Water Specialist

WS2H and WS3 Control Valve

Manual

HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC., MAY DAMAGE

PRODUCTS THAT CONTAIN O-RINGS OR PLASTIC COMPONENTS. EXPOSURE TO SUCH

HYDROCARBONS MAY CAUSE THE PRODUCTS TO LEAK. DO NOT USE THE PRODUCT(S)

CONTAINED IN THIS DOCUMENT ON WATER SUPPLIES THAT CONTAIN HYDROCARBONS

SUCH AS KEROSENE, BENZENE, GASOLINE, ETC.

Page 2 WS2H and WS3 Manual

WS2H and WS3 Manual Page 3

TABLE OF CONTENTS

General Speci cations and Pre-Installation Checklist .................................................... 4

Software and Power Supply Compatibility....................................................................... 5

Communication Cable Connection to PC Board Layout ................................................. 5

Wiring for custom AC Adapter ......................................................................................... 6

Custom Meter Wiring ....................................................................................................... 6

Main PC Board with System Board .................................................................................. 7

Typical System Examples ................................................................................................. 8

Button Function and Programing Key Sequence ........................................................... 10

Programming Quick Reference ...................................................................................... 12

Typical User Screens ...................................................................................................... 14

Setting Time of Day ........................................................................................................ 16

Noti cations ................................................................................................................... 16

Errors .............................................................................................................................. 16

System Setup Screens ................................................................................................... 17

Cycle Setup Screens ...................................................................................................... 22

Timer Screens ................................................................................................................ 24

Installer Setup Screens .................................................................................................. 28

Diagnostic Screens ........................................................................................................ 30

Valve History ................................................................................................................... 34

Custom Motorized Drive Timing ..................................................................................... 35

Installation ...................................................................................................................... 36

Installation Summary ...................................................................................................... 39

Control Positions / Flow Diagrams ................................................................................. 40

Front Cover and Drive Assembly .................................................................................... 43

WS2H Drive Cap Assembly, Down ow Piston, Regenerant Piston,

Spacer Stack Assembly, Drive Back Plate, Main Body and Meter ................................ 44

WS3 Drive Cap Assembly, Down ow Piston, Regenerant Piston,

Spacer Stack Assembly, Drive Back Plate and Main Body............................................ 45

WS2H and WS3 Brine Valve Body and Injector Components ....................................... 46

Standard Injector Graphs ............................................................................................... 47

V3064 WS2H/2QC 4 INCH BASE ASY........................................................................... 49

V3055 WS2H/2QC 6 INCH FLANGE BASE ASY ............................................................ 49

WS2H/2QC SIDE MOUNT BASE ASSEMBLY ................................................................ 49

V3260BSPT-02 WS2H/2QC SIDE MOUNT BASE BSPT ASSEMBLY ............................ 49

Drain Line Flow Controls ................................................................................................ 50

M X F STAINLESS STEEL, 0.7 – 150 GPM ..................................................................... 51

V3764 WS3 DLFC NPT ASY or V3764BSPT WS3 DLFC BSPT ASY ............................. 52

Drain Line Flow Control Washers ................................................................................... 53

WS2H/ WS3 Trouble Shooting Guide ............................................................................. 54

Page 4 WS2H and WS3 Manual

GENERAL SPECIFICATIONS AND PRE-INSTALLATION CHECKLIST

TABLE 1

Minimum/Maximum Operating Pressures 20 psi (138 kPa) -125 psi (862 kPa)

Minimum/Maximum Operating

Temperatures

Power Adapter:

Supply Voltage

Supply Frequency

Output Voltage

Output Current

40°F (4°C) – 110°F (43°C)

U.S.

120V AC

60 Hz

18V, 20V or 24V AC (see Table 2)

800 mA

International

230V AC

50 Hz

18V, 20V or 24V AC

800 mA

No user serviceable parts are on the PC board, the motor, or the Power adapter. The means of disconnection from

the main power supply is by unplugging the Power adapter from the wall.

Service ow rate

Backwash ow rate

CV Service

CV Backwash

WS2H Valve: 125 gpm (473 lpm, 28.4 m

WS3 Valve: 250 gpm (946 lpm, 56.8 m3/h) @ 15 psig (103 kPa) drop

WS2H Valve: 125 gpm (473 lpm, 28.4 m3/h) @ 25 psig (172 kPa) drop

WS3 Valve: 220 gpm (833 lpm, 50.0 m3/h) @ 25 psig (172 kPa) drop

WS2H Valve: 32.3

WS3 Valve: 64.6

WS2H Valve: 25.0

WS3 Valve: 44.0

3/h) @ 15 psig (103 kPa) drop

WS2H Valve:

Meter:

Accuracy

Flow Range

Internal Meter

+ 5 %

1.5 – 125 gpm

WS3 Valve: Optional External Meter

+ 5 %

3.5 – 350 gpm (13.3 – 1325 lpm)

(5.7 – 473 lpm)

Regenerant Re ll Rate

WS2H and WS3 Valves: Variable - Shipped from Factory with 2.2 gpm

(8.33 lpm)

Injectors WS2H & WS3 Valves: See Injector Graphs V3010-2A through 2H

Brine Line Adapters Included 1” Male NPT Elbow & ¾” x 1” Solvent Weld Elbow

Inlet, Outlet and Drain Line Openings

WS2H Valve: 2” Female NPT or BSPT or 2.5” Groove Lock

WS3 Valve: 3” Female NPT or BSPT, No Groove Lock

Female NPT Inlet & Outlet Female BSPT Inlet & Outlet

*Distributor Tube Sizing:

WS2H Valve

WS3 Valve

Tank Connection:

WS2H Valve

WS3 Valve

Shipping Weight

PC Board Memory

Compatible with the following typical

concentrations of regenerants/chemicals

2.375” OD (2.0” NPS)

3.5” OD (3” NPS)

+2.25” -

+2.5”

+2.5” – 2.75”

63 mm OD

90 mm OD

4”-8UN, 6” Flange, Side Mount (2” Female NPT or BSPT or 2.5”

Groove Lock)

6” Flange or Side Mount (3” Female NPT or BSPT)

WS2H Valve with Meter: 50 lbs. (22.7 kg)

WS3 Valve: 57 lbs. (25.9 kg) Meter Sold Separately

Nonvolatile EEPROM (electrically erasable programmable read only

memory)

Sodium chloride, potassium chloride, potassium permanganate,

sodium bisul te, chlorine and chloramines

+57 mm - +64

+64 mm - + 70

*Height is based off the top of tank. Installer to verify proper engagement and allowance for tank expansion

mm

mm

WS2H and WS3 Manual Page 5

SOFTWARE AND POWER SUPPLY COMPATIBILITY

TABLE 2

Software Version Power Supply

V3242-01BOARD Main Board

114.10

114.11

115.17

200.01

215.02

215.04

215.10 1.11 or 1.13 20 VAC

216.04 or greater 1.13 or greater

1

It is recommended to maintain one version throughout a system.

2

Replacement V3461 power supplies have screw terminals and are shipped less a cord. Use cord from existing power

supply to connect to the screw terminals.

3

V3461EU-01 and V3461UK-01 will not be available for sale until August 2010.

1

V3243-01BOARD

System Board

1.03

1.07 or 1.08115.25

1.11 or 1.13215.03

Output

Voltage

24 VAC

20 VAC

18 VAC

Part # and Description

V34612 WS2H/3 AC ADAPTER

V3461EU WS2H/3 AC ADAPTER EU

V3461UK WS2H/3 AC ADAPTER UK

V3461-01 WS2H/3 AC ADAPTER 20V

3

V3461EU-01 WS2H/3 AC ADAPTER EU 20V

V3461UK-01 WS2H/3 AC ADAPTER UK 20V

V3461-01 WS2H/3 AC ADAPTER 18V

V3461EU-01 WS2H/3 AC ADAPTER EU 18V

V3461UK-01 WS2H/3 AC ADAPTER UK 18V

COMMUNICATION CABLE CONNECTION TO PC BOARD LAYOUT

Revised communication cable connectivity.

Refer to diagram (below) when combining 3- and 4-wire communication hardware.

View Of Revised 3 Wire Communication

Cable On 4 Terminal Header

3 Wire Cables Being Installed On 4

Terminal Headers Need Left Polarizer

Remove

Ear

"Ear" Removed

Install cable flush to the

right side leaving left terminal

pin with no connection

C

View Of 4 Wire Communication Cable On 3

Terminal Header (System Board Is Optional)

A

Install right side of cable flush

to terminal leaving a vacant

position on the left of the cable

Page 6 WS2H and WS3 Manual

WIRING FOR CUSTOM AC ADAPTER

1. See Table 2 Software and Power Supply Compatibility.

2. Cable should be one unshielded pair of 22AWG, UV resistant

UL2464 compliant wire.

3. Connector details:

a. Terminate end with one Molex white housing,

P/N 09-50-8043 and four Molex pins, P/N 08-50-0108.

b. Pin 1 = AC from power supply (White)

Pin 2 = Jumper to Pin 3

Pin 3 = Jumper to Pin 2

Pin 4 = AV from power supply (Black)

CUSTOM METER WIRING

1) Terminate end with a Molex series 2695 housing, part num-

ber 22-01-3037 and (3) Molex series 41572 (or 40445) pins,

part number 08-65-0805 (or 97-00-44).

2) Auxilliary meter must be able to operate on 5VDC

Pin 1 = +5VDC,

Pin 2 (Center) = Signal

Pin 3 = Ground

Molex

Housing

Pin 1

3) Acceptable pulse input is .1 – 999 pulses/gallon, or

.4 –519 pulses / liter.

WS2H and WS3 Manual Page 7

MAIN PC BOARD WITH SYSTEM BOARD

1) Power Supply

2) Manual Override Switch

3) Flow

Meter

4) Motorized

Alternating

Valve

5) POD

Display

Connection

10) System Board

Connection

6) Auxiliary

Input

11) Auxiliary

Drive

11) Programming

Port

13) Relay 2 12 ) Relay 1

9) Drive Motor

8) Communication Port

Item Board label Description

1 POWER Connect to proper power supply

2 SW1

3 FLOW Input for the units ow meter

4 BYPASS Drive circuit for factory motorized isolating valve (MAV or NoHBP)

5 DISPLAY Connection for POD display or data extraction with the proper software and cabling

6 AUX INPUT Connect to external dry contacts to control functionality based on the unit’s settings

7 PROGRAM Factory use only

8 MASTER/SLAVE Communication port on the main board can be used on the master of a 2 unit system &

9 REGENERATION Motor circuit used to power the main drive of the unit during regeneration

10 SYSTEM BOARD

11 AUX DRIVE 2nd Drive circuit for factory motorized isolating valve (MAV or NoHBP)

12 AUX 1 Dry contact outputs to operate external devices based on the program settings of

13 AUX 2 Dry contact outputs to operate external devices based on the program settings of

14 SLAVE 1, 2 or 3

Manual override switch used to force isolation (On Line or Standby status)

The units corresponding LED will ash twice / second to alert its override condition

**Wiring units inputs in parallel requires matching each units polarity**

is the communication port for any slave unit

**Greater than 2 unit systems require the optional system board on the master for

additional ports**

The following connections are for an optional expansion board

Connection for the optional V3243 system board to expand communication ports, add

a second motor circuit or relay output functionality

Relay 1

Relay 2

Maximum power through either relay to be:

A) 1A, 30 VDC

B) 1A, 30 VAC

Expanded communication ports for connecting up to 3 additional units to the master

unit in a system

7) Programming

Port

14) Communication Ports

Page 8 WS2H and WS3 Manual

TYPICAL SYSTEM EXAMPLES

Twin Tank System, Simple Alternator (Sharing a MAV)

System consists of 2 power heads, 1 communication cable and 1 MAV

Electrical Connections:

• The MAV’s motor wire is connected to the 2-pin connector labeled BYPASS on Unit 2 (Unit B) PC board

• The communication cable is connected to each unit’s 3-pin connector labeled MASTER/SLAVE

• If a single external meter is used, it should be connected to the 3-pin connector on Unit 2 (Unit B) labeled FLOW.

NOTE: When using a single external meter, “SYSTEM PULSES” and the proper pulse rate must be selected in the

programming section.

Plumbing Connections:

• To regenerate with raw/untreated water, the outlet of each unit is piped to the MAV. Port A will be piped to the Master

(Unit A) , Port B to the slave (Unit B), and Port C to the common supply outlet.

• To regenerate with soft/treated water, the inlet of each unit is piped to the MAV. Port A will be piped to the Master

(Unit A), Port B to the slave (Unit B) and Port C to the common supply outlet.

