Page 1

- 1 -

PH-2416I

Published by Service Dept.

Printed in Japan

Clarion Co., Ltd.

5-35-2, Hakusan, Bunkyouku, Tokyo, 112-8608 Japan

Service Dept.- 50 kamitoda,Toda-shi,Saitama,335-8511 Japan Tel: 048-443-1111 FAX:048-433-6996

298-5935-00

Oct.2001 P

Service Manual

Model

HONDA Automobile Genuine

AM/FM Radio CD Stereo

PH-2416I

※ Prevent damage caused by static electricity when re-

pairing the pick-up.

The pattern of the pick-up is short-circuiting for prevention.

Remove the soldering with a solder iron whose insulation resistance is larger than 10M

Ω(DC500V) after com-

plete connection to the main PWB

For repair table shall use copper or conductive sheet

(with impedance is lower to 100M

Ω from 1MΩ)such as

a sheet.

Be sure to put on a wrist-strap for prevent electric

static's.(with impedance is to 100M

Ω from 1MΩ) The

strap works to drain away the static electricity build-up

on the human body.

And as static electricity build-up on clothes is not drained

away, be careful and not your clothes to touch the pickup.

Position of short soldering for pick-up protection position is different by model.

Some units have two short soldering points.

Always short LD circuit to open the short circuit and removes by soldering iron.

■COMPONENTS

PH-2416I-A

Main unit −−−−− 1

CATS CARD 287-1681-03 1

Label 290-7868-02 1

■SPECIFICATIONS

Radio setion

Receive range: FM 87.75 & 87.9 to 107.9MHz

(200kHz step)

AM 530 to 1,710Hz(10kHz step)

Intermediate frequency:

FM 10.7

±0.2MHz

AM 450

±3kHz

Quieting sensitivity: FM Less than 12dB

μ

(at 30dB S/N)

AM Less than 35dB

μ

(at 20dB S/N)

Auto tuning stop sensitivity:

FM 24

±6dBμ

AM 35±6dBμ

CD section

System: Compact disc audio system

Usable Discs: Compact disc

Signal to Noise Ratio: More then 60dB

Separation: More then 55dB

General

Load impedance: 4Ω

Output power: More then 30W×2

Power supply voltage: DC13.2V(10.8 to 15.6V)

Negative ground

Dimensions(mm): 187.5(W)

×60(H)×160(D)

Weight: 1.65kg

■NOTE

※ Specification and design are subject to change without

notice for further improvement.

※ We cannot supply PWB with component parts in prin-

ciple. When a circuit on PWB has failure, please repair

it by component parts base. Parts which are not mentioned in service manual are not supplied.

(Genuine No.39100-S6M-A000)

(ID No.4XJ0)

■ To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow

the instructions so that customers and Engineers

in charge of repair or inspection can avoid suffering any risk or injury.

2005.05.25

Page 2

- 2 -PH-2416I

■COMPUTER ANTI-THEFT SYSTEM

This unit has a built-in Computer Anti-Theft System(CATS)

which makes the radio inoperative if power to the unit is

interrupted for any reason whatsoever(including disconnection and reconnection of the car battery). The radio will remain inoperative unless you enter the correct CATS number.

RELEASE the CATS

1. Turn on the power switch, "COdE" appear on the display.

2. Enter the code number of five figures using the preset

buttons.

3. If the entered code number is correct, make a beep sound

(about 1 second) and radio operating.

4. If the entered code number is incorrect, "Err1" appear

on the display for 1 secound and make a beep sound. It

repeats three times.

5. To enter the code number again, "COdE" reappears after 1 second on the display. Enter the correct code number.

6. If you enter an incorrect code number ten times in succession, "ErrE" appear on the display.

7. The system will not accept another code input for one

hour. If at the end of that hour make a beep sound (about

1 second) and you enter an incorrect code number again,

you will have to wait another hour to try once more and

so on.

■ADJUSTMENT

Clock accuracy

Item Procedure

Measuring

instrument

1. Turn on the ACC switch.

2. Set a universal timer to TP101(T-BASE), adjust TC102 so that a reading of the

meter is 0 to 1.0 sec./day.

Chronometer

1. Use specified parts.

The system uses parts with special safety features against

fire and voltage. Use only parts with equivalent characteristics when replacing them.

The use of unspecified parts shall be regarded as remodeling for which we shall not be liable. The onus of

product liability (PL) shall not be our responsibility in cases

where an accident or failure is as a result of unspecified

parts being used.

2. Place the parts and wiring back in their original positions

after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding, gaps to PWB, etc, is involved. The wiring connection and routing to the PWB are specially planned

using clamps to keep away from heated and high voltage

parts. Ensure that they are placed back in their original

positions after repair or inspection.

If extended damage is caused due to negligence during

repair, the legal responsibility shall be with the repairing

company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely in their original position after repair. Ensure for

safety reasons there is no possibility of secondary

ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the

battery connected, a short circuit and/or fire may occur.

If extensive damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality

is observed in their appearance. Always replace them

with new ones. (The chip parts include resistors, capacitors, diodes, transistors, etc). The negative pole of tantalum capacitors is highly susceptible to heat, so use special care when replacing them and check the operation

afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270

℃. Take care not to

apply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with

force.

7. Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

8. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through

the lens of the optical pickup. When checking that the

laser optical diode lights up, keep your eyes more than

30cms away from the lens. Prolonged viewing of the laser within 30cms may damage your eyesight.

9. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by

electrostatic charge caused by your clothes and body.

Make sure to avoid electrostatic charges on your clothes

or body, or discharge static electricity before handling the

optical pickup.

9-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage.

After replacement, open the shorted circuit. When

removing the pickup from the mechanism, short

the terminals by soldering them to prevent this

damage.

9-2. Actuator

The actuator has a powerful magnetic circuit. If a

magnetic material is put close to it. Its characteristics will change. Ensure that no foreign substances enter through the ventilation slots in the

cover.

9-3. Cleaning the lens

Dust on the optical lens affects performance. To

clean the lens, apply a small amount of isopropyl

alcohol to lens paper and wipe the lens gently.

Page 3

- 3 -

PH-2416I

■EXPLANATION OF IC

052-3154-11 M30622MA-F08GP Radio CD system controller

1.Terminal Description

pin 1: REM +5V : O : REM5V Power supply ON signal output.

pin 2: CD +8V : O : Power supply ON signal output for the

Loading motor and the Photo sensors.

pin 3: CD +5V : O : Power supply control signal output for the

CD DSP. "H"= ON.

pin 4: NU : - : Not in use.

pin 5: TIME BASE : IN : Time base signal input.

pin 6: BYTE : IN : Input "L" .

pin 7: CN VSS : IN : Input "L" .

pin 8: NU : - : Not in use.

pin 9: NU : - : Not in use.

pin 10: RESET_ : IN : Reset signal input. Negative logic.

pin 11: X OUT : O : Crystal connection.

pin 12: VSS : - : Negative supply voltage.

pin 13: X IN : IN : Crystal connection. Ceramic resonator con-

nection.

pin 14: VCC : - : Positive supply voltage.

pin 15: NU : - : Not in use.

pin 16: SBSY_ :IN : Sub Q data input from CD.

pin 17: ACC DET_ : IN: ACC detection terminal. "L"= ACC ON.

pin 18: B/U DET_ : IN : Backup voltage ON signal input. "L"= Back-

up ON.

pin 19: H bus In/Rx int : IN : H bus data input, and IE-bus start bit de-

tection signal input.

