Claind NiGen LCMS, NiGen HF User Manual

User’s Manual

Nitrogen

Generator

NiGen HF NiGen LCMS

2

Table of contents

1. Introduction 3

2. Safety 4

3. Description of the generator 6

4. Installation area requirements 12

5. Installation 14

6. Disassembly and transport 19

7. Use 20

8. Maintenance 28

9. Troubleshooting 33

10. Guarantee 37

11. Declaration of conformity 38

12. Notes 39

Nitrogen Generator NiGen HF - NiGen LCMS

3

1.

Introduction

This document is intended for users of nitrogen generator models NiGen HF and

NiGen LCMS, and provides all information regarding installation, use and maintenance.

The generator is intended to be used as a source of nitrogen gas for laboratory

applications, including gas chromatography, ICP, LCMS, sample preparation,

etc..

The manual covers the following models:

As regards installation and maintenance, it is assumed that the user is familiar

with pneumatic circuit components, and in particular is aware of the safety aspects of compressed air and nitrogen.

The margin of the text contains the following symbols, indicating:

m

compulsory safety standards to be observed

c

electrical hazard

e

recommendations and important information

It is strongly recommended to carefully read all safety warnings (

par. 2.1.

) be-

fore carrying out any operation on the generator.

Serial number Model

422.02.0310 NiGen HF-0

422.02.0440 NiGen HF-1 115 Vac 60Hz

422.02.0450 NiGen HF-1 230 Vac 50Hz

422.02.0460 NiGen HF-1 230 Vac 60Hz

422.02.0710 NiGen LCMS 40-0

422.02.0640 NiGen LCMS 40-1 115 Vac 60Hz

422.02.0650 NiGen LCMS 40-1 230 Vac 50Hz

422.02.0660 NiGen LCMS 40-1 230 Vac 60Hz

422.02.0810 NiGen LCMS 100-0

Safety

4

2.

Safety

e

The unit must be installed and used in observance of the instructions in this booklet. Furthermore, use of the generator must be limited to that described in

Chapter 1 Introduction

. Failure to observe the foregoing will render the guarantee null and void and release CLAIND from all liability for direct or indirect damage or physical injury.

e

The user is responsible for asking local authorities if there are local safety regulations that are stricter than what is described in this manual.

2.1.

Warnings

m

Place the generators FAR FROM SOURCES OF HEAT

m

Place the generators in an environment PROTECTED AGAINST RAIN

AND WIND

c

NEVER OPEN the generator while it is connected to the electrical

mains: RISK OF FATAL INJURY BY ELECTROCUTION

e

Repairs and inspections must be carried out exclusively by QUALIFIED PERSONNEL: in the event of faults which cannot be resolved according to the pro-

cedures listed in the TROUBLESHOOTING chapter, contact exclusively our

authorized Technical Assistance.

e

If the generator is not to be used for a prolonged period of time, it must be depressurised (par. 7.6. and par. 7.7.).

2.2.

Notes on the use of nitrogen

Nitrogen is not a toxic gas, but when the percentage in the air exceeds specific

values there is a risk of asphyxia.

Therefore NEVER DIRECTLY INHALE the gas produced and avoid working in the

vicinity of a flow of nitrogen.

However, given the low quantities produced, it is sufficient that the flow of nitrogen occurs in a normally ventilated environment to avoid the risk of accumulation

(par 4.2.1.).

Nitrogen Generator NiGen HF - NiGen LCMS

5

2.3.

Safety devices

MAXIMUM PRESSURE: the control system constantly monitors the pressure.

In case of anomalous pressure, a safety valve (which operates independently of

the control system) prevents it exceeding 10.5 bar (152 psi).

2.4.

Technical assistance

The CLAIND technical assistance can be contacted as follows:

Phone ++39 0344 56603

Fax ++39 0344 56627

Email: service@claind.it

Website: filling the form on the website www.claind.it at the “Service” section

Description of the generator

6

3.

Description of the generator

3.1.

Equipment supplied

Unless otherwise agreed, the forniture includes:

• n°1 nitrogen generator;

• n°1 CD user’s manual;

• n°1 applicable declarations of conformity of tank and safety valve;

• n°1 cable for the electrical mains;

• n°1 fitting for plastic tube external diameter 4mm;

• n°1 fitting for plastic tube external diameter 6mm;

• n°1 fitting for plastic tube external diameter 10mm;

• 2 mt of plastic tube external diameter 4mm;

only for generator NiGen HF the forniture includes:

• n°1 brass fitting for copper tube external diameter1/4”.

