Page 1

Xiamen Clarion Electrical Enterprise Co., Ltd

8/F., Xiamen Mail Processing Centre, No.275 Lujiang Road , Xiamen,China

Tel:+86-592-2389080 Fax:+86-592-2389089

Clarion Co., Ltd.

7-2, Shintoshin, Chuo-Ku, Saitama-Shi, Saitama 330-0081, Japan

Service Manual

CD/MP3/WMA Receiver

Published by Service Dept.

298-6524-00 JAN. 2008P

Printed in P.R.C.

(DB188RMP)

This product is a lead free model.

Lead free solder is used in PWB stamped LF mark.

Please keep the following conditions when you repair.

1. Use lead free solder.

* Koki's lead free solder S3X-55M 0.6mm

(CLARION Parts No.642-0231-01)

* Koki's lead free solder S3X-55M 1.0mm

(CLARION Parts No.642-0231-02)

2. Use a nitrogen solder system.

3. Do not use "General solder" and "Lead free solder"

together.

SPECIFICATIONS

Radio section

Tuning system: PLL synthesizer tuner

Receiving frequencies: FM : 87.5 MHz to 108 MHz

(0.05 MHz steps)

MW : 531 kHz to 1602 kHz

(9 kHz steps)

LW : 153 kHz to 279 kHz

(3 kHz steps)

CD player section

System: Compact disc digital audio system

Frequency response: 5Hz to 20kHz(+1/-1dB)

Dynamic range: 90dB(1kHz)

Harmonic distortion: 0.01%

MP3/WMA mode

MP3 Sampling rate: 8kHz to 48kHz

MP3 Bit rate: 8kbps to 320kbps / VBR

WMA Bit rate: 48kbps to 192kbps

Logical format: ISO9660 level1, 2

JOLIET or Romeo

General

Output power: 25 W x 4

(DIN45324, +B=14.4V)

Model

DB188RMP

(PE-3050E-A)

DB189RMP

(PE-3050E-B)

DB189RGMP

(PE-3050E-C)

Power supply voltage: 14.4V DC(10.8 to 15.6V allowable),

negative ground

Power consumption: Less than 15A

Speaker impedance: 4ohm(4ohm to 8ohm allowable)

Weight: 1.2kg

Dimensions(mm): 178(W)x50(H)x155(D)

COMPONENTS

PE-3050E-A/PE-3050E-B/PE-3050E-C

1. Source unit 1

2. Mounting bracket 300-7742-00 1

3. DCP case 335-6035-22

4. Escutcheon(OUT-ES)

5. Parts bag

5-1. Removal key 331-2497-00

5-2. Rubber part 345-3653-20

5-3. Stopper 335-4899-20 1

5-4. Screw(M5x10) 716-0726-51 1

5-5. A-lead 850-6681-50

370-6286-00

NOTE

We cannot supply PWB with component parts in principle. When

*

a circuit on PWB has failure, please repair it by component parts

base. Parts which are not mentioned in service manual are not

supplied.

Specifications and design are subject to change without notice for

*

further improvement.

Use only compact discs bearing the or mark.

*

Some CDs recorded in CD-R/CD-RW mode may not be usable.

* Windows Media , and the Windows logo are trademarks, or re-

gistered trademarks of Microsoft Corporation in the United States

and/or other countries.

* WMA is the abbreviation of Windows Media Audio, an audio file

format developed by Microsoft Corporation.

* This product includes technology owned by Microsoft Corporation

and cannot be used or distributed without a license from MSLGP.

1

1

1

2

1

1

-1-

DB188/189RMP/DB189RGMP

Page 2

To engineers in charge of repair or inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in charge

of repair or inspection can avoid suffering any risk or

injury.

1. Use specified parts.

The system uses parts with special safety features against fire

and voltage. Use only parts with equivalent characteristics

when replacing them.

The use of unspecified parts shall be regarded as remodeling

for which we shall not be liable. The onus of product liability

(PL) shall not be our responsibility in cases where an accident

or failure is as a result of unspecified parts being used.

2. Place the parts and wiring back in their original positions after

replacement or re-wiring.

For proper circuit construction, use of insulation tubes, bond-

ing, gaps to PWB, etc, is involved. The wiring connection and

routing to the PWB are specially planned using clamps to keep

away from heated and high voltage parts. Ensure that they are

placed back in their original positions after repair or inspec-

tion.

If extended damage is caused due to negligence during repair, the legal responsibility shall be with the repairing company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely

in their original position after repair. Ensure for safety reasons

there is no possibility of secondary ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the parts

for the automobile.

Disconnect the battery terminal after turning the ignition key

off. If wrong wiring connections are made with the battery con-

nected, a short circuit and/or fire may occur. If extensive damage is caused due to negligence of repair, the legal responsibility shall be with the repairing company.

5. Cautions in soldering

Please do not spread liquid flux in soldering.

Please do not wash the soldering point after soldering.

6. Cautions in soldering for chip capacitors

Please solder the chip capacitors after pre-heating for replace-

ment because they are very weak to heat.

Please do not heat the chip capacitors with a soldering iron

directly.

7. Cautions in handling for chip parts.

Do not reuse removed chips even when no abnormality is ob-

served in their appearance. Always replace them with new

ones. (The chip parts include resistors, capacitors, diodes, transistors, etc).

Please make an operation test after replacement.

8. Cautions in handling flexible PWB.

Before working with a soldering iron, make sure that the iron

tip temperature is around 270 . Take care not to apply the

iron tip repeatedly (more than three times) to the same patterns.

Also take care not to apply the tip with force.

9. Turn the unit OFF during disassembly and parts replacement.

Recheck all work before you apply power to the unit.

10. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through the

lens of the optical pickup. When checking that the laser optical diode lights up, keep your eyes more than 30cms away

from the lens. Prolonged viewing of the laser within 30cms

may damage your eyesight.

11. Cautions in handling the optical pickup.

The laser diode of the optical pickup can be damaged by electrostatic charge caused by your clothes and body. Make sure

to avoid electrostatic charges on your clothes or body, or discharge static electricity before handling the optical pickup.

11-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage. After replacement, open

the shorted circuit. When removing the pickup from the mechanism, short the terminals by soldering them to prevent this

damage.

11-2. Actuator

The actuator has a powerful magnetic circuit. If a magnetic

material is put close to it. Its characteristics will change. Ensure that no foreign substances enter through the ventilation

slots in the cover.

11-3. Cleaning the lens

Dust on the optical lens affects performance.

To clean the lens, apply a small amount of isopropyl alcohol to

lens paper and wipe the lens gently.

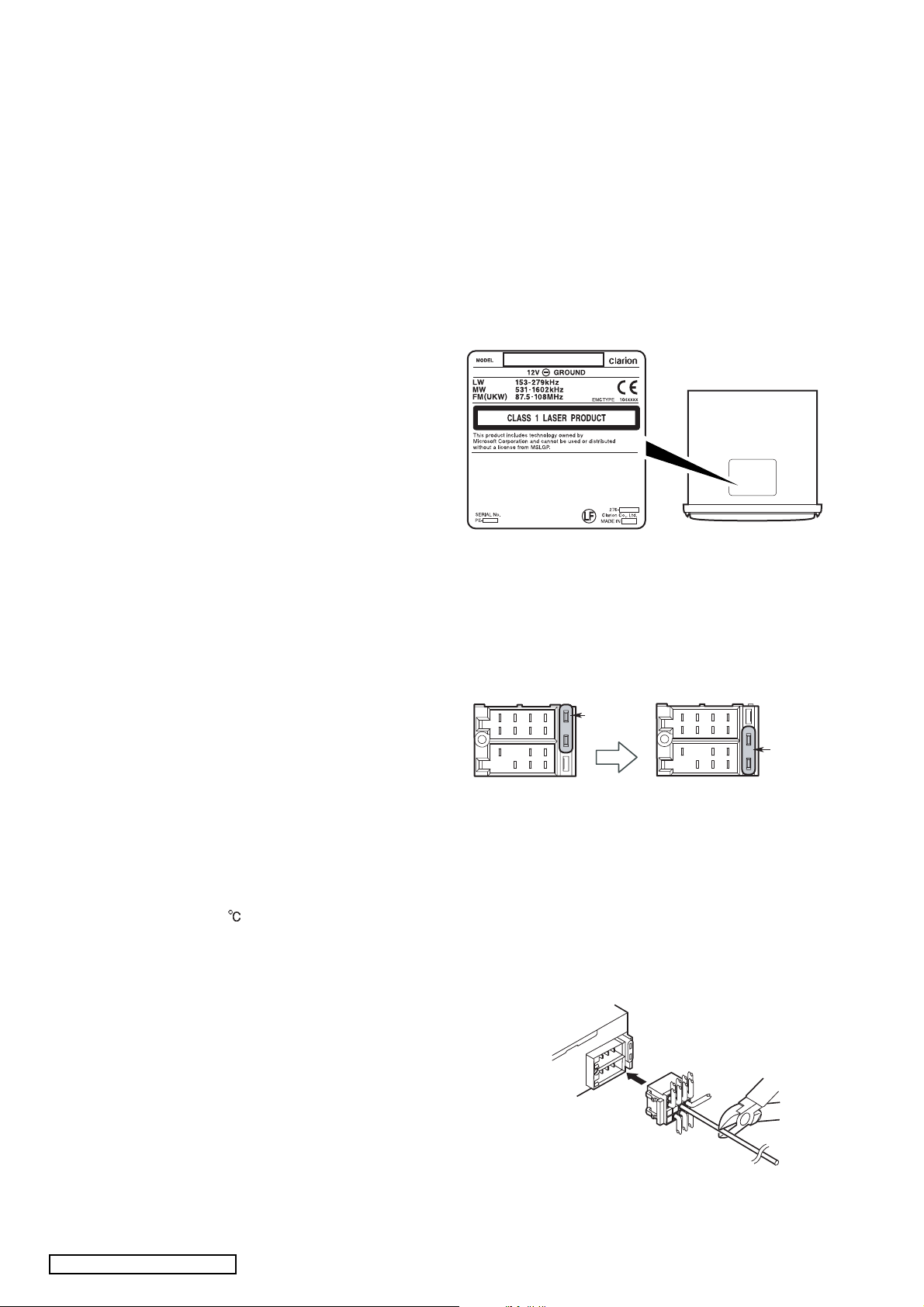

CAUTION

This appliance contains a laser system and is classified as a

"CLASS 1 LASER PRODUCT". In case of any trouble with this

player, please contact your nearest"authorized service station".

