Page 1

Clarion Co., Ltd.

5-35-2, Hakusan, Bunkyouku, Tokyo, 112-8608 Japan

Service Dept.- 50 kamitoda,Toda-shi,Saitama,335-8511 Japan Tel: 048-443-1111 FAX:048-433-6996

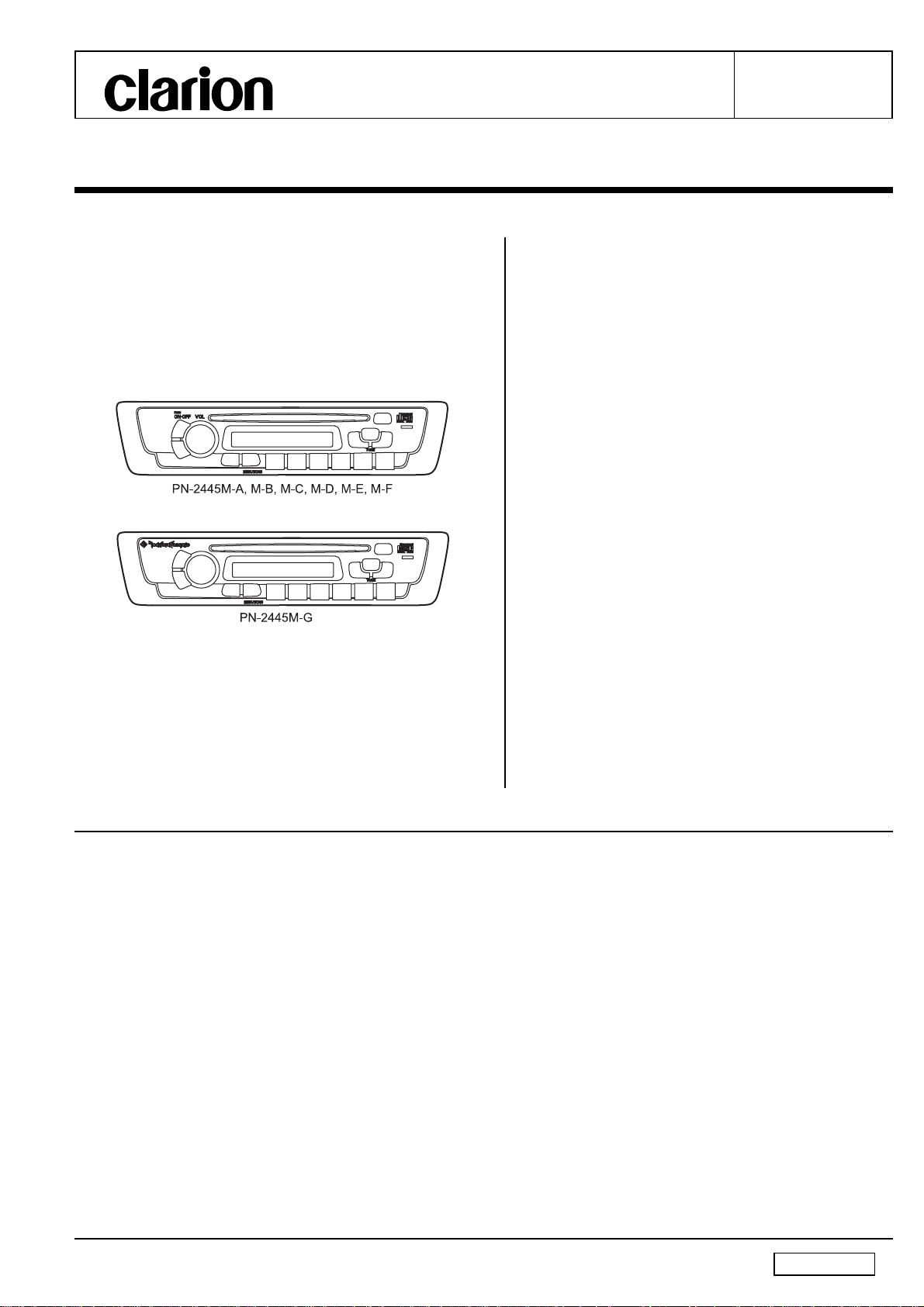

Service Manual

NISSAN Automobile Genuine

FM/AM Radio CD Stereo

Published by Service Dept.

298-5971-00

Printed in Japan

Mar.2002 P

Model

Model

Model

Model

Model

Model

Model

PN-2445M-A

(Genuine No.28185 4Z500/ID No.CY290)

PN-2445M-B

(Genuine No.28185 4Z510/ID No.CY300)

PN-2445M-C

(Genuine No.28185 4Z520/ID No.CY310)

PN-2445M-D

(Genuine No.28185 4Z400/ID No.CY260)

PN-2445M-E

(Genuine No.28185 4Z410/ID No.CY270)

PN-2445M-F

(Genuine No.28185 4Z420/ID No.CY280)

PN-2445M-G

(Genuine No.28185 4Z700/ID No.CY320)

■SPECIFICATIONS

Radio section

Tuning system: PLL frequency synthesizer system

Receive range: AM 530kHz to 1,710kHz

FM 87.75MHz to 107.9MHz

Intermediate frequency:

±3kHz

AM 450

FM 10.7

Quieting sensitivity: AM Less than 32dB

FM Less than 10dB

Separation: FM More than 22

S/N ratio: AM More than 45dB

FM More than 50dB

Auto tuning stop sensitivity:

AM 32

FM 25

(87.9/98.1/107.9MHz)

±0.3MHz

μ(at 20dB S/N)

μ(at 30dB S/N)

+5/−7dB(1kHz)

±6dBμ(600/1000/1400kHz)

±6dBμ

- 1 -

CD section

Disc: 12cm Disc

Separation: More than 50dB(Filter:20kHz LPF)

S/N ratio: More than 74dB

Distortion: Less than 0.4%

(Filter:20kHz LPF)

General

Load impedance: 4Ω/CH

Power output: 30W

Power supply voltage: DC13.2V(10.8V to 16.0V)

Back-up consumption: Less than 3mA

Dimensions(mm): 180(W)

Weight: 1.4kg

※ Specifications and design are subject to change without

notice for further improvement.

×4

Negative ground

×52(H)×159(D)

PN-2445M

Page 2

■COMPONENTS

PN-2445M-A/M-B/M-C/M-D/M-E/M-F/M-G

Main unit −−−−− 1

■NOTE

We cannot supply PWB with component parts in principle.

When a circuit on PWB has failure, please repair it by component parts base. Parts which are not mentioned in service manual are not supplied.