3.2.

Technical specifications

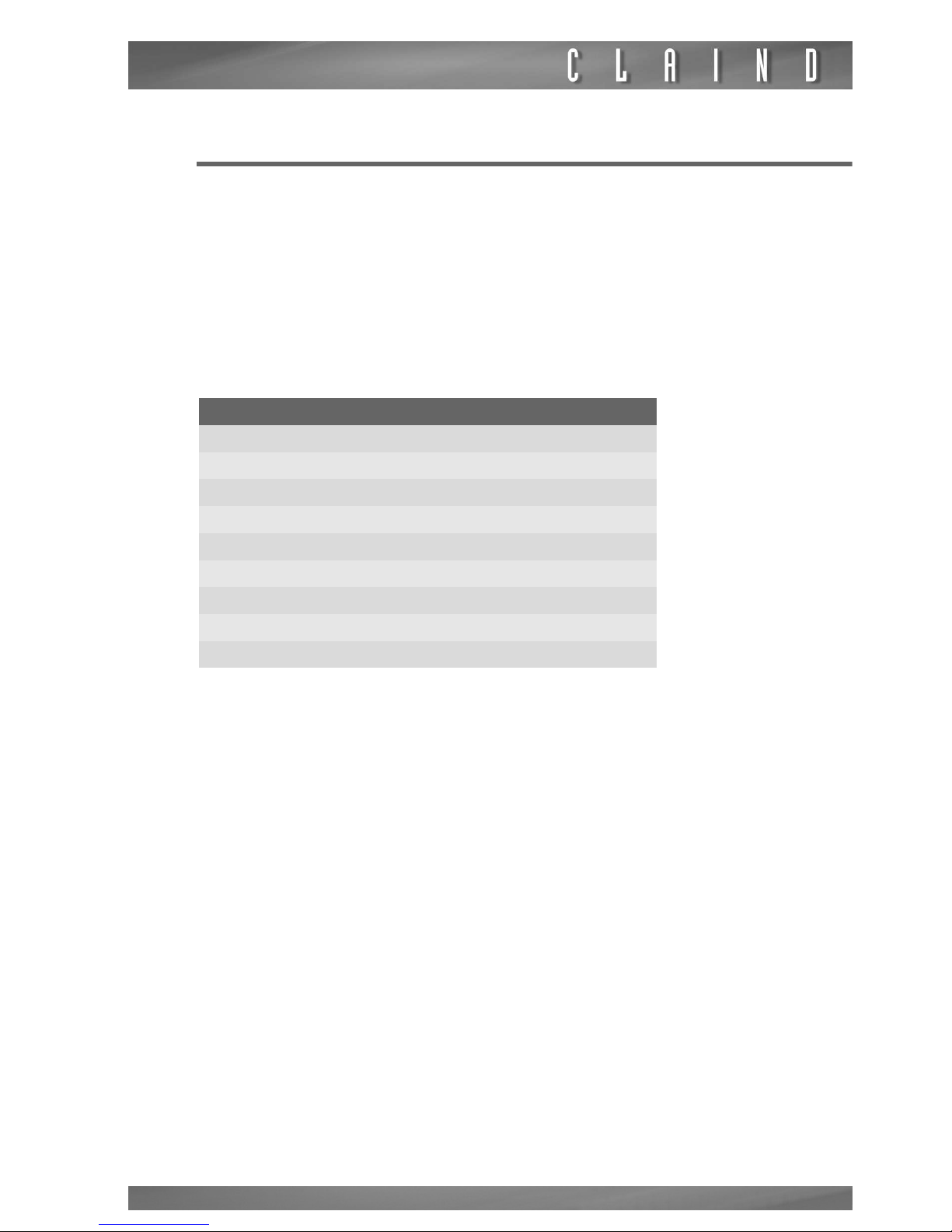

3.2.1.

