Page 1

PRIVATE CARS

CITROËN C5 - CITROËN C8

«The technical information contained in this document is intended for the exclusive use of the trained personnel

of the motor vehicle repair trade. In some instances, this information could concern the security and safety of

the vehicle. The information is to be used by the professional vehicle repairers for whom it is intended and they

alone would assume full responsibility to the exclusion of that of the manufacturer».

«The technical information appearing in this brochure is subject to updating as the characteristics of each

model in the range evolve. Motor vehicle repairers are invited to contact the CITROËN network periodically for

further information and to obtain any possible updates».

CAR 000.020

Volume 3

22000055

Page 2

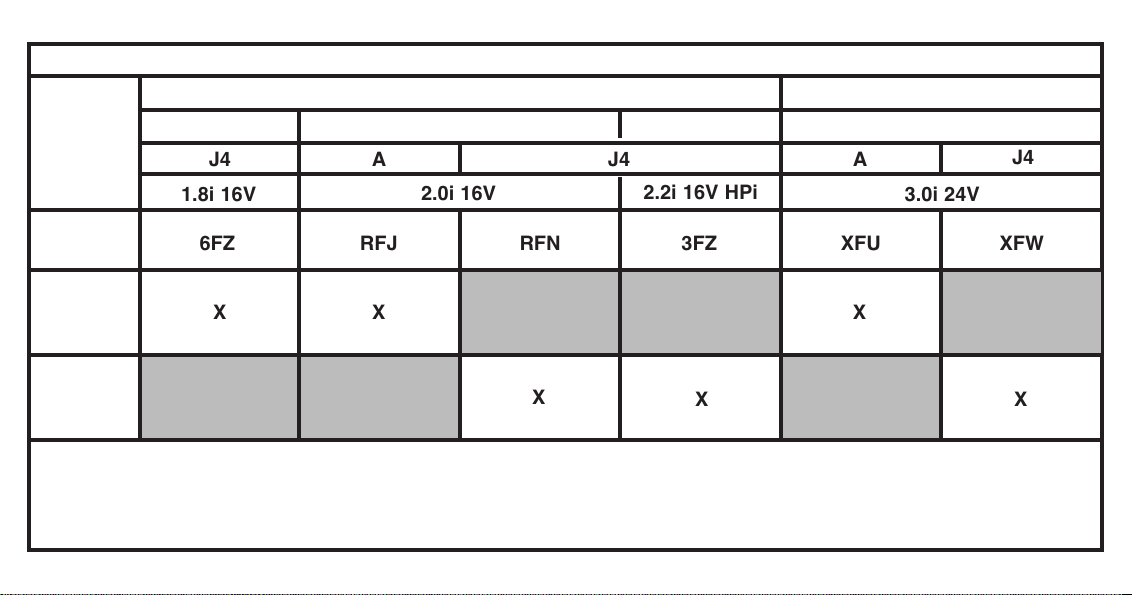

Engine

families

Engine

types

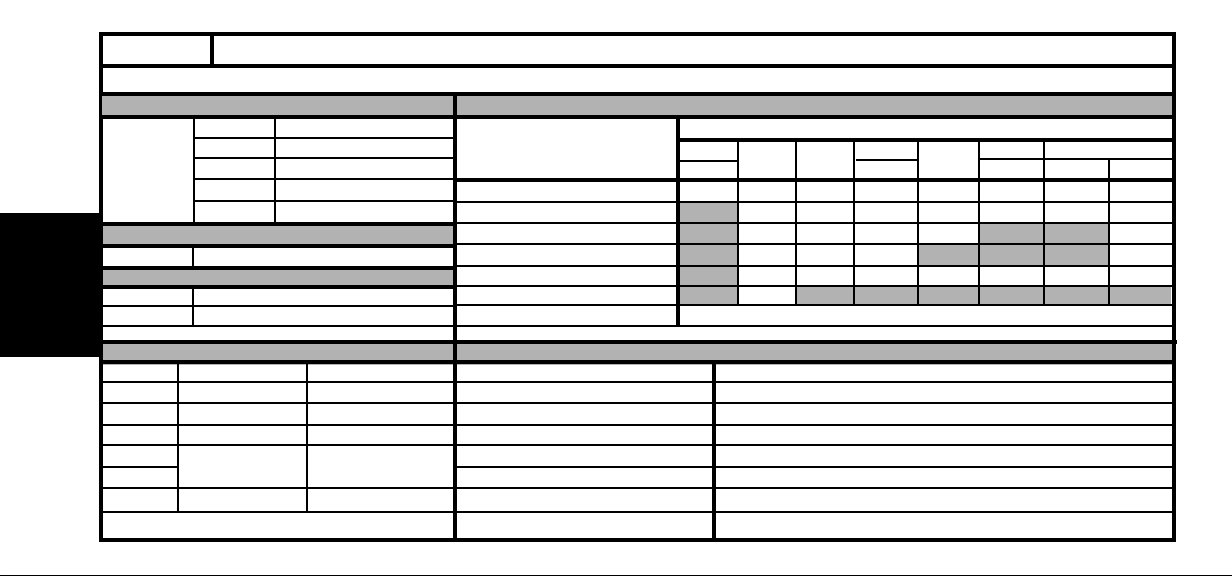

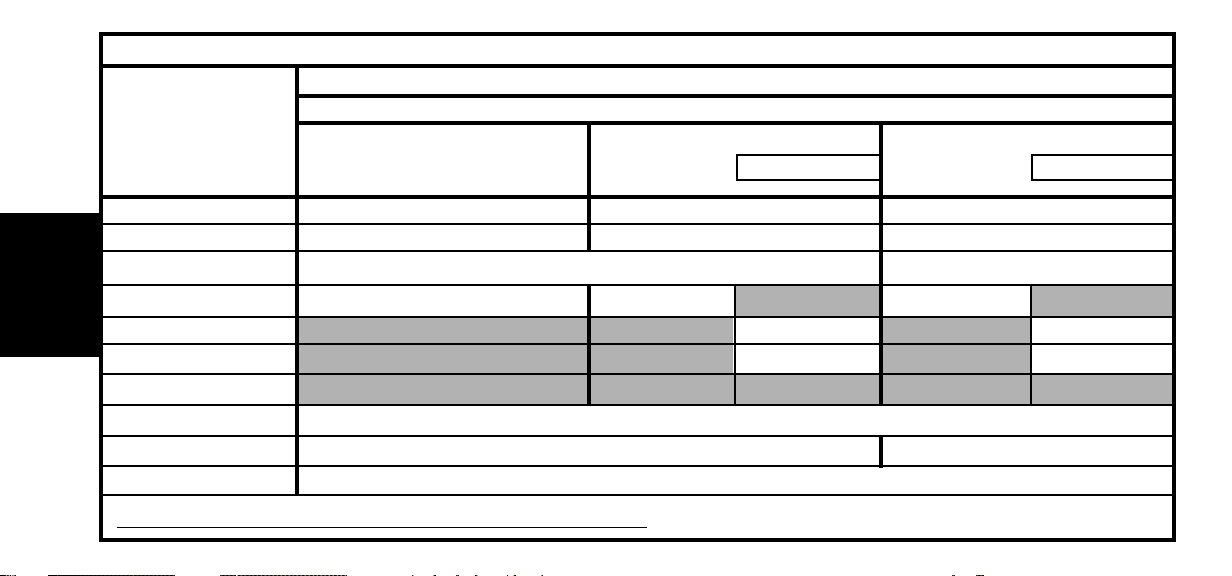

