CK WORLDWIDE MR140 User Manual

H EA D

S TYL E

C AB LE

S TYL E

C AB LE

L EN GT H

PA RT #

Ri gid H ea d -

w/o va lve

3 Pi ec e

12 -1 /2 f t. (3 .8 m)

M R1 41 2S F

25 ft. (7. 6 m )

M R1 42 5S F

CK WORLDWIDE INC.

WARRANTY:

CK Worldwide, Inc. warrants products manufactured by CK Worldwide, Inc. to

be free of defects in materials and workmanship. CK Worldwide, Inc. limits this

warranty to replacement of the product or parts thereof and excludes liability for

injury, property damage or economic loss attributable to product use or misuse.

In any event, CK Worldwide, Inc. will only be responsible for its products when

used with accessory items manufactured by CK Worldwide, Inc.

INSTALLATION:

Before using this torch, - tighten regulator, hose and power cable fittings with

proper wrenches. Using small pliers, securely tighten all knurled hose fittings

(Slide the torch handle back for access to the torch connections). Purge the

regulator and TIG torch with inert gas at 20 cubic feet per hour. Following these

steps will ensure contamination free welds. Repeat this procedure whenever

torch or regulator fittings have been detached.

CONNECTION

DIAGRAM:

CAUT

ION:

Personal harm will result from touching the hot parts of a TIG torch without

insulative protection, or from looking directly or indirectly at an arc or reflected

arc. At no time should bare skin be exposed to a welding arc.

TUNGSTEN

PREPARATION:

GRINDING PREPARATION:

Use a 60 Grit or finer aluminum

oxide wheel

EXTENSION INSTRUCTION:

STANDARDPARTS

General Purpose:

Flat:

1/4 to 1/2 x Diameter

Taper:

2 to 3 x Diameter

3 x Diameter from end of cup.

END PREPARATION:

DCSP (EN)

General Purpose:

Ball tip by arcing on clean metal

at low current DCRP (EP) then

slowly increase current to form

the desired ball diameter.

The included angle determines weld

bead shape and size. Generally,

as the included angle increases,

penetration increases and bead

width decreases.

Maximum extension:

6 x Diameter from end of cup.

(In draft - free areas)

Ball:

Maximum 1 x Diameter

Remove sharp point to leave a

truncated point with a flat spot.

Diameter of flat spot determines

amperage.

3 x Diameter from end of cup.

Shape tungsten by grinding

logitudinally, never radially.

ACHF

General Purpose:

GAS LENS PARTS

General Purpose:

INFORMATION

CHA

RT:

ARGON FLOW

-ALUMINUM

ARGON FLOW

- FERROUS METALS

WELDING CURRENT (AMPS)

-TUNGSTEN TYPE

Gas Lens

Body

(Liters)

Standard

Body

(Liters)

Gas Lens

Body

(Liters)

Standard

Body

(Liters)

DCSP

Thoriated

DCSP

Pure

AC

Thoriated

AC

Pure

.020 (0.50)

.040 (1.00)

1/16 (1.60)

3/32 (2.40)

1/8 (3.20)

5/32 (4.00)

3/16 (4.80)

1/4 (6.40)

Cup

Size

Electrode

Diameter

in inches

(mm)

5-8 (3-4)

5-10 (3-5)

7-12 (4-6)

10-15 (5-7)

10-20 (5-10)

12-25 (6-12)

15-30 (7-14)

25-45 (12-21)

5-8 (3-4)

5-12 (3-6)

8-15 (4-7)

10-20 (5-10)

12-25 (6-12)

15-30 (7-14)

25-40 (12-19)

30-55 (14-26)

5-8 (3-4)

5-8 (3-4)

5-10 (3-5)

8-10 (4-5)

8-12 (4-6)

12-25 (6-12)

20-35 (10-17)

10-15 (5-7)

5-8 (3-4)

5-10 (3-5)

7-12 (4-6)

10-15 (5-7)

10-18 (5-9)

15-25 (7-12)

20-35 (10-17)

25-50 (12-24)