pin 20: NAVI INT L_ : O : Front Left Navi audio signal ON. Negative

logic.

pin 21: NAVI INT R_ : O : Front Right Navi audio signal ON. Negative

logic.

pin 22: MUTE F/L : O : Audio mute signal output to "Front Left".

pin 23: MUTE F/R : O : Audio mute signal output to "Front Right".

pin 24: MUTE REAR : O : Audio mute signal output to "Rear".

pin 25: MUTE AMP : O : Amplifier Mute signal output.

pin 26: BEEP : O : Beep out(3.0kHz).

pin 27: RX_ : IN : GA-NET RX terminal.

pin 28: HB O/GA TX : O : H bus data output, and GA-NET TX.

pin 29: F-ROM/T TXD : O : With testing box, TX terminal.

pin 30: F-ROM/T RXD : IN : With testing box, RX terminal.

pin 31: F-ROM K/T Req : IN

:

With testing box, REQ input.

pin 32: F-ROM BUSY : O : Fixed to the low level in the normal condi-

tion.

pin 33: E VOL DO : O : Serial data output to the volume IC.

pin 34: NAVI MUTE_ : IN : NAVI mute signal input. Negative logic.

pin 35: E VOL CLK : O : Clock pulse output to the E VOL IC.

pin 36: E VOL CE : O : Chip enable signal output to the E VOL IC.

pin 37: SYS ACC ON : O : System ACC ON signal output.

pin 38: Power IC Diag : IN : Power IC diagnosis signal input.

pin 39: F ROM EPM_ : O : Fixed to the low level in the normal condi-

tion.

pin 40 : TEST : IN: Test key signal input.

pin 41: EJECT :IN : Eject key input. Negative logic.

pin 42: POWER : IN : "L"= power ON.

pin 43: NU : - : Not in use.

pin 44: F ROM CE_ : O : Fixed to the low level in the normal condi-

tion.

pin 45: EEPROM DI : IN : Serial data input from the EEPROM.

pin 46: EEPROM DO : O : Serial data output to the EEPROM.

pin 47 : EEPROM CLK : O : Serial clock output to EEPROM.

pin 48: EEPROM CE : O : Chip enable signal output to the EEPROM.

pin 49: NU : - : Not in use.

pin 50: FM SD : IN : FM station detect signal input.

pin 51 : AM SD : IN : AM station detect signal input.

pin 52: FM STEREO_ : IN : FM STEREO ON signal input. Negative log-

ic.

pin 53: PLL DI : IN : PLL serial data input.

pin 54: PLL DO : O : PLL serial data output.

pin 55: PLL CLK : O : PLL clock pulse output

pin 56: PLL CE : O : Chip enable signal output to PLL.

pin 57: AREA 1 : IN : Destination setting input. Ref. Table 1.

pin 58: AREA 2 : IN: Destination setting input. Ref. Table 1.

pin 59: Clock ON_/OFF : IN : Clock ON_/OFF initial setting input.

pin 60: VCC : - : Positive supply voltage.

pin 61 : NU : - : Not in use.

pin 62: VSS : - : Negative supply voltage.

pin 63: 12_ / 24 : IN : "H"= 24 hour mode.

pin 64 : A MODE : IN : Sub volume initial setting.

pin 65: X MODE : IN : "L"= X MODE ON.

pin 66: SW+B_/Rd ON : IN : Radio on port control input. "H"= with Ra-

dio mode, "L"= with Power mode.

pin 67: CD_/AUX : O : The converter input select signal output.

pin 68 : RADIO ON : O : Radio ON signal output.

pin 69: CATS KEY_ : IN : Special signal input.

pin 70 : Disc ind : O : Disc indicator ON signal output.

pin 71 : CATS ind : O : CATS indicator ON signal output.

pin 72 : BUC 0 :I/O: CD IC Data input / output.

pin 73 : BUC 1 :I/O: CD IC Data input / output.

pin 74 : BUC 2 :I/O: CD IC Data input / output.

pin 75 : BUC 3 :I/O: CD IC Data input / output.

pin 76 : BUC CLOCK : O : CD IC clock pulse output.

pin 77 : CCE : O : Chip enable signal output to CD IC.

pin 78: CD RESET : O : Reset signal output to CD mechanism con-

troller. Negative logic.

pin 79: CHUCK : IN : Chucking switch signal input.

pin 80: TR A :IN: Photo sensor signal input from the CD

mechanism.

pin 81: TR B :IN: Photo sensor signal input from the CD

mechanism.

pin 82: TR C : IN : Photo sensor signal input from the CD

mechanism.

pin 83: CW : O : Loading motor control output.

Ref. Table 2.

pin 84: CCW : O : Loading motor control output.

Ref. Table 2.

pin 85 : Main Volume A : IN : Main volume control pulse input.

pin 86 : Main Volume B : IN : Main volume control pulse input.

pin 87 : Sub Volume A : IN: Sub volume control pulse input.

pin 88 : Sub Volume B : IN: Sub volume control pulse input.

pin 89 : LCD DI_ : IN : LCD driving data input.

pin 90 : LCD DO : O : Serial data output to the LCD driver.

pin 91 : LCD CLK : O : Serial data clock output to LCD driver.

pin 92: LCD CE : O : Chip enable signal output to the LCD driv-

er.

pin 93 : S METER :IN : Input terminal of Internal A/D converter to

detect the Voltage of FM S meter.

pin 94: A VSS : - : Analog ground.

pin 95: REMOCON : IN : Steering wheel remote control switch signal

input.

pin 96: Vref : IN : Reference voltage terminal for the bulit-in A/

D converter.

pin 97 : A VCC : - : Positive supply voltage for the internal an-

alog section.

pin 98 : Back light ON : O : Back light On signal output.

pin 99 : NU : - : Not in use.

pin100: AUDIO ON : O : "H"= Audio power supply ON.

Table 1. Destination setting input

Area1(pin57) Area2(pin58)

