to calibrate the block position and axis of the chuck.

Power Checks: The number of times the camera will take a shot and be analyzed.

Power Offset: In the Calibration screen; used if a consistent power error occurs. For

example, all minus lenses are coming out .25 diopters weak so you would put a +.25

adjustment in this field.

Power Targets: The number of different sized targets that will be used in the analysis.

Prescribed: The prescription as written by the optician – sent from the retail location to the

lab.

Red Circle Superimposed on the Lens on the Analysis Screen: This is the position of the

block on the lens and is the geometric center of the frame shape.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 45

Page 46

Shutter: Length of time of the exposure of the camera.

Slope: For both plus and minus powered lenses. These fields in the Calibration screen are a

linear correction for the range of powers the Clarity can check.

NOTE

Call Technical Support before making any changes to the Technician screen.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 46

Page 47

Appendix A - General Specifications

Machine Identification

Clarity

Ophthalmic Lens Analyzer and Finish Blocker

Name and Address of Manufacturer

National Optronics

100 Avon Street

Charlottesville, VA 22902 USA

Name and Address of Manufacturer’s Representative for Service

National Optronics

100 Avon Street

Charlottesville, VA 22902 USA

434-295-9126

External Connections

Electric Power Supply

USB Data Connectors (2: Data Backup/Restore and USB Barcode Reader)

9-Pin Subminiature D-Connectors (2: DCS Serial Communications)

RJ-45 Ethernet Connector (DCS Ethernet Communications)

PS-2 Connectors (2: Keyboard and Mouse)

Manufacturer’s Serial Number Plate Information

A facsimile of the Manufactuer’s Serial Number Plate appears below. The characters “XXXX” will

be replaced by four digits on an actual plate.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 47

Page 48

Technical Specifications

External Power Supply: Input: 100-240 V ~ 50 – 60 Hz 2A

Output: +12 V DC 12.5 A

150 watts maximum

Clarity Power Requirements: Input +12 V DC 5A

Temperature: Operating 60°F to 90°F (10°C – 32.2°C)

Storage 20°F to 110°F (-6.7°C – 43.3°C)

Fuse Specifications: 5 x 20mm, 5.0 Amp, Slow Blow

Relative Humidity: 50% - 90% (non-condensing)

Altitude: 0 ft to 6000 ft (0m to 1829m)

Pollution Degree: 2

Weight: 45.35 lbs. (20.57 kg)

Height: 23.5” (596.90mm)

Width: 10.4” (264.16mm)

Manufacturer: National Optronics

Charlottesville, Virginia USA

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 48

Page 49

Appendix B

- Certifications & Standards

FCC Class A Device Compliance [Testing in Progress]

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 49

Page 50

(This page left blank intentionally for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 50

Page 51

Appendix C - Electrical Diagram

[To be supplied.]

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 51

Page 52

(This screen intentionally left blank for duplexing purposes.)

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 52

Page 53

Appendix D - Certificate of Compliance

Note

The following Declaration of Conformity shall not be regarded as operative unless it is included in a

released (non-draft) version of this manual. In draft versions, it is included for planning purposes only.

Clarity User Guide, March 1, 2011 - Rev. 1.06

Page 53

Loading...

Loading...