Water Specialist 2H

Control Valve Manual

Page 2 WS2H Control Valve Manual

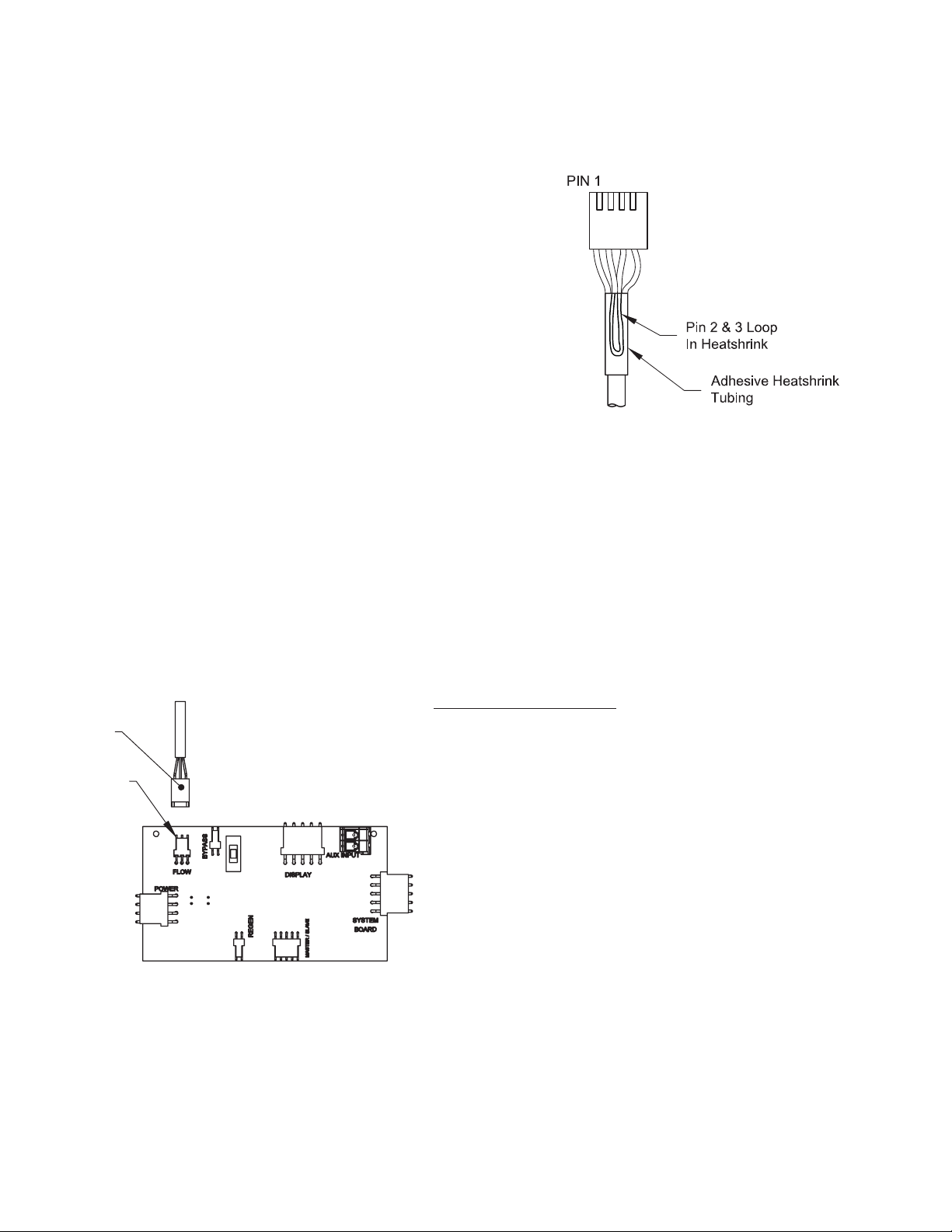

AC Adapter for European Use

1. 220-240 VAC 50Hz input, 24.0 VAC 750mA output.

2. Cable should be one unshielded pair of 22AWG, UV resistant

UL2464 compliant wire.

3. Connector details:

a. Terminate end with one Molex white housing,

P/N 09-50-8043 and four Molex pins, P/N 08-50-0108.

b. Pin 1 = 24.0 VAC White

Pin 2 = Jumper to Pin 3

Pin 3 = Jumper to Pin 2

Pin 4 = 24.0 VAC Black

Molex

Housing

Pin 1

Custom Meter Wiring:

1) Terminate end with a Molex series 2695 housing, part

number 22-01-3037 and (3) Molex series 41572 (or

40445) pins, part number 08-65-0805 (or 97-00-44).

2) Auxilliary meter must be able to operate on 5VDC

Pin 1 = +5VDC,

Pin 2 (Center) = Signal

Pin 3 = Ground

3) Acceptable pulse input is .1 – 999 pulses/gallon, or

.4 –519 pulses / liter.

WS2H Control Valve Manual Page 3

g

g

Separate

Relay 2 Output

Dry Contacts

Motorized Drive Operation

Viewing the piston rod through the clear dome is a visual indicator of the

drives current positon. On the WS2 motorized bypass drive viewing the

rod indicates that the unit is in service. Viewing the rod as sho wn on the

MAV indicates that the common port is currently connected to the “B”

port. If the rod is not visible the unit is offline in the case of a bypass, or

connected to the “A” port of a MAV. This drive logic is reversible to meet

specific plumbing applications by reversing the polarity of the drive

motor wirin

harness as shown below.

Source Inlet

Motor Drive

Non

Functional

Relay 1 Output

Dry Contacts

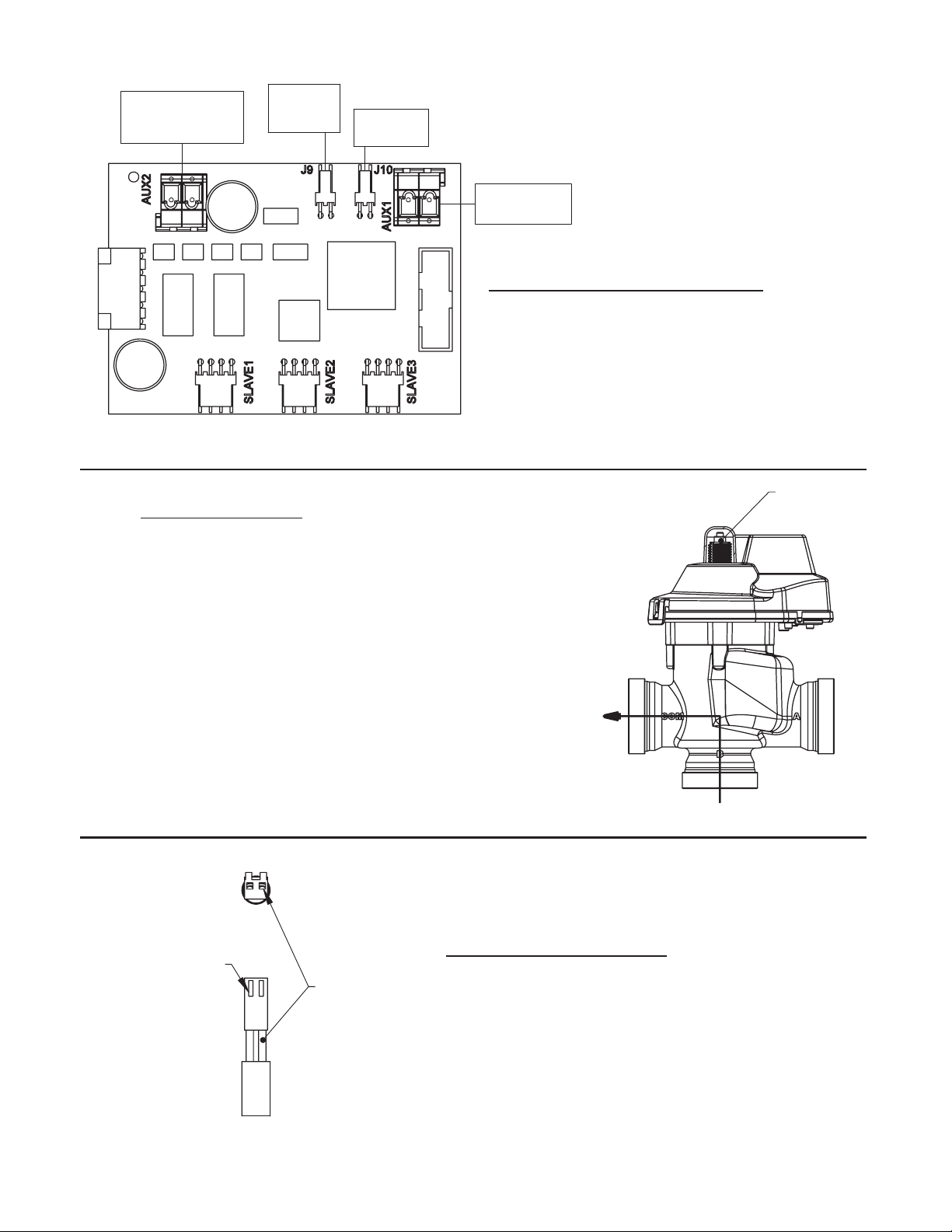

Optional System Board, Required For

Relay Output And Separate Source Inlet

1) Relay outputs 1 & 2 are N.O. SPST dry contacts.

2) Maximum power through relays to be:

3) Separate source inlet drives require connection to a

a. 3A, 30 VDC

1A

1A

b. 3A, 30 VAC

V3063 or V3063BSPT motorized alternating valve

.

(MAV)

Piston Rod

Is Visible

Hold Locking Tab

While Pulling On Wire

Factory Wired

As White Wire

"Com" Port

Flow Path

Reversing Motorized Drive Direction

WS2 motorized bypass and MAV drives are factory wired with the white

wire on the right when viewing the wiring harness as shown, reversing

the wires reverses the logic of the drive. The wires can be removed

from the housing by holding down the locking tab in the small window

while applying light pressure to the wire, being careful not to disengage

the wire from its crimped on connector. The wires can then be reinserted, bein

sure the locking tab re-engages in the window.

"B" Port

"A" Port

Page 4 WS2H Control Valve Manual

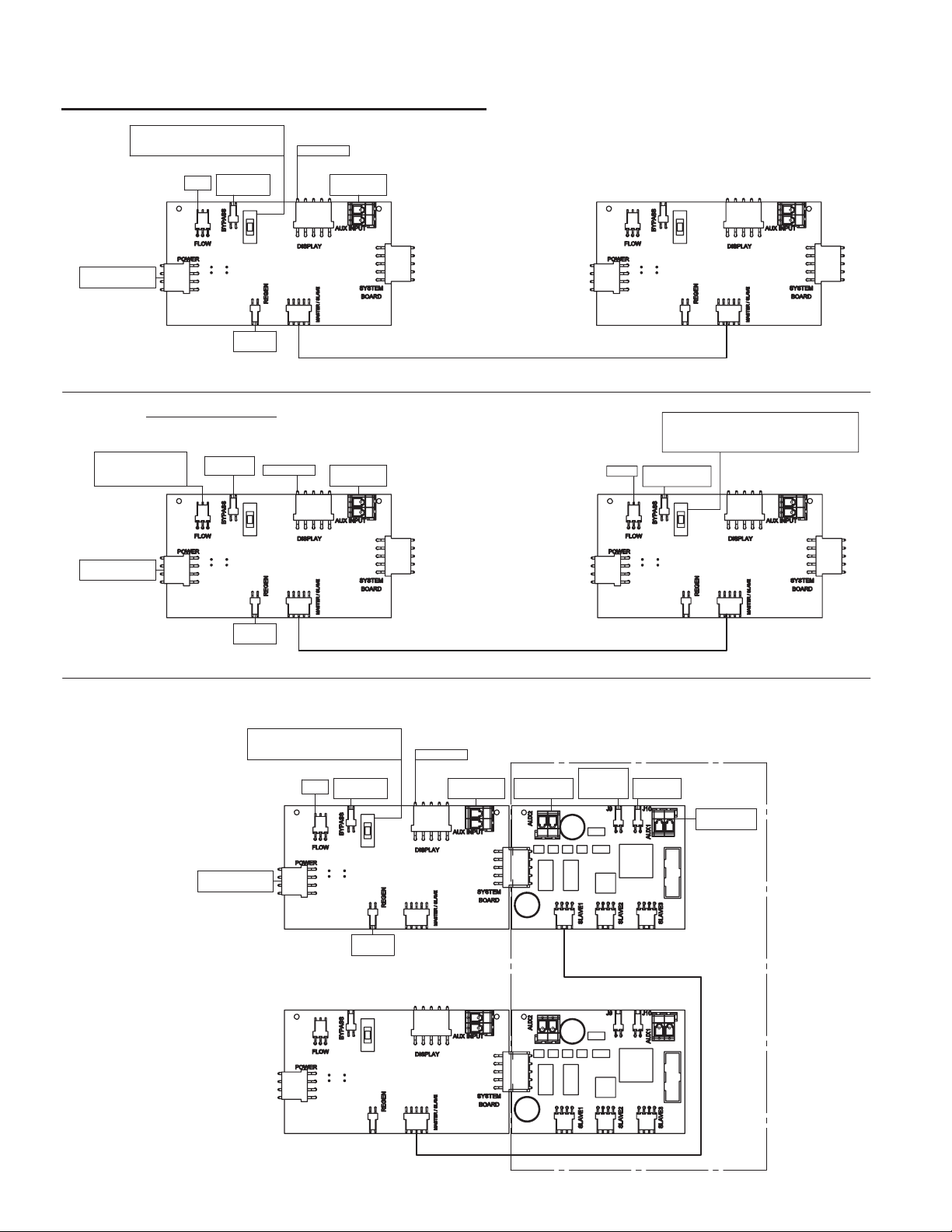

Wiring Diagram Examples, 2 Unit Systems

Motor Driven Bypass Manual Over Ride

Place in center for normal operation.

Up forces online, down forces offline

Transformer Power

(24 VAC)

Meter

Motor Driven

Bypass

Display Pod

Auxilliray (DP)

Switch Input

Two units, no system boards.

All Wiring Connections

Apply To Both Units

Unit 1 Unit 2

Simple Alternator

One Alternating Valve Replaces

Both Units Motorized Bypass

Meter; No Connection

If Both Units Are

Sharing A Single Meter

Transformer Power

(24 VAC)

Unit 1, Plumbed To

"A" Port On MAV

Main Drive

No

Connection

Main Drive

Motor

Motor

Display Pod

Auxilliray (DP)

Switch Input

Communication Cable

All Wiring Connections Apply To

Both Units. Connections For

Shared Meter And A MAV

Are Made On Unit 2 Only

Communication Cable

Motorized Alternating Valve Manual Over Ride

Up forces unit 2 online, down forces unit 1 online

Meter Motorized

Alternating Valve

Place in center for normal operation.