To prevent direct exposure to the laser beam, do not try to open

the enclosure.

Bottom view of

main unit

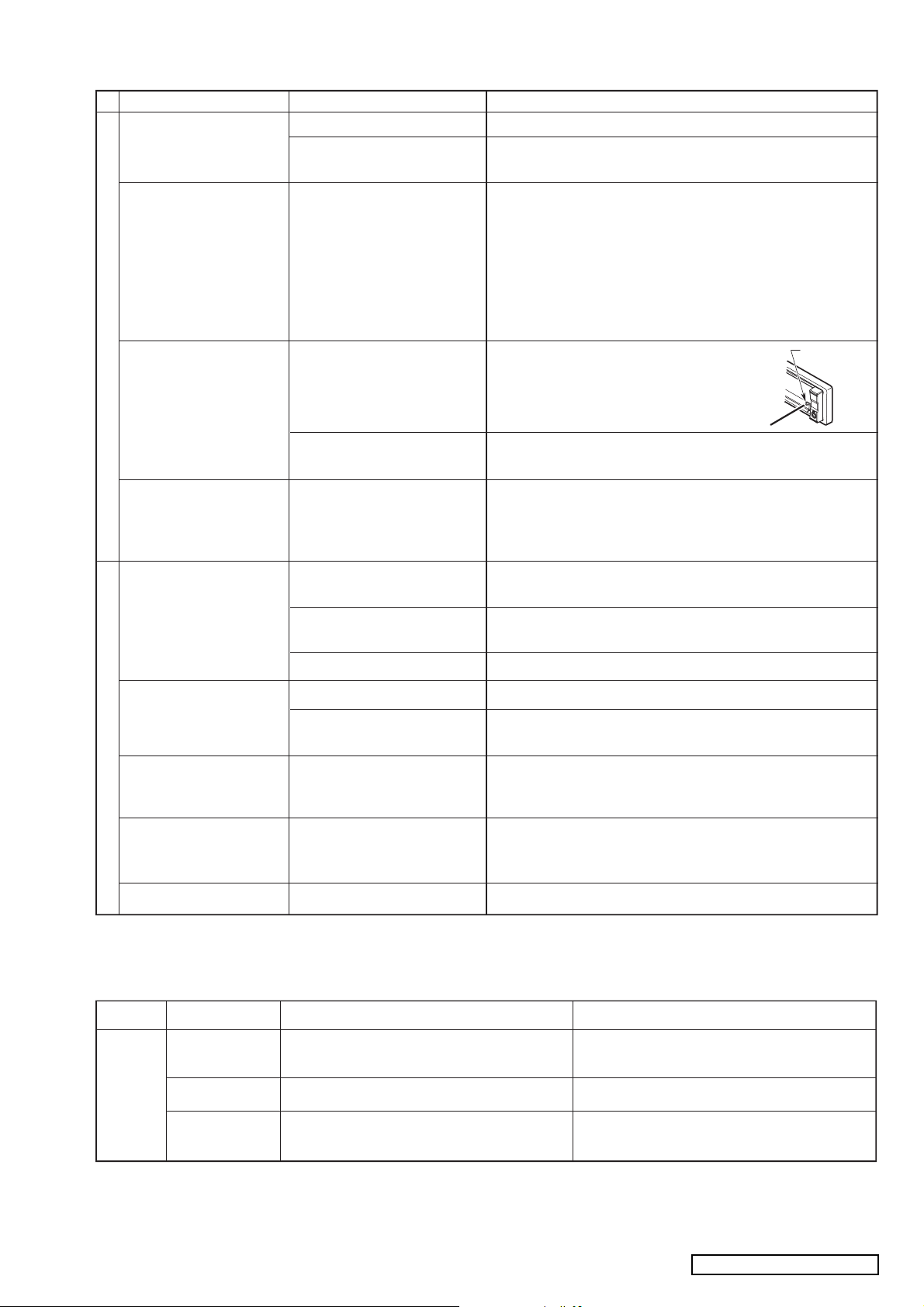

NOTES OF ISO CONNECTOR

1. For VW and Audi vehicles, change the position of fuse

installation as shown on the diagram.(Figure 1)

ISO CONNECTOR type

For other vehicles (initial position)

FUSE

(15A)

Main unit side ISO connector

Figure 1

2. When the car stereo is installed in 1998 and later Volkswagen

models, make sure to cut the car lead wire connected the A-5

terminal. (A breakdown could occur if the lead wire is not cut.)

After cutting the lead wire, isulate the front end of the lead wire

with insulation tape to prevent the risk of short-circuits.(Figure 2 )

Note: Before cutting the lead wire, disconnect the car battery --

(negative) cable.

3. When the main unit is also connected to an external amplifier,

connect REMOTE on the external amplifier to the previously

cut lead wire on the side of the connector.

For VW and Audi vehicles

FUSE

(15A)

Figure 2

DB188/189RMP/DB189RGMP

-2-

Page 3

TROUBLESHOOTING

Problem

Power does not turn on.

(No sound is produced.)

Fuse is blown.

Incorrect wiring.

Cause

Measure

Replace with a fuse of the same amperage as the old fuse.

Read the attached "Installation/Wire connection Guide" once again

and wire properly.

No sound output when

operating the unit with

amplifiers or power

antenna attached.

Nothing happens when

buttons are pressed.

GeneralCD/MP3/WMA

Display is not accurate.

No sound heard. The speaker protection circuit is

No sound heard. MP3/WMA files are absent in

Power antenna lead is shorted

to ground or excessive current

is required for remote-on the

amplifiers or power antenna.

The microprocessor has

malfunctioned due to noise,

etc.

DCP or main unit connectors

are dirty.

operating.

a disc.

Files are not recognized as an

MP3/WMA file.

File system is not correct. Use ISO9660 level 1,2 or JOLIET or Romeo file system.

1. Turn the unit off.

2. Remove all wires attached to the power antenna lead. Check

each wire for a possible short to ground using an ohm meter.

3.Turn the unit back on.

4. Reconnect each amplifier remote wire to the power antenna lead

one by one. If the amplifiers turn off before all wires are attached,

use an external relay to provide remote-on voltage

(excessive current required).

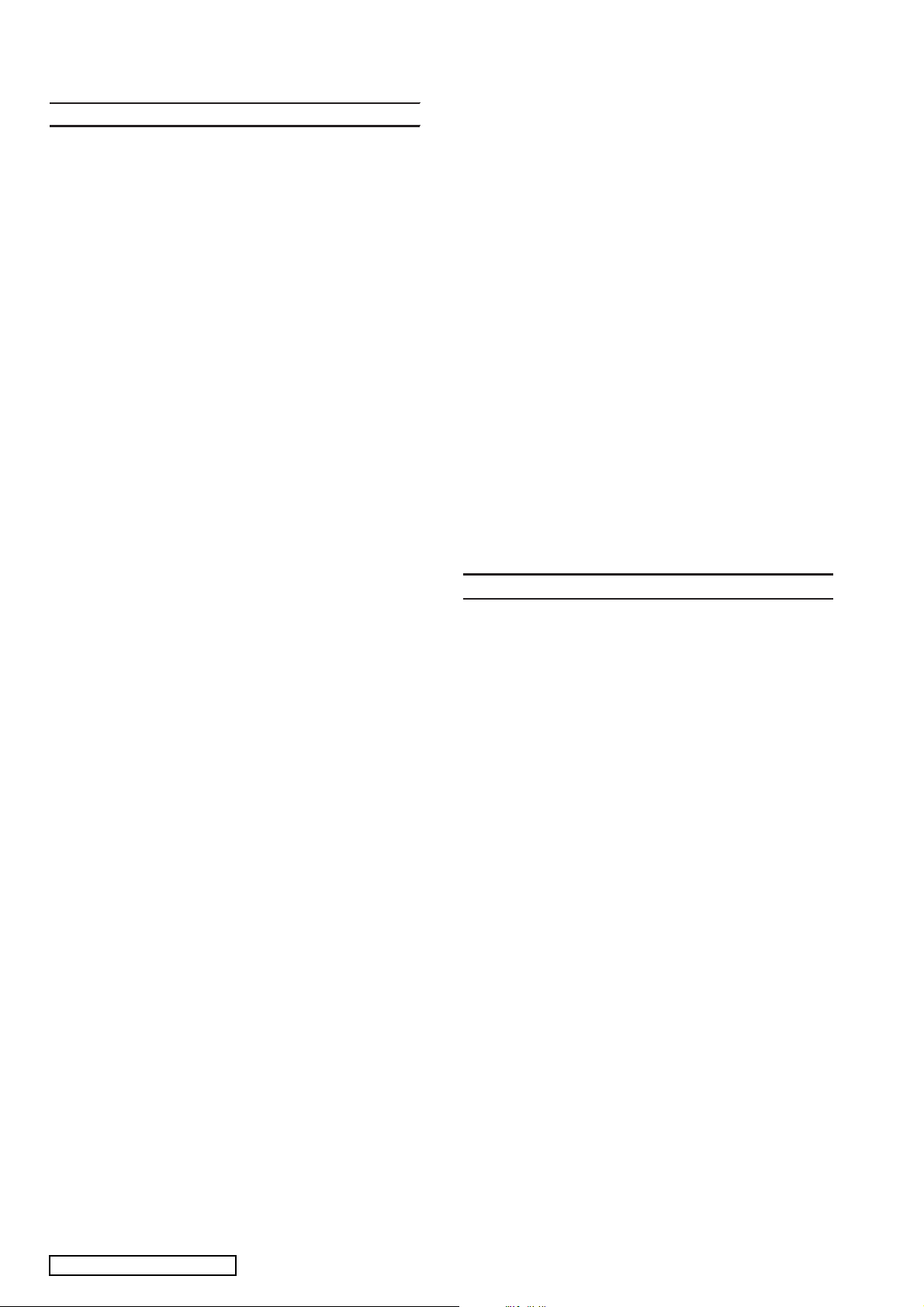

Turn off the power, then press the

[RELEASE] button and remove the DCP.

