Page 1

Water Specialist CI

Control Valve

Programming and Cover Drawing Manual

Page 2

Page 2 CI Man u al

Page 3

CI Man u al Page 3

Table of Contents

CI Front Cover and Drive Assembly .......................................................................................................................4

OEM General Instructions .......................................................................................................................................5

OEM Cycle Sequence ..............................................................................................................................................6

OEM Softener System Setup .................................................................................................................................11

Setting Options Table .............................................................................................................................................13

OEM Filter System Setup ......................................................................................................................................14

Installer Display Settings .......................................................................................................................................16

User Display Settings ............................................................................................................................................17

Diagnostics ............................................................................................................................................................20

Valve History .........................................................................................................................................................22

Page 4

Page 4 CI Man u al

CI Front Cover and Drive Assembly

Drawing No. Order No. Description Quantity

1 V3175CI-01 WS1CI FRONT COVER ASSEMBLY 1

2 V3107-01 WS1 MOTOR 1

3 V3106-01 WS1 DRIVE BRACKET & SPRING CLIP 1

4 V3108CI-05BOARD WS1 THRU2L/2 CI PCB XMEGA REPL 1

5 V3110 WS1 DRIVE REDUCING GEAR 12X36 3

6 V3109 WS1 DRIVE GEAR COVER 1

V3186 WS1 AC ADAPTER 120V-12V

Not Shown

V3186EU WS1 AC ADAPTER 220-240V-12V EU

V3186UK WS1 AC ADAPTER 220-240V-12V UK

V3186-01 WS1 AC ADAPTER CORD ONLY

Not Shown V3178 WS1 DRIVE BACKPLATE 1

AC Adapter U.S. International

Supply Voltage 120 V AC 230V AC

Supply Frequency 60 Hz 50 Hz

Output Voltage 12 V AC 12 V AC

Output Current 500 mA 500 mA

When replacing the battery, align

positives and push down to fully seat.

Correct

Battery

Orientation

Battery Fully Seated

1

Battery replacement is

3 volt lithium coin cell

type 2032.

4

1

5

3

2

6

Page 5

CI Man u al Page 5

OEM General Instructions

The control valve offers multiple procedures that allow the valve to be modifi ed to suit the needs of the installation. These

procedures are:

• OEM Cycle Sequence

• OEM Softener System Setup

• OEM Filter System Setup

• Installer Display Settings

• User Display Settings

• Diagnostics

• Valve History

Once the OEM Cycle Sequence has been set, the other procedures can be accessed in any order. Details on each of the procedures

are provided on the following pages.

To “lock out” access to diagnostic and valve history displays and modifi cations to settings except hardness, day override, time of

regeneration and time of day by anyone but the manufacturer, press ▼, NEXT, ▲, and SET CLOCK in sequence after settings

are made. To “unlock”, so other displays can be viewed and changes can be made, press ▼, NEXT, ▲, and SET CLOCK in

sequence.

When in operation normal user displays such as time of day, volume remaining before regeneration, present fl ow rate or days

remaining before regeneration are shown. When stepping through a procedure, if no buttons are pressed within fi ve minutes, the

display returns to a normal user display. Any changes made prior to the fi ve minute time out are incorporated.

To quickly exit OEM Softener Setup, OEM Filter Setup, Installer Display Settings, Diagnostics or Valve History press SET

CLOCK. Any changes made prior to the exit are incorporated.

When desired, all programming and all information in Diagnostics may be reset to defaults when the valve is installed in a

new location. To reset to defaults, press NEXT and ▼ simultaneously to go to the Softening/Filtering screen. Press ▲ and

▼ simultaneously to reset diagnostic values and all programming to defaults. Screen will return to User Display.

Sometimes it is desirable to have the valve initiate and complete two regenerations within 24 hours and then return to the preset

regeneration procedure. It is possible to do a double regeneration if the control valve is set to “NORMAL” or “NORMAL + on 0”

in OEM Softener System Setup or OEM Filter System Setup. To do a double regeneration:

1. Press the “REGEN” button once. REGEN TODAY will fl ash on the display.

2. Press and hold the “REGEN” button for three seconds until the valve regeneration initiates.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time at the preset regeneration time.

For Valve Type 1.0T, press and hold SET and ▲ for about 3 seconds to initiate an exchange of the tank in Service without cycling

the regeneration valve. After tank switch, days remaining and capacity remaining status is retained for each tank until the next

regeneration.

Page 6

Page 6 CI Man u al

OEM Cycle Sequence

OEM Cycle Sequence instructions allows the OEM to set the order of

the cycle. The OEM Softener System Setup or the OEM Filter System

Setup allow the OEM to set how long cycles will last. The OEM may

choose up to 9 cycles in any order.

BACKWASH DN BRINE FILL

RINSE UP BRINE

Cycle Options

(WS1 Only)

SOFTENING

OR FILTERING

END

END must be used as the last cycle option. The SERVICE cycle

should only be used in brine prefi ll applications.

The upfl ow cycle can not be used on the WS1.25, WS1.5, WS2L or WS2 control valves. The V3407 piston used on the WS1.25,

WS1.5 and WS2L is designed for downfl ow use only. The components for converting the operation of a WS2 valve from

downfl ow to upfl ow are not yet available. For WS1 valves, prior to selecting DN brine or UP brine or not selecting a regenerant

fl ow cycle, verify the correct valve body, main piston, regenerant piston, and stack are being used, and that the injector or injector

plug(s) are in the correct locations. See Valve Body Compliance Table in WS1 & WS1.25 OEM Drawings and Service Manual.

The following is an example of how to set a valve so that when regeneration is initiated BACKWASH occurs fi rst, dn BRINE

occurs second, RINSE occurs third, and FILL occurs fourth.

