2C

Chapter 2 Part C:

K1G engine

Specifications are as for the type 150 engine (see Chapter 2A) except for the following:

General

Model application:

BX 14 after August 1988 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K1G

Maximum power DIN (BHP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 at 5600 rpm

Maximum torque DIN (lbf ft) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 at 3400 rpm

Valves

Valve clearance (cold):

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 mm

Valve timing

Inlet opens* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7º14’ BTDC

Inlet closes* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39º 45’ ABDC

Exhaust opens* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54º 30’ BBDC

Exhaust closes* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0º 45’ BTDC

*With valve clearance of 0.7 mm

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.052 to 0.452 mm

Cylinder liners

Protrusion from block - without seal . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.10 mm

Protrusion difference between liners . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm

Lubrication system

Oil pressure at 90ºC (194ºF):

650 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 bar

4000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 bar

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion F104

Oil capacity - with filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 litres (6.2 pints)

Dipstick minimum to maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 litres (2.5 pints)

Camshaft drivebelt - removal and refitting . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - dismantling, decarbonising, inspection and

reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Cylinder liners - checking protrusion . . . . . . . . . . . . . . . . . . . . . . . . . 17

Engine - complete dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Engine - complete reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Engine dismantling - ancillary items . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . . 9

Engine - examination and renovation . . . . . . . . . . . . . . . . . . . . . . . . 13

Engine - initial start-up after overhaul . . . . . . . . . . . . . . . . . . . . . . . . 20

Engine - preparation for reassembly . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . . 15

Engine - reconnection to transmission . . . . . . . . . . . . . . . . . . . . . . . 19

Engine - separation from transmission . . . . . . . . . . . . . . . . . . . . . . . 11

Engine/transmission - removal and refitting . . . . . . . . . . . . . . . . . . . 8

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Major operations possible with engine in vehicle . . . . . . . . . . . . . . . 3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . 4

Oil filter - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Valve rocker clearances - checking and adjustment . . . . . . . . . . . . . 5

2C•1

Specifications

Contents

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

5

4

3

2

1

Torque wrench settings Nm lbf ft

Crankshaft pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 74

Camshaft sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 59

Big-end bearing cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 28

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 48

Clutch pressure plate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

Distributor/fuel pump housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Camshaft thrust fork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 13

Thermostat housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Main bearing cap casting main bearing bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 15

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten a further 45º

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Main bearing cap casting to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Coolant pump housing:

8 mm bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 22

6 mm bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 37

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 15

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten a further 240º

Timing belt tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 15

Timing cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

Valve cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 4

Dipstick tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

Oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 21

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

1 General information and

precautions

General information

The K1G engine is fitted to all Citroën BX 14

models after August 1988. It is an all-alloy unit

and although the dimensions, clearances and

tolerances are similar to those of the type

150C engine dealt with in Chapter 2A, there

are several major differences. These

differences include the camshaft drive, which

is of toothed belt type, and the oil pump,

which is chain-driven from the crankshaft.

Precautions

Because of the unusual layout of the engine

and transmission systems, extra care and

attention are necessary during maintenance

and overhaul procedures which, in many

instances, differ from more conventional

systems.

Read through the various Sections

concerned before tackling any job, and

analyse the instructions, so that any snags or

possible difficulties can be noted in advance.

Because the sub-assembly castings are made

from aluminium alloy it is of utmost importance

that, where specified, all fastenings are

tightened to the correct torque and, in some

instances, in the correct sequence.

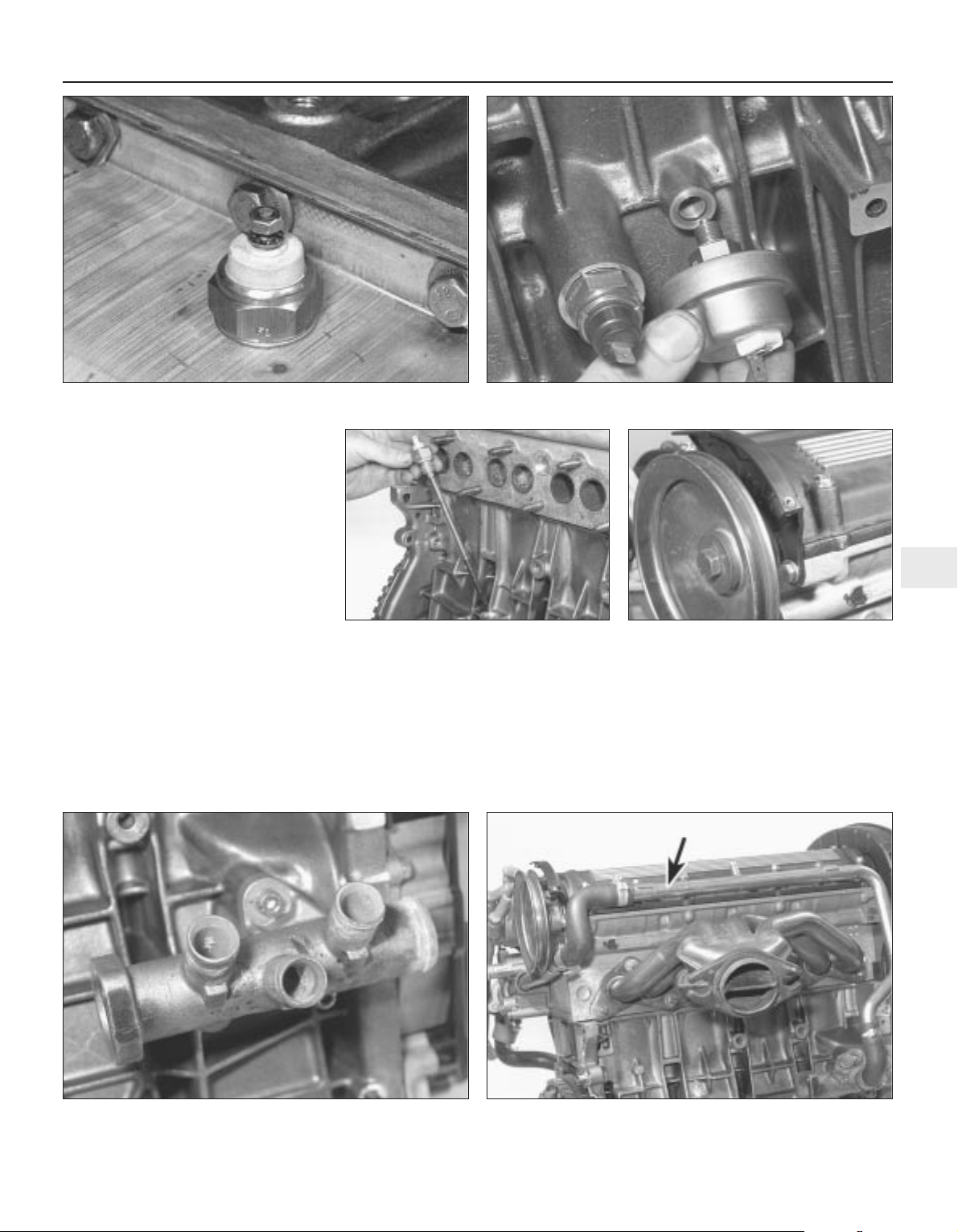

2 Oil filter - removal and refitting

2

Refer to Chapter 1, Section 9.

3 Major operations possible

with engine in vehicle

Note: Since the sump and cylinder head can

be removed in situ, it is possible to renew the

pistons, liners and big-end bearings without

removing the engine. However, this is not

recommended, since the tasks can be

performed more easily with the engine

removed

The following components can be removed

and refitted with the engine in the vehicle:

a) Timing belt and camshaft

b) Cylinder head

c) Sump and oil pump

d) Clutch and flywheel (after removal of

gearbox)

4 Major operations requiring

engine removal

The engine must be removed for the

following operations:

a) Removal and refitting of the transmission

b) Removal and refitting of the crankshaft

and main bearings

c) Removal and refitting of the piston and

connecting rod assemblies - see Note,

Section 3

d) Renewal of the big-end bearings - see

Note, Section 3

5 Valve rocker clearances -

checking and adjustment

3

Refer to Chapter 1, Section 21.

6 Camshaft drivebelt - removal

and refitting

3

Note: If there is the slightest doubt about the

condition of the timing belt then it must be

renewed.

Note: The following operation can be carried

out with the engine in the vehicle.

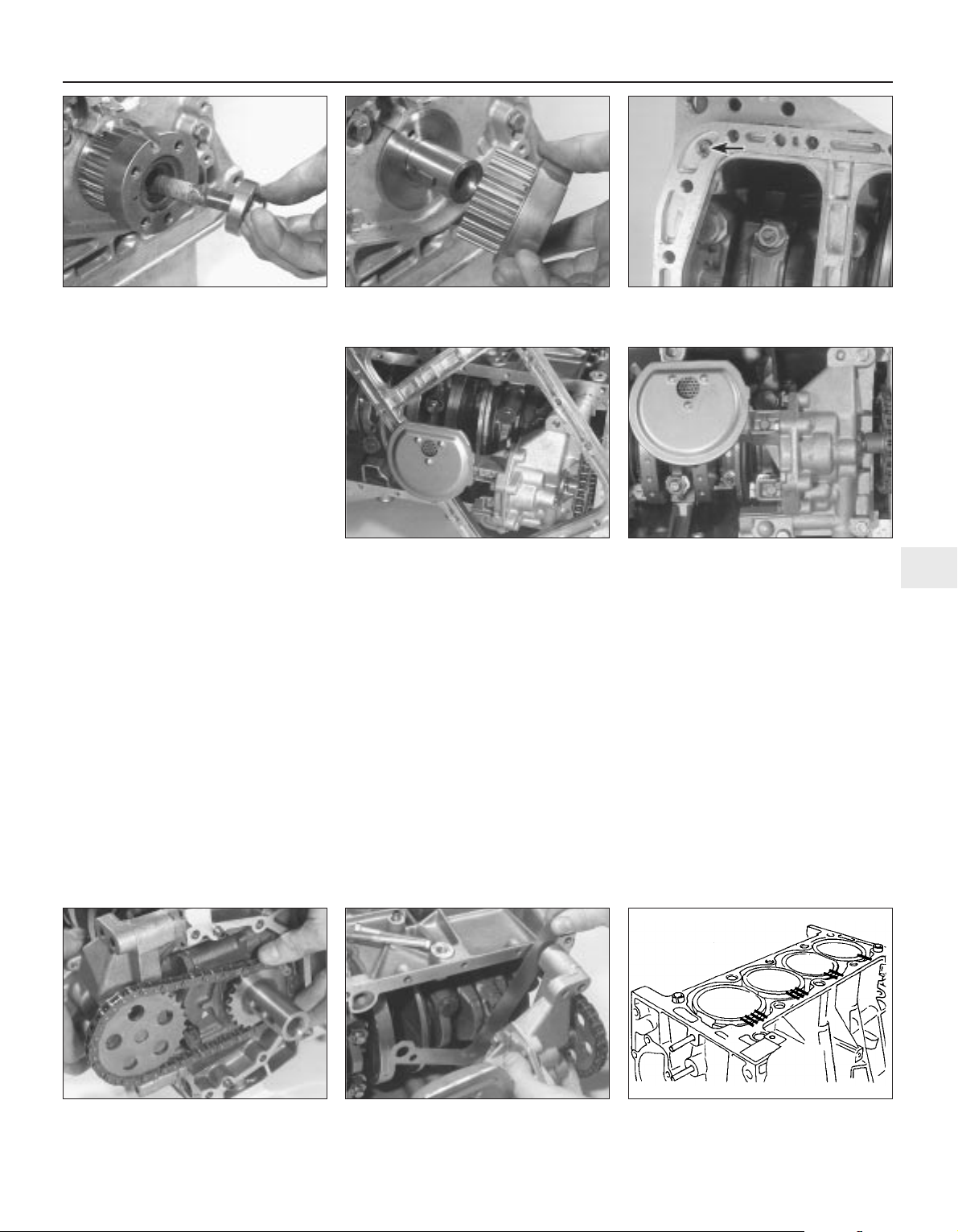

Removal

1 Disconnect the battery earth lead.

2 Remove the hydraulic pump (outer) and the

alternator (inner) drivebelts.