Unit 2, Plumbed To

Two unit system, with optional system boards

Motor Driven Bypass Manual Over Ride

Place in center for normal operation.

Up forces online, down forces offline

Motor Driven

Meter

Bypass

Display Pod

Auxilliray (DP)

for relay outputs and separate source inlet

Separate

Switch Input

Relay 2 Output

Dry Contacts

Source Inlet

Motor Drive

Non

Functional

Relay 1 Output

Dry Contacts

"B" Port On MAV

All Wiring Connections

Apply To Both Units

Transformer Power

(24 VAC)

Unit 1

Unit 2

Main Drive

Motor

Input On Slaves Must

Use Master / Slave Port

Communication Cable

WS2H Control Valve Manual Page 5

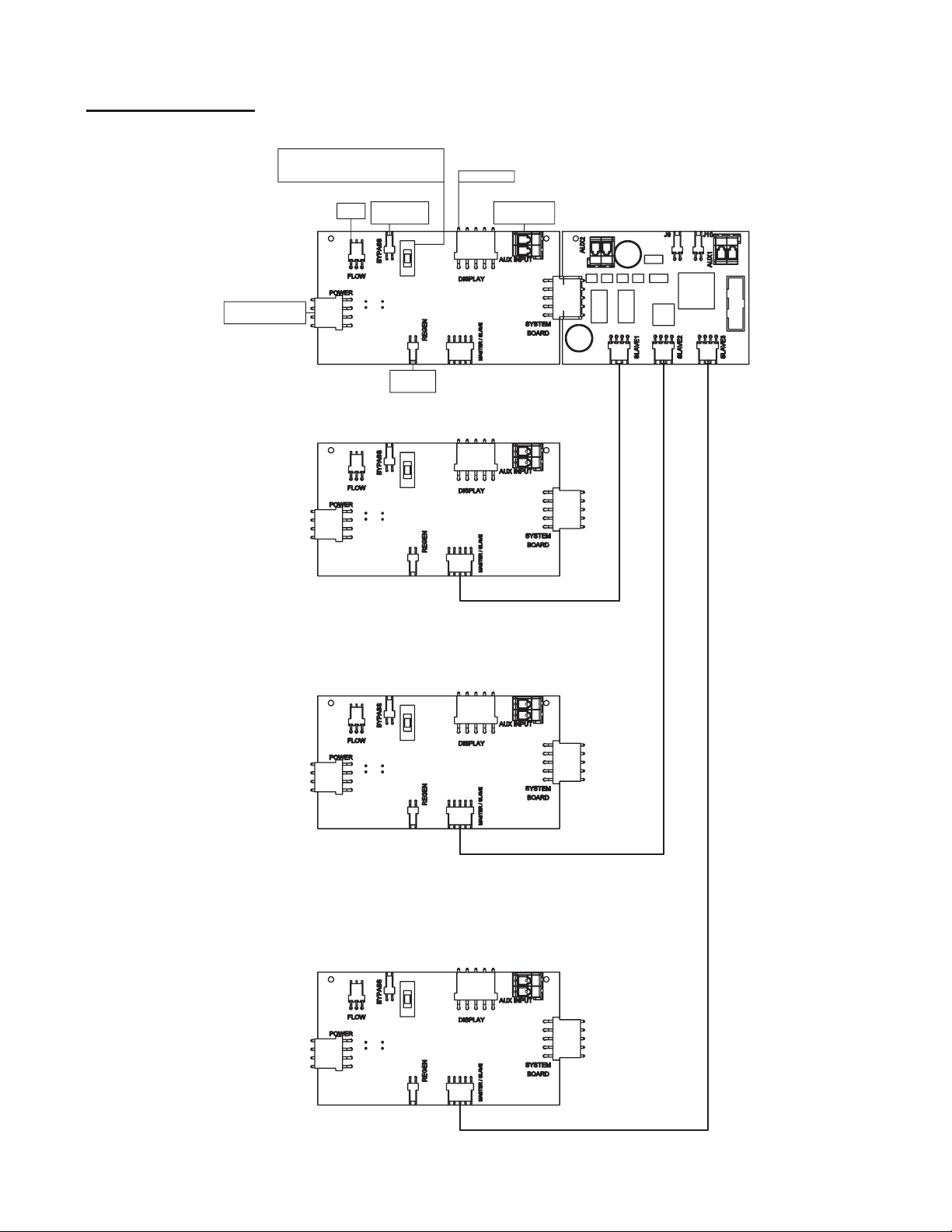

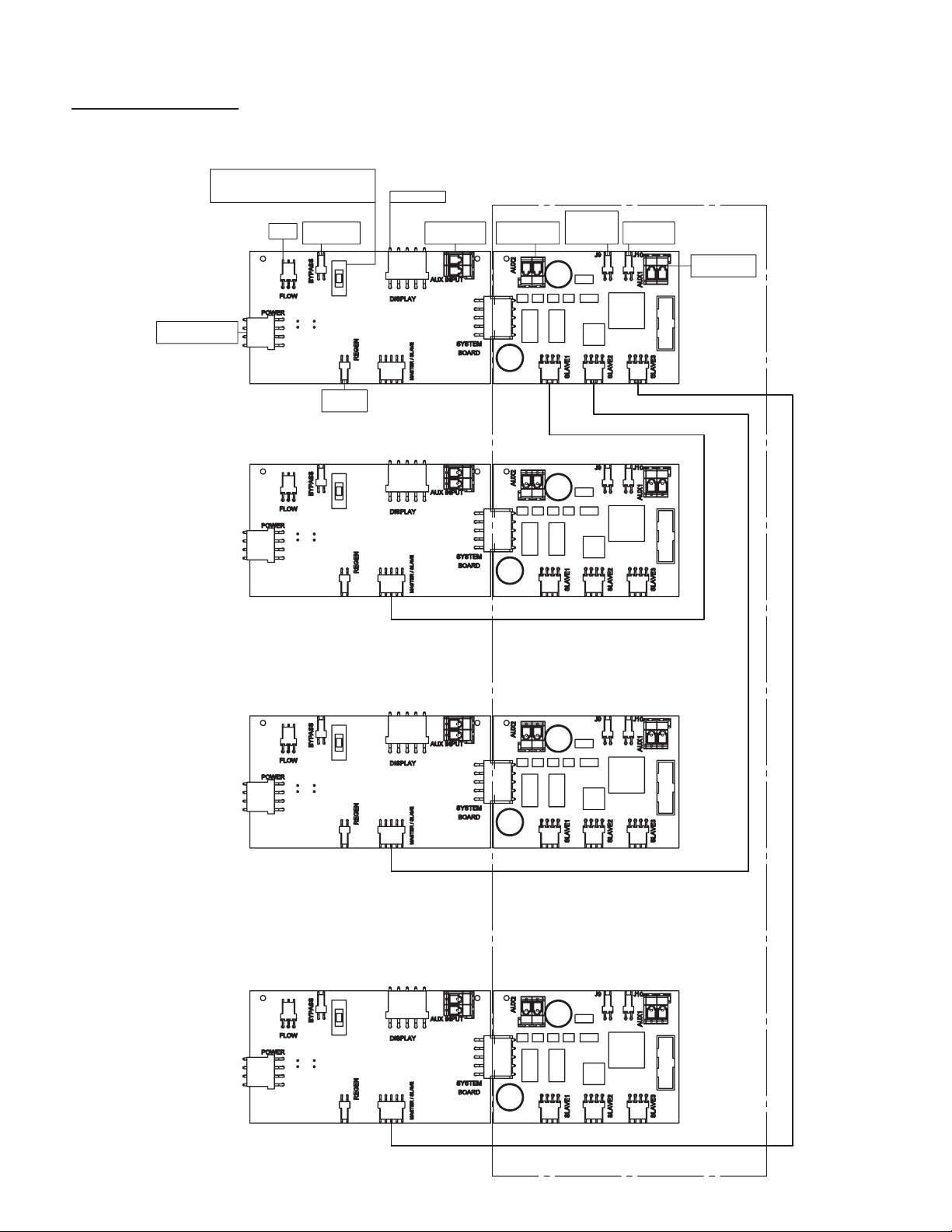

Wiring Diagrams

Transformer Power

Unit 1

All Wiring Connections

Apply To All Units

Motor Driven Bypass Manual Over Ride

Place in center for normal operation.

Up forces online, down forces offline

Meter

(24 VAC)

Motor Driven

Bypass

Main Drive

Motor

3 & 4 unit systems with no optional system boards

(4 unit shown)

Display Pod

Auxilliray (DP)

Switch Input

Communication

Cables

Unit 2

Unit 3

Unit 4

Page 6 WS2H Control Valve Manual

Wiring Diagrams

Motor Driven Bypass Manual Over Ride

Place in center for normal operation.

Up forces online, down forces offline

Transformer Power

(24 VAC)

Unit 1

All Wiring Connections

Apply To All Units

Meter

Motor Driven

Bypass

Main Drive

Motor

Display Pod

Auxilliray (DP)

Switch Input

3 & 4 unit systems with optional system boards

for relay outputs and separate source inlet

(4 unit shown)

Relay 2 Output

Dry Contacts

Separate

Source Inlet

Motor Drive

Non

Functional

Relay 1 Output

Dry Contacts

Communication

Cables

Unit 2

Unit 3

Input On Slaves Must

Use Master / Slave Port

Unit 4

WS2H Control Valve Manual Page 7

Page 8 WS2H Control Valve Manual

WS2H Control Valve Manual Page 9

Page 10 WS2H Control Valve Manual

WS2H Control Valve Manual Page 11

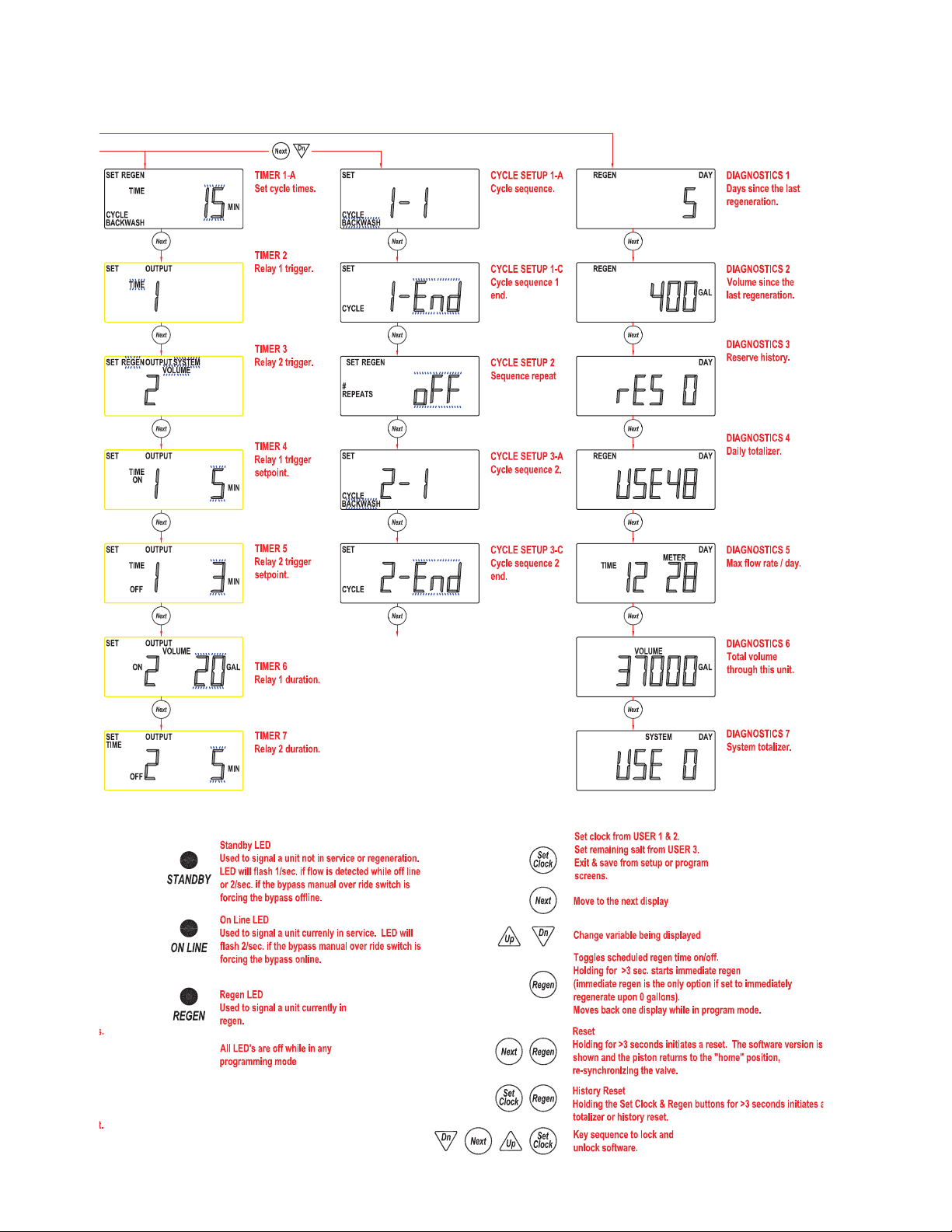

Typical User Screens

“REGEN TODAY” will

display when a regeneration

is scheduled, or fl ash for a

manually set regeneration.

“HOLD” or “START” REGEN

will fl ash in all user screens while

the auxiliary input is actuated.

USER 1

USER 1

Displays capacity remaining Does not

display if volumetric capacity is set to OFF.

Capacity remaining can be adjusted in 10 gallon

increments by holding the DOWN arrow for >3 seconds.

USER 2

USER 2

Displays days remaining Does not display if days

override is set to OFF.

Days remaining can be decremented one day at a

time by holding the DOWN arrow >3 seconds.

USER 3

USER 3

Displays time of day.

USER 4

USER 4

Displays the unit’s current fl ow rate.

USER 5

USER 6

USER 7

USER 5

Displays total unit volume since

install/reset Individually re-settable

using history reset sequence.

USER 6

Displays the current system fl ow rate

Does not display on single tank units.

USER 7

Displays total system volume since install/reset

Individually re-settable using history reset sequence

Does not display on single tank units.

User 1

Page 12 WS2H Control Valve Manual

Setting Time of Day

SET TIME

Accessed by pressing Set Clock while in the

User Screens. Use UP and DOWN arrows to

scroll hours. AM/PM alternates at midnight.