5 - 20

20 - 80

80 - 150

150 - 250

240 - 350

400 - 500

475-800

700 - 1100

5 - 15

15 - 70

70 - 130

150 - 220

220 - 330

375 - 475

475-800

5 - 20

15-80

70 - 150

140 - 235

220 - 325

300 - 425

400 - 525

500 - 700

5 - 15

10 - 60

50 - 100

100 - 160

150 - 210

200 - 275

250 - 350

325 - 700

4 or 5

4 or 5

4, 5 or 6

6, 7 or 8

7, 8 or 10

8 or 10

8 or 10

10

750 - 1000

CK WORLDWIDE INC. PHONE: (253) 854-5820 www.ckworldwide.com

3501 “C” ST. N.E. PHONE: (800) 426-0877 ck@ckworldwide.com

AUBURN, WA. 98002 FAX: (253) 939-1746

USA

IMPORTANT !!

READ AND UNDERSTAND THE

INFORMATION CONTAINED IN THIS

MANUAL BEFORE OPERATING THE EQUIPMENT !

TECHNICAL INFORMATION

TIG TORCH MANUAL

RATING @ 100% DUTY CYCLE:

COOLING METHOD:

HEAD ACCESSORIES:

POWER CABLE ADAPTOR:

140 AMP ACHF OR DCSP

WATER COOLED

MICRO TORCH

45V11 (2PCA)