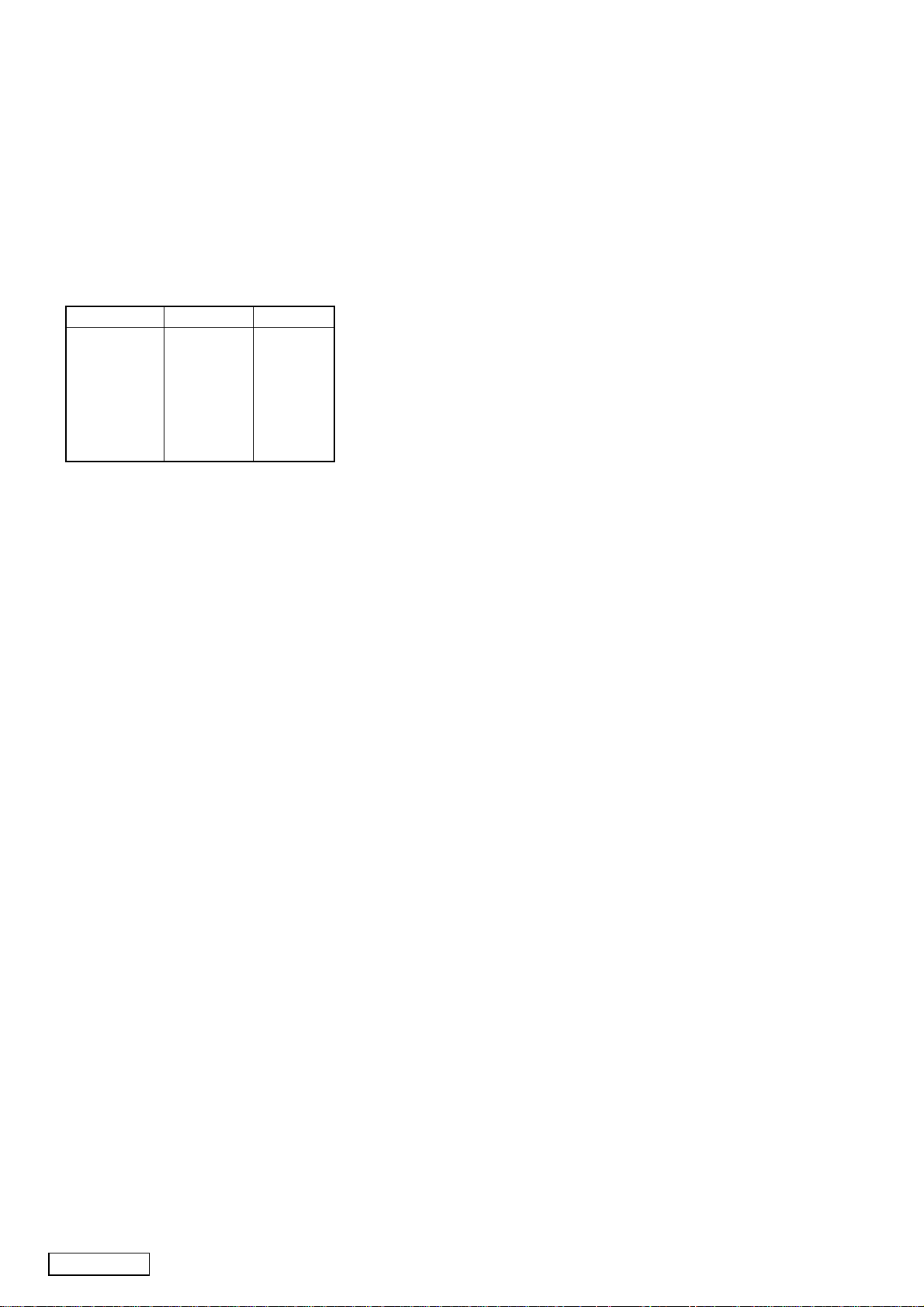

■DIFFERENCE FEATURE LIST

Esctcheon Equalizer

PN-2445M-A Black

PN-2445M-B Brown ○

PN-2445M-C Gray ○

PN-2445M-D Black ×

PN-2445M-E Brown ×

PN-2445M-F Gray ×

PN-2445M-G Black ○

○

■ To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow

the instructions so that customers and Engineers

in charge of repair or inspection can avoid suffering any risk or injury.

1. Use specified parts.

The system uses parts with special safety features against

fire and voltage. Use only parts with equivalent characteristics when replacing them.

The use of unspecified parts shall be regarded as remodeling for which we shall not be liable. The onus of

product liability (PL) shall not be our responsibility in cases

where an accident or failure is as a result of unspecified

parts being used.

2. Place the parts and wiring back in their original positions

after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding, gaps to PWB, etc, is involved. The wiring connection and routing to the PWB are specially planned

using clamps to keep away from heated and high voltage

parts. Ensure that they are placed back in their original

positions after repair or inspection.

If extended damage is caused due to negligence during

repair, the legal responsibility shall be with the repairing

company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely in their original position after repair. Ensure for

safety reasons there is no possibility of secondary

ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the

battery connected, a short circuit and/or fire may occur. If

extensive damage is caused due to negligence of repair,

the legal responsibility shall be with the repairing company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality

is observed in their appearance. Always replace them

with new ones. (The chip parts include resistors, capacitors, diodes, transistors, etc). The negative pole of tantalum capacitors is highly susceptible to heat, so use special care when replacing them and check the operation

afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270

apply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with

force.

7. Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

8. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through

the lens of the optical pickup. When checking that the

laser optical diode lights up, keep your eyes more than

30cms away from the lens. Prolonged viewing of the laser within 30cms may damage your eyesight.

9. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by

electrostatic charge caused by your clothes and body.

Make sure to avoid electrostatic charges on your clothes

or body, or discharge static electricity before handling the

optical pickup.

9-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage.

After replacement, open the shorted circuit. When

removing the pickup from the mechanism, short

the terminals by soldering them to prevent this

damage.

9-2. Actuator

The actuator has a powerful magnetic circuit. If a

magnetic material is put close to it. Its characteristics will change. Ensure that no foreign substances

enter through the ventilation slots in the cover.

9-3. Cleaning the lens

Dust on the optical lens affects performance. To

clean the lens, apply a small amount of isopropyl

alcohol to lens paper and wipe the lens gently.

℃. Take care not to

- 2 -PN-2445M

Page 3

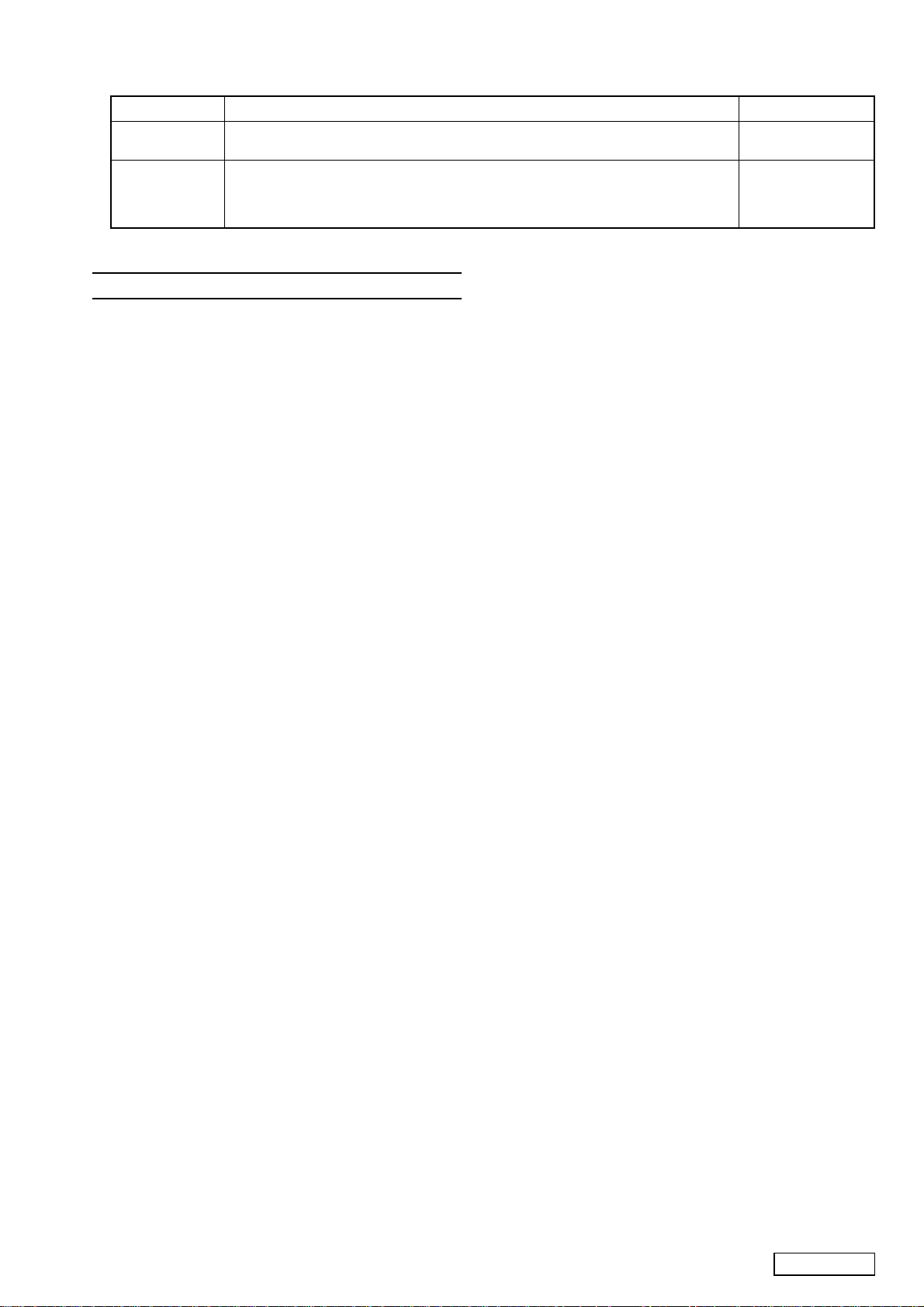

■ADJUSTMENT

Item Procedure

FM noise

convergence

Clock accuracy

1. Input the 98.1MHz/55dB

2. Adjust the outputs to

1. Turn off and on the ACC switch twice, while holding the buttons of power switch

μ(1kHz 30% MOD) signal.