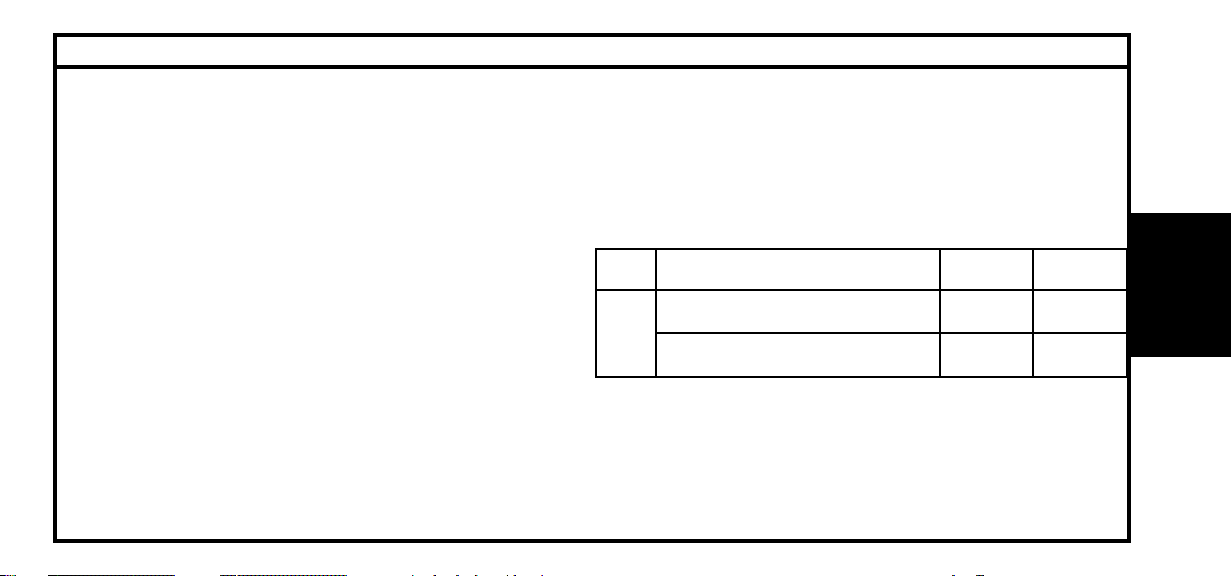

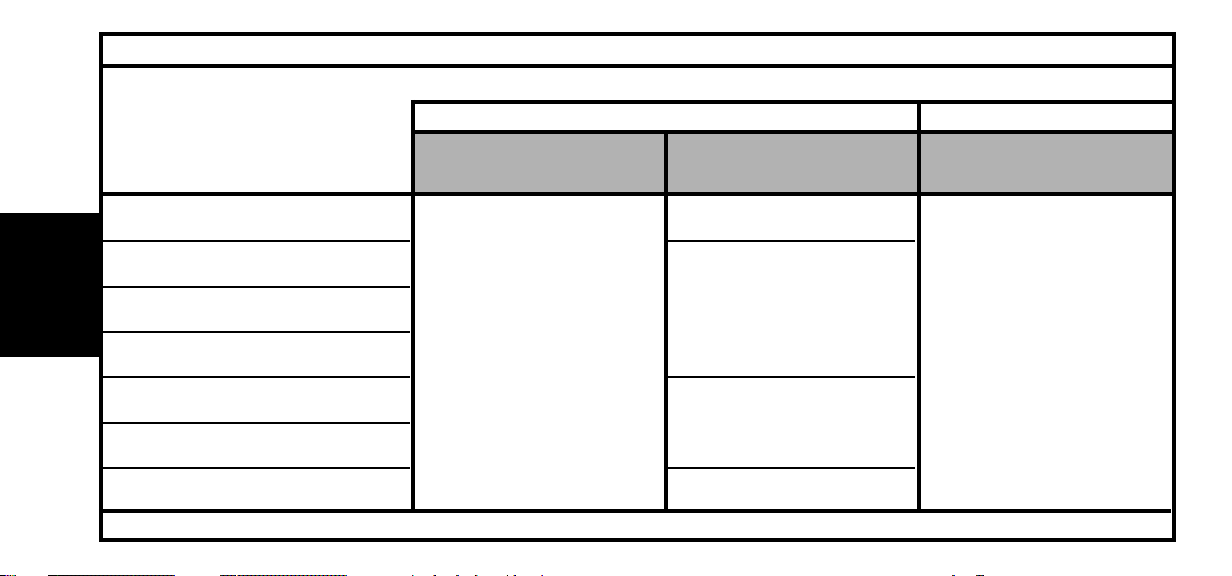

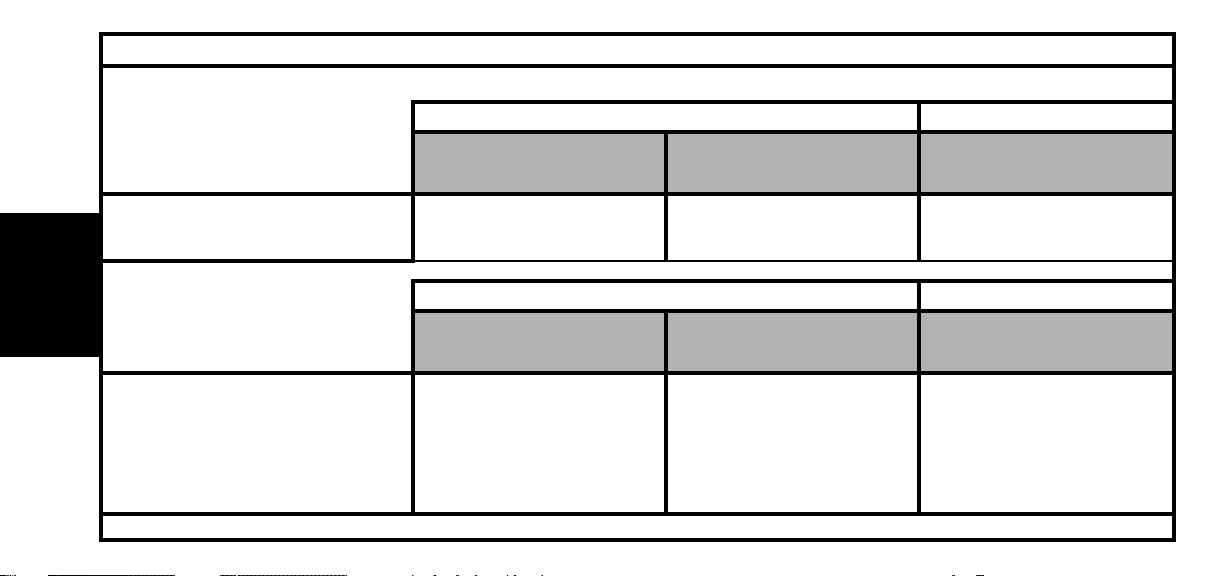

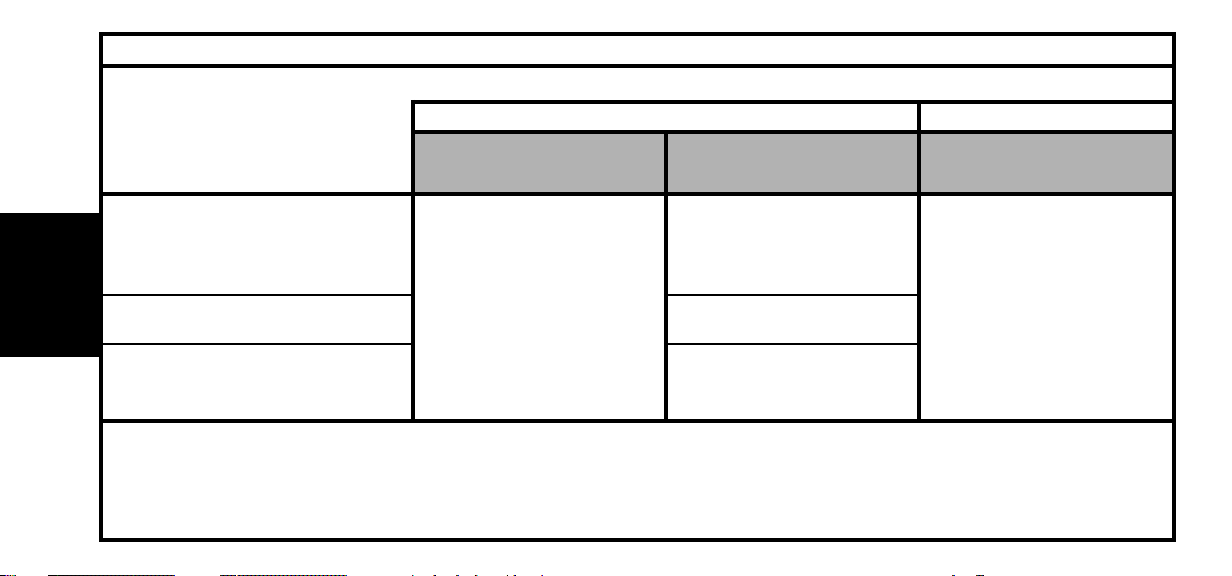

CORRESPONDENCE TABLE FOR PETROL ENGINES

EW DWES

7

J4 J4 A

A

1.8i 16V

10 12

2.0i 16V

2.2i 16V HPi

6FZ RFJ 3FZRFN XFWXFU

9 12

J4

3.0i 24V

C5

C8

XX X

X

X

X

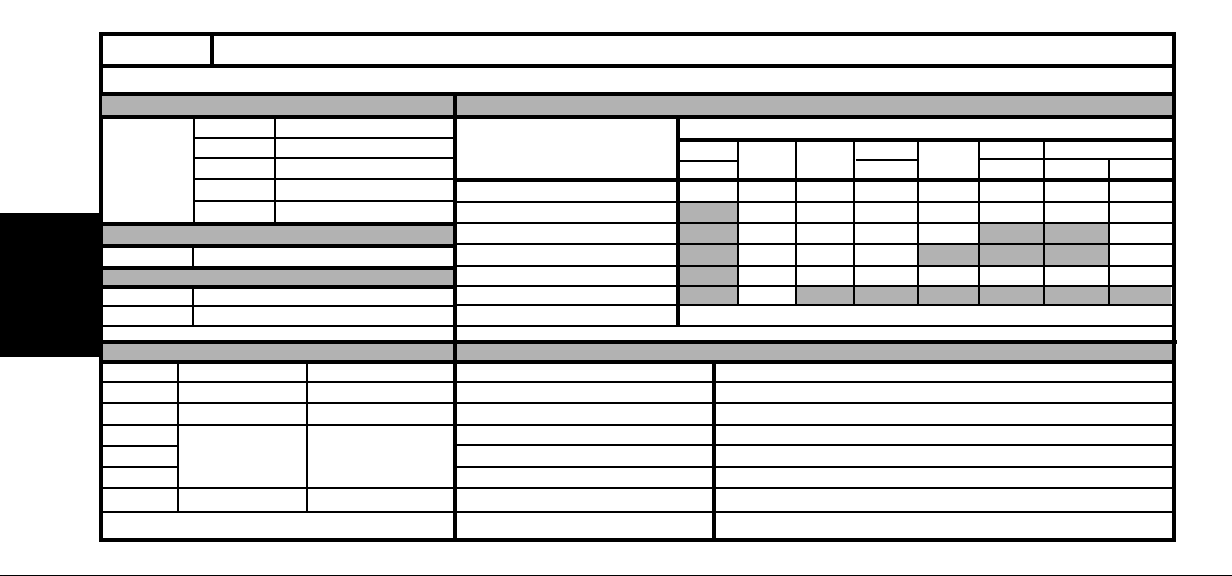

Page 3

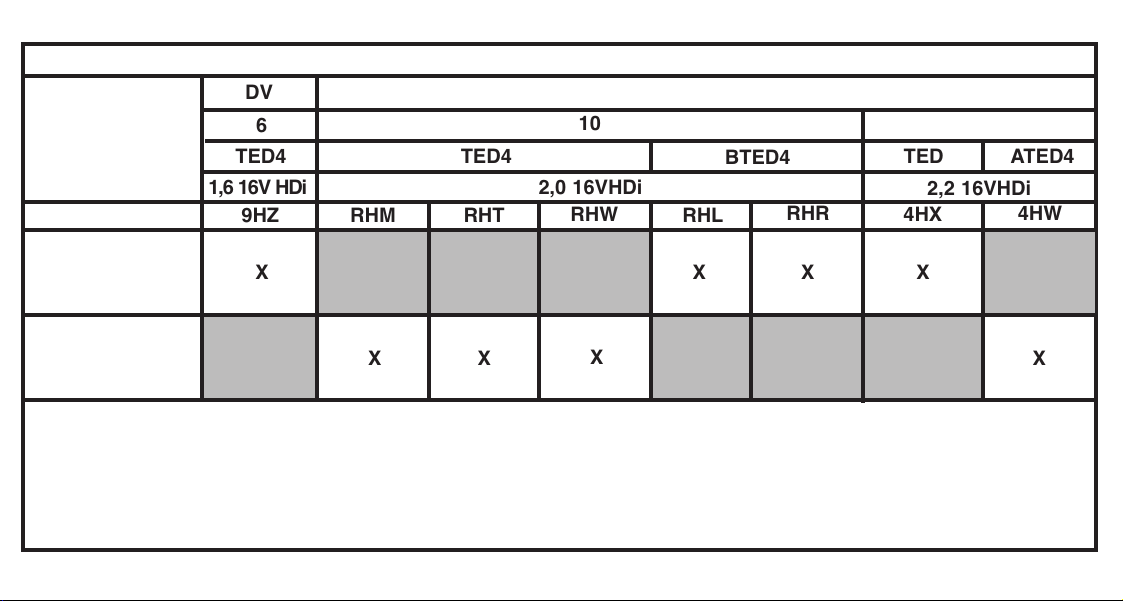

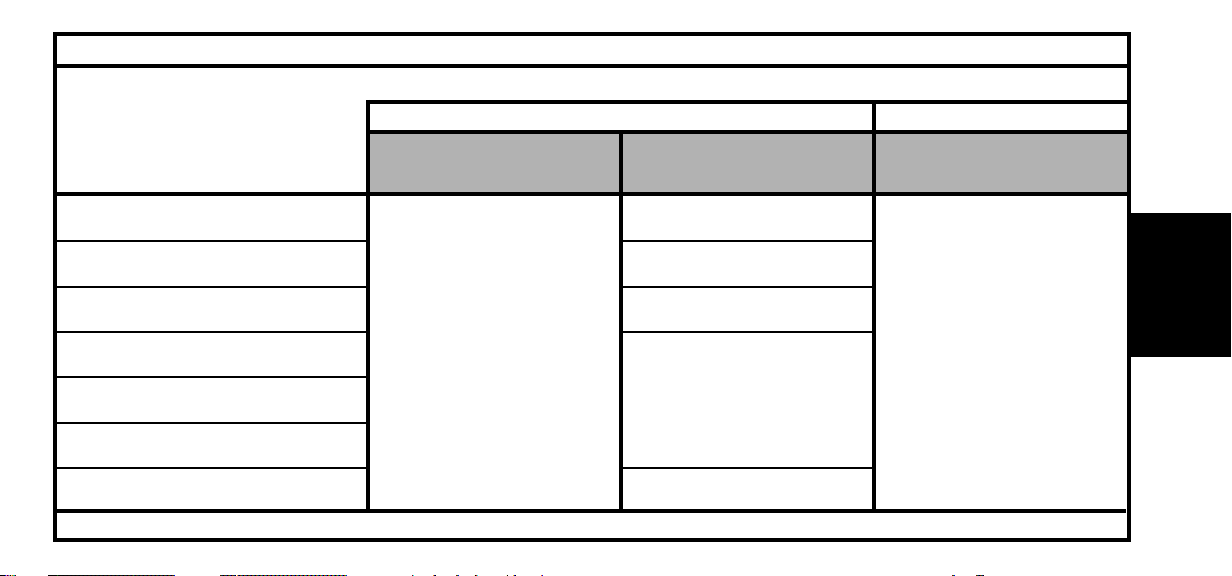

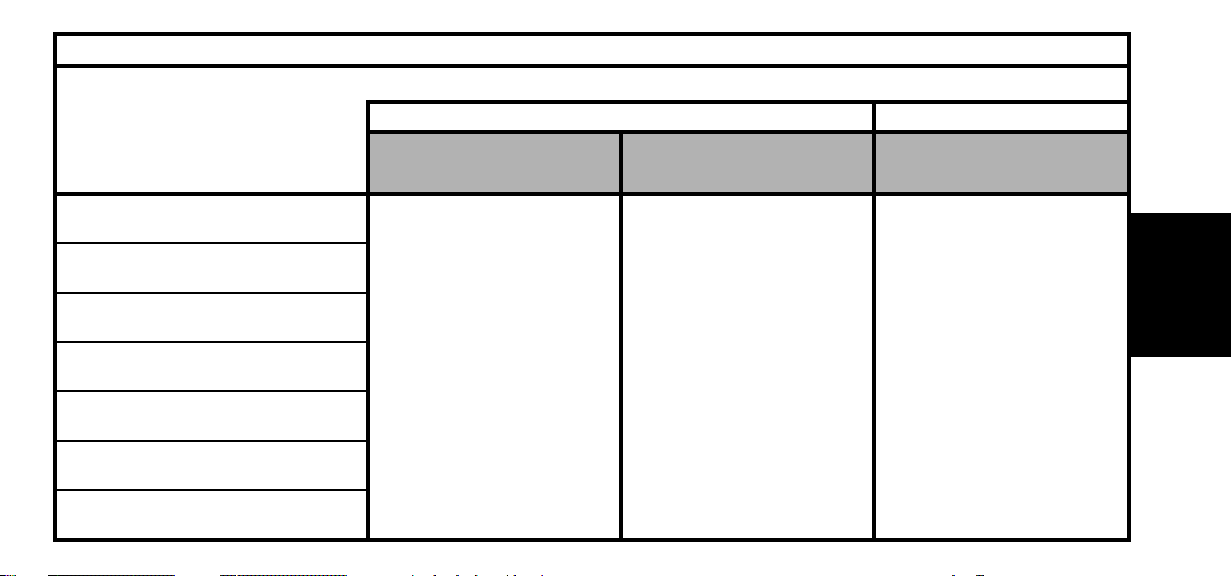

Engine families

Engine types

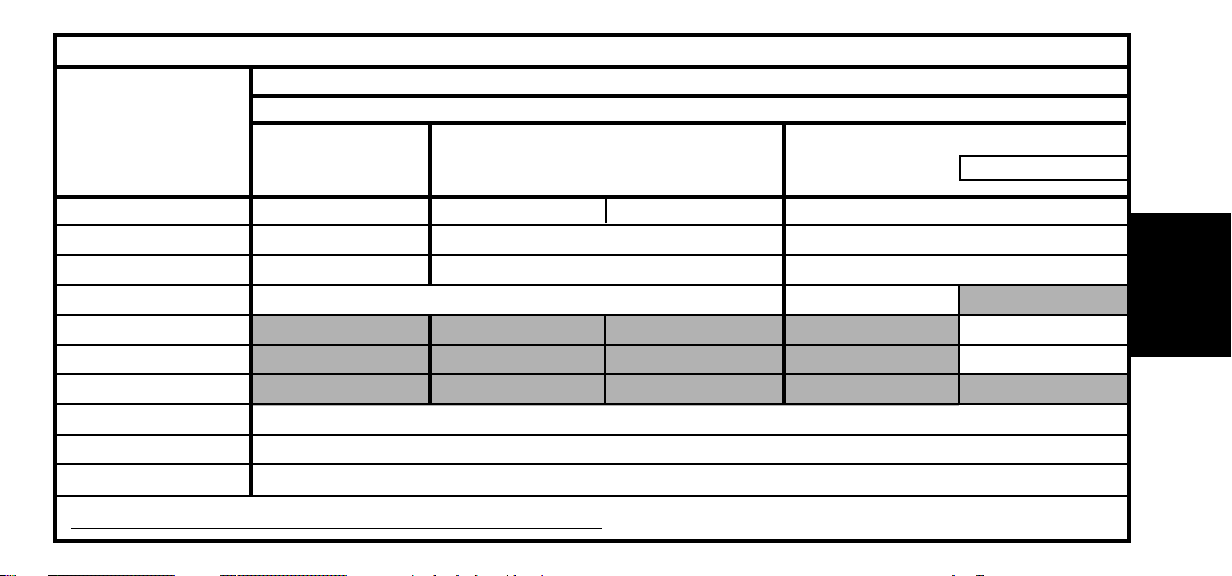

DV

6

TED4

1,6 16V HDi

9HZ

CORRESPONDENCE TABLE FOR DIESEL ENGINES

10

TED4

BTED4

2,0 16VHDi

RHM

RHT

RHW

RHL

RHR

TED ATED4

2,2 16VHDi

4HX

4HW

C5

C8

X

X

X

X

X

X

X

X

Page 4

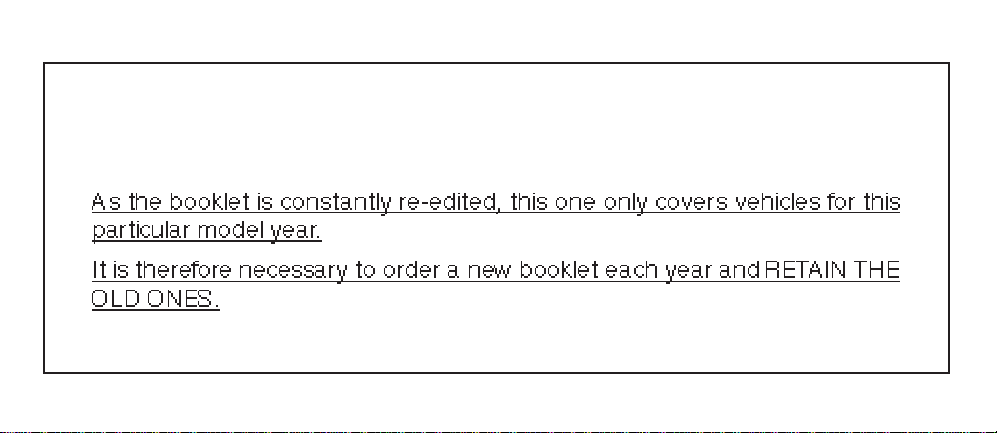

VERY IMPORTANT

As the booklet is constantly re-edited, this one only covers vehicles for this

particular model year .