U.S.A. H-BUS L L

EXP H-BUS H L

Table 2. Loading motor control output

Loadin g Eject Brake Stop

CW ( pin 83 ) H L H L

CCW ( pin 84 ) L H H L

Page 4

- 4 -PH-2416I

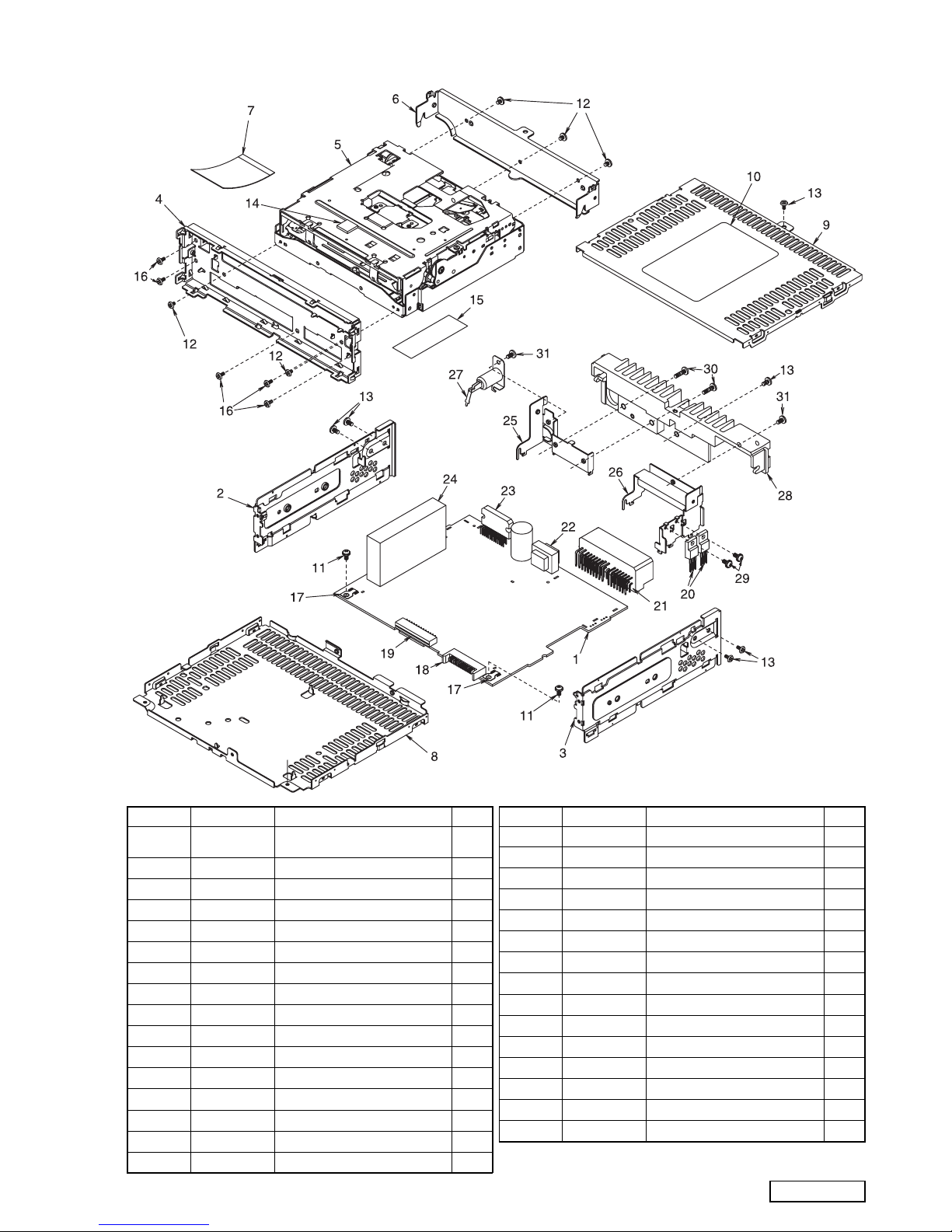

■EXPLODED VIEW・PARTS LIST

Escutcheon section

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

1 940-7949-02 ESCUTCHEON ASSY 1

1-1 716-0872-00 PAD SCREW(M1.7×5 SILVER) 2

2 331-3029-00 LCD COVER 1

3 379-1208-32 INDICATOR 1

4 335-6413-00 COLOR FILTER 1

5 335-6515-10 LCD ILLUMI 1

6 335-6441-00 ILLUMI HOLDER 1

7 039-1974-00 SWITCH PWB 1

(WITHOUT COMPONENT)

8 016-0014-05 VR W-SHAFT 2

9 017-0433-77 PILOT LAMP(14V40mA RED) 7

10 017-0429-13 PILOT LAMP(8V105mA RED) 2

11 013-6201-50 PUSH SWITCH 13

12 074-1151-20 OUTLET SOCKET (20P) 1

13 001-0518-96 LED(GREEN) 1

14 340-4323-00 SPACER 1

15 001-0412-17 DIODE 1

16 380-5522-00 KNOB 2

17 373-0963-02 DIAL COVER 1

18 335-6650-00 FILTER 1

19 346-0124-10 LEATHER SHEET 1

20 331-3030-00 SHIELD PLATE 1

21 335-6567-00 DISC GUIDE 1

22 335-6566-00 DISC INDICATOR 1

23 347-6410-00 DOUBLE FACE 1/100

24 345-8188-20 ES-RUBBER 1

25 716-0872-11 PAD SCREW(M1.7×6 BLACK) 4

26 716-1889-00 SCREW(M2.6×5) 2

Page 5

- 5 -

PH-2416I

Main section

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

1 039-1797-02 MAIN PWB 1

(WITHOUT COMPONENT)

2 305-0293-10 SIDE PLATE LH 1

3 305-0294-10 SIDE PLATE RH 1

4 331-3034-00 ES PLATE 1

5 929-0091-80 CD MECHA MODULE 1

6 331-2874-00 MECHA BRACKET 1

7 816-2490-00 FLAT WIRE 1

8 311-1799-00 LOWER CASE 1

9 310-1703-00 UPPER CASE 1

10 286-9412-24 SETPLATE 1

11 716-0878-00 IT SCREW(M2.6×5) 2

12 714-2303-81 MACHINE SCREW (M2.3×3) 5

13 714-2606-81 MACHINE SCREW (M2.6×6) 6

14 345-4138-00 RUBBER PARTS 1

15 347-2022-02 PAPER PARTS 1

16 714-2606-11 MACHINE SCREW(M2.6×6) 5

17 073-0762-90 TERMINAL 2

18 076-0540-20 PLAG (20P) 1

19 074-1186-26 OUTLET SOCKET (26P) 1

20 103-2012-00 TRANSISTOR 2

21 074-1166-00 OUTLET SOCKET 1

22 009-0666-0L CHOKE 1

23 051-2023-01 IC(TA8260AH) 1

24 880-1914H TUNER PACK (AM/FM) 1

25 307-0658-00 REAR PLATE LH 1

26 307-0659-00 REAR PLATE RH 1

27 092-0702-00 ANT RECEPT 1

28 313-1824-00 HEAT SINK 1

29 716-1494-00 IT SCREW (M2.6×6) 2

30 714-2612-81 MACHINE SCREW (M2.6×12) 2

31 714-2606-81 MACHINE SCREW (M2.6×6) 2

Page 6

- 6 -PH-2416I

CD mechanism section

※ The parts list is on page 8.