WS2H and WS3 Manual Page 9

TYPICAL SYSTEM EXAMPLES (CONTINUED)

Multi-tank System, 3 Unit shown

System consists of 3 power heads, 2 communication cables and 3 No Hard Water Bypass (Isolation) valves

Electrical Connections:

• Each unit’s isolation valve motor wire is connected to the 2-pin connector labeled BYPASS on each unit’s PC board.•

The communication cable is connected to each unit’s 3-pin connector labeled MASTER/SLAVE

• Communication cables are connected to each unit’s 3-pin connector labeled MASTER/SLAVE. NOTE: Systems with

more than 2 units require the Master Unit to have the optional System Board for communication port expansion,

routing communications from the expansion ports (Slave 1, 2 or 3) to each unit’s MASTER/SLAVE connector.

Plumbing Connections:

• To regenerate with raw/treated water, the isolation valve is piped into the outlet of each unit.

• To regenerate with soft/treated water, the isolation valve is piped into the inlet of each unit.

Page 10 WS2H and WS3 Manual

BUTTON FUNCTION AND PROGRAMING KEY SEQUENCE

Standby LED

•

Signals that a unit is not in service,

or regen

•

Flashes to alert status conditions

- 1 per second indicates flow had

been detected while the unit was

offline

- 2 per second indicates the bypass

override switch is being used to

force the unit offline.

Online LED

•

Signals that a unit is currently in

service

•

Flashes to alert status conditions

- 2 per second indicates the bypass

override switch is being used to

force the unit online.

Regen LED

•

Signals that a unit is currently in

regen

WS2H and WS3 Manual Page 11

THIS PAGE WAS INTENTIONALLY LEFT BLANK

Page 12 WS2H and WS3 Manual

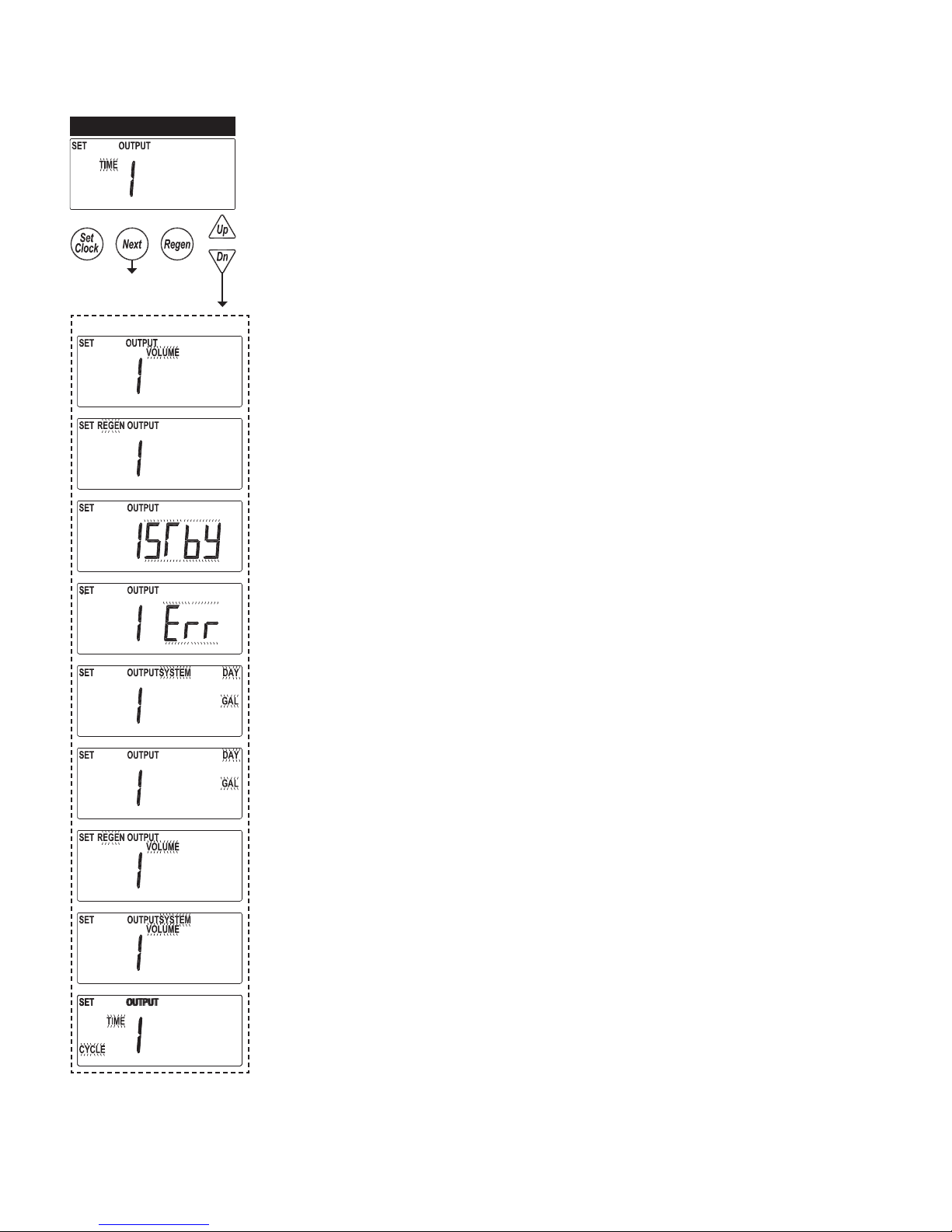

PROGRAMING QUICK REFERENCE

Recommended System Setup Sequence

1. Connect all wiring and communication cables

2. Apply power.

3. Enter system setup screens and set screen 2 to number of

units in the particular system.

a. Setting this value assigns master status to that unit

b. The master unit will establish communication with the

remaining units and transfer the remaining settings to them.

4. Set cycle sequence

5. Set cycle times

6. Set installer data

WS2 Programming Screen Quick Reference

1. Individual screen descriptions and settings are detailed on the

following pages.

2. Some screens have been omitted for clarity.

WS2H and WS3 Manual Page 13

PROGRAMING QUICK REFERENCE

List Of Error Codes

Code Description

1001 No Encoder Pulses

1002 Unexpected Stall, Main Drive

1003 Run Time Too Long, Main Drive

14001 Message Queue Full

15003 Run Time Too Long, Bypass Drive

15010

15011

16001 Communication Lost With Unit 2

16002 Communication Lost With Unit 3

16003 Communication Lost With Unit 4

17000

17002

18000 Reset Performed

18001 Power Loss

18002 Power Restored

Run Time Too Short, Bypass Drive

Could Not Drive Of ine

Run Time Too Short, Bypass Drive

Could Not Drive Online

Run Time Too Long, Auxiliary Drive Of

Option Board

Run Time Too Short, Auxiliary Drive Of

Option Board

Page 14 WS2H and WS3 Manual

TYPICAL USER SCREENS

USER 1

USER 2

USER 2B

USER 1 - Capacity Remaining

• Displays the units current capacity remaining

• This screen does not display on units with volumetric capacity turned off

• Can be manually decremented by holding the down arrow

USER 2 - Days Remaining, Single Unit

• Displays a single units days until a regeneration, based on the day override setting

• This screen does not display on units with day override turned off

• On systems the master unit displays the days remaining on the lead unit

• Days can be manually reduced by holding the down arrow

USER 2B - Days Remaining, System

• The master in a system displays the days until a regeneration, based on the day override

settings.

• The displays also indicates which unit the day over ride is currently pertaining to

- Series regen systems do not display a unit as they will regenerate all units sequentially

USER 3

USER 4

USER 5

USER 3 - Time

• Displays the current time of day

USER 4 - Flow Rate, Unit

• Displays that units current ow rate

USER 5 - Volume Totalizer, Unit

• Displays the total volume since install / reset

• Re-settable to zero, while in this screen, by holding the “Set Clock” & “Regen” buttons

WS2H and WS3 Manual Page 15

TYPICAL USER SCREENS (CONTINUED)

USER 6

USER 7

USER 1

USER 6 – Flow Rate, System

• Displays the current combined ow rate of all the units in the system

• This screen does not display on single tank units, or systems with volumetric capacity turned

off

USER 7 – Volume Totalizer, System

• Displays the total volume of the system since install / reset

• Re-settable to zero, while in this screen, by holding the “Set Clock” & “Regen” buttons

• This screen does not display on single tank units

Page 16 WS2H and WS3 Manual

SETTING TIME OF DAY

SET TIME

Accessed by pressing Set Clock while in the User Screens. Use UP and DOWN

arrows to scroll hours. AM/PM alternates at midnight.

RETURN TO

NORMAL OPERATION

NOTIFICATIONS

• REGEN TODAY

- Flashing indicates a regeneration has been manually set and can be turned off

by pressing and releasing the REGEN button

- A solid display indicates the regeneration has been scheduled by input

requirements and can’t be manually turned off

• REGEN START / REGEN HOLD

- The display will ash “REGEN” or “REGEN HOLD”, depending on settings, to

indicate an external switch closure to the Aux. Input

• HIGH USAGE

- Screen ashes indicating setpoint was reached when using relay outputs to

signal high water usage. All LED lights ash and the relay with that setpoint

closes.

• Screen and the relay are re-set by pressing any button

• System operates as normal behind the indicator screen.

- Only active if Timer 2 or Timer 3 is set to “Day & Gal” or “Day & Gal & System”

ERRORS

• NUMBER OF UNITS ERROR

- The master unit of a system would ash an error screen alerting of a loss of

communication with a unit

- Check for proper operation and connectivity of the unit speci ed as lost

communications

- Pressing any button will return the user to the # units set up screen to correct /

verify the value of units in the system. Exiting will re-establish communications

- Each unit of the system will regenerate, based on its settings, with hard water

bypass

• FUNCTIONAL ERROR

- “Error” and its code alternate on the display

- The unit attempts to return to service but will not

regenerate until the error is cleared

- See troubleshooting section for a description of

possible error codes.

WS2H and WS3 Manual Page 17

SYSTEM SETUP SCREENS

Accessed by pressing NEXT and DOWN simultaneously for >3 seconds.

• System setup screens will be hidden on units determined to be a slaves of a system

- Slave units need to be reset, “Next” & “Regen”, from the Timer 1 screen to have their

slave status tuned off.

SYSTEM SETUP 1

SYSTEM SETUP 2A

SYSTEM SETUP 2B

Non-Default Settings

SYSTEM SETUP 1 – Select units of operation

US: Volume measurements are in gallons, time is displayed in 12 hour format, meter

selections are in inches.

SI: Volume measurements are in liters or cubic meters, time is displayed in 24 hour format,

meter selections are in mm.

SYSTEM SETUP 2A - Set number of units

1 – 2 Up to 2 units can be connected off the communicate port of the main board

3 – 4 Requires an optional system board to expand communication ports

SYSTEM SETUP 2B – Select System Type / Operation

• Setting a ow rate adder point determines the system operation

0: Parallel Flow; All units are always online unless they are regenerating.

• Units in a parallel ow system will determine the need to regenerate based on:

- Any one unit reaching 0 capacity

- Day over ride

• Any one units need to regenerate will initiate sequential regenerations of all units (series

regeneration)

• On0 systems will regenerate all units in series at the rst available time slot

• Delayed units will regenerate at each available time slot, one unit per time slot

ALT: Operates the system as an alternator, having one unit off line at all times either

regenerating or fully regenerated.

• A unit in an alternator system will determine the need to regenerate based on:

- The current “lead” unit reaching 0 capacity

• On0 systems immediately regenerate and alternate the exhausted unit with a fully

regenerated standby unit.

• Delayed systems will immediately alternate the exhausted unit with a fully regenerated

standby unit, and regenerate at the next available time slot.

- “Lead” unit regenerates based on “Lag” units

• The rst “lag” unit depleting down to 15% less than its ratio of system capacity

- 1/3 for a 4 unit; ½ for a 3 unit

- The second “lag” unit depleting down to 15% less than its ratio of system capacity

• 2/3 for a 4 unit

• Delayed systems will ag “lead” units based on “lag” capacity, but will not alternate

with remaining capacity until the next available delayed time.

- Day over ride

• 1 day; 1 unit will regen

• Day triggered regens will run at the time set in DEL-1

CONTINUED...

Page 18 WS2H and WS3 Manual

SYSTEM SETUP SCREENS (CONTINUED)

1 – 499: Demand Recall; one unit is always online & additional units are added as the

online units exceed this ow rate / unit set point.

• Additional units are brought online when:

- The adder point is exceeded for 30 seconds

- All required units required to cover the ow conditions will be brought into service

immediately if the ow exceeds 120% of the adder point.

• Units will go of ine when

- System ow reduces to 95% of the set adder point / unit for 1 minute.

• Any unit in a demand recall system will determine the need to regenerate based on:

- Each unit individually reaching 0 capacity

• On 0 systems will regenerate depleted units immediately after current ow conditions

allow depleted units of ine.

• Delayed units will alternate lead units immediately upon exhaustion & regenerate them

at the next available time slot.