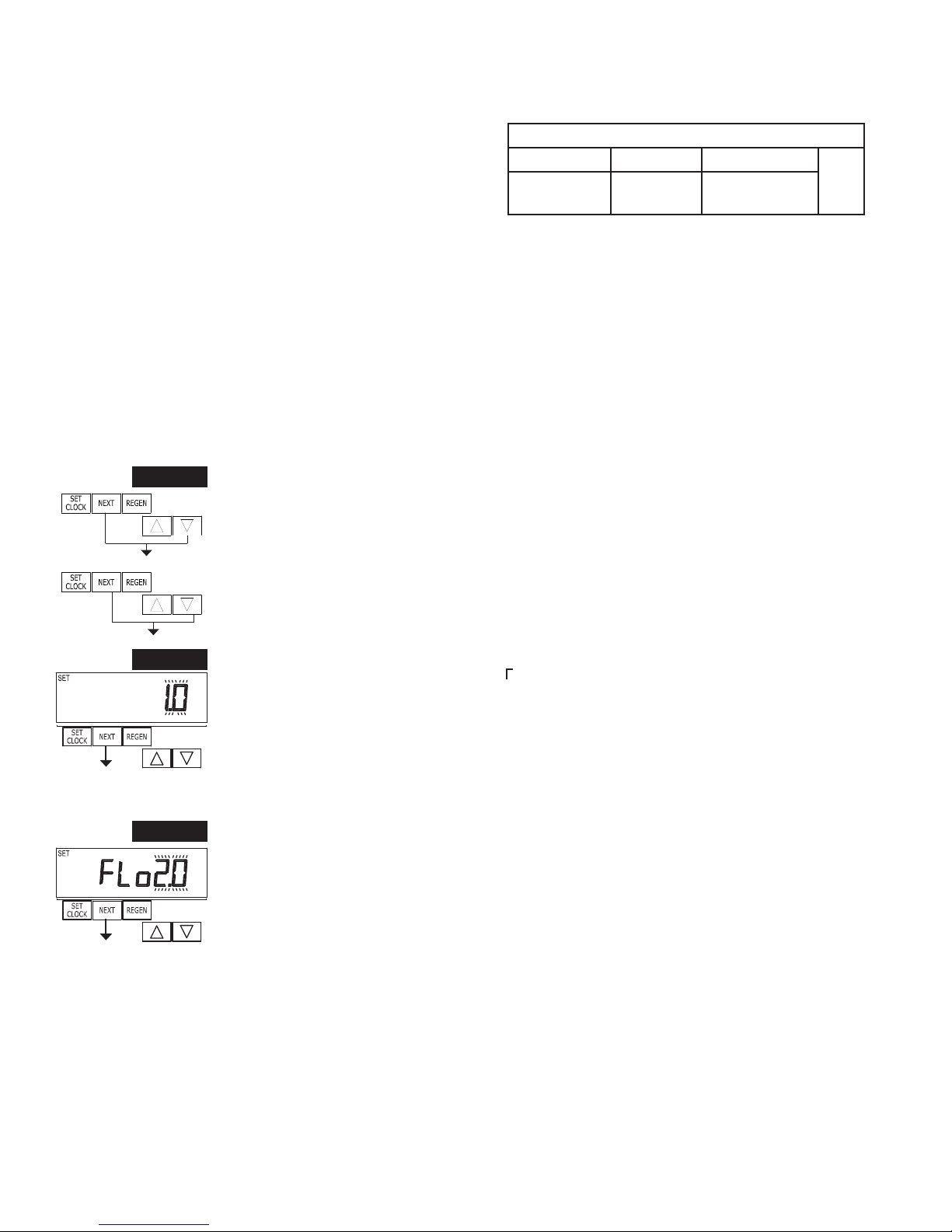

STEP 1CS

Step 1CS – Press NEXT and ▼ simultaneously for 3 seconds and release. Then press NEXT and ▼

simultaneously for 3 seconds and release. If screen in Step 2CS does not appear in 5 seconds the lock

on the valve is activated. To unlock press ▼, NEXT, ▲, and SET CLOCK in sequence, then press

NEXT and ▼ simultaneously for 3 seconds and release. Then press NEXT and ▼ simultaneously for

3 seconds and release.

STEP 2CS

Step 2CS – Use ▲ or ▼ to select 1.0 for WS1 valve, 1.25 for WS1.25 valve, 1.5 for WS1.5 valve,

2.0 for WS2 or 2.0L for a WS2L valve1, 1.0 for a twin valve.

Note: When using the WS2 valve, if “2.0L” is set instead of “2.0”, when the valve is in regeneration

and the piston drives to the “DRAW” cycle the piston will stall and generate a 1002 error code. Clear

the error code by pressing “NEXT” and “REGEN” buttons simultaneously until the valve resets, then

re-program valve to proper valve type setting. Press NEXT to go to Step 3CS. Press REGEN to exit

OEM cycle sequence.

STEP 3CS

Step 3CS – When 2.0 or 2.0L is selected, and additional screen will appear. It is used to select which

size fl ow meter is to be used with the valve, 1.5” or 2”.

Press NEXT to go to Step 4CS. Press REGEN to return to previous step.

¹ When using the WS2 control valve, the circuit board software must have meter selection choices of 2.0 and 2.0L. The WS2 valve must be set

for the 2.0 meter selection during programming. If the software version does not have both the 2.0 and 2.0L selections, consult your equipment

supplier for a replacement circuit board. When using the WS2L valve with older version software that does not have both 2.0 and 2.0L selection

choices, the valve must be set to 2.0 if using a 2” meter or 1.5 if using a 1.5” meter during programming. If a WS2L valve is being used with

newer version software that has both 2.0 and 2.0L selection choices, the valve must be set for 2.0L during programming.

Page 7

CI Man u al Page 7

STEP 4CS

Step 4CS – Allows selection of one of the following using ▲ or ▼:

• the Control Valve to have no hard water bypass;

• the Control Valve to act as an alternator; or

• the Control Valve to have a separate source during the regeneration cycle; or

• the Control Valve to operate with the Clack System Controller.

Select OFF when none of these features are used.

This display will not appear if 1.0

was selected in Step 2CS.