−18±3dB by VR102 when the SG output is set to −20dBμ.

and CD eject to make the unit the test mode.

2. Set a universal timer to TP101(T-BASE), adjust TC201 so that a reading of the

meter is 0

±0.1 sec./day.

■EXPLANATION OF IC

052-1163-20 uPD178076GF-540-3BA CD & Radio System control

1.Terminal Description

pin 1: EJECT SW : IN : Eject switch ON signal input.

pin 2: NU : - : Not in use.

pin 3: NU : - : Not in use.

pin 4: VOL DATA : O : The serial data output to the volume IC.

pin 5: VOL CLK : O : The clock pulse output to the volume IC.

pin 6: VOL CE : O : The chip enable signal output to the vol-

pin 7: NU : - : Not in use.

pin 8: LCD DI : IN : The srial data input from the LCD driver.

pin 9: LCD DO : O : The srial data output to the LCD driver.

pin 10: LCD CLK : O : The clock pulse output to the LCD driv-

pin 11: LCD CE : O : The chip enable signal output to the LCD

pin 12: NU : - : Not in use.

pin 13: POWER SW :IN: Power switch ON signal input.

pin 14: VOL 1 : IN: Volume control pulse input from the rota-

pin 15: VOL 2 : IN: Volume control pulse input from the rota-

pin 16: ILL : IN : Illumination ON signal input.

pin 17: NU : - : Not in use.

pin 18: NU : - : Not in use.

pin 19: NU : - : Not in use.

pin 20: NU : - : Not in use.

pin 21: NU : - : Not in use.

pin 22: NU : - : Not in use.

pin 23: NU : - : Not in use.

pin 24: NU : - : Not in use.

pin 25: NU : - : Not in use.

pin 26: NU : - : Not in use.

pin 27: A VDD : - : Positive supply voltage for the Analog sec-

pin 28: NU : - : Not in use.

pin 29: NU : - : Not in use.

pin 30: NU : - : Not in use.

pin 31: NU : - : Not in use.

pin 32: A VSS : - : Analog ground.

pin 33: REG CPU : IN : The capacitor connection terminal to sup-

pin 34: VDD : - : Positive supply voltage.

pin 35: REG OSC :IN : The capacitor connection terminal to sup-

pin 36: X 2 : - : Crystal connection.

pin 37: X 1 : - : Crystal connection.

pin 38 : GND : - : Ground.

pin 39: NU : - : Not in use.

pin 40 : GND : - : Ground.

pin 41: AM IF :IN : Input terminal of the internal universal

pin 42: FM IF : IN: Input terminal of the internal universal

pin 43: VDD PLL : - : Positive supply voltage for the PLL.

pin 44: FM OSC : IN : Input terminal of the internal counter for

pin 45: AM OSC : IN: Input terminal of the internal counter for

pin 46: GND PLL : - : Ground for the PLL.

pin 47: Voltage Tune : O : PLL error output.

ume IC.

er.

driver.

ry encoder.

ry encoder.

tion.

press the ripple.

press the ripple.

counter for AM IF.

counter for FM IF.

FM OSC( Local Oscillation ).

AM OSC( Local Oscillation ).

Measuring

instrument

SSG

AC volt meter

Chronometer

pin 48: NU : - : Not in use.

pin 49: IC : IN : Connected to the ground.

pin 50: RESET :IN : Reset signal input.

pin 51: NU : - : Not in use.

pin 52: NU : - : Not in use.

pin 53: ST/TWEET :I/O: Outputs "L" at AM 900kHz receiving. In-

pin 54: CLK INT :IN: Without a clock = "H".

pin 55: AUX ON :IN: AUX ON signal input.

pin 56: TEST : - : For the Test.

pin 57: LCD ON : O : LCD back light ON signal output.

pin 58: NU : - : Not in use.

pin 59: BEEP : O : Beep out.

pin 60: NU : - : Not in use.

pin 61: NU : - : Not in use.

pin 62: CD RESET : O : The reset pulse output to the CD IC.

pin 63: NU : - : Not in use.

pin 64: AF MUTE : O : Audio frequency signal muting.

pin 65: NU : - : Not in use.

pin 66: FM ON : O : FM ON signal output.

pin 67: AM ON : O : AM ON signal output.

pin 68: CD ON : O : CD ON signal output.

pin 69: NU : - : Not in use.

pin 70: NU : - : Not in use.

pin 71: NU : - : Not in use.

pin 72: RF MUTE : O : Radio frequency signal muting.

pin 73: DX/LO : O : DX/Local select signal output.

pin 74: SYS ON : O : System ON signal output.

pin 75: AMP ON : O : Audio power amplifier ON signal output.

pin 76: COMBI ON : O : Combi ON signal output.

pin 77: NU : - : Not in use.

pin 78: ACC IN :IN : ACC detection signal intput.

pin 79: RADIO ON : O : Radio ON signal output.

pin 80: NU : - : Not in use.

pin 81: SBSY :IN : Sub code sync input.

pin 82 : GND : - : Ground.

pin 83: CD CONNECT : IN : CD connection check signal input.

pin 84: BUS 0 :I/O: CD IC Data input / output.

pin 85: BUS 1 :I/O: CD IC Data input / output.

pin 86: BUS 2 :I/O: CD IC Data input / output.

pin 87: BUS 3 :I/O: CD IC Data input / output.

pin 88: BUS CK : O : Clock pulse output to the CD IC.

pin 89: CCE : O : The chip enable signal output.

pin 90: GS1 TEST : O : Test data output.

pin 91: S STOP : IN : In side limit signal input.

pin 92: CHU SW :IN: CD disc chucking signal input.

pin 93: TR B : IN: Photo sensor signal input from the CD

pin 94: TR A : IN: Photo sensor signal input from the CD

pin 95: LD CONT :IN : Loading control signal input.

pin 96: LD MUTE : O : Muting signal output to the CD mecha-

pin 97: NU : - : Not in use.

pin 98: BAND SEL :IN : Band selection input.

pin 99: VDD : - : Positive supply voltage.

pin100: GND : - : Ground.

puts "L" at FM stereo receiving.

mechanism.

mechanism.

nism.