Return to

Normal Operation

UNIT COUNT ERROR

Error and the slave’s unit number will fl ash when it is

not detected. Pressing any button will return the user

to the #units set up screen to correct the value.

ERROR SCREEN

Error and its code alternate. The unit returns to home

and fl ashes its 3 LEDs. The unit continues to try and

function, but must be reset to correct the error screen.

Automatically toggles.

WS2H Control Valve Manual Page 13

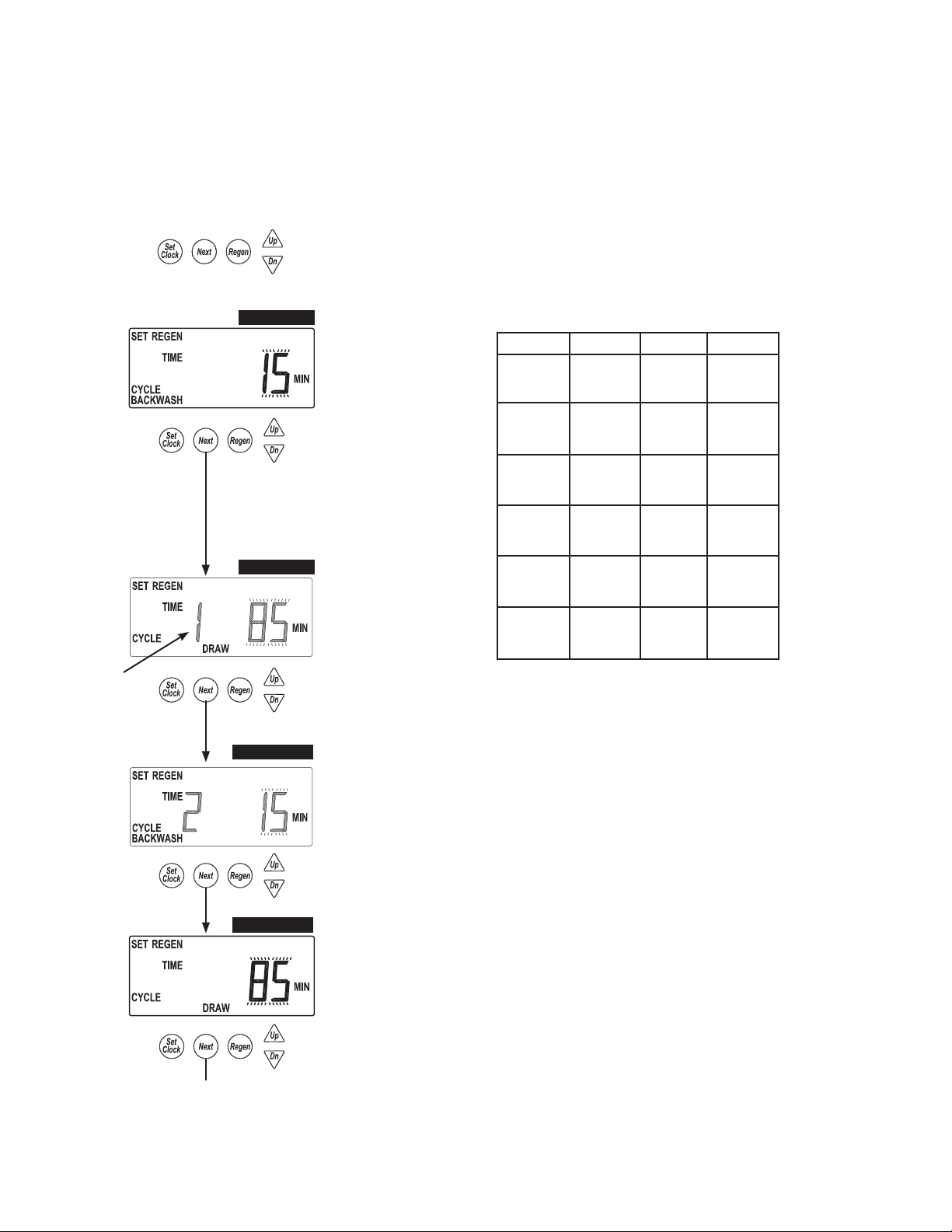

Installer Setup Screens

Accessed by pressing NEXT and

UP simultaneously for >3 seconds.

Set current day and regen days

when set as a 7 day time clock

or hybrid in System Setup 1.

INSTALLER 1

INSTALLER 2 INSTALLER 2

INSTALLER 3

Returns to normal operation after 5 minutes.

INSTALLER 1

Set volumetric capacity or OFF. OFF will not be an

option if the day control is set to OFF.

X1000 Indicator Illuminates At 10,000 Gallons

Units Range Increments

US

(GAL)

SI

(L)

INSTALLER 2

Set day override. 1-28 days between regenerations, or if set to

7 day time clock, see 7 day setup below. OFF will display if

selected in Day Control screen.

INSTALLER 3

Select time of regen. Use up and down arrows to scroll

hours. AM/PM alternates at midnight. “on0” will be

displayed on units with no time dependent regen control.

(“1” only shows if set for multiple regens.)

10-10,000

10,000-100.00 x 1000

100.00-999.00 x 1000

38-38,000

38,000-380.00 x 1000

380.00-3796.2 x 1000

10

100

1000

38

38

3800

Return To

Normal Operation.

INSTALLER 4

7 Day Option

INSTALLER 2

INSTALLER 2B

INSTALLER 2C

INSTALLER 4

Select time of regen. Use up and

down arrows to scroll minutes.

INSTALLER 5

INSTALLER 5

Select time of 2nd regen

(if confi gured as a multiple

regenerating unit.)

INSTALLER 2

7 day time clock option.

Set current day of the week:

1 = Sunday

2 = Monday

3 = Tuesday

4 = Wednesday

5 = Thursday

6 = Friday

7 = Saturday

INSTALLER 2B

Scroll through days 1-7 using the UP and DOWN arrows.

Pressing the Set Clock will toggle regen ON or OFF for

that day. (i.e., regen on Monday.)

INSTALLER 2C

(i.e., no regeneration on Saturday.)

Installer 3

Page 14 WS2H Control Valve Manual

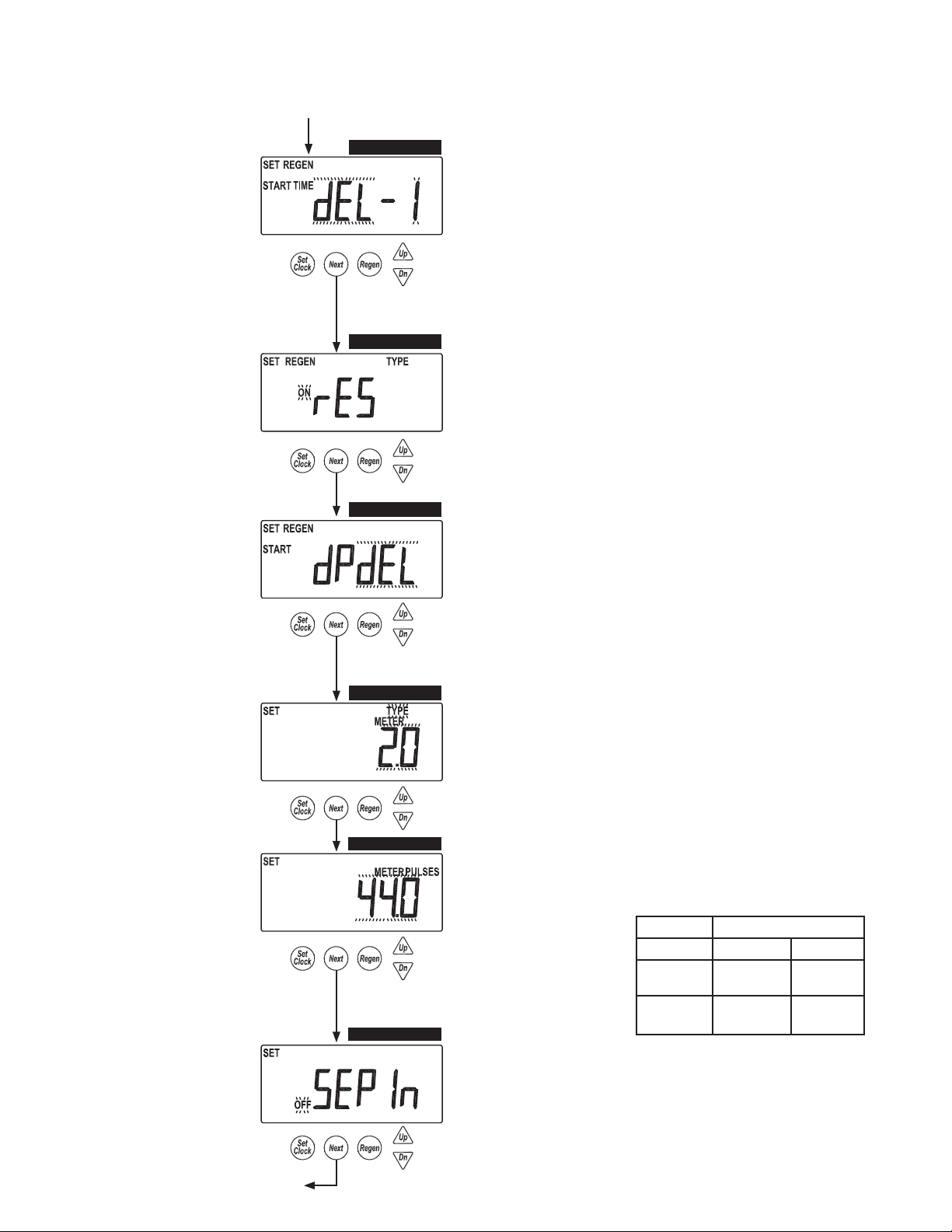

System Setup Screens

Returns to normal operation after 5 minutes

Accessed by pressing NEXT and DOWN

simultaneously for >3 seconds.

SYSTEM SETUP 1

SYSTEM SETUP 1

Select country.

US or SI.

This sets the use of a 12 or 24 hour clock

and the display of gallons or liters.

SYSTEM SETUP 2

SYSTEM SETUP 2

Select the total number of units, from 1-4, in a

system. This screen will only allow 1 or 2 if a

system board is not installed.

SYSTEM SETUP 3

SYSTEM SETUP 4

SYSTEM SETUP 5

SYSTEM SETUP 3

Select unit fl ow rate unit add point.

1. If set to 0, all units are online unless one is regenerating.

2. If greater than 0, the system acts as a stage by fl ow adding units as fl ow

capacity increases.

3. If set to ALT the system acts as an alternator

system, keeping one unit off line at all times.

The screen will not display if set to 1 unit.

SYSTEM SETUP 4

Single units have a selection of hard water bypass, no hard water bypass or relay operation.

When the units starts a regen, HbP will allow hard water bypass, noHbp and RELAY

will not allow hard water bypass. Systems will allow setting noHbP or RELAY & 2 unit

alternators have an additional selection of ALT-A. Setting noHbP requires a motor driven

bypass, ALT-A requires a motor driven alternator valve on the controlling unit and RELAY

relys on external valving for noHbP control.

SYSTEM SETUP 5

Select day control type.

Time clock 1-28 day; Time clock 7 day; or OFF.

When volumetric capacity is set, volume regeneration can

be combined with time clock control. OFF will not be an

option if volumetric capacity is OFF.

Units Range Increments

US

SI

(L)

0-500 1

0-1896 4

(GAL)

continued on Page 15

WS2H Control Valve Manual Page 15

System Setup Screens (continued)

SYSTEM SETUP 6

SYSTEM SETUP 7

SYSTEM SETUP 8

SYSTEM SETUP 6

Select regeneration type.

Delayed (dEL-1)

Delayed, 2 regenerations per day (dEL-2)

Delayed, 3 regenerations per day (dEL-3)

Delayed, 4 regenerations per day (dEL-4)

On 0

Delayed with multiple regenerations allowed per day would be

used either to reduce the reserve volume, or to accommodate a

small system relative to the treatment demand.

SYSTEM SETUP 7

Select reserve calculation ON or OFF.

OFF will schedule a regen when the volumetric

capacity reaches 0. This screen will not display

for “on0” units or systems.

SYSTEM SETUP 8

Set auxiliary initiated regen.

START TIME REGEN: regeneration will start immediately after 2 cumulative

minutes of switch closure.

START TIME REGEN dEL: regeneration will start at the delayed time after 2

cumulative minutes of switch closure.

START REGEN: regeneration will start immediately upon switch closure.

START REGEN dEL: regeneration will start at the delayed time upon switch closure.

HOLD REGEN: regeneration will not be allowed as long as there is switch closure.

SYSTEM SETUP 9

SYSTEM SETUP 9B

SYSTEM SETUP 10

SYSTEM SETUP 9

Select meter type or pulses.

2.0 meter (type)

1.5 meter (type)

System Pulses

SYSTEM SETUP 9B

Select meter type pulses.

Screen does not show if Pulses or System Pulses is not

selected in the previous screen.

Units Range Increments

US

(Pulse/Gal)

SI (Pulse/L)

0.1 - 30.0

30.0 - 999.0

0.4 - 114.0

114.0 - 519.4

SYSTEM SETUP 10

Separate source inlet. This screen will not

display if a system board is not installed.

Pulses/ Unit Flow

0.1

1.0

0.4

3.8

Return To

Normal Operation

Page 16 WS2H Control Valve Manual

Timer Screens

Returns to normal operation after 5 minutes.

Accessed by pressing NEXT and DOWN simultaneously

for >3 seconds, then by pressing NEXT and DOWN

simultaneously again for >3 seconds.

“1” is displayed if

set for more than

one sequence

TIMER 1-A

TIMER 1-B

TIMER 1-A2

TIMER 1-A

Select time of cycle 1.

A NEXT & DN reset from

this screen unlocks the

setup screens.

TIMER 1-B

Select time of cycle 2.

The following screens only show if the unit is

programmed for multiple regenerations in the

Cycle Setup 2 screen.

TIMER 1-A2

Select time of alternate regen, cycle 1.