Only use Clack No Hard Water Bypass Valves or Clack Motorized Alternating Valves (MAV) with

these selections. Clack No Hard Water Bypass Valves (1” or 1.25” V3070FF or V3070FM) are not

designed to be used with the alternator or separate source functions.

Confi guring the Control Valve for No Hard Water Bypass Operation:

Select nHbP for control operation. For no hard water bypass operation the three wire connector is not

used.

Selection requires that a connection to MAV or a Clack No Hard Water Bypass Valve is made to the

two pin connector labeled MAV located on the printed circuit board. If using a MAV, the A port of the

MAV must be plugged and the valve outlet connected to the B port. When set to nHbP the MAV will

be driven closed before the fi rst regeneration cycle that is not FILL or SOFTENING or FILTERING,

and be driven open after the last regeneration cycle that is not FILL.

NOTE: If the control valve enters into an error state during regeneration mode, the no hard water

bypass valve will remain in its current state until the error is corrected and reset.

Confi guring the Control Valve for Separate Source Operation:

Select SEPS for control operation. For separate source operation the three wire connector is not used.

Selection requires that a connection to a Clack Motorized Alternator Valve (MAV) is made to the

two pin connector labeled MAV located on the printed circuit board. The C port of the MAV must be

connected to the valve inlet and the A port connected to the separate source used during regeneration.

The B port must be connected to the feed water supply.

When set to SEPS the MAV will be driven closed before the fi rst regeneration cycle, and be driven

open after the last regeneration cycle.

NOTE: If the control valve enters into an error state during regeneration mode, the MAV will remain

in its current state until the error is corrected and reset.

Selecting the Control Valve to act as an alternator:

Software Rev Level 320.0 and higher = Use 3-wire Interconnect Cable for all communication between units.

Software Rev Level 319.5 and lower = Use 2-wire Interconnect Cables for twin alternators with independent fl ow meters.

Prior to starting the programming steps, connect the interconnect cable to each control valve board’s three pin connector labeled ‘COMM

CABLE’. Also connect the meter cord to either control valve to the three pin connector labeled ‘METER’.

Softener Valve Programming Steps

Set to ALT A

Connect ALT A valve to the MAV’s A port and

OEM Cycle Sequence Step 4CS

OEM Cycle Sequence Step 6CS Select ppm, FH or dH Select ppm, FH or dH

Softener System

Setup

Softener System

Setup

Softener System

Setup

Installer Display

Setting

Step 7S Set Volume Capacity Set Volume Capacity

Step 8S Set to ‘AUTO’ Set to ‘AUTO’

Step 9S Set regeneration time option to ‘On O’. Set regeneration time option to ‘On O’.

Step 4I Set Day Over ride to “oFF” Set Day Over ride to “oFF”

connect the MAV’s two pin wire connector to the

two pin connector labeled “DRIVE” on the ALT

A valve

Connect ALT b valve to the MAV’s B port. No

connections between the ALT b valve and the

Set to ALT b

MAV are made.

Page 8

Page 8 CI Man u al

If set up for a fi lter, in Step 7F set Volume Capacity in M3; in Step 8F select Regeneration Time Option “on 0”; and in Step 4I

select Day Override “oFF”.

NOTE: If the control valve is in an error state during regeneration mode the MAV will close the B port and keep open the A port

until the error is corrected and reset.

For Clack Corporation alternator systems using WS1, WS1.25,

WS1.5, and WS2L valves there will be an option to delay the last

two cycles of regeneration (only “Rinse” and “Fill”). This feature

splits the regeneration into two portions. The fi rst portion of the

regeneration will start immediately and all programmed cycles

before the “Rinse” and “Fill” cycles will be performed. After

all programmed cycles before “Rinse” and “Fill” are completed

the control valve will drive to the service position (displaying

“Delayed Rinse + Fill Pending”). When the volume of the online unit is depleted to 10% of its programmed capacity, the

control valve will be triggered to fi nish the second portion of the

regeneration. Once “Rinse” and “Fill” are completed, the valve

will re-enter Standby mode until requested to come on-line for

Service.

For Clack Corporation alternator systems using the WS2 valve,

when NEXT is pressed after selecting ALT A or ALT b, a display

will allow the user to set the amount of pre-service rinse time for

the stand by tank just prior to returning to service.

WS1, WS1.25, WS1.5,

WS2L Valves

WS2

Valve

Retracted

Valve “A” in Service Position =

MAV piston rod Retracted

Note: Clack Twin Alternator Operations

• Twin alternating systems can be programmed with a day override setting combined with the normal volume-based

regeneration programming. A twin alternating system in this confi guration will then regenerate based on the volume used or

the day override if there is a period of low water usage.

• Twin alternating systems can be programmed as a time clock only based regenerating system. In this confi guration, the days

remaining are counted only on the unit that is in service. The unit in Stand-by Mode only notes days in diagnostics, which

results in time clock only twin regeneration initiation.

• Twin alternating systems can be programmed for a delayed regeneration time. The system will allow an immediate transfer

of the MAV to switch tanks and place a fully regenerated unit in service once a unit becomes exhausted. The exhausted unit

will then be placed into Stand-by Mode and allowed to have a delayed regeneration at the pre-set time.

Extended

Valve “B” in Service Position = MAV

piston rod Extended

Page 9

CI Man u al Page 9

Confi guring the Control Valve to operate with Clack System Controller:

Select SYS to link the Control Valve to the Clack System Controller. For communication between

the Control Valve and the System Controller, a three-wire communication cable is required.

Press NEXT to go to Step 5CS. Press REGEN to return to previous step.

STEP 5CS

Step 5CS – Allows selection of one of the following using ▲ or ▼:

• an outside signal to initiate a regeneration;

• an outside signal to prevent or delay regeneration.

Selection only matters if a connection is made to the two pin connector labeled DP SWITCH located on

the printed circuit board. Following is an explanation of the options:

OFF - Feature not used.

NOTE: In a twin alternating system each control must have a separate dP signal or dP switch.