- Day Override

• One unit will be regenerated per delayed time slot (i.e. a 4 unit system will need 4

delayed times to regenerate all units / set number of days).

• Day triggered regens will run at the time set in DEL-1

- Units cannot regenerate if ow demands them to remain online

• On 0 units regen immediately after ow allows them of ine

• Del units regen at the next available time slot

• Day units regen at the next time slot

SYSTEM SETUP 2C

SYSTEM SETUP 3A

Non-Default Settings

SYSTEM SETUP 2C – Set Pre-Service Rinse

- Only available on Alternator systems

- Standby units will run through a rinse cycle before coming into service

SYSTEM SETUP 3A - Select isolation timing

• Selections allow enabling and timing control of motorized drive

• Selection availability can vary by the type of system

• Custom timing sequences can be con gured under “Custom Motorized Drive Timing” at

the end of the programming section

HbP: Hardwater Bypass

• Only available on single units

• Unit will internally bypass hard water to the service lines while in regeneration

no.HbP: No Hardwater Bypass

• Each unit has isolation to control system operation and will not supply service water

during regeneration

• Drive timing will bring the unit into service during ll

SEP.In: Separate Source

• Each unit has isolation to control system operation and will not supply service water

during regeneration

• Drive timing will keep units isolated through the entire regeneration sequence

ALT-A: Simple Alternator Sharing 1 MAV

• Only available when set to a 2 unit alternator

• A “Simple 2 Unit” shares one MAV to be electrically connected to the bypass connection

of the “B” (slave) unit

WS2H and WS3 Manual Page 19

SYSTEM SETUP SCREENS (CONTINUED)

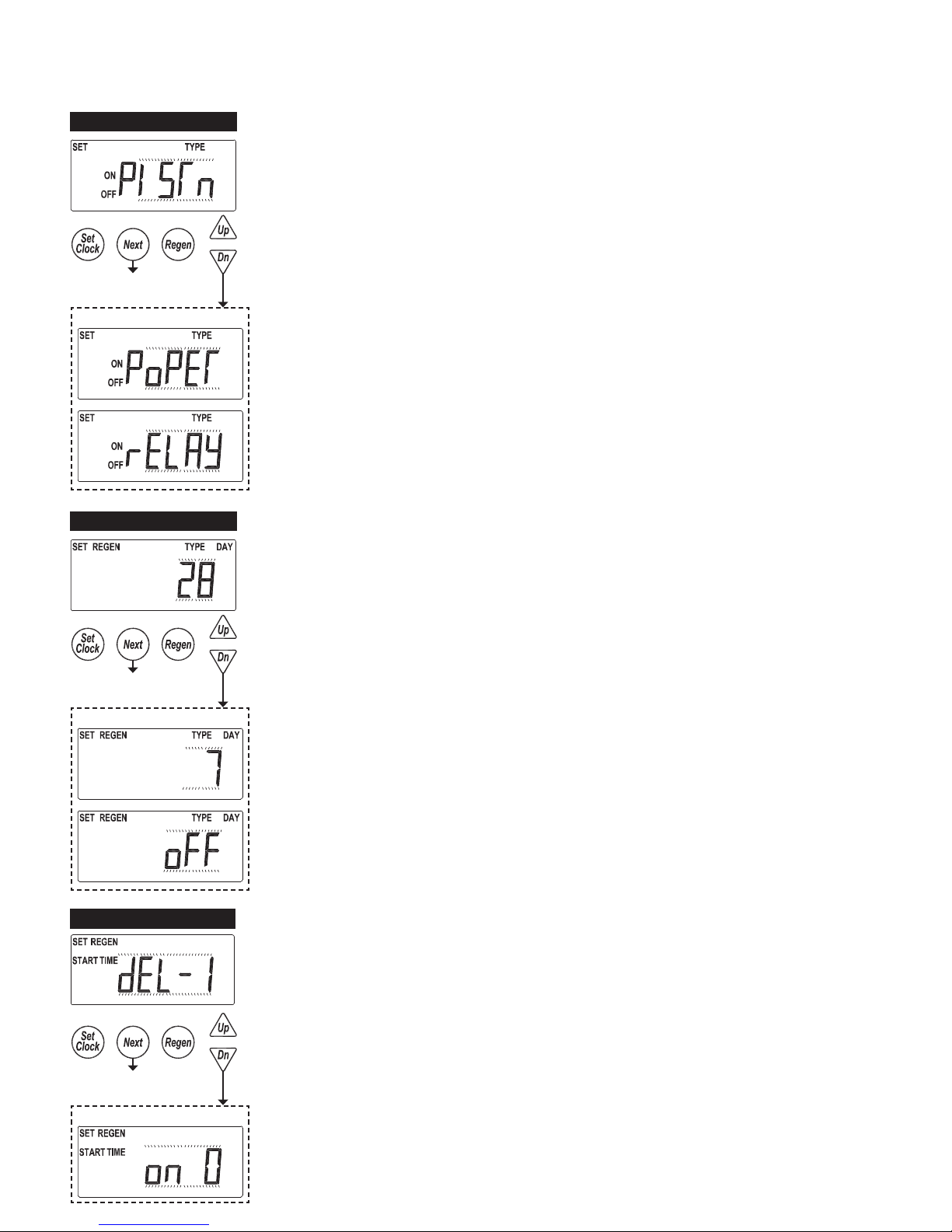

SYSTEM SETUP 3B

Non-Default Settings

SYSTEM SETUP 3B - Select isolation type

• Piston: Factory motorized isolation drive has an internal piston & seals similar to the main

piston

• Poppet: Factory motorized isolation drive uses a at disc “face” seal

• Relay: Isolation will be done through the optional board relays & does not initialize the

BYPASS motorized drive circuit

SYSTEM SETUP 4

Non-Default Settings

SYSTEM SETUP 5

SYSTEM SETUP 4 - Day override control

• 28 day time clock: Used to regenerate units based on a set number of days between

regenerations

• 7 Day Time Clock: Used to control regeneration based on speci c days

• OFF: Days have no control on regenerations, and will not be a selection if volumetric

capacity is set to OFF

SYSTEM SETUP 5 - Regeneration control

Delayed 1 – 4

• Delays regeneration of units upon reaching 0 gallons capacity

• Allows setting of up to 4 regeneration times per day

• Systems with delayed regen will remove a unit from service based upon 0 capacity and

regenerate at the scheduled regen time.

- Only one unit will regen / scheduled time

• Day driven regens will regen at the DEL-1 time slot

• Depleted units will regen at the next available delayed time slot

Non-Default Settings

On 0

-Immediate regeneration of units upon reaching 0 capacity

-Series regeneration systems set to On0 will sequentially regenerate all units at the

delayed time based on day override

Page 20 WS2H and WS3 Manual

SYSTEM SETUP SCREENS (CONTINUED)

SYSTEM SETUP 6

SYSTEM SETUP 7A

Non-Default Settings

SYSTEM SETUP 6 – Automatic reserve calculation

This screen will not display on units set to On 0, capacity set to Off, or any systems

On: Unit will regenerate before reaching 0 capacity, based on previous usage trends

Requires delayed regeneration

OFF: Regeneration is scheduled after reaching 0 capacity

SYSTEM SETUP 7A - Auxiliary Input

START REGEN

• Control will start an immediate regeneration upon switch closure

• Systems follow “on0 logic” regenerating all agged units sequentially

START TIME REGEN dEL

• Control will immediately schedule a regeneration upon accumulating 2 minutes of

intermittent switch closures

• Systems follow “Delayed Logic” regenerating agged units in available time slots

START REGEN dEL

• Control will immediately schedule a regen upon switch closure

• Systems follow “Delayed Logic” regenerating agged units in available time slots

LEVEL

• Only available on single units

• External switching can be used to control the On Line / Standby status

- Switch closure will trigger the unit to go to a standby condition

HOLD

• Regeneration will not be allowed as long as there is switch closure

- On0 units will regenerate immediately after the hold switch opens

- Delayed regenerations will be delayed until the next scheduled time if the hold is active

when the scheduled time passes

START TIME REGEN

• Control will immediately regenerate upon accumulating 2 minutes of intermittent switch

closures

• Systems follow “on0 logic” regenerating all agged units sequentially

SYSTEM SETUP 7B

SYSTEM SETUP 7B - Level option selected

Set a time duration of switch closure when Level option is selected

WS2H and WS3 Manual Page 21

SYSTEM SETUP SCREENS (CONTINUED)

SYSTEM SETUP 8A

Non-Default Settings

SYSTEM SETUP 8A - Meter Calibration

2.0: Setting for using a factory 2” meter

3.0: Setting for using a factory 3” meter

Pulses: Used to set meter input off custom pulse rate, typically for non-factory meters

System Pulses: Only available on 2 unit alternators. The system shares 1 external meter

which is connected to the slave unit’s meter connection.

SYSTEM SETUP 8B

SYSTEM SETUP 9

SYSTEM SETUP 8B - Set Meter Pulses / Gallon

-Only displays if “Pulses” or “System Pulses” is selected in the previous screen

-Set to the desired pulse rate of the installed metering device

SYSTEM SETUP 9 – Auxiliary Drive

• Selections allow enabling and timing control of the Auxilliary

motorized drive circuit

- This screen does not display if the unit does not have a

system board

• Requires a factory motorized drive to be connected to the

drive circuit of the system board

• Custom timing sequences can be con gured under “Custom

Motorized Drive Timing” at the end of the programming

section

Non-Default Settings

no.HbP: No Hard Water Bypass

• Each unit has isolation to control system operation and will not

supply service water during regeneration

• Drive timing will bring the unit into service during ll

SEP.In: Separate Source

-Each unit has isolation to control system operation and will not

supply service water during regeneration

-Drive timing will keep units isolated through the entire

regeneration sequence

Page 22 WS2H and WS3 Manual

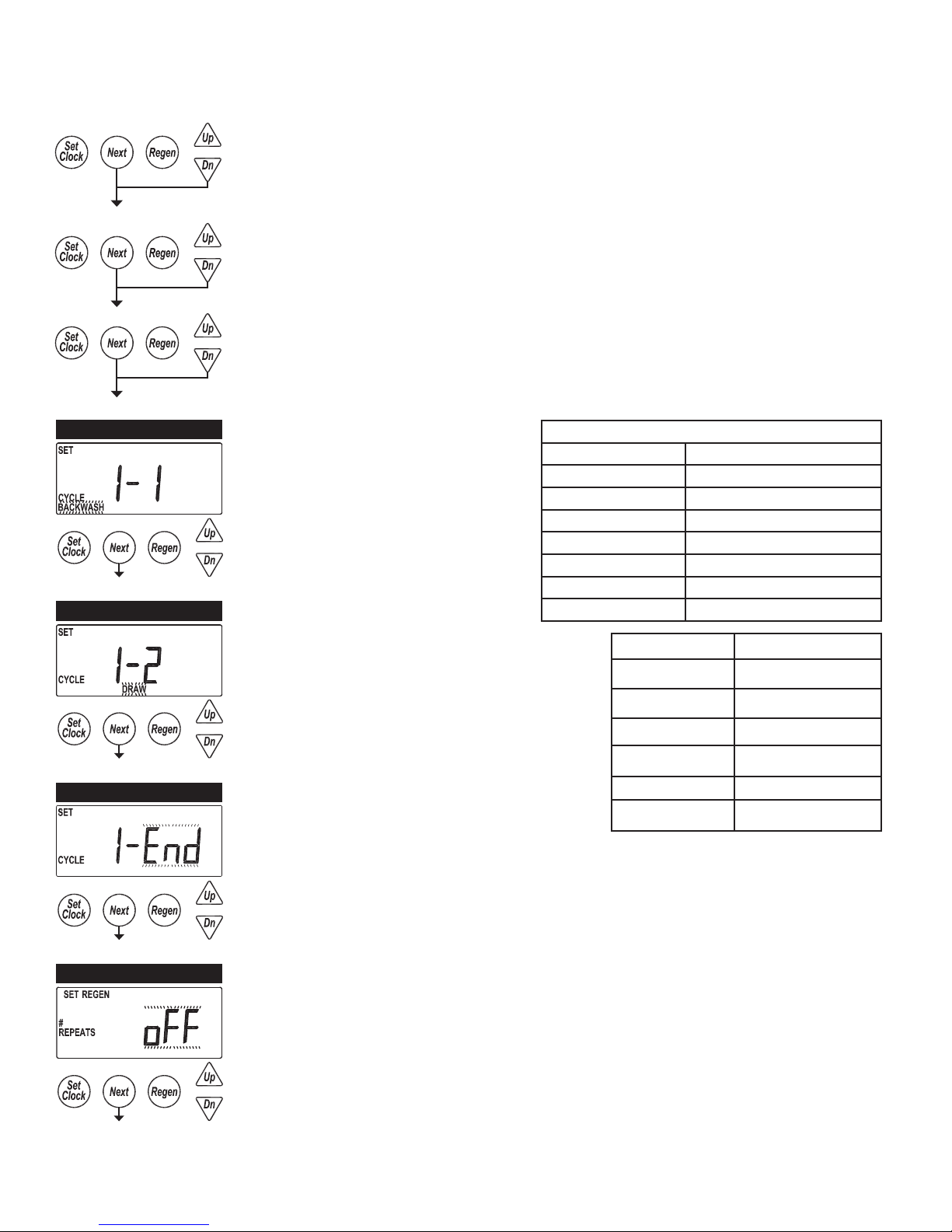

CYCLE SETUP SCREENS

Accessed by pressing NEXT and DOWN simultaneously for >3 seconds, then by pressing

NEXT and DOWN simultaneously again for >3 seconds, then by pressing NEXT and

DOWN simultaneously again for >3 seconds

CYCLE SETUP 1A

CYCLE SETUP 1B

CYCLE SETUP 1C

CYCLE SETUP 1A

Select rst regeneration cycle.