- 3 -

PN-2445M

Page 4

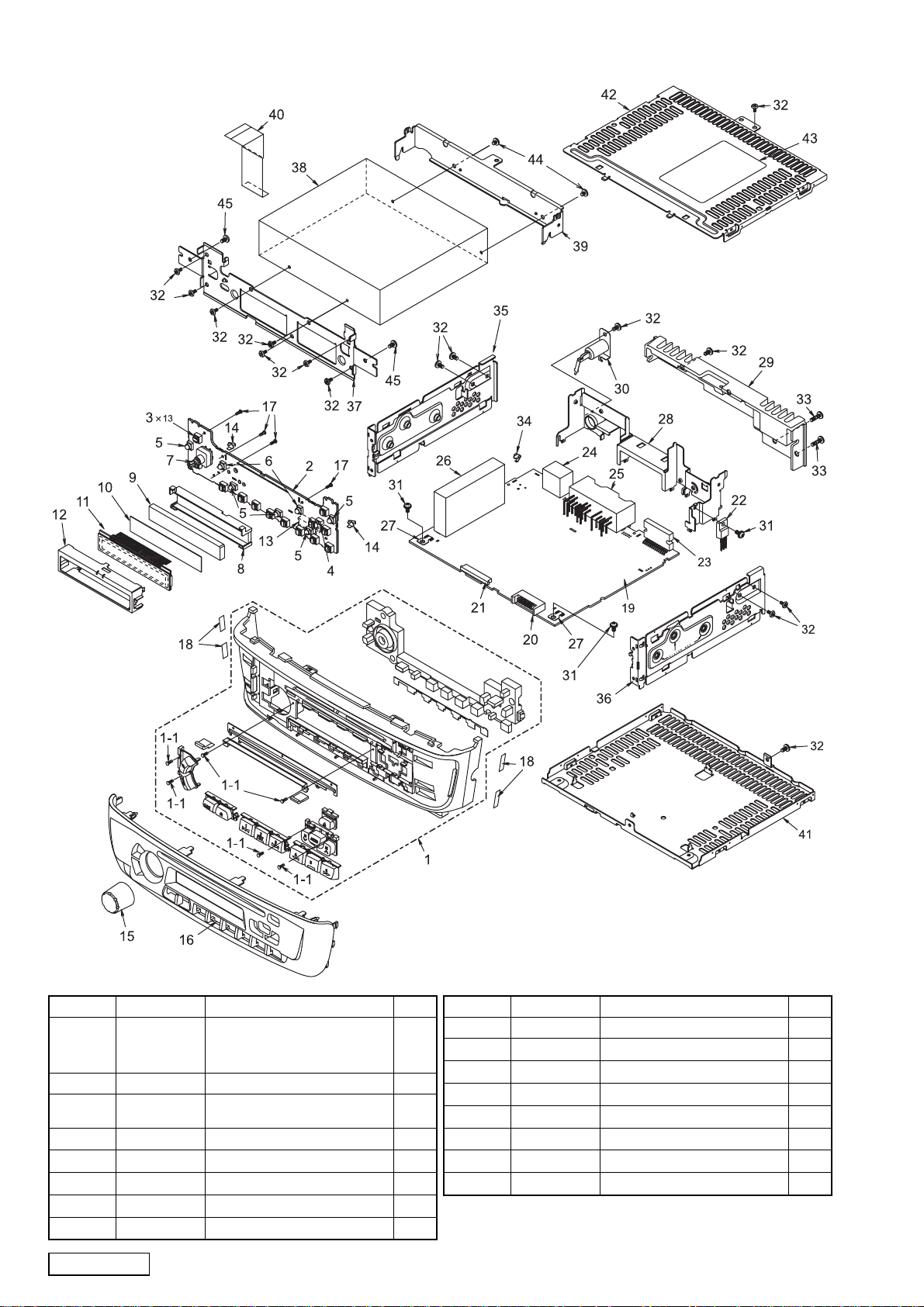

■EXPLODED VIEW・PARTS LIST

Main section

1 940-7943-86 ESCUTCHEON ASSY 1

940-7943-87 ESCUTCHEON ASSY(M-B,M-E)

940-7943-88 ESCUTCHEON ASSY(M-C,M-F)

1-1 716-0872-00 PAD SCREW(M1.7×5 SILVER) 6

2 039-2055-00 SWITCH PWB 1

3 013-6300-51 SWITCH 13

4 013-6302-50 SWITCH 1

5 017-0433-58 PILOT LAMP(14V40mA) 5

6 017-0447-59 PILOT LAMP(8V105mA) 2

7 016-0010-15 VR-W/SHAFT 1

(M-A,M-D,M-G)

(WITHOUT COMPONENT)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

8 335-6541-80 ILLUMI HOLDER 1

9 335-5777-00 LCD ILLUMI 1

10 335-5779-00 COLOR FILTER 1

11 379-1217-30 INDICATOR 1

12 331-2448-01 LCD COVER 1

13 074-1151-14 OUTLET SOCKET(14P) 1

14 073-0774-00 TERMINAL 2

15 380-5515-80 KNOB 1

- 4 -PN-2445M

Page 5

16 373-0957-04 DIAL COVER(M-A) 1

17 716-0872-00 PAD SCREW(M1.7×5 SILVER) 4

18 347-2510-00 CUSHION TAPE 4

19 039-2054-00 MAIN PWB 1

20 076-0540-14 PLUG(14P) 1

21 074-1191-26 OUTLET SOCKET(26P) 1

22 103-2012-00 TRANSISTOR(2SD2012) 1

23 051-2040-00 IC(TA8276H) 1

24 074-0850-08 OUTLET SOCKET(DIN8P) 1

25 074-1068-11 OUTLET SOCKET 1

26 880-1917B AM/FM TUNER 1

27 073-0762-90 TERMINAL 2

28 307-0683-05 REAR PLATE 1

29 313-1825-15 HEAT SINK 1

30 092-0702-00 ANT RECEPT 1

373-0957-05 DIAL COVER(M-B)

373-0957-06 DIAL COVER(M-C)

373-0957-07 DIAL COVER(M-D)

373-0957-08 DIAL COVER(M-E)

373-0957-09 DIAL COVER(M-F)

373-0957-22 DIAL COVER(M-G)

(WITHOUT COMPONENT)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

31 716-0878-00 IT SCREW(M2.6×5) 3

32 714-2606-81 MACHINE SCREW(M2.6×6) 15

33 714-2612-81 MACHINE SCREW(M2.6×12) 2

34 073-0774-00 TERMINAL 1

35 305-0316-00 SIDE COVER(L) 1

36 305-0317-00 SIDE COVER(R) 1

37 331-3268-00 ES-PLATE 1

38 929-0220-81 CD MECHANISM 1

39 331-3254-10 MECHANISM BRACKET 1

40 816-2549-00 FLAT WIRE 1

41 311-1833-10 LOWER CASE 1

42 310-1739-10 UPPER CASE 1

43 286-9269-13 SETPLATE(M-A) 1

44 714-2603-81 MACHINE SCREW(M2.6×3) 2

45 702-3008-81 TAP SCREW(φ3×8) 2

286-9269-14 SETPLATE(M-B)

286-9269-15 SETPLATE(M-C)

286-9269-16 SETPLATE(M-D)

286-9269-17 SETPLATE(M-E)

286-9269-18 SETPLATE(M-F)

286-9269-19 SETPLATE(M-G)

CD mechanism section : 929-0220-81

※The exploded view of CD mechanism is on page 6.

1 966-0595-24 DRIVE PLATE ASSY 1

2 969-0060-30 PICK UP UNIT 1

3 039-1944-21 LED PWB 1

4 039-1945-20 CD PWB 1

5 SMA-182-100 MOTOR ASSY(SPINDLE) 1

6 SMA-183-100 MOTOR ASSY(SLED) 1

7 HBS-516-100 CLAMPER SUB ASSY 1

8 803-4906-60 VINYL COAT WIRE(ORG) 1

9 816-2591-00 LEAD WIRE(YEL) 1

10 620-1025-21 ID-LOCK PLATE 1

11 620-1026-21 SPRING PLATE 1

12 620-1027-24 LOWER CHASSIS 1

13 620-1028-21 UPPER CHASSIS 1

14 620-1029-21 SH-SPRING 1

15 621-0598-25 UPPER GUIDE 1

16 621-0599-25 ROLLER GUIDE 1

17 621-0600-25 SHIFT LEVER 1

18 621-0601-21 RACK 1

19 621-0602-22 LOCK ARM L 1

20 621-0603-23 LOCK ARM R 1

21 621-0604-21 GEAR BASE 1

22 621-0605-21 GEAR COVER 1

23 621-0606-21 IDLE CASE 1

24 816-2590-00 VINYL COAT WIRE(GRN) 1

25 621-0608-21 SECOND GEAR 1

26 621-0609-20 BASE GEAR 1

27 621-0610-20 IDLE GEAR A 1

28 621-0611-20 IDLE GEAR B 1

29 621-0612-21 ROLLER GEAR A 1

(WITHOUT COMPONENT)

(WITHOUT COMPONENT)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

30 621-0613-20 ROLLER GEAR B 1

31 621-0614-20 ROLLER GEAR C 1

32 621-0615-21 ROLLER GEAR D 1

33 621-0616-20 POWER GEAR A 1

34 621-0617-20 POWER GEAR B 1

35 621-0618-20 POWER GEAR C 1

36 621-0619-20 POWER GEAR D 1

37 621-0620-20 THREAD GEAR A 1

38 621-0621-20 THREAD GEAR B 1

39 621-0622-21 ROLLER SLEEVE 2

40 621-0623-21 LS-HOLDER 1

41 621-0624-21 GUIDE RAIL 1

42 816-2593-00 LEAD WIRE(PUR) 1

43 816-2542-01 FLAT WIRE(10P) 1

44 716-3473-00 SCREW 2

45 621-0628-21 SH-BASE 1

46 621-0629-20 LOADING ROLLER 2

47 345-8704-20 CUSHION RUBBER 1

48 622-1571-21 ROLLER SHAFT 1

49 624-0018-01 LEAD SCREW 1

50 629-0081-20 DAMPER F 2

51 629-0082-20 DAMPER R 1

52 714-2003-81 MACHINE SCREW 2

53 716-1507-00 SCREW 8

54 716-1733-00 SCREW 2

55 716-3469-00 SPECIAL SCREW 2

56 716-3446-00 SCREW 2

57 750-3465-21 ROLLER SPRING L 1

58 750-3466-20 ROLLER SPRING R 1

59 750-3467-21 SHIFT SPRING 1

- 5 -

PN-2445M

Page 6

60 750-3468-20 RACK SPRING 1

61 750-3469-20 CLAMPER SPRING 1

62 750-3470-20 ID-LOCK SPRING 1

63 816-2592-00 LEAD WIRE(BLU) 1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