Press the reset button for about 2 seconds

with a thin rod.

Wipe the dirt off with a soft cloth moistened with cleaning alcohol.

Turn down sound volume. Function can also be restored by turning

the power off and on again.

(Speaker volume is reduced automatically when the speaker prote-

ction circuit operates).

Write MP3/WMA files onto the disc properly.

Use MP3/WMA files encoded properly.

Reset button

Sound skips or is noisy. Compact disc is dirty.

Compact disc is heavily scratch-

ed or warped.

Sound is cut or skipped.

Noise is generated or noise

is mixed with sound.

Sound is bad directly after

power is turned on.

Wrong filename File system is not correct. Use ISO9660 level 1, 2 or JOLIET or Romeo file system.

MP3/WMA files are not

encoded properly.

Water droplets may form on

the internal lens when the car

is parked in a humid place.

Clean the disc with a soft cloth.

Replace with a disc with no scratches.

Use MP3/WMA files encoded properly.

Let dry for about 1 hour with the power on.

ERROR DISPLAYS

If an error occurs, one of the following displays is displayed. Take the measures described below to eliminate the problem.

Error Display Cause Measure

CD/MP3/

WMA

ERROR 2

ERROR 3 A CD cannot be played due to scratches, etc. Replace with a non-scratched, non-warped disc.

ERROR 6

A CD is caught inside the CD deck and is not

ejected.

A CD is loaded upside-down inside the CD deck

and does not play.

This is a failure of CD deck's mechanism.

Eject the disc then reload it properly.

If an error display other than the ones described above appears, press the reset button.

-3-

DB188/189RMP/DB189RGMP

Page 4

EXPLANATION OF IC

:

:O:

:

:O:

:

:O:

:

:IN:

:

:

:IN:

:

:

:IN:

:

:IN:

:

:O:

:

:-:

:

:IN:

:

:O:

:

:-:

:

:O:

:

:O:

:

:IN:

:

:

:IN:

:

:IN:

:

:

:IN:

:

:IN:

:

:

:

:O:

:

:IN:

:

:-:

:

:O:

:

:

:O:

:

:O:

:

:

:

:

:

:

:O:

:

:-:

:

:-:

:

:

:

:O:

:

:O:

:

RDS NOISE_DCHG

:O:

:

:

:

:O:

:

:O:

:

:IN:

:

:-:

:

:O:

:

:

:

:-:

:

:-:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:O:

:

:IN:

:

:

:O:

:

:IN:

:

:

:

:

:

:

:

:O:

:

:IN:

:

:IN:

:

:

:O:

:

:IN:

:

:O:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:IN:

:

:O:

:

:O:

:

:O:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:O:

:

:O:

:

:O:

:

:IN:

:

:IN:

:

:IN:

:

:O:

:

:IN:

:

:O:

:

:IN:

:

:-:

:

:-:

:

:O:

:

:O:

:

:O:

:

:O:

:

:-:

:

:O:

:

:O:

:

:IN:

:

:-:

:

:O:

:

:

:

:O:

:

:O:

:

:O:

:

:-:

:

:-:

Main section

052-1955-00 LC8783J2PA-59H6-E Main System Controller

Terminal Description

DBGP0

pin 1

DBGP1

pin 2

DBGP2

pin 3

B/U_DET

pin 4

pin 5

ACC_DET:IN:ACC detection signal input.

pin 6

REMCON

RDS_CLK:IN:RDS clock pulse input.

pin 7

RES

pin 8

XT1

pin 9

XT2

pin 10

VSS

pin 11

pin 12

CF1

CF2

pin 13

VDD

pin 14

pin 15

N.C

N.C

pin 16

N.C

pin 17

S-METER:IN:RDS S-METER signal input.

pin 18

NOISE

pin 19

KEY_A/D

pin 20

pin 21

AMP_MUTE:O:Muting signal output to internal audio power

pin 22

N.C

N.C

pin 23

pin 24

MODEL_INT3:IN:The destination setting input.

TEXT PORT:O:For CD text pin, Hi=OK, Lo=NG.

pin 25

pin 26

CD_DI

pin 27

CD_DO

CD_CLK

pin 28

pin 29

CD_CE

pin 30

CD_MUTE:IN:Connect to LC786920 CD_MUTE pin.

pin 31

CD_RST

IF_REQ

pin 32

pin 33

SUB_RDY:IN:Connect to USB_READY pin.

pin 34

REG_RDY:IN:Connect to REG_READY pin.

CD_INSW1:IN:Connect to CD MECHA SW1.

pin 35

CD_INSW2:IN:Connect to CD MECHA SW2.

pin 36

pin 37

CD_DMUTE:O:Connect to CD driver IC MUTE pin.

CD_S/L

pin 38

VSS

pin 39

VDD

pin 40

pin 41

CD_ERROR:IN:Connect to CD_ERROR pin.

CD_LIMIT_SW:IN:Inside limit switch signal input.

pin 42

CD_EM

pin 43

pin 44

CD_LM

pin 45

pin 46

RDS_MUTE:O:RDS mute signal output.

pin 47

SYS_MUTE:O:System mute signal output.

N.C

pin 48

LCD_DI

pin 49

pin 50

LCD_DO

LCD_CLK

pin 51

LCD_CE

pin 52

EVOL_DATA:I/O:The serial data output to the volume IC.

pin 53

EVOL_CLK:O:Clock pulse output to the volume IC.

pin 54

VDD

pin 55

VSS

pin 56

INT_1

pin 57

pin 58

INT_2

VER_1

pin 59

pin 60

VER_2

pin 61

N.C

N.C

pin 62

pin 63

N.C

pin 64

N.C

N.C

pin 65

pin 66

N.C

pin 67

N.C

DISP_REM:O:The power supply control signal output for LCD

pin 68

pin 69

ILL_REM

pin 70

KEY_INT

INT_AMPREM:O:ON signal output to the internal amplifier.

pin 71

pin 72

AMP_REMOUT:O:The control signal output to internal audio power

Not in use.

Not in use.

Not in use.

Backup detection signal input.

Remote controller signal input terminal.

Reset signal input.

32.768kHz crystal input, sub clock

32.768kHz crystal output, sub clock

Connect to GND.

13.5MHz crystal input, main clock

13.5MHz crystal output, main clock

Positive supply voltage, connect to 5V

Not in use.

Not in use.

Not in use.

RDS noise signal input.

Input terminal of A/D converter for key judgement.

amplifier.

Connect to GND.

Connect to GND.

Connect to LC786920 DI pin.

Connect to LC786920 DO pin.

Connect to LC786920 CLK pin.

The chip enable signal output to LC786920.

Connect to LC786920 REST pin.

The tuner pack IF buffer control signal output.

Connect to CD driver IC VIN-SW pin.

Connect to GND.

Positive supply voltage, connect to 5V.

CD eject signal output for CD dirver IC.

CD_LM="L", CD_EM="H"

CD loading signal output for CD dirver IC.

CD_LM="H", CD_EM="L"

RDS noise discharge signal output.

Not in use.

Connect to LCD driver IC DI pin

Connect to LCD driver IC DO pin

The clock pulse output to the LCD dirver IC.

The chip enable signal output to the LCD dirver

IC.

Positive supply voltage, connect to 5V.

Connect to GND.

The destination setting input.

The destination setting input.

Pefrence vlotage input for A/D converter.

Pefrence vlotage input for A/D converter.

Connect to GND.

Connect to GND.

Connect to GND.

Connect to GND.

Not in use.

Not in use.

Not in use.

power and LCD backlight.

The power supply control signal output for

illumination.

Key interrupting signal input.

amplifier.

AUTO_ANT:O:Motor antenna control signal output.

pin 73

PHONE_INT:IN:The telephone interrupt signal input.

pin 74

RDS TEST 1:O:The power supply ON signal output for the

pin 75

RDS TEST 2:IN:For debug when RDS TEST.

pin 76

pin 77

N.C

pin 78

N.C

pin 79

JOG_CW

JOG_CCW:IN:JOG key signal input.

pin 80

pin 81

CD TEST

pin 82

ILL_DET

CTRL

pin 83

pin 84

OFFSET_DET:IN:The emergency signal input from the power IC.

RDS_TEST_DSR :IN

pin 85

RDS_TEST_DTR :O

pin 86

VERG : O:The reference voltage.

pin 87

VSS : -:Connect to GND.

pin 88

VDD : -:Positive voltage supply, connect to 5V.

pin 89

OSC_FM/AM : IN:FM/AM oscillation input.

pin 90

N.C : IN:Connect to GND.

pin 91

FM/AM_IFC : IN:FM/AM IF signal input.

pin 92

N.C : IN:Connect to GND.

pin 93

EO : O:PLL phase compare ERROR output.

pin 94

pin 95

SUBPD : O:For high speed lock up.

FM ON : O:The power supply control signal outpur for tuner

pin 96

pin 97

AM ON : O:The power supply control signal outpur for tuner

pin 98

MUTE_SPEED_UP: O : Station detection speed up command output

pin 99

FM-ST/SD : IN:At receiving the FM station, this port detects

RDS_DATA : IN:RDS serial data input.

pin100

051-6743-00 LC786920E

Terminal Description

pin 1

EFMIN

RFOUT

pin 2

pin 3

LPF

PHLPF

pin 4

pin 5

AIN

CIN

pin 6

pin 7

BIN

pin 8

DIN

SLCISET

pin 9

pin 10

RFMON

pin 11

VREF

JITTC

pin 12

pin 13

EIN

FIN

pin 14

PCNCNT

pin 15

TE OUT

pin 16

TE IN

pin 17

pin 18

LDD

LDS

pin 19

AVSS

pin 20

AVDD

pin 21

FDO

pin 22

TDO

pin 23

pin 24

SLDO

SPDO

pin 25

pin 26

VVSSI

pin 27

PDOUT1

PDOUT0

pin 28

PCKIST

pin 29

pin 30

VVDD1

pin 31

DMUTEB

PUIN

pin 32

pin 33

DEFECT

pin 34

FSEQ

pin 35

C2F

pin 36

DVDD

DVSS

pin 37

Not in use.

Not in use.

JOG key signal input.

For CD mecha test pin.

illumination ON signal input.