One dP signal or one dP switch cannot be used for both controls.

dPon0 – If the dP switch is closed for an accumulative time of 2 minutes a regeneration will be

signaled to the unit. In a twin alternating system the MAV will transition fi rst to switch units so that

the signaled unit can start regeneration. After the MAV has fully transitioned, the regeneration begins

immediately. Note: For WS1 – WS2L control valves programmed for twin alternating: if the dP function

“dPon0” is set, the Delayed Rinse and Fill feature is not available.

dPdEL – If the dP switch is closed for an accumulative time of 2 minutes a regeneration will occur at

the scheduled delayed regeneration time. In a twin alternating system, once the dP switch is triggered

the PC board will display REGEN TODAY and switch tanks immediately. At the Delayed Regeneration

Time, the triggered unit will then regenerate. Note: For WS1 – WS2L control valves programmed for

twin alternating: if the dP function “dPdEL” is set, the Delayed Rinse and Fill feature is not available.

HoLd – If the dP switch is closed a regeneration will be prevented from occurring while there is switch

closure. In a twin alternating system the regeneration of a unit can be prevented upon switch closure.

If the unit depletes the capacity down to zero, it will not be allowed to switch tanks to regenerate until

the switch is open. Note: For WS1 – WS2L control valves programmed for twin alternating the Delayed

Rinse and Fill feature can be set in conjunction with the “HoLd” if desired.

Press NEXT to go to Step 6CS. Press REGEN to return to previous step.

Page 10

Page 10 CI Man u al

STEP 6CS

Step 6CS – Determine the measurement to calculate volumetric capacity. The

choices are:

ppm parts per million

FH French degrees

dH German degrees

NOTE: If control is going to be used in a fi lter application none of these

settings can be used.

Press NEXT to go to Step 7CS. Press REGEN to return to previous step.

STEP 7CS

STEP 8CS

STEP 9CS

STEP 10CS

Step 7CS – Press ▼ or ▲ until BACKWASH appears. Press NEXT to go to Step 8CS. Press REGEN

to return to previous step.

Step 8CS - Press ▼ or ▲ until dn BRINE appears. For a WS1 control valve; prior to selecting a

regenerant fl ow cycle, verify the correct valve body, main piston, regenerant piston and stack are being

used, and the injector or injector plug(s) are in the correct location. Refer to WS1 & WS1.25 Drawings

and Service Manual, Valve Body Compliance Table. Press NEXT to go to Step 9CS. Press REGEN to

return to previous step.

Step 9CS - Press ▼ or ▲ until RINSE appears. Press NEXT to go to Step 10CS. Press REGEN to

return to previous step.

Step 10CS - Press ▼ or ▲ until FILL appears. Press NEXT to go to Step 11CS. Press REGEN to

return to previous step.

STEP 11CS

Step 11CS - Press ▼ or ▲ until END appears. Press NEXT to go to Step 12CS. Press REGEN to

return to previous step.

STEP 12CS

Step 12CS - Fill Units: If set as a softener, if Step 2CS is set to 1.5, and FILL is part of the

Regeneration Cycle Sequence, FILL UNITS of MIN or kg can be selected.

Press NEXT to exit OEM Cycle Sequence. Press REGEN to return to

previous step.

RETURN TO NORMAL MODE

Page 11

CI Man u al Page 11

OEM Softener System Setup

In OEM Softener System Setup the OEM chooses the time for the cycles selected in OEM Cycle Sequence and specifi es other

operating parameters for the system. The upper and lower limits of the allowable values for the cycles are as follows:

Cycle Options Units Lower/Upper Limit

Backwash Minutes 1 to 120

Rinse (fast) Minutes 1 to 120

dn Brine (combination of brining and slow rinse) Minutes 1 to 180

up Brine (combination of brining and slow rinse) Minutes 1 to 180

Fill for 1”, 1.25”, 1.5”and 2.0L kg 0.05 to 90.00

Fill for WS2 valves or WS1.5 set to MIN Minutes 0.1 to 99.0

Service Minutes 1 to 480

Since no time is associated with the END cycle, the END cycle will not appear in the OEM Softener System Setup sequence.

STEP 1S

Step 1S – Press NEXT and ▼ simultaneously for 3 seconds and release. If screen in Step 2S does not

appear in 5 seconds the lock on the valve is activated. To unlock press ▼, NEXT, ▲, and SET CLOCK

in sequence, then press NEXT and ▼ simultaneously for 3 seconds and release.

STEP 2S

STEP 3S

STEP 4S

STEP 5S

Step 2S – Choose SOFTENING using ▼ or ▲. Press NEXT to go to Step 3S. Press REGEN to exit

OEM Softener System Setup.

Step 3S – Select the time for the fi rst cycle (which in this example is BACKWASH) using ▼ or ▲.

Press NEXT to go to Step 4S. Press REGEN to return to previous step.

Step 4S – Select the time for the second cycle (which in this example is dn BRINE) using ▼ or ▲.

Press NEXT to go to Step 5S. Press REGEN to return to previous step.

NOTE: The display will fl ash between cycle number and time, and brine direction (dn).

Step 5S – Select the time for the third cycle (which in this example is RINSE) using ▼ or ▲. Press

NEXT to go to Step 6S. Press REGEN to return to previous step.

STEP 6S

Step 6S – Select the kg or MIN for the fourth cycle (which in this example is FILL) using ▼ or ▲.

When both 2.0 and 2.0L are options in Step 2CS, and 2.0 is selected, or MIN is selected in Step 12CS,

FILL is in minutes. WS2 valves are shipped from the factory with a refi ll fl ow contol of 2.2 gpm (8.3

lpm). Press NEXT to go to Step 7S. Press REGEN to return to previous step.

Page 12

Page 12 CI Man u al

STEP 7S

STEP 8S

Step 7S – Set System Capacity using ▼ or ▲. See chart. The System

Capacity setting should be based on the volume of resin and Kg of salt fi ll

set in Step 6S. When using ppm, dH, or FH the system capacity and hardness

levels entered are used to determine the Volume Capacity. Press NEXT to go

Setting Units

PPM

dH or FH M

Kg of

CaCO

3

to Step 8S. Press REGEN to return to previous step.