64 750-3472-21 DR-SPRING F 2

65 750-3473-20 DR-SPRING RA 1

66 750-3474-20 DR-SPRING RB 1

67 750-3475-21 DR-SPRING C 1

- 6 -PN-2445M

Page 7

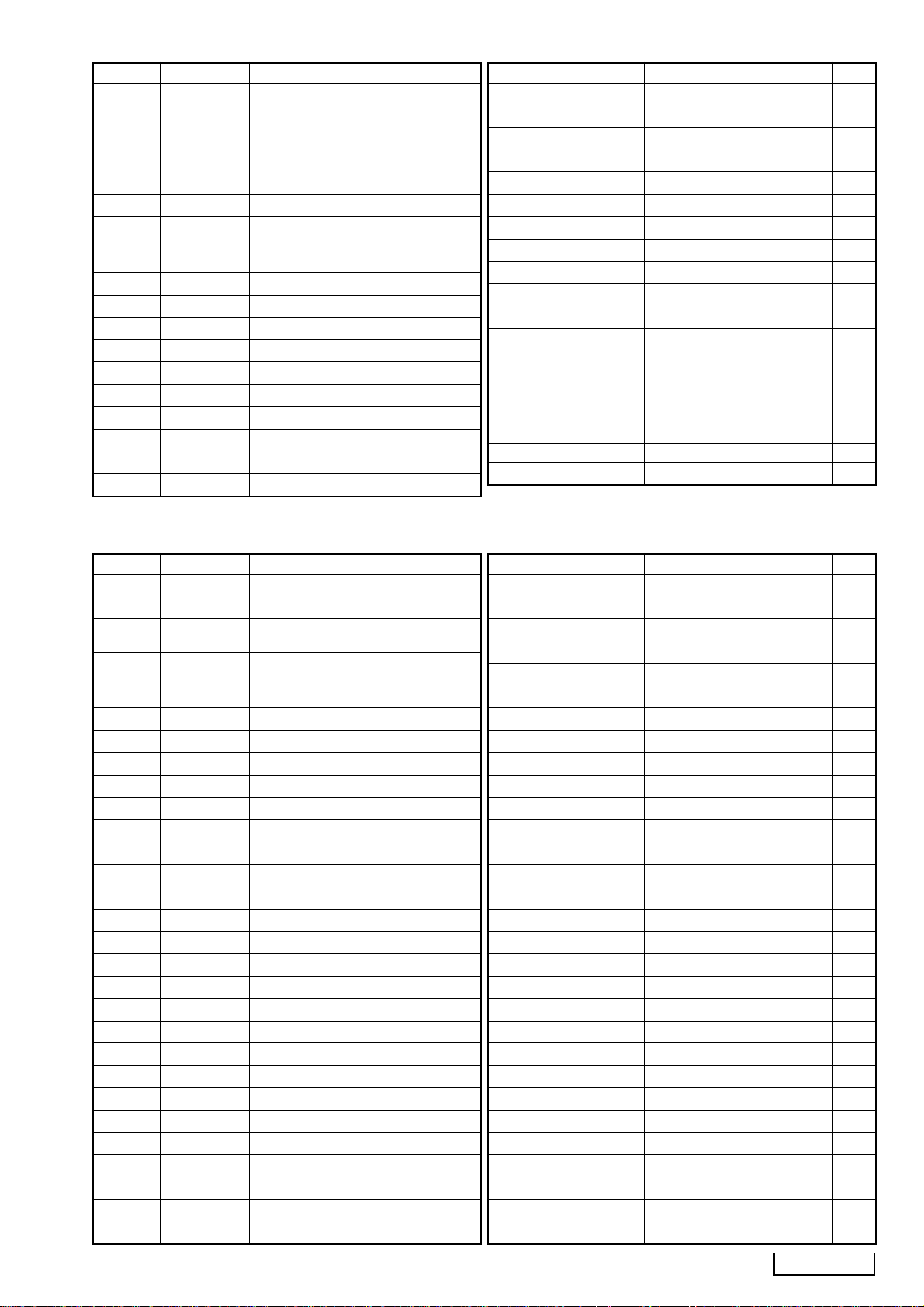

■ELECTRICAL PARTS LIST

Main PWB section(B1)

Note) Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

The parts on marks ※ are used PN-2445M-A, M-B, M-C.

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

ANT101 092-0702-00 ANT RECEPT

BL101 880-1917B AM/FM TUNER

C104 119-0000-05 1/16W 0Ω JW

C114 166-1007-50 10pF CH

C116 168-1042-78 16V 0.1μF

C117 043-0277-51 0.022μF

C118 168-1022-55 1000pF

C119 182-1073-29 10V100μF

C120 042-0458-93 50V2.2μF

C122 182-1073-29 10V100μF

C123 182-1073-29 10V100μF

C125 182-4763-39 16V47μF

C126 183-1056-68 50V1μF NP

C127 168-1832-55 0.018μF

C128 168-4732-78 0.047μF

C129 168-4732-78 0.047μF

C130 166-1201-50 12pF CH

C131 166-1201-50 12pF CH

C132 166-1201-50 12pF CH

C133 166-1501-50 15pF CH

C134 168-1022-55 1000pF

C135 168-1042-78 16V 0.1μF

C136 168-1042-78 16V 0.1μF

C137 168-1042-78 16V 0.1μF

C138 168-1042-78 16V 0.1μF

C201 168-1022-55 1000pF

C202 168-1022-55 1000pF

C203 166-1011-50 100pF CH

C204 166-1011-50 100pF CH

C205 166-1011-50 100pF CH

C206 166-1011-50 100pF CH

C207 168-1042-78 16V 0.1μF

C208 168-1042-78 16V 0.1μF

C212 166-8097-50 8pF CH

C213 184-2273-29 10V220μF

C214 168-1042-78 16V 0.1μF

C215 184-2273-29 10V220μF

C216 168-1042-78 16V 0.1μF

C217 042-0403-55 16V33μF

C218 042-0403-55 16V33μF

C219 168-1042-78 16V 0.1μF

C301 168-4722-55 4700pF

C303※ 182-4763-39 16V47μF

C306※ 184-2273-29 10V220μF

C307※ 182-1063-39 16V10μF

C311 183-1063-37 16V10μF

C312 183-1063-37 16V10μF

C313 183-1063-37 16V10μF

C314 183-1063-37 16V10μF

C315 182-2263-19 6.3V22μF

C316 182-1053-69 50V1μF

C318 178-1042-78 0.1μF

C319 178-1042-78 0.1μF

C321 182-1053-69 50V1μF

C322 178-3942-78 0.39μF

C323 178-3942-78 0.39μF

C325 182-1053-69 50V1μF

C326 182-1053-69 50V1μF

C332 178-1842-78 0.18μF

C333 178-1842-78 0.18μF

C334 178-1842-78 0.18μF

C335 178-1842-78 0.18μF

C336 168-8212-55 820pF

C337 168-8212-55 820pF

C338 168-8212-55 820pF

C339 168-8212-55 820pF

C340 182-1063-39 16V10μF

C341 182-1063-39 16V10μF

C342 168-1832-55 0.018μF

C343 182-1063-39 16V10μF

C344 182-1063-39 16V10μF

C345 182-1063-39 16V10μF

C346 182-1063-39 16V10μF

C502※ 168-5612-55 560pF

C504※ 168-5612-55 560pF

C505※ 166-2201-50 22pF CH

C506※ 166-2201-50 22pF CH

C508※ 166-2201-50 22pF CH

C509※ 166-2201-50 22pF CH

C512※ 166-2201-50 22pF CH

C513※ 166-2201-50 22pF CH

C515※ 166-2201-50 22pF CH

C516※ 166-2201-50 22pF CH

C529※ 178-2242-78 0.22μF

C530※ 178-5632-78 0.056μF

C531※ 178-4742-78 0.47μF

C532※ 178-4742-78 0.47μF

C533※ 178-5632-78 0.056μF

C534※ 178-1842-78 0.18μF

C535※ 178-3932-78 0.039μF

C536※ 178-3932-78 0.039μF

C537※ 166-2201-50 22pF CH

C538※ 166-2201-50 22pF CH

C539※ 166-2201-50 22pF CH

C540※ 166-2201-50 22pF CH

C541※ 166-2201-50 22pF CH

C542※ 166-2201-50 22pF CH

C543※ 166-2201-50 22pF CH

C544※ 166-2201-50 22pF CH

C545※ 178-1832-78 0.018μF

C546※ 178-1832-78 0.018μF

C547※ 178-1032-78 0.01μF

C548※ 178-1032-78 0.01μF

C549※ 178-2232-78 0.022μF

C550※ 178-3332-78 0.033μF

C551※ 178-6832-78 0.068μF

C552※ 178-6832-78 0.068μF

C553 178-8232-78 0.082μF

(M-A,M-B,M-C)