It is therefore necessarytoorder a new booklet each year and RETAIN THE

OLD ONES.

Page 5

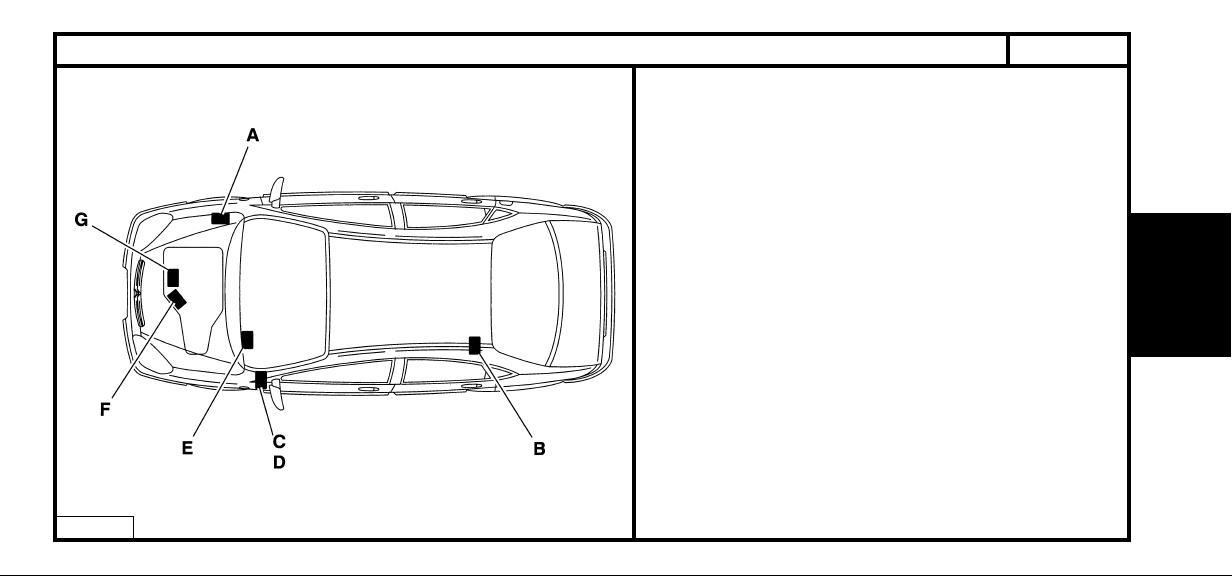

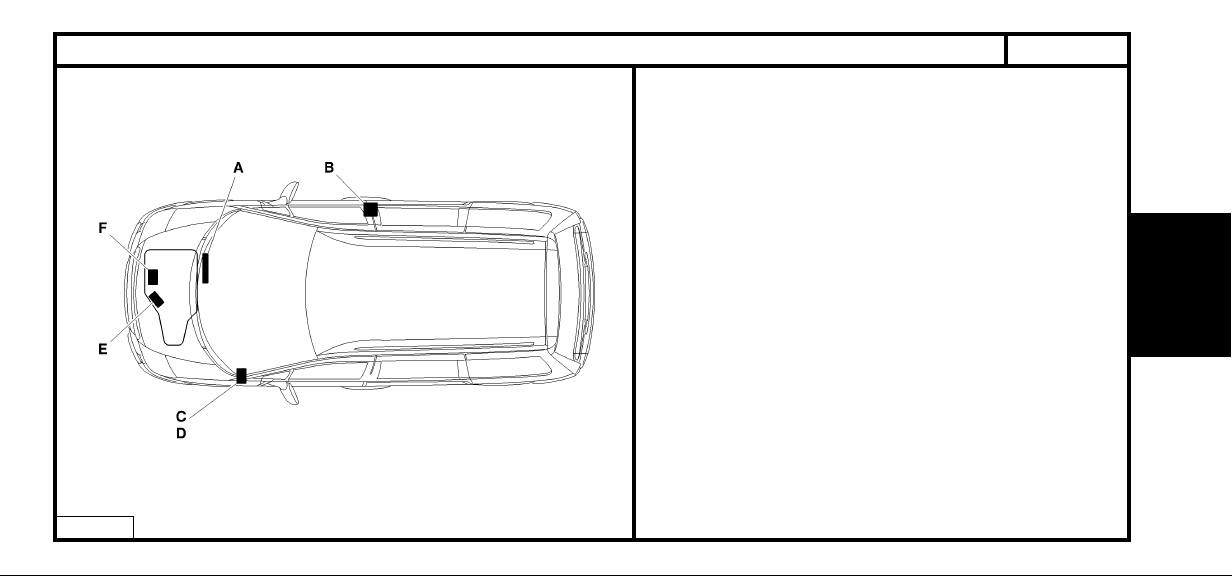

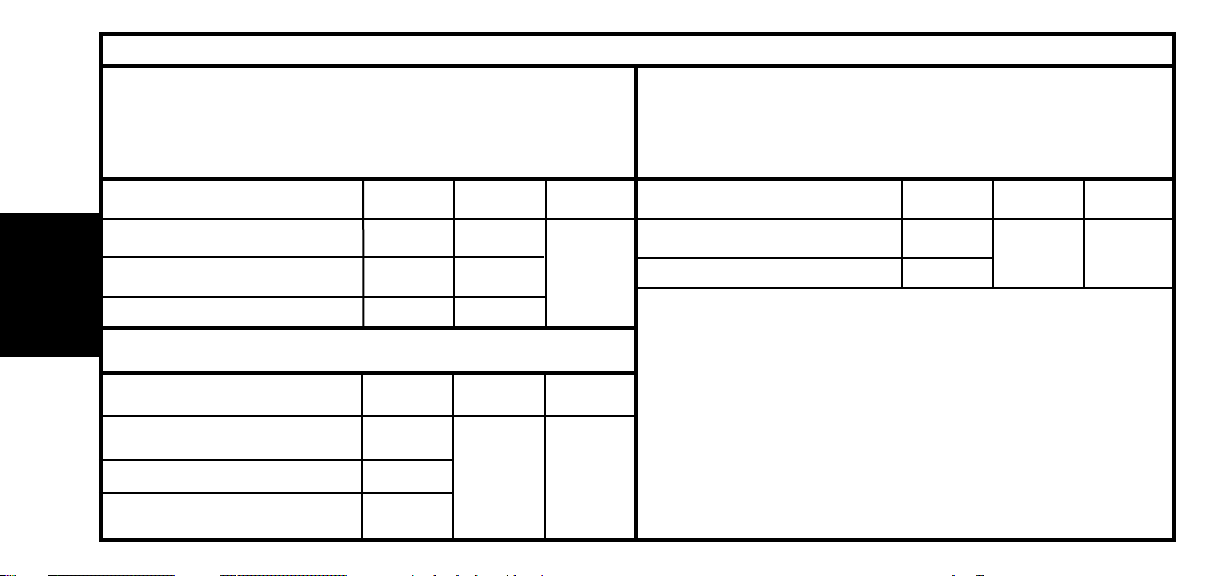

IDENTIFICATION OF VEHICLES

A- Chassis stamp

B - Manufacturer's data plate

C - A-S/RP No. and RP paint code

C5

(cold stamp on bodywork).

(under the rear bench seat).

(label on front pillar close to driver's door).

E1APO8RD

D - Inflation pressures and tyre references

(label on front pillar close to driver's door).

E - Serial no. on bodywork.

F - Gearbox reference - Factory serial no.

G - Engine legislation type - Factory serial no.

1

GENERALGENERAL

Page 6

GENERAL

C5

Structure

D Family (1)

DC

RFNC/IF

DC5

C 5-door saloon

E Estate

C Bodywork (2)

RFN Engine (3)

C Version (4)

/IF Variant (5)

Family (1)

Body shape (2)

IDENTIFICATION OF VEHICLES

Type approval

Version (4)

Depollution levels

L3

W3 83/87 K’ L3/L4 Euro IV

Manual 5-speed gearbox A B C P V 5 8 1

Manual 4-speed gearbox E F R W 6 9 2

Manual 6-speed gearbox ts G H S X 3

Automatic 6-speed gearbox D J N U

Axle and/or gearbox gears K L T Y 7 0 4

Other possible combinations M

No gearbox Z

L4 Euro IV

US

Other

K Alcohol

Engine (3)

6FZ EW7J4 1.8i 16V

RFJ EW10A 2.0i 16V

XFU ES9A 3.0i 24S

9HZ DV6TED4 1.6i 16 HDi

RHL

RHR

4HX DW12TED4 2.2 16V HDi

DW10BTED4 2.0i 16V HDi

Variants (5)

Entreprise convertible T

Integral alternator-starter (ADIN) AD

Without FAP SF

Fiscal incentives IF

Piloted manual gearbox P

Downgraded depollution D

LPG dual fuel GL

STT2 (stop and start) S

2

Page 7

E1AP0A2D

IDENTIFICATION OF VEHICLES

A- Chassis stamp

B - Manufacturer's data plate

C - A-S / RP No. and RP paint code

D - Inflation pressures and tyre references

E - Gearbox reference - Factory serial no.

F - Engine legislation type - Factory serial no.

3

(cold stamp on bodywork).

(under RH centre pillar).

(label on front pillar).

(label on front pillar).

C8

GENERALGENERAL

Page 8

GENERAL

C8

Structure

E Family (1)

EA

XFWF/IF

EC8

A Monospace 7 seats maximum

B Monospace 8 seats maximum

A Bodywork (2)

XFW Engine (3)

F Version (4)

/IF Variant (5)

Family (1)

Body shape (2)

IDENTIFICATION OF VEHICLES

Type approval

Version (4)

Depollution levels

L3

W3 83/87 K’ L3/L4 Euro IV

Manual 5-speed gearbox A B C P V 5 8 1

Manual 4-speed gearbox E F R W 6 9 2

Manual 6-speed gearbox ts G H S X 3

Automatic 6-speed gearbox D J N U

Axle and/or gearbox gears K L T Y 7 0 4

Other possible combinations M

No gearbox Z

L4 Euro IV

US

Other

K Alcohol

Engine (3)

RFN EW10J4 2.0i 16V

3FZ EW12J4 2.2i 16V Hpi

XFW ES9J4 3.0i 24S

RHM

DW10TED4 2.0i 16V HDiRHT

RHW

4HW DW12ATED4 2.2i 16V HDi

Variants (5)

Entreprise convertible T

Integral alternator-starter (ADIN) AD

Without FAP SF

Fiscal incentives IF

Piloted manual gearbox P

Downgraded depollution D

LPG dual fuel GL

STT2 (stop and start) S

4

Page 9

CAPACITIES (in litres)

Oil capacities are defined according to the following methods

Draining of the engine lubrication system by GRAVITY

Place the vehicle on horizontal ground (in the high position if

hydropneumatic suspension).

The engine should be hot (oil temperature 80°C).

Drain the sump by gravity.

Remove the oil filter cartridge (time for draining and drip-drip = 15

minutes approx.).

Refit the cap with a new seal.

Refit a new oil filter cartridge.

Refill the engine with oil (see table for oil capacity).

Start the engine to fill the oil filter cartridge.

Stop the engine (allow to stabilise for 5 minutes).

ESSENTIAL: Systematically check the oil level using the oil dipstick.

Draining methods

Place the vehicle on horizontal ground (in the high position if

hydropneumatic suspension).

The engine should be hot (oil temperature 80°C).

Remove the oil by suction through the dipstick tube.

Remove the oil filter cartridge.

Maintain the suction of oil in the sump (15 minutes approx.).

Refit a new oil filter cartridge.

Refill the engine with oil (see table for oil capacity).

Start the engine to fill the oil filter cartridge.

Stop the engine (allow to stabilise for 5 minutes).

WARNING: Remove the suction container before starting the engine.

5

Draining of the engine lubrication system by SUCTION

GENERALGENERAL

Page 10

GENERAL

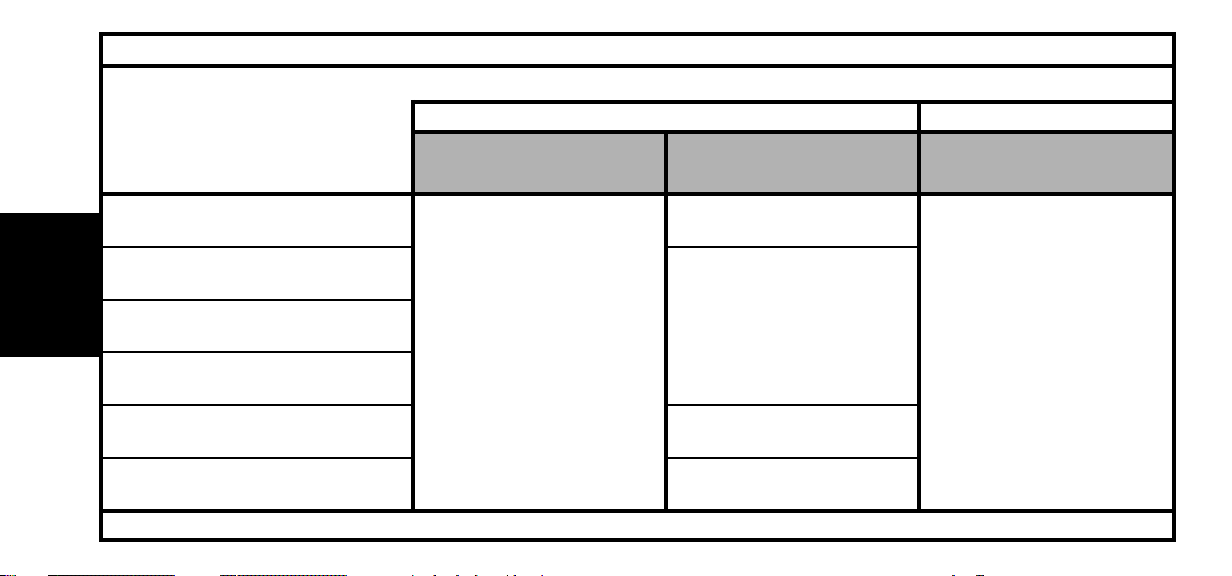

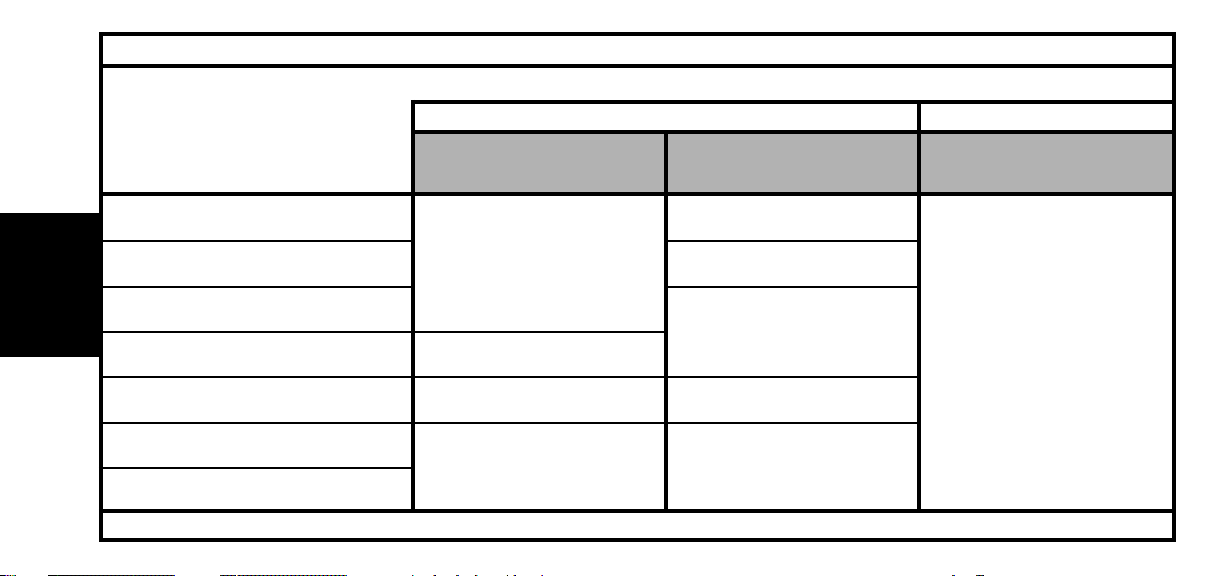

CAPACITIES (in litres)

C5

Petrol

2.0i 16V1.8i 16V

AUTO.