L1

K

A11

L1

N

A5

D1

A10

P

D2

D5

D6

D7

D4

D3

L2

D4

D7

H2

H1

M

D5

D6

J

I2

H2

H1

C2

C1

I1

I2

I3

I1

P

N

A7

Page 7

- 7 -

PH-2416I

B

F2

F1

E3

M

A4

I3

D2

D3

A11

A7

K

A4

A6

F1

A5

A8

G

A9

A1

A10

D1

G

A9

E4

E4

A1

A3

B

E1

E2

E3

A2

A6

F2

A8

C2

E1

E2

A3

A2

C1

A7

Page 8

- 8 -PH-2416I

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

1 HBS-463-100 DRIVE UNIT 1

1-1 966-0314-21 STOP LINK ASSY 1

1-2 966-0447-23 DR-PLATE ASSY 1

1-3 966-0448-21 SIDE PLATE ASSY 1

1-4 966-0449-23 CLAMP LINK ASSY 1

1-5 969-0050-04 PICK UP UNIT 1

969-0050-34 PICK UP UNIT

969-0050-52 PICK UP UNIT

1-6 013-7100-00 LIMIT SWITCH 1

1-7 620-0198-03 CLAMPER PLATE 1

1-8 620-0491-03 SPRING PLATE 1

1-9 620-0690-01 RATTLE PLATE 1

1-10 621-0205-02 CLAMPER LINK 1

1-11 621-0251-03 LOCK LINK 1

1-12 621-0252-03 DISC STOPPER 1

1-13 621-0253-02 MOTOR HOLDER 1

1-14 621-0255-02 SECOND GEAR 1

1-15 621-0375-00 SH-BASE 1

1-16 621-0357-03 PICK UP GUIDE 1

1-17 621-0358-02 LS-HOLDER F 1

1-18 621-0359-02 LS-HOLDER R 1

1-19 622-1073-02 CLAMPER ROLLER 1

1-20 714-2003-81 MACHINE SCREW(M2×3) 10

1-21 716-0675-00 SCREW(M2×2.5) 2

1-22 716-1468-00 SCREW(M2×2.5) 2

1-23 716-1555-00 WAVE SCREW 1

1-24 716-1733-00 SCREW(M2×2.5) 2

1-25 732-2004-11 SEMS SCREW 2

1-26 739-1735-17 PRECISION SCREW 2

1-27 746-0761-00 SCREW(M2×2.5) 2

1-28 750-3097-03 CLAMPER SPRING 1

1-29 750-3098-00 L-LINK SPRING 1

1-30 750-3099-00 ES-SPRING 1

1-31 816-2372-00 WIRE(BLU) 1

1-32 816-2373-00 WIRE(WHT) 1

1-33 966-0454-00 SH-RACK ASSY 1

1-34 HBS-432-100 LS-GEAR ASSY 1

1-35 SMA-146-100 SLED MOTOR ASSY 1

1-36 SMA-151-100 SPINDLE MOTOR ASSY 1

2 966-0308-11 CHASSIS ASSY 1

3 966-0309-20 L-DISC-G-ASSY 1

4 966-0310-21 SHIFT-P-CH-ASSY 1

5 966-0312-21 SHIFT-P-ASSY 1

6 966-0358-21 DRIVE-L-PL-ASSY 1

7 966-0359-21 SIDE-L-PL-ASSY 1

8 013-3879-01 CHUCKING SWITCH 1

9 039-0586-01 CHUCKING SWITCH PWB 1

(WITHOUT COMPONENT)

10 039-0588-01 SENSOR PWB 1

(WITHOUT COMPONENT)

11 060-0252-01 PHOTO TR (PT4850F) 3

12 345-7513-01 CLAMPER SHEET 1

13 345-7514-00 S-PWB SHEET 1

14 620-0485-04 FRONT PLATE 1

15 620-0488-01 S-L-LINK PLATE 1

16 620-0489-02 MOTOR PLATE 1

17 620-0492-01 MOTOR BRACKET 1

18 620-0773-01 MECH BRACKET 1

19 621-0402-02 U-DISC GUIDE F 1

20 621-0243-02 ROLLER SLAVE 2

21 621-0248-07 RACK GEAR 1

22 621-0249-02 ROLLER GEAR 1

23 621-0250-21 DAMPER HOLDER 4

24 621-0258-03 LOADING ROLLER 2

25 622-1072-05 ROLLER SHAFT 1

26 622-1219-01 SHIFT ROLLER 1

27 629-0058-00 DAMPER-VA 4

28 714-2003-81 MACHINE SCREW(M2X3) 9

29 714-2603-81 MACHINE SCREW(M2.6X3) 5

30 716-1468-00 SCREW(M2×2.5) 3

31 716-1507-00 SCREW(M2×3) 2

32 716-1670-00 SCREW(M2×4) 6

33 716-1677-00 SCREW(M2×5) 1

34 716-1704-00 SCREW(M2×7) 1

35 716-1742-00 SCREW(M2×5) 1

36 743-1500-10 E-RING 3

37 746-0712-03 WASHER 1

38 746-0762-00 WASHER 1

39 746-0877-02 WASHER 2

40 750-3090-02 RO-SPRING L 1

41 750-3091-03 RO-SPRING R 1

42 750-3092-03 SHIFT SPRING 1

43 750-3094-00 S-ARM SPRING 1

44 750-3096-01 DR-SPRING R 1

45 750-3098-00 L-LINK SPRING 1

46 750-3164-00 DR-SPRING-LR 1

47 750-3188-00 DR-SPRING-F-B 1

48 750-3189-00 SIDE-L-SPRING 1

49 750-3201-00 DR-SPRING-F-R 1

50 750-3348-00 CENTER SPRING 1

51 800-4904-60 WIRE(BLK) 1

52 800-4910-60 WIRE(BLK) 1

53 801-4910-60 WIRE(BRN) 1

54 802-4904-60 WIRE(RED) 1

55 802-4910-60 WIRE(RED) 1

56 804-4910-60 WIRE(YEL) 1

57 001-0563-00 DIODE 3

58 HBS-430-100 GEAR PLATE ASSY 1

59 039-1088-03 CD MECH PWB 1

(WITHOUT COMPONENT)

60 SMA-147-100 LOADING MOTOR ASSY 1

61 620-0804-00 CE-SP-PLATE F 1

62 620-0803-00 CE-SP-PLATE R 1

Page 9

- 9 -

PH-2416I

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

Note) Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

■ELECTRICAL PARTS LIST

Main PWB section(B1)