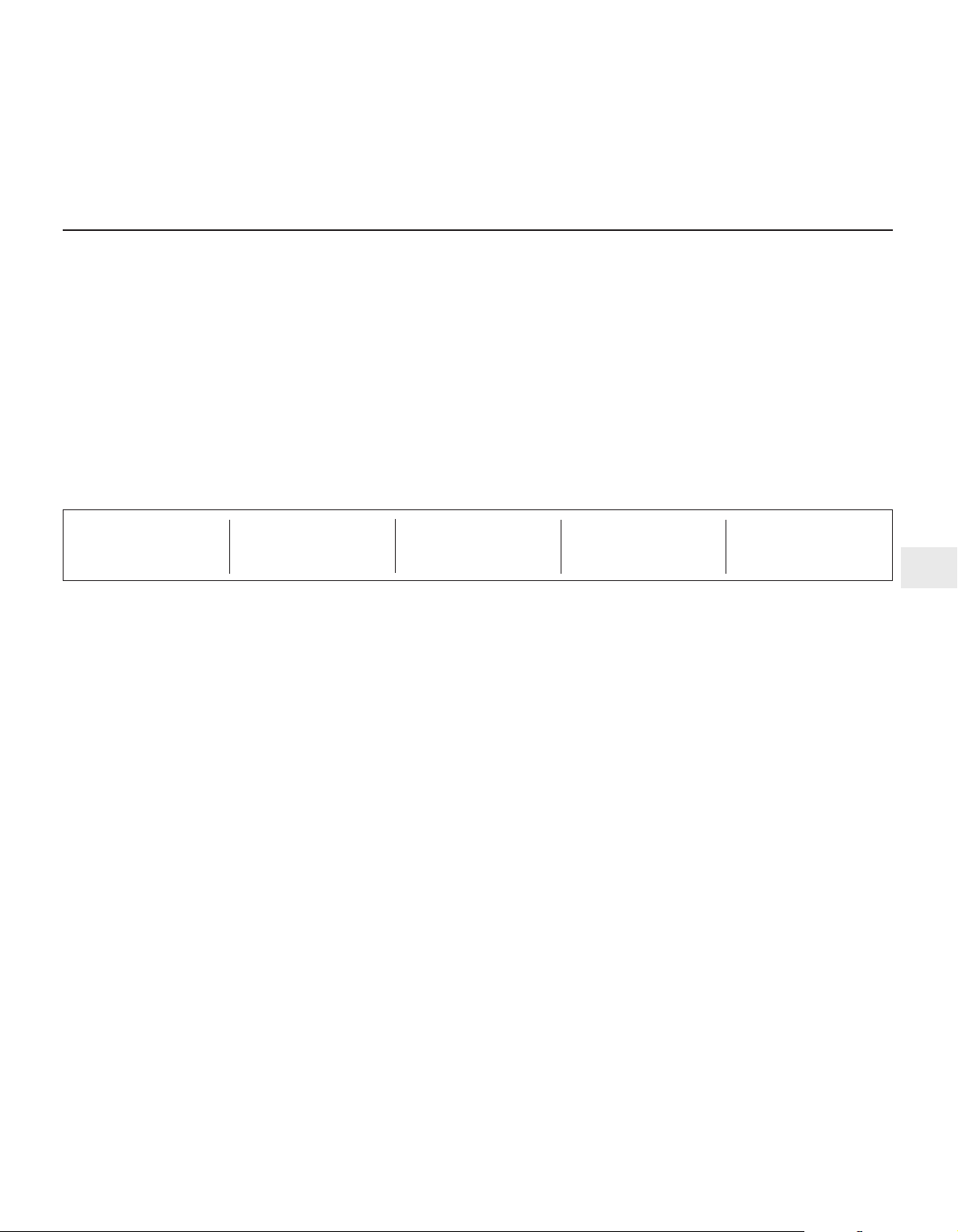

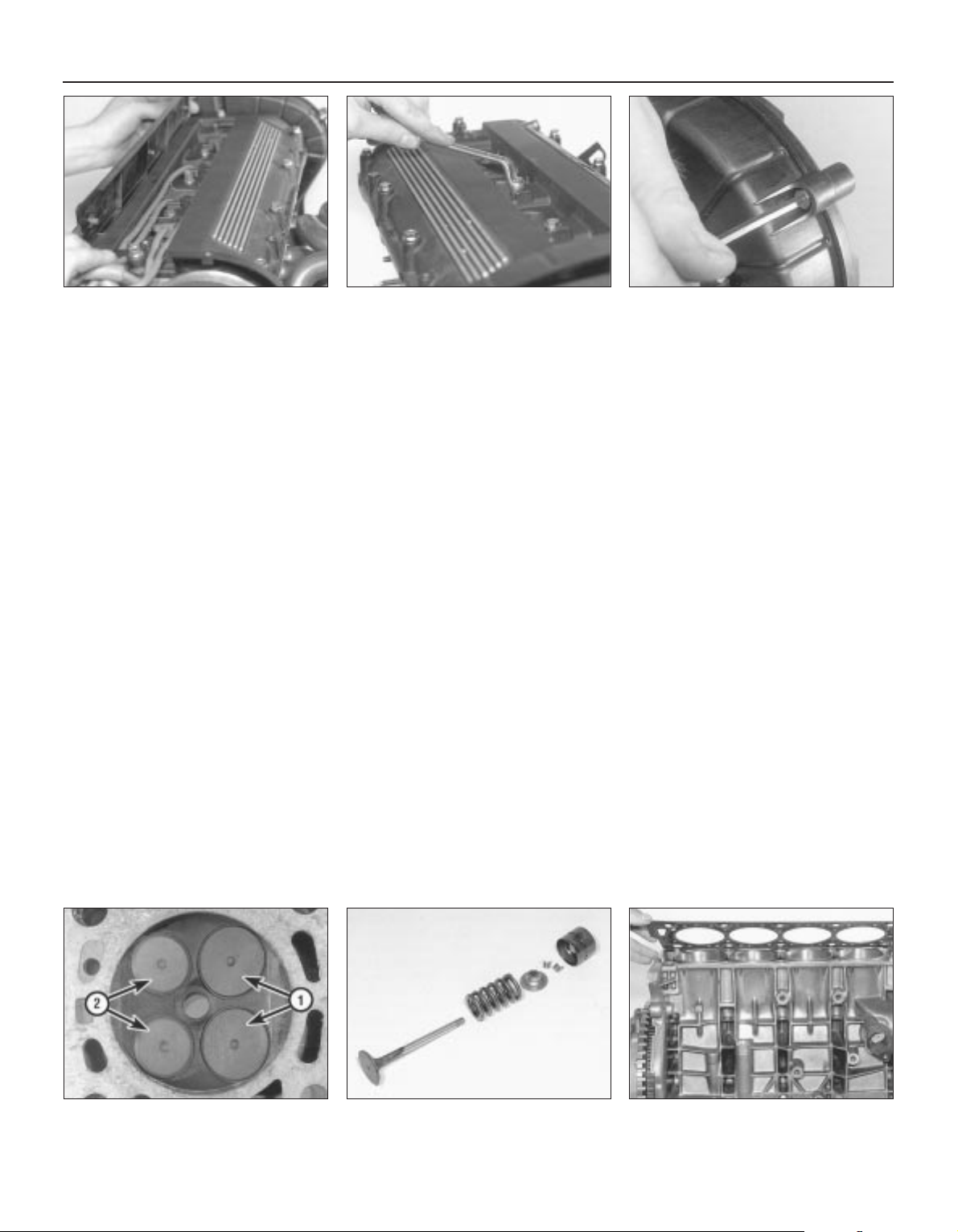

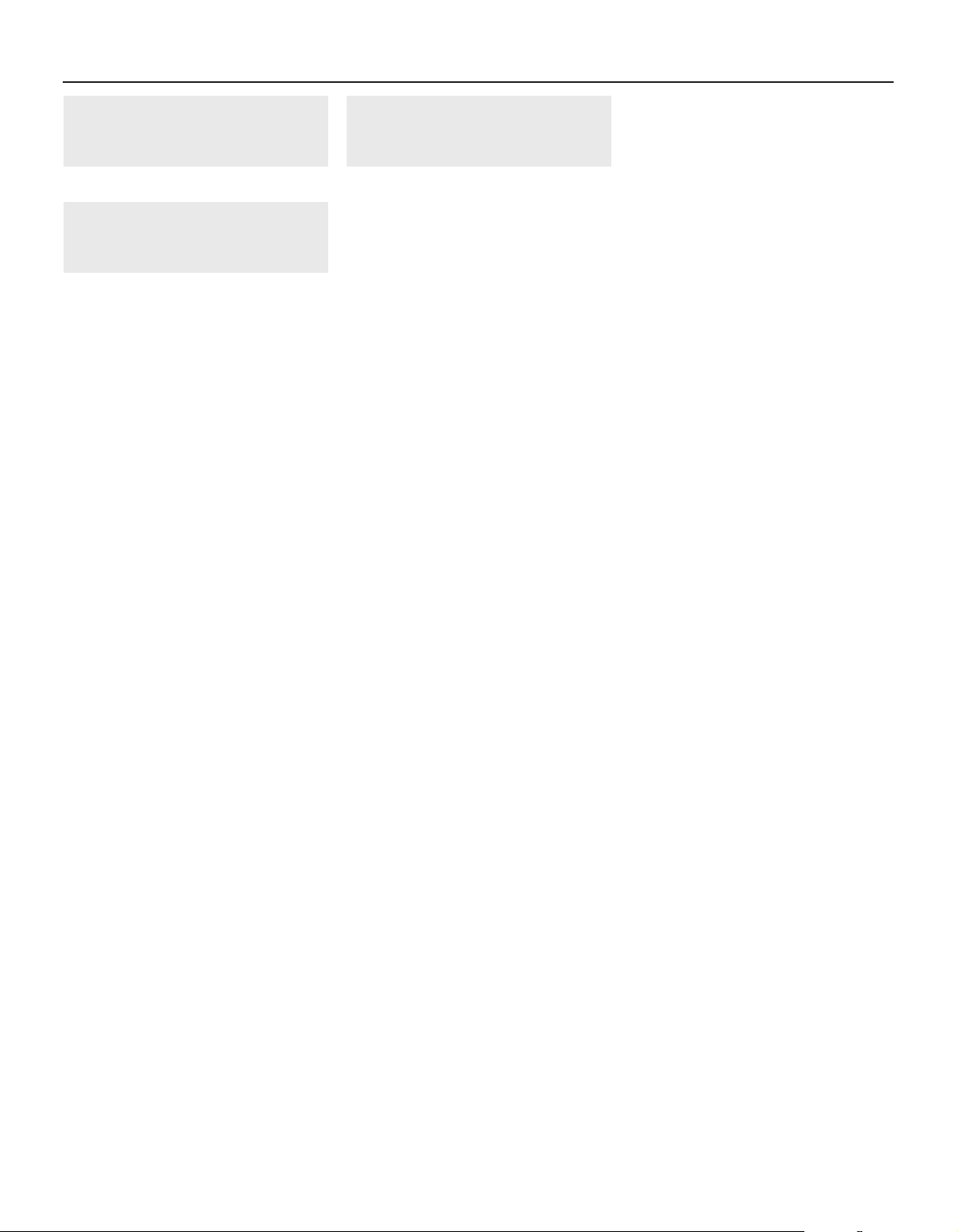

3 Remove the rocker cover and remove the

rubber gasket from the cover (see

illustrations).

4 Remove the two spacers and baffle plate

from the studs (see illustrations).

5 Unbolt the upper timing cover, followed by

the intermediate cover and lower cover (see

illustrations).

6 Turn the engine clockwise, using a socket

on the crankshaft sprocket bolt, until the small

hole in the camshaft sprocket is aligned with

the corresponding hole in the cylinder head.

Insert the shank of a close-fitting twist drill

into the holes (see illustration).

7 Align the TDC holes in the flywheel and

cylinder block rear flange, then insert a further

twist drill or long bolt (see illustration).