Engine type 6FZ RFJ XFU

Engine with filter change 4,25 5 5,25

Between Min. and Max. 1,7 2

5-speed gearbox 1,8 1,8 1,8

Automatic gearbox 67

After oil change 34

Braking circuit

Hydraulic circuit 4,3

Cooling system 8,8 14

Fuel tank capacity 65

IMPERATIVE: Systematically check the oil level using the oil dipstick.

6

3.0i 24S

AUTO.

Page 11

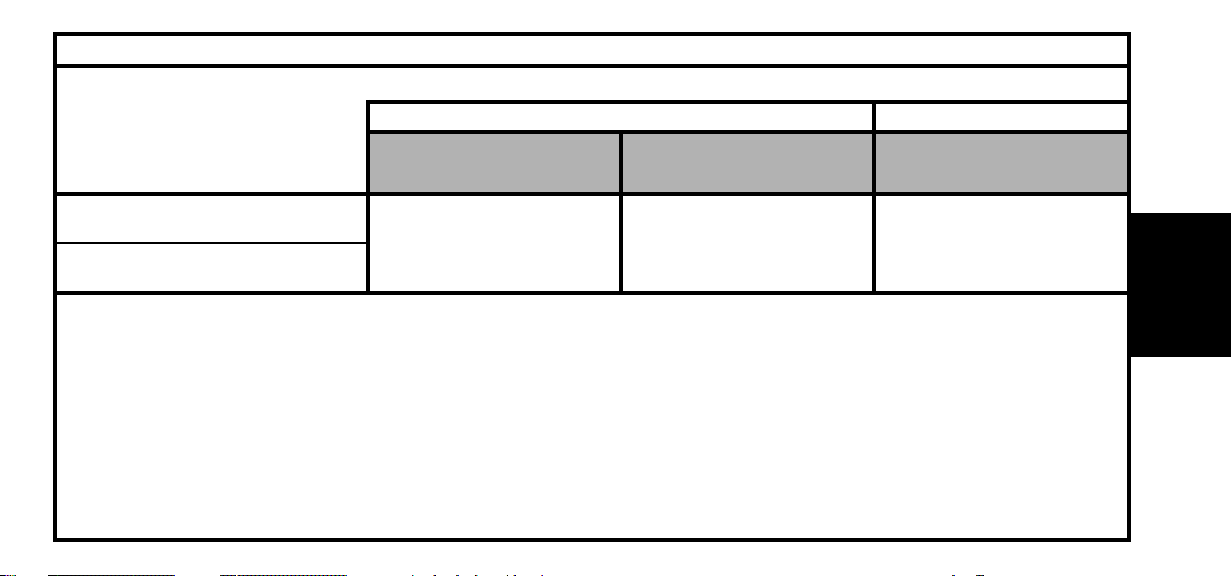

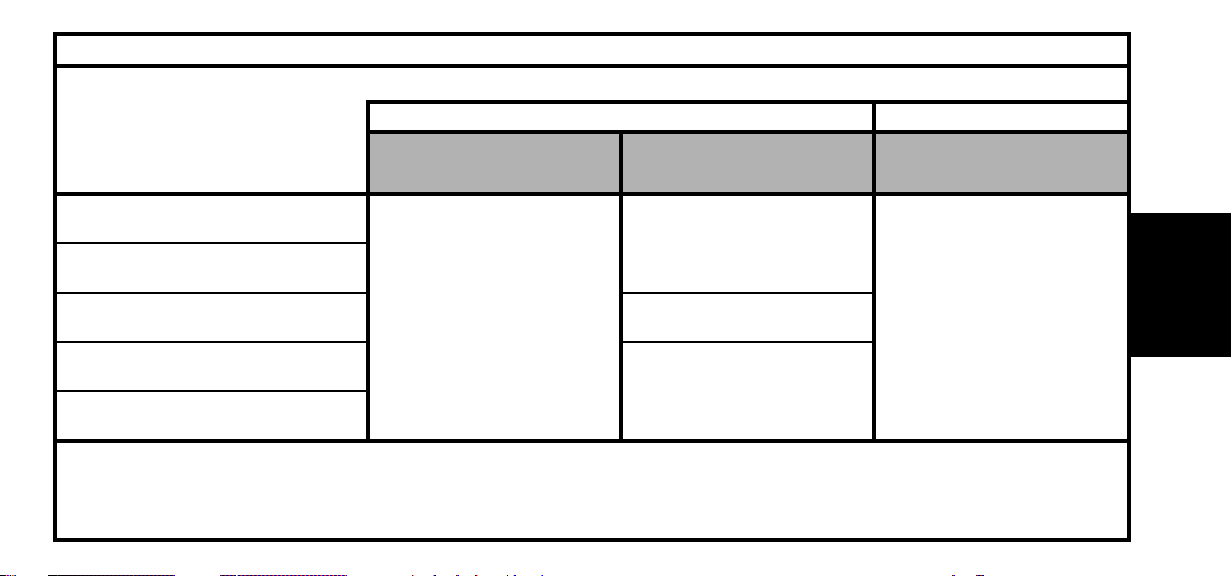

CAPACITIES (in litres)

C5

Diesel

2.0 16V HDi1.6 16V HDi

Engine type 9HZ RHL RHR 4HX

Engine with filter change 3,75 5,25 4,75

Between Min. and Max. 1,55 1,9 1,5

5-speed gearbox 1,8 1,8

Automatic gearbox 8,3

After oil change 5,3

Braking circuit

Hydraulic circuit 4,3

Cooling system 10,5 11,7 (with additional heating)

Fuel tank capacity 65

IMPERATIVE: Systematically check the oil level using the oil dipstick.

7

2.2 16V HDi

AUTO.

GENERALGENERAL

Page 12

GENERAL

CAPACITIES (in litres)

C8

Petrol

2.0 16V HDi2.0i 16v 2.2i 16V 3.0i 24V

AUTO.

Engine type RFN 3FZ XFW RHM RHT RHW 4HW

Engine with filter change 4,25 5,25 4,75 4,75

Between Min. and Max. 1,7 2 1,9 1,5

5-speed gearbox 1,8 2 2

Automatic gearbox 8,3 6

After oil change 5,3 3

Hydraulic circuit 0,66

Cooling system 7 7,2 10,5 10 11,3

Fuel tank capacity 80

8

Diesel

2.2 16V HDi

AUTO.

Page 13

LUBRICANTS - TOTAL recommended oils

EVOLUTIONS (YEAR 2004).

CITROËN C4

Petrol engine versions except 2.0 i 16V 180 hp (132 kW):

- Normal maintenance interval: 30 000 km (20 000 miles).

- Severe maintenance interval: 20 000 km (12 000 miles).

Petrol engine version 2.0L i 16V 180 hp (132 kW):

- Normal maintenance interval: 20 000 km (12 500 miles).

- Severe maintenance interval: 15 000 km (10 000 miles).

Diesel engine versions.

WARNING: Vehicles HDi FAP (*) do not accept the energy economy

oil TOTAL ACTIVA FUTUR 9000 5W30 for France, TOTAL QUARTZ

FUTURE 9000 5W30 outside France .

DV6 engines:

- Normal maintenance interval: 20 000 km (12 500 miles).

- Severe maintenance interval: 15 000 km (10 000 miles).

DW engines:

- Normal maintenance interval: 30 000 km (20 000 miles).

- Severe maintenance interval: 20 000 km (12 000 miles).

New Look CITROËN C5

Petrol engine versions:

- Normal maintenance interval: 30 000 km (20 000 miles).

- Severe maintenance interval: 20 000 km (12 000 miles).

Diesel engine versions.

WARNING: Vehicles HDi FAP (*) do not accept the energy economy

oil TOTAL ACTIVA FUTUR 9000 5W30 for France, TOTAL QUARTZ

FUTURE 9000 5W30 outside France.

DV6 engines:

- Normal maintenance interval: 20 000 km (12 500 miles).

- Severe maintenance interval: 15 000 km (10 000 miles).

DW engines :

- Normal maintenance interval: 30 000 km (20 000 miles).

- Severe maintenance interval: 20 000 km (12 000 miles).

ESSENTIAL: For all vehicles with a 30 000 km (20 000 miles) maintenance interval, use exclusively TOTAL ACTIVA/QUARTZ 7000 or

9000 or any other oils offering identical specifications to these.

These oils offer specifications that are superior to those defined by

norms ACEA A3 OR API SJ/CF.

Failing this, it is essential to adhere to the maintenance programmes

covering severe operating conditions.

9

GENERAL

GENERAL

Page 14

GENERAL

LUBRICANTS - TOTAL recommended oils

Use of oil grade 10W40.

It is possible to use the semi-synthetic oil 7000 10W40 on HDi and HDi

FAP vehicles.

WARNING: To avoid difficulties when starting from cold (< 20°C), use

5W40 oil.

For more details, see the oil usage table (paragraph 3.3).

Commercial description for energy economy oil.

TOTAL ACTIVA FUTUR 9000 5W30 (France only).

TOTAL QUARTZ FUTUR 9000 5W30 (except France).

The exclusions for use of this oil are the following:

- XSARA VTS 2.0 16V (XU10J4RS).

- JUMPER/RELAY 2.8 HDi and 2.8 TDi (SOFIM engine).

- HDi FAP vehicles.

- CITROËN C3 HDi 16V (DV4TED4).

- CITROËN C8 2.2i (EW12J4).

- CITROËN C4 and C5 2.0i (EW10A).

- CITROËN C4 (EW10J4S).

Engine oil norms.

Current norms.

The classification of these engine oils is established by the following

recognised organisations:

- S.A.E : Society of Automotive Engineers.

- API : American Petroleum Institute.

- ACEA : Association des Constructeurs Européens d'Automobiles.

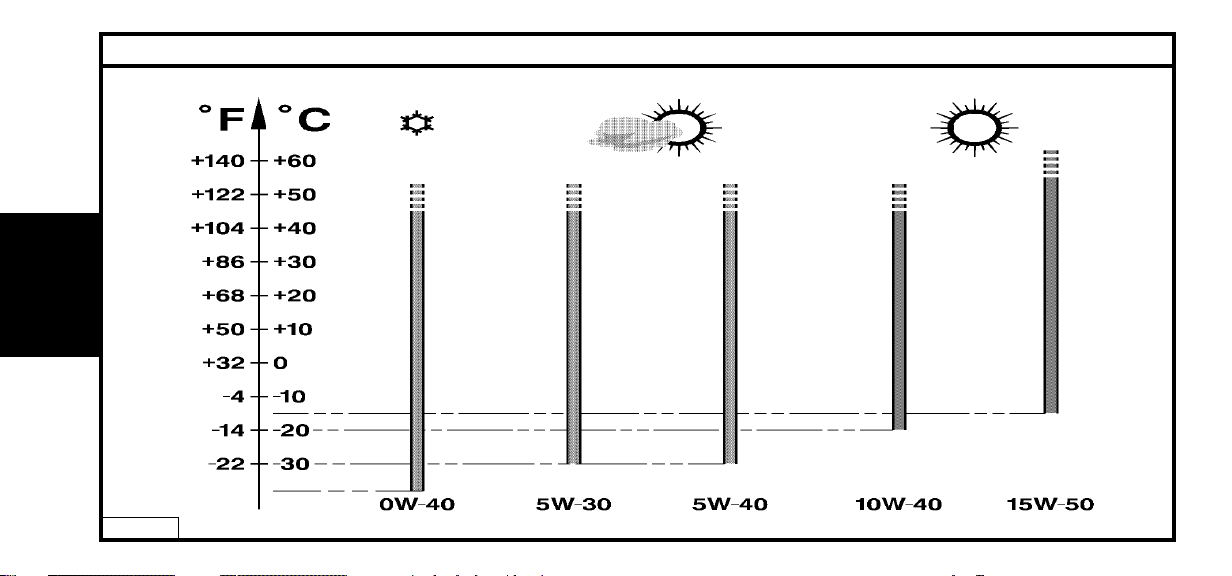

S.A.E. Norms - Table for selection of engine oil grade.

Selection of engine oil grades recommended for climatic conditions in

countries of distribution (see table, paragraph 3.3).

Evolution of the norms to 01/01/2003.

ACEA 2003 norms.

The meaning of the first letter has not changed, it still corresponds

to the type of engine:

- A: petrol and dual fuel petrol / LPG engines.

- B: diesel engines.

The figure following the first letter corresponds to the type of oil:

- 3: high performance oils.

- 4: oils specifically for direct injection diesel engines.

- 5: very high performance oils permitting lower fuel consumption, specific to

direct injection diesel engines.

Example:

- ACEA A3: high performance oils specifically for petrol and dual fuel petrol/

LPG engines.

- ACEA A/B: blended oils giving very high performance for all engines, also

permitting better fuel economy, specifically for direct injection diesel engines.

NOTE: From 01/01/2003 there is no longer any reference to the year of

creation of the norm (example : ACEA A3/B3 98 becomes ACEA

10

A3/B3).

Page 15

LUBRICANTS - TOTAL recommended oils

API Norms:

The meaning of the first letter has not changed, it still corresponds to the

type of engine:

- S: petrol and dual fuel petrol / LPG engines.

- C: diesel engines.

The second letter corresponds to the degree of evolution of the oil

(ascending order).

Example: Norm SL is more severe than norm SJ, corresponding to

a higher level of performance.

Recommendations.

ESSENTIAL: To preserve engine performances, all engines fitted in

CITROËN vehicles must be lubricated with high quality oils (synthetic

or semi-synthetic).

CITROËN engines are lubricated at the factory with TOTAL oil of grade

S.A.E 5W-30.

TOTAL oil of grade S.A.E 5W-30 allows improved fuel economies

(approx 2.5%).