CYCLE SETUP 1B

Select second cycle.

CYCLE SETUP 1C

After cycles are con gured, an END is added.

(9 cycles maximum.)

Backwash

Draw

Slow Rinse Separate cycle from Draw

2nd Backwash

Rinse (fast)

Fill

End

Hold Piston in Service position

Available Cycles

Cycle Number Cycle Default

1 Backwash

2 Draw

3 2nd Backwash

4 Rinse

5 Fill

6 End

CYCLE SETUP 2

CYCLE SETUP 2

Select regeneration repeats, 1-9 or OFF.

Repeats regeneration cycle Sequence 1 a selected number of times before regenerating a

single time with Sequence 2.

The following screens will not appear if Cycle Setup 2 is set to OFF.

WS2H and WS3 Manual Page 23

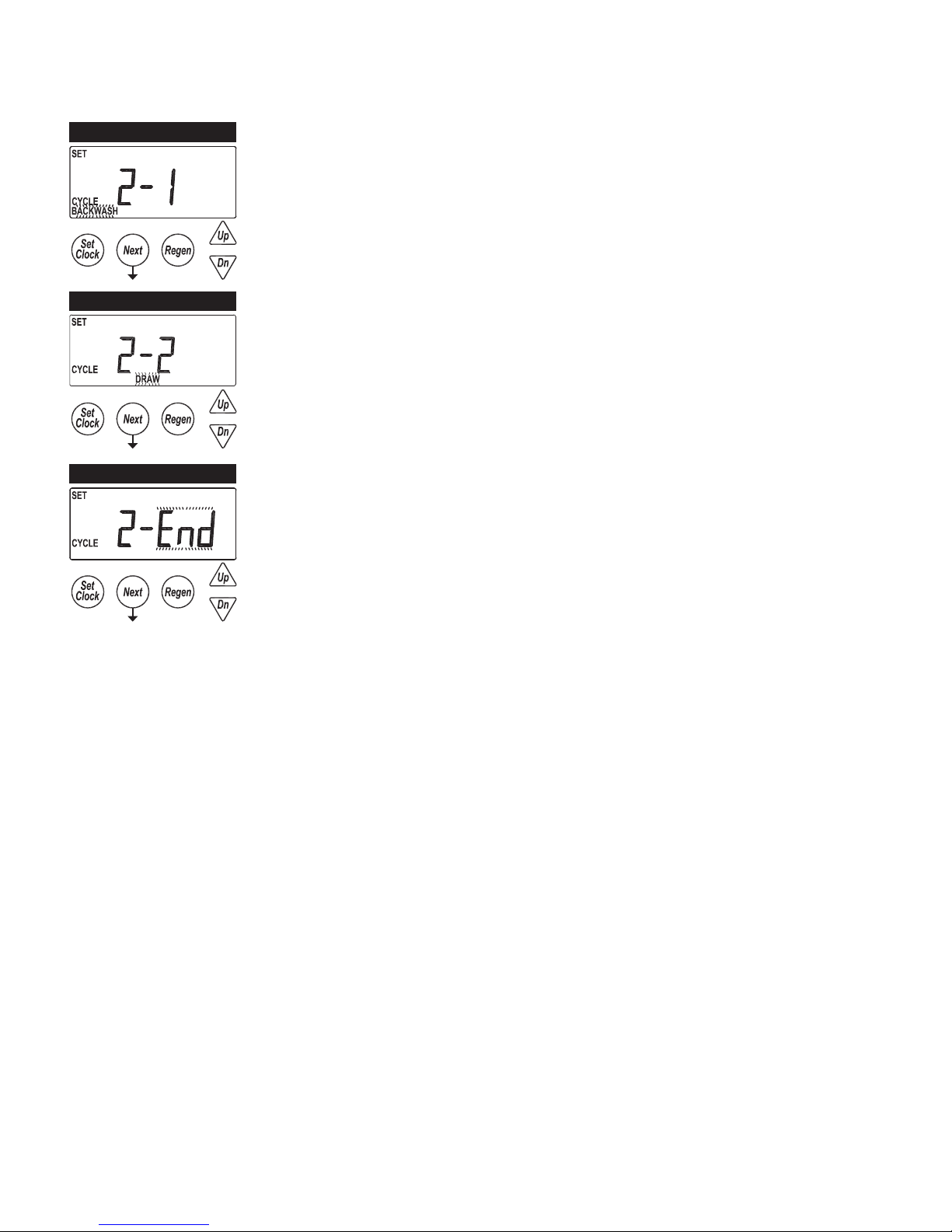

CYCLE SETUP SCREENS (CONTINUED)

CYCLE SETUP 3A

CYCLE SETUP 3B

CYCLE SETUP 3C

CYCLE SETUP 3A

Select rst cycle of “alternate” regeneration sequence (Sequence 2).

CYCLE SETUP 3B

Select second cycle of ‘alternate’ regeneration sequence.

CYCLE SETUP 3C

After cycles are con gured, an END is added. (9 cycles maximum.)

RETURN TO NORMAL

OPERATION

Page 24 WS2H and WS3 Manual

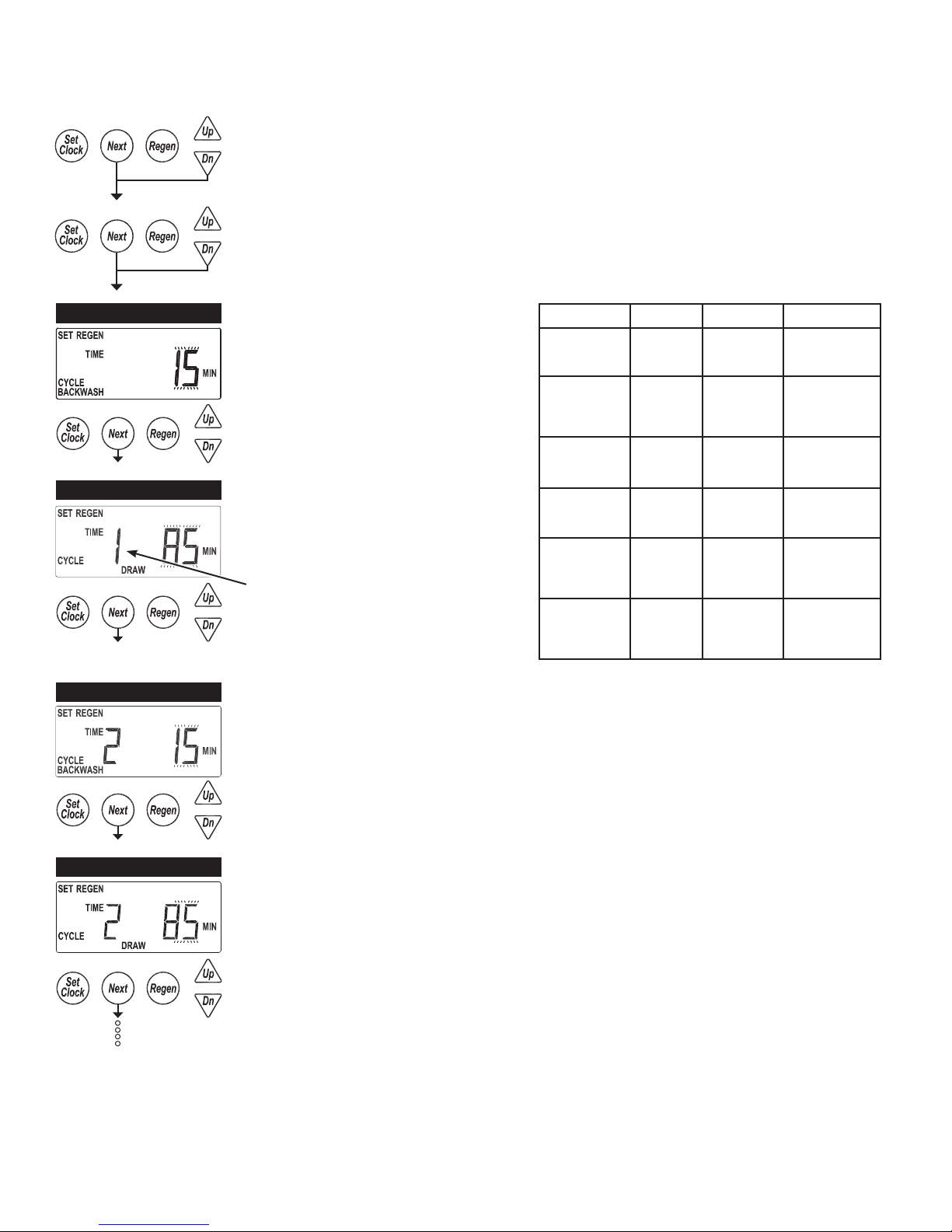

TIMER SCREENS

Accessed by pressing NEXT and DOWN simultaneously for >3 seconds, then by pressing

NEXT and DOWN simultaneously again for >3 seconds.

TIMER 1A

TIMER 1B

TIMER 1A2

TIMER 1A

Select runtime of cycle 1.

TIMER 1B

Select runtime of cycle 2.

1 or 2 will be displayed if set for

Alternate Regenerations in Cycle

Setup 2.

TIMER 1A2

If Alternate Regenerations has been selected in Cycle Setup 2, select runtime of Alternate

Regeneration Cycle 1.

Cycle Units Range Increments

Backwash Minutes

Draw Minutes

Slow Rinse Minutes

Rinse Minutes

Fill Minutes

Hold Minutes

1-30

30-95

1-30

30-100

100-180

1-30

30-95

1-30

30-95

0.1-10.0

10.0-30.0

30.0-99.0

1-30

30-100

100-480

0.1

0.2

1.0

0.1

2.0

10.0

1

5

1

5

10

1

5

1

5

TIMER 1B2

TIMER 1B2

Select runtime of Alternate Regeneration, cycle 2.

WS2H and WS3 Manual Page 25

TIMER SCREENS (CONTINUED)

TIMER 2

Non-Default Settings

TIMER 2 – Set Trigger for Output 1

•Timer screens are only available with a system board installed

Time

•The relay is actuated based on a set amount of time after the start of regeneration

Volume

• The relay is actuated, during service only, every speci ed amount of volume usage

Regen

• Relay actuation is based on regen status

Standby

• Relay actuation is based on the units Standby status

• Relays would be used to control external valving or signaling a units Online status.

Error

• Relay actuates to signal an error condition

Day & Gal & System

• Relay actuates, based on system usage, at a speci ed daily volume to signal a usage

alarm.

• “Usage High” ashes on the screen with unit continues to operate as normal. Pressing

any button resets the relay and returns the unit to the user screens.

• Only available on the master unit of a system

Day & Gal

• Relay actuates, based on a units usage, at a speci ed daily volume to signal a usage

alarm

• “Usage High” ashes on the screen with unit continues to operate as normal. Pressing

any button resets the relay and returns the unit to the user screens.

Volume & Regen

• Relay is actuates, during service & while in regen, every speci ed amount of service

ow

Volume & System

• Relay actuates, at a speci ed amount, based on combined volume usage of all units in

the system

• Only available on the master unit of a system

Cycle

• Relay actuation is based on the start of a speci ed cycle

Page 26 WS2H and WS3 Manual

TIMER SCREENS (CONTINUED)

TIMER 3

TIMER 4

TIMER 5

TIMER 3 – Set Trigger for Output 2

• Trigger options are the same as for output 1

TIMER 4 – Set Output 1 Trigger

• Set the trigger point in these screens are based on the selection in the previous screens

TIMER 5 – Set the relays ON

time duration

• A unit’s ON time does not

accumulate; ie a unit set to

trigger the relay every 10

gallons and stay on for 5

minutes is owing 10 gpm.

The unit would not add 5

minutes every 10 gallons,

it would reset the 5 minute

countdown every 10 gallons

• A unit which is manually

stepped through regeneration

will reset the relay.