Step 8S – Set Volume Capacity using ▼ or ▲. If value is set to:

• “AUTO” capacity will be automatically calculated and reserve capacity will be automatically

estimated;

• “oFF” regeneration will be based solely on the day override set (see Installer Display/Settings Step

4I);

• a number, regeneration initiation will be based on the value specifi ed (in M3); or

If “oFF” or a number is used, hardness display will not be allowed to be set in Installer Display

Settings Step 2I&3I. See Setting Options Table for more detail. Press NEXT to go to Step 9S. Press

REGEN to return to previous step.

3

STEP 9S

STEP 10S

RETURN TO NORMAL MODE

Step 9S – Set Regeneration Time Options using ▼ or ▲. If value is set to:

• “NORMAL” means regeneration will occur at the preset time;

• “on O” means regeneration will occur immediately when the volume capacity reaches 0 (zero); or

• “NORMAL + on 0” means regeneration will occur at one of the following:

— the preset time when the volume capacity falls below the reserve or the specifi ed number of

days between regenerations is reached whichever comes fi rst; or

— immediately after 10 minutes of no water usage when the volume capacity reaches 0 (zero).

“NORMAL” is the default if Step 4CS is set to ALT A or ALT b, and “NORMAL + on 0” is not

available.

This step will not appear if Step 8S is set to off.

See Setting Options Table for more detail. Press NEXT to go to Step 10S. Press REGEN to return to

previous step.

Step 10S – Set Low Salt Warning using ▼ or ▲. If value is set to:

• “oFF” no low salt level warning will appear for the user; or

• a specifi c value, “FILL SALT” will fl ash on the display when the

calculated remaining kg of salt falls below that level. Allowable values

range from 5 to 200 Kg in 5 Kg increments. When both 20 and 2.0L are options in Step 2CS, and 20

is selected, this step is skipped and not active.

Press NEXT to exit OEM Softener System Setup. Press REGEN to return to previous step.

Page 13

CI Man u al Page 13

Setting Options Table

Filters should only use shaded options

Volume

Capacity

AUTO NORMAL oFF

AUTO NORMAL Any number

Any

number

oFF NORMAL Any number

Any

number

AUTO On O oFF

Any

number

AUTO NORMAL on 0 oFF

AUTO NORMAL on 0 Any number

Any

number

Regeneration Time

Option

NORMAL oFF

NORMAL Any number

On O oFF

NORMAL on 0 Any number

Day

Override

2

Result

Reserve capacity automatically estimated.

Regeneration occurs when volume capacity falls below the reserve capacity at the next

Regen Set Time.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when volume capacity falls below the

reserve capacity or the specifi ed number of days between regenerations is reached.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when volume

capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specifi ed number of days

between regenerations is reached.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when volume

capacity reaches 0 or the specifi ed number of days between regenerations is reached.

Reserve capacity NOT automatically estimated.

Regeneration occurs immediately when volume capacity reaches 0. Time of

regeneration will not be allowed to be set because regeneration will always occur when

volume capacity reaches 0.

Reserve capacity NOT automatically estimated.

Regeneration occurs immediately when volume capacity reaches 0. Time of

regeneration will not be allowed to be set because regeneration will always occur on 0.

Reserve capacity automatically estimated.

Regeneration occurs when volume capacity falls below the reserve capacity at the next

Regen Set Time or regeneration occurs after 10 minutes of no water usage when volume

capacity reaches 0.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when volume capacity falls below the

reserve capacity or the specifi ed number of days between regenerations is reached or

regeneration occurs after 10 minutes of no water usage when volume capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specifi ed number of days

between regenerations is reached or regeneration occurs after 10 minutes of no water

usage when volume capacity reaches 0.

2

Reserve Capacity estimate is based on history of water usage. Reserve Capacity estimate is not available with

alternator systems or Twin Tank Valve.

Page 14

Page 14 CI Man u al

OEM Filter System Setup

In OEM Filter System Setup the OEM chooses the time for the cycles selected in OEM Cycle Sequence and specifi es other

operating parameters for the system. The upper and lower limits of the allowable values for the cycles are as follows:

Cycle Options Units Lower/Upper Limit

Backwash Minutes 1 to 120

Rinse (fast) Minutes 1 to 120

dn Brine (combination of regenerant and slow rinse) Minutes 1 to 180

Fill for all valves except WS2 Liters 0.2 to 76.00

Fill for WS2 Valves Minutes 0.01 to 99.0

Service Minutes 1 to 480

NOTE: Fill is in liters (except for WS2).

Since no time is associated with the END cycle, the END cycle will not appear in the OEM Filter System Setup sequence.

STEP 1F

STEP 2F

STEP 3F

STEP 4F

Step 1F – Press NEXT and ▼ simultaneously for 3 seconds and release. If screen in Step 2F does not

appear in 5 seconds the lock on the valve is activated. To unlock press ▼, NEXT, ▲, and SET CLOCK

in sequence, then press NEXT and ▼ simultaneously for 3 seconds and release.

Step 2F – Choose FILTERING using ▼ or ▲. Press NEXT to go to Step 3F. Press REGEN to exit

OEM Filter System Setup.

Step 3F – Select the time for the fi rst cycle (which in this example is BACKWASH) using ▼ or ▲.

Press NEXT to go to Step 4F. Press REGEN to return to previous step.

Step 4F – Select the time for the second cycle (which in this example is dn BRINE) using ▼ or ▲.

Press NEXT to go to Step 5F. Press REGEN to return to previous step.

NOTE: The display will fl ash between cycle number and time, and brine direction (dn Brine).

STEP 5F

Step 5F – Select the time for the third cycle (which in this example is RINSE) using ▼ or ▲. Press

NEXT to go to Step 6F. Press REGEN to return to previous step.