Cycle Units Range Increments

Backwash Minutes

Draw Minutes

Slow Rinse Minutes

Rinse Minutes

Fill Minutes

Hold Minutes

1-30

30-95

1-30

30-100

100-180

1-30

30-95

1-30

30-95

0.1-10.0

10.0-30.0

30.0-99.0

1-30

30-100

100-480

1

5

1

5

10

1

5

1

5

0.1

0.2

1.0

0.1

2.0

10.0

TIMER 1-B2

TIMER 1-B2

Select time of alternate regen, cycle 2.

continued on Page 17

WS2H Control Valve Manual Page 17

Timer Screens (continued)

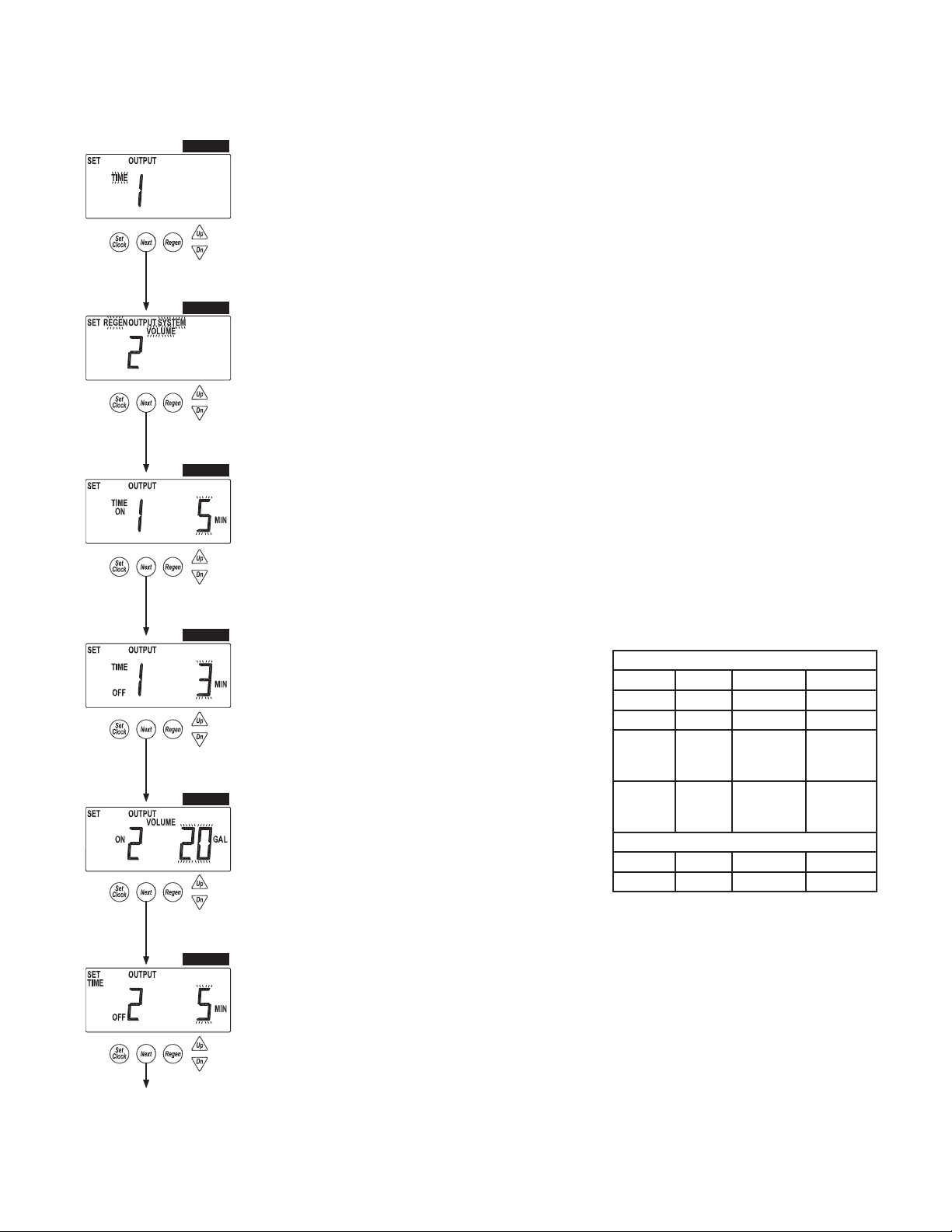

TIMER 2

TIMER 2

TIMER 2

Set output 1.

These settings will only be allowed with the system board installed.

Time: Relay is turned on after specifi ed time from the start of regen and is left on for a specifi ed time.

Cycle: Relay is turned on after the start of a specifi ed cycle and is left on for a specifi ed time.

Volume: Relay is turned on, during service fl ow only, every specifi ed number of volume units and is left on for a specifi ed time.

Volume & Regen: Relay is turned on every specifi ed number of volume units, and is left on for a specifi ed time.

STbY: Relay would be used to control external valving, closing for unit regeneration, or when it would be offl ine in system operation.

REGEN: Relay closes when the unit is in regen.

Err: Relay closes when the unit is in any error mode.

TIMER 3

TIMER 4

TIMER 5

TIMER 6

TIMER 3

Set output 2.

These settings will only be allowed with the system board installed.

Time: Relay is turned on after specifi ed time from the start of regen and is left on for a specifi ed time.

Cycle: Relay is turned on after the start of a specifi ed cycle and is left on for a specifi ed time.

Volume: Relay is turned on, during service fl ow only, every specifi ed number of volume units and is left on for a specifi ed time.

Volume & Regen: Relay is turned on every specifi ed number of volume units and is left on for a specifi ed time.

STbY: Relay would be used to control external valving, closing for unit regeneration, or when it would be offl ine in system operation.

REGEN: Relay closes when the unit is in regen.

Err: Relay closes when the unit is in any error mode.

TIMER 4

Select output 1, On trigger set point, per units previously selected.

This screen will not display if the unit does not have a system board, or if STbY was selected as the trigger.

Time: Time after the start of a regen before switch is closed.

Cycle: Select a cycle which will close output 1.

Volume: Volume of water interval during service between switch closures.

Timer 4 and 6 screens will not display if display if STbY, REGEN or Err are selected in TIMER 2 and TIMER 3.

TIMER 5

Select output 1 On duration before turning OFF. This screen will

not display if the unit does not have a system board.

TIMER 6

Select output 2, On trigger set point, per units previously selected.

This screen will not display if the unit does not have a system board, or if

STby was selected as the trigger

Time: Time after the start of a regen before switch is closed.

Cycle: Select a cycle which will close output 2.

Volume: Volume of water interval during service between switch closures.

Trigger Units Range Increments

Time Minutes :01-20:00 :01

Cycle Slow Rinse

Volume Gallons

Volume Liters

Trigger Units Range Increments

Time Minutes :01-20:00 :01

Relay Trigger Settings

1-200

200-1000

100-10000

1-760

760-13800

13800-38000

Relay Duration Settings

1

5

10

4

19

38

Return To

Normal Operation.

TIMER 7

TIMER 7

Select output 2 On duration before turning OFF.

This screen will not display if the unit does not have a

system board.

Page 18 WS2H Control Valve Manual

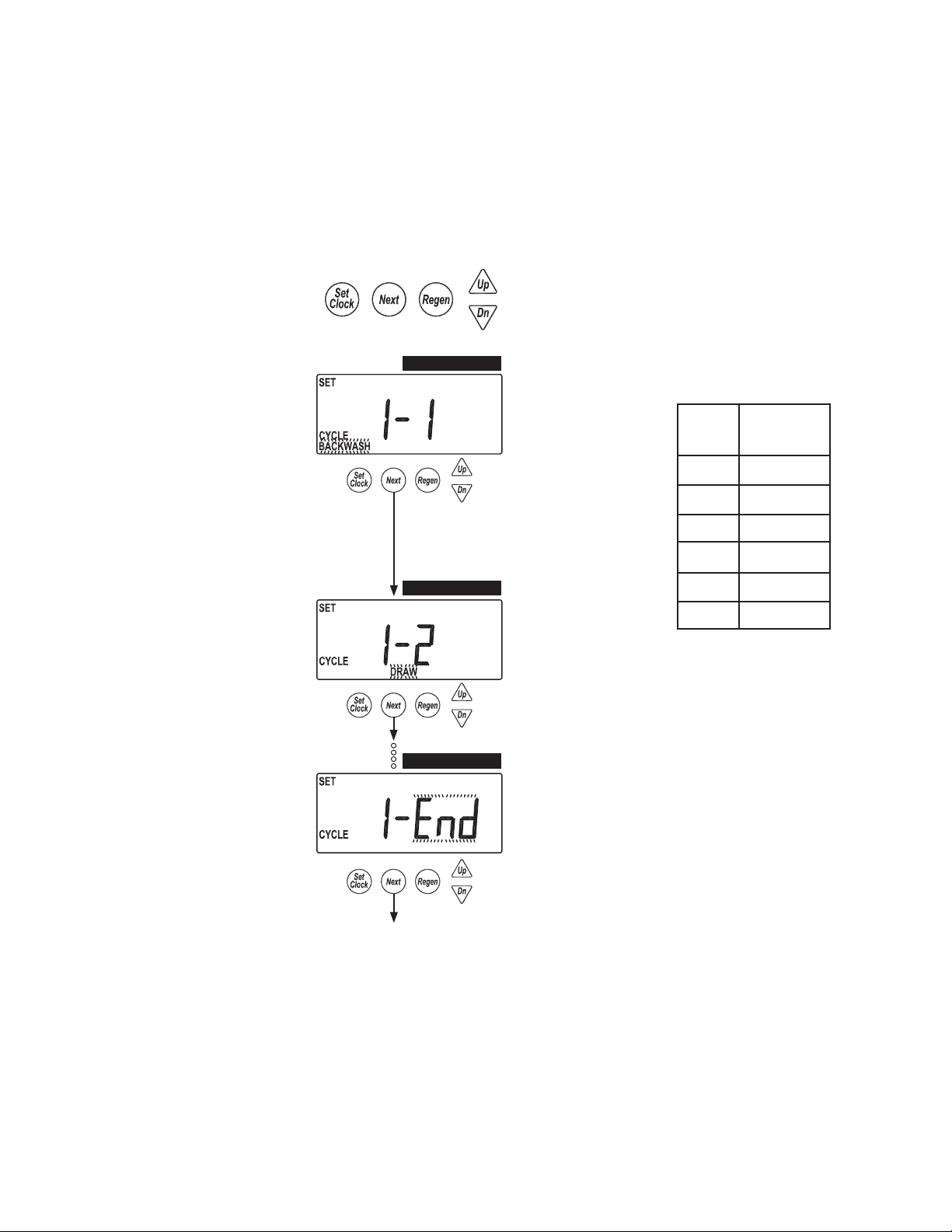

Cycle Setup Screens

Returns to normal operation after 5 minutes.

Accessed by pressing NEXT and DOWN simultaneously for >3 seconds,

then by pressing NEXT and DOWN simultaneously again for >3 seconds,

then by pressing NEXT and DOWN simultaneously for >3 seconds a third time.

CYCLE SETUP 1-A

CYCLE SETUP 1-A

Select fi rst cycle.

CYCLE SETUP 1-B

CYCLE SETUP 1-C

Cycle #

1 Backwash

2 Draw

3 2nd Backwash

4 Rinse

5 Fill

CYCLE SETUP 1-B

Select second cycle.

CYCLE SETUP 1-C

After cycles are confi gured, an END is added.

(9 cycles maximum.)

6 End

Cycle

Default

continued on Page 19

WS2H Control Valve Manual Page 19

Cycle Setup Screens (continued)

CYCLE SETUP 2

CYCLE SETUP 3-A

CYCLE SETUP 3-B

CYCLE SETUP 2

Select regeneration repeats, 1-10 or OFF.

Repeats regeneration cycle sequence 1 a selected number

of times before regenerating a single time with sequence 2.

The following screens only show if the unit is

programmed for multiple regenerations in the

previous screen.

CYCLE SETUP 3-A

Select fi rst cycle of “alternate”

regeneration sequence.

CYCLE SETUP 3-B

Select second cycle of ‘alternate’

regeneration sequence.

Return To

Normal Operation

CYCLE SETUP 3-C

CYCLE SETUP 3-C

After cycles are confi gured, an END is added.

(9 cycles maximum.)

