Claind NiGen GC, Nigen MICRO, AirGen User Manual

User’s Manual

Nitrogen

Generator

NiGen GC

Nigen MICRO

2

Table of contents

1. Introduction 3

2. Safety 4

3. Description of the generator 6

4. Installation 11

5. Disassembly and transport 16

6. Use 17

7. Maintenance 27

8. Troubleshooting 28

9. Guarantee 32

10. Declaration of conformity 33

11. Notes 34

Nitrogen Generator NiGen GC Nigen MICRO

3

1.

Introduction

This document is intended for users of nitrogen generator models NiGen GC and

NiGen MICRO, and provides all information regarding installation, use , maintenance and guarantee.

The generator is intended to be used as a source of nitrogen gas for laboratory

applications, including gas chromatography, thermal analysis, ELSD, LCMS, sample preparation, etc.

The manual covers the following models:

As regards installation and maintenance, it is assumed that the user is familiar

with pneumatic circuit components, and in particular is aware of the safety aspects of compressed air and nitrogen.

The margin of the text contains the following symbols, indicating:

m

compulsory safety standards to be observed

c

electrical hazard

e

recommendations and important information

It is strongly recommended to carefully read all safety warnings (

par. 2.1.

) be-

fore carrying out any operation on the generator.

Serial number Model

422.02.0110 NiGen GC

422.02.0220 NiGen GC HC 115 V AC

422.02.0230 NiGen GC HC 230 V AC

422.02.0510 NiGen MICRO

Safety

4

2.

Safety

e

The unit must be installed and used in observance of the instructions in this booklet. Furthermore, use of the generator must be limited to that described in

Chapter 1 Introduction

. Failure to observe the foregoing will render the guarantee null and void and release CLAIND from all liability for direct or indirect damage or physical injury.

e

The user is responsible for asking local authorities if there are local safety regulations that are stricter than what is described in this manual.

2.1.

Warnings

m

Place the generators FAR FROM SOURCES OF HEAT

m

Place the generators in an environment PROTECTED AGAINST RAIN

AND WIND

c

NEVER OPEN the generator while it is connected to the electrical

mains: RISK OF FATAL INJURY BY ELECTROCUTION

e

Repairs and inspections must be carried out exclusively by QUALIFIED PERSONNEL: in the event of faults which cannot be resolved according to the pro-

cedures listed in the TROUBLESHOOTING chapter, contact exclusively our

authorized Technical Assistance.

e

If the generator is not to be used for a prolonged period of time, it must be depressurised (par. 6.7. and par. 6.8.).

Nitrogen Generator NiGen GC Nigen MICRO

5

2.2.

Notes on the use of nitrogen

Nitrogen is not a toxic gas, but when the percentage in the air exceeds specific

values there is a risk of asphyxia.

Therefore NEVER DIRECTLY INHALE the gas produced and avoid working in the

vicinity of a flow of nitrogen.

However, given the low quantities produced, it is sufficient that the flow of nitrogen occurs in a normally ventilated environment to avoid the risk of accumulation.

m

If the generator and the user utility are located in different rooms, the

following minimum ventilation must be provided to prevent increasing

or decreasing the oxygen content in the air:

2.3.

Safety devices

MAXIMUM PRESSURE: the control system constantly monitors the pressure.

In case of anomalous pressure, a safety valve (which operates independently of

the control system) prevents it exceeding 10.5 bar (152 psi).

MAXIMUM TEMPERATURE (

HC version only

): the purifier is fitted with an

internal catalyser, the temperature of which is constantly maintained at 420°C

To guarantee safety, a completely independent device is fitted which shuts off

power supply to the heating element when temperature values exceed 480°C

2.4.

Technical assistance

The CLAIND technical assistance can be contacted as follows:

Phone ++39 0344 56603

Fax ++39 0344 56627

Email: service@claind.it

Website: filling the form on the website www.claind.it at the “Service” section

Model

Minimum generator

room ventilation

Minimum point-of-use

room ventilation

NiGen GC

NiGen GC HC

9 Nm3/h

318 SCFH

16 Nm3/h

565 SCFH

NiGen MICRO

3 Nm3/h

106 SCFH

5 Nm3/h

177 SCFH

Description of the generator

6

3.

Description of the generator

3.1.