2C•2 K1G engine

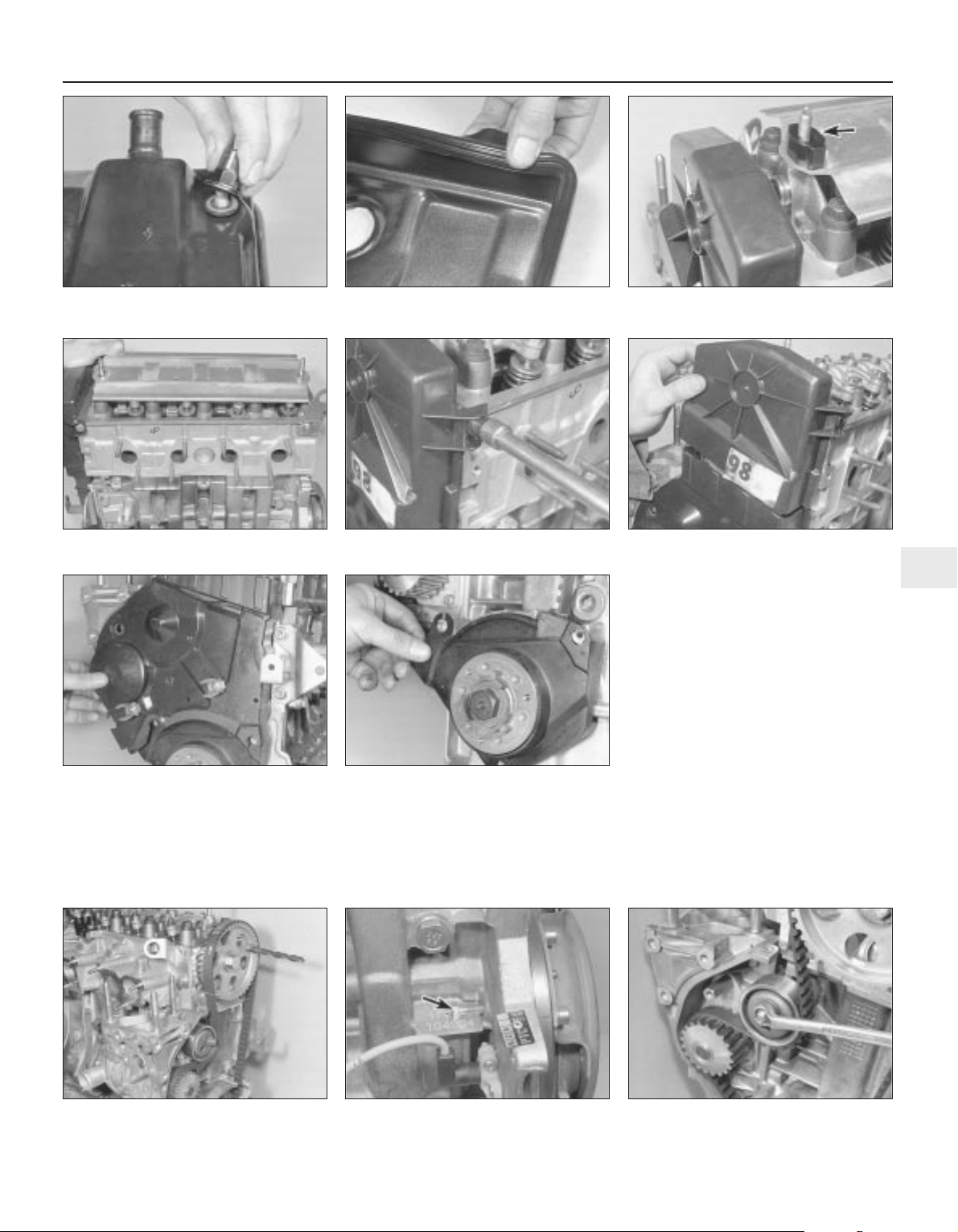

8 Loosen the timing belt tensioner roller nut

(see illustration), turn the tensioner clockwise

using a screwdriver or square drive in the

special hole, then re-tighten the nut.

9 Mark the normal direction of rotation on the

timing belt, then remove it from the camshaft,

coolant pump, and crankshaft sprockets.

Refitting

Caution: Take care not to kink or

contaminate the timing belt with oil

10 Engage the timing belt with the crankshaft

sprocket then, keeping it taut, feed it onto the

camshaft sprocket, around the tensioner

pulley, and onto the coolant pump sprocket.

11 Loosen the nut and turn the tensioner

roller anti-clockwise by hand. Tighten the nut.

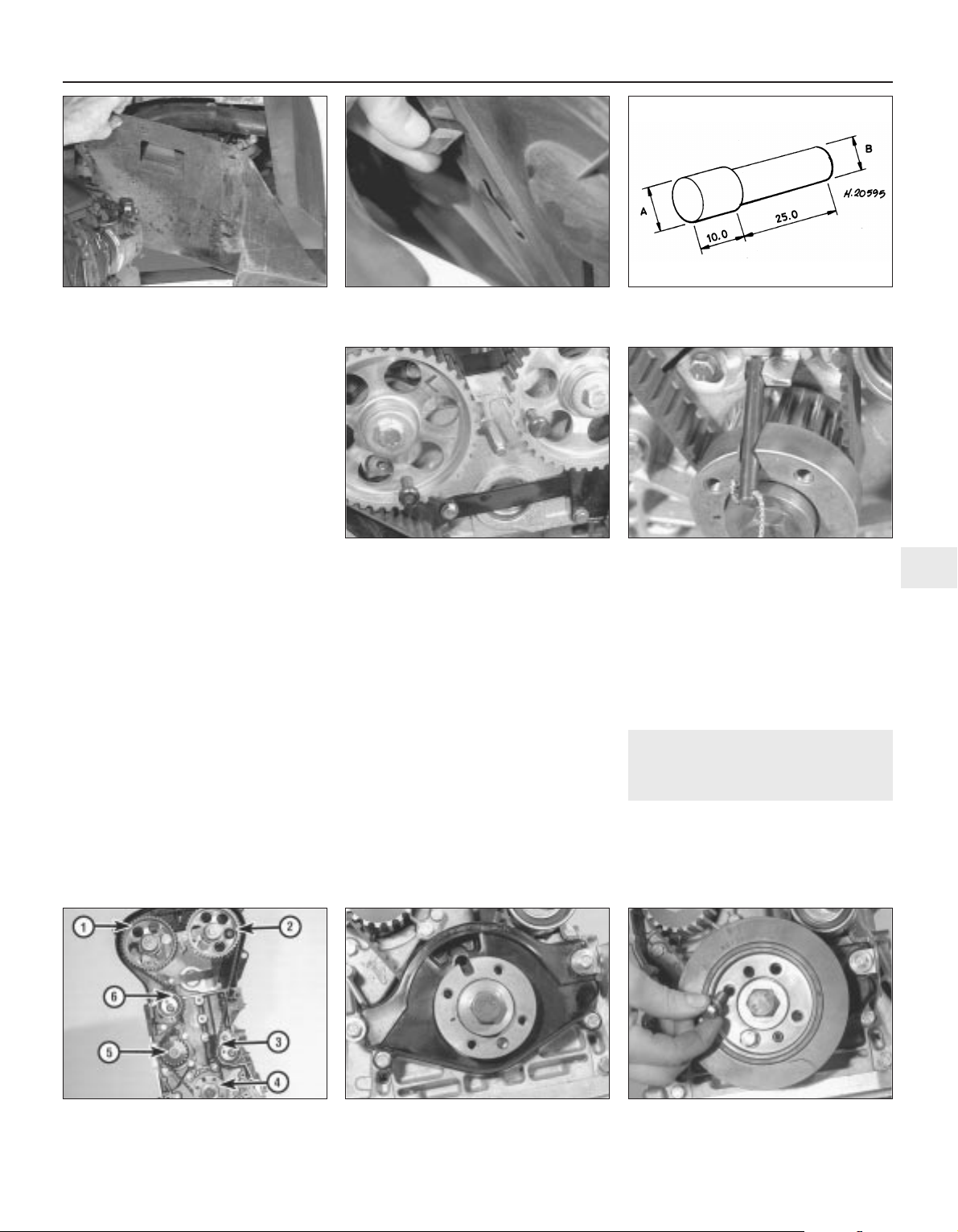

12 Citroën dealers use the special tool

shown (see illustration) to tension the timing

belt. A similar tool may be fabricated using an

8.0 cm long arm and a 1.5 kg (3.3 lb) weight.

The torque applied to the roller will

approximate 12 Kgf (10.5 lbf in). Pre-tension

the timing belt with the tool and tighten the

nut, then remove the timing pins and rotate

the crankshaft through two complete turns.

Loosen the nut and allow the roller to

re-position itself. Tighten the nut.