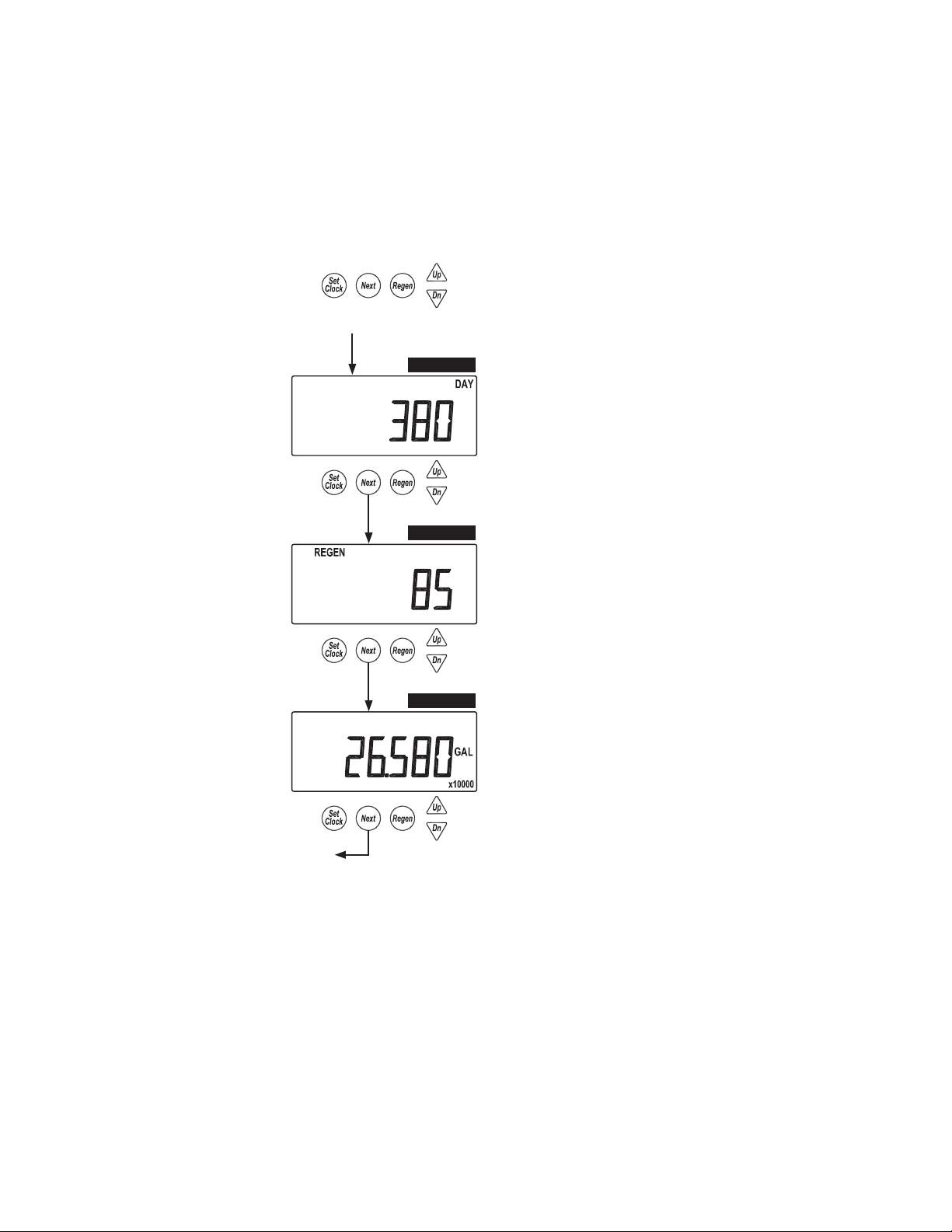

Page 20 WS2H Control Valve Manual

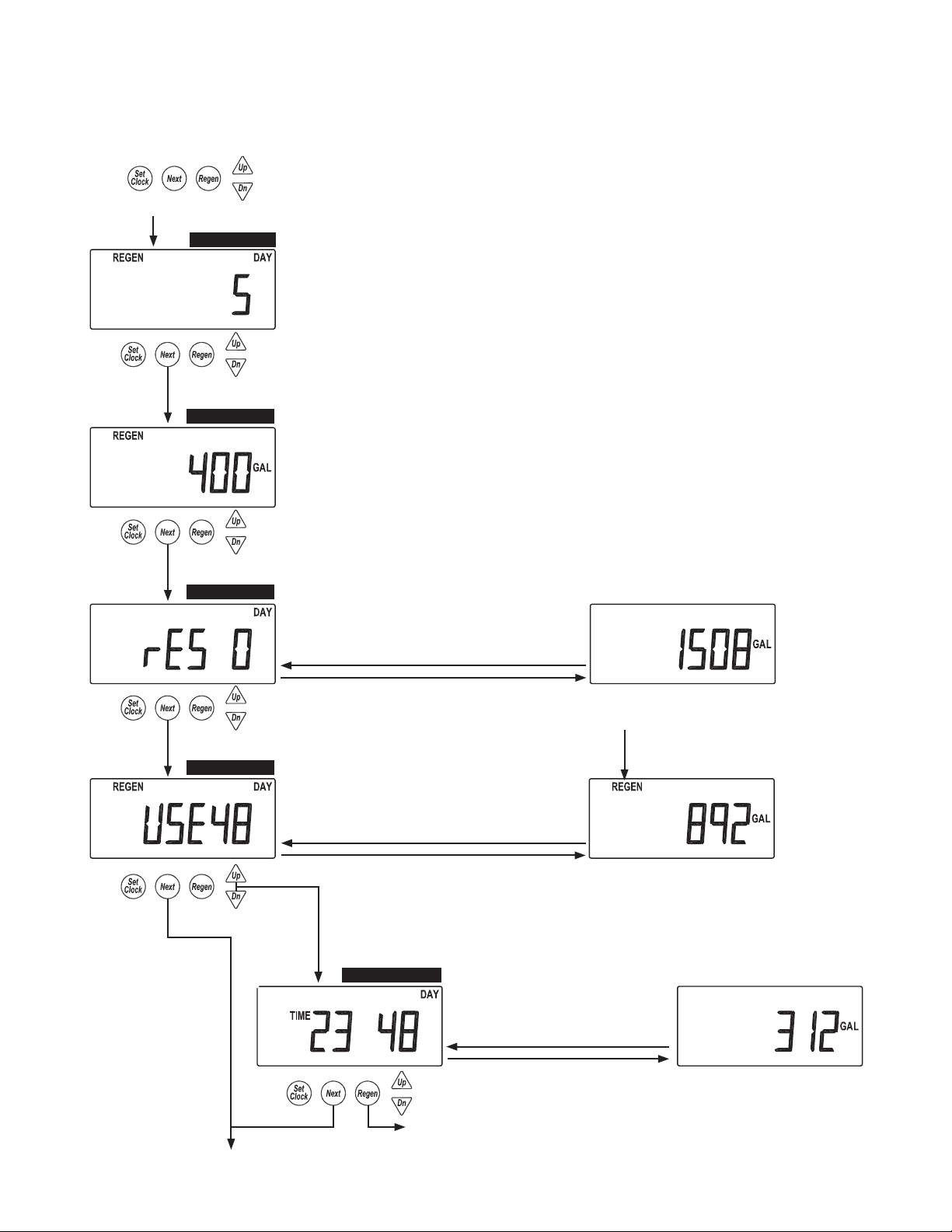

Diagnostic Screens

Accessed by pressing UP and DOWN

simultaneously for >3 seconds.

DIAGNOSTIC 1

DIAGNOSTIC 2

DIAGNOSTIC 3

Returns to normal operation after 5 minutes.

DIAGNOSTICS 1

Days since the last regeneration.

DIAGNOSTICS 2

Gallons or Liters x1000 since the last

regeneration.

DIAGNOSTICS 3

Reserve history. This screen only appears if valve

is set to calculate Reserve in System Setup 7.

Use arrows to select a day.

0 = Today

1 = Yesterday

6 = 6 days ago (max.)

All Diagnostic History screens are resettable

with the History Reset sequence while in the

Diagnostics1 screen. Holding the Set Clock

and Regen buttons for > 3 seconds initiates a

totalizer or history reset.

Reserve Value

DIAGNOSTIC 4

Automatically T oggles

DIAGNOSTICS 4

History of volume used.

Use arrows to select a day.

0 = Today

1 = Yesterday

63 = 63 days ago (max.)

Automatically T oggles

Simultaneously press

UP and DOWN.

DIAGNOSTIC 4-B

Diagnostic 4

REGEN will display if a

regeneration occurred that day.

DIAGNOSTICS 4-B

Hourly history of volume use. Use

the UP and DOWN arrow to select

the hours of the day from screen 4.

Automatically T oggles

Gallons Used

Volume used within the selected hour

continuned on Page 21

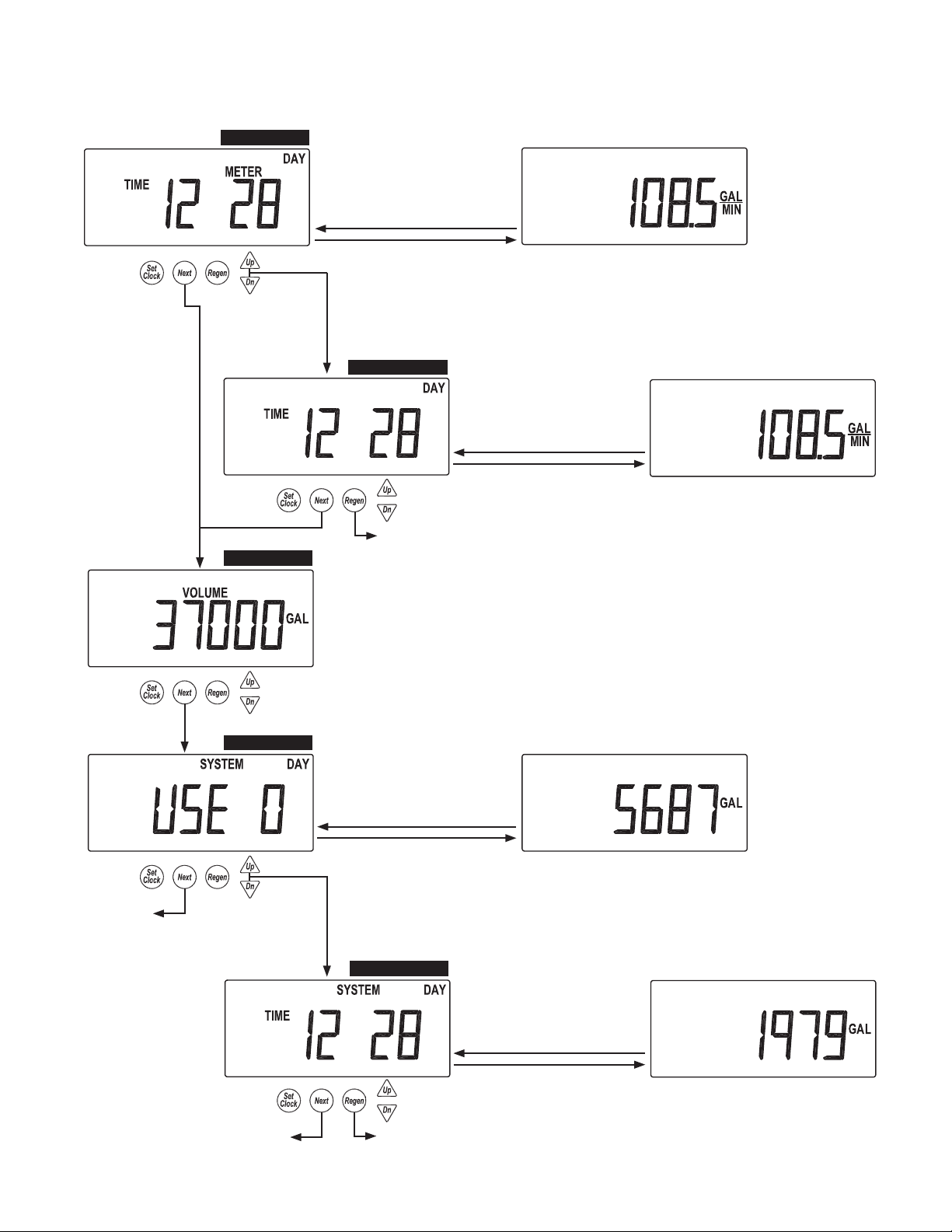

WS2H Control Valve Manual Page 21

Diagnostic Screens (continued)

DIAGNOSTIC 5

DIAGNOSTIC 6

DIAGNOSTICS 5

Maximum fl ow rate

for the last 28 days.

Automatically T oggles

Simultaneously press

UP and DOWN.

DIAGNOSTIC 5-B

Diagnostics 5

DIAGNOSTICS 6

Total volume through the unit.

Max fl ow rate of the day

DIAGNOSTICS 5-B

Hourly history of maximum

fl ow rate. Use the UP and

DOWN arrow to select the

hours of the day from screen 5.

Automatically T oggles

Max fl ow within the selected hour

Return To

Normal Operation

DIAGNOSTIC 7

Return To

Normal Operation

DIAGNOSTICS 7

System totalizer for the last

63 days. Only displays in a

master unit.

Automatically T oggles

Simultaneously press

UP and DOWN.

DIAGNOSTIC 7-B

Diagnostics 7

System use for that day

DIAGNOSTICS 7-B

Hourly system totalizer. Use

the UP and DOWN arrow to

select the hour of the day from

screen 7.

Automatically T oggles

Total system fl ow for the selected hour

Page 22 WS2H Control Valve Manual

Valve History

Returns to normal operation after 5 minutes.

Non-Resettable

Accessed by pressing UP and DOWN simultaneously

for >3 seconds, then by pressing UP and DOWN

simultaneously again for >3 seconds.

HISTORY 1

HISTORY 1

Total days since startup.

Time only accumulates while

the unit is plugged in.

Return To

Normal Operation

HISTORY 2

HISTORY 2

Total regenerations since startup.

HISTORY 3

HISTORY 3

Total volume since startup.