The oil 5W30 is used only for the following engines (year 2004):

- XU10 J4RS : XSARA VTS 2.0i 16V (3-door).

- SOFIM : JUMPER / RELAY 2.8 TDi and 2.8 HDi.

- HDi : With particle filter (FAP).

- DV4 TED4 : CITROËN C3 1.4 16V HDi.

- EW 12J4 : CITROËN C8 2.2i.

- EW 10A : CITROËN C4 and C5 2.0i.

- EW10J4S engine : CITROËN C4.

WARNING: CITROËN engines prior to model year 2000 do not have

to be lubricated with oils adhering to the norms:

- ACEA AI-98 and API SJ/CF EC or current norms ACEA A5/B5.

Denomination of TOTAL oils according to country of marketing:

- TOTAL ACTIVA (France only).

- TOTAL QUARTZ (outside France).

Summary.

Norms to be respected for engine oils (year 2004).

Year Engine types concerned

Petrol and LPG dual fuel engines

2003

Diesel engines

(*) It is essential not to use engine oils respecting these norms for

XU10J4RS, SOFIM 2.8 TDi and SOFIM 2.8 HDi engines, HDi engines

with particle filter EW10A, EW12J4, DV4TED4.

11

ACEA API

Norms Norms

A3 or A5

(*)

B3, B4

or B5 (*)

SJ or SL

GENERALGENERAL

CF

Page 16

GENERAL

LUBRICANTS - TOTAL recommended oils

Classes and grades of TOTAL recommended engine oils.

The oils distributed in each country are suited to the local climatic

conditions.

Blended oils for all engines (petrol, diesel and dual fuel

petrol/LPG):

S.A.E. ACEA API

norms norms norms

TOTAL ACTIVA 9000 A3/B3/

TOTAL QUARTZ 9000

TOTAL ACTIVA FUTUR 9000 (*) SL/CF

TOTAL QUARTZ FUTUR 9000 (*)

TOTAL ACTIVRAC 10W40 A3/B3

(*) Blended oils for all engines giving fuel economy.

Oils for petrol, diesel and dual fuel petrol/LPG engines:

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

TOTAL QUARTZ 9000 0W40 A3 SL

TOTAL ACTIVA 7000

TOTAL QUARTZ 7000

5W40

5W30 A5/B5

S.A.E. ACEA API

norms norms norms

10W40

15W50

B4

Oils specifically for diesel engines:

TOTAL ACTIVA DIESEL 7000

TOTAL QUARTZ DIESEL 7000

TOTAL ACTIVA DIESEL 7000 15W50

12

S.A.E. ACEA API

norms norms norms

10W40

B3 CF

Page 17

LUBRICANTS - TOTAL recommended oils

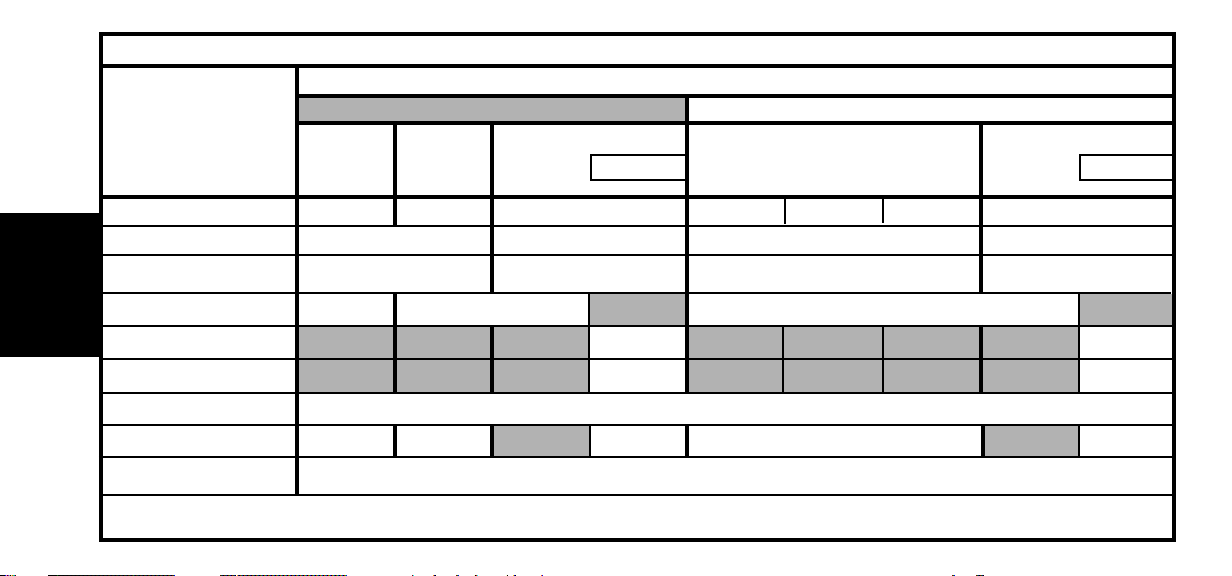

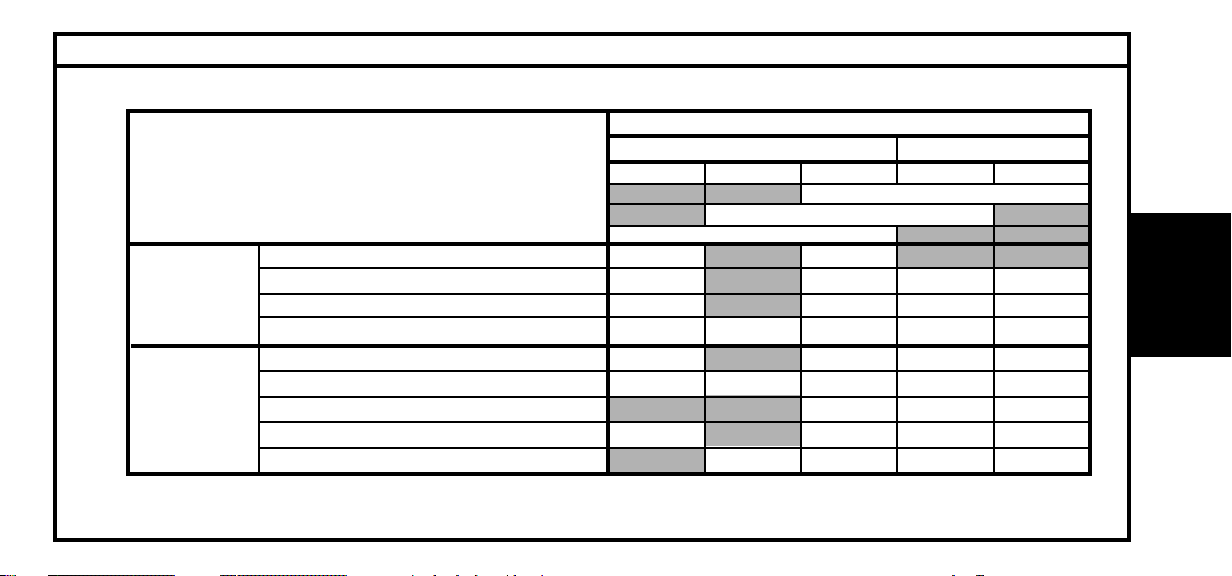

Oil usage table

TOTAL ACTIVA QUARTZ

Engine types

EW10J4S (CITROËN C4) X

Petrol engines

Diesel engines

(*) Do not use this oil in cold climatic conditions (temperature less than - 20°C).

See the table below for the choice of TOTAL engine oil grades to be used according to the climatic conditions in the country of marketing.

EW12J4 (CITROËN C8 2.2i 16V)

EW10A (CITROËN C4 and C5)

Others petrol engines

HDi engines with FAP (*)

Others HDi engines

SOFIM 2.8 HDi and 2.8 TDi (RELAY)

DV4 TED4 (C3 1.6 16V HDi)

Indirect injection diesel engines

0W40 5W30 5W40 10W40 15W50

Cold countries

X

X

X

X

X

X

13

Temperate countries

X

X

X

X

X

X

X

X

X

X

X

X

Semi-synthetic 7000Synthetic 9000

Hot countries

XX

XX

XX

X (*)

XX

XX

XX

XX

X

GENERALGENERAL

Page 18

GENERAL

LUBRICANTS - TOTAL recommended oils

E4AP006D

14

Page 19

FRANCE

Metropolitan FRANCE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

Blended oils for all engines, supplied in bulk

TOTAL ACTIVRAC Norms S.A.E: 10W40

TOTAL ACTIVA

Blended oils for all engines

Metropolitan FRANCE

New Caledonia

Guadeloupe

Saint martin

Reunion

Martinique 7000 10W40 7000 10W50

Guyana

Tahiti

Mauritius

Mayotte

(*) Blended oils for all engines, giving fuel economy.

9000 5W40

FUTUR 9000 5W30 (*)

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

7000 15W50 7000 15W50

15

TOTAL ACTIVA DIESEL

Oils specifically for diesel

engines

7000 10W40

9000 5W40

GENERALGENERAL

Page 20

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Blended oils for all engines

Germany

Austria

Belgium

Bosnia

Bulgaria

Cyprus

Croatia

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

9000 0W40

7000 10W40

7000 10W40

9000 0W40

7000 10W40

9000 0W40

7000 10W40

7000 10W40

9000 15W40

7000 10W40

16

Oils specifically for diesel

engines

7000 10W40

Page 21

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Denmark

Spain

Estonia

Finland

FUTUR 9000 5W30 (*)

Great Britain

Greece

Holland

(*) Blended oils for all engines, giving fuel economy.

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

9000 0W40

7000 10W40

7000 15W40

7000 10W40

9000 0W40

7000 10W40

7000 10W40

7000 15W40

7000 10W40

9000 0W40

17

Oils specifically for diesel

engines

GENERALGENERAL

7000 10W40

Page 22

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Blended oils for all engines

Hungary

Italy

Ireland

Iceland

Latvia

Lithuania

Macedonia

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

9000 0W40

7000 10W40

7000 10W40

9000 0W40

7000 10W40

18

Oils specifically for diesel

engines

7000 10W40

Page 23

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Malta

Moldavia

Norway

Poland

Portugal

Slovakia

Czech Republic

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

7000 15W50

7000 10W40

7000 10W40

9000 0W40

7000 10W40

7000 10W40

9000 0W40

19

Oils specifically for diesel

engines

GENERALGENERAL

7000 10W40

Page 24

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Blended oils for all engines

Romania

Russia

Slovenia

Sweden

Switzerland

Turkey

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

7000 15W50

9000 0W40

7000 10W40

9000 0W40

7000 10W40

7000 10W40

9000 15W50

9000 0W40

20

Oils specifically for diesel

engines

7000 10W40

Page 25

EUROPE

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Ukraine

FUTUR 9000 5W30 (*)

Serbia-Montenegro

(*) Blended oils for all engines, giving fuel economy.

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

9000 0W40

21

Oils specifically for diesel

engines

7000 10W40

GENERALGENERAL

Page 26

OCEANIA

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Blended oils for all engines

Australia

New Zealand

AFRICA

Algeria, South Africa,

Ivory Coast, Egypt,

Gabon, Ghana, Kenya,

Madagascar, Morocco,

Nigeria, Senegal, Tunisia

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

Blended oils for all engines

9000 5W40

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

TOTAL QUARTZ

Oils specifically for petrol and

dual-fuel petrol/LPG engines

22

7000 10W40

7000 10W40

7000 15W50

Oils specifically for diesel

engines

7000 10W40

TOTAL QUARTZ DIESEL

Oils specifically for diesel

engines

7000 10W40

Page 27

CENTRAL AND SOUTH AMERICA

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Argentina

Brazil

Chile

Cuba

Mexico

Paraguay

Uruguay

Blended oils for all engines

9000 5W40

23

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W40

7000 15W50

Oils specifically for diesel

engines

GENERALGENERAL

7000 10W40

Page 28

SOUTH-EAST ASIA

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Blended oils for all engines

China

South Korea

Hong Kong

India - Indonesia

Japan

Malaysia

Pakistan

(*) Blended oils for all engines, giving fuel economy.

FUTUR 9000 5W30 (*)

FUTUR 9000 5W30 (*)

9000 5W40

9000 5W40

9000 5W40

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 10W50

7000 15W50

7000 10W40

7000 15W50

7000 10W40

7000 15W50

7000 15W50

24

Oils specifically for diesel

engines

7000 10W40

Page 29

SOUTH-EAST ASIA

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

Blended oils for all engines

Philippines

Singapore

Taiwan

Thailand

Vietnam

(*) Blended oils for all engines, giving fuel economy.

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 15W50

7000 10W40

7000 15W50

7000 15W50

25

Oils specifically for diesel

engines

7000 10W40

GENERALGENERAL

Page 30

MIDDLE EAST

LUBRICANTS - TOTAL recommended oils

ENGINE OILS

TOTAL QUARTZ

TOTAL QUARTZ DIESEL

GENERAL

Saudi Arabia - Bahrain

Dubai

United Arab Emirates

Iran

Israel - Jordan - Kuwait - Lebanon

Oman - Qatar - Syria - Yemen

Blended oils for all engines

9000 5W40

Oils specifically for petrol and

dual-fuel petrol/LPG engines

7000 15W50

7000 10W40

7000 15W50

7000 15W50

26

Oils specifically for diesel

engines

7000 10W40

Page 31

LUBRICANTS - TOTAL recommended oils

GEARBOX OILS

Manual and piloted manual

gearboxes

MB3 automatic gearbox

4HP20 and AL4 autoactive

automatic gearboxes

AM6 autoactive automatic gearbox

Transfer box and rear axle

All countries

27

TOTAL TRANSMISSION BV

Norms S.A.E: 75W80

Part No.: 9730 A2

TOTAL FLUIDE ATX

TOTAL FLUIDE AT 42

Special oil distributed by

CITROËN

Part No.: 9730 A6

Special oil distributed by

CITROËN

Part No.: 9736 22

Special oil distributed by

CITROËN

Part No.: 9980 D4

TOTAL TRANSMISSION X4

Part No.: 9730 A7

GENERALGENERAL

Page 32

Power steering all vehicles

(except CITROËN C4 and C5)

Power steering

C4 and C5

LUBRICANTS - TOTAL recommended oils

POWER STEERING OILS

All countries

TOTAL FLUIDE ATX

TOTAL FLUIDE LDS

Special oil distributed by CITROËN

Part No.: 9979 A3

GENERAL

Power steering

All countries

CITROËN fluid

Protection: -35C°

Very cold countries

ENGINE COOLANT FLUID

Packs

2 Litres

5 Litres

20 Litres

210 Litres

28

TOTAL FLUIDE DA

Special oil distributed by CITROËN

Part No.: 9730 A1

CITROËN Part No.

REVKOGEL 2000GLYSANTIN G33

9979 70

9979 71

9979 76

9979 77

9979 72

9979 73

9979 74

9979 75

Page 33

LUBRICANTS - TOTAL recommended oils

BRAKE FLUID

Synthetic brake fluid

Packs

0,5 Litre

All countries

All countries

TOTAL FLUIDE LDS

TOTAL LHM PLUS

TOTAL LHM PLUS

Very cold countries

WARNING: TOTAL FLUIDE LDS fluid cannot be blended with TOTAL LHM PLUS.