C553 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C554 178-8232-78 0.082μF

(M-A,M-B,M-C)

C554 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C555 178-1242-78 0.12μF

(M-A,M-B,M-C)

C555 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C556 178-1242-78 0.12μF

(M-A,M-B,M-C)

C556 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C557※ 178-8232-78 0.082μF

C558※ 178-1242-78 0.12μF

C559※ 166-2201-50 22pF CH

C560※ 166-2201-50 22pF CH

C561※ 166-2201-50 22pF CH

C562※ 166-2201-50 22pF CH

C563※ 178-8232-78 0.082μF

C564※ 178-1242-78 0.12μF

C565 168-1032-55 0.01μF

C566 168-2232-55 0.022μF

C567 168-1032-55 0.01μF

C568 178-6832-78 0.068μF

(M-A,M-B,M-C)

C568 178-3332-78 0.033μF

(M-D,M-E,M-F)

C568 178-1242-78 0.12μF(M-G)

C569 178-6832-78 0.068μF

(M-A,M-B,M-C)

C569 178-3332-78 0.033μF

(M-D,M-E,M-F)

C569 178-1242-78 0.12μF(M-G)

C570 178-2242-78 0.22μF

(M-A,M-B,M-C)

C570 178-1242-78 0.12μF

(M-D,M-E,M-F,M-G)

C571 178-2242-78 0.22μF

(M-A,M-B,M-C)

C571 178-1242-78 0.12μF

(M-D,M-E,M-F,M-G)

C573 182-1053-69 50V1μF

C574 183-2253-69 50V2.2μF

C577 178-1052-78 1μF(M-A,M-B,M-C)

C577 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C578 178-1052-78 1μF(M-A,M-B,M-C)

C578 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C579 178-1052-78 1μF(M-A,M-B,M-C)

C579 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C580 178-1052-78 1μF(M-A,M-B,M-C)

C580 117-0000-05 1/10W 0Ω JW

(M-D,M-E,M-F,M-G)