WS2H Control Valve Manual Page 23

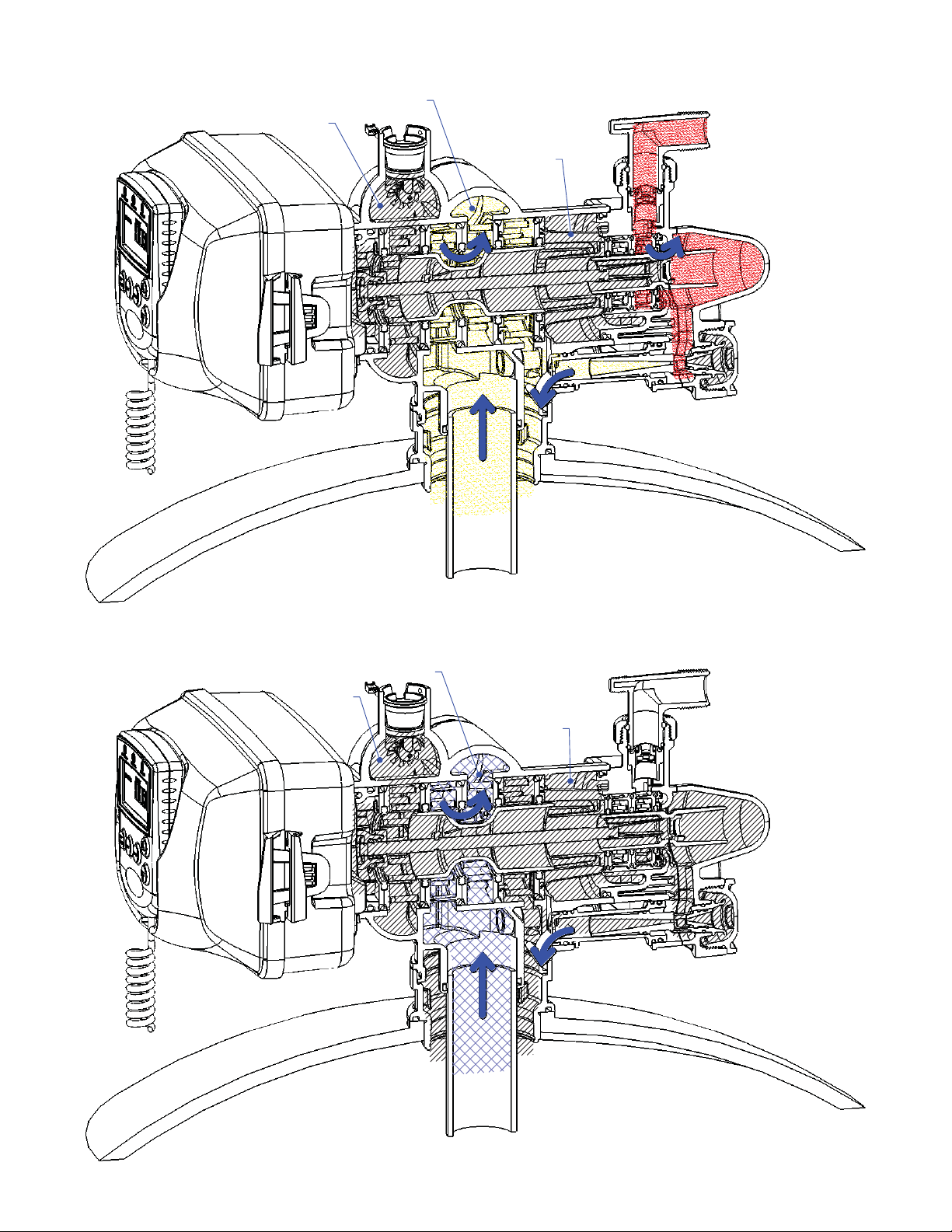

Treated Water

Supply

Raw Water

Inlet

Hard Water

Supply

Service

To Drain

Raw Water

Inlet

Backwash

Page 24 WS2H Control Valve Manual

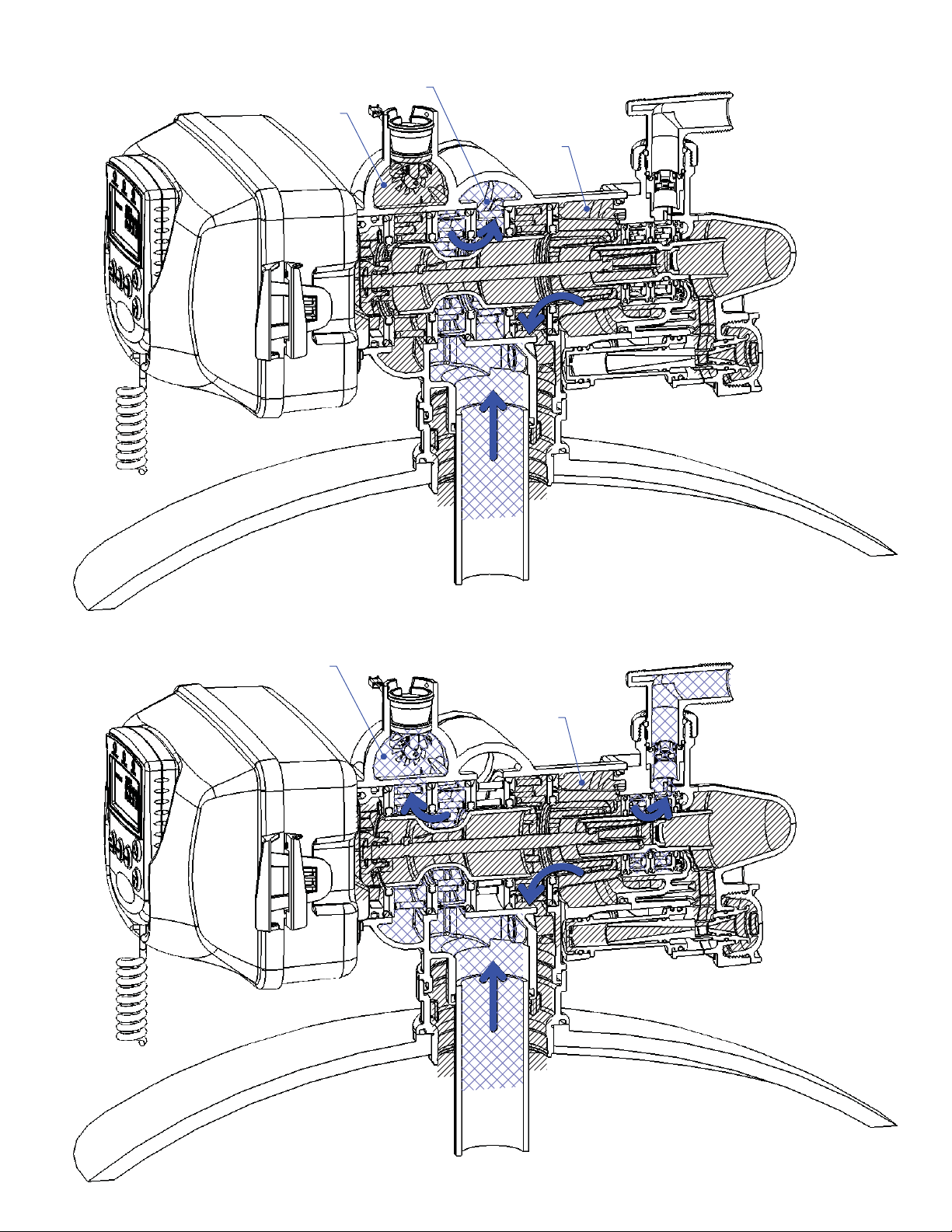

Hard Water

Supply

To Drain

Solution Is

Drawn In

Raw Water

Inlet

Hard Water

Supply

Draw

To Drain

Raw Water

Inlet

Slow Rinse

WS2H Control Valve Manual Page 25

To Drai

Hard Water

Supply

n

Raw Water

Inlet

Treated Water

Supply

Raw Water

Inlet

Rinse

Treated Water

To Tank

Softwater Fill

Page 26 WS2H Control Valve Manual

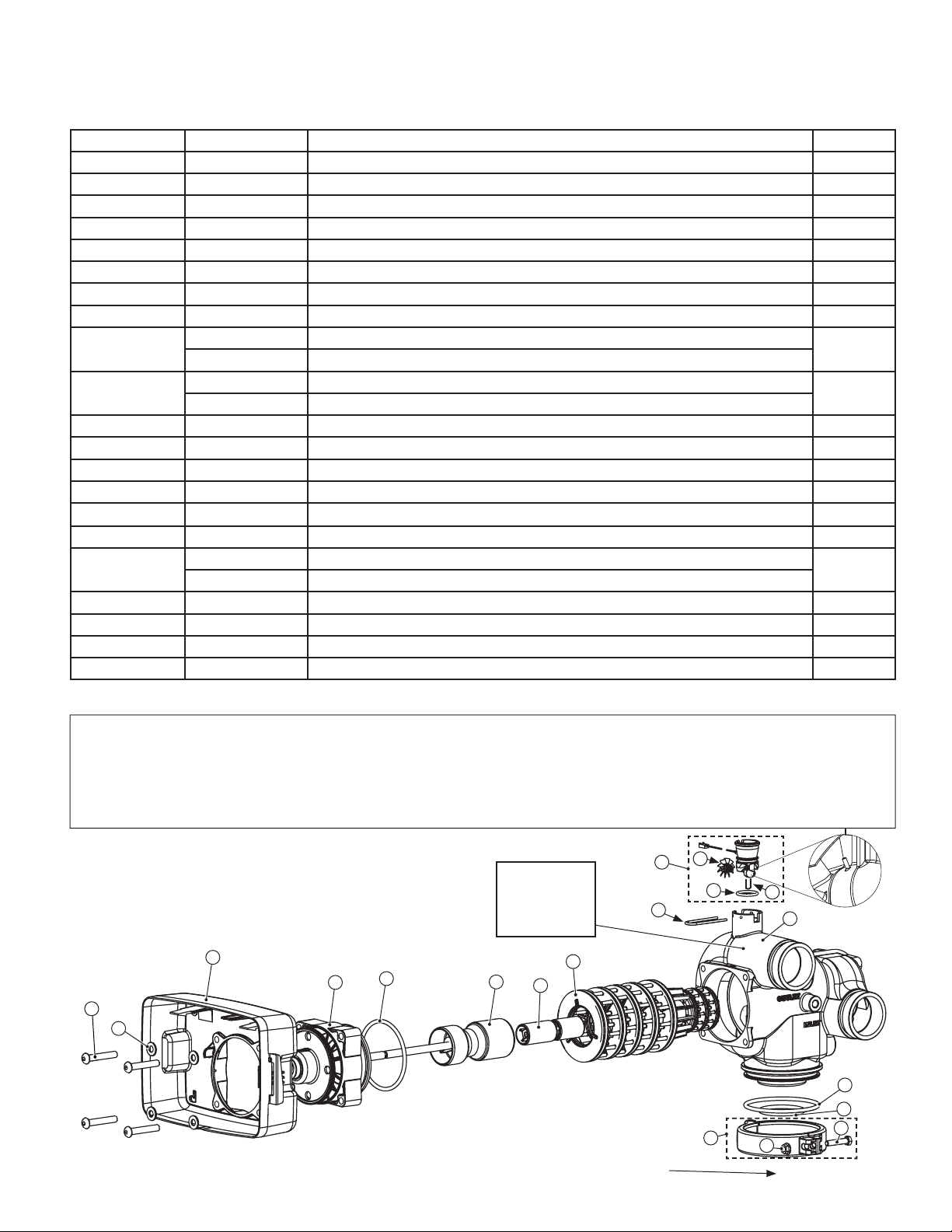

Front Cover and Drive Assembly

Drawing No. Order No. Description Quantity

1 V3068 WS2 POD ASY 1

2 V3241-01 WS2 PC BOARD DISPLAY 1

3 V3248 WS2 CABLE DISPLAY POD 1

4 V3242-01 WS2 PC BOARD VALVE 1

5 V3224-01R WS2 COVER ASY PLATINUM 1

6 V3107-01 WS1 MOTOR ASY 1

7 V3226-01 WS2 DRIVE BRACKET ASY 1

8 V3110 WS1 DRIVE GEAR 12X36 3

9 V3109 WS1 DRIVE GEAR COVER 1

Not Shown V3461 WS2 AC ADAPTER 24V

1Not Shown V3461EU WS2 AC ADAPTER 24V EU

Not Shown V3461UK WS2 AC ADAPTER 24V UK

10 V3243-01 WS2 PC BOARD SYSTEM Optional

Not Shown V3475-12 WS2 SYS CONNECT CORD 12 FT RED Optional

Not Shown V3475-24 WS2 SYS CONNECT CORD 24 FT BL Optional

Not Shown V3475-36 WS2 SYS CONNECT CORD 36 FT YEL Optional

5

1

7

8

2

3

9

4

6

10

WS2H Control Valve Manual Page 27

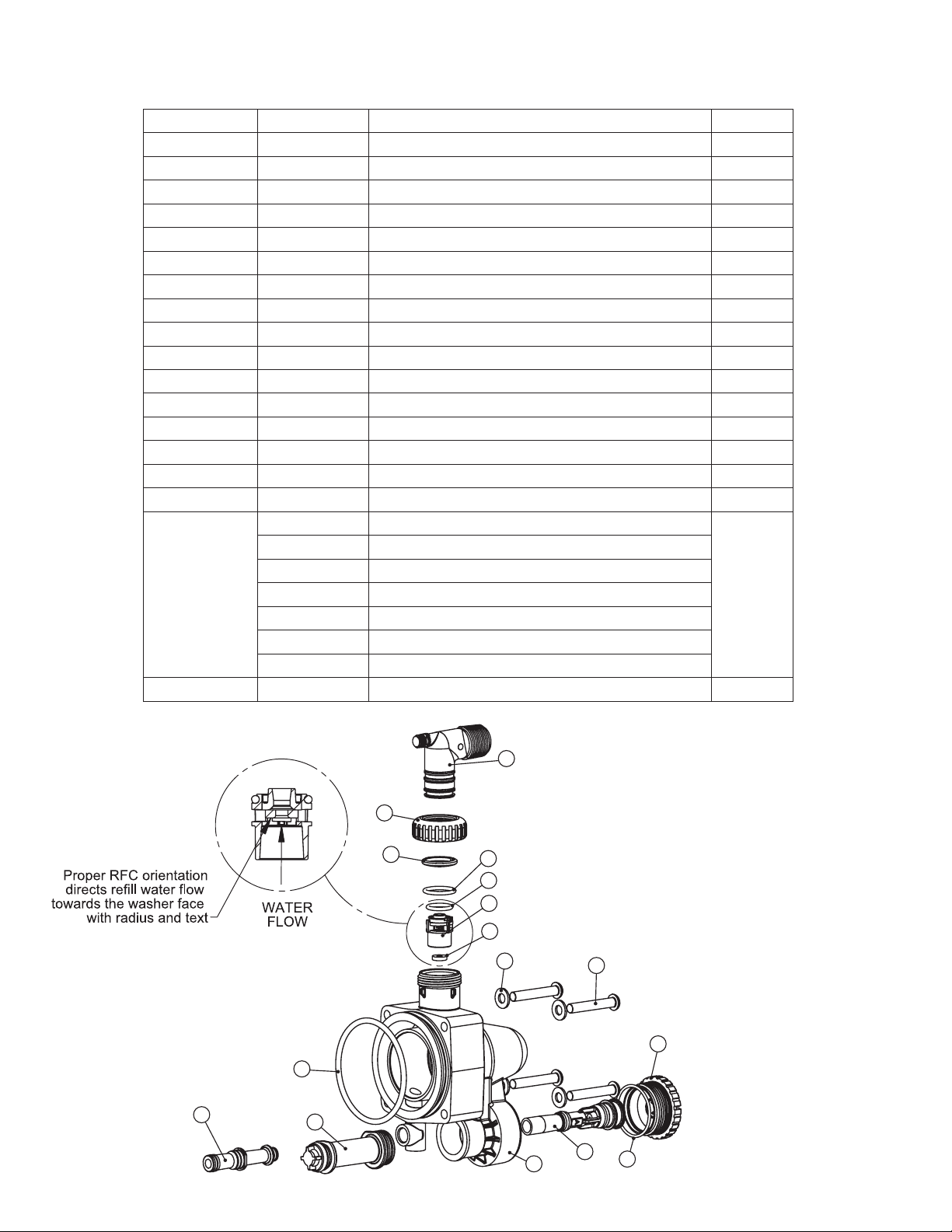

Drive Cap Assembly, Downfl ow Piston, Regenerant Piston, Spacer Stack Assembly, Drive Back Plate,

Main Body and Meter

Drawing No. Order No. Description Quantity

1 V3274 WS2 SCREW BTNSKT HD SS3/8-16X2 4

2 V3291 WS2 WASHER SS 3/8 4

3 V3225 WS2 BACK PLATE 1

4 V3066 WS2 DRIVE ASY 1

5 V3289 O-RING 344 1

6 V3204-01 WS2 PISTON 1

7 V3238-01 WS2 BRINE PISTON 1

8 V3065 WS2 STACK ASY 1

Not Shown

9

10 V3223 WS15/WS2 METER CLIP 1

11 V3003-02 WS1.5/2H METER COMMERCIAL ASY 1

12 V3118-03 WS1.5/2 TURBINE ASY 1

13 V3105 O-RING 215 1

14 V3501

15 V3279 O-RING 346 1

16

17 V3054** WS2 4 IN BASE CLAMP ASY 1

18 V3276 WS2 BOLT HEX SS 5/16-18X1-3/4 1

19 V3269 WS2 NUT 5/16-18 SS HEX 1

Not Shown D1300-01 TOP BAFFLE DFSR CLACK 2/63MM 1

**V3054 WS2 4 IN BASE CLAMP ASY includes a V3276 WS2 BOLT HEX SS 5/16-18X1-3/4 and V3269 WS2 NUT 5/16-18 SS HEX.

V3468 WS2 PLUG 1/4 HEX NPT (included when ordering V3201-03)

V3465 WS2 PLUG 1/4 HEX BSPT (included when ordering V3201BSPT-03)

V3201-03 WS2 BODY W/V3468 PLUG

V3201BSPT-03 WS2 BSPT BODY W/V3465 PLUG

WS1.5/2 TURBINE CLIP

V3280 O-RING 332 FOR VALVE BODIES WITH NPT THREADS

V3452 O-RING 230 FOR VALVE BODIES WITH BSPT THREADS

2

1

1

1

In 2007, a u-shaped retaining clip (V3501) was added to commercial meter assemblies to hold the turbine assembly in place. If V3501 is present, service or replace

the turbine by:

1. Removing bend from the two exposed tips of the retaining clip and remove clip.

2. Service or replace the V3118-03 WS1.5/2 Turbine Assembly and place back on the turbine shaft.

3. Insert the V3501 WS1.5/2 Turbine Clip and rebend the exposed tips.

The V3118-03 has a groove to line up with the V3501 WS1.5/2 Turbine Clip. If the meter assembly does not have two holes in the bottom to insert the clip, use a

V3118-01 Turbine Assembly or replace the entire meter.