ANT101 092-0702-00 ANT RECEPT

BL101 880-1914H AM/FM TUNER

C102 166-1801-50 18pF CH

C103 166-1007-50 10pF CH

C104 168-2232-55 0.022μF

C105 168-4735-56 0.047μF

C106 183-1073-27 10V100μF

C107 166-1801-50 18pF CH

C109 183-1073-27 10V100μF

C111 183-1073-27 10V100μF

C112 042-0458-50 50V 1μF LN

C113 168-1045-56 0.1μF

C114 166-1011-50 100pF CH

C115 166-1011-50 100pF CH

C116 168-2222-55 2200pF

C117 166-1011-50 100pF CH

C118 166-1011-50 100pF CH

C119 166-2201-50 22pF CH

C120 168-3322-55 3300pF

C121 183-1063-37 16V10μF

C124 168-1022-55 1000pF

C125 183-4763-37 16V47μF

C126 168-4735-56 0.047μF

C127 183-1543-67 50V0.15μF

C128 168-8222-55 8200pF

C129 168-2722-55 2700pF

C130 183-1543-67 50V0.15μF

C131 168-4735-56 0.047μF

C132 168-8222-55 8200pF

C133 168-2722-55 2700pF

C134 168-2232-55 0.022μF

C135 168-2232-55 0.022μF

C137 183-1056-67 50V1μF NP

C138 168-1232-55 0.012μF

C139 168-2232-55 0.022μF

C140 168-2232-55 0.022μF

C141 166-1007-50 10pF CH

C142 166-1007-50 10pF CH

C143 168-2232-55 0.022μF

C201 183-3343-67 50V0.33μF

C202 183-3343-67 50V0.33μF

C203 183-4763-37 16V47μF

C204 183-1053-67 50V1μF

C205 183-1053-67 50V1μF

C208 178-2242-78 0.22μF

C209 178-2242-78 0.22μF

C210 183-1063-37 16V10μF

C211 183-1063-37 16V10μF

C212 183-1063-37 16V10μF

C213 183-1063-37 16V10μF

C214 043-0309-90 10V 1μF

C215 043-0309-90 10V 1μF

C216 168-6835-56 0.068μF

C217 168-6835-56 0.068μF

C218 168-1032-55 0.01μF

C219 168-1032-55 0.01μF

C220 168-4712-55 470pF

C221 168-4712-55 470pF

C222 183-1063-37 16V10μF

C223 183-1063-37 16V10μF

C224 168-3335-56 0.033μF

C225 166-1011-50 100pF CH

C226 166-1011-50 100pF CH

C227 183-2253-67 50V2.2μF

C228 183-2253-67 50V2.2μF

C229 183-2263-37 16V22μF

C230 183-2263-37 16V22μF

C238 168-5612-55 560pF

C241 183-1063-37 16V10μF

C243 168-4735-56 0.047μF

C244 178-1242-78 0.12μF

C245 178-1242-78 0.12μF

C246 178-2242-78 0.22μF

C247 178-5642-78 0.56μF

C248 178-6832-78 0.068μF

C249 178-1542-78 0.15μF

C250 178-2242-78 0.22μF

C251 178-5642-78 0.56μF

C252 178-6832-78 0.068μF

C253 178-1542-78 0.15μF

C254 178-1832-78 0.018μF

C255 178-2732-78 0.027μF

C256 178-1032-78 0.01μF

C257 178-1032-78 0.01μF

C258 178-1832-78 0.018μF

C259 178-2732-78 0.027μF

C260 178-1032-78 0.01μF

C261 178-1032-78 0.01μF

C262 178-1532-78 0.015μF

C263 178-1032-78 0.01μF

C264 178-2232-78 0.022μF

C265 178-5622-78 5600pF

C266 178-1532-78 0.015μF

C267 178-1032-78 0.01μF

C268 178-2232-78 0.022μF

C269 178-5622-78 5600pF

C270 178-2242-78 0.22μF

C271 178-2242-78 0.22μF

C272 183-2256-57 35V2.2μF NP

C273 183-2256-57 35V2.2μF NP

C274 183-2256-57 35V2.2μF NP

C275 183-2256-57 35V2.2μF NP

C276 183-1073-27 10V100μF

C279 183-1073-27 10V100μF

C282 168-1022-55 1000pF

C283 168-1022-55 1000pF

C284 168-1022-55 1000pF

C285 168-1022-55 1000pF

C286 042-0466-00 16V4700μF

C287 183-2263-37 16V22μF

C288 166-1011-50 100pF CH

C290 166-1011-50 100pF CH

C292 168-1545-56 0.15μF

C293 168-1545-56 0.15μF

C294 168-1545-56 0.15μF

C295 168-1545-56 0.15μF

C296 172-1041-15 0.1μF

C298 183-2253-67 50V2.2μF

C299 183-2253-67 50V2.2μF

C301 183-4763-37 16V47μF

C302 168-2212-55 220pF

C303 168-2212-55 220pF

C304 183-2263-37 16V22μF

C305 183-2263-37 16V22μF

C308 183-1063-37 16V10μF

C309 183-1063-37 16V10μF

C312 168-8232-78 0.082μF

C313 168-8232-78 0.082μF

C314 168-1822-55 1800pF

C315 168-1822-55 1800pF

C316 168-2722-55 2700pF

C319 168-2722-55 2700pF

C320 183-2253-67 50V2.2μF

C321 183-2253-67 50V2.2μF

C330 168-2222-55 2200pF

C331 168-2222-55 2200pF

C332 183-2253-67 50V2.2μF

C333 183-2253-67 50V2.2μF

C334 183-2253-67 50V2.2μF

C335 183-2253-67 50V2.2μF

C336 183-2253-67 50V2.2μF

C337 183-2253-67 50V2.2μF

C338 183-2253-67 50V2.2μF

C339 183-2253-67 50V2.2μF

C340 183-1073-27 10V100μF

C341 183-3363-25 10V33μF

C342 183-3363-25 10V33μF

C343 183-1073-27 10V100μF

C344 183-2253-67 50V2.2μF

C345 183-2253-67 50V2.2μF

C346 183-2253-67 50V2.2μF

C347 183-2253-67 50V2.2μF

C348 183-2253-67 50V2.2μF

C349 183-2253-67 50V2.2μF

C350 178-2242-78 0.22μF

C351 178-2242-78 0.22μF

C352 166-1011-50 100pF CH

C353 166-1011-50 100pF CH

C354 183-1063-37 16V10μF

C355 183-1063-37 16V10μF

C358 166-1011-50 100pF CH

C359 166-1011-50 100pF CH

C401 168-1045-56 0.1μF

C403 166-1501-50 15pF CH

C404 166-1801-50 18pF CH

C405 168-1045-56 0.1μF

C406 168-1045-56 0.1μF

C407 168-4735-56 0.047μF

C408 168-1045-56 0.1μF

C412 168-3312-55 330pF

C414 119-0000-05 1/16W 0Ω JW

C416 183-6853-47 25V6.8μF

C501 183-2263-37 16V22μF

C502 183-2263-37 16V22μF

C503 168-1022-55 1000pF

C508 183-1063-37 16V10μF

C509 168-1022-55 1000pF

C510 183-1063-37 16V10μF

C512 168-1032-55 0.01μF

C513 168-1022-55 1000pF

C516 183-2253-67 50V2.2μF

C517 178-2242-78 0.22μF

C518 178-2242-78 0.22μF

C519 178-2242-78 0.22μF

C520 184-4773-12 6.3V470μF

C521 183-1063-37 16V10μF

C522 042-0452-81 10V220μF

C523 183-4763-37 16V47μF

C527 172-1041-15 0.1μF

C528 183-1063-37 16V10μF

C529 184-4773-12 6.3V470μF

C530 183-3353-61 50V3.3μF

C531 172-1041-15 0.1μF

C532 172-1041-15 0.1μF