Equipment supplied

Unless otherwise agreed, the consignment includes:

• n°1 nitrogen generator model NiGen;

• n°1 CD user’s manual;

• n°1 applicable declarations of conformity of tank and safety valve;

• n°1 cable for the electrical mains;

• n°4 self-tapping screws;

• n°2 elastic spline;

• n°2 check pin;

• n°1 anchor plate;

• n°2 fitting for the connection of the plastic tube external diameter 6mm;

• n°1 fitting for the connection of the copper tube external diameter 1/8”.

3.2.

Technical specifications

3.2.1.

Nitrogen

(*) the flow rate is given at 20°C and 1 atm

(**) purity referred to residual oxygen

Maximum flow rate (*)

NiGen GC 0.5 Nl/min 0.5 slpm

NiGen GC HC 0.5 Nl/min 0.5 slpm

NiGen MICRO 4 Nl/min 4 slpm

Pressure

settable from 0 to

6 bar

settable from 0 to

87 psi

Purity (**)

NiGen GC up to 99.999 %

NiGen GC HC up to 99.999 %

NiGen MICRO up to 99.5 %

Nitrogen Generator NiGen GC Nigen MICRO

7

3.2.2.

Compressed air supply, specifications

(***) for further details on the air quality, see the specifications for Class 1-4-1,

ISO 8573-1

3.2.3.

Electrical requirements

3.2.4.

Pneumatic connections

3.2.5.

Electrical connections

Pressure

minimum 8 bar 116 psi

maximum 10 bar 145 psi

Capacity

NiGen GC 6 Nl/min 6 slpm

NiGen GC HC 6 Nl/min 6 slpm

NiGen MICRO 12 Nl/min 12 slpm

Particulates: maximum concentra-

tion of particles of diameter less

than 0.1 µm (***)

less than 0.1 mg/m³

Oil concentration less than 0.01 mg/m³

Humidity dewpoint under pressure less than 3°C

NiGen GC 115-230 V~ (±10%), 1 ph, 50-60Hz;

50W

NiGen GC HC

115 V~ (±10%); 60Hz; 1ph; 200W

or

230 V~ (±10%) 50Hz; 1 ph; 200W

NiGen MICRO

115-230 V~ (±10%), 1 ph, 50-60Hz;

50W

Nitrogen outlet G 1/8" female

Compressed air supply G 1/8" female

Power supply IEC320

CAN bus IN; CAN bus OUT RJ45

Description of the generator

8

3.2.6.

Dimensions

3.2.7.

Environmental requirements

3.2.8.

Noise

Width 38 cm 14.9”

Depth 53 cm 20.8”

Height 47cm 15.8” + 2.8”

Weight

NiGen GC

NiGen MICRO

37 kg 82 lbs

Weight

NiGen GC HC

41 kg 90 lbs

Installation site enclosed, indoors

Relative humidity up to 90%, no condensation

Use temperature from 5°C to 40°C

from 40°F to

100°F

Protection rating IP20

Noise level at 1 meter 60 dB(A)

Nitrogen Generator NiGen GC Nigen MICRO

9

3.3.

Generator components

3.3.1.