C582 183-1053-69 50V1μF

C584 166-2201-50 22pF CH

C585 166-2201-50 22pF CH

C586 166-2201-50 22pF CH

C587 166-2201-50 22pF CH

C701 172-1041-15 0.1μF

C702 042-0447-00 16V2200μF

C703 168-2222-55 2200pF

C704 168-2222-55 2200pF

C705 168-2222-55 2200pF

C706 168-2222-55 2200pF

C707 168-2222-55 2200pF

C708 168-2222-55 2200pF

C709 168-2222-55 2200pF

C710 168-2222-55 2200pF

C711 168-2222-55 2200pF

C712 172-1041-15 0.1μF

C713 182-1063-39 16V10μF

C714 183-6843-69 50V0.68μF

C802 182-4763-39 16V47μF

C803 182-1063-39 16V10μF

C804 182-4763-19 6.3V47μF

C805 182-4763-19 6.3V47μF

C806 182-1063-39 16V10μF

C807 182-1063-39 16V10μF

C808 168-1042-78 16V 0.1μF

C809 184-4773-39 16V470μF

C810 183-4756-58 35V4.7μF NP

C811 168-1042-78 16V 0.1μF

C812 168-1042-78 16V 0.1μF

C813 168-1042-78 16V 0.1μF

CCT201 050-0140-53 1/32W 0Ω×4J

CCT202 050-0140-53 1/32W 0Ω×4J

CCT203 050-0140-53 1/32W 0Ω×4J

CCT204 050-0140-53 1/32W 0Ω×4J

CCT205 050-0140-54 1/32W 1kΩ×4J

CCT206 050-0140-54 1/32W 1kΩ×4J

CCT207 050-0140-54 1/32W 1kΩ×4J

CCT209 050-0140-54 1/32W 1kΩ×4J

CCT210 050-0140-54 1/32W 1kΩ×4J

D701 001-2015-00 RL253

D702 001-0626-91 1A2

D703 001-0347-34 MA4062L

D703 001-0346-34 MTZJ6.2A

D703 001-0401-34 HZS6C1

D704 001-0626-91 1A2

D802 001-0347-48 MA4091H

D802 001-0401-48 HZS9.1JB3

D802 001-0346-49 MTZJ10A

D803 001-0516-90 MA111

D804 001-0504-31 HZS6 A2L

D806 001-0504-31 HZS6 A2L

D808 001-0504-45 HZS9B1L

- 7 -

PN-2445M

Page 8

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D809 001-0347-45 MA4082H

D809 001-0346-46 MTZJ9.1A

D809 001-0401-45 HZS8.2JB3

D810 001-0347-46 MA4091L

D810 001-0401-46 HZS9.1JB1

D810 001-0347-47 MA4091M

IC201 052-1163-20 uPD178076GF-540-

3BA

IC301※ 051-3034-90 NJM4558V

IC302 051-5027-00 LC75412WH

IC501※ 051-3019-90 NJM2060V

IC503※ 051-3019-90 NJM2060V

IC504※ 051-3019-90 NJM2060V

IC505※ 051-3019-90 NJM2060V

IC506 051-2040-00 TA8276H

J201 074-1191-26 26P

J302 074-0850-08 8P

J701 074-1068-11 NS10+6

L104 010-2003-04 COIL

L202 010-2230-64 2.2μH

L701 009-0670-71 CHOKE

L701 009-0670-01 CHOKE

P701 076-0540-14 14P

Q104 198-0669-00 2SK669

Q106 190-1150-00 2SA1150

Q107 125-2020-92 DTC114EK

Q107 125-2005-91 UN2211

Q107 125-2031-92 MUN2211

Q107 125-2004-92 RN1402

Q108 190-1150-00 2SA1150

Q304 125-2020-92 DTC114EK

Q304 125-2004-92 RN1402

Q304 125-2005-91 UN2211

Q304 125-2031-92 MUN2211

Q305 125-9002-92 RN4602

Q305 125-9003-92 IMD3

Q701 192-2412-00 2SC2412

Q701 192-2712-00 2SC2712

Q801 193-2118-00 2SD2118

Q802 125-2004-92 RN1402

Q802 125-2031-92 MUN2211

Q802 125-2005-91 UN2211

Q802 125-2020-92 DTC114EK

Q803 190-1150-00 2SA1150

Q804 125-2031-92 MUN2211

Q804 125-2020-92 DTC114EK

Q804 125-2005-91 UN2211

Q804 125-2004-92 RN1402

Q805 125-0001-91 UN2111

Q805 125-0002-92 RN2402

Q805 125-0014-92 DTA114EK

Q805 125-0024-92 MUN2111

Q806 193-1858-00 2SD1858

Q807 125-9003-92 IMD3

Q807 125-9002-92 RN4602

Q811 193-2118-00 2SD2118

Q812 125-9003-92 IMD3

Q812 125-9002-92 RN4602

Q813 103-2012-00 2SD2012

Q814 125-2005-91 UN2211

Q814 125-2020-92 DTC114EK

Q814 125-2004-92 RN1402

Q814 125-2031-92 MUN2211

Q815 125-2004-92 RN1402

Q815 125-2020-92 DTC114EK

Q815 125-2005-91 UN2211

Q815 125-2031-92 MUN2211

Q816 193-2118-00 2SD2118

Q817 193-1306-00 2SD1306

Q818 192-2412-00 2SC2412

Q818 192-2712-00 2SC2712

Q819 125-9002-92 RN4602

Q819 125-9003-92 IMD3

R111 119-2221-15 1/16W 2.2kΩ

R112 119-2221-15 1/16W 2.2kΩ

R113 119-1821-15 1/16W 1.8kΩ

R114 111-2701-98 1/4W 27Ω

R115 119-3321-15 1/16W 3.3kΩ

R116 111-1501-98 1/4W 15Ω

R117 119-4721-15 1/16W 4.7kΩ

R118 119-4741-15 1/16W 470kΩ

R119 111-1001-98 1/4W 10Ω

R120 111-2221-98 1/4W 2.2kΩ

R121 111-1031-98 1/4W 10kΩ

R122 119-1021-15 1/16W 1kΩ

R123 111-1031-98 1/4W 10kΩ

R124 111-2221-98 1/4W 2.2kΩ

R126 119-8201-15 1/16W 82Ω

R198 119-0000-05 1/16W 0Ω JW

R199 119-0000-05 1/16W 0Ω JW

R201 119-1021-15 1/16W 1kΩ

R202 119-1021-15 1/16W 1kΩ

R203 119-1031-15 1/16W 10kΩ

R204 119-0000-05 1/16W 0Ω JW

R205 119-1031-15 1/16W 10kΩ

R206 119-4731-15 1/16W 47kΩ

R207 119-4731-15 1/16W 47kΩ

R208 119-4731-15 1/16W 47kΩ

R209 119-1041-15 1/16W 100kΩ

R210 119-1041-15 1/16W 100kΩ

R214 119-2231-15 1/16W 22kΩ

R215 119-1031-15 1/16W 10kΩ

R216 119-1021-15 1/16W 1kΩ

R221 119-1031-15 1/16W 10kΩ

R222 119-4731-15 1/16W 47kΩ

R223 119-1031-15 1/16W 10kΩ

R224 119-1021-15 1/16W 1kΩ

R225 119-1031-15 1/16W 10kΩ

R226 119-1021-15 1/16W 1kΩ

R227 119-4731-15 1/16W 47kΩ

R230 119-1021-15 1/16W 1kΩ

R231 119-1021-15 1/16W 1kΩ

R232 119-4731-15 1/16W 47kΩ

R233 119-4731-15 1/16W 47kΩ

R234 119-1031-15 1/16W 10kΩ

R236 119-4731-15 1/16W 47kΩ

R243 119-1031-15 1/16W 10kΩ

R245 119-1031-15 1/16W 10kΩ

R246 119-1031-15 1/16W 10kΩ

R248 119-1021-15 1/16W 1kΩ

R249 119-0000-05 1/16W 0Ω JW

R301 119-1021-15 1/16W 1kΩ

R302 119-1021-15 1/16W 1kΩ

R308※ 119-4731-15 1/16W 47kΩ

R309※ 119-0000-05 1/16W 0Ω JW

R310※ 119-4731-15 1/16W 47kΩ

R315 119-4731-15 1/16W 47kΩ

R316 032-0106-64 1/10W 56kΩ 0.5%

R317 119-3011-15 1/16W 300Ω

R318 032-0106-64 1/10W 56kΩ 0.5%

R319 111-8211-98 1/4W 820Ω

R320 111-8211-98 1/4W 820Ω

R323 032-0106-64 1/10W 56kΩ 0.5%

R324 119-3011-15 1/16W 300Ω

R325 032-0106-64 1/10W 56kΩ 0.5%

R334 119-1021-15 1/16W 1kΩ

R335 119-1021-15 1/16W 1kΩ

R342 119-4721-15 1/16W 4.7kΩ

R343 119-4721-15 1/16W 4.7kΩ

R346 119-4721-15 1/16W 4.7kΩ

R347 119-4721-15 1/16W 4.7kΩ

R501 119-3331-15 1/16W 33kΩ

(M-A,M-B,M-C)

R501 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R502 119-3331-15 1/16W 33kΩ

(M-A,M-B,M-C)

R502 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R503 119-3331-15 1/16W 33kΩ

(M-A,M-B,M-C)

R503 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R504 119-3331-15 1/16W 33kΩ

(M-A,M-B,M-C)

R504 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R505※ 119-2231-15 1/16W 22kΩ

R506※ 119-2231-15 1/16W 22kΩ

R507※ 119-2231-15 1/16W 22kΩ

R508※ 119-2231-15 1/16W 22kΩ

R510※ 119-2731-15 1/16W 27kΩ

R512※ 119-2731-15 1/16W 27kΩ

R513※ 119-4721-15 1/16W 4.7kΩ

R514※ 119-1031-15 1/16W 10kΩ

R515※ 119-1031-15 1/16W 10kΩ

R516※ 119-4721-15 1/16W 4.7kΩ

R521※ 119-4721-15 1/16W 4.7kΩ

R522※ 119-4721-15 1/16W 4.7kΩ

R523※ 119-1031-15 1/16W 10kΩ

R524※ 119-1031-15 1/16W 10kΩ

R525※ 119-2221-15 1/16W 2.2kΩ

R526 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F)

R526 119-2221-15 1/16W 2.2kΩ(M-G)

R527 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F)

R527 119-2221-15 1/16W 2.2kΩ(M-G)

R528※ 119-2221-15 1/16W 2.2kΩ

R529※ 119-2221-15 1/16W 2.2kΩ

R530 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F)

R530 119-2221-15 1/16W 2.2kΩ(M-G)

R531 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F)

R531 119-2221-15 1/16W 2.2kΩ(M-G)

R532※ 119-2221-15 1/16W 2.2kΩ

R549※ 119-1521-15 1/16W 1.5kΩ

R550※ 119-1521-15 1/16W 1.5kΩ

R551※ 119-1021-15 1/16W 1kΩ

R552※ 119-1021-15 1/16W 1kΩ

R553※ 119-1511-15 1/16W 150Ω

R554※ 119-1511-15 1/16W 150Ω

R555※ 119-1511-15 1/16W 150Ω

R556※ 119-1511-15 1/16W 150Ω

R557※ 119-1541-15 1/16W 150kΩ

R558※ 119-1541-15 1/16W 150kΩ

R559※ 119-1541-15 1/16W 150kΩ

R560※ 119-1541-15 1/16W 150kΩ

R561※ 119-1541-15 1/16W 150kΩ

R562※ 119-1541-15 1/16W 150kΩ

R563※ 119-1541-15 1/16W 150kΩ

R564※ 119-1541-15 1/16W 150kΩ

R565※ 119-1511-15 1/16W 150Ω

R566※ 119-1511-15 1/16W 150Ω

R567※ 119-1511-15 1/16W 150Ω

R568※ 119-1511-15 1/16W 150Ω

R569※ 119-1021-15 1/16W 1kΩ

R570※ 119-1521-15 1/16W 1.5kΩ

R571※ 119-1221-15 1/16W 1.2kΩ

R572※ 119-1221-15 1/16W 1.2kΩ

R573 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C)

R573 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R574 119-1831-15 1/16W 18kΩ

(M-A,M-B,M-C)

R574 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R575※ 119-1021-15 1/16W 1kΩ

R576※ 119-1021-15 1/16W 1kΩ

R577※ 119-1031-15 1/16W 10kΩ

R578※ 119-1031-15 1/16W 10kΩ

R579※ 119-5131-15 1/16W 51kΩ

R580※ 119-5131-15 1/16W 51kΩ

R581※ 119-5131-15 1/16W 51kΩ

R582※ 119-5131-15 1/16W 51kΩ

R583※ 119-1031-15 1/16W 10kΩ

R584※ 119-1031-15 1/16W 10kΩ

- 8 -PN-2445M

Page 9

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R585 119-1831-15 1/16W 18kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R585 119-8231-15 1/16W 82kΩ(M-G)

R586※ 119-1021-15 1/16W 1kΩ

R587※ 119-1021-15 1/16W 1kΩ

R588 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C)

R588 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R589 119-1831-15 1/16W 18kΩ

(M-A,M-B,M-C)

R589 119-0000-05 1/16W 0Ω JW

(M-D,M-E,M-F,M-G)

R590 119-1021-15 1/16W 1kΩ

R591 119-2221-15 1/16W 2.2kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R591 119-1231-15 1/16W 12kΩ(M-G)

R592 119-2221-15 1/16W 2.2kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R592 119-1231-15 1/16W 12kΩ(M-G)

R593 119-2221-15 1/16W 2.2kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R593 119-1231-15 1/16W 12kΩ(M-G)

R594 119-2221-15 1/16W 2.2kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R594 119-1231-15 1/16W 12kΩ(M-G)

R595 119-5631-15 1/16W 56kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R595 119-2221-15 1/16W 2.2kΩ(M-G)

R596 119-5631-15 1/16W 56kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R596 119-2221-15 1/16W 2.2kΩ(M-G)

R597 119-5631-15 1/16W 56kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R597 119-2221-15 1/16W 2.2kΩ(M-G)

R598 119-5631-15 1/16W 56kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R598 119-2221-15 1/16W 2.2kΩ(M-G)

R599 119-4721-15 1/16W 4.7kΩ

R604 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R604 119-0000-05 1/16W 0Ω JW(M-G)

R605 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R605 119-0000-05 1/16W 0Ω JW(M-G)

R606 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R606 119-0000-05 1/16W 0Ω JW(M-G)

R607 119-2231-15 1/16W 22kΩ

(M-A,M-B,M-C,

M-D,M-E,M-F)