C533 183-1063-37 16V10μF

D301 001-0516-90 MA111

D404 001-0516-90 MA111

D503 001-0529-55 MA8120-L

D505 001-0529-42 MA8075-H

D506 001-0529-33 MA8056-H

D507 001-0529-45 MA8082-H

D508 001-0529-43 MA8082-L

D509 001-0330-00 1SS119

D510 001-0516-90 MA111

D511 001-0516-90 MA111

D512 001-0516-90 MA111

D513 001-0535-90 MA729

D514 001-0529-47 MA8091-M

D515 001-0504-34 HZS6 C1L

D515 001-0503-34 HZS6 C1L

D516 001-0516-90 MA111

D517 001-0592-00 RM4Z

D518 001-0466-90 S5688B

Page 10

- 10 -PH-2416I

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D519 001-0466-90 S5688B

D521 001-0466-90 S5688B

D522 001-0535-90 MA729

D523 001-0503-42 HZS7C3L

D523 001-0504-42 HZS7C3L

D524 001-0516-90 MA111

IC102 051-6201-90 LC72146M

IC201 051-5012-10 LC75386NE-L

IC204 051-1080-91 NJM4560M

IC205 051-2023-01 TA8260AH

IC206 051-1979-90 M5243FP09

IC207 051-1979-90 M5243FP09

IC208 051-1080-91 NJM4560M

IC301 051-3013-90 M5203AFP

IC302 051-3013-90 M5203AFP

IC306 051-0722-90 SA571D

IC307 051-0722-90 SA571D

IC401 052-3154-11 M30622MA-F08GP

IC402 051-9400-18 AT93C46-10SI

IC501 051-1822-08 S-80732AN-DW-X

J301 074-1186-26 26P

J302 076-0540-20 20P

J901 074-1166-00 34P

L101 010-2003-04 COIL

L102 010-6009-88 220μH

L701 010-6009-64 2.2μH

Q101 190-1298-00 2SA1298

Q102 190-1298-00 2SA1298

Q103 125-2004-92 RN1402

Q210 192-2712-00 2SC2712

Q211 192-2712-00 2SC2712

Q301 192-2712-00 2SC2712

Q302 192-2712-00 2SC2712

Q304 125-2004-93 RN1403

Q305 192-2712-00 2SC2712

Q306 192-2712-00 2SC2712

Q402 190-1162-00 2SA1162

Q403 125-2004-92 RN1402

Q404 192-2712-00 2SC2712

Q406 125-2004-92 RN1402

Q501 125-0002-93 RN2403

Q502 193-1858-00 2SD1858

Q503 193-1858-00 2SD1858

Q504 193-1858-00 2SD1858

Q505 125-0002-92 RN2402

Q506 125-2004-92 RN1402

Q507 125-0013-96 RN2426

Q508 193-1858-00 2SD1858

Q509 103-2012-00 2SD2012

Q511 125-0002-92 RN2402

Q512 125-2004-92 RN1402

Q513 193-1858-00 2SD1858

Q514 193-1858-00 2SD1858

Q515 125-0002-92 RN2402

Q516 125-2004-92 RN1402

Q517 103-2012-00 2SD2012

Q518 125-0002-92 RN2402

Q519 125-2004-92 RN1402

Q520 192-2712-00 2SC2712

Q522 125-0013-97 RN2427

Q523 125-2004-92 RN1402

Q524 193-1858-00 2SD1858

Q525 125-2004-92 RN1402

Q526 193-1858-00 2SD1858

Q527 193-1858-00 2SD1858

Q528 125-0002-92 RN2402

Q529 125-2004-92 RN1402

Q530 190-1431-00 2SA1431

Q533 193-1858-00 2SD1858

Q537 192-2712-00 2SC2712

Q538 192-2712-00 2SC2712

Q539 193-1858-00 2SD1858

Q540 193-1858-00 2SD1858

Q541 192-2712-00 2SC2712

Q542 193-1858-00 2SD1858

R101 119-4721-15 1/16W 4.7kΩ

R102 119-2221-15 1/16W 2.2kΩ

R103 111-6891-94 1/4WS 6.8Ω

R104 119-2221-15 1/16W 2.2kΩ

R105 119-2221-15 1/16W 2.2kΩ

R106 119-3321-15 1/16W 3.3kΩ

R107 119-2221-15 1/16W 2.2kΩ

R108 119-2231-15 1/16W 22kΩ

R109 119-2221-15 1/16W 2.2kΩ

R110 119-1221-15 1/16W 1.2kΩ

R111 119-4731-15 1/16W 47kΩ

R112 119-1031-15 1/16W 10kΩ

R113 119-1031-15 1/16W 10kΩ

R114 119-1221-15 1/16W 1.2kΩ

R117 119-1021-15 1/16W 1kΩ

R118 119-1041-15 1/16W 100kΩ

R119 111-6891-94 1/4WS 6.8Ω

R120 119-0000-05 1/16W 0Ω JW

R121 119-1021-15 1/16W 1kΩ

R122 119-1831-15 1/16W 18kΩ

R123 111-1001-94 1/4WS 10Ω

R124 119-1021-15 1/16W 1kΩ

R125 119-2221-15 1/16W 2.2kΩ

R201 119-1031-15 1/16W 10kΩ

R202 119-3931-15 1/16W 39kΩ

R203 119-1041-15 1/16W 100kΩ

R204 119-1041-15 1/16W 100kΩ

R205 119-3931-15 1/16W 39kΩ

R206 119-1031-15 1/16W 10kΩ

R209 119-3321-15 1/16W 3.3kΩ

R210 119-3321-15 1/16W 3.3kΩ

R211 119-4741-15 1/16W 470kΩ

R212 119-2221-15 1/16W 2.2kΩ

R213 119-2221-15 1/16W 2.2kΩ

R214 119-2221-15 1/16W 2.2kΩ

R215 119-4731-15 1/16W 47kΩ

R216 119-1031-15 1/16W 10kΩ

R217 119-4721-15 1/16W 4.7kΩ

R218 119-4721-15 1/16W 4.7kΩ

R224 119-1031-15 1/16W 10kΩ

R225 119-1031-15 1/16W 10kΩ

R228 119-3331-15 1/16W 33kΩ

R229 119-3331-15 1/16W 33kΩ

R232 119-1031-15 1/16W 10kΩ

R233 119-1031-15 1/16W 10kΩ

R234 119-1521-15 1/16W 1.5kΩ

R235 119-1521-15 1/16W 1.5kΩ

R236 119-6821-15 1/16W 6.8kΩ

R237 119-6821-15 1/16W 6.8kΩ

R238 119-2221-15 1/16W 2.2kΩ

R239 119-2221-15 1/16W 2.2kΩ

R244 119-1031-15 1/16W 10kΩ

R245 119-1031-15 1/16W 10kΩ

R246 119-1031-15 1/16W 10kΩ

R247 119-1031-15 1/16W 10kΩ

R251 119-1031-15 1/16W 10kΩ

R256 119-1021-15 1/16W 1kΩ

R257 119-1531-15 1/16W 15kΩ

R258 117-4721-15 1/10W 4.7kΩ

R259 117-4721-15 1/10W 4.7kΩ

R261 117-4721-15 1/10W 4.7kΩ

R263 117-4721-15 1/10W 4.7kΩ

R264 117-1831-15 1/10W 18kΩ

R266 117-1831-15 1/10W 18kΩ

R268 117-8211-15 1/10W 820Ω

R269 117-2231-15 1/10W 22kΩ

R270 117-8211-15 1/10W 820Ω

R271 117-2231-15 1/10W 22kΩ

R280 117-6811-15 1/10W 680Ω

R281 117-3931-15 1/10W 39kΩ

R282 117-6811-15 1/10W 680Ω

R283 117-3931-15 1/10W 39kΩ

R284 117-4721-15 1/10W 4.7kΩ

R285 117-4721-15 1/10W 4.7kΩ

R286 117-4721-15 1/10W 4.7kΩ

R287 117-4721-15 1/10W 4.7kΩ

R288 117-4721-15 1/10W 4.7kΩ

R289 117-4721-15 1/10W 4.7kΩ

R290 119-1001-15 1/16W 10Ω

R291 119-1031-15 1/16W 10kΩ

R292 119-1001-15 1/16W 10Ω

R293 119-2721-15 1/16W 2.7kΩ

R294 119-2221-15 1/16W 2.2kΩ

R295 119-2721-15 1/16W 2.7kΩ

R296 119-2221-15 1/16W 2.2kΩ

R297 119-1821-15 1/16W 1.8kΩ