12

B or indent

indicates BSPT

N or no mark

indicates NPT

3

4

1

2

Install D1300-01 upper diffuser (not shown) when using the 4” Quick Dissconnect (V3064)

5

6

8

7

11

13

10

17

14

9

15

16

18

19

Page 28 WS2H Control Valve Manual

Brine Valve Body and Injector Components

Drawing No. Order No. Description Quantity

1 V3237-01 WS2 SOFTFILL TUBE ASY 1

2 V3236-01 WS2 INJECTOR TUBE ASY 1

3 V3289 O-RING 344 1

4 V3067 WS2 BRINE BODY ASY 1

5 V3477 WS2 INJECTOR CAP 1

6 V3152 O-RING 135 1

7 V3275 WS2 SCREW BSHD SS 3/8-16X2-1/4 4

8 V3291 WS2 WASHER SS 3/8 4

9 V3162-022* WS1 DLFC 022 FOR 3/4 1

10 V3231 WS2 REFILL FLOW CNTRL RETAINER 1

11 V3277 O-RING 211 1

12 V3105 O-RING 215 1

13 V3150 WS1 SPLIT RING 1

14 V3151 WS1 NUT 1 QC 1

15 V3149 WS1 FTG 1 PVC MALE NPT ELBOW 1

Not Shown V3189 WS1 FTG 3/4&1 PVC SLVNT 90 Optional

V3010-2A WS2 INJECTOR ASY A

V3010-2B WS2 INJECTOR ASY B

V3010-2C WS2 INJECTOR ASY C

16

Not Shown V3499** WS2 FITTING CAP 1 IN THREADED 1

V3010-2D WS2 INJECTOR ASY D

V3010-2E WS2 INJECTOR ASY E

V3010-2F WS2 INJECTOR ASY F

V3010-2G WS2 INJECTOR ASY G

1

*Any V3162-XXX fl ow control may be used.

V3237-01 WS2 SOFTFILL TUBE ASY contains a

15

14

13

3

1

2

12

11

10

9

8

V3155 O-RING 112, V3287 O-RING 110 and a V3288

O-RING 206.

V3236-01 WS2 INJECTOR TUBE ASY contains a

V3285 O-RING 213 and a V3286 O-RING 216.

V3010-2X injectors contains a V3283 O-RING 117 and

a V3284 O-RING 114.

** Install V3499 on V3149 if valve is to be set up as a

backwash only valve

7

5

16

4

6

WS2H Control Valve Manual Page 29

V3064 WS2H/2L 4 INCH BASE ASY

Drawing No. Order No. Description Quantity

1

2 V3281 O-RING 348 1

1 V3202-01 WS2 BASE 1

2

V3055 WS2H/2L FLANGE BASE ASY

Drawing No. Order No. Description Quantity

1

1 V3444 WS2 SCREW HEXCAP 5/16-18X2.5SS 12

2 V3293 WS2 WASHER SS 5/16 FLAT 24

2

6

3

4

5

3 V3445 WS2 WASHER SPLIT LOCK 5/16 SS 12

4 V3447 WS2 NUT HEX 5/16-8 FULL SS 12

5 COR60FL O RING 6 FLANGE ADAPTER(PARK) 1

6 V3261-01 WS2 FLANGE BASE 1

V3260-02 WS2 SIDE MOUNT BASE NPT

V3260BSPT-02 WS2 SIDE MOUNT BASE BSPT ASY

1

Drawing No. Order No. Description Quantity

1 V3280 O-RING 332 1

2 V3260BSPT-01 WS2 SIDE MOUNT BASE BSPT 1

When using a side mount base with 2H BSPT valves replace distributor

pilot o-ring V3452 O-RING 230 with V3280 O-RING 332. See

exploded view of 2H valve in WS2H manual for specifi c location of

2

distributor pilot o-ring.

Page 30 WS2H Control Valve Manual

Washer

Radius

Direction

Of Flow

Direction

Of Flow

1

V3051 WS2 DLFC ASY NPT and V3051BSPT WS2 DLFC ASY BSPT

Drawing No. Order No. Description Quantity

1 V3052 WS2 DLFC Retainer ASY 1

2

3

4 V3273 BOLT HEX HD S/S HCS 3/8-16X3/4 4

5 V3278 O-ring 338 1

Not Shown

Assemblies are shipped without drain line fl ow control (DLFC). Assembly instructions:

1. Determine the desired fl owrate. Select a combination of V3162-XXX’s and V3190-XXX’s to arrive at the desired fl ow rate. Up to fi ve of the

smaller V3162-XXX’s may be used. Up to four of the larger V3190-XXX’s may be used.

2. Using a drill or punch remove the desired knockout(s) in V3052.

3. Smooth hole(s).

4. Install appropriate size(s) of drain line fl ow control washers. Pay close attention to proper DLFC orientation.

5. Assemble. Properly orientate the V3052 in the direction of fl ow.

6. Inlet and outlet threads are 2” NPT. Couplings for iron pipe may also be used.

V3245 WS2 DLFC FLANGE INLET NPT

V3245BSPT WS2 DLFC FLANGE INLET BSPT

V3246 WS2 DLFC FLANGE OUTLET NPT

V3246BSPT WS2 DLFC FLANGE OUTLET BSPT

V3162-007 WS1 DLFC 0.7 gpm for 3/4

V3162-010 WS1 DLFC 1.0 gpm for 3/4

V3162-013 WS1 DLFC 1.3 gpm for 3/4

V3162-017 WS1 DLFC 1.7 gpm for 3/4

V3162-022 WS1 DLFC 2.2 gpm for 3/4

V3162-027 WS1 DLFC 2.7 gpm for ¾

V3162-032 WS1 DLFC 3.2 f gpm or 3/4

V3162-042 WS1 DLFC 4.2 gpm for 3/4

V3162-053 WS1 DLFC 5.3 gpm for 3/4

V3162-065 WS1 DLFC 6.5 gpm for 3/4

V3162-075 WS1 DLFC 7.5 gpm for 3/4

V3162-090 WS1 DLFC 9.0 gpm for 3/4

V3162-100 WS1 DLFC 10.0 gpm for 3/4

V3190-090 WS1 DLFC 9.0 gpm for 1

V3190-100 WS1 DLFC 10.0 gpm for 1

V3190-110 WS1 DLFC 11.0 gpm for 1

V3190-130 WS1 DLFC 13.0 gpm for 1

V3190-150 WS1 DLFC 15.0 gpm for 1

V3190-170 WS1 DLFC 17.0 gpm for 1

V3190-200 WS1 DLFC 20.0 gpm for 1

V3190-250 WS1 DLFC 25.0 gpm for 1

1

1

Install One or

More DLFC’s.

Up to 5 of

the V3162-

XXX may be

installed in the

small holes.

Up to 4 of

the V3190-

XXX may be

installed in the

large holes.

4

3

B indictates BSPT

N indicates NPT

2

5

1

WS2H Control Valve Manual Page 31

V3060 WS2 BYPASS AUTO NPT, V3060BSPT WS2 BYPASS AUTO BSPT,

V3061BSPT WS2 BYPASS MANUAL BSPT and V3061 WS2 BYPASS MANUAL NPT

Drawing No. Order No. Description

1 V3056 WS1.5&2AL T/2BYPASS AUTO CVRASY 1 N/A

2 V3476 WS MOTOR ASY 8 FT 1 N/A

3 V3272 WS2 SCREW 8X1 SS HEX SELF TAP 3 N/A

4 V3262-01 WS1.5&2ALT/2BY REDUCGEARCVRASY 1 N/A

5 V3110 WS1 DRIVE GEAR 12X36 3 N/A

6 V3264 WS2 BYPASS REDUCTION GEAR AXLE 3 N/A

7 V3292 WS2 SCREW BSHD SS 1/4-20X1-1/2 8 8

8 V3059 WS1.5&2AL T/2BYPAS AUTODRIVEASY 1 N/A

9 V3268 WS2 BYPASS COVER DOME MANUAL 1 2

10 V3058 WS2 BYPASS MANUAL DRIVE ASY 1 2

11

Not Shown V3053 WS2 2-1/2 GROOVELOCK CLAMP ASY 2 2

V3057 WS2 BYPASS BODY ASY NPT

V3057BSPT WS2 BYPASS BODY ASY BSPT

Treated water is used for refi ll whether or

not an auto or manual bypass is installed to

either the inlet or outlet of a control valve.

The Auto Drive Assembly may be connected

to the inlet or outlet of the control valve to

achieve no hard water bypass. If the Auto

Drive Assembly is connected to the control

valve:

Quantity

V3060 V3061

11

1

2

3

• inlet then all regeneration cycles occur

with treated water.

• outlet then all regeneration cycles except

for refi ll occur with untreated water.