13 If the special tool is not available, an

approximate setting may be achieved by

turning the roller hub anti-clockwise, until it is

K1G engine 2C•3

2C

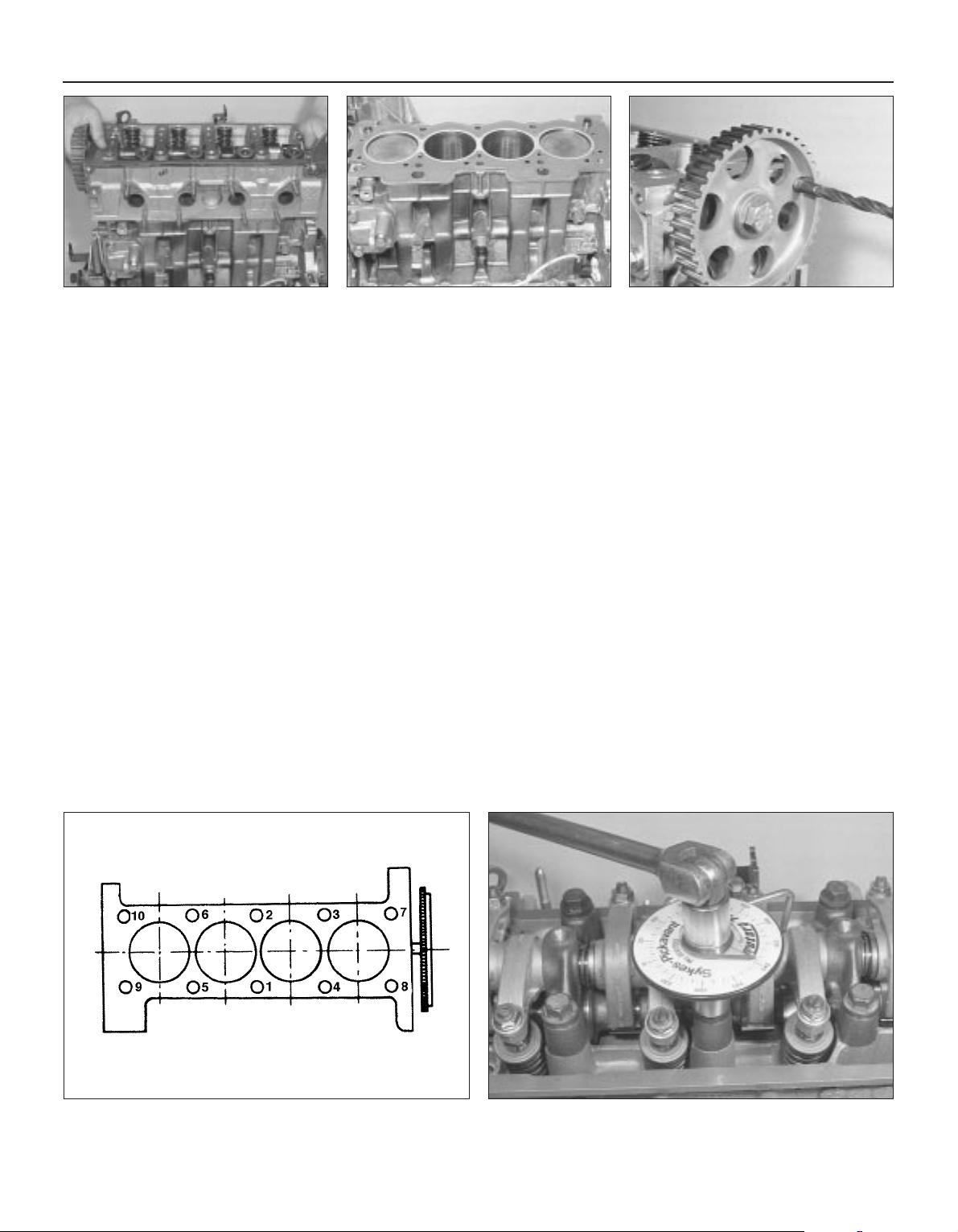

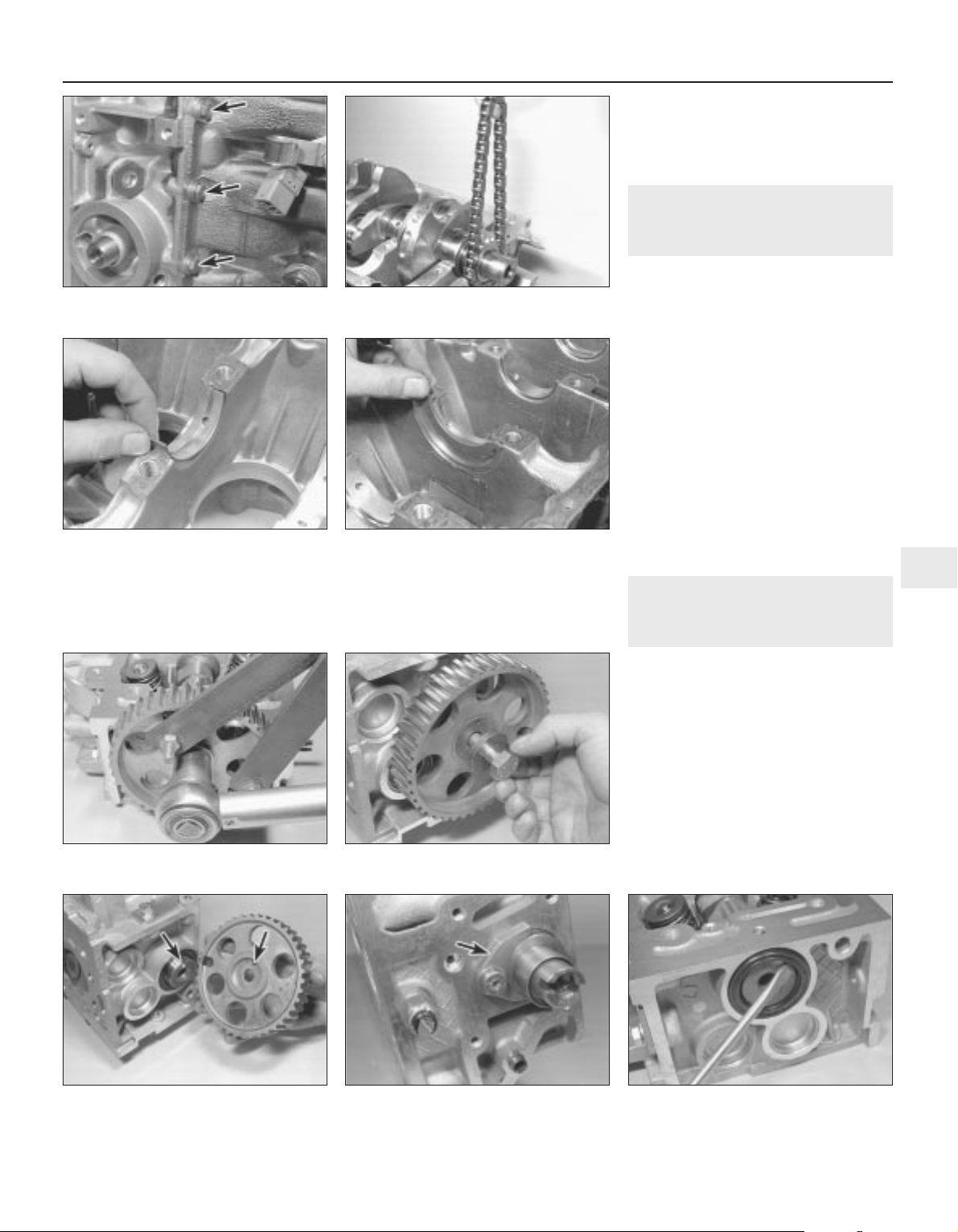

6.3a Removing a rocker cover nut 6.3b Removing rocker cover gasket 6.4a Remove rocker cover spacers

(arrowed) . . .

6.6 Camshaft sprocket held at TDC 6.7 Using long bolt (arrowed) to align TDC

holes in flywheel and cylinder block

6.5c Removing intermediate timing cover 6.5d Removing lower timing cover

6.8 Loosening timing belt tensioner roller

nut

6.4b . . . and baffle plate 6.5a Unbolting upper timing cover 6.5b Removing upper timing cover

just possible to turn the timing belt through

90º by finger and thumb midway between the

crankshaft and camshaft sprockets. The

square in the roller hub should then be directly

below the adjustment nut, and the deflection

of the belt in the midway position should be

approximately 6.0 mm. If using this method,

the tension should be re-checked by a Citroën

dealer at the earliest opportunity.

14 Refit the lower, intermediate, and upper

timing covers, then tighten the bolts (see

illustration).

15 Adjust the valve clearances.

16 Refit the baffle plate with its edges

pointing downwards, followed by the two

spacers.

17 Fit the rubber gasket to the rocker cover,

locate the cover in position and tighten the

nuts.

18 Refit and tension the hydraulic pump and

the alternator drivebelts.

19 Reconnect the battery earth lead.

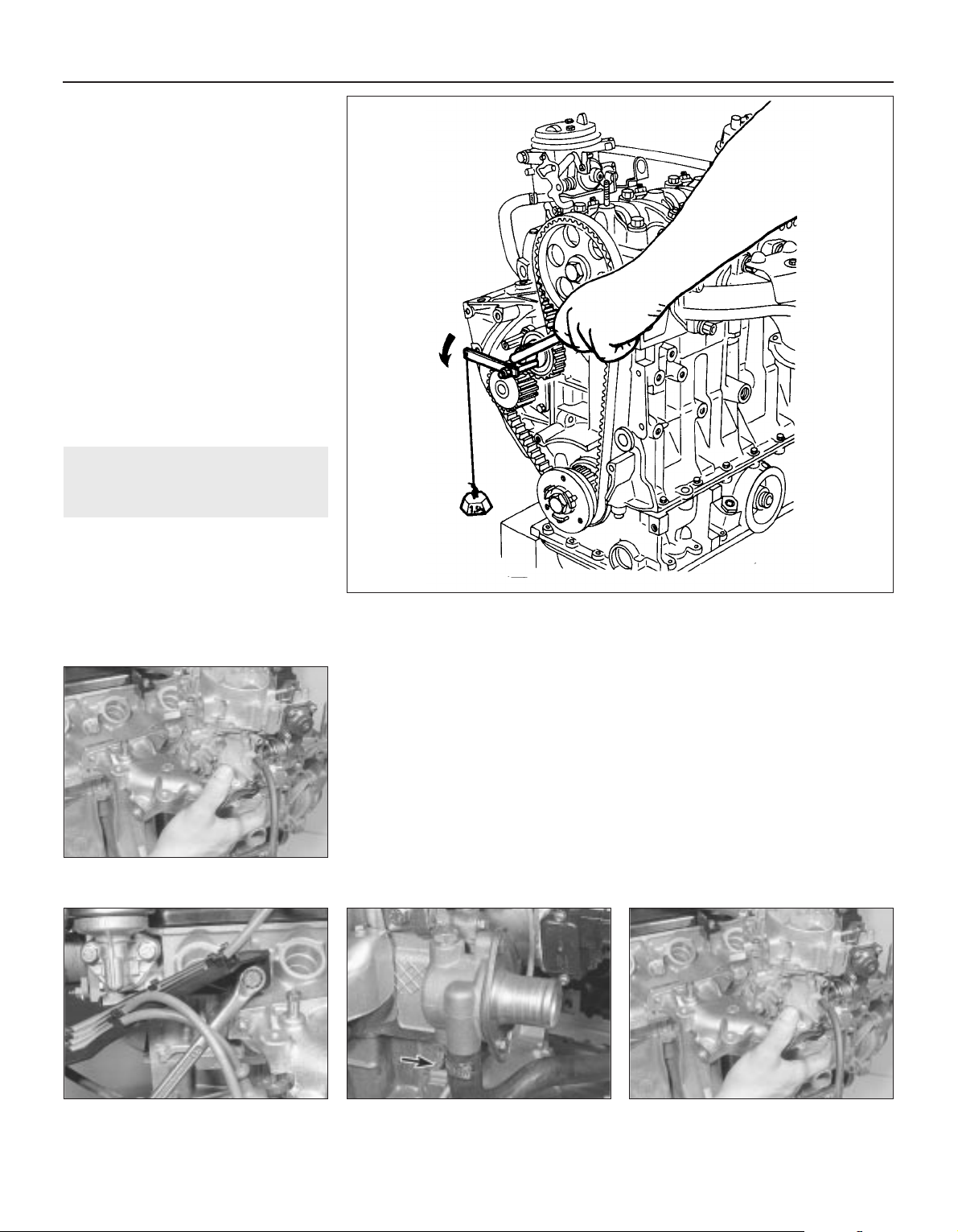

7 Cylinder head - removal and

refitting

3

Note: The following operation can be carried

out with the engine in the vehicle

Note: Illustrations for paragraphs 21 to 26

inclusive can be found in Section 6

Removal

1 Disconnect the battery.

2 Drain the cooling system.

3 Remove the air cleaner.

4 Disconnect the choke and throttle cables

from the carburettor.

5 Unbolt the exhaust downpipe.

6 Disconnect the HT leads from the spark

plugs, unbolt the lead support (see

illustration), disconnect the HT lead from the

coil, and remove the distributor cap. Remove

the spark plugs.

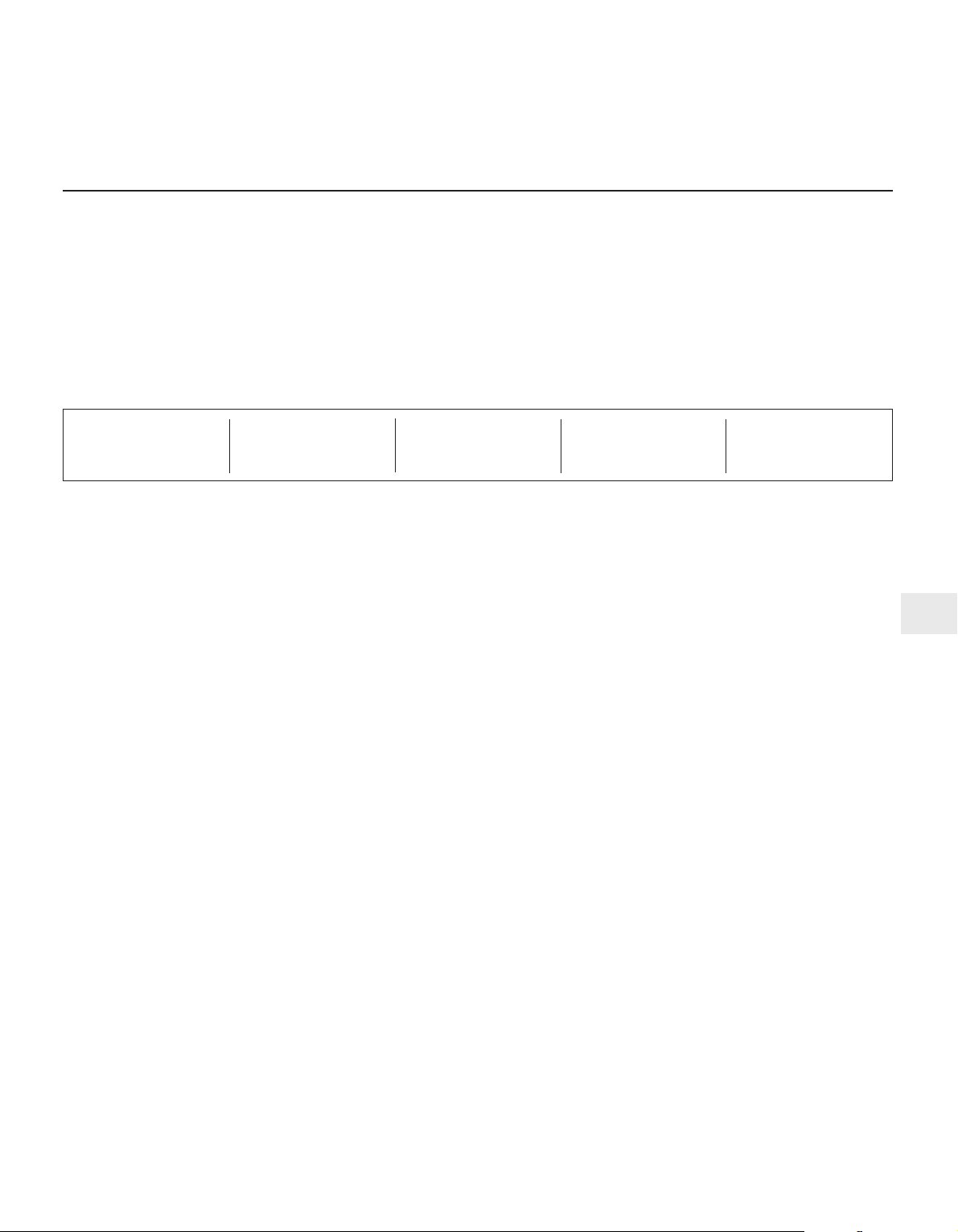

7 Disconnect the vacuum hose between the

distributor and carburettor.

8 Disconnect the hoses between the fuel

pump and carburettor (beware of fuel spillage

and take adequate fire precautions) and

between the coolant pump and thermostat

housing (see illustration).

9 Unscrew the nuts and remove the inlet

manifold complete with carburettor from the

studs on the cylinder head (see illustration).

Note that there is no gasket.

10 Unbolt and remove the fuel pump and

remove the gasket.

11 Loosen the alternator pivot and

adjustment bolts, then unscrew the tension

bolt and slip the drivebelt from the pulleys.

