CKD WKF2, WFK2-005, WFK2-050, WFK2-020, WFK2-250 Series Manual

...

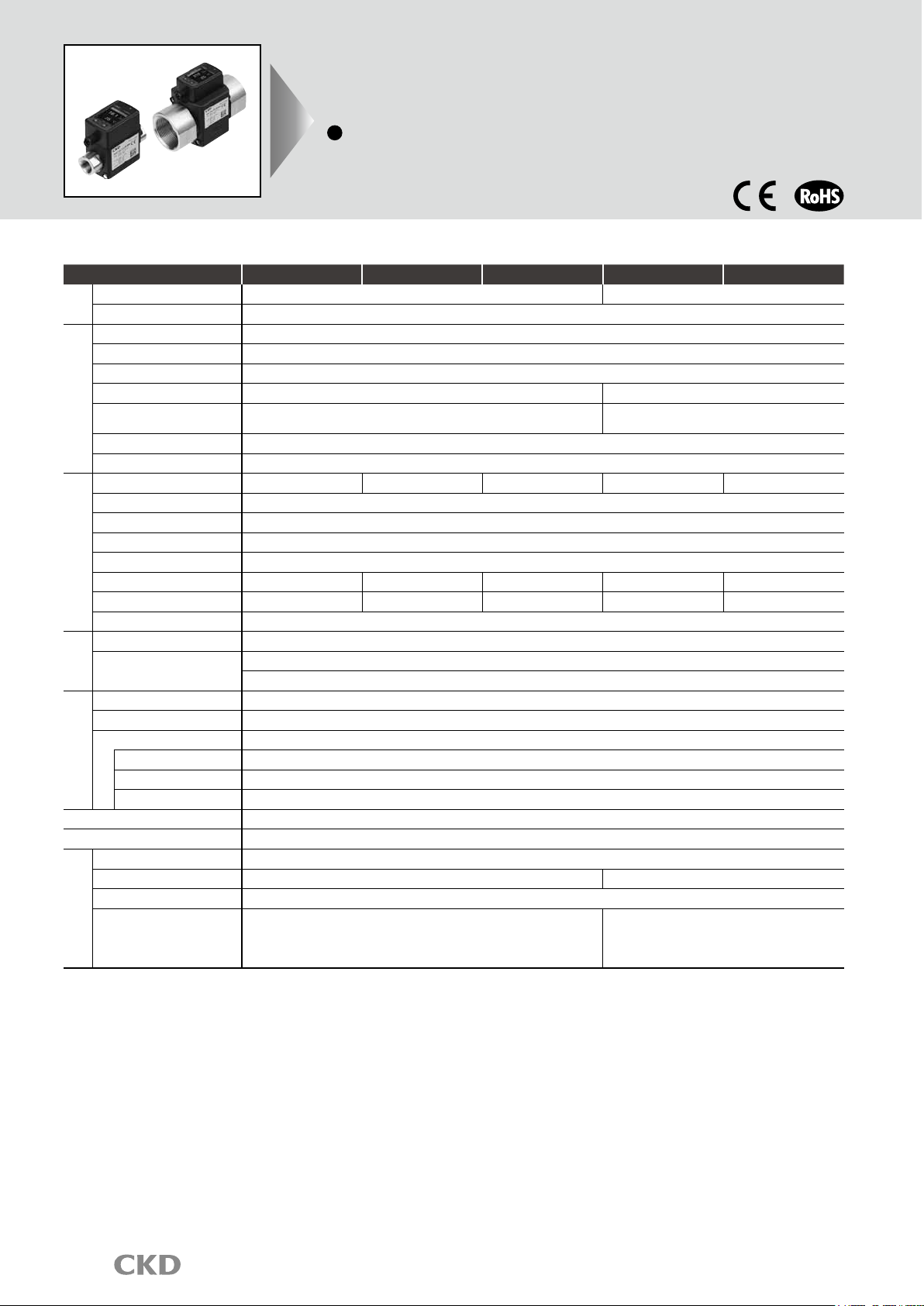

Flow Sensor for Water

WFK2 Series

Diversied and Unrestricted

Output

Compatible

CC-1342A

DIVERSIFIED

Diversified

Peak hold reset

Compatible with ow rates of 0.4 to 250 L/min

Compatible with a wide range of ow rates.