Nitrogen

(*) the flow rate is given at 20°C and 1 atm

(**) purity referred to residual oxygen

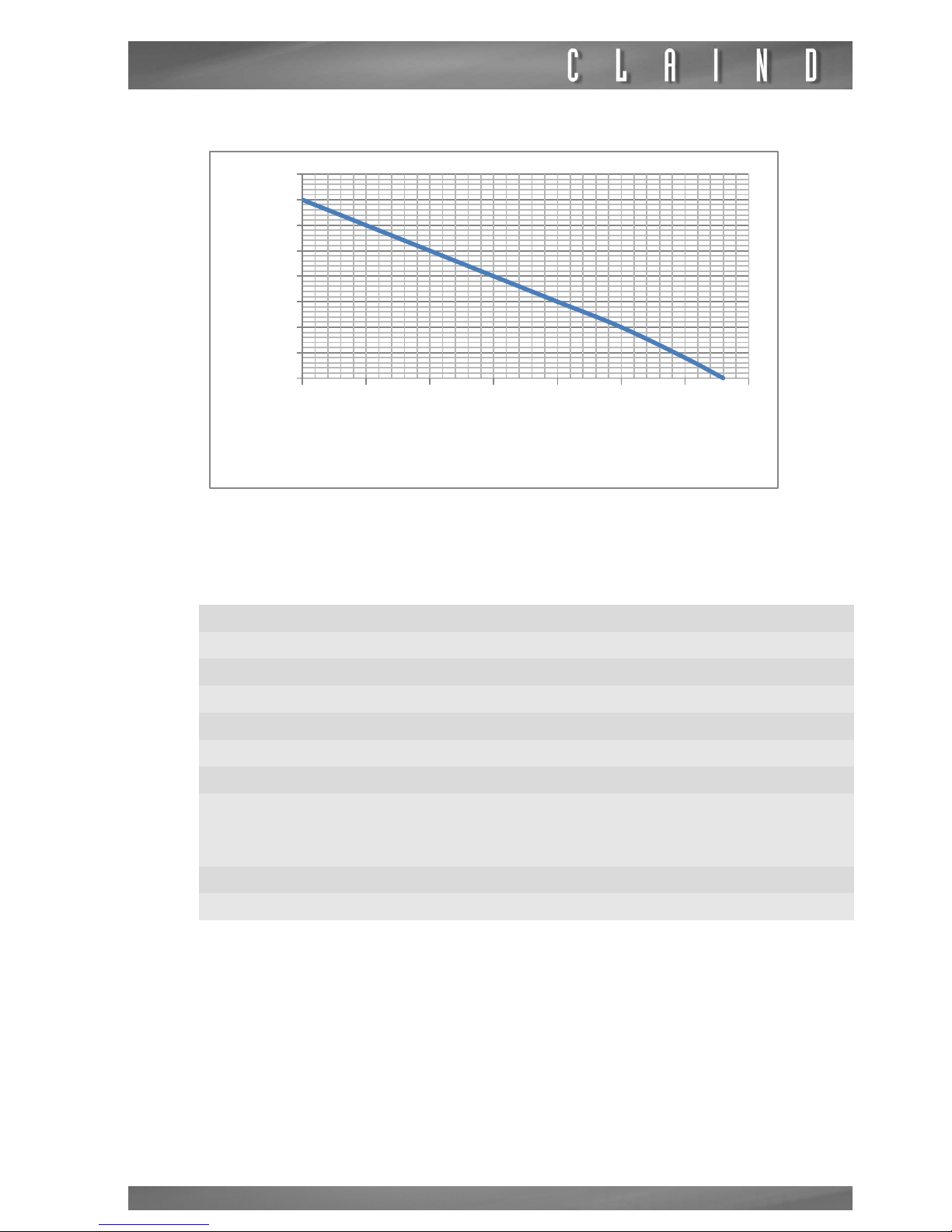

3.2.2.

Compressed air supply table

NiGen LCMS 40-1 and HF-1 produce nitrogen and compressed air.

This table shows on X axes the nitrogen product, and on Y axes the compressed

air available only for the model LCMS 40-1.

Max flow rate (*)

NiGen HF-0 6 Nl/min 6 slpm

NiGen HF-1 6 Nl/min 6 slpm

NiGen LCMS 40-0 40 Nl/min 40 slpm

NiGen LCMS 40-1 40 Nl/min 40 slpm

NiGen LCMS 100 100 Nl/min 100 slpm

Pressure

settable from 0 to

7 bar

settable from 0 to

100 psi

Purity (**)

NiGen HF up to 99.9995 %

NiGen LCMS up to 99.9 %

Nitrogen Generator NiGen HF - NiGen LCMS

7

For the HF-1 the maximum flow of outlet compressed air is 14 Nl/min.