WARNING: CITROËN C5: Use exclusively TOTAL FLUIDE LDS suspension fluid.

All countries TOTAL HYDRAURINCAGE

CITROËN fluid

Norm

Colour

1 Litre

5 Litres

HYDRAULIC SYSTEM

Packs

Orange 9979 A3

Green

1 Litre

29

CITROËN Part No.

9979 05

9979 06

9979 07

CITROËN Part No.

9979 A1

9979 A2

GENERALGENERAL

Page 34

LUBRICANTS - TOTAL recommended oils

SCREEN WASH FLUID

GENERAL

Packs

Concentrated: 250 ml

All countries

All countries

Note: NLGI = National Lubrificating Grease Institude.

Fluid ready

to use

1 Litre

5 Litres

9980 33

9980 06

9980 05

GREASING

General use

TOTAL MULTIS 2

TOTAL SMALL MECHANISMS

30

CITROËN Part No.

ZC 9875 953U

ZC 9875 784U

ZC 9885 077U

9980 56

ZC 9875 279U

Norms NLGI

2

Page 35

ENGINE OIL CONSUMPTION

I - Oil consumption depends on:

- the engine type.

- how run-in or worn it is.

- the type of oil used.

- the driving conditions.

II - An engine can be considered RUN-IN after:

- 3,000 miles (5,000 km) for a PETROL engine.

- 6,000 miles (10,000 km) for a DIESEL engine.

III - MAXIMUM PERMISSIBLE oil consumption for a RUN-IN engine:

- 0.5 litres per 600 miles (1,000 km) for a PETROL engine.

- 1 litre per 600 miles (1,000 km) for a DIESEL engine.

DO NOT INTERVENE BELOW THESE VALUES.

IV - OIL LEVEL: The level should NEVER be above the MAX. mark on the dipstick after changing or topping up the oil:

- This excess oil will be used up rapidly.

- It will reduce the engine output and adversely affect the operation of the air circuits and gas recycling.

31

GENERALGENERAL

Page 36

C5 - C8

ENGINE SPECIFICATIONS

Engines: 6FZ - RFJ - RFN - 3FZ - XFU - XFW

Petrol

ENGINE

Engine type

Cubic capacity (cc)

Bore/stroke

Compression ratio

Power ISO or EEC (KW - rpm)

Torque ISO or EEC (m.daN - rpm)

1.8i 16V

6FZ RFJ RFN 3FZ XFU XFW

1749 1997 2230 2946

82,7/81,4 85/88 86/96 87/82,5

10,8/1 11/1 10,8/1 10,9/1

85-5500 103-6000 100-6000 116-5650 152-6000

16-4000 20-4000 19-4100 21,7-3900 28,5-3750

2.0i 16V 3.0i 24S

32

2.2i 16V

Page 37

ENGINE SPECIFICATIONS

Engines: 9HZ - RHM - RHT - RHW - RHL - RHR - 4HX - 4HW

C5 - C8

ENGINE

Diesel

Engine type

Cubic capacity (cc)

Bore/stroke

Compression ratio

Power ISO or EEC (KW - rpm)

Torque ISO or EEC (m.daN - rpm)

1.6 16V

HDi

9HZ RHM RHT RHW RHL RHR 4HX 4HW

1560 1997 2179

75/88,3 85/88 85/96

18/1 17,3/1 18/1 17,6/1

80-4000 79-4000 80-4000 93-4000 100-4000 98-4000 94-4000

24-1750 25-1750 27-1750 32-2000 31,4-2000

33

2.0 16V HDi 2.2 16V HDi

Page 38

ENGINE

COMPRESSION RATIO - DIESEL ENGINESC5

ENGINE

DV6 DW12

DW10

COMPRESSION

RATIO

20 ± 5

30 ± 5

34

MAX. DIFFERENCE

BETWEEN CYLINDERS

In bars

5

Page 39

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: 6FZ - RFJ

1 4,5 ± 0,5

2 6 ± 0,6

3 6 ± 0,6

4 5,5 ± 0,5

5 4,5 ± 0,4

6 6 ± 0,6

7 2,8 ± 0,2

8 4,5 ± 0,4

9 6 ± 0,6

10 6 ± 0,6

11 6 ± 0,6

Fitting of the LH support.

A = EW10A and EW7J4 engines with BE4 gearbox.

B = EW10A engine with AL4 gearbox.

B1BP32ZP

35

C5

ENGINE

Page 40

ENGINE

C5

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: 6FZ - RFJ

Crankshaft

6FZ

Accessories drive pulley

Tightening 4 ± 0,4 4 ± 0,4

Angular tightening 53° ± 4° 40° ± 4°

Con rod cap screws

Pre-tightening 1 ± 0,1

Tightening 2,3 ± 0,2

Angular tightening 46° ± 5°

Cylinder block

Sump 0,8 ± 0,2

Timing belt guide roller 3,7 ± 0,3

Timing belt tensioner roller 2,1 ± 0,2

Accessories drive belt guide roller

Pre-tightening 1,5 ± 0,1

Tightening 3,7 ± 0,3

Accessories drive belt tensioner roller 2 ± 0,2

RFJ

36

Page 41

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: 6FZ - RFJ

Cylinder block

6FZ RFJ

Camshaft bearing covers 0,9 ± 0,1

Exhaust manifold 3,5 ± 0,3

Valve cover 1,1 ± 0,1

Camshaft pulley

Pre-tightening 3 ± 0,5

Tightening 8,5 ± 0,5

Inlet camshaft pulley

Pre-tightening 2 ± 0,2

Tightening 11 ± 1

Exhaust camshaft pulley

Pre-tightening 3 ± 0,5

Tightening 8,5 ± 0,5

Cap 1,1 ± 0,1

Flywheel/clutch

Flywheel

Pre-tightening 2,5 ± 0,2

Angular tightening 21° ± 3°

Clutch mechanism 2 ± 0,2

37

C5

ENGINE

Page 42

ENGINE

C5

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: 6FZ - RFJ

6FZ

Lubrication circuit

Oil pump 0,9 ± 0,1

Injection circuit

Common injection rail fixing screw 0,9 ± 0,1

Cylinder block

Coolant pump 1,4 ± 0,1

Coolant outlet housing 0,9 ± 0,1

Coolant outlet housing

Tightening the screws to: 0,3 ± 0,1

Tightening the nuts to: 1 ± 0,1

RFJ

38

Page 43

SPECIAL FEATURES: POWER UNIT SUSPENSION

Upper RH engine support Engines: RFN - 3FZ

Description RFN 3FZ

Gearbox type

Intermediate engine support

B1BK1X5D

B1BK1X6D

Ref.

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Rod/body fixing screw(1)

Engine support/torque reaction rod

flexible stop pin

Upper support/intermediate

support fixing screw

Upper support/body fixing screw

Upper support/flexible

support fixing nut

Support

LH flexible support/LH engine support

fixing nut

LH flexible support/body fixing screw

Intermediate engine support/gearbox

casing fixing screw

LH intermediate support/gearbox

fixing screw

Flexible support pin

39

C8

BE4/5 AL4

5 ± 0,5

4,5 ± 0,4

6,5 ± 0,6

3 ± 0,3

4,5 ± 0,4

6,5 ± 0,6

3 ± 0,3

4,5 ± 0,4

6 ± 0,6 4,5 ± 0,4

5 ± 0,5

ML5C

ENGINE

Page 44

ENGINE

C8

B1BK1X7D

SPECIAL FEATURES: POWER UNIT SUSPENSION

Intermediate engine support Engines: RFN - 3FZ

Ref.

(12)

(13)

(14)

Lower RH rod/subframe fixing screw

Lower RH engine support/cylinder

block fixing screw

Lower rod/lower RH engine support

fixing screw

40

Description RFN 3FZ

Gearbox type

BE4/5 AL4

9 ± 0,9

4,5 ± 0,4

6,5 ± 0,6

ML5C

Page 45

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RFN - 3FZ

Crankshaft bearing cap cover (15)

Description M11 M6

Pre-tightening 1 ± 0,1 0,5

Slackening Yes No

Re-tightening 1 ± 0,1 then 2 ± 0,2 1 ± 0,1

Angular tightening 70° ± 5°

C8

ENGINE

Crankshaft

B1BK1X8D

Description

Pre-tightening 1 ± 0,1 2,5 ± 0,2

Slackening Yes 18° ± 1°

Re-tightening 2,5 ± 0,2 1 ± 0,1

41

(16) Con rod caps

(17) Crankshaft

flywheel fixing

22° ± 2°Angular tightening 46° ± 5°

Page 46

ENGINE

C8

Engine: RFN Engine: 3FZ

Description (18) Camshaft bearing cap covers (19) Cylinder head covers

Pre-tightening

Tightening

Description

Tightening

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Equipment on cylinder head

B1BK1X9D B1BK1XAD

0,5 0,5

1 ± 0,1 1,5 ± 0,1

(20) Inlet manifold (21) Exhaust manifold

1 ± 0,1 3,5 ± 0,3

42

Page 47

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFU

Lower RH engine support/torque reaction rod

1 6 ± 0,5

2 1 ± 0,1

3 6 ± 0,5

LH engine support

4 3 ± 0,3

5 6,5 ± 0,6

6 5 ± 0,5

7 4,5 ± 0,4

RH engine support

8 and 9 6 ± 0,6

10 4,5 ± 0,4

11 6 ± 0,6

12 6 ± 0,6

B1BP32YP

43

C5

ENGINE

Page 48

ENGINE

C5

B1BP27DP

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFU

1

Pencil type ignition coil 0,8 ± 0,3

Sparking plug

Pre-tightening 1 ± 0,1

Angular tightening 90° ± 5°

Valve cover

2

Pre-tightening 0,5 ± 0,1

Tightening 1 ± 0,1

Camshaft bearing cap cover

Pre-tightening 0,2 ± 0,1

3

Tightening 1 ± 0,1

Cylinder block

Pre-tightening 2 ± 0,2

Slackening Yes

4

Tightening 1,5 ± 0,1

Angular tightening 225° ± 5°

44

Page 49

B1JP02LD

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Exhaust manifold (with a new gasket)

5

Pre-tightening (sequence from 1 to 10) 1 ± 0,1

Tightening (sequence from 1 to 10) 3 ± 0,3

Con rod caps

Pre-tightening 2 ± 0,2

6

Angular tightening 74° ± 5°

Flywheel

Pre-tightening 2 ± 0,2

7

Angular tightening 60° ± 5°

45

Engine: XFU

C5

ENGINE

Page 50

ENGINE

C5

B1BP2D3D

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFU

8

Crankshaft bearing

NOTE: Maximum length under heads for screws M11 = 131,5 mm.

NOTE: Maximum length under heads for screws M8 = 119 mm.

Perform the following operations:

- Brush the screw threads.

- Refit the screws having first pre-coated them with «MOLYKOTE G

RAPID PLUS» grease on the threads and under heads.

Check the presence of the eight centring pins

Pre-tighten the screws M11 (sequence from 1 to 8) 3 ± 0,3

Pre-tighten the screws M8 (sequence from A to H) 1 ± 0,1

Tighten the screws M6 (sequence from a to 1) 1 ± 0,1

Slacken the screws M11 and M8 Yes

Proceeding screw by screw

Tighten the screws M11 (sequence from 1 to 8) 3 ± 0,3

Angular tightening 180°

Tighten the screws M8 (sequence from A to H) 1 ± 0,1

Angular tightening 180°

46

Page 51

B1BP1GZD

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Sump

9

Pre-tightening (sequence from 1 to 20) 0,5 ± 0,1

Tightening (sequence from 1 to 20) 0,8 ± 0,1

Crankshaft pinion

Pre-tightening 4 ± 0,4

10

Angular tightening 80°± 5°

Crankshaft pulley 2,5 ± 0,2

11

Inlet distributor (with new seals)

Pre-tightening 0,4 ± 0,1

12

Tightening 0,8 ± 0,1

Air inlet manifold

Pre-tightening 0,4 ± 0,1

13

Tightening 0,8 ± 0,1

47

Engine: XFU

C5

ENGINE

Page 52

ENGINE

C5

B1EP1FXD

B1FP04KC

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFU

Camshaft hubs

14

Pre-tightening 2 ± 0,2

Angular tightening 57° ± 5°

15

Cap 1,5 ± 0,1

Guide roller 8 ± 0,8

16

Camshaft pulleys

Pre-tightening 2 ± 0,2

17

Angular tightening 115 ° ± 5°

Camshaft pulleys 1 ± 0,1

18

Timing belt tensioner roller 2,5 ± 0,2

20

21

Plate for the dynamic tensioner roller 2,5 ± 0,2

Coolant pump

22

Pre-tightening 0,5 ± 0,1

Tightening 0,8 ± 0,1

Oil pump

Pre-tightening 0,5 ± 0,1

19

Tightening 0,8 ± 0,1

48

Page 53

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

Power unit suspension

B1BK24RD B1BK24SD

(2) Link rod fixing : 5 ± 0,5

(3) Link rod fixing : 4,5 ± 0,4

(4) Fixing of upper RH engine support

on intermediate engine support flexible mounting : 6 ± 0,6

(5) Fixing of RH engine support on flexible mounting : 4,5 ± 0,4

(6) Fixing of flexible mounting : 3 ± 0,3

(7) Fixing of RH intermediate engine support on cylinder block : 6 ± 0,6

C8

ENGINE

Gearbox suspensionRH engine support (suspension)

(8) Fixing of gearbox support on LH flexible mounting : 6,5 ± 0,6

(9) Shaft : 6,5 ± 0,6

(10) Fixing of flexible mounting on suppor : 3 ± 0,3

(11) Fixing of flexible mounting support on body : 2,5 ± 0,2

(12) Fixing of flexible mounting support on body : 2,5 ± 0,2

49

Page 54

ENGINE

C8

(13) Torque reaction link rod fixing : 9 ± 0,9

(14) Fixing of link rod on torque reaction flexible mounting : 6,5 ± 0,6

(15) Fixing of torque reaction flexible mounting : 4,5 ± 0,4

(16) Fixing of heat shield on torque reaction flexible mounting : 1 ± 0,1

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

B1BK24TD B1BK24UD

CrankshaftPower unit suspension - Engine support (lower)

(17) Bearing plug Tightening : 2 ± 0,2

Angular tightening : 74° ± 7°

(18) Timing pinion Tightening : 4 ± 0,4

Angular tightening : 80° ± 8°

(19) Fixing of starter gear support flange, plus crankshaft converter support

Tightening : 2 ± 0,2

Angular tightening : 60° ± 6°

(20) Accessory pulley on timing pinion : 2,5 ± 0,2

50

Page 55

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

Crankshaft

Bearing cap cover

Respect the sequence of stages and the order of tightening

Ref./description

M11 (bolts

from 1 to 8)

M8 (bolts

from 9 to 16)

C8

ENGINE

M6

B1BK24VD

(21) Fixings of bearings/plug covers or

bearings/plugs

21) Fixings of bearings/plug covers or

bearings/plugs

(slacken to zero torque

(21) Fixings of bearing plug cover or

bearing plugs (tighten bolt by bolt

Tightening

+ Angular tightening

)

)

51

Stage 1

3 ± 0,3

Stage 4

YES

Stage 5

3 ± 0,3

180°

Stage 2

1 ± 0,1

Stage 4

YES

Stage 6

1 ± 0,1

180°

Stage 3

1 ± 0,1

NO

Page 56

ENGINE

C8

(22) Oil separator : 0,8

(23) Strainer : 0,8

(24) Induction pipe : 0,8

(25) Drain plug : 3 ± 0,3

(26) Oil filter sleeve (with coolant/oil exchanger) : 0,5

Oil filter : 0,2

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Lubrication circuit

B1BK24WD B1BK24XD

Engine: XFW

Oil sumpLubrication circuit.