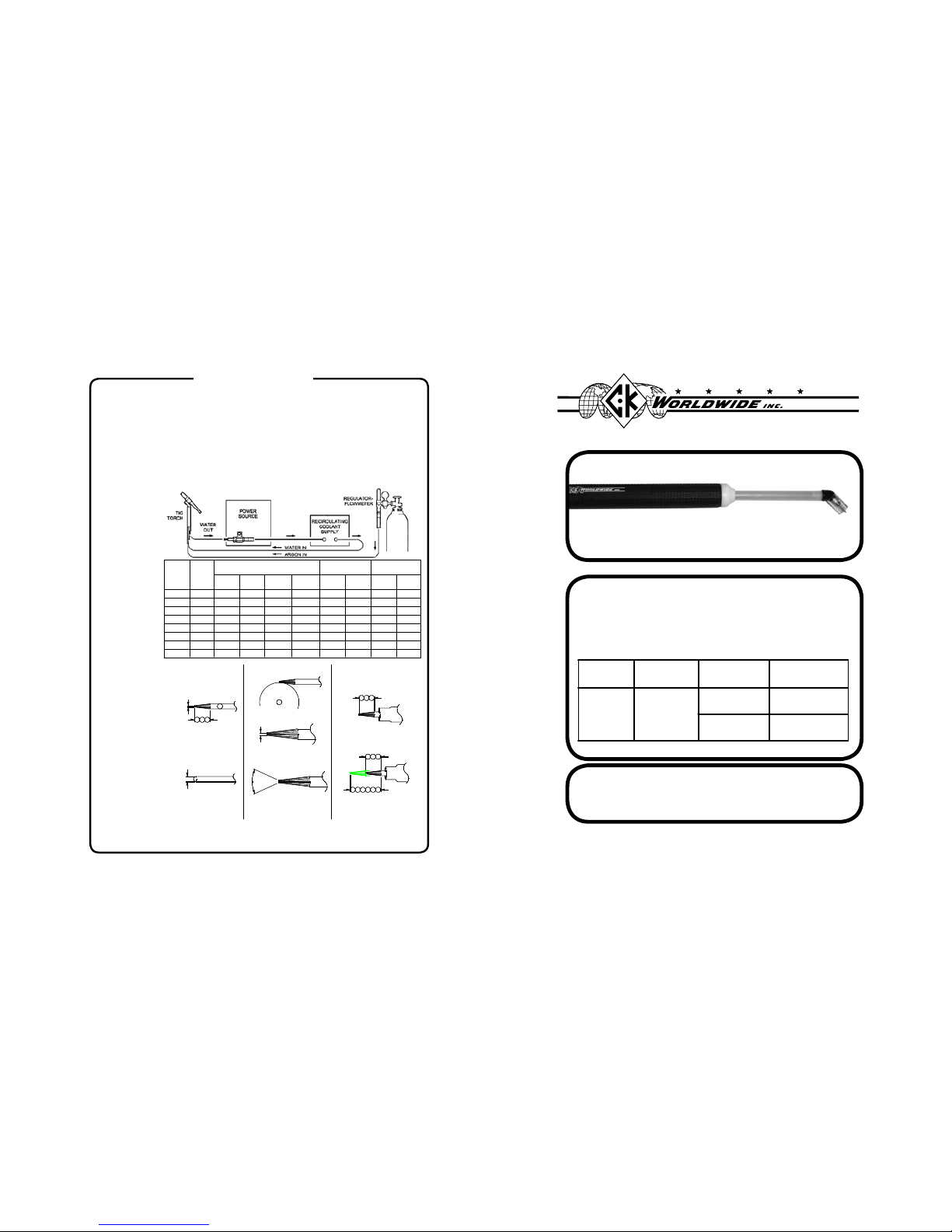

MR140 MICRO TORCH

MR140

ACCESSORY ITEMS REQUIRED FOR COMPLETE INSTALLATION:

MODEL SELECTOR - TORCH PACKAGES

PARTS:

MR140.. ......... ......... .

140H... ......... ......... ...

212WHSF ......... .......

225WHSF ......... .......

212PCSF ......... ........

225PCSF ......... ........

212AHSF ......... ........

225AHSF .. ......... .....

MRHB.........................

MR4P..........................

MR040C......................

MR116C......................

MR332C......................

MR180H......................

MR45H........................

MR90H.......................

MRTI...........................

T0409S20GC2............

T1169S20GC2............

T3329S20GC2............

PART NUMBER DESCRIPTION

PARTS LIST:

212PCSF (12-1/2 ft.) 225PCSF (25 ft.)

140H

MRHB

212AHSF (12-1/2 ft.) 225AHSF (25 ft.)

212WHSF (12-1/2 ft.) 225WHSF (25 ft.)

2WN

3HF

2AN

3HF

2PN

2PF2

2PF1

PART NUMBER DESCRIPTION

ACCESSORIES:

1192

1192

MR180H, MR45H, MR90H

Torch B ody, 140 Amp

Handle

Water H ose, Supe r Flex, 1 2-1/2 ft.

Water H ose, Supe r Flex, 2 5 ft.

Power C able, Sup er Flex, 12-1/2 ft .

Power C able, Sup er Flex, 25 ft.

Gas Hos e, Super Flex, 12- 1/2 ft.

Gas Hos e, Super Flex, 25 ft.

Handle Bushing

Cup Cle ar Pyrex

Collet .040

Collet 1/16

Collet 3/32

Head 18 0°

Head 45 °

Head 90 °

Neck In sulator

Tungste n .040” 2 % Ceriate d

Tungste n 1/16” 2 % Ceriate d

Tungste n 3/32” 2 % Ceriate d

2PCA (4 5V11).... .......

SLWHAT- T........ ........

SLWHAT- 25....... .......

SLWHAT- 35....... .......

SLWHAT- 35M...... .....

Power C able Adap ter

TWECO

DINSE 2 5

DINSE 3 5

DINSE 3 5 Flow-Th ru Gas

Safe-Lo c Quick C onnectors

MRTI

MR040C, MR116C, MR332C

MR4P

MR140

2

CK WORLDWIDE INC.

3

CK WORLDWIDE INC.

Tungsten Stick-Out Gauge and Wrench (included in torch package)

Part # TG1-24

TURBO-SHARP® V is an enclosed electrode grinder, which

eliminates grinding-dust exposure to both the user and the environment.

TURBO-SHARP® V includes a metal carrying case containing:

Standard head for diameters:

.040”(1.0mm),1/16”(1.6mm), 3/32”(2.4mm) and 1/8”(3.2mm)

Accessory for stationary mounting

Adapter for vacuum cleaning

Pen style electrode holder

Multi-functional cover

Tools for assembling and replacement

of grinding wheel

User instructions

•

•

•

•

•

•

•

Consistent Results:

Part # TS5

Loading...

Loading...