R607 119-0000-05 1/16W 0Ω JW(M-G)

R619 119-4721-15 1/16W 4.7kΩ

R701 119-1031-15 1/16W 10kΩ

R702 119-5611-15 1/16W 560Ω

R703 111-1531-98 1/4W 15kΩ

R704 114-2291-11 1W 2.2Ω

R705 119-0000-05 1/16W 0Ω JW

R803 111-4711-98 1/4W 470Ω

R804 111-1021-98 1/4W 1kΩ

R805 119-2231-15 1/16W 22kΩ

R806 119-4741-15 1/16W 470kΩ

R807 119-2231-15 1/16W 22kΩ

R808 111-8211-98 1/4W 820Ω

R809 111-8211-98 1/4W 820Ω

R814 111-2211-98 1/4W 220Ω

R815 119-1041-15 1/16W 100kΩ

R818 111-3911-98 1/4W 390Ω

R819 119-1041-15 1/16W 100kΩ

R821 111-2021-98 1/4W 2kΩJ

R822 111-2021-98 1/4W 2kΩJ

R824 119-4731-15 1/16W 47kΩ

R825 111-1801-98 1/4W 18Ω

R826 119-5611-15 1/16W 560Ω

R827 119-4721-15 1/16W 4.7kΩ

R828 111-1831-98 1/4W 18kΩ

R829 111-1801-98 1/4W 18Ω

R831 111-8211-98 1/4W 820Ω

R832 111-8211-98 1/4W 820Ω

R833 111-3911-98 1/4W 390Ω

SUP101 060-0122-10 DSP-201M-S00B

TC201 004-1580-02 11pF

TM101 073-0762-90 TERMINAL

TM801 073-0762-90 TERMINAL

VR102 012-5203-56 10kΩ

X201 061-3055-00 4.5MHz

Switch PWB section(B2)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C901 168-1042-78 16V 0.1μF

C902 168-1042-78 16V 0.1μF

C903 168-6812-55 680pF

C904 168-1042-78 16V 0.1μF

C905 042-0423-92 6.3V4.7μF

C906 168-1042-78 16V 0.1μF

C907 042-0423-92 6.3V4.7μF

CCT901 050-0140-54 1/32W 1kΩ×4J

CCT902 050-0140-54 1/32W 1kΩ×4J

D901 001-0516-90 MA111

D902 001-0516-90 MA111

D903 001-0516-90 MA111

D904 001-0516-90 MA111

D905 001-0516-90 MA111

D906 001-0516-90 MA111

D907 001-0516-90 MA111

D908 001-0516-90 MA111

IC901 051-6000-20 LC7583NW

J901 074-1151-14 14P

PL901 017-0447-59 8V105mA

PL902 017-0447-59 8V105mA

PL903 017-0433-58 14V40mA

PL904 017-0433-58 14V40mA

PL905 017-0433-58 14V40mA

PL906 017-0433-58 14V40mA

PL907 017-0433-58 14V40mA

R902 119-6831-15 1/16W 68kΩ

S901 013-6300-51 SJPGAA032A

S902 013-6300-51 SJPGAA032A

S903 013-6300-51 SJPGAA032A

S904 013-6300-51 SJPGAA032A

S905 013-6300-51 SJPGAA032A

S906 013-6300-51 SJPGAA032A

S907 013-6300-51 SJPGAA032A

S908 013-6300-51 SJPGAA032A

S909 013-6300-51 SJPGAA032A

S910 013-6300-51 SJPGAA032A

S912 013-6302-50 SKQMAL

S913 013-6300-51 SJPGAA032A

S914 013-6300-51 SJPGAA032A

S915 013-6300-51 SJPGAA032A

VR903 016-0010-15 ROTALY ENCODER

CD PWB section(B3):CD mechanism

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C101 168-1042-78 0.1μF

C102 045-4701-50 47pF

C103 046-4722-58 4700pF

C104 168-1042-78 0.1μF

C105 046-1532-78 0.015μF

C106 046-1032-78 0.01μF

C107 046-1032-78 0.01μF

C108 046-4722-58 4700pF

C109 046-1522-58 1500pF

C110 046-3332-78 0.033μF

C111 168-1042-78 0.1μF

C112 046-3332-78 0.033μF

C113 168-1042-78 0.1μF

C114 168-1042-78 0.1μF

C115 046-4712-58 470pF

C116 046-4712-58 470pF

C117 043-0533-50 0.047μF

C118 043-0533-50 0.047μF

C119 045-2701-50 27pF

C120 045-1801-50 18pF

C121 163-1063-35 16V10μF

C122 178-1052-78 1μF

C123 046-1032-78 0.01μF

C124 163-1073-05 4V100μF

C125 168-1042-78 0.1μF

C126 168-1042-78 0.1μF

C129 178-1052-78 1μF

C201 163-3363-05 4V33μF

C202 168-1042-78 0.1μF

C203 178-1052-78 1μF

C204 163-1073-05 4V100μF

C205 163-3363-05 4V33μF

C206 168-1042-78 0.1μF

C207 043-0533-50 0.047μF

C208 046-6822-58 6800pF

C209 168-1042-78 0.1μF

C210 043-0533-50 0.047μF

C211 168-1042-78 0.1μF

C212 168-1042-78 0.1μF

C213 045-5096-50 5pF

C214 045-5601-50 56pF

C215 043-0533-50 0.047μF

C216 178-1052-78 1μF

C217 045-1011-50 100pF

C301 163-1073-35 16V100μF

C302 168-1042-78 0.1μF

C303 043-0533-50 0.047μF

D201 001-0516-90 MA111

IC101 051-6376-00 TC94A14FA

IC102 051-3279-90 BA033LBSG

IC201 051-5710-90 TA2157F

IC301 051-6049-08 BA5983FP-E2

J101 074-1228-76 26P

J201 074-1138-65 15P

J301 074-1138-60 10P

L101 010-2285-57 BLM21B102SPT

L102 010-2285-57 BLM21B102SPT

L103 010-2285-57 BLM21B102SPT

L104 010-2285-57 BLM21B102SPT

L105 010-2285-57 BLM21B102SPT

L401 010-3050-93 10μH

Q201 131-1188-50 2SB1188

R102 033-5621-15 1/16W 5.6kΩ

R104 033-4731-15 1/16W 47kΩ

R105 033-1041-15 1/16W 100kΩ

R108 033-1531-15 1/16W 15kΩ

R109 033-1031-15 1/16W 10kΩ

R110 033-1051-15 1/16W 1MΩ

R111 033-3321-15 1/16W 3.3kΩ

- 9 -

PN-2445M

Page 10

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R114 033-2211-15 1/16W 220Ω

R115 033-2211-15 1/16W 220Ω

R116 033-1031-15 1/16W 10kΩ

R117 033-1021-15 1/16W 1kΩ

R131 033-4711-15 1/16W 470Ω

R132 033-2211-15 1/16W 220Ω

R201 117-2201-15 1/10W 22Ω

R202 117-2201-15 1/10W 22Ω

R203 033-1041-15 1/16W 100kΩ

R204 033-1041-15 1/16W 100kΩ

R205 033-1041-15 1/16W 100kΩ

R206 033-1041-15 1/16W 100kΩ

R207 033-1041-15 1/16W 100kΩ

R208 033-8231-15 1/16W 82kΩ

R209 033-6811-15 1/16W 680Ω

R210 033-6831-15 1/16W 68kΩ

R211 033-1831-15 1/16W 18kΩ

R212 033-2721-15 1/16W 2.7kΩ

R213 033-1011-15 1/16W 100Ω

R214 033-1021-15 1/16W 1kΩ

R215 033-1031-15 1/16W 10kΩ

R217 033-1041-15 1/16W 100kΩ

R218 033-2211-15 1/16W 220Ω

R301 117-6811-15 1/16W 680Ω

R304 033-3921-15 1/16W 3.9kΩ

R305 033-3921-15 1/16W 3.9kΩ

R306 033-1041-15 1/16W 100kΩ

R307 033-2211-15 1/16W 220Ω

X102 060-1528-90 16.934M

LED PWB section(B4):CD mechanism

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D1 001-7058-90 AN1105W-RR

D2 001-7058-90 AN1105W-RR

J1 074-1138-60 10P

Q1 060-4015-90 PS1192H

Q2 060-4015-90 PS1192H

S1 013-7414-50 CHUCKING

S2 013-7413-50 LIMIT

■BLOCK DIAGRAM

Main section

CD mechanism section

- 10 -PN-2445M

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Loading...

Loading...