Easy ow rate adjustment

Can be adjusted with a

manual valve.

(option)

Various output functions available

OUT1 OUT2

Analog output

Instantaneous flow rate

❯

Temperature

❯

Switch output

NPN/PNP switchable

Instantaneous flow rate 1, 2

❯

Temperature 1, 2

❯

Integrating flow

❯

Water temperature measuring feature

is standard for all models

There is no need to for an external water temperature

sensor, reducing space and wiring work.

Handles water up to 95 °C

Molding machine cooling Laser oscillator cooli ngHeated water for mold

Analog output

Instantaneous flow rate

❯

Temperature

❯

temperature controlling

NPN/PNP switchable

Instantaneous flow rate 1, 2

❯

Temperature 1, 2

❯

Integrating flow

❯

Switch output

Pulse output External input

Integrating flow

❯

Integrating flow reset

❯

❯

Pulse output IO-Link

Integrating flow

❯

IO-Link model released

IO-Link is a digital communication standard for factory sensors and actuators. (IEC61131-9)

Parameters and event data that could not be transmitted by analog communication can now be transmitted.

Features of IO-Link

Cloud

Plant

PLC

Case identification

Parameter change

Production site

Ethernet

Permanent monitoring

Alarm notification

Digital signal

Parameter r emote

operation

Case identification

Plug & Play

Malfunction

notification

Permanent monitoring made possible by

digital data.

Parameters can be set and changed from

the network, so the system can be operated

remotely.

Model No. and serial No. can be checked via

the network.

Settings can be copied from the master,

making cumbersome resetting of parameters

during maintenance unnecessary.

Malfunctions and disconnections of the device

can be checked.

I/O

Connection to fieldbus

Connection to an Ethernet network is possible,

enabling the creation of an IoT system.

USER-FRI ENDLY

Easier to use

WFK2

Display screen rotation

The liquid crystal display can be rotated in 90° increments without moving the body. There is no interference even when

installed parallel.

Example of applications

Semiconductor

Cooling and temperature control of semiconductor

manufacturing equipment. Etching, grinder, dicer, CVD.

Semiconductor manufacturing equipment

Control equipment

I/O

Communication

Recorder

Monitor (displaying

ow rate)

Detecting abnormalities

Controlling peripheral

Unit

devices

A/D c onversi on

unit

Easy to read 2-screen color liquid crystal display

Set values, temperature, etc., can be displayed

simultaneously.

Hardening Induction hardening device

Quantitative management of

cooling water.

PLC

I/O Unit

Input

Controlling

Output

terminal

solenoid valve

Detect ing abnor mal

terminal

Water

Air

ow rate

Karman vortex ow rate sensor for water FLUEREX

Model variations Port size

WFK2-005

Rc3/8

WFK2-020

WFK2-050

WFK2-100

WFK2-250

Rc1/2

Rc3/4

Rc1

Rc1 1/4

Rc1 1/2

Soleno id valve

Flow rate

measurement data

Water temperature

measurement data

SERIES

Flow rate range (L/min)

0 5 10 20 50 100 250

50.4

1.6

4

8

20

50

20 250

Air operated

valve

100

Option

Manual valve

integration

for easy

flow rate

adjustments

Contact CKD for support for food manufacturing processes FP Series.

FLUEREX (Karman vortex ow rate sensor for water)

WFK2 Series

Flow rate range: 0.4 to 5, 1.6 to 20, 4 to 50, 8 to 100, 20 to 250 L/min

Specications

Descriptions WFK2-005 WFK2-020 WFK2-050 WFK2-100 WFK2-250

Port size Rc, G, NPT 3/8, 1/2, 3/4 1, 1 1/4, 1 1/2

Port material Stainless steel: SUS304

Connection

Applicable uid Pure water, industrial water

Max. working pressure MPa

Proof pressure MPa 1.5

Manual valve internal leakage mL/min

Manual valve allowable

back pressure

Ambient temperature °C 0 to 50 (85% RH or less, no condensation)

Working conditions

Fluid temperature °C 1 to 95

Flow rate range L/min 0.4 to 5 1.6 to 20 4 to 50 8 to 100 20 to 250

Repeatability (*1) Analog accuracy: ±2.5%F.S. Display accuracy: ±2.5%F.S. ±1 digit (min. display unit)

Temperature characteristics (*1)

Low ow cut 5% of F.S.