Trigger Units Range Increment Default

Time Min-

Cycle Slow

Volume Gal-

Volume Liters 5-750

Trigger Units Range Increment Default

Time Min-

Relay Trigger Settings

0-240 1 10

utes

1-200

lons

utes

200-1000

1000-

10000

750-4000

4000-

38000

Relay Duration Settings

:01-2:00

2:00-20:00

20-240

1

5

10

5

20

40

:01

:05

1

Rinse

20

75

3:00

TIMER 6

TIMER 6

Select Relay 2 output “ON”, per units previously selected.

Time

Time after the start of a regen before relay is actuated.

Cycle

Select a cycle which will actuate output 1.

Volume

Volume of water interval during service between relay actuations.

WS2H and WS3 Manual Page 27

TIMER SCREENS (CONTINUED)

TIMER 7

RETURN TO NORMAL

OPERATION

TIMER 7 – Set the relays ON time duration

• A unit’s ON time does not accumulate; ie a unit set to trigger the relay every 10 gallons

and stay on for 5 minutes is owing 10 gpm. The unit would not add 5 minutes every 10

gallons, it would reset the 5 minute countdown every 10 gallons

• A unit which is manually stepped through regeneration will reset the relay.

Page 28 WS2H and WS3 Manual

INSTALLER SETUP SCREENS

Accessed by pressing NEXT and UP simultaneously for >3 seconds.

INSTALLER 1

INSTALLER 2

INSTALLER 3

INSTALLER 1 – Set Volumetric Capacity

Capacity: Set the units Volumetric Capacity in

gallons or cubic meters

OFF

• Units will not regenerate based on volume

but will track usage history

• Will not be an option on units with no day

override set

Set current day and regen days when set

as a 7 day time clock in System Setup 1.

See next page.

INSTALLER 2 – Set Days Between Regenerations (Day override)

Set day override. 1-28 days between regenerations, or if set to 7 day time clock, see 7 day

setup on next page. OFF will only be displayed if “OFF” is selected in System Setup 4.

• Settings will be based on the type of day override control set in system setup.

• Off will be displayed for units with day override turned off

1 – 28: When set as a 28 day override

• Set the days between regens

1 – 7: When set as a 7 day timeclock

• First, set 1 – 7 to signify the current day (1 = Sunday – 7 = Saturday)

• Next turn regen on or off for each speci c day of the week, 1 - 7

INSTALLER 3 – Set Delayed Regeneration Time

• Set the delayed time of regeneration, hour (AM / PM toggles at midnight)

• Units with no time dependent control (Aux Input settings or Day Override) will display on0

X1000 Indicator Illuminates At 10,000

Gallons

Units

US

(GAL)

SI

(L)

10,000-100.00 x 1000

100.00-999.00 x 1000

50,000-50.00 x 1000

500.00-5000.0 x 1000

Range Increments

10-10,000

100

1000

50-50,000

5000

10

50

50

INSTALLER 4

INSTALLER 5

RETURN TO NORMAL

OPERATION

INSTALLER 4 – Set Delayed Regeneration Time

• Set delayed time of regeneration, minutes

INSTALLER 5 – Set Multiple Delayed Regeneration Times

• When con gured for multiple delayed regeneration times, repeat steps 3 & 4 for each

additional time slot

WS2H and WS3 Manual Page 29

INSTALLER SETUP SCREENS (CONTINUED)

7 DAY OPTION

INSTALLER 2A

INSTALLER 2A

7 day time clock option. Set current day of the week:

1 = Sunday

2 = Monday

3 = Tuesday

4 = Wednesday

5 = Thursday

6 = Friday

7 = Saturday

INSTALLER 2B

INSTALLER 2C

INSTALLER 3

(see previous page)

INSTALLER 2B

1 – 7: Signi es each day of the week, Sunday thru Saturday

• Scroll through each day using the up & down arrow

• Use Set Clock to toggle between ON or OFF to control regeneration for each day

- i.e., regen on Monday, no regen on Sunday

INSTALLER 2C

(i.e., no regeneration on Saturday.)

Page 30 WS2H and WS3 Manual

DIAGNOSTIC SCREENS

Accessed by pressing UP and DOWN simultaneously for >3 seconds.

DIAGNOSTIC 1

DIAGNOSTIC 2

DIAGNOSTIC 3

DIAGNOSTIC 1

Days since the last regeneration.

All Diagnostic History screens are resettable with the History Reset sequence while in the

Diagnostics 1 screen. Holding the Set Clock and Regen buttons for > 3 seconds initiates a

totalizer or history reset.

DIAGNOSTIC 2

Volume since the last regeneration.

DIAGNOSTIC 3

• Displays the reserve history

• Does not display on systems, or units with

AUTOMATICALLY

TOGGLES

Reserve Value

reserve set to OFF

• Use the UP & DN arrows to scroll through

each days history

- Day 0 is today’s reserve (tomorrows

anticipated usage)

- 1 was yesterday’s reserve (today’s

anticipated usage)

DIAGNOSTIC 4A

AUTOMATICALLY

TOGGLES

Simultaneously

press UP and

GO TO

DOWN.

DIAGNOSTIC 5A

GO TO

DIAGNOSTIC 4B

Gallons Used

DIAGNOSTIC 4A

History of volume used.

Use UP and DOWN arrows to select a day.

0 = Today

1 = Yesterday

63 = 63 days ago (max.)

REGEN will display if a regeneration occurred

that day.

WS2H and WS3 Manual Page 31

DIAGNOSTIC SCREENS (CONTINUED)

DIAGNOSTIC 4A

DIAGNOSTIC 5A

GO TO

DIAGNOSTIC 6

DIAGNOSTIC 4B

Hourly history of volume use. Use the UP and

DOWN arrow to select the hours of the day.

AUTOMATICALLY

TOGGLES

Volume used within the

selected hour

Returns user back to USE Day 0 in Diagnostic 4 screen.

DIAGNOSTICS 5A

• Displays the max ow rate and the hour it

occurred

AUTOMATICALLY

TOGGLES

Max ow rate of the day

• Use the UP & DN arrows to scroll through 28

days history

- Day 0 is today

- Day 1 was yesterday

Simultaneously

press UP and

DOWN.

DIAGNOSTIC 5B

DIAGNOSTIC 6

DIAGNOSTIC 7A

GO TO

DIAGNOSTIC 6

DIAGNOSTICS 5B

Hourly history of maximum ow rate. Use the

UP and DOWN arrow to select the hours of the

AUTOMATICALLY

TOGGLES

day from screen 5.

Max ow within the

selected hour

Returns user back to USE Day 0 in Diagnostic 5 screen.

DIAGNOSTIC 6

Total volume through the unit.

DIAGNOSTICS 7A

Total system history of volume used use UP and

DOWN arrows to select a day.

AUTOMATICALLY

TOGGLES

Max ow rate of the day

0 = Today

1 = Yesterday

63 = 63 days ago (max.)

Simultaneously

press UP and

DOWN.

GO TO

DIAGNOSTIC 7B

Page 32 WS2H and WS3 Manual

DIAGNOSTIC SCREENS (CONTINUED)

DIAGNOSTIC 7B

AUTOMATICALLY

TOGGLES

Volume used within the

selected hour

Returns user back to USE Day 0 in Diagnostic 7 screen.

DIAGNOSTIC 8

AUTOMATICALLY

TOGGLES

RETURN TO USER

SCREEN

DIAGNOSTICS 7B

Total system hourly history of volume use Up

and Down arrow to select the hours of the day

from Screen 7.

WS2H and WS3 Manual Page 33

THIS PAGE LEFT INTENTIONALLY BLANK

Page 34 WS2H and WS3 Manual

VALVE HISTORY

Accessed by pressing UP and DOWN simultaneously for >3 seconds,

then by pressing UP and DOWN simultaneously again for >3 seconds.

Non-Resettable

HISTORY 1

HISTORY 2

HISTORY 3

HISTORY 1

Total days since startup.

Time only accumulates while the unit is plugged in.

HISTORY 2

Total regenerations since startup.

HISTORY 3

Total volume treated since startup.

HISTORY 4

HISTORY 5

RETURN TO NORMAL

OPERATION

HISTORY 4

Main board software

HISTORY 5

System board software revision. Will display -nA- if no system board is detected.

WS2H and WS3 Manual Page 35

CUSTOM MOTORIZED DRIVE TIMING

• Used to alter the standard timing sequence of the motorized isolation valve for

complete custom timing of the drive circuits

- Setup procedure applies to both the “Bypass” drive of the main board and “Aux

Drive” of the optional expansion board

• Customization needs to be done after de ning the regeneration cycle sequence

• Accessed by pressing the Up & Dn arrows simultaneously while in the No Hard

Water Bypass selection

- Next will scroll through each cycle of the regeneration program

- Arrow buttons toggle Standby and Online indicating the desired position the

drive during that cycle of the regeneration.

- In the example screens the “Bypass” drive will be transitioning of ine for

Backwash (Cycle 1) and coming online for Fill (Cycle 5).

• Timing can be further customized per cycle by adding a time delay to the

sequence

- Accessed by pressing the Up & Dn arrows simultaneously while in the drive

sequence screens

- Setting a “Start Time” delays the start of that transition after reaching set cycle

- A second time screen then sets the time the drive maintains that set position

before transition back to its previous position.

- “Regen” will be illuminated to identify that a sequence has a time modi er

associated with it

- In the example screens the “Bypass” drive will delay its transition to of ine until 2

minutes into Backwash (Cycle 1) and coming online for Fill (Cycle 5).

Page 36 WS2H and WS3 Manual

INSTALLATION

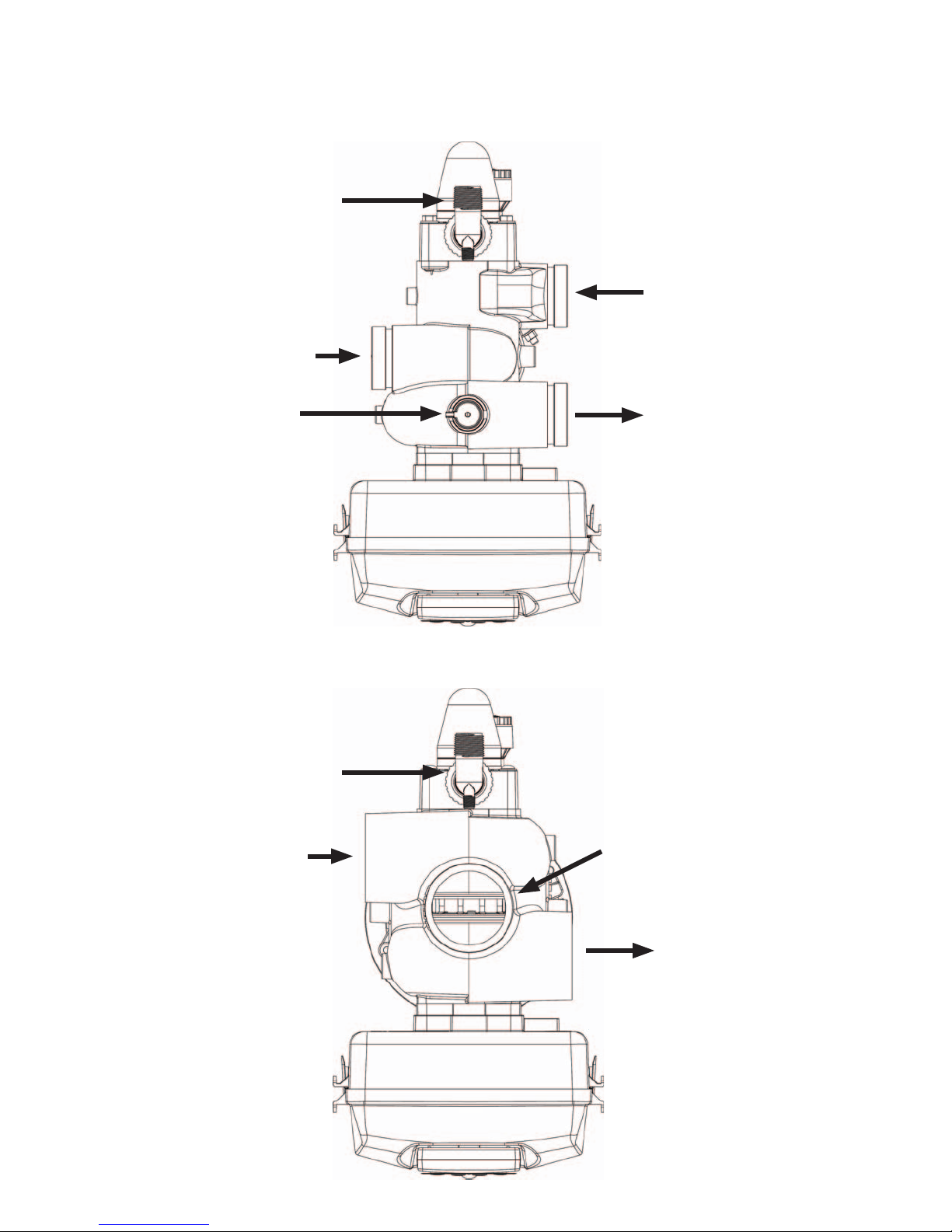

WS2H CONTROL VALVE TOP VIEW

BRINE/REFILL

INLET

DRAIN

INTERNAL

FLOW METER

BRINE/REFILL

INLET

OUTLET

WS3 CONTROL VALVE TOP VIEW

DRAIN

OUTLET

WS2H and WS3 Manual Page 37

INSTALLATION (CONTINUED)

GENERAL INSTALLATION & SERVICE WARNINGS

The control valve and ttings are not designed to support the weight of the system or the plumbing.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on

black o-rings but is not necessary.

HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC., MAY DAMAGE PRODUCTS THAT

CONTAIN O-RINGS OR PLASTIC COMPONENTS. EXPOSURE TO SUCH HYDROCARBONS MAY CAUSE THE

PRODUCTS TO LEAK. DO NOT USE THE PRODUCT(S) CONTAINED IN THIS DOCUMENT ON WATER SUPPLIES

THAT CONTAIN HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC.

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING DEVICE FOR CRITICAL OR

HEALTH EFFECT APPLICATIONS

Do not use pipe dope or other sealants on threads. Te on tape is recommended to be used on all threads.

Use of pipe dope may break down the plastics in the control valve.

When servicing the valve, water may leak

from the valve. Water from the valve may

create a slip hazard. Clean up water spills.

Allow two feet of clearance to service WS2H and WS3 valves.

The valve will withstand transportation and storage temperatures of -13 ˚F (-25 ˚C) to 131 ˚F (55 ˚C) and for short

periods up to 158 ˚F (70 ˚C). If valve has been exposed to freezing conditions let valve warm up to room temperature

before running water through it. The valve has been packaged to prevent damage from the effects of normal humidity,

vibration and shock.

SITE REQUIREMENTS:

• The plug-in Power adapter is for dry locations only

• The tanks should be on a rm, level surface

• Electrical: Use an uninterrupted outlet installed within 15 feet (4.57 meters) of the water conditioner.

All plumbing should be done in accordance with local codes.

1. Locate the water conditioner so the distance between the drain and the water conditioner is as short as possible.

2. Regenerant tanks that must be re lled should be located where they are easily accessible. It is recommended a

safety brine valve be used.

3. Do not install any water conditioner with less than 10 feet of piping between its outlet and the inlet of a water heater.

Disconnect from electrical power

prior to servicing the valve.

4. Do not locate unit where it or its connections (including the drain and over ow lines) will ever be subjected to room

temperatures under 40° F (4° C).

5. The use of resin cleaners in a non-vented enclosure is not recommended.

Page 38 WS2H and WS3 Manual

INSTALLATION (CONTINUED)

6. INLET/OUTLET PLUMBING: Connect to a supply line downstream of outdoor spigots. Install inlet and outlet

shutoff valves for the control valve; see top view drawings for control valve inlet and outlet locations. Installation of a

three valve bypass is recommended. If using plastic ttings ground the water conditioner per local electric codes. If an

external water meter is used, install the water meter on the outlet side of the control valve. It is recommended that the

meter assembly be installed horizontally or in a down ow vertical position to reduce turbine bearing wear. The turbine

assembly may be orientated in any direction. Remove the cover and drive bracket and thread the water meter cord

through the hole in the back plate. Reinstall the drive bracket. Weave the cord through the strain relief on the backplate

and connect the end to the three prong connector labeled FLOW on the printed circuit board. Re-install the cover.

7. Drain: Verify that the drain can handle the backwash rate of the water conditioner. Correctly size the drain line

and install an appropriately sized drain line ow control. For WS2H and WS3 valves a drain line ow control are

NOT supplied with a valve. For WS2H valves the drain outlet is 2” Female NPT or BSPT threads or 2.5” groove lock

connection. For WS3 valves the drain port is 3” Female NPT or BSPT, no groove lock connection. If using copper,

solder joints near the drain must be done prior to connecting the drain line ow control tting. Leave at least 6” (152.4

mm) between the drain line ow control tting and solder joints to prevent heat from damaging the ow control.

Avoid elevating the drain line above the control valve where possible. Discharge the drain line through an air gap to a

receptacle in accordance with local plumbing codes.

IMPORTANT: Never insert a drain line directly into a drain, sewer line, or trap. Always allow an air gap between

the drain line and the receptacle to prevent back siphonage.

8. Regeneration: If the control valve is to be used to regenerate the water conditioner with brine (saturated salt

solution) or other regenerants. The WS2H and WS3 control valves regenerant port has a 1” 90° Male NPT threaded

outlet connection that swivels 360°. To ensure acceptable operation of the injectors use 1” pipe to connect to the brine

tank. Smaller drain line ow controls may result in the injector performance not matching the injector graphs. Use an

adequately size drain line ow control to ensure proper brine draw.

See Table 3 for injector order number and size for tank diameter. An over ow drain line from the regenerant tank that

discharges into an acceptable drain is recommended, as a regenerant over ow could damage furnishings or the

building structure. Connect a line to the over ow tting on the regenerant tank. If an over ow tting is not already

installed on the regenerant tank, install one. Do not elevate the over ow drain line. Discharge the over ow drain line

through an air gap to a receptacle in accordance with local plumbing codes.

9. Power Adapter: If a Power Adapter is already connected to the control valve, plug the Power Adapter into an

uninterrupted outlet. If the Power Adapter cord has not yet been connected to the control valve, remove the control

valve cover and the drive bracket and thread Power Adapter cord through the hole in the back plate. Reinstall the drive

bracket. Weave the cord through the strain relief on the backplate and connect the end to the four pin connector on

the printed circuit board labeled POWER. Reinstall the cover. Plug the Power Adapter into an uninterrupted outlet.

10. Program the control valve: It is very important to program the control valve for the type of system (e.g. water

softener of lter) and the end use application. Check the program used prior to testing the system.

WS2H and WS3 Manual Page 39

INSTALLATION SUMMARY

Installation Date: ___________________________________________

Installation Location: _______________________________________

Installer(s): ________________________________________________

Phone Number:

Application Type: (Softener) __________Other: _____________

Water Source: ____________________________________________

Water Test Results:

Hardness: ______________Iron: _______________pH: ___________

Other: ____________________________________________________

__________________________________________________________

Misc:

Service Flow Rates: min. ______________ max. ______________

Tank Size: Diameter ______________ Height: __________________

Resin or Media Volume: ____________________________________

Resin or Media Type: _______________________________________

Capacity: _________________________________________________

Salt or Fill Setting per Regeneration: _________________________

Brine Tank Size: ___________________________________________

Control Valve Con guration:

Valve Type:________________________________________________

Valve Part Number: ________________________________________

Valve Serial Number: _______________________________________

Regenerant Re ll Control: _________________________ gpm/lpm

Injector Size: ______________________________________________

Drain Line Flow Control: __________________________ gpm/lpm

Page 40 WS2H and WS3 Manual

CYCLE POSITIONS / FLOW DIAGRAMS

SERVICE

Raw Water

Treated Water Outlet

Inlet

Raw/Hard Water is bypassed

during regeneration

BACKWASH

Backwash Water

to Drain

Raw Water

Inlet

WS2H and WS3 Manual Page 41

CYCLE POSITIONS / FLOW DIAGRAMS (CONTINUED)

DRAW

Backwash Water

to Drain

Raw/Hard Water is bypassed

during regeneration

Raw Water

Inlet

Regenerant

solution being

drawn in

Injector feed

water from

Raw Water Inlet

supply

Raw/Hard Water is bypassed

during regeneration

SLOW RINSE

Slow Rinse Water

to Drain

Raw Water

Inlet

Injector feed

water from

Raw Water Inlet

supply

Page 42 WS2H and WS3 Manual

CYCLE POSITIONS / FLOW DIAGRAMS (CONTINUED)

RINSE

Rinse Water to

Drain

Raw/Hard Water is bypassed

during regeneration

Raw Water

Inlet

Treated Water Supply

Re ll port to re ll

tube for treated water

SOFT WATER REFILL

Raw Water

Inlet

Treated Water to

Regenerant Tank

Treated water

from Re ll Tube

WS2H and WS3 Manual Page 43

FRONT COVER AND DRIVE ASSEMBLY

Drawing No. Order No. Description Quantity

1 V3068 WS2H/3 POD FRNT-BK COVERS 1

1a V3082 WS2H/3 POD ASY COMPLETE W/BOARD* Optional

2 V3241-01 BOARD WS2H/3 PC BOARD DISPLAY 1

3 V3248 WS2H/3 CABLE DISPLAY POD 1

1

4 V3242-01BOARD WS2H/3 PC BOARD VALVE

5 V3224-01R WS2H/3 COVER ASY PLATINUM 1

6 V3107-01 WS1 MOTOR ASY 1

7 V3226-01 WS2H/3 DRIVE BRACKET ASY 1

8 V3110 WS1 DRIVE GEAR 12X36 3

9 V3109 WS1 DRIVE GEAR COVER 1

V3461-01 WS2H/3 AC ADAPTER 18VAC 1

Not Shown

V3461EU-01 WS2H/3 AC ADAPTER EU 18VAC

V3461UK-01 WS2H/3 AC ADAPTER UK 18VAC

10 V3243-01BOARD WS2H/3 PC BOARD SYSTEM

Not Shown V3475-12 WS2H/3 SYS CONNECT CORD 12 FT RED Optional

Not Shown V3475-24 WS2H/3 SYS CONNECT CORD 24 FT BL Optional

Not Shown V3475-36 WS2H/3 SYS CONNECT CORD 36 FT YEL Optional

See Table 2 Software and

Power Supply Compatibility

for option Selection

See Table 2 Software and Power

Supply Compatibility for option

selection

1

See Table 2 Software and

Power Supply Compatibility

for option Selection

*Contains items 1,2 & 3 Pod Assembly, PC Board and Cable

1a

1

2

3

5

7

9

8

4

6

10

Page 44 WS2H and WS3 Manual

WS2H DRIVE CAP ASSEMBLY, DOWNFLOW PISTON, REGENERANT PISTON, SPACER

STACK ASSEMBLY, DRIVE BACK PLATE, MAIN BODY AND METER

Drawing No. Order No. Description Quantity

1 V3275 WS2H/3 SCW BSHD SS3/8-16X2-1/4 (7/32” hex allen wrench required) 4

2 V3291 WS2H/3 WASHER SS 3/8 4

3 V3225 WS2H/3 BACK PLATE 1

4 V3066 WS2H DRIVE ASY 1

5 V3289 O-RING 344 1

6 V3204-01 WS2H PISTON 1

7 V3238-01*** WS2H/3 BRINE PISTON 1

8 V3065 WS2H STACK ASY 1

Not Shown

9

10 V3632* WS1.5/2/3 METER RETAINING CLIP 1

11 V3003-02 WS1.5/2H METER COMMERCIAL ASY 1

12 V3118-03 WS1.5/2 TURBINE ASY 1

13 V3105 O-RING 215 1

14 V3501 WS1.5/2 TURBINE CLIP 1

15 V3279 O-RING 346 1

16

17 V3054** WS2H 4 IN BASE CLAMP ASY 1

18 V3276 WS2H/3 BOLT HEX SS 5/16-18X1-3/4 1

19 V3269 WS2H/3 NUT 5/16-18 SS HEX 1

Not Shown D1300-01 TOP BAFFLE DFSR CLACK 2/63MM 1

* In 2008 a modi cation was made to Meter Housings to use V3632 WS1.5/2/3 Meter Retaining Clip. Do not use V3632 on old style

housings which have holes through the castings to accept the U-shaped V3223 WS2 Meter Clip.

**V3054 WS2 4 IN BASE CLAMP ASY includes a V3276 WS2 BOLT HEX SS 5/16-18X1-3/4 and V3269 WS2 NUT 5/16-18 SS HEX.

***V3238-01 Brine Piston is used for Backwash Only valves.

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING DEVICE FOR CRITICAL OR HEALTH EFFECT APPLICATIONS.

Service or replace the turbine by:

1. Turn the bypass for the system off and relieve the pressure on the system.

2. Press downward on the remote meter assembly to relieve tension on the retaining clip V3632 (or the U-shaped V3223 WS2 Meter Clip). Remove

the clip and take the meter assembly out of the housing.