B indictates BSPT

N indicates NPT

4

7

5

6

8

11

7

9

10

Page 32 WS2H Control Valve Manual

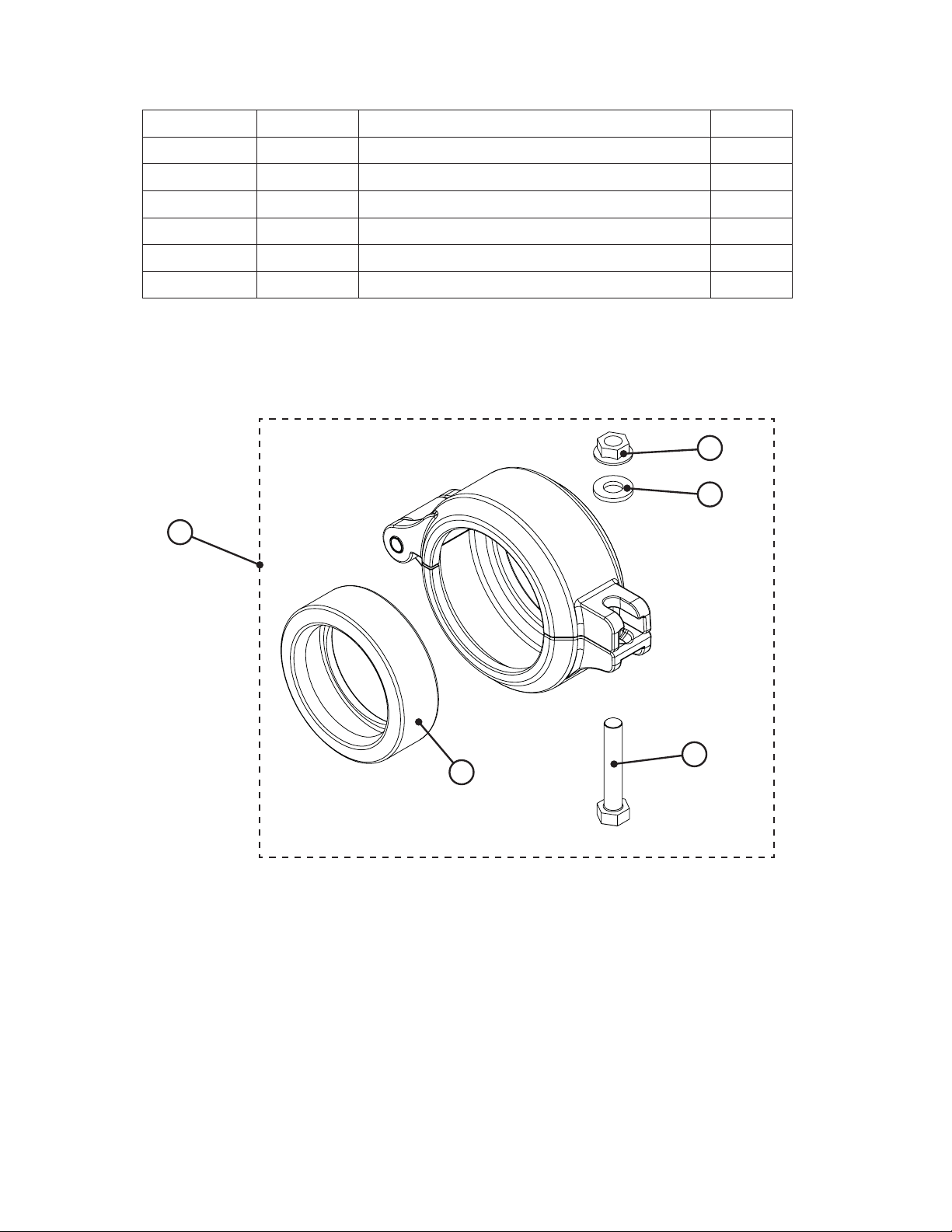

V3053 WS2 2-1/2 GROOVELOCK CLAMP ASY

Drawing No. Order No. Description Quantity

1 V3053 WS2 2-1/2 GROOVELOCK CLAMP ASY 1

2 V3290 WS2 GROOVE LOCK SEAL 2.5 1

3 V3269 WS2 NUT 5/16-18 SS HEX 1

4 V3293 WS2 WASHER SS 5/16 FLAT 1

5 V3276 WS2 BOLT HEX SS 5/16-18X1-3/4 1

Not Shown S3086 SILICONE LUBRICANT 1

3

4

1

5

2

WS2H Control Valve Manual Page 33

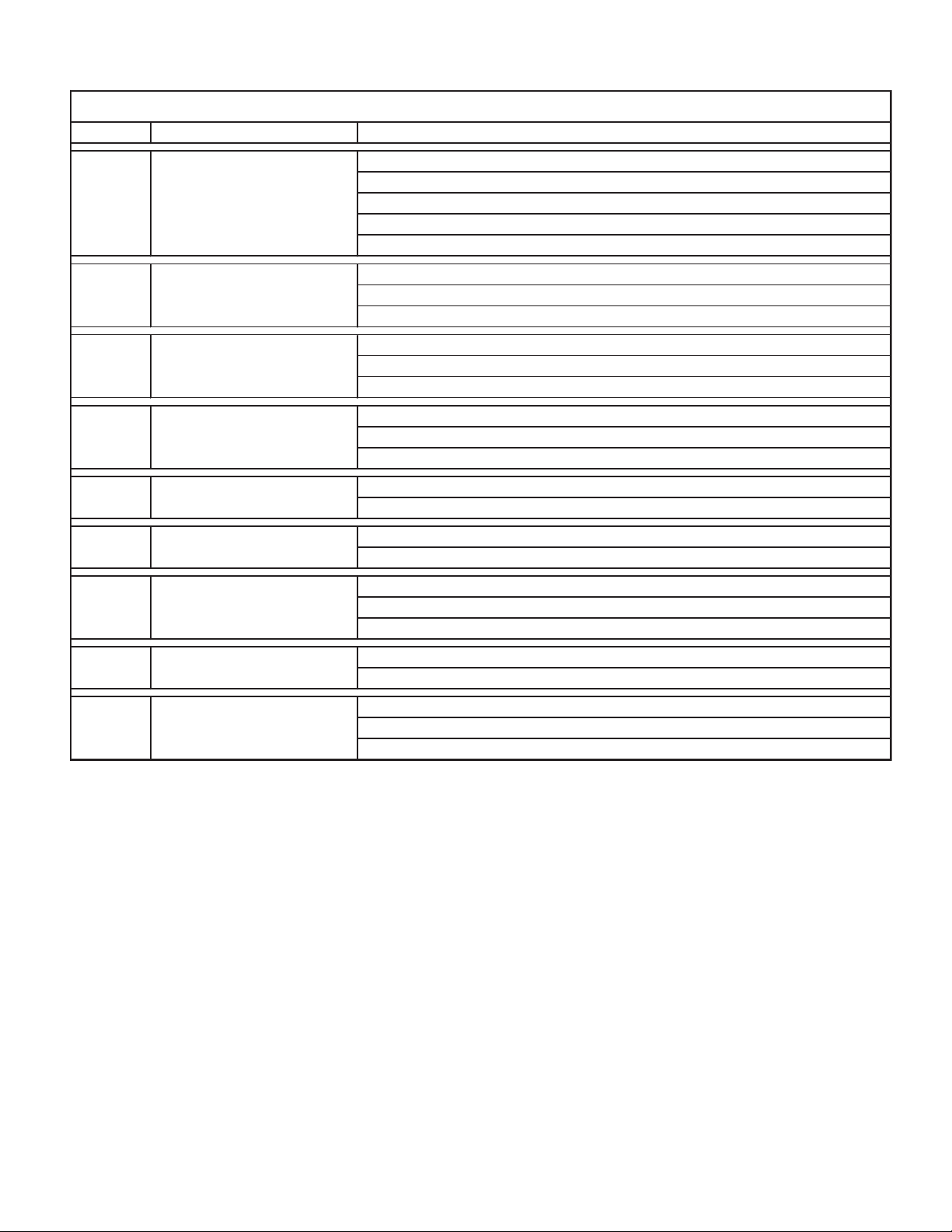

Erro r Codes

Error Descriptio n Possible Cause

Drive m otor is notengaged with mating gear

1001

1003 Run time to long

Encoderon m ain board is

not r egisteringpulses

Unexpected s tall1002

Faultydrivemotor or wiring

Reflectors on reductiongear are dirtyor d amaged

Circuitboard is not properlyengaged with drive bracket

Faultyencoder /ma in board

Debris jam ming pis ton

Faultydrive m o tor

Faultydr ive component creating drag

Main drive gear not properlyengaged

Motorpinion s l ipping on s haft

Faulty motor or wiring

15003

15010

15011

17000

17002

# Units

Bypass motor runtime to

long

Bypassruntimetoshort

while tr ying to driv eoffline

Bypassruntimetoshort

while trying to drive online

Separate source inletdrive

runtim e to long

Separate source inletdrive

error

Master has los t

comm unication with another

unit

Mis sing engagem ent between bypass drive mo torand main gear

Bypass drive motornotconnected tom ain board

Faultybypass drive m otor or wiring

Debris jam ming drive

Faultydr ive component creating drag

Debris jam ming drive

Faultydr ive component creating drag

Mis sing engagem ent between separates ource drive m otorand main gear

Separate source drive m otor not connected to s ystem board

Faultyseparate s ource drive m o toror wiring

Debris in separ ate s ource valve

Faultydr ive component creating drag

Faultycom munication cable

Other unit has los t power or is in error m ode

More than one unit is programmed as master

Page 34 WS2H Control Valve Manual

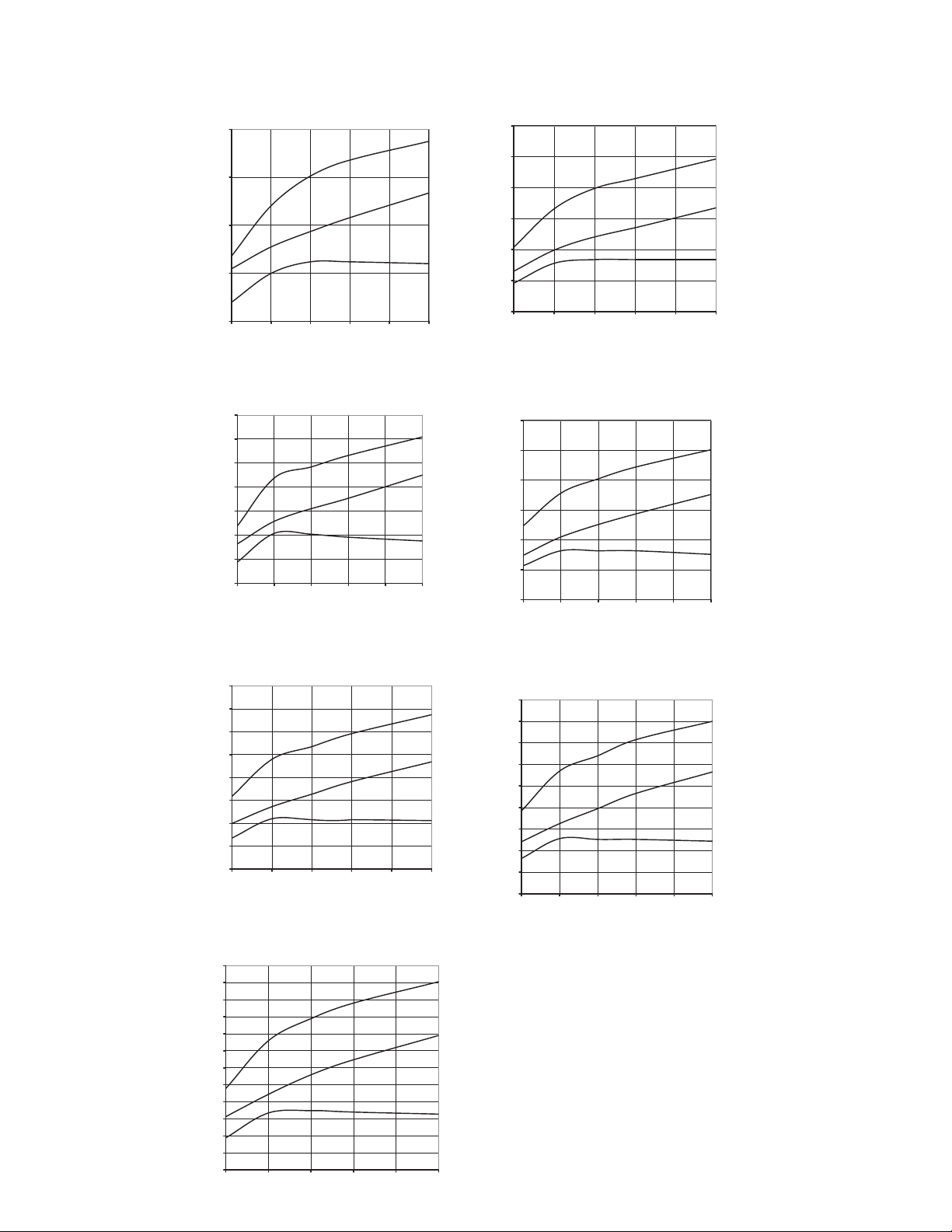

Order No. V3010-2A

4

3

2

Flow Rate (gpm)

1

0

20 40 60 80 100 120

US Units

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2C

US Units

7

6

5

4

3

Flow Rate (gpm)

2

1

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2B

6

5

4

3

2

Flow Rate (gpm)

1

0

20 40 60 80 100 120

US Units

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2D

US Units

12

10

8

6

4

Flow Rate (gpm)

2

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2E

16

14

12

10

8

6

Flow Rate (gpm)

4

2

0

20 40 60 80 100 120

US Units

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2G

US Units

24

22

20

18

16

14

12

10

8

Flow Rate (gpm)

6

4

2

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

Order No. V3010-2F

US Units

18

16

14

12

10

8

6

Flow Rate (gpm)

4

2

0

20 40 60 80 100 120

Total

Slow Rinse

Draw

Pressure (psi)

WS2H Control Valve Manual Page 35

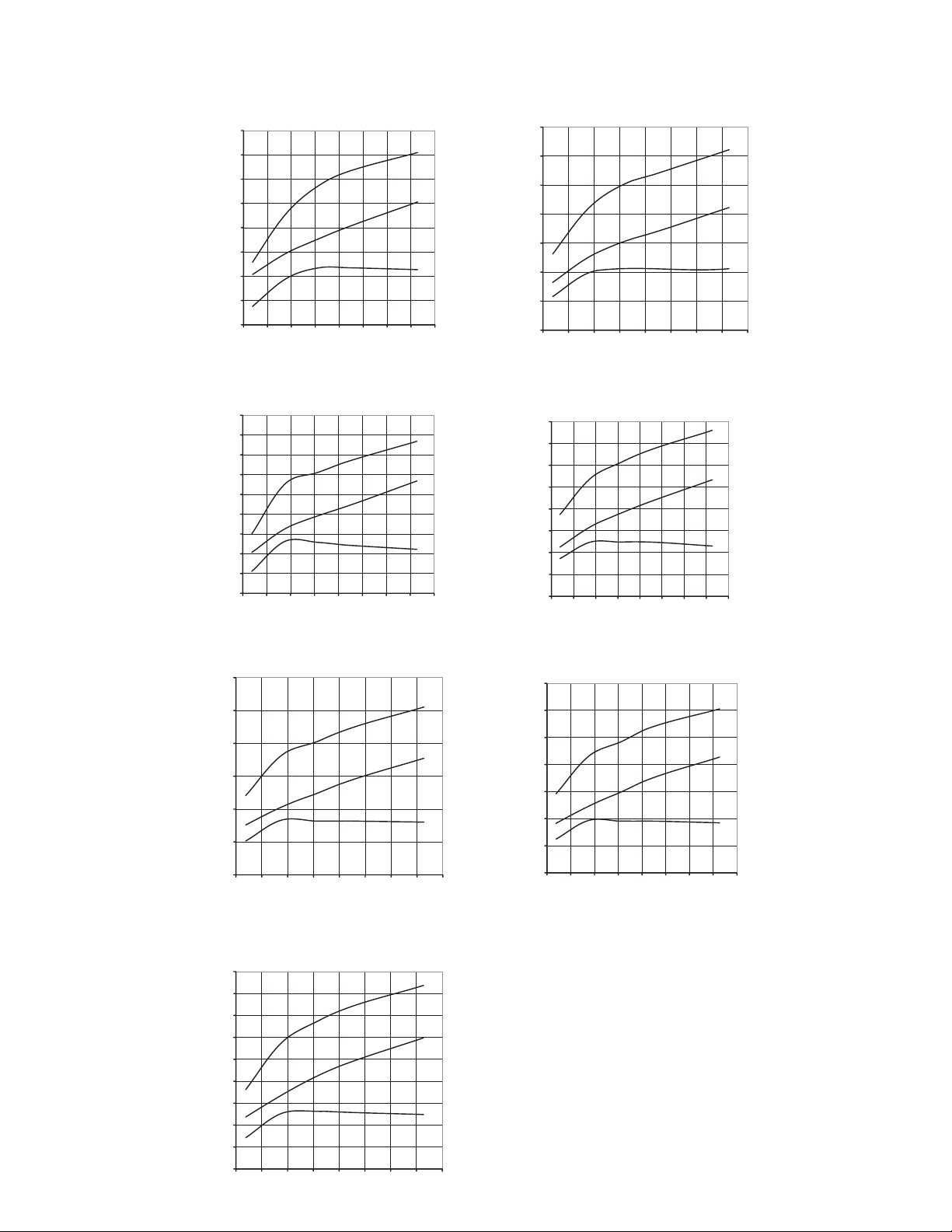

Order No. V3010-2A

Metric Units

16

14

12

10

8

6

Flow Rate (lpm)

4

2

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2C

27

24

21

18

15

12

9

Flow Rate (lpm)

6

3

0

100 200 300 400 500 600 700 800 900

Metric Units

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2E

Metric Units

60

Order No. V3010-2B

21

18

15

12

9

Flow Rate (lpm)

6

3

0

100 200 300 400 500 600 700 800 900

Metric Units

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2D

Metric Units

40

35

30

25

20

15

Flow Rate (lpm)

10

5

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2F

Metric Units

70

50

40

30

20

Flow Rate (lpm)

10

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Order No. V3010-2G

Metric Units

90

80

70

60

50

40

30

Flow Rate (lpm)

20

10

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

60

50

40

30

Flow Rate (lpm)

20

10

0

100 200 300 400 500 600 700 800 900

Total

Slow Rinse

Draw

Pressure (kPa)

Page 36 WS2H Control Valve Manual

Revision History:

06/21/07

PAGE 3:

2) Maximum power through relays

a. 1A, 30 VDC

b. 1A, 30 VAC

PAGE 29:

V3260BSPT-02 WS2 SIDE MOUNT BASE BSPT ASY

Added drawing and table

PAGE 31:

6 V3264 WS2 BYPASS REDUCTION GEAR AXLE 3 N/A

06/25/07

PAGE 29:

V3260-02 WS2 SIDE MOUNT BASE NPT

09/06/07

PAGE 27:

Update Tubine Asy. part# V3118-03 and Turbine Asy. drawing

Form No. V3215 – 9/06/07

U.S. Patents: 6,402,944; 6,444,127; and 6,776,901

Loading...

Loading...