Integrating ow range 99,999 L or 99,999 m

Flow rate

Integrated pulse rate L/pulse

Pressure loss MPa 0.07 (at F.S.) 0.05 (at F.S.) 0.05 (at F.S.) 0.05 (at F.S.) 0.03 (at F.S.)

Response time (*2) sec 0.25, 0.5, 1, 5, 10 (Initial value 1)

Measurable temperature range

Accuracy

Temperature

Display

Analog output (*3) Standard: 0 to 5 VDC/1 to 5 VDC, option: 4 to 20 mA DC, 0 to 10 VDC/1 to 10 VDC

Switch output NPN or PNP transistor open collector output (can be switched from settings)

Max. load current 50 mA

Output

Max. applied voltage 30 VDC

Internal voltage drop 2.0 V or less

Power supply voltage Analog output standard: 12 to 24 VDC ±10%, analog output option: 24 VDC ±10%

Current consumption (*4) 50 mA or less

Mounting orientation Unrestricted in vertical/horizontal direction

Straight piping section None IN side: 10 D, OUT side: 5 D

Degree of protection IP65 or equiv.

Mounting

Weight g

*1: Accuracy is the average value over 10 sec (for conditions not containing air bubbles). F.S. stands for full scale ow rate.

*2: The time to attain 70% of the original output after the normal ow rate (used) drops instantly to 0.

*3: Check the allowable load on the wiring method page.

*4: Current for when 24 VDC is connected, and no load is applied. The current consumption will vary depending on how the load is connected.

MPa

°C 0 to 100

0.1, 0.5, 1 0.1, 0.5, 1, 10 0.5, 1, 10, 50 1, 10, 50, 100 10, 50, 100

Less than 50: analog accuracy ±2, display accuracy ±2 ±1 digit (min. display unit 1)

50 to 100: analog accuracy ±3, display accuracy ±3 ±1 digit (min. display unit 1)

Two-screen LCD display, instantaneous ow rate: 3 digits, water temperature: 2 digits, integrating ow: 5 digits, with screen rotation

3/8 (Rc, G, NPT): approx. 320

1/2 (Rc, G, NPT): approx. 320

3/4 (Rc, G, NPT): approx. 400

0 No manual valve settings

0.3 No manual valve settings

±5%F.S. (base temperature 25°C, 10 to 50°C)

3

(unit selectable), reset when the power is turned off.

1.0

1 (Rc, G, NPT): approx. 870

1 1/4 (Rc, G, NPT): approx. 1,010

1 1/2 (Rc, G, NPT): approx. 1,100

1

WFK2

How to order

Series

How to order

AWFK2 A N A C005 AA

A

Flow rate

range

B

Port size

C

IO-Link analog output

D

Display unit

Precautions for model No. selection

*1: The unit display "B" is for overseas use and

cannot be used in Japan.

*2: Option A (with manual valve) has a flow rate

range of 005, 020, or 050 only.

*3: When selecting option A and the bracket (C),

it is a bracket 2 set attachment.

[Example of model No.]

