Clamp-All 10 in. Clamp Stainless Steel Coupling Installation

TM

HI-TORQ 80

Coupling

The easy way to worry-free coupling installations

Quick & Easy Installation

1 2

3 4

1 - The cut ends of the pipe should be smooth and square.

2 - Place neoprene gasket on end of pipe or fitting until it is firmly seated against the center stop.

3 - Place stainless steel housing with clamps on end of other pipe and slip the pipe into the gasket until it is also firmly

seated against the center stop.

4 - Slide the housing into position directly over the gasket. Using preset torque wrench, alternately tighten clamps to 80

in/lbs (9N/m) of torque Recheck torque on all clamps before proceeding to next installation to assure an even and

proper torque.

Note: Couplings 5" & larger - tighten innermost clamps first, then tighten outermost clamps to ensure even tightening

of the coupling.

Hanging

Hubless Cast Iron Soil Pipe joined by Clamp-All HI-TORQ 80 couplings may be hung the same as Bell and Spigot Cast Iron

Pipe with Lead and Oakum.

Vertical Piping shall be supported at each stack base and at each floor. Free standing vertical pipe should be adequately

staked or braced during construction to maintain alignment.

Horizontal Piping shall be supported within 24 inches of the coupling joint at 10 foot intervals for 10 foot pipe lengths and

at 5 foot intervals for 5 foot pipe lengths. Supports or hangers should be properly placed to maintain alignment and grade

with provision made to prevent shear. Horizontal runs of pipe 5" diameter & larger must be braced at changes of direction

and sway braced as necessary to prevent horizontal movement and maintain alignment.

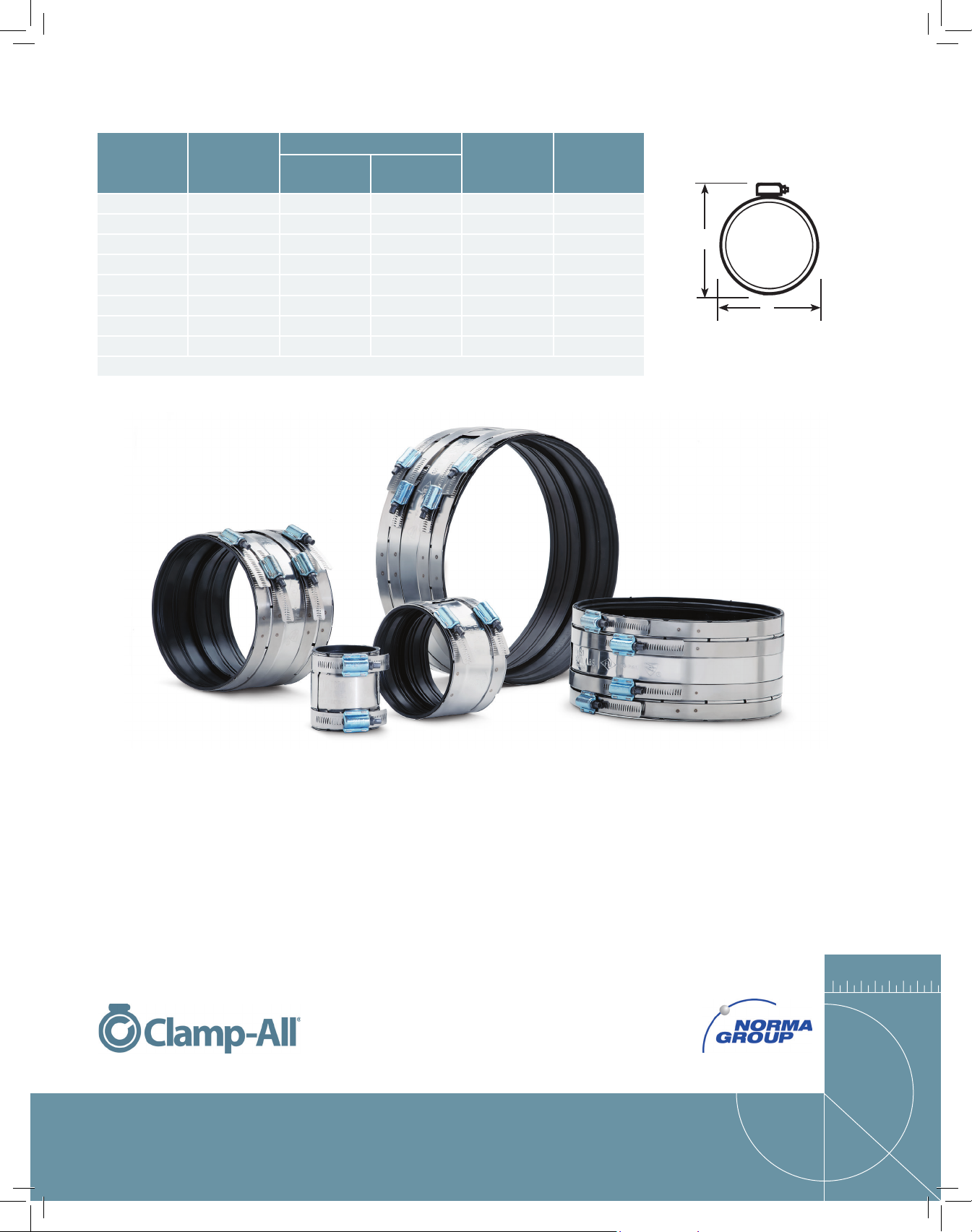

How to Order

Pipe Size

in. (mm)

1.5" (38)

2" (50)

3" (75)

4" (100)

5" (125)

6" (150)

8" (200)

10" (250)

99080 Order HI-TORQ 80 Pre-set Torque Wrench for proper installation.

HI-TORQ 80

Part Numbers

❑ 81015

❑ 81020

❑ 81030

❑ 81040

❑ 81050

❑ 81060

❑ 81080

❑ 81000

Installed Dimension

A

in. (mm)Bin. (mm)

2.75" (70) 2.25" (57) 1.44" (37) 3" (75)

3.25" (83) 2.75" (70) 1.44" (37) 3" (75)

4.25" (108) 3.75" (95) 1.44" (37) 3" (75)

5.25" (133) 4.75" (121) 1.44" (37) 3" (75)

6.25" (159) 5.75" (146) 1.94" (49) 4" (100)

7.25" (184) 6.75" (171) 1.94" (49) 4" (100)

9.25" (235) 8.75" (222) 1.94" (49) 4" (100)

11.50" (292) 11" (279) 1.94" (49) 4" (100)

Depth to

Center Stop

in. (mm)

Width of

Coupling

in. (mm)

A

B

Guarantee

Clamp-All Products Corporation guarantees its hubless couplings, Approved to Factory Mutual Standard FM-1680 Class 1

at 15 PSI rated working pressure, to be free from defects in material and workmanship. Clamp-All further warrants that

these couplings will not fail due to rust, rot or corrosion for the normal life expectancy of the materials joined, when

installed in a normal building environment or in naturally occurring soils.

Note: Installation must be in accordance with our printed installation instructions and in conformance with local code

requirements.

For information, technical support or to order . . . call or email:

Clamp-All Products • 325 W. Silverbell Rd. Suite 230 Lake Orion, MI 48359

TOLL FREE: 855-NORMA2U (667-6228) • FAX: 248-373-3068 • www.ClampAll.com

E-mail: Norma2u@normagroup.com

2-7H-6-140729-US

Loading...

Loading...