Respect the sequence of stages and the order of tightening

Stage 1: Do up bolts 13,15 and 17.

Stage 2: Tighten bolts 13,15 and 17 to : 0,2.

Stage 3: Do up the 17 remaining bolts.

Stage 4: Tighten the remaining bolts to : 0,5.

Stage 5: Tighten all the bolts : 0,8.

Stage 6: Repeat the tightening a few times in the same order to obtain a

tightening torque of 0,8 m.daN on all the bolts.

52

Page 57

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

B1BK3B6D B1BK3B7D

Respect the sequence of stages and the order of tightening

Stage 1: Position the screws and do them up by hand.

Stage 2: Pre-tighten the screws : 0,5.

Stage 3: Tighten the screws : 0,8.

Stage 4: Repeat the tightening a few times in the same order to obtain

a tightening torque of 0,8 m.daN on all the screws.

C8

Cooling circuitLubrication circuit

Coolant pumpOil pump

Stage 1: Position the screws and do them up by hand.

Stage 2: Pre-tighten the screws : 0,5.

Stage 3: Tighten the screws : 0,8.

Stage 4: Repeat the tightening a few times in the same order to obtain a

tightening torque of 0,8 m.daN on all the screws.

53

ENGINE

Page 58

ENGINE

C8

Coolant manifold

(27) Screws : 2,5 ± 0,2

(28) Screws : 0,8

(29) Screws : 0,8

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

B1BK24YD

Engine: XFW

Cylinder head equipmentLubrication circuit

B1BK24ZD

54

Page 59

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Respect the sequence of stages and the order of tightening

(30) Camshaft bearing cap cover or camshaft bearing:

- Pre-tightening : 0,2

- Tightening : 1

Engine: XFW

Cylinder head equipment

Camshaft bearing cap cover (left hand side)Camshaft bearing cap cover (right hand side)

B1EK0GCC B1BK3B8D

55

C8

ENGINE

Page 60

ENGINE

C8

(31) Valve cover:

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

Cylinder head equipment

Valve covers (left hand side)Valve covers (right hand side)

B1EK0GEC B1EK0GFC

Respect the sequence of stages and the order of tightening

- Pre-tightening : 0,5

- Tightening : 0,8

56

Page 61

(32) Inlet manifold:

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Cylinder head equipment

Respect the sequence of stages and the order of tightening

- Pre-tightening : 0,4

- Tightening : 0,8

Engine: XFW

Inlet manifold

57

C8

ENGINE

B1BK251D

Page 62

ENGINE

C8

(33) Exhaust manifold:

- Pre-tightening : 1

- Tightening : 3 ± 0,3

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: XFW

Cylinder head equipment

Exhaust manifold (left hand side)Exhaust manifold (right hand side)

B1JK03ND B1JK03LD

Respect the sequence of stages and the order of tightening

58

Page 63

(34) Inlet distributor:

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Cylinder head equipment

Respect the sequence of stages and the order of tightening

- Pre-tightening : 0,4

- Tightening : 0,8

Engine: XFW

Inlet distributor

59

C8

ENGINE

B1BK252D

Page 64

ENGINE

C5

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 9HZ

Torque reaction rod

1 6 ± 0,6

2 6 ± 0,6

10 6 ± 0,6

Upper LH engine support

3 5,5 ± 0,5

Lower LH engine support

4 6 ± 0,6

Lower RH engine support

5 5,5± 0,5

RH engine support

6 4,5 ± 0,4

7 6 ± 0,6

8 6 ± 0,6

9 6 ± 0,6

B1BP32EP

60

Page 65

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 9HZ

Crankshaft

Bearing cap fixing screws

Pre-tightening 1 ± 0,2

Slackening 180° ± 5°

Tightening 3 ± 0,3

Angular tightening 140° ± 5°

Con rod screws

Pre-tightening 1 ± 0,1

Angular tightening 100° ± 5°

Accessories drive belt pulley

Pre-tightening 3,5 ± 0,3

Angular tightening 190° ± 5°

Cylinder block

Sump 1,3 ± 0,1

Timing belt guide roller 3,7 ± 0,3

Timing belt tensioner roller 2,7 ± 0,2

61

C5

ENGINE

Page 66

ENGINE

C5

Camshaft bearing covers

Pre-tightening 0,5 ± 0,1

Tightening 1 ± 0,1

Oil trap 1 ± 0,1

Air inlet manifold

Tightening 1 ± 0,1

Pre-tightening 0,1

Tightening 0,9 ± 0,1

Exhaust manifold 3 ± 0,3

Camshaft pulleys

Pre-tightening 2 ± 0,2

Angular tightening 50° ± 5°

Cylinder block

Pre-tightening 2 ± 0,2

Tightening 4 ± 0,4

Angular tightening 260° ± 5°

Exhaust gas recycling (EGR) electrovalve 1 ± 0,1

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 9HZ

Cylinder block

62

Page 67

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 9HZ

Flywheel

Double damping flywheel

Pre-tightening 3 ± 0,3

Angular tightening 90° ± 5°

Clutch mechanism 2 ± 0,2

Lubrication circuit

Oil pump assembly

Pre-tightening 0,5 ± 0,1

Tightening 0,9 ± 0,1

Oil/coolant heat exchanger 1 ± 0,1

Lubrication pipe for turbocharger 3 ± 0,3

63

C5

ENGINE

Page 68

ENGINE

C5

Injector fixing flange nut

Pre-tightening 0,4 ± 0,1

Angular tightening 65° ± 5°

Fuel high pressure common injection rail on engine block 2,2 ± 0,2

Unions on fuel high pressure common injection rail

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Union on diesel injector

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Diesel injection pump on support 2,2 ± 0,2

Diesel injection pump pulley 5 ± 0,5

Union on diesel high pressure pump

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Coolant pump

Pre-tightening 0,3 ± 0,1

Tightening 0,9 ± 0,1

Coolant outlet housing

Pre-tightening 0,3 ± 0,1

Tightening 0,7 ± 0,1

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 9HZ

Diesel injection circuit

Cooling circuit

64

Page 69

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHL - RHR

1 6 ± 0,6

2 6 ± 0,6

3 6 ± 0,6

4 5,6 ± 0,5

5 4,5 ± 0,4

6 5 ± 0,5

7 5 ± 0,5

8 5 ± 0,5

9 5,5 ± 0,5

10 6 ± 0,6

11 5 ± 0,5

B1BP337P

65

C5

ENGINE

Page 70

ENGINE

C5

Bearing cap fixing screws

Pre-tightening 2,5 ± 0,2

Angular tightening 60° ± 5°

Con rod nuts

Pre-tightening 1 ± 0,1

Slackening 180° ± 5°

Tightening 2,3 ± 0,2

Angular tightening 45° ± 5°

Accessories drive pulleys

Pre-tightening 7 ± 0,7

Angular tightening 60° ± 5°

Piston skirt spray jet (renovation) 1 ± 0,1

Sump 1,6 ± 0,1

Timing belt guide roller 2,5 ± 0,2

Timing belt tensioner roller 2,1 ± 0,2

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHL RHR

Crankshaft

Cylinder block

66

Page 71

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHL RHR

Cylinder block

Camshaft bearing covers 1 ± 0,1

Exhaust manifold 3 ± 0,3

Inlet valve cover 0,9 ± 0,1

Camshaft pinion 4,3 ± 0,4

Cylinder head

Pre-tightening 2,2 ± 0,2

Tightening 6 ± 0,6

Slackening (1 turn) 360°

Tightening 6 ± 0,6

Angular tightening 220° ± 5°

Flywheel/clutch

Flywheel

Pre-tightening 1,5 ± 0,1

Tightening 4,8 ± 0,4

Clutch mechanism 2 ± 0,2

67

C5

ENGINE

Page 72

ENGINE

C5

Oil pump 1,3 ± 0,1

Oil/coolant heat exchanger 5,8 ± 0,5

Lubrication pipe for turbocharger

Engine end 4,7 ± 0,4

Turbocharger end 2,2 ± 0,2

Diesel injector

Tightening by hand yes

Tightening 0,4 ± 0,1

Angular tightening 45° ± 5°

Union on injection rail 2,5 ± 0,2

Injection pump 2 ± 0,2

Union on diesel injector 2,5 ± 0,2

Union on injection pump 2,5 ± 0,2

Coolant pump 1,6 ± 0,1

Coolant inlet housing 2 ± 0,2

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHL - RHR

Lubrication circuit

Diesel injection circuit

Cooling circuit

68

Page 73

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHL - RHR

Diesel injection circuit

Injector fixing flange nut

Pre-tightening 0,4 ± 0,1

Angular tightening 65° ± 5°

Fuel high pressure common injection rail on engine block 2,2 ± 0,2

Unions on fuel high pressure common injection rail

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Injection on diesel injector

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Diesel injection pump on support 2,2 ± 0,2

Diesel injection pump pulley 5 ± 0,5

Union on diesel high pressure pump

Pre-tightening 2 ± 0,2

Tightening 2,5 ± 0,2

Cooling circuit

Coolant pump

Pre-tightening 0,3 ± 0,1

Tightening 0,9 ± 0,1

Coolant outlet housing

Pre-tightening 0,3 ± 0,1

Tightening 0,7 ± 0,1

69

C5

ENGINE

Page 74

ENGINE

C8

(*) = Re-use prohibited.

(**) = Tighten in a spiral commencing from the inside.

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

(1) Pulley screw M14x150-70

Pre-tightening 5 ± 0,5

Angular tightening 62°

(2) Screws M7x100-20 (x 4)

Pre-tightening 0,7 ± 0,1

Tightening 1,5 ± 0,1

(3) Screws M7x100-40 (x 2) (*)

Pre-tightening 0,7 ± 0,1

Tightening 1,5 ± 0,1

(4) Plug CHC M12x150-16 (x 1) 2,5 ± 0,2

(5) Plug M15x150 (x 1) 2,5 ± 0,2

(6) Plugs M15x150 (x 2) 4 ± 0,4

(7) Screws M9x100-24 (+loctite FRENETANCH) (x8) 4,8 ± 0,5

(8) Screws M12x150-81 (x10)

Pre-tightening 2,5 ± 0,2

Angular tightening (**) 60°

(9) Nuts M9x100 (x8)

Pre-tightening 2 ± 0,2

B1BK3EPD

Angular tightening 70°

(10) Screws M16x10-16 (x4) 1 ± 0,1

70

Crankshaft

Page 75

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

Engine suspension (identification)

(1) Upper RH torque reaction rod

(2) Upper RH engine support

(3) RH engine flexible support

(4) Upper RH intermediate engine support

(5) Lower RH engine support

(6) Torque reaction rod

(7) Upper LH intermediate engine support

(8) LH engine support

(9) LH engine flexible support

(10) Lifting attachment, flywheel end

B1BK3EED

(11) Lifting attachment, timing end

71

C8

ENGINE

Page 76

ENGINE

C8

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

Engine suspension (tightening torques)

(12) Spherical-base screw M10x150-75 (x 1) 5 ± ,05

(13) Shaft screw (x 1) 4,5 ± 0,4

(14) Nut M10x150 (x 1) 4,5 ± 0,4

(15) Screws M10x150-60 (x 3) 6 ± 0,6

(16) Screws M8x125-25 (x 2) 3 ± 0,3

(17) Shouldered shaft screw M8x125-15 (x 1) 2 ± 0,2

(18) Locking screw M10x125-85 (x 1) 4,5 ± 0,4

(19) Locking screw M10x125-70 (x 2) 4,5 ± 0,4

(20) Spherical-base screw M10x150-35 (x 3) 4,5 ± 0,4

(21) Spherical-base screw M10x150-72 (x 1) 6,5 ± 0,6

(22) Spherical-base screw M12x175-60 (x 1) 9 ± 0,9

(23) Nut M10x150 (x 1) 4,5 ± 0,4

(24) Screws M10 x150-55 (x 2) 4,5 ± 0,4

(25) Support shaft (x 1) 5 ± 0,5

(26) Screws M8x125-25 (x 4) 2,5 ± 0,2

(27) Screws M8x125-25 (x 2) 3 ± 0,3

(28) Locking nut M12x175-18 (x 1) 6,5 ± 0,6

(29) Screws M8x125-25 (x 1) 1,5 ± 0,1

B1BK3EDD

(30) Screws M6x100-20 (x 2) 1,2 ± 0,1

72

Page 77

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

Power steering pump

(1) Power steering pump

(2) Screws M8x125-30 (x 1) 2,5 ± 0,2

(3) Shouldered shaft screw M8x125-22 (x 1) 2,2 ± 0,2

(4) Shouldered shaft screw M8x125-48 (x 1) 2,2 ± 0,2

NOTE: Tightening the fixings (2) and (3) before the fixing (4), to ensure that

the auxiliary drive belt is correctly aligned.

B1BK3E8D

(5) Alternator

(6) Spherical-base screw M10 x150-50 (x 2) 4,1 ± 0,4

(7) Screws M10x150-40 (x 1) 3,9 ± 0,4

NOTE: Tightening the fixings (6) before the fixing (7), to ensure that the

auxiliary drive belt is correctly aligned.

B1BK3E7D

73

C8

ENGINE

Alternator

Page 78

ENGINE

C8

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

Air conditioning compressor

(8) Air conditioning compressor

(9) Spherical-base screw M10x150-60 (x 1) 4 ± 0,4

(10) Shouldered shaft screw M10x150-52 (x 2) 4,2 ± 0,4

NOTE: Tightening the fixing (9) before the fixing (10), to ensure that the

auxiliary drive belt is correctly aligned.

B1EK3E9D

Accessories support

(11) Power steering pump support

(12) Spherical-base screw M8 x125-35 (x 2) (*)

Pre-tightening 1 ± 0,1

Tightening 2 ± 0,2

(13) Screws M8x125-80 (x 1) (*)

Pre-tightening 1 ± 0,2

Tightening 2 ± 0,2

B1EK3EAD

(*) = In the order indicated (1 to 5).