STEP 6F

Step 6F – Select the volume in liters for the fourth cycle (which in this example is FILL) using ▼

or ▲. When both 2.0 and 2.0L are options in Step 2CS, and 2.0 is selected, FILL is in minutes. WS2

valves are shipped from the factory with a refi ll fl ow control of 2.2 gpm (8.3 lpm). Press NEXT to go

to Step 7F. Press REGEN to return to previous step.

Page 15

CI Man u al Page 15

STEP 7F

STEP 8F

RETURN TO NORMAL MODE

Step 7F – Set Volume Capacity using ▼ or ▲. If value is set to:

• “oFF” regeneration will be based solely on the day override set (see Installer Display/Settings Step

4I); or

• a number, regeneration initiation will be based off the value specifi ed (in M3).

See Setting Options Table for more detail. Press NEXT to go to Step 8F. Press REGEN to return to

previous step.

Step 8F – Set Regeneration Time Options using ▼ or ▲. If value is set to:

• “NORMAL” means regeneration will occur at the preset time;

• “on O” means regeneration will occur immediately when the volume capacity reaches 0 (zero); or

• “NORMAL + on 0” means regeneration will occur at one of the following:

— the preset time when the volume capacity falls below the reserve or the specifi ed number of

days between regenerations is reached whichever comes fi rst;

or

— immediately after 10 minutes of no water usage when the volume capacity reaches 0 (zero).

“NORMAL” is the default if Step 4CS is set to ALTA or ALTB, and “NORMAL + on 0” is not

available.

This step will not appear if Step 7F is set to “oFF”.

See Setting Options Table for more detail. Press NEXT to exit OEM Filter System Setup. Press

REGEN to return to previous step.

Page 16

Page 16 CI Man u al

Installer Display Settings

STEP 1I

STEP 2I

STEP 3I

STEP 4I

STEP 1I - Press NEXT and ▲ simultaneously for 3 seconds.

STEP 2I – Hardness: Set the amount of infl uent hardness using ▼ or ▲. This display

will show “–nA–” if “FILTER” is selected in Step 2F OR if “oFF” or a number

was selected in Step 8S. Press NEXT to go to step 3I. Press REGEN to exit Installer

Display Settings.

Units

Available

PPM

FH

dH

STEP 3I – Hardness 2: If using a mixing valve, set the amount of effl uent hardness using ▼ or ▲.

Range of available values may vary depending on system capacity selected and hardness selected in

Step 2I. This display will show “-nA-” if “FILTER” is selected in Step 2F OR if -nA- was selected

in Step 5CS OR “oFF” or a number was selected in Step 8S. Press NEXT to go to Step 4I. Press

REGEN to return to previous step.

STEP 4I – Day Override: When volume capacity is set to “oFF”, sets the number of days between

regenerations. When volume capacity is set to AUTO or to a number, sets the maximum number of

days between regenerations. If value set to “oFF”, regeneration initiation is based solely on volume

used. If value is set as a number (allowable range from 1 to 28) a regeneration initiation will be

called for on that day even if suffi cient volume of water were not used to call for a regeneration. Set

Day Override using ▼ or ▲:

• number of days between regeneration (1 to 28); or

• “oFF”.

See Setting Options Table for more detail on setup. Press NEXT to go to step 5I. Press REGEN to

return to previous step.

RETURN TO

NORMAL MODE

STEP 5I

STEP 6I

STEP 5I – Next Regeneration Time (hour): Set the hour of day for regeneration using ▼ or ▲

buttons. The default time is 2:00. This display will show “REGEN on 0 m3” if “on 0” is selected in

Set Regeneration Time Option in OEM Softener System Setup or OEM Filter System Setup. Press

NEXT to go to step 6I. Press REGEN to return to previous step.

STEP 6I – Next Regeneration Time (minutes): Set the minutes of day for regeneration

using ▼ or ▲. This display will not be shown if “on 0” is selected in Set Regeneration

Time Option in OEM Softener System Setup or OEM Filter System Setup. Press

NEXT to exit Installer Display Settings. Press REGEN to return to previous

step.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for three

seconds. The system will begin to regenerate immediately. The control valve may be stepped through

the various regeneration cycles by pressing the “REGEN” button.

Page 17

CI Man u al Page 17

User Display Settings

General Operation

When the system is operating, one of fi ve displays may be

shown. Pressing NEXT will alternate between the displays. One

of the displays is always the current time of day. The second

display is one of the following: days remaining or volume

remaining. Days remaining is the number of days left before the

system goes through a regeneration cycle. Capacity remaining

is the cubic meters that will be treated before the system goes

through a regeneration cycle. The third display shows the current

treated water fl ow rate through the system. If 1.0 is selected

in Step 2CS, an “A” in front of the fl ow rate indicates that the

tank with the control valve on it is in service. If “b” is displayed,

the tank with the in/out head is in service. The fourth display

will show either dP or hold if the dP switch is closed. The fi fth

display shows the kg of salt remaining or fl ashes “SALT” fi ll

when the calculated kg of salt falls below a safety level. The fi fth

display will not appear if the valve is a WS2, set up as a fi lter or

if the Set Low Salt Warning is set to off (see last step in OEM

Softener System Setup). The user can scroll between the displays

as desired.

If the system has called for a regeneration that will occur at the

preset time of regeneration, the words REGEN TODAY will

appear on the display.

If a water meter is installed, the word “Softening” or “Filtering”

fl ashes on the display when water is being treated (i.e. water is

fl owing through the system).

or

REGEN TODAY will

Flash if a regeneration

is expected “Tonight.”

In Alternator Systems when a unit is waiting to initiate the fi rst cycle step of regeneration,

“REGEN PndG” is displayed.

“STbY” is displayed in Alternator Systems when a valve is in Standby state.

“REGEN PndG FILL RINSE” is displayed whenever a zero-capacity tank has transferred to

an off-line state and is currently waiting to initiate the second portion of a regeneration cycle.

Viewed only when Delayed Rinse and Fill is set to ON.