Power supply ON signal input.

The communication control signal input for RDS

PC test.

The communication control signal output for

RDS PC test.

FM+B.

AM+B.

for RDS.

the stereo signal. At seeking or scanning, this

port detects the station detection signal.

CMOS LSI for compact disc player

RF signal input terminal.

RF signal output terminal.

RF signal DC label detection LPF capacitor

connection terminal.

Wound detection LPF capacitor connection

terminal.

A signal input terminal.

C signal input terminal.

B signal input terminal.

D signal input terminal.

SLCO output Resistance connection terminal.

Inside LSI analog signal monitor terminal.

VREF voltage output terminal.

Getta detection capacitor connection terminal.

E signal input terminal.

F signal input terminal.

EFM PLL Charge Pump Control voltage input

terminal.

TE signal output terminal.

TES signal generation input terminal.

Laser power control signal output terminal.

Laser power control signal input terminal.

Connect to GND.

Analogue power supply terminal.

Focus signal output terminal. D/A output.

Tracking signal output terminal. D/A output.

Thread signal output terminal. D/A output.

Spindle signal output terminal. D/A output.

Connect to GND.

Built-in VCO control phase comparison output

terminal 1.

Built-in VCO control phase comparison output

terminal 0.

PDOUT0 output 1 Resistance connection terminal.

Connect to GND.

Not in use.

I/O:PUIN input output terminal.

Wound detection signal output terminal.

Synchronous signal output terminal, It becomes

"H" when Synchronous Idle detected from the

EFM signal is corresponding to Synchronous Idle

of internal generation.

C2 error signal output terminal.

Digital system power supply terminal.

Digitalsystem earth terminal, Must connect to 0V.

DB188/189RMP/DB189RGMP

-4-

Page 5

pin 38:DVDD15

:O:

:

:-:

:

:-:

:

:-:

:

:-:

:CE:IN:

:CL:IN:

:

:IN:

:DO:O:

:

:IN:

:

:

:

:

:

:

:

:IN:

:

:

:

:

:

:

:

:IN:

:

:O:

:

:O:

:

:O:

:

:-:

:

:IN:

:

:IN:

:

:

:-:

:

:O:

:

:-:

:

:-:

:

:O:

:

:O:

:

:-:

:

:O:

:

:IN:

:

:-:

:

:-:

:

:O:

:

:O:

:

:O:

:

:-:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:S5:O:

:S6:O:

:S7:O:

:S8:O:

:S9:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:O:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:IN:

:

:-:

:

:-:

:

:IN:

:

:IN:

:

:-:

:

:IN:

:

:

:DO:O:

:CE:IN:

:CL:IN:

:DI:IN:

VVDD3

pin 39

pin 40

VVSS3

pin 41

DVDD

DVSS

pin 42

pin 43

pin 44

DIN

pin 45

pin 46

RESB

pin 47

REG_READYO:O:Host IF:REG_READY output.

pin 48

pin 49

SUB_READYO:O:Host IF:SUB_READYSY output.

pin 50

CD_MUTEO:I/O:Output L fixation after reset is released.

pin 51

LOW_BAT1:I/O:Host IF:Standby control input.

CONT

pin 52

pin 53

MODE

STREQ

pin 54

STCK

pin 55

STDATA

pin 56

TEST

pin 57

DATA

pin 58

pin 59

DATACK

LRSY

pin 60

pin 61

VVDD2

pin 62

VPREF2

VCOC2

pin 63

VPDOUT2:O:Building VCO into control output terminal.

pin 64

VVSS2

pin 65

DVDD15

pin 66

DVSS

pin 67

DVDD

pin 68

DOUT

pin 69

AMUTEB

pin 70

pin 71

XVSS

XOUT

pin 72

XIN

pin 73

XVDD

pin 74

LRVDD

pin 75

pin 76

LCHO

LRREF

pin 77

RCHO

pin 78

pin 79

LRVSS

SLCO

pin 80

051-6095-00 LC75857W

Terminal Description

P1/S1

pin 1

P2/S2

pin 2

P3/S3

pin 3

P4/S4

pin 4

pin 5

pin 6

pin 7

pin 8

pin 9

S10

pin 10

pin 11

S11

Digital circuit power source capacitor earth terminal.

Building PLL into power supply terminal.

Connect to GND.

Digital system power supply terminal.

Digital system earth terminal, Must connect to 0V.

Host IF:Enable signal input terminal.

Host IF:Data transfer clock input terminal.

Host IF:Data input terminal.

Host IF:Data output terminal.

(Nch opening drain output)

The external of the Pull-Up resistance is necessary.

LIS reset input terminal.

Once you turn on the power supply , It turn to "L" .

(Nch opening drain output)

The external of the Pull-Up resistance is necessary.

(Nch opening drain output)

The external of the Pull-Up resistance is necessary.

Host IF:CD_MUTE request output.

(Nch opening drain output)

The external of the Pull-Up resistance is necessary.

I/O:Connect to GND.

Setting Input terminal, Must connect to DVDD.

I/O:Stream data demand signal output terminal.

I/O:Stream data bit clock input terminal.

I/O:Stream data input terminal.

Connect to GND.

Lch/Rch channel data output terminal.

Bit clock output terminal.

Lch/Rch clock output terminal.

Building VCO into Power supply terminal.

Building VCO into oscillation cooking stove setting

input terminal.

Building VCO into Control setting voltage terminal.

Building VCO into earth terminal, Must connect

to 0V.

Digital circuit power source capacitor earth terminal.

Digital system power supply terminal, Must

connect to 0V.

Digital system power supply terminal

Digital out output terminal, EIAJ format.

CD_MUTE0 signal output terminal.

Connect to GND.

16.9344MHz departure pendulum Connected

terminal.

16.9344MHz departure pendulum Connected

terminal.

Oscillation circuit Power supply terminal.

LR channel power supply terminal.

L channel output terminal.

LR channel Reference output terminal.

R channel output terminal.

Connect to GND.

Slice label control output terminal.

CMOS IC 1/3, 1/4 Duty LCD Display

Drivers with Key Input Function

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

pin 12

S12

pin 13

S13

S14

pin 14

S15

pin 15

S16

pin 16

S17

pin 17

pin 18

S18

S19

pin 19

S20

pin 20

S21

pin 21

:

pin 22 S22

S23

pin 23

S24

pin 24

S25

pin 25

S26

pin 26

S27

pin 27

S28

pin 28

S29

pin 29

S30

pin 30

S31

pin 31

S32

pin 32

S33

pin 33

S34

pin 34

S35

pin 35

S36

pin 36

S37

pin 37

S38

pin 38

COM4/S39:O:Common driver outputs.

pin 39

:

pin 40 COM3 : O

COM2

pin 41

pin 42

COM1

pin 43

KS1/S40

KS2/S41

pin 44

pin 45

KS3/S42

pin 46

KS4

KS5

pin 47

pin 48

KS6

pin 49

KI1

KI2

pin 50

pin 51

KI3

pin 52

KI4

pin 53

KI5

VDD

pin 54

pin 55

VLCD

pin 56

VLCD1

VLCD2

pin 57

VSS

pin 58

pin 59

TEST

pin 60

OSC

pin 61

pin 62

pin 63

pin 64

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Segment outputs for displaying the display data

transferred by serial data input.

Common driver outputs.

Common driver outputs.

Common driver outputs.

Key scan outputs.

Key scan outputs.

Key scan outputs.

Key scan outputs.

Key scan outputs.

Key scan outputs.

Key scan inputs.

Key scan inputs.

Key scan inputs.

Key scan inputs.

Key scan inputs.

Logic block power supply connection.

LCD driver block power supply connection.

Used for applying the LCD drive 2/3 bias voltage

externally.

Used for applying the LCD drive 1/3 bias voltage

externally.

Power supply connection. Connect to ground.

This pin must be connected to ground.

I/O:The OSC pin can be used to form an oscillator

circuit with an external resistor and an external

capacitor.

Serial data interface connections to the controller.

Serial data interface connections to the controller.

Serial data interface connections to the controller.

Serial data interface connections to the controller.