74

Page 79

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engines: RHM - RHT - RHW

(14) Dynamic tensioner roller

(15) Eccentric guide roller

(16) Screws M10x150-50 (x 1)

Pre-tightening 1 ± 0,1

Tightening 4,3 ± 0,4

(17) Screws M8x150-60 (x 1)

Pre-tightening 2 ± 0,2

Tightening 4,5 ± 0,4

B1BK3EWD

75

Guide roller

C8

ENGINE

Page 80

ENGINE

C5

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HX

Tightening torques (m.daN).

(1) : 4,5 ± 0,5

(2) : 5 ± 0,5

(3) : 5 ± 0,5

(4) : 2,7 ± 0,3

(5) : 4,5 ± 0,5

(6) : 2,1 ± 0,2

(7) : 4,5 ± 0,5

(8) : 6,1 ± 0,6

(9) : 4,5 ± 0,5

(10) : 5 ± 0,5

(11) : 5 ± 0,5

B1BP284P

76

Page 81

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HX

Crankshaft

Crankshaft bearing cap screws

Pre-tightening 2,5 ± 0,2

Angular tightening 60°

Con rod cap screws

Tightening 1 ± 0,1

Slackening 180°

Tightening 2,3 ± 0,1

Angular tightening 46° ± 5°

Accessories drive pulley

Tightening 7 ± 0,25

Angular tightening 60° ± 5°

77

C5

ENGINE

Page 82

ENGINE

C5

Piston skirt spray jets 1 ± 0,1

Sump

Pre-tightening 1 ± 0,1

Tightening 1,6 ± 0,3

Timing belt guide roller

Pre-tightening 1,5 ± 0,1

Tightening 4,3 ± 0,4

Timing belt tensioner roller 2,5 ± 0,2

RH engine support

Pre-tightening the 4 screws 1 ± 0,1

Tightening the screws Ø 8 2 ± 0,2

Tightening the screws Ø 10 4,5 ± 0,2

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HX

Cylinder block

78

Page 83

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HX

Cylinder block

Camshaft bearing cap cover

Tightening 1 ± 0,1

Pre-tightening the 28 screws Ø 6 6 ± 0,5

Tightening the 28 screws Ø 6 1 ± 0,1

Exhaust manifold

Pre-tightening the 8 nuts 1,5 ± 0,1

Tightening the 8 nuts 0,3 ± 0,3

Valve cover

Pre-tightening the 13 screws 0,5 ± 0,15

Tightening the 13 screws 9 ± 0,1

Camshaft pulley hub 4,3 ± 0,4

Pulley on hub 2 ± 0,2

Flywheel - Clutch

Flywheel

Pre-tightening 1,5 ± 0,1

Tightening 4,7 ± 0,4

Clutch mechanism 2 ± 0,2

79

C5

ENGINE

Page 84

ENGINE

C5

Oil pump

Pre-tightening 0,7

Tightening 0,9 ± 0,1

Oil/coolant heat exchanger 5,8 ± 0,5

Turbocharger lubrication tube

Engine end 3 ± 0,3

Turbocharger end 2 ± 0,2

Diesel injector

Do up the 2 nuts By hand

Tightening 4 ± 0,3

Angular tightening 45° ± 5°

Union on injection rail 2 ± 0,2

Injection pump on support 2,25 ± 0,3

Union on diesel injector 2 ± 0,2

Injection pump pulley 5 ± 0,5

Union on injection pump 2 ± 0,2

Coolant pump 1,6 ± 0,3

Coolant inlet housing 2 ± 0,2

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HX

Lubrication circuit

Diesel injection circuit

Cooling circuit

80

Page 85

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

(*) = Re-use prohibited.

(**) = Tighten in a spiral commencing from the inside.

B1BK3EMD

Engine: 4HW

Crankshaft

(1) Pulley screw M14x150-70

Pre-tightening 7 ± 0,5

Angular tightening 82°

(2) Screws M7x100-40 (x 2) (*)

Pre-tightening 0,7 ± 0,1

Tightening 1,5 ± 0,1

(3) Screws M7x100-20 (x 4)

Pre-tightening 0,7 ± 0,1

Tightening 1,5 ± 0,1

(4) Plug CHC M12x150-16 (x 1) 2,5 ± 0,2

(5) Plugs M15x150 (x 2) 4 ± 0,4

(6) Screws M9x100-24 (+loctite FRENETANCH) (x8)

Pre-tightening 1,5 ± 0,1

Tightening 5 ± 0,5

(7) Screws M12x150-81 (x10) (**)

Pre-tightening 1 ± 0,1

Tightening 2,5 ± 0,2

Angular tightening 60°

81

C8

ENGINE

Page 86

ENGINE

C8

(*) = Re-use prohibited.

(**) = Tighten in a spiral, commencing from the inside.

(***) = Tighten in the order indicated 1 to 8.

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

Crankshaft (continued)

(8) Screws M7x100-20 (x8) (*) (screw by screw

and part stage)

Stage 1: Tightening 1

Stage 2: Slackening 180°

Stage 3: Tightening 2,3 ± 0,2

Stage 4: Angular tightening 46°

(9) Screws M9x100-45 (x4) (*) 1 ±

(10) Screws M8x125-60 (x8) (***)

Pre-tightening 0,5

Tightening 1 ± 0,1

Angular tightening 60°

B1BK3EMD

82

Page 87

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

Engine suspension (identification)

(1) Upper RH torque reaction rod

(2) Upper RH engine support

(3) RH engine flexible support

(4) Upper RH intermediate engine support

(5) Lower RH engine support

(6) Torque reaction rod

(7) Upper LH intermediate engine support

(8) LH engine support

(9) LH engine flexible support

(10) Lifting attachment, flywheel end

(11) Lifting attachment, timing end

B1BK3EED

83

C8

ENGINE

Page 88

ENGINE

C8

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

Engine suspension (tightening torques)

(12) Spherical-base screw M10x150-75 (x 1) 5 ± ,05

(13) Shaft screw (x 1) 4,5 ± 0,4

(14) Nut M10x150 (x 1) 4,5 ± 0,4

(15) Screws M10x150-60 (x 3) 6 ± 0,6

(16) Screws M8x125-25 (x 2) 3 ± 0,3

(17) Shouldered shaft screw M8x125-15 (x 1) 2 ± 0,2

(18) Locking screw M10x125-85 (x 1) 4,5 ± 0,4

(19) Locking screw M10x125-70 (x 2) 4,5 ± 0,4

(20) Spherical-base screw M10x150-35 (x 3) 4,5 ± 0,4

(21) Spherical-base screw M10x150-72 (x 1) 6,5 ± 0,6

(22) Spherical-base screw M12x175-60 (x 1) 9 ± 0,9

(23) Nut M10x150 (x 1) 4,5 ± 0,4

(24) Screws M10 x150-55 (x 2) 4,5 ± 0,4

(25) Support shaft (x 1) 5 ± 0,5

(26) Screws M8x125-25 (x 4) 2,5 ± 0,2

(27) Screws M8x125-25 (x 2) 3 ± 0,3

(28) Locking nut M12x175-18 (x 1) 6,5 ± 0,6

(29) Screws M8x125-25 (x 1) 1,5 ± 0,1

B1BK3EDD

(30) Screws M6x100-20 (x 2) 1,2 ± 0,1

84

Page 89

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

Power steering pump

(1) Power steering pump

(2) Screws M8x125-30 (x 1) 2,5 ± 0,2

(3) Shouldered shaft screw M8x125-22 (x 1) 2,2 ± 0,2

(4) Shouldered shaft screw M8x125-48 (x 1) 2,2 ± 0,2

NOTE: Tightening the fixings (2) and (3) before the fixing (4), to ensure that

the auxiliary drive belt is correctly aligned.

B1BK3E8D

(5) Alternator

(6) Spherical-base screw M10 x150-50 (x 2) 4,1 ± 0,4

(7) Screws M10x150-40 (x 1) 3,9 ± 0,4

NOTE: Tightening the fixings (6) before the fixing (7), to ensure that the

auxiliary drive belt is correctly aligned.

B1BK3E7D

85

C8

ENGINE

Alternator

Page 90

ENGINE

C8

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

Air conditioning compressor

(8) Air conditioning compressor

(9) Spherical-base screw M10x150-60 (x 1) 4 ± 0,4

(10) Shouldered shaft screw M10x150-52 (x 2) 4,2 ± 0,4

NOTE: Tightening the fixing (9) before the fixing (10), to ensure that the

auxiliary drive belt is correctly aligned.

B1EK3E9D

Accessories support

(11) Power steering pump support

(12) Spherical-base screw M8 x125-35 (x 2) (*)

Pre-tightening 1 ± 0,1

Tightening 2 ± 0,2

(13) Screws M8x125-80 (x 1) (*)

Pre-tightening 1 ± 0,2

Tightening 2,3 ± 0,2

B1EK3EAD

(*) = In the order indicated (1 to 5).

86

Page 91

SPECIAL FEATURES: TIGHTENING TORQUES (m.daN)

Engine: 4HW

(14) Dynamic tensioner roller

(15) Eccentric guide roller

(16) Screws M10x150 (x 1)

Pre-tightening 1,5 ± 0,1

Tightening 3 ± 0,3

(17) Screws M8x150-60 (x 1)

Pre-tightening 2 ± 0,2

Tightening 4,5 ± 0,4

B1BK3EBD

87

Guide roller

C8

ENGINE

Page 92

ENGINE

SPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts.

Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

B1DP05BC

NOTE: Tightening of the cylinder head after a repair is prohibited.

Cleaning to be carried out just prior to refitting the cylinder head

Engines

6FZ

RFJ

RFN

3FZ

Pre-tightening 1,5 ± 0,1

Tightening 5 ± 0,5

Slackening 360°

Tightening 2 ± 0,2

Angular tightening 285° ± 5°

Pre-tightening 1,5 ± 0,1

Tightening 5 ± 0,5

Slackening 360°

Tightening 2 ± 0,2

Angular tightening 285° ± 5°

Pre-tightening 1,5 ± 0,1

Tightening 5 ± 0,5

Slackening 360°

Tightening 2 ± 0,2

Angular tightening 270° ± 5°

Tightening (m.daN)

88

Cylinder head bolts

(Max. reusable length in mm)

147

129,5

147

129,5

Page 93

SPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts.

Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

B1DP05BC

B1DP1CLC

NOTE: Tightening of the cylinder head after a repair is prohibited.

Cleaning to be carried out just prior to refitting the cylinder head

Engines

Tightening (m.daN)

Pre-tightening 2 ± 0,2

RHM RHT

RHW RHL

RHR

4HX 4HW

Tightening 6 ± 0,6

Slackening 360°

Pre-tightening 2 ± 0,2

Tightening 6 ± 0,6

Angular tightening 220° ± 5°

Pre-tightening 2 ± 0,2

9HZ

Tightening 4 ± 0,4

Angular tightening 230° ± 5°

89

ENGINE

Cylinder head bolts

(Max. reusable length in mm)

134,5

147

Page 94

ENGINE

SPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts.

Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

B1DP1KCC

B1DP1KHC

NOTE: Tightening of the cylinder head after a repair is prohibited.

Cleaning to be carried out just prior to refitting the cylinder head

Engines

Tightening (m.daN)

Pre-tightening 2 ± 0,2

XFU

Slackening 360°

Pre-tightening 1,5 ± 0,2

Angular tightening 225° ± 5°

A= Front cylinder head.

B = Rear cylinder head.

90

Cylinder head bolts

(Max. reusable length in mm)

149,5

Page 95

SPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts.

Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

B1EK0XAD

NOTE: Tightening of the cylinder head after a repair is prohibited.

Cleaning to be carried out just prior to refitting the cylinder head

Engines

XFW

Pre-tightening 2 ± 0,2

Slackening 360°

Pre-tightening 1,5 ± 0,2

Angular tightening 225° ± 5°

Tightening (m.daN)

91

ENGINE

Cylinder head bolts

(Max. reusable length in mm)

149,5

Page 96

ENGINE

! 4099-T (C.TRONIC.105)

B1EP135D

BELT TENSION/SEEM UNITS CORRESPONDENCE TABLE

!

Tools

!

4122-T (C.TRONIC.105.5)

!

Page 97

AUXILIARY EQUIPMENT DRIVE BELT

Petrol

EW ES

71012 9 10

J4 J4 J4 TED4 BTED4 TED ATED4

Engine type 6FZ RFJ RFN 3FZ XFU XFW 9HZ RHM RHT RHW RHL RHR 4HX 4HW

A

A

DV

6

Diesel

DW

12

ENGINE

C5

C8

See pages: 95 96 97 98 99 102 to 103 104

1.8i 2.0i 3.0i

16V 16V 24S 2.0 16V HDi

2.2i

16V

HPi

1.6

16V

HDi

2.0 16V HDi

100 to

101

93

2.2

16V

HDi

105 to

106

2.2

16V

HDi

107 to

108

Page 98

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engines: All types Petrol and Diesel

Tools.

Belt tension measuring instrument : 4122-T .(C.TRONIC 105.5).

WARNING: If using tool 4099-T (C.TRONIC 105), refer to the correspondence table on page 93.

Essential.

Before refitting the auxiliary equipment drive belt, check that:

- 1 / The roller(s) rotate freely (no play or stiffness).

- 2 / The belt is correctly engaged in the grooves of the various pulleys.

94

Page 99

AUXILIARY EQUIPMENT DRIVE BELT

Without aircon With aircon

[1] Pliers for removing plastic pegs : 7504-T

Remove the belt.

Detension the belt (3) by turning the tensioner roller (1), by the screw (2)

(anti-clockwise).

WARNING: the screw (2) has a left hand thread.

Remove the belt (3), while keeping the tensioner roller (1) tensioned.

Refit the belt.

Compress the tensioner roller (1).

Fit the belt (3).

Release the tensioner roller (1).

Tightening torques (m.daN).

Tensioner roller screw (4) : 2 ± 0,2

Guide roller screw (5) : 3,5 ± 0,3

B1BP23PC B1BP23QC B1BP23PC B1BP23RC

Engine: 6FZ

Tool.

95

C5

ENGINE

Page 100

ENGINE

C5

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1] «Junior» T extension : (-).1608.E

Removing.

Engage tool [1] in the notch «a».

Exert on the roller (1) an effort upwards to hold it at maximum.

Remove the auxiliaries drive belt.

Carefully release the tensioner roller (1) to reach its minimum.

Remove tool [1].

IMPERATIVE: Check that the roller (1) turns freely (without play and without tight spots).

Refitting.

If removing the auxiliaries drive belt tensioner roller, tighten the screws 2 ± 0,2 m.daN.

Engage tool [1] in the notch at «a».

Exert on the roller (1) an effort upwards to hold it at maximum.

Position the (new) auxiliaries drive belt, in the following sequence:

- Auxiliaries drive pulley (4), aircon compressor pulley (3), tensioner roller (1) and alternator pulley (2).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Release the tensioner roller (1).

Remove tool [1].

Check the tension of the auxiliaries drive belt:

- Mark «b» at the level of mark «c», new belt.

- Mark «b» at the level of mark «d», belt to be changed.

96

Loading...

Loading...