Remove the pivot and adjustment bolts then

remove the alternator (see illustration).

12 Unbolt the pulley from the front of the

crankshaft (see illustration).

13 Unbolt and remove the coil (see

illustration) after unclipping the TDC sensor

connector.

2C•4 K1G engine

7.6 Unbolting HT lead support

6.14 Timing cover correctly refitted

7.8 Water pump hose (arrowed) at

thermostat housing

7.9 Removing inlet manifold complete with

carburettor

6.12 Using special tool (0132X) to tension timing belt

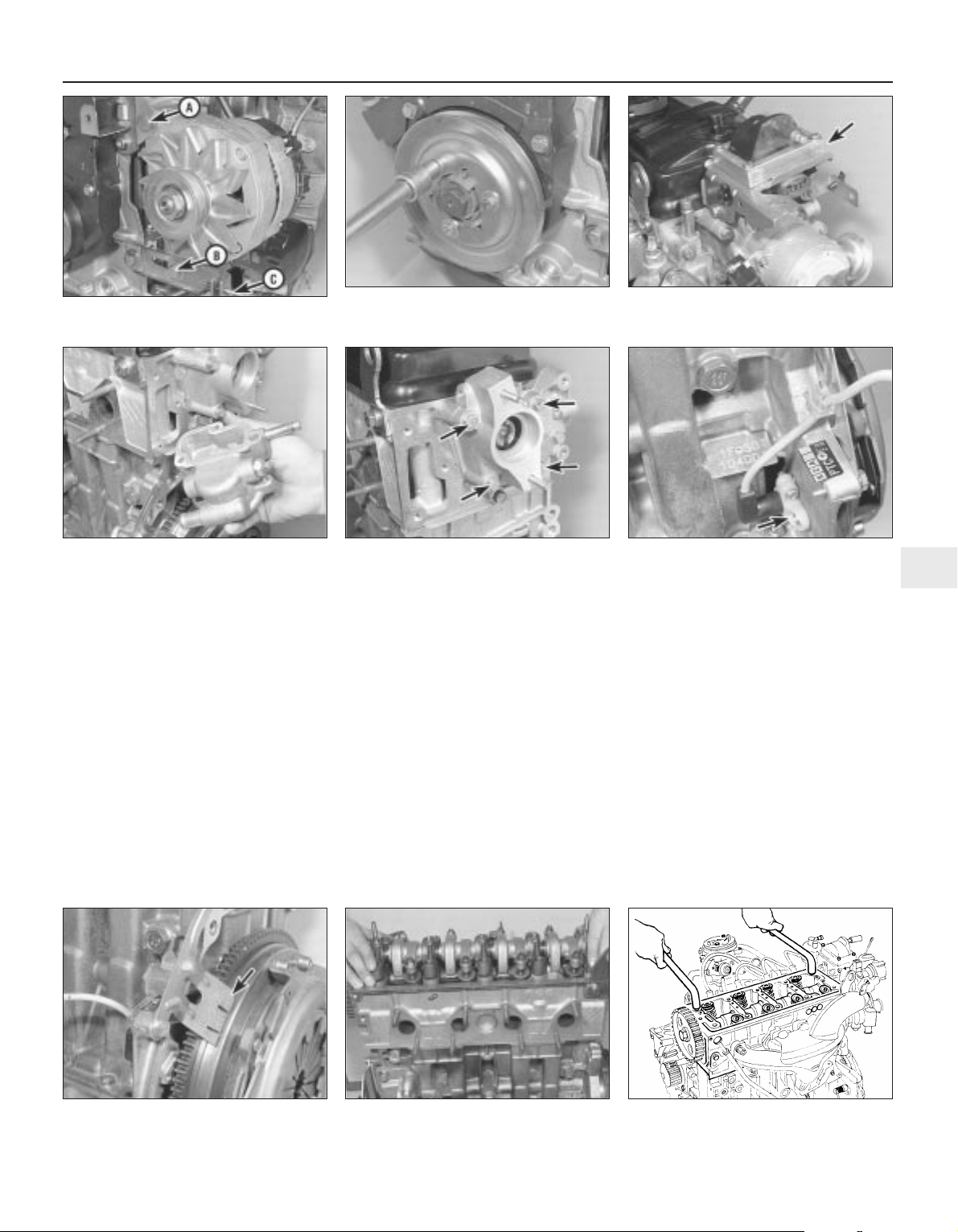

14 Unbolt the exhaust manifold hot air

shroud.

15 Unscrew the brass nuts, remove the

washers and remove the exhaust manifold

from the studs on the cylinder head. Remove

the gaskets.

16 Remove the distributor.

17 Remove the thermostat, then unbolt the

thermostat housing from the cylinder head

(see illustration).

18 Unbolt the distributor mounting flange

from the cylinder head (see illustration).

19 Unbolt the TDC sensor from the flywheel

end of the cylinder block and unclip the lead

from the timing plate (see illustration).

20 Unbolt and remove the timing plate (see

illustration).

21 Unscrew the nuts and remove the rocker

cover. Remove the rubber gasket from the

cover.

22 Remove the two spacers and baffle plate

from the studs.

23 Unbolt the upper timing cover, followed

by the intermediate cover and lower cover.

24 Turn the engine clockwise, using a socket

on the crankshaft sprocket bolt, until the small

hole in the camshaft sprocket is aligned with

the corresponding hole in the cylinder head.

Insert the shank of a close-fitting twist drill

into the holes.

25 Align the TDC holes in the flywheel and

cylinder block rear flange, then insert a further

twist drill or long bolt.

26 Loosen the timing belt tensioner roller nut,

turn the tensioner clockwise using a

screwdriver or square drive in the special

hole, then re-tighten the nut.

27 Mark the normal direction of rotation on

the timing belt, then remove it from the

camshaft, coolant pump, and crankshaft

sprockets.

28 Unscrew the tensioner nut and remove

the tensioner roller.

29 Progressively loosen the cylinder head

bolts using the reverse sequence to that

shown for tightening, then remove all the

bolts.

30 Lift off the rocker arm assembly (see

illustration).

31 Rock the cylinder head to free it from the

block, then lift it from the location dowels. The

two angled metal rods shown may be used for

this purpose (see illustrations).

32 Remove the cylinder head gasket from the

block.

33 Fit liner clamps (see Section 16 in Part A

of this Chapter) if it is not proposed to remove

the pistons and liners.

K1G engine 2C•5

2C

7.11 Alternator pivot (A) adjuster (B) and

tensioner (C) bolts

7.12 Unbolting crankshaft pulley 7.13 Ignition coil (arrowed) located above

distributor

7.20 Timing plate (arrowed) 7.30 Removing rocker arm assembly 7.31a Using two metal rods to free

cylinder head from cylinder block

7.17 Removing thermostat housing 7.18 Distributor mounting flange retaining

bolts (arrowed)

7.19 TDC sensor mounting bolt (arrowed)

Refitting

34 Clean the cylinder head and block joint

faces thoroughly. Also clean the cylinder head

bolt holes.

35 Locate the new cylinder head gasket on

the block dowels, with the manufacturer’s

name uppermost (see illustration).

36 Align the TDC holes in the flywheel and

block rear flange and insert a twist drill or long

bolt.

37 Align the small hole in the camshaft

sprocket with the hole in the cylinder head

and insert a twist drill or bolt (see

illustration).

38 Lower the cylinder head onto the block so

that it engages the two dowels.

39 Refit the rocker arm assembly.

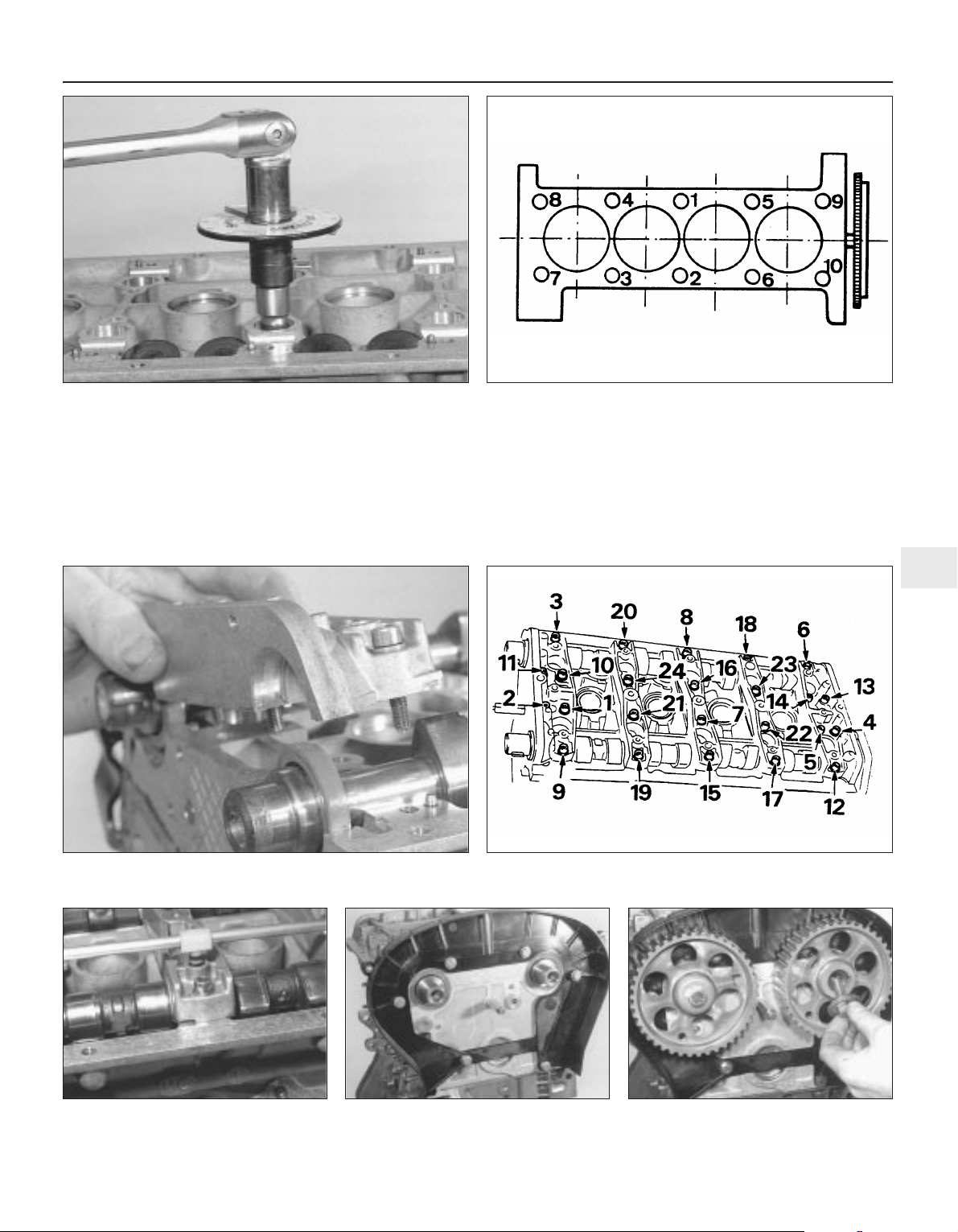

40 Lubricate the cylinder head bolt threads

and heads with molybdenum disulphide

grease. Insert them and tighten to the initial

torque using the sequence shown (see

illustration).

41 Using the same sequence, angle-tighten

the bolts through the specified angle (see

illustration).

42 Refit the timing belt tensioner roller, turn it

clockwise and tighten the nut.

43 Engage the timing belt with the crankshaft

sprocket then, keeping it taut, feed it onto the

camshaft sprocket, around the tensioner

pulley, and onto the coolant pump sprocket.

44 Loosen the nut and turn the tensioner

roller anti-clockwise by hand. Tighten the nut.

45 Citroën dealers use the special tool

shown in illustration 6.12 to tension the

timing belt. A similar tool may be fabricated

using an 8.0 cm long arm and a 1.5 kg (3.3 lb)

weight. The torque applied to the roller will

approximate 12 Kgf (10.5 lbf in). Pre-tension

the timing belt with the tool and tighten the

nut, then remove the timing pins and rotate

the crankshaft through two complete turns.

Loosen the nut and allow the roller to

re-position itself. Tighten the nut.

46 If the special tool is not available, an

approximate setting may be achieved by

turning the roller hub anti-clockwise, until it is

just possible to turn the timing belt through

90º by finger and thumb midway between the

crankshaft and camshaft sprockets. The

square in the roller hub should then be directly

below the adjustment nut, and the deflection

of the belt in the midway position should be

approximately 6.0 mm. If using this method,

the tension should be re-checked by a Citroën

dealer at the earliest opportunity.

47 Refit the lower, intermediate, and upper

timing covers, then tighten the bolts - see

Section 6.