-5-

DB188/189RMP/DB189RGMP

Page 6

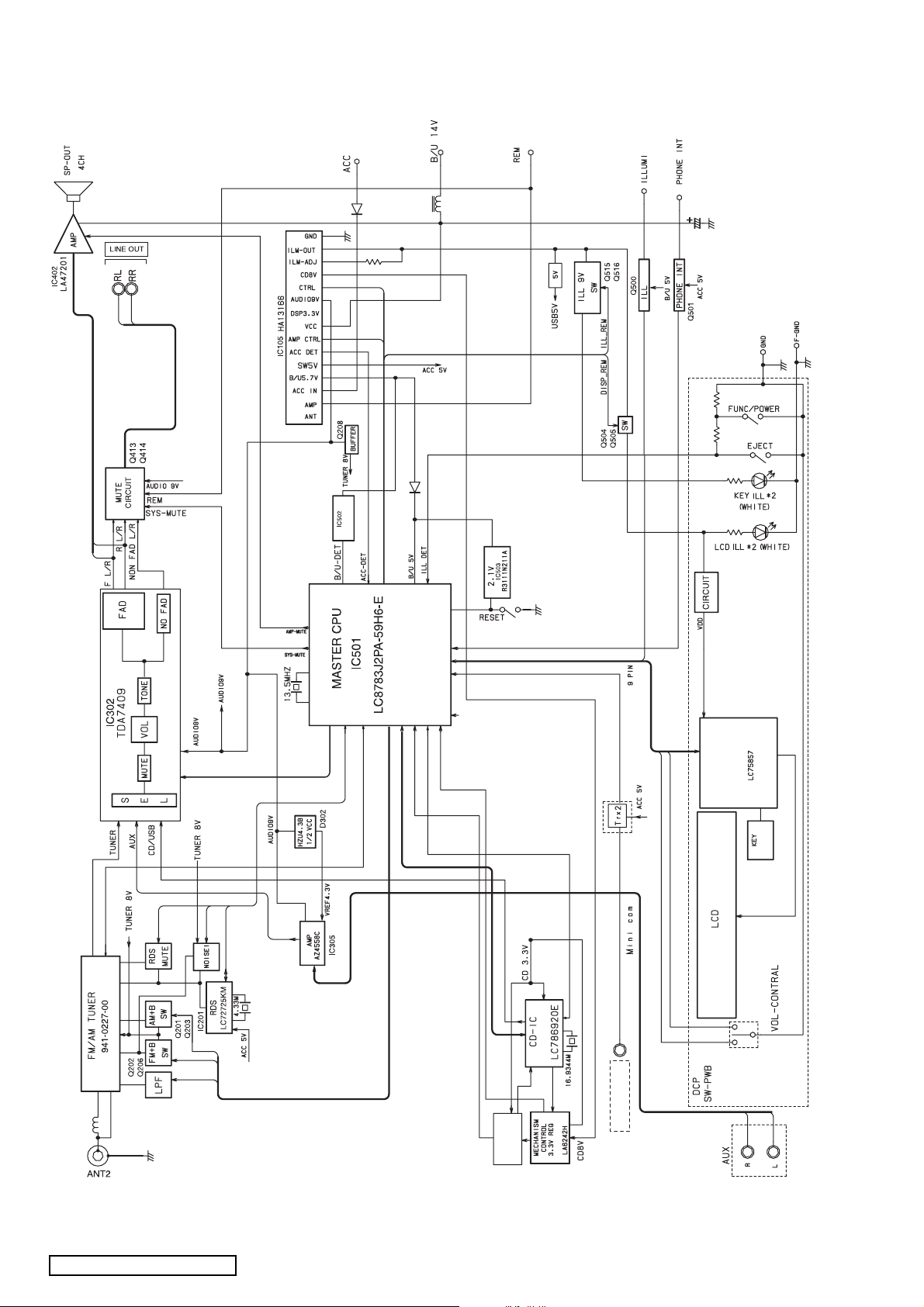

BLOCK DIAGRAM

Main section

DET

S80850CNMC

DET

IC 701

DISPLAY

DRIVER

MATRIX

DIF

DB188/189RMP/DB189RGMP

-6-

MECH

IC801

WIRE REMOTE

IC802

Page 7

EXPLODED VIEW / PARTS LIST

(

)

(

)

)

(

)

(

)

)

(

)

)

(

)

)

(

)

(

)

(

)

)

(

)

(FW)(

)

(FW)(

)

(

)

T

(

(

)

(

)

(FF)(

)

(FF)(

)

(

)

(

)

(TA)(

)

(TA)(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

DCP section

1-17

1-40

1-41

1-16

1-15

1-18

1-19

1-18

1-4

1-3

1-13

1-7

1-6

1-5

1-14

1-8

1-9

1-43

1-12

1-39

1-11

1-21

1-46

1-46

1-44

1-42 (PE3050EA)

1-23

1-39

1-38

1-45

1-22

1-24

1-20

1-33

1-36

1-35

1-33

1-34

1-34

1-33

1-34

1-32

1-34

1-31

1-10

1-37

1-30

1-29

1-2

1-1

: SANKOL application

Note) SANKOL uses CFD-409Z

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 DCP-622-700 DCP ASSY

DCP-623-700 DCP ASSY

DCP-624-700 DCP ASSY

1-1 373-1162-00 DIAL-CVR

373-1162-07 DIAL-CVR

373-1162-08 DIAL-CVR

1-2 347-7999-00 DOUBLE FACE 1 1-23 382-8589-00 BUTTON

1-3 347-8265-00 DOUBLE FACE 2 1-24 382-8584-00 BUTTON

1-4 380-5717-01 KNOB 1 1-25 331-4527-00 LCD COVER 1

1-5 382-8583-00 BUTTON

382-8583-01 BUTTON

1-6 382-8586-00 BUTTON

382-8586-01 BUTTON

1-7 382-8579-00 BUTTON

382-8579-01 BUTTON

1-8 382-8580-00 BUTTON

382-8580-02 BUTTON

1-9 382-8585-00 BUTTON

382-8585-01 BUTTON

1-10 382-8581-00 BUTTON

382-8581-02 BUTTON

1-11 382-8582-00 BUTTON

382-8582-03 BUTTON

1-12 382-8578-00 BUTTON

382-8578-02 BUTTON

1-13 370-6321-00 ESCUTCHEON 1-42 347-8428-00 FILM

1-14 382-8587-00 BUTTON

1-15 750-6858-00 SPRING

1-16 335-8224-00 BAR ILLUMI

335-8224-01 BAR ILLUMI

PE-3050E-A

PE-3050E-B

PE-3050E-C

PE-3050E-A

PE-3050E-B

PE-3050E-C

SRC)(PE-3050E-A

SRC)(PE-3050E-B/C

PE-3050E-A

PE-3050E-B/C

EJECT)(PE-3050E-A

EJECT)(PE-3050E-B/C)1 1-31 335-8228-00 LCD HOLDER 1

DISP)(PE-3050E-A

DISP)(PE-3050E-B/C

PE-3050E-A

PE-3050E-B/C

BND)(PE-3050E-A

BND)(PE-3050E-B/C

PE-3050E-A

PE-3050E-B/C

ENT)(PE-3050E-A

ENT)(PE-3050E-B/C

RELEASE

RELEASE

PE-3050E-A

PE-3050E-B/C

1-26

1-25

1 1-17 335-8226-00 ILLUMI PLATE 1

1 1-18 716-0872-62 SCREW(M1.7X6

1 1-19 335-8225-00 REAR COVER 1

1 1-20 716-1764-50 PAD SCREW(M1.7X6

1 1-21 382-8588-00 BUTTON(1/3

1 1-22 382-8617-00 BUTTON(4/6

1

1-26 379-1401-41 INDICATOR(LCD

1 1-27 347-8410-00 BLACK FILM 1

1-28 347-8411-00 SHADE FILM 1

1

1 1-29 335-8227-00 LCD ILLUMI 1

1 1-30 345-6177-00 RUBBER PAR

1-32 ----------- SWITCH PWB 1

1

1 1-33 013-6312-50 TACT SWITCH 15

1-34 001-7114-90 DIODE 6

1

1-35 076-0615-50 PLUG 1

1

1-36 016-9901-02 VR W/SHAFT 1

1

1 1-37 347-8412-00 REFLECTOR 1

1

1-38 347-8413-00 FILM 1

1-39 347-8414-00 FILM 3

1

1-40 347-8421-00 SHADE 1

1

1 1-41 347-8426-00 FILM 1

1

1 1-43 347-8429-00 FILM 1

1 1-44 347-8431-00 FILM 1

1

1-45 347-8481-00 FILM 2

1-46 345-6224-00 CUSHION 2

1

1-27

1-28

Note)Several different parts of the same

reference number are alternative parts.

One of those parts is used in the set.

PE-3050E-A

1

2/5

SOUND

4

1

1

1

1

1

1

1

1

-7-

DB188/189RMP/DB189RGMP

Page 8

Main section

(

)

)

(

)

K

(

)

(

)

(

)

T

(

(

)

(P)

)

K

(

)

(

)

(P)

35

34

35

34

33

35

33

34

32

35

24

27

25

37

24

26

28

41

24

39

20

38

40

27

21

28

23

43

44

43

42

35

10

14

13

9

8

12

11

19

36

17

15

16

7

1

2

3

4

5

6

29

18

31

30

22

Note) CD MECHANISM 929-4002-00 is exchanged

correspondence, it is not being possible to repair.