Page 18

Page 18 CI Man u al

Regeneration Mode

Typically a system is set to regenerate at a time of low water usage. An example of a time with

low water usage is when a household is asleep. If there is a demand for water when the system is

regenerating, untreated water will be used.

When the system begins to regenerate, the display will change to include information about the step of the regeneration process

and the time remaining for that step to be completed. The system runs through the steps automatically and will reset itself to

provide treated water when the regeneration has been completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner than when the

system calls for it, usually referred to as manual regeneration. There may

be a period of heavy water usage because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regeneration

time, when the regeneration time option is set to “NORMAL” or “NORMAL + on 0”, press and release “REGEN”. The words

“REGEN TODAY” will fl ash on the display to indicate that the system will regenerate at the preset delayed regeneration time. If

you pressed the “REGEN” button in error, pressing the button again will cancel the request. Note: If the regeneration time option

is set to “on 0” there is no set delayed regeneration time so “REGEN TODAY” will not activate if “REGEN” button is pressed.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

REGEN TODAY will be

displayed if a regeneration

is expected “Tonight.”

Note: For softeners, if brine tank does not contain salt, fi ll with salt and wait at least two hours before regenerating.

Set Time of Day

The user can also set the time of day. Time of day should only need to be set after power outages lasting more than 24 hours, if

the battery has been depleted and a power outage occurs or when daylight saving time begins or ends. If a power outage lasting

more than 24 hours occurs, the time of day will fl ash on and off which indicates the time of day should be reset. If a power outage

lasts less then 24 hours and the time of day fl ashes on and off, the time of day should be reset and the non rechargeable battery

replaced.

STEP 1U

STEP 2U

STEP 1U – Press SET CLOCK.

STEP 2U - Current Time (hour): Set the hour of the day using ▼ or ▲. Press NEXT to go to step

3U.

STEP 3U

STEP 3U - Current Time (minutes): Set the minutes of the day using ▼ or ▲. Press NEXT to exit

Set Clock. Press REGEN to return to previous step.

RETURN TO NORMAL MODE

Page 19

CI Man u al Page 19

Salt Remaining or Adding Salt (not available for WS2 valves)

If the Low Salt Warning was activated in the last step of OEM Softener System Setup the following screens will be viewed in the

User Display.

Note: The salt used per regeneration setting can be set in increments of 0.05 Kg, but the Kg REMAINING screen will round up or

down to the closest whole number.

Once the salt remaining has gone below the set point the display will automatically fl ash Salt Fill.

When adding salt to the brine tank (if the salt remaining feature is activated) the following steps must be completed:

STEP 1US

STEP 2US

STEP 3US

STEP 4US

Step 1US – Press the NEXT button until SALT appears in the display. It does not matter if the SALT

display alternates with the Kg REMAINING display.

Step 2US – Press SET CLOCK.

Step 3US – Set Kg REMAINING: Use ▼ or ▲ to adjust the Kg remaining in the brine tank.

NOTE: Estimate the Kg of salt in the brine tank and add it to the amount of salt added to the brine

tank. The example at the left would indicate 100 Kg of salt being added to a brine tank that has 20

Kg remaining.

Step 4US – Press SET CLOCK or NEXT to exit Adding Salt.

RETURN TO NORMAL MODE

Power Loss

If the power goes out, the system will keep time for 24 hours or until the battery is depleted. If a power

outage of more than 24 hours occurs, the time of day will fl ash on and off which indicates the time of

day should be reset. The system will remember the rest. If a power outage lasts less then 24 hours and

the time of day fl ashes on and off, the time of day should be reset and the non rechargeable battery

replaced.

Error Message

If the word “ERROR” and a number are alternately fl ashing on the display contact the OEM for help.

This indicates that the valve was not able to function properly.

Page 20

Page 20 CI Man u al

Diagnostics

STEP 1D

STEP 2D

STEP 3D

STEP 4D

STEP 1D – Press ▲ and ▼ simultaneously for three seconds. If screen in step 2D does not appear

in 5 seconds the lock on the valve is activated. To unlock press ▼, NEXT, ▲, and SET CLOCK in

sequence, then press ▲ and ▼ simultaneously for 3 seconds.

STEP 2D

– Days, since last regeneration: This display shows the days since the last regeneration

occurred. Press NEXT to go to Step 3D. Press REGEN to exit Diagnostics.

STEP 3D – Volume, since last regeneration: This display shows the volume of water that has been

treated since the last regeneration. This display will equal zero if a water meter is not installed. Press

NEXT to go to Step 4D. Press REGEN to return to previous step.

STEP 4D – Volume, reserve capacity used for last 7 days: If the

valve is set up as a softener, a meter is installed and Set Volume

Capacity is set to “Auto,” this display shows 0 day (for today) and

fl ashes the reserve capacity. Pressing ▲ will show day 1 (which

would be yesterday) and fl ashes the reserve capacity used. Pressing

▲ again will show day 2 (the day before yesterday) and the reserve capacity. Keep pressing ▲ to

show the capacity for days 3, 4, 5 and 6. ▼ can be pressed to move backwards in the day series.

Display does not appear if 1.0 is selected in Step 2CS. Press NEXT at any time to go to Step 5D.

Press REGEN to return to previous step.

STEP 5D

STEP 6D

STEP 5D - Volume, 63-day usage history: This display shows day

1 (for yesterday) and fl ashes the volume of water treated yesterday.

Pressing ▲ will show day 2 (which would be the day before

yesterday) and fl ashes the volume of water treated on that day.

Continue to press ▲ to show the maximum volume of water treated

for the last 63 days. If a regeneration occured on the day the word

“REGEN” will also be displayed. This display will show dashes if

a water meter is not installed. Press NEXT at any time to go to Step 6D. Press REGEN to return to

previous step.

STEP 6D – Twin Tank Valve Transfer History only displays when

1.0 was selected in Step 2CS. Use ▲ or ▼ to scroll through the last

10 tank transfers.