48 Adjust the valve clearances.

49 Refit the baffle plate with its edges

pointing downwards, followed by the two

spacers.

50 Fit the rubber gasket to the rocker cover,

locate the cover in position and tighten the

nuts.

51 Refit the timing plate and tighten the

bolts.

52 Refit the TDC sensor and tighten the bolt.

Fix the lead in the plastic clip on the timing

plate. Note that the main body of the TDC

sensor should be 1.0 mm from the flywheel.

53 Apply jointing compound to the distributor

mounting flange, then refit it to the cylinder

head and tighten the bolts.

54 Apply jointing compound to the

thermostat housing, then refit it to the cylinder

head and tighten the bolts to the specified

torque.

55 Refit the thermostat.

56 Refit the distributor.

57 Refit the exhaust manifold together with

new gaskets. Refit the nuts and washers, and

tighten securely.

58 Refit the exhaust manifold hot air shroud

and tighten the bolts.

59 Locate the coil and bracket over the

distributor and tighten the bolts.

60 Position the pulley on the front of the

crankshaft. Insert and tighten the bolts.

2C•6 K1G engine

7.31b Lifting cylinder head from cylinder

block

7.35 Cylinder head gasket correctly

located

7.37 Camshaft sprocket held at TDC using

twist drill

7.40 Cylinder head bolt tightening sequence 7.41 Angle-tightening cylinder head bolts

61 Refit the alternator and insert the pivot

and adjustment bolts. Slip the drivebelt onto

the pulleys and tighten the tension bolt until

the deflection of the belt midway between the

pulleys is approximately 6.0 mm under firm

thumb pressure. Tighten the pivot and

adjustment bolts.

62 Refit the fuel pump with a new gasket and

tighten the bolts.

63 Thoroughly clean the mating faces of the

inlet manifold and cylinder head and apply

jointing compound.

64 Refit the inlet manifold complete with

carburettor and tighten the nuts.

65 Reconnect the hose between the fuel

pump and carburettor and tighten the clips.

66 Reconnect the vacuum hose between the

distributor and carburettor.

67 Refit and tighten the spark plugs.

68 Refit the HT leads and distributor cap.

69 Reconnect the exhaust downpipe.

70 Reconnect the choke and throttle cables

to the carburettor.

71 Refit the air cleaner.

72 Replenish the cooling system.

73 Reconnect the battery.

8 Engine/transmission -

removal and refitting

4

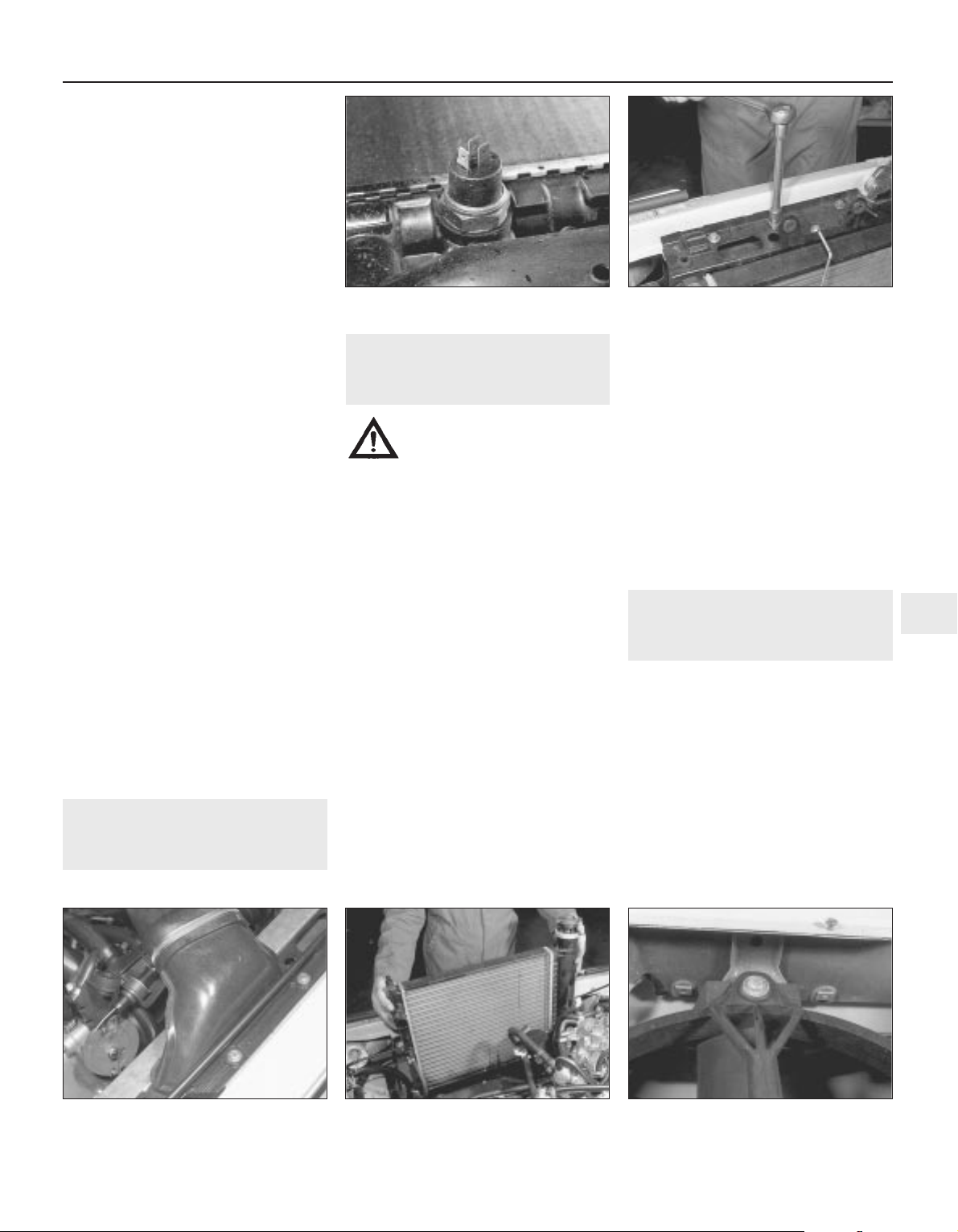

Removal

1 The engine/transmission is removed by

lifting it upwards out of engine compartment.

2 Remove the bonnet.

3 Remove the battery.

4 Raise the front of the car, and support it

securely on axle stands placed under the

body sill jacking points.

5 Drain the cooling system.

6 Drain the engine oil.

7 Drain the transmission oil.

8 Disconnect the choke and throttle cables

from the carburettor (see illustration).

9 Remove the air cleaner.

10 Disconnect the fuel supply hose from the

fuel pump, and the return hose from the Tunion.

11 Remove the radiator.

12 Remove both driveshafts.

13 Unbolt and remove the front downpipe

from the exhaust manifold, and also the front

section of the exhaust system, noting the

support bracket on the transmission.

14 Pull out the rubber cotter pin and

disconnect the speedometer cable from the

transmission (see illustration).

15 Disconnect the gearchange control rods

by prising the sockets off the balljoints with an

open-ended spanner (see illustration).

16 Remove the bolt from the engine rear

mounting (see illustration).

17 Unbolt the rear mounting yoke and the

driveshaft support bearing bracket, then

remove them.

18 Release the clips which hold the

suspension levelling pipeline to the underside

of the engine and transmission.

19 Loosen the mounting and belt adjuster

link bolts on the hydraulic pump and remove

the drivebelt.

20 Set the suspension height control lever in

the “low” position and then gently release the

screw on the hydraulic pressure regulator

through one turn (see illustration).

21 Disconnect the small pipe union on the

hydraulic pressure regulator and the one on

K1G engine 2C•7

2C

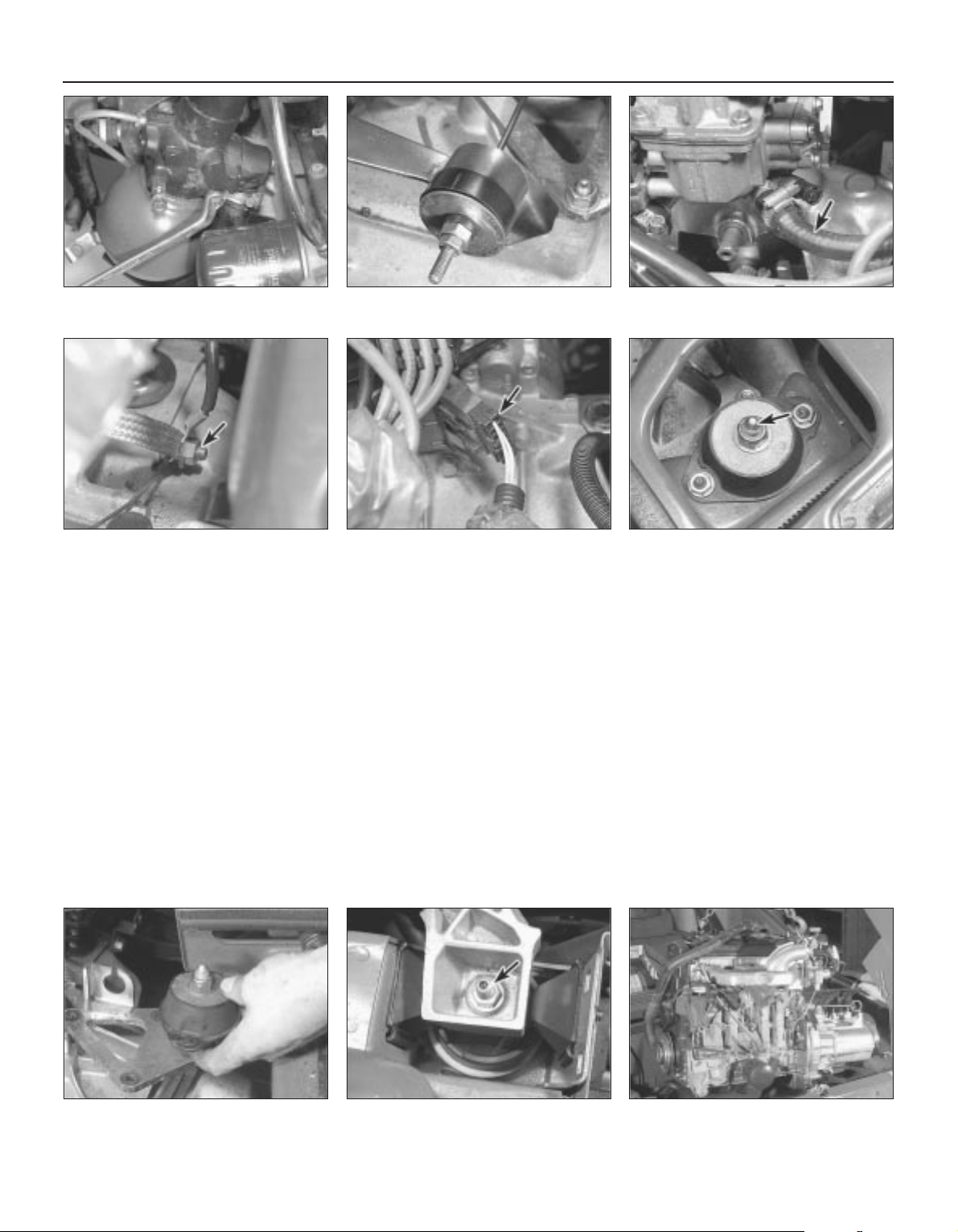

8.15 Using an open-ended spanner

(arrowed) to disconnect a gearchange rod

balljoint

8.16 Engine rear mounting and yoke 8.20 Hydraulic pressure regulator

A Pipe union B Pressure relief screw

8.8 Carburettor connections

A Choke cable

B Throttle cable

C Distributor vacuum

hose

8.14 Speedometer cable rubber cotter pin (arrowed)

the security valve. Release the fixing clips and

withdraw the disconnected section of pipeline

from below the car, noting carefully its

routing.

22 Unbolt the hydraulic pump/regulator

assembly from the cylinder block bracket (see

illustration).

23 Raise the assembly and rest it on the

crossmember with the hydraulic flexible hose

still connected.

24 Disconnect the clutch cable from the

release lever on the transmission (see

illustration).

25 Disconnect the heater hoses from the

engine.

26 Disconnect the heater hose from the

carburettor (see illustration).

27 Disconnect the earth cables from the

transmission casing (see illustration).

28 Disconnect the wiring from the alternator

and the plug which serves the temperature

switch, oil pressure switch and reversing light

switch (see illustration).

29 Connect a suitable hoist to the engine

lifting eyes and take the weight of the

engine/transmission.