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 074-1217-50 OUTLET SOCKET

2 074-2246-67 OUTLET SOCKET

3 ----------- MAIN PWB 1 26 347-8456-00 FILM 1

4 013-6100-00 TACT SWITCH 1 27 345-6201-00 CUSHION 2

5 941-0227-30 TUNER PAC

6 092-4000-51 ANT-RECEPT 1 29 347-8427-00 FILM 1

7 075-0393-50 JACK 1 30 276-0372-00 SETPLATE

8 051-3349-00 IC 1 276-0396-00 SETPLATE

9 051-2060-00 IC 1 276-0397-00 SETPLATE

10 009-9006-60 CHOKE 1 31 311-1859-05 LOWER CASE 1

009-9006-70 CHOKE 1 32 345-3799-20 RUBBER PAR

11 331-4533-00 JACK HOLDER 1 33 714-2610-85 MACHINE SCREW

12 331-3935-02 IC HOLDER 1 34 714-3006-85 MACHINE SCREW

13 074-1285-00 OUTLET SOCKET

14 060-0057-57 AUTO FUSE(15A) 1 36 313-2006-02 HEAT SIN

15 855-5426-53 RCA PIN CORD

16 ----------- ISO PWB 1 38 929-4002-00 CD MECHANISM 1

17 331-3562-02 CONNECTOR-HOLD 1 39 341-1627-00 SHAFT 1

18 854-4619-50 AUX LEAD 1 40 750-3219-00 SPRING

19 347-8489-00 FILM 1 41 335-5915-01 HOOK 1

20 382-8567-00 BUTTON

21 750-6861-00 SPRING 1 43 076-0502-55 PLUG 1

22 346-0194-00 LEATHER SHEET 1 44 ----------- AUX PWB 1

23 075-9021-50 JACK 1

12P

12P

2CH

1 24 731-2606-8B TAPTIGHT(M2.6X6

1 25 347-8490-00 FILM 1

1 28 345-6195-00 CUSHION 2

PE-3050E-A

PE-3050E-B

PE-3050E-C

M2.6X10)3

M3X6

1 35 731-3008-89 TAPTIGHT(M3X8

1 37 310-1871-00 UPPER CASE 1

F-HOOK

1 42 370-6322-01 INNER-ES 1

3

1

1

1

2

3

5

1

1

DB188/189RMP/DB189RGMP

-8-

Page 9

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

ANT2 092-4000-51 ANT-RECEPT C319 043-1735-90 100pF C820 043-1608-90 0.1uF

BL1 941-0227-30 TUNER PACK C320 043-1735-90 100pF C821 043-1804-90 0.1uF

C118 043-1608-90 0.1uF C321 187-1063-35 16V 10uF C822 043-1802-90 0.01uF

C119 043-1608-90 0.1uF C322 187-1063-35 16V 10uF C824 043-1804-90 0.1uF

C120 187-1073-15 6.3V 100uF C337 187-1063-35 16V 10uF C825 043-1824-90 0.22uF

C121 043-1608-90 0.1uF C338 187-1063-35 16V 10uF C826 043-1625-90 0.022uF

C122 187-1073-35 16V 100uF C339 187-1063-35 16V 10uF C827 043-1608-90 0.1uF

C123 043-1608-90 0.1uF C340 187-1063-35 16V 10uF C828 187-1073-15 6.3V 100uF

C124 187-1073-35 16V 100uF C346 043-1841-90 0.047uF C829 043-1608-90 0.1uF

C125 043-1608-90 0.1uF C401 042-1715-00 16V 3300uF C830 043-1804-90 0.1uF

C200 187-1063-35 16V 10uF C413 178-4742-78 0.47uF C831 187-1073-15 6.3V 100uF

C201 043-1804-90 0.1uF C414 178-4742-78 0.47uF C833 189-3373-11 6.3V 330uF

C202 043-1727-90 47pF C415 178-4742-78 0.47uF C834 189-4773-22 10V 470uF

C203 043-1817-90 0.018uF C416 178-4742-78 0.47uF C835 043-1804-90 0.1uF

C204 043-1817-90 0.018uF C421 043-1620-90 4700pF C836 163-4753-55 50V 4.7uF

C205 043-1623-90 560pF C428 187-1063-35 16V 10uF C837 163-4753-55 50V 4.7uF

C206 043-1804-90 0.1uF C435 178-4742-78 0.47uF C838 043-1800-90 1000pF

C207 189-2273-21 10V 220uF C442 187-1053-65 50V 1uF C839 043-1800-90 1000pF

C208 043-1617-90 6800pF C445 172-1041-15 0.1uF C840 043-1800-90 1000pF

C209 187-1073-25 10V 100uF C447 043-1751-90 470pF C841 043-1800-90 1000pF

C210 187-1073-25 10V 100uF C449 043-1751-90 470pF C842 043-1731-90 68pF

C211 043-1804-90 0.1uF C450 043-1751-90 470pF C843 043-1731-90 68pF

C212 043-1804-90 0.1uF C451 043-1751-90 470pF C844 043-1608-90 0.1uF

C213 187-1073-25 10V 100uF C452 043-1751-90 470pF C845 043-1608-90 0.1uF

C214 043-1804-90 0.1uF C453 043-1751-90 470pF C846 043-1608-90 0.1uF

C215 172-6831-15 0.068uF C454 043-1751-90 470pF C847 187-1053-65 50V 1uF

C216 043-1607-90 0.01uF C455 043-1751-90 470pF C848 187-1073-15 6.3V 100uF

C217 043-1607-90 0.01uF C500 187-3363-45 10V 33uF C849 043-1804-90 0.1uF

C218 043-1601-90 100pF C501 168-1052-78 50V 1uF C850 043-1804-90 0.1uF

C219 043-1713-90 12pF C502 043-1608-90 0.1uF C853 189-4773-22 10V 470uF

C220 043-1713-90 12pF C503 043-1608-90 0.1uF C854 043-1841-90 0.047uF

C221 043-1622-90 330pF C504 168-1052-78 50V 1uF C855 043-1608-90 0.1uF

C222 043-1719-90 22pF C505 043-1804-90 0.1uF C856 043-1804-90 0.1uF

C223 043-1804-90 0.1uF C506 043-0540-00 16V 10uF C857 187-1073-15 6.3V 100uF

C224 187-1073-25 10V 100uF C507 163-1063-35 16V 10uF C858 043-1804-90 0.1uF

C226 187-1053-65 50V 1uF C508 043-1710-90 9pF C859 187-1073-15 6.3V 100uF

C227 043-1804-90 0.1uF C509 043-1710-90 9pF C860 187-1073-15 6.3V 100uF

C230 043-1607-90 0.01uF C510 043-1719-90 22pF C861 043-1608-90 0.1uF

C231 187-4763-15 6.3V 47uF C511 043-1719-90 22pF C870 187-1073-35 16V 100uF

C232 043-1802-90 0.01uF C512 043-1607-90 0.01uF D100 001-0592-61 1N5404

C233 187-4753-65 50V 4.7uF C513 043-1601-90 100pF D109 001-0466-61 1A4

C234 043-1735-90 100pF C514 042-1577-00 6.3V 100uF D201 001-1323-90 L1SS355T1G

C235 043-1735-90 100pF C515 043-1607-90 0.01uF D202 001-1323-90 L1SS355T1G

C236 043-1618-90 0.018uF C516 189-1083-12 6.3V 1000uF D302 001-4316-17 LM3Z4V3T1G

C237 043-1625-90 0.022uF C800 187-1073-15 6.3V 100uF D401 001-4316-24 LM3Z8V2T1G

C238 043-1626-90 820pF C801 043-1620-90 4700pF D402 001-1323-90 L1SS355T1G

C239 043-1624-90 680pF C802 043-1802-90 0.01uF D403 001-1323-90 L1SS355T1G

C240 043-1600-90 10pF C803 043-1804-90 0.1uF D500 001-1323-90 L1SS355T1G

C244 043-1625-90 0.022uF C804 043-1804-90 0.1uF D502 001-4301-26 HZU4.7B2

C245 043-1607-90 0.01uF C805 187-3363-25 6.3V 33uF D503 001-1323-90 L1SS355T1G

C250 187-4763-35 16V 47uF C806 043-1804-90 0.1uF D504 001-1323-90 L1SS355T1G

C307 187-1053-65 50V 1uF C807 187-1073-15 6.3V 100uF D505 001-1323-90 L1SS355T1G

C308 187-1053-65 50V 1uF C809 043-1804-90 0.1uF D506 001-1323-90 L1SS355T1G

C309 187-1053-65 50V 1uF C810 043-1804-90 0.1uF D507 001-1323-90 L1SS355T1G

C310 187-1053-65 50V 1uF C811 043-1802-90 0.01uF D509 001-4301-41 HZU7.5B2

C311 187-1053-65 50V 1uF C812 043-1606-90 1000pF D510 001-4301-41 HZU7.5B2

C312 187-1053-65 50V 1uF C813 043-1804-90 0.1uF D511 001-4301-41 HZU7.5B2

C313 187-4763-15 6.3V 47uF C814 043-1607-90 0.01uF D512 001-4301-41 HZU7.5B2

C314 187-1063-35 16V 10uF C815 187-1073-15 6.3V 100uF D521 001-1323-90 L1SS355T1G

C315 043-1735-90 100pF C816 168-1052-78 50V 1uF D801 001-1323-90 L1SS355T1G

C316 043-1735-90 100pF C817 043-1606-90 1000pF D802 001-0644-90 MA113

C317 043-1804-90 0.1uF C818 043-1608-90 0.1uF IC105 051-3349-00 HA13166

C318 187-4763-35 16V 47uF C819 187-1073-15 6.3V 100uF IC201 051-4620-90 LC72725KM

ELECTRICAL PARTS LIST

Main PWB(B1) section

Note)1. Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

2. Some parts depend on each model. The model name is specified in the description.

-9-

DB188/189RMP/DB189RGMP

Page 10

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

IC202 051-0350-93 NJM4558 Q516 125-0021-91 DTA114EUA R454 119-2231-15 1/10W 22k ohm

IC302 051-5028-90 TDA7409 Q516 125-0034-92 RT1P141M R456 119-3311-15 1/10W 330 ohm

IC305 051-3060-90 AZ4558C Q801 190-2060-00 2SA2060 R457 119-2231-15 1/10W 22k ohm

IC402 051-2060-00 LA47201 Q802 101-0941-00 2SB941 R459 033-1021-15 1/16W 1k ohm

IC501 052-1955-00 LC8783J2PA- R154 116-1521-15 1/4WS 1.5k ohm R500 116-4721-15 1/4WS 4.7k ohm

59H6-E R156 119-1241-15 1/10W 120k ohm R501 119-4731-15 1/10W 47k ohm

IC502 051-5443-38 S80850CNMC R200 119-1031-15 1/10W 10k ohm R502 033-4721-15 1/16W 4.7k ohm

IC503 051-5437-58 R3111N211A R201 119-5631-15 1/10W 56k ohm R503 033-4731-15 1/16W 47k ohm

IC801 051-6743-00 LC786920E R202 033-1001-15 1/16W 10 ohm R504 033-4721-15 1/16W 4.7k ohm

IC802 051-6096-90 LA6242H R203 116-3311-15 1/4WS 330 ohm R505 033-1031-15 1/16W 10k ohm

J501 074-1217-50 12P R204 033-1011-15 1/16W 100 ohm R506 033-1041-15 1/16W 100k ohm

J502 075-0393-50 JACK R205 119-5121-15 1/10W 5.1k ohm R507 033-6831-15 1/16W 68k ohm

J801 074-2246-67 17P R206 119-5111-15 1/10W 510 ohm R509 119-1031-15 1/10W 10k ohm

L201 010-2003-04 30uH(Variable) R207 119-0000-05 1/10W 0 ohm J W R512 119-0000-05 1/10W 0 ohm JW

L202 010-3105-67 1k ohm/100MHz R208 119-0000-05 1/10W 0 ohm JW R513 033-4731-15 1/16W 47k ohm

L203 010-3105-67 1k ohm/100MHz R209 119-2711-15 1/10W 270 ohm R514 033-4731-15 1/16W 47k ohm

L205 010-2275-53 220uH R212 119-0000-05 1/10W 0 ohm JW R515 119-1841-15 1/10W 180k ohm

L206 010-6009-57 0.56uH R213 119-1021-15 1/10W 1k ohm R516 033-4731-15 1/16W 47k ohm

L301 010-6009-84 100uH R214 119-5621-15 1/10W 5.6k ohm R518 033-1031-15 1/16W 10k ohm

L302 010-3105-67 1k ohm/100MHz R222 119-4721-15 1/10W 4.7k ohm R521 033-5641-15 1/16W 560k ohm

L303 010-3105-67 1k ohm/100MHz R223 119-4721-15 1/10W 4.7k ohm R526 033-1031-15 1/16W 10k ohm

L501 010-3112-90 1k ohm/100MHz R224 119-2231-15 1/10W 22k ohm R527 033-1031-15 1/16W 10k ohm

L502 010-3123-90 2.2uH R226 033-3311-15 1/16W 330 ohm R528 033-5621-15 1/16W 5.6k ohm