The fi rst position in the display ranges from 0 to 9 with the lowest number being the most recent

transfer. The second position in the display will be either “A” or “b”. If “A” then the tank with the

valve on it was in service, if “b” the tank with the in/out head on it was in service. The next three

digits represent the number of hours ago that the transfer occurred. The display alternates with the

volume that was treated before the tank transferred. Press NEXT at any time to go to Step 7D. Press

REGEN to return to previous step.

Page 21

CI Man u al Page 21

STEP 7D

STEP 7D – Flow rate, maximum last seven days: The maximum fl ow rate in liters per minute that

occurred in the last seven days will be displayed. This display will equal zero if a water meter is not

installed. Press NEXT to go to Step 8D. Press REGEN to return to previous step.

STEP 8D

STEP 8D – MAV Drive History in the direction of extended piston

rod position. Display will not be shown if 1.0

Step 2CS and OFF is selected in Step 4CS. If the display does

appear up to a four digit number will appear after the “L” which

stands for latest and “A” which stands for average. Drive time is

measured in 1/100 of a second; i.e., a 17.10 second move is displayed as 1710. Press NEXT at any

time to go to Step 9D. Press REGEN to return to previous step.

Press and hold ▲ and ▼ buttons for 3 seconds while in Step 8D to

reset the MAV drive history in both the retracted and extended piston

rod position. To view the old MAV drive history data for retracted

and extended rod position press and hold SET CLOCK and ▲ while

in Step 8D. Press NEXT to advance display to the old MAV drive

history.

STEP 9D

STEP 9D – MAV Drive History in the direction of retracted piston

rod position. Display will not be shown if 1.0 is not selected in Step

2CS and OFF is selected in Step 4CS. If the display does appear,

up to a four digit number will appear after the “L” which stands for

latest and “A” which stands for average. Drive time is measured in

1/100 of a second; i.e., a 17.15 second move is displayed as 1715. Press and hold ▲ and ▼ for 3

seconds while in Step 9D to reset the MAV drive history in both the extended and retracted piston

RETURN TO NORMAL MODE

rod position. To view the old MAV drive history data see Step 8D. Press the NEXT button at any

time exit Diagnostics. Press REGEN to return to previous step.

is not selected in

When desired, all programming and all information in Diagnostics may be reset to defaults when the valve is installed in a

new location. To reset to defaults, press NEXT and ▼ buttons simultaneously to go to the Softening/Filtering screen. Press

▲ and ▼ simultaneously to reset diagnostic values and all programming to defaults. Screen will return to User Display.

Page 22

Page 22 CI Man u al

Valve History

STEP 1VH

STEP 2VH

STEP 3VH

STEP 4VH

STEP 1VH – Press ▲ and ▼ simultaneously for three seconds and release. Then press ▲ and ▼

simultaneously and release. If screen in step 2VH does not appear in 5 seconds the lock on the valve

is activated. To unlock press ▼, NEXT, ▲, and SET CLOCK in sequence, then press ▲ and ▼

simultaneously for 3 seconds and release. Then press ▲ and ▼ simultaneously and release.

STEP 2VH3 – Software version: This display shows the software version of the valve. Press the

NEXT button to go to Step3VH. Press REGEN to exit the valve history.

STEP 3VH – Days, total since start-up: This display shows the total days since startup. Press the

NEXT button to go to Step 4VH. Press REGEN to return to previous step.

STEP 4VH – Regenerations, total number since start-up: This display shows the total number of

regenerations that have occurred since startup. Press the NEXT button to go to Step 5VH. Press

REGEN to return to previous step.

STEP 5VH

STEP 5VH – Volume, total used since start-up: This display shows the total volume of water treated

since startup. This display will equal zero if a water meter is not installed. Press the NEXT button to

go to Step 6VH. Press REGEN to return to previous step.

STEP 6VH

STEP 6VH – Error Log: This display shows a history of the last 10 errors generated by the control

during operation. Press the ▲ or ▼ buttons to view each recorded error. Press the next button to exit

Valve History. Press REGEN to return to previous step.

RETURN TO NORMAL MODE

3

Values in steps 2VH through 6VH cannot be reset.

Page 23

CI Man u al Page 23

Revision History:

4/13/2012

PAGE 4:

V3186 WS1 AC ADAPTER 120V-12V

12/18/2012

PAGE 4:

4 V3108CI-05BOARD WS1 THRU2L/2 CI PCB XMEGA REPL 1

Added new board drawing

PAGE 6:

Revised Step 2CS, 3CS and drawings

PAGE 7:

Revised Step 4CS

PAGE 10:

Revised Step 6CS, added Step 12CS

PAGE 11:

Revised Cycle Options table, Step 6S

PAGE 12:

Revised Step 7S, 8S, 9S and 10S, drawing for 10S

PAGE 13:

Revised Setting Options Table

PAGE 14:

Revised Step 6F

PAGE 15:

Revised Step 8F

PAGE 16:

Revised Step 2I

PAGE 18:

Revised Regeneration Mode display

PAGE 19:

Revised Error Mode display

PAGE 20:

Revised Step 4D

Added Step 6D

PAGE 21:

Added Step 7D, 8D and 9D

PAGE 22:

Added Step 2VH

Revised Step 6VH

Page 24

Page 24 CI Man u al

1/23/2013

PAGE 9:

dPdEL – Revisions

PAGE 13:

2

Reserve Capacity estimate is based on history of water usage. Reserve Capacity estimate is not available with

alternator systems or Twin Tank Valve.

PAGE 20:

STEP 5D - revised drawing

PAGE 21:

STEP 8D – MAV Drive History in the direction of extended...

STEP 9D – MAV Drive History in the direction of retracted...

4/9/2013

PAGE 5:

For Valve Type 1.0T, press and hold SET and ▲ for about 3 seconds to initiate an exchange of the tank in Service without cycling

the regeneration valve. After tank switch, days remaining and capacity remaining status is retained for each tank until the next

regeneration.

Form No. V3435CI – 4/9/2013 U.S. Patents: 6,402,944 • 6,444,127 • 6,776,901

Loading...

Loading...