R298 119-1821-15 1/16W 1.8kΩ

R301 119-1031-15 1/16W 10kΩ

R302 119-1021-15 1/16W 1kΩ

R303 119-1021-15 1/16W 1kΩ

R306 119-4731-15 1/16W 47kΩ

R307 119-4731-15 1/16W 47kΩ

R308 119-6821-15 1/16W 6.8kΩ

R309 119-6821-15 1/16W 6.8kΩ

R310 119-1031-15 1/16W 10kΩ

R311 119-2221-15 1/16W 2.2kΩ

R312 119-1031-15 1/16W 10kΩ

R313 119-2221-15 1/16W 2.2kΩ

R314 119-1521-15 1/16W 1.5kΩ

R317 119-1031-15 1/16W 10kΩ

R318 119-1031-15 1/16W 10kΩ

R321 119-1521-15 1/16W 1.5kΩ

R322 119-1531-15 1/16W 15kΩ

R323 119-1531-15 1/16W 15kΩ

R326 119-2231-15 1/16W 22kΩ

R327 119-2231-15 1/16W 22kΩ

R328 119-2731-15 1/16W 27kΩ

R329 119-2731-15 1/16W 27kΩ

R334 119-6831-15 1/16W 68kΩ

R335 119-4731-15 1/16W 47kΩ

R336 119-4731-15 1/16W 47kΩ

R337 119-6831-15 1/16W 68kΩ

R338 119-2231-15 1/16W 22kΩ

R339 119-6821-15 1/16W 6.8kΩ

R340 119-1031-15 1/16W 10kΩ

R341 119-1031-15 1/16W 10kΩ

R342 119-6821-15 1/16W 6.8kΩ

R343 119-2231-15 1/16W 22kΩ

R344 119-1031-15 1/16W 10kΩ

R345 119-1031-15 1/16W 10kΩ

R346 119-1031-15 1/16W 10kΩ

R347 119-1031-15 1/16W 10kΩ

R348 119-1031-15 1/16W 10kΩ

R349 119-1031-15 1/16W 10kΩ

R350 119-2731-15 1/16W 27kΩ

R351 119-1031-15 1/16W 10kΩ

R352 119-2221-15 1/16W 2.2kΩ

R353 119-1021-15 1/16W 1kΩ

R354 119-1031-15 1/16W 10kΩ

R355 119-2731-15 1/16W 27kΩ

R356 119-1021-15 1/16W 1kΩ

R357 119-2221-15 1/16W 2.2kΩ

R360 119-1021-15 1/16W 1kΩ

R361 119-1021-15 1/16W 1kΩ

R362 119-1021-15 1/16W 1kΩ

R363 119-1021-15 1/16W 1kΩ

R364 119-1021-15 1/16W 1kΩ

R365 119-1021-15 1/16W 1kΩ

R366 119-1021-15 1/16W 1kΩ

R367 119-1021-15 1/16W 1kΩ

R368 119-1031-15 1/16W 10kΩ

R369 119-1031-15 1/16W 10kΩ

R370 119-2721-15 1/16W 2.7kΩ

R371 119-2721-15 1/16W 2.7kΩ

R401 119-4741-15 1/16W 470kΩ

R402 119-4721-15 1/16W 4.7kΩ

R403 119-4721-15 1/16W 4.7kΩ

Page 11

- 11 -

PH-2416I

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R404 119-4721-15 1/16W 4.7kΩ

R406 119-4731-15 1/16W 47kΩ

R409 119-2231-15 1/16W 22kΩ

R411 119-2231-15 1/16W 22kΩ

R413 119-2231-15 1/16W 22kΩ

R415 119-2231-15 1/16W 22kΩ

R417 119-2231-15 1/16W 22kΩ

R419 119-2231-15 1/16W 22kΩ

R421 119-2231-15 1/16W 22kΩ

R422 119-1021-15 1/16W 1kΩ

R423 119-2231-15 1/16W 22kΩ

R424 119-4721-15 1/16W 4.7kΩ

R425 119-4721-15 1/16W 4.7kΩ

R426 119-4721-15 1/16W 4.7kΩ

R427 119-4721-15 1/16W 4.7kΩ

R436 119-1021-15 1/16W 1kΩ

R437 119-1021-15 1/16W 1kΩ

R438 119-4721-15 1/16W 4.7kΩ

R439 119-4731-15 1/16W 47kΩ

R440 119-4731-15 1/16W 47kΩ

R441 119-4731-15 1/16W 47kΩ

R442 119-4731-15 1/16W 47kΩ

R443 119-2231-15 1/16W 22kΩ

R444 119-2231-15 1/16W 22kΩ

R445 119-2231-15 1/16W 22kΩ

R446 111-2211-94 1/4WS 220Ω

R447 119-4721-15 1/16W 4.7kΩ

R448 119-4731-15 1/16W 47kΩ

R450 119-4721-15 1/16W 4.7kΩ

R452 119-3921-15 1/16W 3.9kΩ

R453 119-4731-15 1/16W 47kΩ

R455 119-4731-15 1/16W 47kΩ

R456 119-1831-15 1/16W 18kΩ

R457 119-1031-15 1/16W 10kΩ

R458 119-4731-15 1/16W 47kΩ

R461 119-4731-15 1/16W 47kΩ

R462 119-4731-15 1/16W 47kΩ

R464 119-1021-15 1/16W 1kΩ

R465 119-4731-15 1/16W 47kΩ

R467 119-4731-15 1/16W 47kΩ

R468 119-1021-15 1/16W 1kΩ

R469 119-1021-15 1/16W 1kΩ

R470 119-1011-15 1/16W 100Ω

R471 119-1011-15 1/16W 100Ω

R472 119-1011-15 1/16W 100Ω

R501 119-4721-15 1/16W 4.7kΩ

R502 119-4721-15 1/16W 4.7kΩ

R503 119-4721-15 1/16W 4.7kΩ

R504 119-4721-15 1/16W 4.7kΩ

R505 111-2291-94 1/4WS 2.2Ω

R506 111-2291-94 1/4WS 2.2Ω

R507 111-6811-94 1/4WS 680Ω

R509 111-3311-94 1/4WS 330Ω

R510 111-2291-94 1/4WS 2.2Ω

R511 111-2291-94 1/4WS 2.2Ω

R525 111-2291-94 1/4WS 2.2Ω

R526 111-2291-94 1/4WS 2.2Ω

R527 119-5611-15 1/16W 560Ω

R528 111-4711-94 1/4WS 470Ω

R529 111-4711-94 1/4WS 470Ω

R530 119-4731-15 1/16W 47kΩ

R531 119-1031-15 1/16W 10kΩ

R532 119-2221-15 1/16W 2.2kΩ

R533 111-1011-94 1/4WS 100Ω

R534 111-2221-94 1/4WS 2.2kΩ

R536 119-1041-15 1/16W 100kΩ

R537 119-2241-15 1/16W 220kΩ

R538 119-2241-15 1/16W 220kΩ

R539 119-3331-15 1/16W 33kΩ

R541 119-1021-15 1/16W 1kΩ

R542 119-4711-15 1/16W 470Ω

R543 111-2291-94 1/4WS 2.2Ω

R544 111-2291-94 1/4WS 2.2Ω

R545 111-1521-94 1/4WS 1.5kΩ

R547 119-1531-15 1/16W 15kΩ

R548 111-3311-94 1/4WS 330Ω

R549 119-4731-15 1/16W 47kΩ

R554 111-2291-94 1/4WS 2.2Ω

R557 119-3311-15 1/16W 330Ω

R558 119-1031-15 1/16W 10kΩ

R559 119-1511-15 1/16W 150Ω

R560 119-1031-15 1/16W 10kΩ

R561 111-1221-94 1/4WS 1.2kΩ

R562 114-4791-11 1W 4.7Ω

R563 111-2291-94 1/4WS 2.2Ω

R565 119-8221-15 1/16W 8.2kΩ

R566 111-1031-94 1/4WS 10kΩ

R568 111-2291-94 1/4WS 2.2Ω

R569 111-6811-94 1/4WS 680Ω

R570 117-4721-15 1/10W 4.7kΩ

R571 119-2721-15 1/16W 2.7kΩ

R572 119-4721-15 1/16W 4.7kΩ

R601 119-2221-15 1/16W 2.2kΩ

R602 119-2221-15 1/16W 2.2kΩ

R603 119-1041-15 1/16W 100kΩ

R604 119-1041-15 1/16W 100kΩ

R605 119-1031-15 1/16W 10kΩ

R606 119-1031-15 1/16W 10kΩ

SUP101 060-0122-20 DSP-141N-S00B

T501 009-0666-0L 0.4mH

TC102 004-1580-60 30pF

TH501 002-0222-90 PTH61G30BD

TM101 073-0762-90 TERMINAL

TM102 073-0762-90 TERMINAL

X102 061-1066-00 7.2MHz

X401 061-3504-90 CX-5F 10MHz

Switch PWB section(B2)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C701 178-1042-78 0.1μF