30 Unscrew the through-bolt of the left-hand

mounting, then unbolt and remove the

mounting bracket (see illustrations).

31 Unscrew the through-bolt from the

right-hand engine mounting (see illustration).

32 Swivel the engine/transmission so that the

transmission faces towards the left-hand front

corner of the engine compartment.

33 Raise the hoist slowly and lift the

engine/transmission out of the engine

compartment (see illustration).

34 The transmission can be separated from

the engine after removing the following

components:

a) Starter motor

b) TDC sensor

c) Flywheel cover plate

d) Reversing light switch lead connections

35 Undo and remove the clutch

bellhousing-to-engine bolts.

Refitting

36 Refitting is a reversal of removal, but

observe the following points:

a) Use a plastic protective sleeve to prevent

damage to the oil seal lips when fitting the

right-hand driveshaft

b) Adjust the clutch cable

c) Refill the engine and transmission with oil

d) Refill the cooling system

e) Tension the drivebelts

2C•8 K1G engine

8.22 Unbolting hydraulic pump/regulator

assembly

8.24 Clutch cable connection at release

lever

8.26 Heater hose connection at

carburettor (arrowed)

8.30b Removing left-hand engine

mounting bracket

8.31 Right-hand engine mounting throughbolt (arrowed)

8.33 Lifting engine/transmission unit from

vehicle

8.27 Earth cables at transmission

(arrowed)

8.28 Temperature switch/oil pressure

switch/reversing light switch wiring

connector (arrowed)

8.30a Left-hand engine mounting throughbolt (arrowed)

f) Top-up the hydraulic system

g) The use of self-locking pliers will facilitate

reconnection of the gearchange rod

balljoints (see illustration)

9 Engine dismantling - general

information

Refer to Section 8 in Part A of this Chapter.

10 Engine dismantling - ancillary

items

Refer to Section 9 in Part A of this Chapter.

11 Engine - separation from

transmission

4

Refer to Section 10 in Part A of this Chapter.

12 Engine - complete dismantling

4

1 Disconnect the HT leads from the spark

plugs, unbolt the lead support, disconnect the

HT lead from the coil, and remove the

distributor cap. Remove the spark plugs.

2 Disconnect the vacuum hose between the

distributor and carburettor.

3 Disconnect the hoses between the fuel

pump and carburettor (beware of fuel spillage

and take adequate fire precautions) and

between the coolant pump and thermostat

housing.

4 Unscrew the nuts and remove the inlet

manifold complete with carburettor from the

studs on the cylinder head. Note that there is

no gasket.

5 Unbolt and remove the fuel pump, then

remove the gasket.

6 Loosen the alternator pivot and adjustment

bolts, then unscrew the tension bolt and slip

the drivebelt from the pulleys. Remove the

pivot and adjustment bolts, then remove the

alternator.

7 Unbolt the pulley from the front of the

crankshaft.

8 Unbolt and remove the coil after unclipping

the TDC sensor connector.

9 Unbolt the exhaust manifold hot air shroud.

10 Unscrew the brass nuts, remove the

washers and remove the exhaust manifold

from the studs on the cylinder head. Remove

the gaskets.

11 Remove the distributor.

12 Remove the thermostat, then unbolt the

thermostat housing from the cylinder head.

13 Unbolt the distributor mounting flange

from the cylinder head.

14 Unbolt the TDC sensor from the flywheel

end of the cylinder block and unclip the lead

from the timing plate.

15 Unbolt and remove the timing plate.

16 Unscrew and remove the oil filter, using a

strap wrench if necessary.

17 Unscrew and remove the oil pressure

switch.

18 Unscrew the mounting bolt and pull the

engine oil dipstick holder from the main

bearing cap casting. Remove the dipstick

from the holder (see illustration).

19 Unscrew the nuts and remove the rocker

cover. Remove the rubber gasket from the

cover.

20 Remove the two spacers and baffle plate

from the studs.

21 Unbolt the upper timing cover, followed

by the intermediate cover and lower cover.

22 Turn the engine clockwise, using a socket

on the crankshaft sprocket bolt, until the small

hole in the camshaft sprocket is aligned with

the corresponding hole in the cylinder head.

Insert the shank of a close-fitting twist drill

into the holes.

23 Align the TDC holes in the flywheel and

cylinder block rear flange, then insert a further

twist drill or long bolt.

24 Loosen the timing belt tensioner roller nut,

turn the tensioner clockwise using a

screwdriver or square drive in the special

hole, then re-tighten the nut.

25 Mark the normal direction of rotation on

the timing belt, then remove it from the

camshaft, coolant pump, and crankshaft

sprockets.

26 Unscrew the tensioner nut and remove

the tensioner roller.

27 Progressively loosen the cylinder head

bolts using the reverse sequence to that

shown, then remove all the bolts.

28 Lift off the rocker arm assembly.

29 Rock the cylinder head to free it from the

block, then lift it from the location dowels.

Two angled metal rods may be used for this

purpose.

30 Remove the cylinder head gasket from the

block.

31 Fit liner clamps (see Section 16 in Part A

of this Chapter) if it is not proposed to remove

the pistons and liners.

32 Progressively loosen the clutch pressure

plate bolts and remove the pressure plate and

friction disc from the flywheel (see

illustration).

K1G engine 2C•9

2C

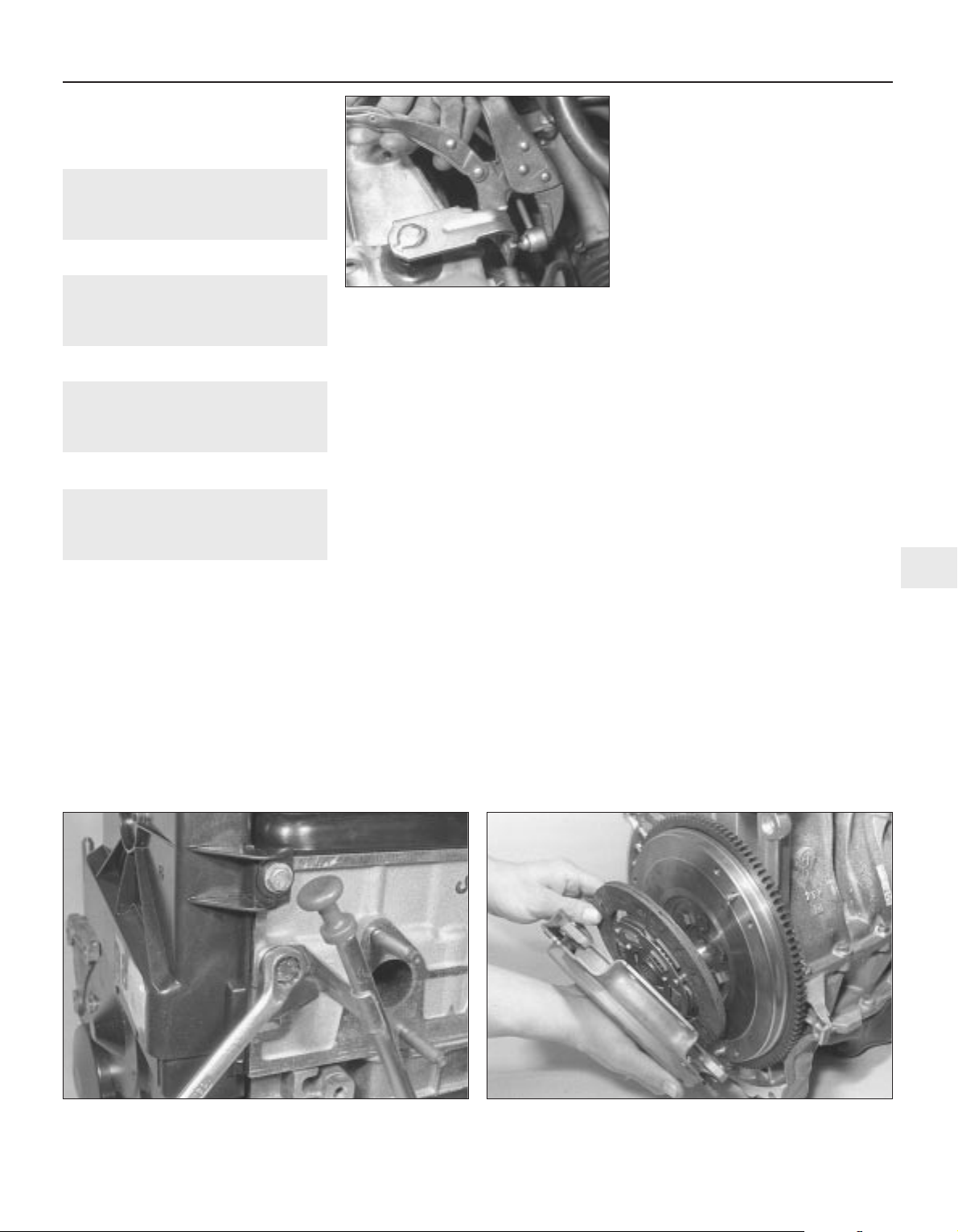

8.36 Reconnecting a gearchange rod

balljoint

12.18 Unbolting dipstick holder upper mounting 12.32 Removing clutch pressure plate and friction disc

33 Unbolt the coolant pump housing from

the side of the block and prise out the O-ring.

34 Have an assistant hold the flywheel

stationary with a wide-bladed screwdriver

inserted between the starter ring gear teeth,

then unscrew the crankshaft sprocket bolt

and remove the hub/sprocket and timing belt

guide plate (see illustrations).

35 Using a screwdriver, prise the front oil

seal from the block and main bearing casting

(see illustration).

36 Hold the flywheel stationary and unscrew

the flywheel bolts. Lift the flywheel from the

dowel on the crankshaft rear flange.

37 Prise out the crankshaft rear oil seal using

a screwdriver.

38 Invert the engine and support it on blocks

of wood.

39 Unscrew the nuts and bolts securing the

sump to the main bearing casting, then

remove it by carefully prising it free of the

jointing compound (see illustration).

40 Unbolt the oil pump and tilt it to release

the drive sprocket from the chain (see

illustrations).

41 Support the block on its flywheel end.

42 Mark the liners for position, starting with

No 1 (at the flywheel end). Similarly mark the

big-end bearing caps.

43 Temporarily refit the crankshaft sprocket

bolt and turn the crankshaft so that Nos 1 and

4 pistons are at bottom dead centre (BDC).

44 Unscrew the nuts and remove the big-end

bearing caps (see illustration). Remove the

lower big-end shells, keeping them identified

for position.

45 Remove the clamps and withdraw the

liners, complete with pistons, from the block

(see illustration).

46 Remove the liner bottom O-rings.

47 Repeat the procedure for Nos 2 and 3

pistons and liners.

48 Invert the engine again and unscrew the

bolts securing the main bearing cap casting to

the block (see illustrations).