3. Remove the bend from the two exposed tips of the retaining clip V3501 and remove clip.

4. Service or replace the V3118-03 WS15/2 Turbine Assembly and place it back in the turbine shaft.

5. Insert the V3501 WS15/2 Turbine Clip and re-bend the exposed ends of the clip. The V3118-03 turbine has a groove to line up with the V3501

WS15/2 Turbine Clip.

6. Insert meter assembly back into the meter housing.

7. Re-install the meter retaining clip V3632 as shown below (or the U-shaped V3223 WS2 Meter Clip).

8. Open the bypass for the system slowly to bring back into service and check to be sure you have no water leaks.

V3468-04 WS15/2/3 PLUG 1/4NPT PLST TAPE

V3465-04 WS15/2/3 PLG 1/4BSPT PLST TAPE

V3201-03 WS15/2/3 PLG 1/4BSPT PLST TAPE

V3201BSPT-03 WS2H BSPT BODY W/V3465 PLUG

V3280 O-RING 332 FOR VALVE BODIES WITH NPT THREADS

V3452 O-RING 230 FOR VALVE BODIES WITH BSPT THREADS

2

1

1

Typical meter retaining clip

installation. Ensure clip is fully

engaged in groove and tabs

positioned in slot as shown.

3

2

4

1

Install D1300-01 upper diffuser (not shown) when using the 4” Quick Disconnect (V3064)

10

11

B or indent

indicates BSPT

N or no mark

indicates NPT

5

6

7

8

12

13

14

9

15

16

17

18

19

WS2H and WS3 Manual Page 45

WS3 DRIVE CAP ASSEMBLY, DOWNFLOW PISTON, REGENERANT PISTON, SPACER STACK

ASSEMBLY, DRIVE BACK PLATE AND MAIN BODY

Drawing No. Order No. Description Quantity

1 V3275 WS2H/3 SCW BSHD SS3/8-16X2-1/4 (7/32” hex allen wrench required) 4

2 V3291 WS2H/3 WASHER SS 3/8 4

3 V3225 WS2H/3 BACK PLATE 1

4 V3093 WS3 DRIVE ASY 1

5 V3289 O-RING 344 1

6 V3666-01 WS3 PISTON 1

7 V3238-01** WS2H/3 BRINE PISTON 1

8 V3092 WS3 STACK ASY 1

Not Shown

9

10 V3763 O-RING 361 1

11 V3762 O-RING 341 FOR VALVE BODIES WITH NPT OR BSPT THREADS 1

12 V3091* WS3 BASE CLAMP ASY 1

13 V3276 WS2H/3 BOLT HEX SS 5/16-18X1-3/4 1

14 V3269 WS2H/3 NUT 5/16-18 SS HEX 1

Not Shown V3672 TOP BAFFLE DFSR CLACK 3/90MM 1

*V3091 WS3 BASE CLAMP ASY includes a V3276 WS2H/3 BOLT HEX SS 5/16-18X1-3/4 and V3269 WS2H/3 NUT 5/16-18 SS HEX.

**V3238-01 Brine Piston is used for Backwash Only valves.

V3468-04 WS15/2/3 PLUG 1/4NPT PLST TAPE

V3465-04 WS15/2/3 PLG 1/4BSPT PLST TAPE

V3667-03 WS3 BODY W/V3468 PLUG

V3667BSPT-03 WS3 BSPT BODY W/V3465 PLUG

2

1

B Indicates BSPT

N Indicates NPT

9

3

4

2

5

6

7

8

1

10

11

14

Install V3672 upper diffuser (not shown) when using the 6” Flange Base (V3090)

12

13

Page 46 WS2H and WS3 Manual

WS2H AND WS3 BRINE VALVE BODY AND INJECTOR COMPONENTS

Drawing No. Order No. Description

1 V3237-01 WS2H/3 SOFTFILL TUBE ASY 1 1

2a V3236-04* WS2H INJECTOR TUBE ASY FOR A THRU H 1

2b V3670-01** WS3 INJECTOR TUBE DOWNFLOW ASY 1

3 V3289 O-RING 344 1 1

4 V3067 WS2H/3 BRINE BODY ASY 1 1

5 V3477 WS2H/3 INJECTOR CAP 1 1

6 V3152 O-RING 135 1 1

7 V3275 WS2H/3 SCREW BSHD SS 3/8-16X2-1/4 (7/32” hex allen wrench required) 4 4

8 V3291 WS2H/3 WASHER SS 3/8 4 4

9 V3162-022*** WS1 DLFC 022 FOR 3/4 1 1

10 V3231 WS2H/3 REFILL FLOW CNTRL RETAINER 1 1

11 V3277 O-RING 211 1 1

12 V3105 O-RING 215 1 1

13 V3150 WS1 SPLIT RING 1 1

14 V3151 WS1 NUT 1 QC 1 1

15 V3149 WS1 FTG 1 MALE NPT ELBOW 1 1

Not Shown V3189 WS1 FTG 3/4&1 PVC SLVNT 90 Optional Optional

Not Shown V3499***** WS2H/3 FITTING CAP 1 IN THREADED 1 1

Not Shown V3797****** WS1 FTG 1 MALE BSPT ELBOW BSPT Only BSPT Only

*V3236-04 WS2H INJECTOR TUBE ASY A thru H contains a V3285 O-RING 213 and a V3286 O-RING 216.

**V3670-01 WS3 INJECTOR TUBE DOWNFLOW ASY contains a V3285 O-RING 213, V3286 O-RING 216 and a V3163 O-RING 019.

***Any V3162-XXX ow control may be used. V3237-01 WS2H SOFTFILL TUBE ASY contains a V3155 O-RING 112, V3287 O-RING 110 and a V3288 O-RING 206.

****V3010-2A through V3010-2G injectors contain a V3283 O-RING 117 and a V3284 O-RING 114. V3010-2H injectors use a V3283 O-RING 117 and D1263 O-RING 116.

Backwash Only Valves include a V3499 but do not include the following parts: V3189, V3162-022, V3231 and V3277.

***** Install V3499 on V3149 if valve is to be set up as a backwash only valve.

****** BSPT valves also include a V3797 WS1 FTG 1 MALE BSPT ELBOW

15

WS2H AND WS3 VALVE INJECTOR

ORDER INFORMATION

Injector Order

Number

Typical Tank

Diameter

1

Proper RFC orientation

directs re ll water ow

towards the washer face

with radius and text.

V3010-2A 18”

V3010-2B 21”

14

V3010-2C 24”

V3010-2D 30”

13

V3010-2E 36”

V3010-2F 42”

V3010-2G 48”

V3010-2H 63”

1

Actual injector size used may

vary depending on the design and

WATER

FLOW

12

11

10

8

9

application of the system. Injectors in

table are sized for a typical down ow

softener using standard mesh synthetic

cation exchange media regenerating

with sodium chloride.

3

Quantity

WS2H WS3

Backwash Only

V3499 Cap

installed

from factory

7

5

1

2A

2B

16

6

4

WS2H and WS3 Manual Page 47

STANDARD INJECTOR GRAPHS

Order No. V3010-2A

4

3

2

Flow Rate (gpm)

1

0

20 40 60 80 100 120

US Units

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2C

US Units

7

6

5

4

3

2

Flow Rate (gpm)

1

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2B

6

5

4

3

2

Flow Rate (gpm)

1

0

20 40 60 80 100 120

US Units

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2D

US Units

12

10

8

6

4

Flow Rate (gpm)

2

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2E

16

14

12

10

8

6

Flow Rate (gpm)

4

2

0

20 40 60 80 100 120

US Units

Pressure (psi)

Order No. V3010-2G

US Units

24

22

20

18

16

14

12

10

8

Flow Rate (gpm)

6

4

2

0

20 40 60 80 100 120

Pressure (psi)

Total

Slow Rinse

Total

Slow Rinse

Order No. V3010-2F

US Units

18

16

14

12

10

Draw

8

6

Flow Rate (gpm)

4

2

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2H

US Units

44

40

36

32

28

24

20

Draw

16

Flow Rate (gpm)

12

8

4

0

20 40 60 80

Total

Slow Rinse

Draw

100 120

Pressure (psi)

Page 48 WS2H and WS3 Manual

STANDARD INJECTOR GRAPHS (CONTINUED)

Order No. V3010-2A

Metric Units

16

14

12

10

8

6

Flow Rate (lpm)

4

2

0

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Order No. V3010-2C

27

24

21

18

15

12

9

Flow Rate (lpm)

6

3

0

100 200 300 400 500 600 700 800 900

Metric Units

Total

Pressure (kPa)

Order No. V3010-2E

Metric Units

60

50

40

30

20

Flow Rate (lpm)

10

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Pressure (kPa)

Order No. V3010-2G

Metric Units

90

80

70

60

50

40

30

Flow Rate (lpm)

20

10

0

100 200 300 400 500 600 700 800 900

Slow Rinse

Pressure (kPa)

Total

Draw

Slow Rinse

Draw

Draw

Total

Draw

Slow Rinse

Order No. V3010-2B

21

18

15

12

9

Flow Rate (lpm)

6

3

0

100 200 300 400 500 600 700 800 900

Metric Units

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2D

Metric Units

40

35

30

25

20

15

Flow Rate (lpm)

10

5

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2F

Metric Units

70

60

50

40

30

Flow Rate (lpm)

20

10

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2H

Metric Units

160

140

120

100

80

60

Flow Rate (lpm)

40

20

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

WS2H and WS3 Manual Page 49

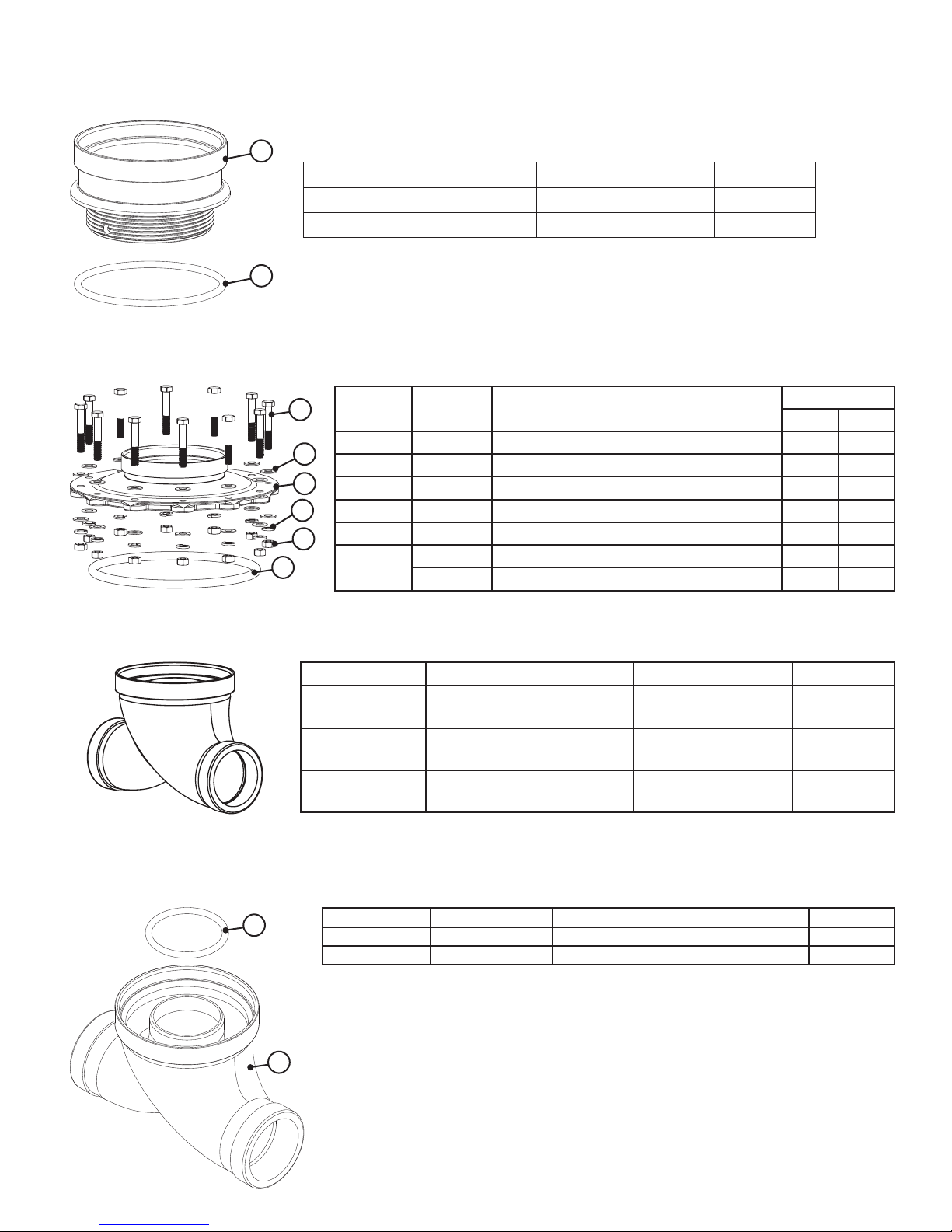

V3064 WS2H/2QC 4 INCH BASE ASY (FOR USE ON WS2H OR WS2QC ONLY)

1

Drawing No. Order No. Description Quantity

1 V3202-01 WS2H BASE 1

2 V3419 O-RING 347 1

2

V3055 WS2H/2QC 6 INCH FLANGE BASE ASY or V3090 WS3 6 INCH FLANGE BASE ASY

2

6

3

4

Drawing

No.