WFK2-005AAAAN-AC

A

Flow rate range : 0.4 to 5 L/min

B

Port size : Rc3/8

C

IO-Link analog output:

Switch/analog output

0 to 5 VDC/1 to 5 VDC

D

Display unit : L/min L m3 °C

E

Manual valve : sensor only

F

Option : standard cable attached

G

Option : attached bracket

E

Manual valve

Pressure loss

F

Option

(attached cable)

G

Bracket

(attached bracket)

Code Content

A

Flow rate range

005 0.4 to 5 L/min

020 1.6 to 20 L/min

050 4.0 to 50 L/min

100 8.0 to 100 L/min

250 20 to 250 L/min

B

Port size

AA Rc3/8

BA Rc1/2

Flow rate range: 005, 020, 050

CA Rc3/4

DA Rc1

Flow rate range: 100, 250EA Rc1 1/4

FA Rc1 1/2

AB G3/8

BB G1/2

Flow rate range: 005, 020, 050

CB G3/4

DB G1

Flow rate range: 100, 250EB G1 1/4

FB G1 1/2

AC NPT3/8

BC NPT1/2

Flow rate range: 005, 020, 050

CC NPT3/4

DC NPT1

EC NPT1 1/4

Flow rate range: 100, 250

FC NPT1 1/2

C

IO-Link analog output

* "D", "E", and "F" have the analog output specications from before IO-Link is used.

A Switch/analog output 0 to 5 VDC/1 to 5 VDC

B Switch/analog output 4 to 20 mA DC

C Switch/analog output 0 to 10 VDC/1 to 10 VDC

D IO-Link compatible 0 to 5 VDC/1 to 5 VDC

E IO-Link compatible 4 to 20 mA DC

F IO-Link compatible 0 to 10 VDC/1 to 10 VDC

D

Display unit

A L/min L m

B L/min us gal/min L m

E

Manual valve

3

°C

3

us gal °C °F *1

N Sensor only

A With manual valve (cock type) *2

F

Option (attached cable)

Blank None

A

Standard cable (M12/4-conductor/ 3 m) attached

B

Double ended connector cable (M12/4-conductor/ 3 m) attached

G

Option (attached bracket)