L503 010-3123-90 2.2uH R227 033-1021-15 1/16W 1k ohm R529 119-4721-15 1/10W 4.7k ohm

L504 010-3123-90 2.2uH R228 033-1231-15 1/16W 12k ohm R530 033-1031-15 1/16W 10k ohm

L801 010-6009-76 22uH R229 033-1031-15 1/16W 10k ohm R531 033-4721-15 1/16W 4.7k ohm

L802 010-6009-76 22uH R231 033-3321-15 1/16W 3.3k ohm R532 119-4721-15 1/10W 4.7k ohm

Q200 198-0669-00 2SK669 R232 033-3331-15 1/16W 33k ohm R533 033-1041-15 1/16W 100k ohm

Q201 125-0025-93 RN2303 R233 119-4741-15 1/10W 470k ohm R534 033-1031-15 1/16W 10k ohm

Q201 125-0034-93 RT1P241M R234 033-1041-15 1/16W 100k ohm R535 033-4731-15 1/16W 47k ohm

Q202 125-0025-93 RN2303 R235 033-2211-15 1/16W 220 ohm R536 033-2231-15 1/16W 22k ohm

Q202 125-0034-93 RT1P241M R236 119-3311-15 1/10W 330 ohm R537 033-1041-15 1/16W 100k ohm

Q203 125-2027-92 DTC124EUA R237 119-5631-15 1/10W 56k ohm R538 119-4711-15 1/10W 470 ohm

Q203 125-2041-93 RT1N241M R313 033-2711-15 1/16W 270 ohm R539 119-4711-15 1/10W 470 ohm

Q204 125-4024-90 3DG3875 R314 033-2711-15 1/16W 270 ohm R540 119-0000-05 1/10W 0 ohm JW

Q205 125-0025-93 RN2303 R315 033-2711-15 1/16W 270 ohm R541 119-1021-15 1/10W 1k ohm

Q205 125-0034-93 RT1P241M R316 033-2711-15 1/16W 270 ohm R542 119-1021-15 1/10W 1k ohm

Q206 125-2027-92 DTC124EUA R317 119-3311-15 1/10W 330 ohm R543 033-4721-15 1/16W 4.7k ohm

Q206 125-2041-93 RT1N241M R319 119-0000-05 1/10W 0 ohm JW R558 119-0000-05 1/10W 0 ohm JW

Q207 125-2027-91 DTC114EUA R321 119-0000-05 1/10W 0 ohm J W R560 033-0000-05 0.5A 0 ohm

Q207 125-2041-92 RT1N141M R325 032-0140-89

1/10W 47k ohm(F)

R561 033-3311-15 1/16W 330 ohm

Q208 125-4011-90 KTD863YAT R326 032-0140-89

1/10W 47k ohm(F)

R562 033-1521-15 1/16W 1.5k ohm

Q209 125-2027-92 DTC124EUA R328 032-0140-89

1/10W 47k ohm(F)

R563 119-0000-05 1/10W 0 ohm JW

Q209 125-2041-93 RT1N241M R329 032-0140-89

1/10W 47k ohm(F)

R801 033-3311-15 1/16W 330 ohm

Q403 125-4024-90 3DG3875 R332 032-0140-89

1/10W 47k ohm(F)

R802 119-1031-15 1/10W 10k ohm

Q404 125-2027-95 DTC143ZUA R333 032-0140-89

1/10W 47k ohm(F)

R804 033-4711-15 1/16W 470 ohm

Q404 125-2041-96 RT1N141M R334 032-0140-89

1/10W 47k ohm(F)

R805 033-4721-15 1/16W 4.7k ohm

Q405 125-2198-90 KRC110S R335 032-0140-89

1/10W 47k ohm(F)

R806 033-4721-15 1/16W 4.7k ohm

Q409 125-0021-95 DTA143ZUA R344 119-1021-15 1/10W 1k ohm R807 116-3391-15 1/4W 3.3 ohm

Q409 125-0034-96 RT1P436M R346 119-1041-15 1/10W 100k ohm R808 119-0000-05 1/10W 0 ohm JW

Q413 125-4012-90 KTD1304 R347 119-1041-15 1/10W 100k ohm R809 119-0000-05 1/10W 0 ohm JW

Q414 125-4012-90 KTD1304 R408 033-8221-15 1/16W 8.2k ohm R810 119-2231-15 1/10W 22k ohm

Q500 125-4024-90 3DG3875 R409 119-1021-15 1/10W 1k ohm R811 119-1531-15 1/10W 15k ohm

Q501 125-3014-90 ISA1602AM1 R410 033-1021-15 1/16W 1k ohm R812 119-2231-15 1/10W 22k ohm

Q501 190-1576-00 2SA1576A R411 033-4711-15 1/16W 470 ohm R813 119-2231-15 1/10W 22k ohm

Q502 125-3014-90 ISA1602AM1 R412 033-2231-15 1/16W 22k ohm R815 033-6811-15 1/16W 680 ohm

Q502 190-1576-90 2SA1576A R413 033-4721-15 1/16W 4.7k ohm R817 033-6811-15 1/16W 680 ohm

Q503 125-2027-91 DTC114EUA R424 033-1231-15 1/16W 12k ohm R818 033-6831-15 1/16W 68k ohm

Q503 125-2041-92 RT1N141M R425 119-0000-05 1/10W 0 ohm JW R820 119-1011-15 1/10W 100 ohm

Q504 125-2027-92 DTC124EUA R427 033-1021-15 1/16W 1k ohm R821 119-1011-15 1/10W 100 ohm

Q504 125-2041-93 RT1N241M R428 033-1021-15 1/16W 1k ohm R825 119-3921-15 1/10W 3.9k ohm

Q505 125-0021-91 DTA114EUA R429 033-1021-15 1/16W 1k ohm R826 119-3921-15 1/10W 3.9k ohm

Q505 125-0034-92 RT1P141M R430 033-1021-15 1/16W 1k ohm R827 119-3921-15 1/10W 3.9k ohm

Q515 125-2027-92 DTC124EUA R446 033-1031-15 1/16W 10k ohm R828 033-2731-15 1/16W 27k ohm

Q515 125-2041-93 RT1N241M R453 119-3311-15 1/10W 330 ohm R829 033-1021-15 1/16W 1k ohm

DB188/189RMP/DB189RGMP

-10-

Page 11

Switch PWB(B2) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C701 043-1841-90 0.047uF Q713 125-2027-92

TRANSISTOR

S703 013-6312-50 SWITCH

C702 043-1841-90 0.047uF Q713 125-2041-93

RT1N241M

S704 013-6312-50 SWITCH

C703 043-1841-90 0.047uF Q714 125-2027-92 TRANSISTOR S705 013-6312-50 SWITCH

C704 043-1800-90 1000pF Q714 125-2041-93 RT1N241M S706 013-6312-50 SWITCH

C705 042-0423-97 16V 10uF TAN R701 119-3311-15 1/10W 330 ohm S707 013-6312-50 SWITCH

C707 043-1841-90 0.047uF

R702 119-3931-15 1/10W 39k ohm

S709 013-6312-50 SWITCH

D702 001-4907-90 PG05GBUSU

R703 119-1041-15 1/10W 100k ohm

S710 013-6312-50 SWITCH

D705 001-4301-29 HZU5.1B2 R704 119-3921-15 1/10W 3.9k ohm S711 013-6312-50 SWITCH

D706 001-4301-29 HZU5.1B2 R709 119-4721-15 1/10W 4.7k ohm S713 013-6312-50 SWITCH

D707 001-4907-90 PG05GBUSU R715 119-1021-15 1/10W 1k ohm S714 013-6312-50 SWITCH

D708 001-4907-90 PG05GBUSU R716 119-1021-15 1/10W 1k ohm S715 013-6312-50 SWITCH

D717 001-4301-29 HZU5.1B2 R717 119-1021-15 1/10W 1k ohm S716 013-6312-50 SWITCH

D718 001-4301-41 HZU7.5B2 R718 119-1021-15 1/10W 1k ohm S717 013-6312-50 SWITCH

D720 001-4301-51 HZU10B3 R723 119-0000-05 1/10W 0 ohm JW S718 016-9901-02 VR W/SHAFT

IC701 051-6095-00 LC75857 S701 013-6312-50 SWITCH PWB 039-3208-01 PWB(WITHOUT

J701 076-0615-50 12P S702 013-6312-50 SWITCH COMPONENT)

LCD701

379-1401-41

INDICATOR(LCD)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D711 001-7114-90 LWL38G-Q1R2 D716 001-7114-90 LWL38G-Q1R2 R719 119-4711-15 1/10W 470 ohm

D712 001-7114-90 LWL38G-Q1R2 R705 119-1221-15 1/10W 1.2k ohm R720 119-4711-15 1/10W 470 ohm

D713 001-7114-90 LWL38G-Q1R2 R706 119-4711-15 1/10W 470 ohm R724 119-1221-15 1/10W 1.2k ohm

D714 001-7114-90 LWL38G-Q1R2 R713 119-4711-15 1/10W 470 ohm R725 119-4711-15 1/10W 470 ohm

D715 001-7114-90 LWL38G-Q1R2 R714 119-4711-15 1/10W 470 ohm

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D711 001-7115-90

VFA1111C-4B93B

R700 119-5611-15 1/10W 560 ohm R719 119-1011-15 1/10W 100 ohm

D712 001-7115-90

VFA1111C-4B93B

R705 119-5611-15 1/10W 560 ohm R720 119-1011-15 1/10W 100 ohm

D713 001-7115-90

VFA1111C-4B93B

R706 119-5611-15 1/10W 560 ohm R724 119-5611-15 1/10W 560 ohm

D714 001-7115-90

VFA1111C-4B93B

R713 119-1011-15 1/10W 100 ohm R725 119-5611-15 1/10W 560 ohm

D715 001-7115-90

VFA1111C-4B93B

R714 119-1011-15 1/10W 100 ohm R726 119-5611-15 1/10W 560 ohm

D716 001-7115-90

VFA1111C-4B93B

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D711 001-7115-91

VUG1111C-4BX3B

D716 001-7115-91

VUG1111C-4BX3B

R719 119-1511-15 1/10W 150 ohm

D712 001-7115-91

VUG1111C-4BX3B

R705 119-8211-15 1/10W 820 ohm R720 119-1511-15 1/10W 150 ohm

D713 001-7115-91

VUG1111C-4BX3B

R706 119-4711-15 1/10W 470 ohm R724 119-8211-15 1/10W 820 ohm

D714 001-7115-91

VUG1111C-4BX3B

R713 119-1511-15 1/10W 150 ohm R725 119-4711-15 1/10W 470 ohm

D715 001-7115-91

VUG1111C-4BX3B

R714 119-1511-15 1/10W 150 ohm

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R830 033-1011-15 1/16W 100 ohm R850 033-1031-15 1/16W 10k ohm R871 032-0140-50