1 V3444 WS2H SCREW HEXCAP 5/16-18X2 SS 12 12

2 V3293 WS2H WASHER SS 5/16 FLAT 24 24

3 V3445 WS2H WASHER SPLIT LOCK 5/16 SS 12 12

4 V3447 NUT HEX 5/16-18 SILICON BRASS 12 12

5 COR60FL O RING 6 FLANGE ADAPTER 1 1

6

1

5

Order

No.

V3261-01 WS2H FLANGE BASE 1

V3671-01 WS3 FLANGE BASE 1

Description

WS2H/2QC SIDE MOUNT BASE ASSEMBLY

Order No. Description Inlet/Outlet For Valve

V3260-02 WS2H/2QC SIDE MOUNT

NPT ASY

V3674-02 WS3 SIDE MOUNT

NPT ASY

V3674BSPT-02 WS3 SIDE MOUNT

BSPT ASY

Quantity

V3055 V3090

2” Female NPT or

2.5” Groove Lock

3” Female NPT WS3 NPT

3” Female BSPT WS3 BSPT

WS2H NPT

V3260BSPT-02 WS2H/2QC SIDE MOUNT BASE BSPT ASSEMBLY

1

2

Drawing No. Order No. Description Quantity

1 V3280 O-RING 332 1

2 V3260BSPT-01 WS2H SIDE MOUNT BASE BSPT 1

When using a side mount base with 2H or 2QC BSPT valves replace distributor

pilot o-ring V3452 O-RING 230 with V3280 O-RING 332. See exploded view of 2H

or 2QC valve for speci c location of distributor pilot o-ring.

Page 50 WS2H and WS3 Manual

DRAIN LINE FLOW CONTROLS

All drain line ow control housings are shipped without ow control washers.

See drain line ow control washer section for available ow selections.

PVC Elbow, 0.7 - 10 GPM

Inline Plastic, 9 - 25 GPM

Item Part# Description Qty.

V3158-04 WS Drain Fitting, 3/4” Elbow

1 V3158-03 Drain Elbow, 3/4 NPT 1

2 V3159-01 DLFC Retainer Assembly 1

3 V3163 O-ring, -019 1

4 H4615 Locking Clip 1

5* V3983 WS2 DLFC Adapter 1

6 V3162-xx See DLFC Section 1

*Also available: V3414 WS1.5 DLFC Adapter

1

Direction of Flow

3

2

6

5*

4

Item Part# Description Qty.

V3008-05 WS Drain Fitting, 1” Straight

1 V3167 WS Drain Fitting Adapter, 1” NPT 1

2 V3166-01 Drain Fitting Body 1

3 V3151 WS1 Nut, QC 1

4 V3150 WS1 Split Ring 1

5 V3105 O-ring -215 1

6 V3163 O-ring -019 1

7 H4615 Locking Clip 1

8** V3983 WS2 DLFC Adapter 1

9 V3190-xx See DLFC Section 1

**Also available: V3414 WS1.5 DLFC Adapter

1

Direction of Flow

3

4

2

5

1

8**

7

Drawing

No.

Order

No.

1 V3081 WS15 RETAINER DLFC ASY 1111

2

V3645 WS15 DLFC FLANGE OUTLET FNPT 1 1

V3645BSPT WS15 DLFC FLANGE OUTLET FBSPT 1 1

3 V3646 WS15 DLFC FLANGE INLET MNPT 1 1

4 V3388 WS125 DLFC FLANGE INLET MNPT 1 1

5 V3652 B S 5/16-18x3/4 4444

6 V3441 O-RING 226 1111

7 V3162-xx See DLFC Table 0-6 0-6 0-6 0-6

8 V3190-xx See DLFC Table 1111

4

Stainless Steel, 9 - 85 GPM

Description

Direction of Flow

6

1

3

DLFC not

supplied.

At least one

V3190-XXX

must be

installed in

center hole.

Quantity

V3079 V3079BSPT V3080 V3080BSPT

B indictates

BSPT

N indicates

2

NPT

5

Plugs may be

knocked out

or drilled to

use up to six

V3162-XXX.

WS2H and WS3 Manual Page 51

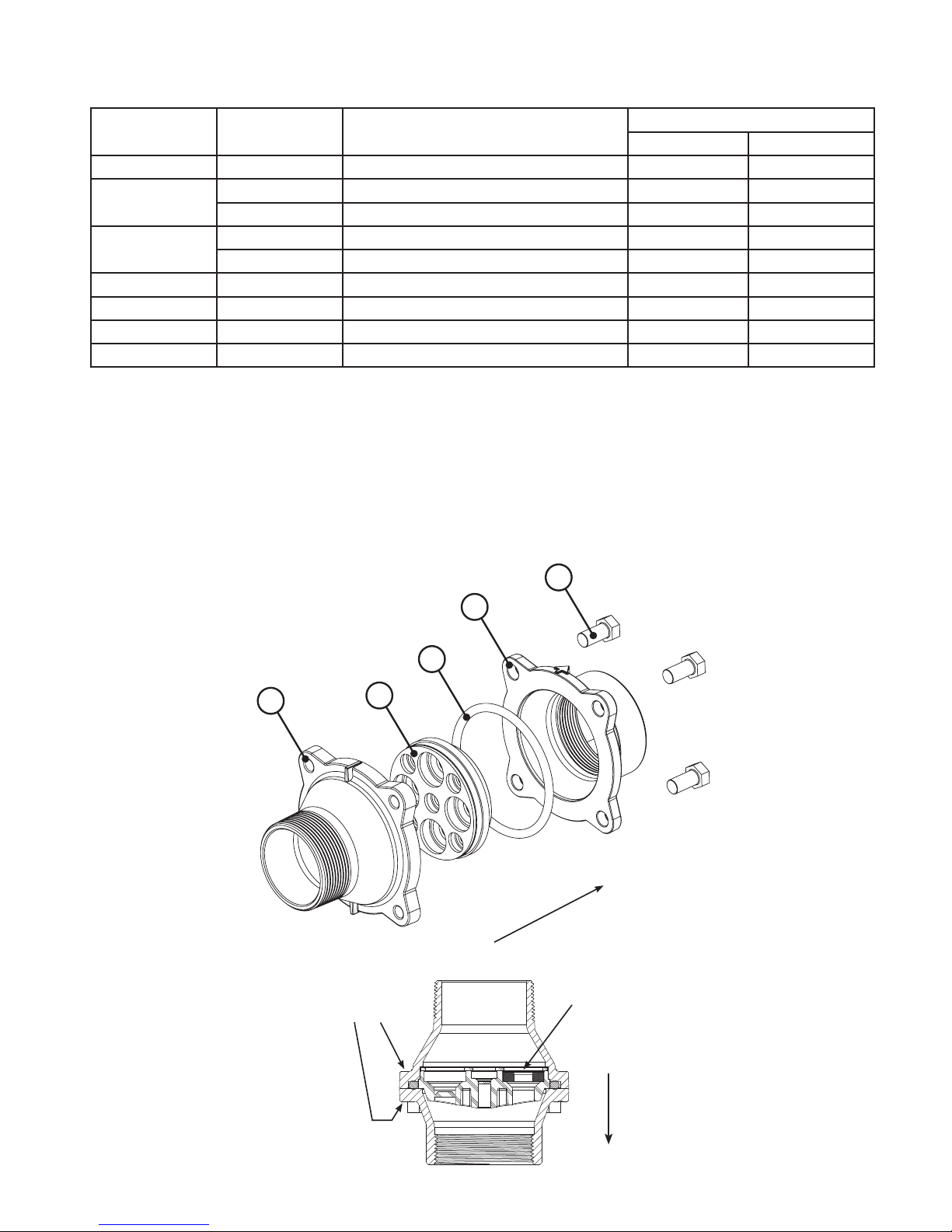

M X F STAINLESS STEEL, 0.7 – 150 GPM

Drawing

No.

1 V3052 WS2 DLFC Retainer Asy 1 1

2

3

4 V3273 Bolt Hex Hd S/S HCS 3/8-16x3/4 4 4

5 V3278 O-ring 338 1 1

6 V3162-XX See DLFC table 0-5 0-5

7 V3190-XX See DLFC table 0-4 0-4

Assemblies are shipped without drain line ow control (DLFC). Assembly instructions:

1. Determine the desired owrate. Select a combination of V3162-XXX’s and V3190-XXX’s to arrive at the

desired ow rate. Up to ve of the smaller V3162-XXX’s may be used. Up to four of the larger V3190-XXX’s

may be used.

2. Using a drill or punch remove the desired knockout(s) in V3052.

3. Smooth hole(s).

4. Install appropriate size(s) of drain line ow control washers. Pay close attention to proper DLFC orientation.

5. Assemble. Properly orientate the V3052 in the direction of ow.

6. Inlet and outlet threads are 2”. Couplings for iron pipe may also be used.

Order

No.

V3245 WS2 DLFC Flange Inlet NPT 1

V3245BSPT WS2 DLFC Flange Inlet BSPT 1

V3246 WS2 DLFC Flange Outlet NPT 1

V3246BSPT WS2 DLFC Flange Outlet BSPT 1

Description

V3051 V3051BSPT

Quantity

2

B indictates BSPT

N indicates NPT

4

3

5

1

Direction of Flow

Washer

Radius

Direction

of Flow

Page 52 WS2H and WS3 Manual

MXF STAINLESS STEEL, 9-225 GPM

Drawing

No.

1

Order No. Description

V3764 V3764BSPT

V3765-01 WS3 DLFC HOUSING NPT 1

V3765BSPT-01 WS3 DLFC HOUSING BSPT 1

Quantity

2 V3766 WS3 DLFC RETAINER 1

3 V3767 WS3 DLFC RETAINER COVER 1 1

4 V3768 WS3 DLFC RETAINER RING 1 1

5 V3769 O-RING 336 1-2 1-2

6 V3190-XX See DLFC table 1-9

Interlock between two V3766’s

Larger hole for DLFC installation

5

Positioning

of V3767 into

V3766

6

1

6

3

1

1

4

3

5

1

1-9

V3768

retainer ring

position if

two V3766

are used

Assemblies are shipped without drain line ow control (DLFC) washers.

Assembly instructions:

1. Determine the desired ow rate. Select a combination of V3190-XXX’s to arrive at the desired ow rate.

2. Using a drill or punch remove the desired knockout(s) in V3766. Each V3766 retainer contains two types of knock

outs. The larger knockouts are removed to install a DLFC. If two V3766 retainers are needed remove the smaller

diameter knockout that lines up with the DLFC installed in the other retainer. One or two V3766 retainers may be

used. When using one V3766 retainer V3190-XXX must be installed in the center hole. When using two V3766

retainers a V3190-XXX must be installed in the center hole of one of the retainers and the center hole on the other

retainer must remain open.

3. Smooth hole(s).

4. Install appropriate size(s) of drain line ow control washers. Pay close attention to proper DLFC orientation.

5. Assemble. Each V3766 retainer must have a V3769 o-ring installed. One each of the V3767 retainer cover and V3768

retainer ring must be used whether one or two V3766 retainers are used. The positioning of the V3768 retainer ring

varies depending on the number of V3766 retainer(s) used. Properly orientate the V3766(s) in the direction of ow.

6. Properly orientate the complete assembly in the direction of ow. Inlet and outlet threads are 3”.

WS2H and WS3 Manual Page 53

DRAIN LINE FLOW CONTROL WASHERS

Order No. Description

V3162-007 .7 GPM Drain line ow control

V3162-010 1.0 GPM Drain line ow control

V3162-013 1.3 GPM Drain line ow control

V3162-017 1.7 GPM Drain line ow control

V3162-022 2.2 GPM Drain line ow control

V3162-027 2.7 GPM Drain line ow control

V3162-032 3.2 GPM Drain line ow control

V3162-042 4.2 GPM Drain line ow control

V3162-053 5.3 GPM Drain line ow control

V3162-065 6.5 GPM Drain line ow control

V3162-075 7.5 GPM Drain line ow control

V3162-090 9.0 GPM Drain line ow control

V3162-100 10.0 GPM Drain line ow control

V3190-090 9.0 GPM Drain line ow control

V3190-100 10.0 GPM Drain line ow control

V3190-110 11.0 GPM Drain line ow control

V3190-130 13.0 GPM Drain line ow control