Front view

A. CPU: generator control unit; it is the user interface by way of the touch screen;

B. FRONT PANEL, removable for maintenance operations.

FIGURE 3.3.1: Front view

Description of the generator

10

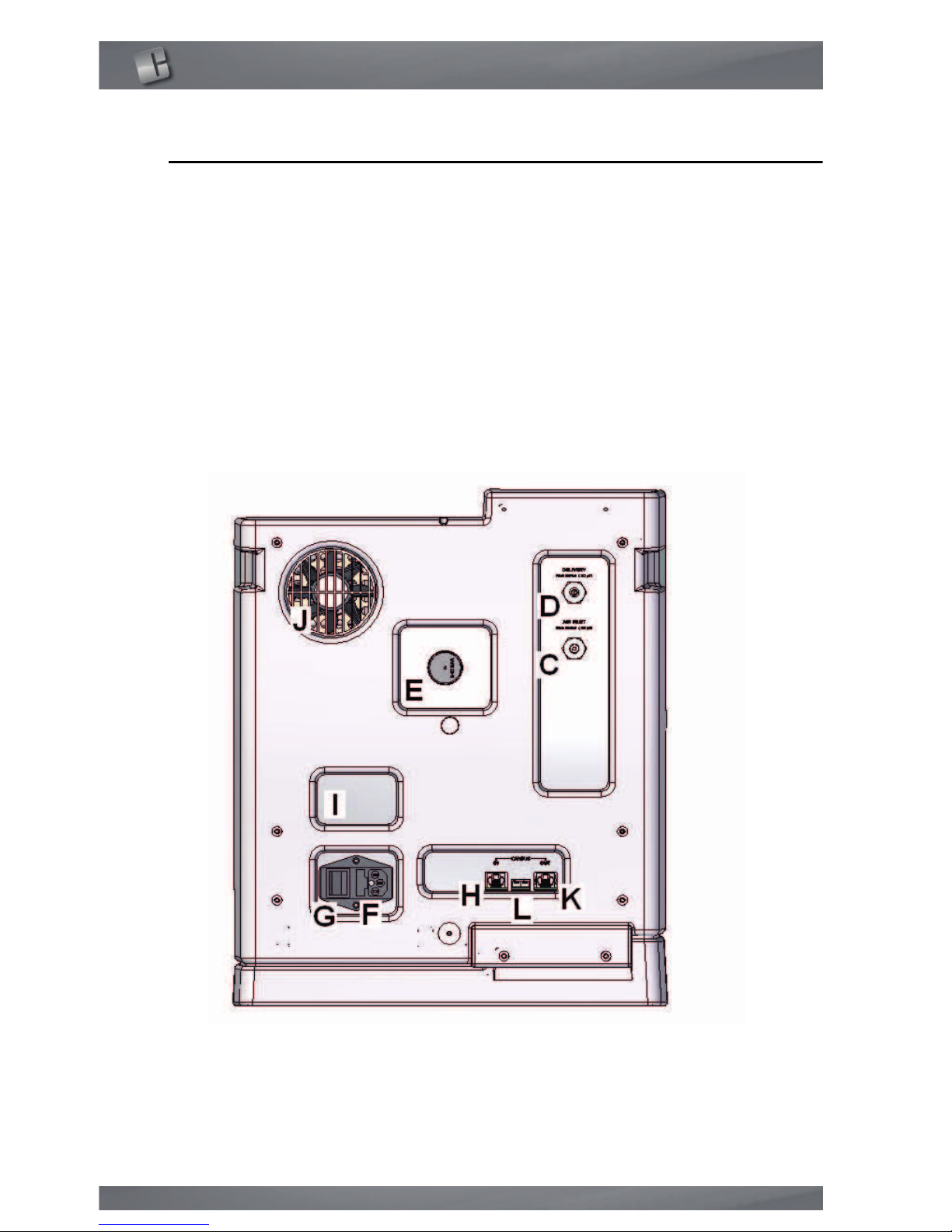

3.4.

Rear view

C. AIR INLET: pneumatic connection for compressed air line inlet.

D. NITROGEN OUTLET: pneumatic connection for the generator’s nitrogen

delivery.

E. PRESSURE REGULATOR nitrogen delivery

F. CONNECTOR for electric power supply cable

G. POWER" KEY: ON-OFF switch; includes housing for the main fuse

H. CAN BUS IN for connection to CPU

I. IDENTIFICATION LABEL: states the model, serial number (SN) and electrical

specifications

J. VENTILATION GRILLE

K. CAN BUS OUT

L. CAN BUS ADDRESS (DIP switch)

FIGURE 3.3.2. Rear view

Nitrogen Generator NiGen GC Nigen MICRO

11

4.

Installation

4.1.

Installation area requirements

4.1.1.

Environment

The area where the generator is installed must meet the requirements listed under

par. 3.2.7.

m

in particular, check if ventilation is adequate. Do not install the generator into a closed cabinet with insufficient ventilation.

In regards to ventilation, refer to

par. 2.2.

4.2.

Generator positioning

4.2.1.

Packaging removal

• Open the packaging from the top

• remove the box containing the accessories

• lift the generator by grasping its side handles (two people are needed for this

operation) and set it momentarily on a flat surface

• remove the support base and place it on the desk where you plan to install the

generator.

e

It is recommended to store the packaging to ensure adequate protection when

moved in the future.

If the generator is to be installed on the tower see the attached.

4.2.2.

Positioning

Position the generator on its support base (two people are needed for this operation).

m

Ensure a clearance of at least 20cm at the rear of the generator. There

must be no potential sources of sparks in this clearance at the rear of

the generator, such as: flames, electrical contacts, hot surfaces, moving parts that can generate sparks, etc.

m

To not decrease ventilation efficiency, also ensure a clearance of at least 20cm at the front of the generator.

The generatore must be positioned on the apposite base, following foregoing instructions:

• place the base in the installation site (you can adjust the plastic feet to the desired height);

Loading...

Loading...