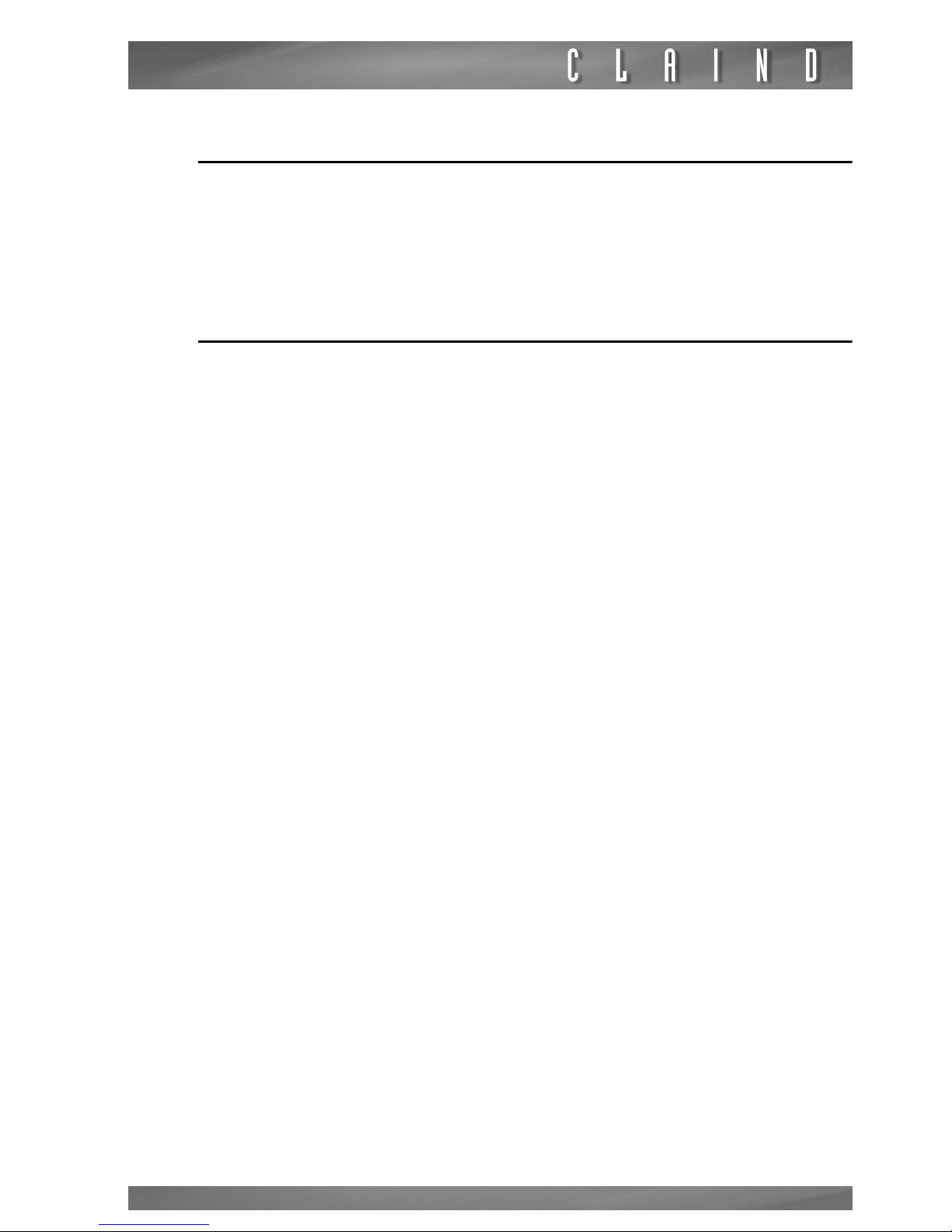

3.2.3.

Compressed air supply, specifications

not applicable to

NiGen HF-1 and NiGen LCMS 40-1

(***) for further details on the air quality, see the specifications for Class 1-4-1,

ISO 8573-1

Pressure

minimum 8.5 bar 120 psi

maximum 10 bar 145 psi

Flow rate

NiGen HF-0 36 Nl/min 36 slpm

NiGen LCMS 40-0 100 Nl/min 100 slpm

NiGen LCMS 100 250 Nl/min 250 slpm

Particulates: maximum concentra-

tion of particles of diameter less

than 0.1 µm (***)

less than 0.1 mg/m³

Oil concentration less than 0.01 mg/m³

Humidity dewpoint under pressure less than 3°C

\

0

5

10

15

20

25

30

35

40

5 10 15 20 25 30 35 40

Air [Nl/min]

N2 [Nl/min]

Description of the generator

8

3.2.4.