Blank None

C Attached bracket *3

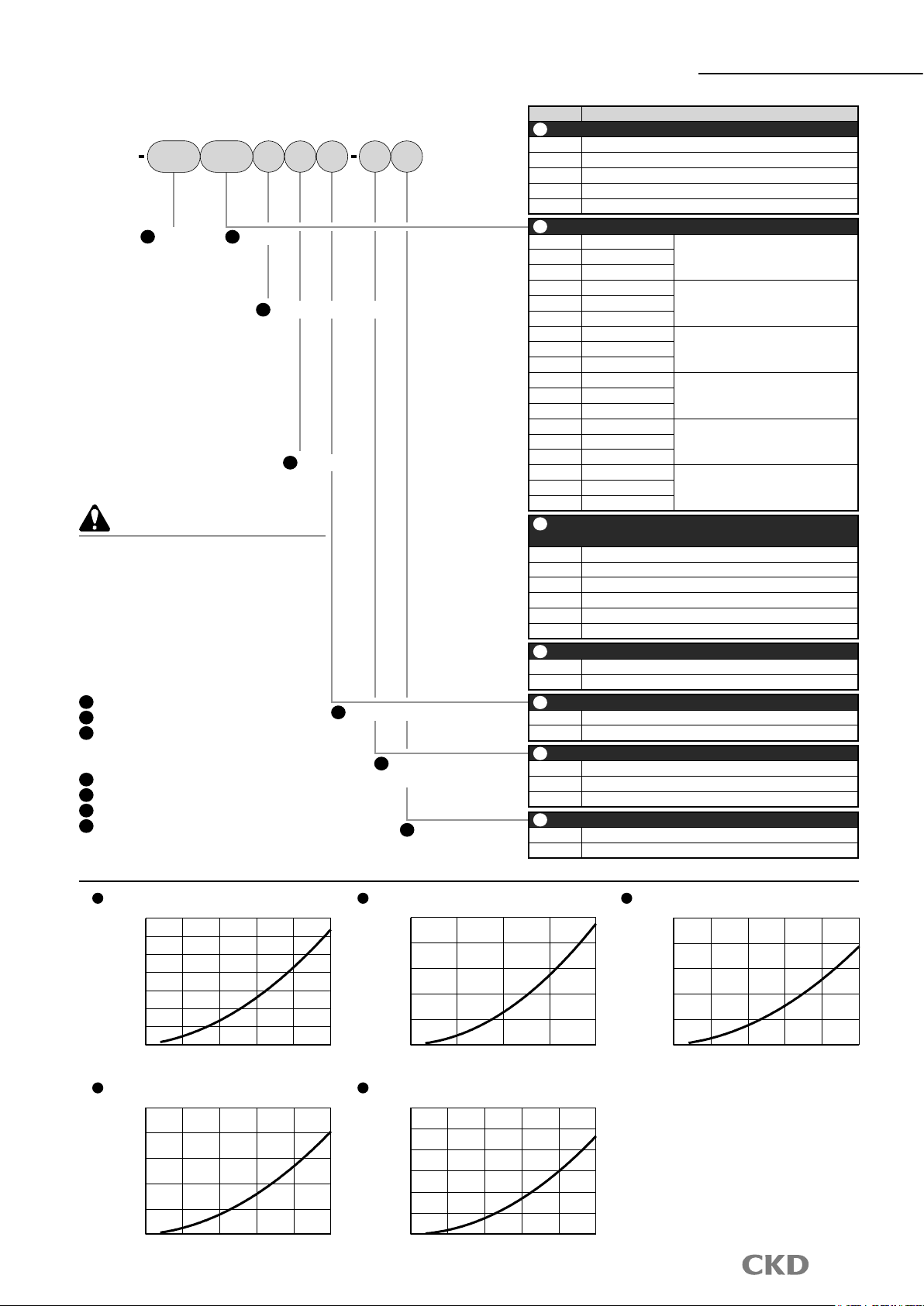

WFK2-005

0.07

[MPa]

0.06

0.05

0.04

0.03

0.02

Pressure loss

0.01

0.00

0

Flow rate [ℓ/min]

WFK2-100

0.050 0.030

[MPa]

0.040

0.030

0.020

Pressure loss

0.010

0.000

0

20

40

60

80

Flow rate [ℓ/min]

100

WFK2-020

0.05 0.05

[MPa]

0.04 0.04

0.03 0.03

0.02 0.02

Pressure loss

0.01 0.01

0.00

0

5

10

Flow rate [ℓ/min]

15

WFK2-250

0.025

[MPa]

0.020

0.015

0.010

0.005

Pressure loss

0.010

0

50

100

150

Flow rate [ℓ/min]

200 250

20

WFK2-050

[MPa]

Pressure loss

0.00

01

102

203

304

Flow rate [ℓ/min]

40 505

2

WFK2

Series

Internal structure and list

WFK2-005, 020, 050

1

2

3

4

5

6

1

7

2

8

3

9

4

10

5

6

11

WFK2-100, 250

Cannot be disassembled

No. Part name Material

1 Packing FKM Fluoro rubber

2 O-ring FKM Fluoro rubber 2 8 CPU Base 1

3 Temperature sensor SUS316L Thermistor 1 9 Sensor board 1

Karman's vortex street detection sensor

4

5 Attachment SUS304 2 11 Bracket (option) SUS304 or SPCC (1)

6 Sensor body PPS Resin GF40% 1

PPS Resin

Piezoelectric element

* The wetted parts are 2, 3, 4, 5, 6 and 10.

Quantity

No. Part name Material

1 or 2

7 Liquid crystal 1

1 10 O-ring FKM Fluoro rubber 2

7

8

9

10

11

Quantity

WFK2-005, 020, 050****A

1

2

3

4

5

6

7

8

9

10

Cannot be disassembled

No. Part name Material

1 Handle POM Resin 1 7 O-ring FKM Fluoro rubber 2

2 O-ring FKM Fluoro rubber 1

3 Stufng PPS Resin GF40% 1 FKM Fluoro rubber

4 Spacer SUS304 1 9 Attachment SUS304 2

5 O-ring FKM Fluoro rubber 1 10 External case PBT Resin GF30% 1

6 Cock body PPS Resin GF40% 1

* The wetted parts are 2, 3, 4, 5, 6, 7, 8, 9 and 10.

Quantity

No. Part name Material

8 Cock

PPS Resin GF40%

Quantity

1

3

Loading...

Loading...