1/10W 10k ohm(F)

R831 033-2221-15 1/16W 2.2k ohm R851 033-1031-15 1/16W 10k ohm R872 119-6221-15 1/10W 6.2k ohm

R832 033-2221-15 1/16W 2.2k ohm R853 119-2721-15 1/10W 2.7k ohm R873 119-1031-15 1/10W 10k ohm

R833 033-2221-15 1/16W 2.2k ohm R854 119-1021-15 1/10W 1k ohm R874 119-6221-15 1/10W 6.2k ohm

R834 119-2201-15 1/10W 22 ohm R855 119-1021-15 1/10W 1k ohm R875 119-6821-15 1/10W 6.8k ohm

R835 033-3321-15 1/16W 3.3k ohm R856 119-1021-15 1/10W 1k ohm R876 033-3331-15 1/16W 33k ohm

R836 033-1511-15 1/16W 150 ohm R857 119-1021-15 1/10W 1k ohm R877 033-3331-15 1/16W 33k ohm

R837 033-2231-15 1/16W 22k ohm R858 033-1031-15 1/16W 10k ohm S501 013-6100-00 SWITCH

R839 119-4701-15 1/10W 47 ohm R859 033-1031-15 1/16W 10k ohm

SUP202

060-0122-20 DSP-141N9S00B

R840 119-3301-15 1/10W 33 ohm R860 033-1031-15 1/16W 10k ohm T101 009-9006-60 0.23mH

R841 119-1511-15 1/10W 150 ohm R861 033-1031-15 1/16W 10k ohm T101 009-9006-70 CHOKE

R842 119-1511-15 1/10W 150 ohm R862 119-6831-15 1/10W 68k ohm X201 061-3013-00 4.33MHz

R845 033-0000-05 0.5A 0 ohm R863 119-2231-15 1/10W 22k ohm X501 061-1056-00 32.768kHz

R846 033-0000-05 0.5A 0 ohm R865 119-3351-15 1/10W 3.3m ohm X502 061-3562-90 13.5MHz

R847 033-0000-05 0.5A 0 ohm R866 033-1031-15 1/16W 10k ohm X801 060-1535-90 16.9344MHz

R848 033-0000-05 0.5A 0 ohm R867 119-1031-15 1/10W 10k ohm PWB 039-3207-00 PWB(WITHOUT

R849 033-1031-15 1/16W 10k ohm R870 032-0140-54

1/10W 22k ohm(F)

COMPONENT)

The same parts for PE-3050E-A/B/C

The parts for PE-3050E-A

The parts for PE-3050E-B

The parts for PE-3050E-C

-11-

DB188/189RMP/DB189RGMP

Page 12

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

J401 074-1285-00 18P JW3 999-0150-06 JUMPER WIRE FUSE 060-0057-57 AUTO FUSE(15A)

JW1 999-0150-06 JUMPER WIRE JW4 999-0150-06 JUMPER WIRE PWB 039-3036-00 PWB(WITHOUT

JW2 999-0150-06 JUMPER WIRE JW5 999-0150-06 JUMPER WIRE COMPONENT)

AUX PWB(B3) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

J1 075-9021-50 JACK L3 010-3105-67 1k ohm/100MHz PWB 039-3209-00 PWB(WITHOUT

L1 010-3105-67 1k ohm/100MHz P1 076-0502-55 5P COMPONENT)

L2 010-3105-67 1k ohm/100MHz

ISO PWB(B4) section

CIRCUIT DIAGRAM 1/6

AUX PWB(B3) section

To AUX Bluetooth BB

PRINTED WIRING BOARD 1/4

AUX PWB(B3) section

To AUX Bluetooth BB

COMPONENT SIDE

Caution:

COMPONENT SIDE: Parts on the component side seen from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen from the solder side are indicated.

To Main PWB(B1)(page 17)

connect with AUX LEAD 854-4619-50

51

P1

To Main PWB(B1) (page 13)

connect with AUX LEAD 854-4619-50

SOLDER SIDE

DB188/189RMP/DB189RGMP

-12-

Page 13

PRINTED WIRING BOARD 2/4

Main PWB(B1) section 1/2

ISO PWB(B4) section

YEL

RED

ISO PWB(B4)

B7

B5

B8

B6

A7

A5

A8

BRN

ORG

B1

B3

B4

B2

J201

A1

1

5

A4A6

JW1

JW2

JW3

JW5

JW4

S-GND

R-R

R-L

RCA PIN CORD(2CH)

(855-5426-53)

BLACK

RED

REAR/RIGHT

WHITE

LINE OUT

REAR/LEFT

1

226

1

25

2

OEM STEERING WHEEL REMOTE

CONTROL INPUT JACK

IC Q

GND

15

14

IN

J201

1

B3

B

A

B1

B2

B4

A3

A1

A2

A4

A

A1

PHONE MUTE

---

A2

---

A3

BACK UP

A4

A5

REMOTE

ILLUMINA TION

A6

ACC

A7

A8

GROUND

B7

B5

B6

A7

A5

A8

A6

B

B1

REAR RIGHT +

B2

REAR RIGHT -

B3

FRONT RIGHT +

FRONT RIGHT -

B4

B5

FRONT LEFT +

FRONT LEFT -

B6

B7

REAR LEFT +

REAR LEFT -

B8

B8

1

15

1

21

61

41

11

1

81

1

51

31

5

10

15

20

26

COMPONENT SIDE

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

-13-

121

To J701 of Switch PWB(B2) (page 14)

DB188/189RMP/DB189RGMP

5

8

5

4

1

1

To P1 of AUX PWB(B3)(page 12)

connect with AUX LEAD 854-4619-50

Page 14

PRINTED WIRING BOARD 3/4

Main PWB(B1) section 2/2

GND

IN

15

14

PRINTED WIRING BOARD 4/4

To CD MECHANISM

Note) CD MECHANISM 929-4002-00 is exchanged

correspondence, it is not being possible to repair.

1

24

2

25

2

1

Swiche PWB(B2) section

[SRC]

[]

[ ] (EJECT]

Q

IC

[BND]

[TA]

[]

[DISP]

[]

12

[ROTARY]

1

(PE-3050E-B)

5

1

D

L

MD

LD-GND

R

V

-

10

T

F-

F+

T+

ND

E

A

PD_G

D

C

B

F

C

17

V

CC

V

[1]

15

[2]

To J501 of Main PWB(B1)

(page 13)

(PE-3050E-B)

1

20

26

SOLDER SIDE

Caution:

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

12 1

The parts of a dashed line express the parts on a component side.

[3]

[4]

[5]

[6]

[SOUND]

COMPONENT SIDE

16

17

32

33

SOLDER SIDE

1

64

49

48

Caution:

COMPONENT SIDE: Parts on the component side seen from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen from the solder side are indicated.

-14-

DB188/189RMP/DB189RGMP

Page 15

CIRCUIT DIAGRAM 2/6

Main PWB(B1) section 1/4

To 2/4(page 16)To 3/4(page 17)

To 3/4(page 17)To 3/4(page 17) To 4/4(page 18)

To J701 of Switch PWB(B2) (page 16)

-15-

DB188/189RMP/DB189RGMP

Page 16

CIRCUIT DIAGRAM 3/6

Main PWB(B1) section 2/4

To 3/4(page 17)

To 1/4(page 15)

To 3/4(page 17)

CIRCUIT DIAGRAM 4/6

Switch PWB(B2) section

To J501 of Main PWB(B1) (page 15)

To 1/4(page 15)

MODEL

PE-3050E-A

PE-3050E-B

PE-3050E-C

R705,R724

1.2k ohm

560 ohm

820 ohm

R706,R725

470 ohm

560 ohm

470 ohm

R713,R714,

R719,R720

470 ohm

100 ohm

150 ohm

R700,R726

X

X

To 1/4(page 15)

5V

7.9V

7.3V

5V

5V

-16-

DB188/189RMP/DB189RGMP

Page 17

CIRCUIT DIAGRAM 5/6

Main PWB(B1) section 3/4

ISO PWB(B4) section

To 2/4(page 16)

To 1/4(page 15)

To 4/4(page 18)

To 1/4(page 15)

LINE OUT

To P1 of USB JACK PWB(B3)(page 12)

connect with AUX LEAD 854-4619-50

To 2/4(page 16)

To 4/4(page 18)

A1

PHONE MUTE

A2

A3

BACK UP

A4

A5

REMOTE

ILLUMINA TION

A6

ACC

A7

A8

GROUND

A

---

---

ISO PWB(B4)

B

B1

REAR RIGHT +

B2

REAR RIGHT -

B3

FRONT RIGHT +

FRONT RIGHT -

B4

B5

FRONTLEFT+

FRONT LEFT -

B6

B7

REAR LEFT +

REAR LEFT -

B8

To 1/4(page 15)

To 1/4(page 15)

To 2/4(page 16)

To 3/4(page 17)

-17-

DB188/189RMP/DB189RGMP

A

A2

A4

A6

A8

B

B2

A1

A3

A5

A7

B1

B4

B3

B6

B5

B7

B8

Page 18

CIRCUIT DIAGRAM 6/6

Main PWB(B1) section 4/4

RED

ORANGE

GREEN

GREEN

RED

BLACK

BLUE

WHITE

BROWN

To CD MECHANISM

To 1/4(page 15)

Note) CD MECHANISM 929-4002-00 is

exchanged correspondence, it is

not being possible to repair.

To 1/4(page 15)

To 3/4(page 17)

-18-

DB188/189RMP/DB189RGMP

Loading...

Loading...