C702 042-0423-94 10V 4.7μF

C703 178-1042-78 0.1μF

C704 178-1042-78 0.1μF

C705 178-6812-78 680pF

D701 001-0412-17 GC-3HD8

D702 001-0518-96 BG1101W-240

IC701 051-6000-20 LC7583NW

P701 074-1151-20 20P

PL701 017-0429-13 8V105mA

PL702 017-0429-13 8V105mA

PL703 017-0433-77 14V40mA

PL704 017-0433-77 14V40mA

PL705 017-0433-77 14V40mA

PL706 017-0433-77 14V40mA

PL707 017-0433-77 14V40mA

PL708 017-0433-77 14V40mA

PL709 017-0433-77 14V40mA

R702 117-0000-05 1/10W 0Ω JW

R703 117-0000-05 1/10W 0Ω JW

R706 117-0000-05 1/10W 0Ω JW

R707 117-0000-05 1/10W 0Ω JW

R711 117-6831-15 1/10W 68kΩ

R721 117-0000-05 1/10W 0Ω JW

R722 117-0000-05 1/10W 0Ω JW

R723 117-0000-05 1/10W 0Ω JW

R724 117-0000-05 1/10W 0Ω JW

S701 013-6201-50 SKPMAA

S702 013-6201-50 SKPMAA

S703 013-6201-50 SKPMAA

S704 013-6201-50 SKPMAA

S705 013-6201-50 SKPMAA

S706 013-6201-50 SKPMAA

S707 013-6201-50 SKPMAA

S708 013-6201-50 SKPMAA

S709 013-6201-50 SKPMAA

S710 013-6201-50 SKPMAA

S711 013-6201-50 SKPMAA

S712 013-6201-50 SKPMAA

S713 013-6201-50 SKPMAA

VR701 016-0014-05 VR W-SHAFT

VR702 016-0014-05 VR W-SHAFT

Chucking switch PWB section(B3) : CD mechanism

REF No. PART No. DESCRIPTION

S2 013-3879-01 CHUCKING

CD mech PWB section(B4) : CD mechanism

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C1 183-1073-12 6.3V100μF

C2 183-4763-11 6.3V47μF

C3 178-1042-78 0.1μF

C4 176-2201-00 22pF CH

C5 176-1801-00 18pF CH

C6 176-1801-00 18pF CH

C7 176-8201-00 82pF CH

C8 178-1042-78 0.1μF

C9 178-2242-78 0.22μF

C10 178-2242-78 0.22μF

C11 176-4701-00 47pF CH

C12 178-1532-78 0.015μF

C13 178-1032-78 0.01μF

C14 178-2722-78 2700pF

C15 178-4722-78 4700pF

C16 176-1201-00 12pF CH

C17 178-4712-78 470pF

C18 178-4712-78 470pF

C19 178-4732-78 0.047μF

C20 178-4732-78 0.047μF

C21 178-4732-78 0.047μF

C22 178-4732-78 0.047μF

C23 178-1032-78 0.01μF

C25 042-0505-01 10V22μF

C26 178-1042-78 0.1μF

C27 178-1042-78 0.1μF

C29 178-1042-78 0.1μF

C30 178-1042-78 0.1μF

C31 178-1032-78 0.01μF

C32 178-1032-78 0.01μF

C33 178-1042-78 0.1μF

C34 176-1501-00 15pF CH

C35 176-1501-00 15pF CH

C38 178-1022-78 1000pF

C39 178-1042-78 0.1μF

C40 178-1042-78 0.1μF

C41 183-1073-12 6.3V100μF

C43 183-1073-12 6.3V100μF

C44 183-4763-11 6.3V47μF

Page 12

- 12 -PH-2416I

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C45 183-1073-12 6.3V100μF

C46 178-1032-78 0.01μF

C47 178-1042-78 0.1μF

C48 178-1032-78 0.01μF

C49 176-6801-00 68pF CH

C51 178-1032-78 0.01μF

C52 178-1032-78 0.01μF

C54 183-4763-11 6.3V47μF

C55 178-1042-78 0.1μF

C56 178-1042-78 0.1μF

C58 178-1042-78 0.1μF

C59 178-2222-78 2200pF

D1 001-0563-00 GL380

D2 001-0563-00 GL380

D3 001-0563-00 GL380

D4 001-0330-00 1SS119

IC1 051-5704-00 TA2096FN

IC2 051-6342-00 TC9462F

IC3 051-6026-08 TA2058F

IC4 051-6027-00 BA6283N

L1 010-2155-03 10μH

L3 010-2199-74 10μH J

Q1 101-1237-50 2SB1237QR

Q2 102-2712-00 2SC2712

R1 117-1011-10 1/10W 100Ω

R2 117-1841-10 1/10W 180kΩ

R3 117-1841-10 1/10W 180kΩ

R4 117-2201-10 1/10W 22Ω

R5 117-8231-10 1/10W 82kΩ

R6 117-1041-10 1/10W 100kΩ

R7 117-1041-10 1/10W 100kΩ

R8 117-1031-10 1/10W 10kΩ

R9 117-2221-10 1/10W 2.2kΩ

R10 117-1031-10 1/10W 10kΩ

R12 117-1031-10 1/10W 10kΩ

R13 117-4731-10 1/10W 47kΩ

R15 117-4741-10 1/10W 470kΩ

R17 117-3331-10 1/10W 33kΩ

R18 117-3311-10 1/10W 330Ω

R19 117-3321-10 1/10W 3.3kΩ

R20 117-1031-10 1/10W 10kΩ

R21 117-3321-10 1/10W 3.3kΩ

R22 117-3321-10 1/10W 3.3kΩ

R23 117-3321-10 1/10W 3.3kΩ

R24 117-3321-10 1/10W 3.3kΩ

R26 117-1041-10 1/10W 100kΩ

R27 117-4711-10 1/10W 470Ω

R28 117-2211-10 1/10W 220Ω

R29 117-2211-10 1/10W 220Ω

R30 117-4721-10 1/10W 4.7kΩ

R34 111-2711-91 1/4WS 270Ω

R40 117-3321-10 1/10W 3.3kΩ

X1 061-3051-00 16.92MHz

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

Sensor PWB section(B5) : CD mechanism

Q101 060-0252-01 PT4850F Q102 060-0252-01 PT4850F Q103 060-0252-01 PT4850F

Limit switch PWB section(B6) : CD mechanism

REF No. PART No. DESCRIPTION

S1 013-7100-00 LIMIT

■BLOCK DIAGRAM

Page 13

■CIRCUIT DIAGRAM

Main PWB section(B1)

- 13 -

PH-2416I

Page 14

- 14 -

PH-2416I

Page 15

- 15 -

PH-2416I

Page 16

- 16 -

PH-2416I

Loading...

Loading...