Electrical requirements

3.2.5.

Pneumatic connections

3.2.6.

Electrical connections

NiGen HF-0,

NiGen LCMS 40-0,

NiGen LCMS 100

115-230 Vac (±10%), 1 ph, 50/60Hz;

50 W

NiGen HF-1,

NiGen LCMS 40-1

depending on model:

115 Vac (±10%); 1ph; 60Hz; 1.9 kVA

or

230 Vac (±10%); 1 ph; 50Hz; 1.6 kVA

or

230 Vac (±10%); 1 ph; 60Hz; 1.9 kVA

Nitrogen outlet G 1/4" female

Air outlet

not applicable to

NiGen HF-0, NiGen

LCMS 40-0 and NiGen LCMS 100

G 1/4" female

Drain

not applicable to

NiGen HF-0, NiGen

LCMS 40-0 and NiGen LCMS 100

G 1/8" female

Compressed air supply

not applicable to

NiGen HF-1 and NiGen

LCMS 40-1

G 1/4" female

Power supply socket IEC320-20

Nitrogen Generator NiGen HF - NiGen LCMS

9

3.2.7.

Dimensions

3.3.

Generator components

3.3.1.

Front view

A. CPU: generator control unit; it is the user interface by way of the touch screen;

B. FRONT PANEL, removable for maintenance operations

C. FULL TURN WHEELS

Width 44 cm 17.3”

Depth 110 cm 43.3”

Height 130 cm 51.1”

Weight

NiGen HF-0 and NiGen LCMS 40-0

190 kg 420 lbs

Weight

NiGen HF-1, NiGen LCMS 40-1

220 kg 485 lbs

Weight

NiGen LCMS 100

200 kg 440 lbs

Description of the generator

10

FIGURE 3.3.1: Front view

Nitrogen Generator NiGen HF - NiGen LCMS

11

3.3.2.

Rear view

D. NITROGEN OUTLET: pneumatic connection for the generator’s nitrogen

delivery

E. AIR INLET: pneumatic connection for compressed air line inlet.

Not used for

NiGen HF-1 and NiGen LCMS 40-1

F. DRAIN: pneumatic connection for the condensation drain line.

Not used for

NiGen HF-0, NiGen LCMS 40-0 and NiGen LCMS 100

G. AIR OUTLET: pneumatic connection for an optional line for compressed air

produced by the compressor.

Not used for NiGen HF-0, NiGen LCMS 40-0 and

NiGen LCMS 100

H. CONNECTOR for electric power supply cable

I. “POWER" KEY: ON-OFF SWITCH

J. IDENTIFICATION LABEL: states the model, serial number (SN) and electrical

specifications

K. VENTILATION GRILLE

FIGURE 3.3.2. Rear view

Installation area requirements

12

4.

Installation area requirements

4.1.

Environmental requirements

m

Place the generators FAR FROM SOURCES OF HEAT, PROTECTED

AGAINST RAIN AND WIND, and SHOULD NOT BE EXPOSED TO THE

SUN.

e

Failure to observe the precautions preclude the guarantee.

4.2.

Environmental ventilation

The environment where the generator is installed must be good ventilated to

prevent the risk of asphyxia and decreased the performance of the generator.

4.2.1.

Oxygen content in the ambient

m

If the generator and the point-of-use are located in different rooms,

the following minimum ventilation air flow must be provided to maintain acceptable oxygen content in the ambient. Don’t seal the rooms.

4.2.2.

Temperature

e

This paragraph is able only for these models: NiGen LCMS 40-1 and NiGen HF-1

m

Claind raccomanded to not go over the maximum environment temperature of 30°C for guarantee correct operations of the generator. If

this value is exceeded, in relation to the use of the generator, could appare the warning of maximum temperature of the compressor (E03)

(par.9.4.).

Are requires two openings of at least 0,5m2 to create a flow of air suffucient to

ensure air exchange.

It is also recommended to avoid danger of asphyxia.

Installation site enclosed, indoors

Relative humidity up to 80%, no condensation

Use temperature from 5°C to 35°C from 40°F to 95°F

Protection rating IP20

Loading...

Loading...