2C•10 K1G engine

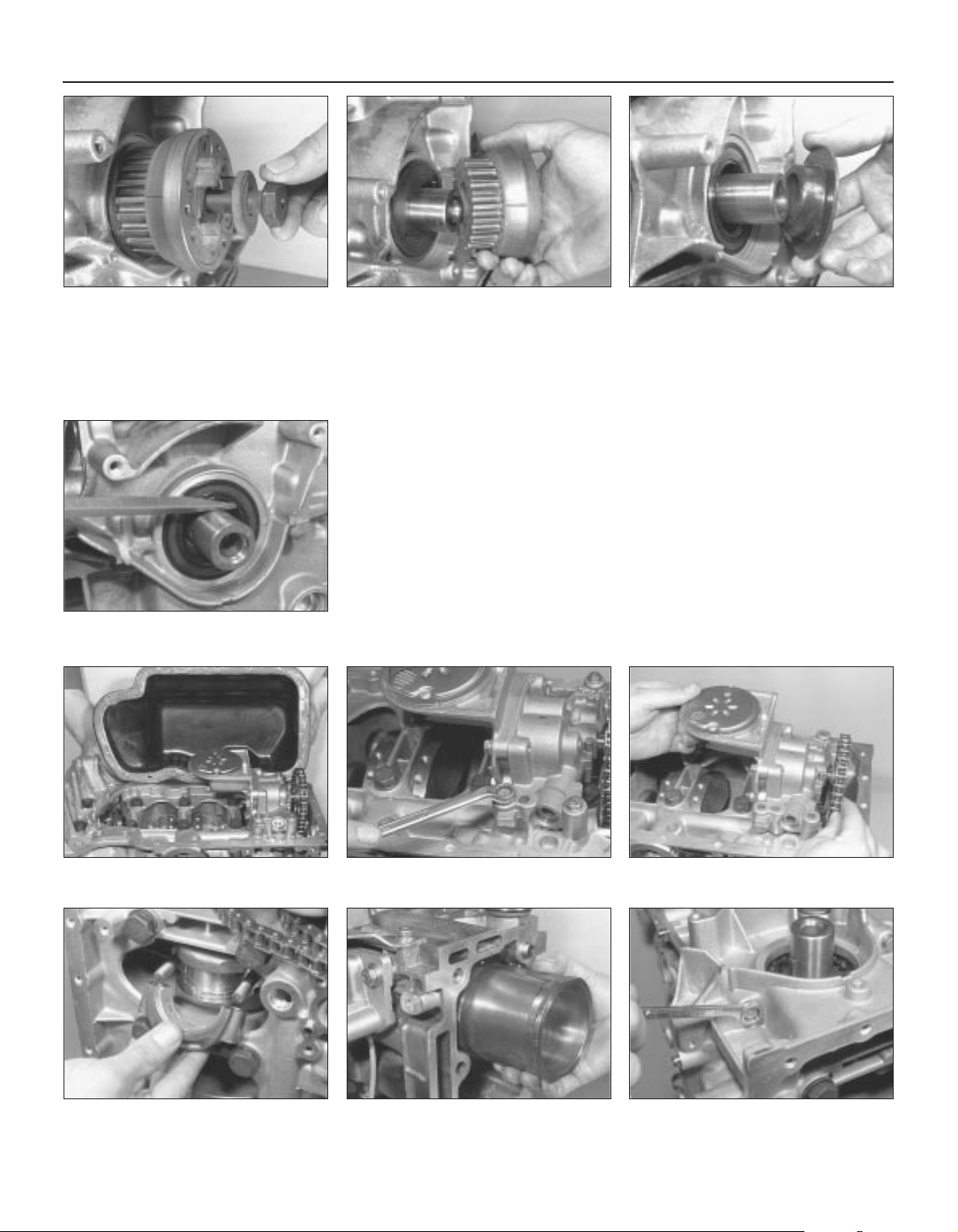

12.34a Removing crankshaft sprocket

bolt . . .

12.34b . . . the hub/sprocket . . . 12.34c . . . and timing belt guide plate

12.44 Removing a big-end bearing cap 12.45 Removing a liner/piston assembly 12.48a Unscrew main bearing cap casting

front bolts . . .

12.39 Removing the sump 12.40a Unscrew oil pump retaining

bolts . . .

12.40b . . . and remove oil pump

12.35 Prising out crankshaft front oil seal

49 Progressively unscrew the main bearing

bolts and lift the main bearing cap casting

from the block. Gently tap it with a wooden or

soft-headed mallet to release it. Prise out the

main bearing shells, keeping them identified

for location.

50 Remove the oil pump sprocket and chain

from the crankshaft (see illustration).

51 Lift the crankshaft from the block and

remove the main bearing shells, keeping them

identified for location. Also remove the

endfloat thrustwashers from No 2 main

bearing location (see illustrations).

13 Engine - examination and

renovation

4

General information

1 Refer to Section 12 in Part A of this Chapter.

Camshaft drivebelt

2 The drivebelt should be renewed when the

engine is overhauled, or if it has become

contaminated with oil. There is no specified

renewal mileage. When handling the timing

belt, do not bend it sharply as this may

damage the internal fibres.

Camshaft

3 Refer to Section 12 in Part A of this Chapter

but note that there is no camshaft lubrication

manifold, as the camshaft runs in an oil bath.

All other components

4 Refer to Section 12 in Part A of this Chapter.

14 Cylinder head - dismantling,

decarbonising, inspection and

reassembly

4

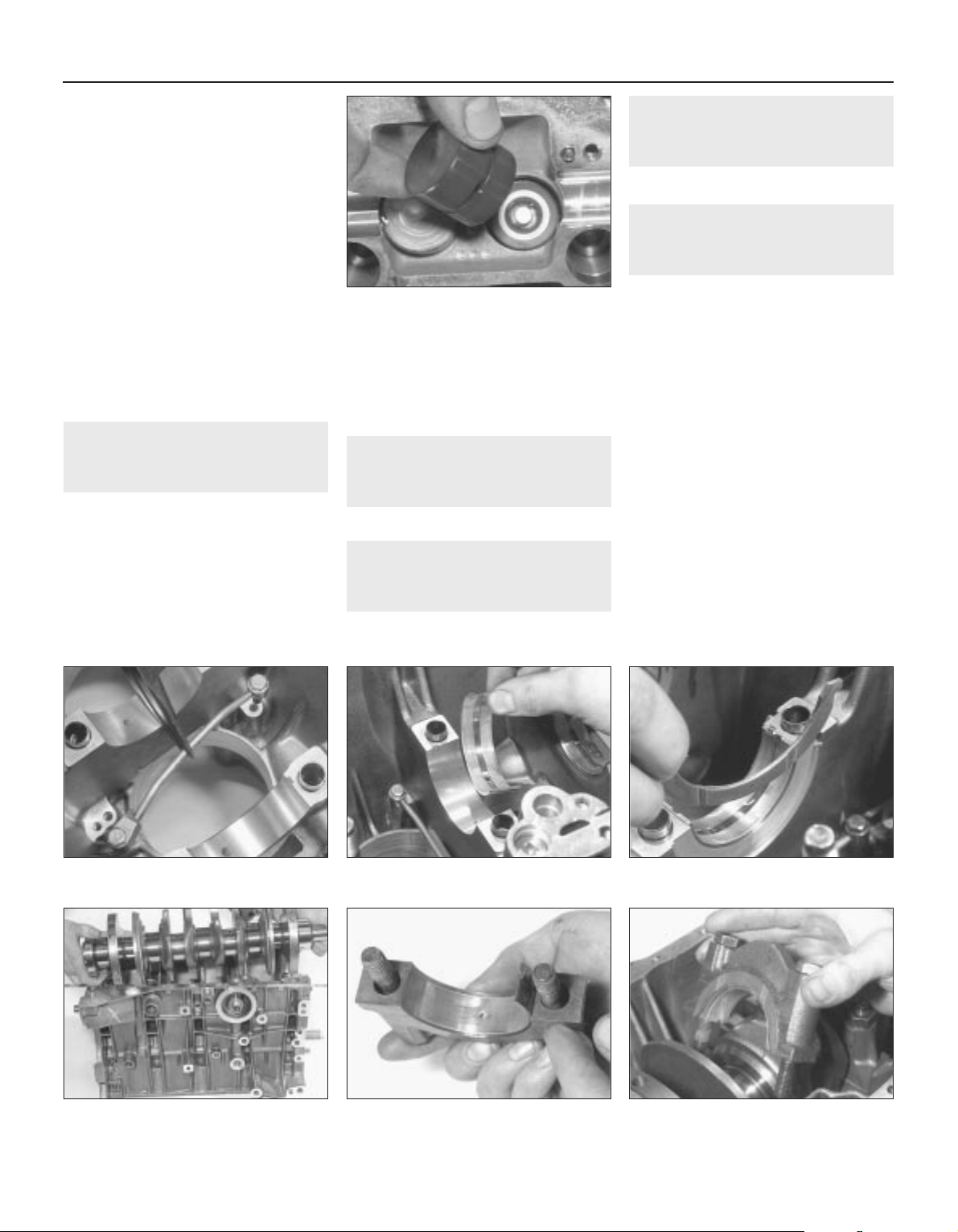

Dismantling

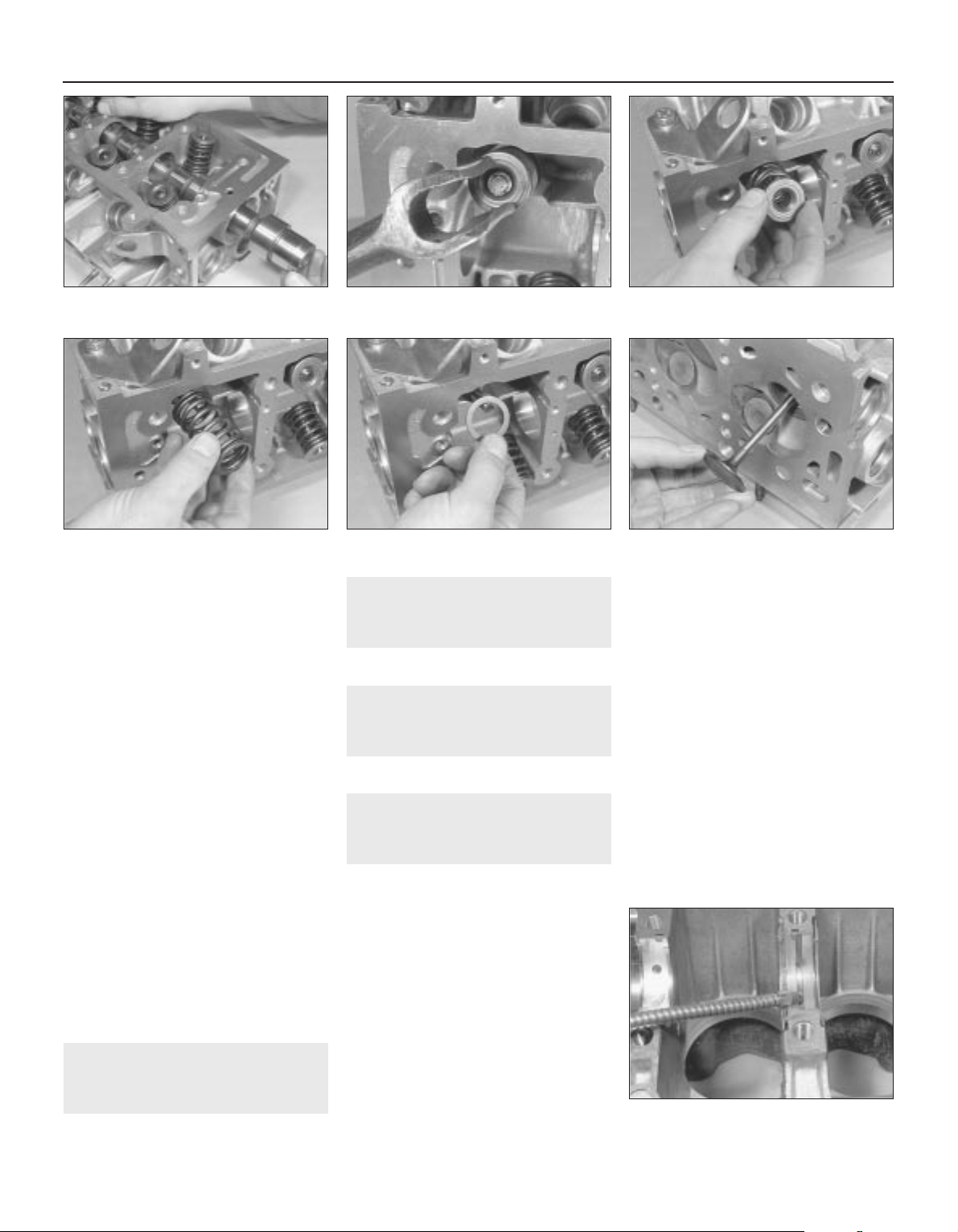

1 Remove the twist drill from the camshaft

sprocket, then hold the sprocket stationary

using an oil filter strap wrench or tool as

shown. Unscrew the bolt and remove the

sprocket (see illustrations).

2 Unbolt and remove the camshaft thrust fork

(see illustration).

3 Prise out the oil seal, and carefully withdraw

the camshaft from the cylinder head (see

illustrations).

K1G engine 2C•11

2C

12.48b . . . and side bolts (arrowed) 12.50 Removing oil pump chain from

crankshaft

12.51a Removing a main bearing shell . . . 12.51b . . . and endfloat thrustwasher

14.2 Camshaft thrust fork (arrowed)14.1c . . . and remove bolt, washer and

sprocket - note location peg and cut-out

(arrowed)

14.1a Using home-made tool to hold

camshaft sprocket stationary

14.1b Unscrew camshaft sprocket bolt . . .

14.3a Prise out camshaft oil seal . . .

4 Remove the valves and springs, keeping

them in order by inserting them in a card

having suitable holes punched in it, numbered

from 1 to 8. Discard the valve stem oil seals

(see illustrations).

Decarbonising

5 Refer to Section 13 in Part A of this

Chapter.

Inspection

6 Refer to Section 13 in Part A of this

Chapter.

Reassembly

7 Refit the valves and springs with reference

to Section 13 in Part A of this Chapter.

8 Oil the camshaft bearings and insert the

camshaft into the cylinder head.

9 Refit the camshaft thrust fork, and tighten

the bolt.

10 Dip the new oil seal in oil then press it into

the cylinder head until flush, using a metal

tube or large socket and hammer.

11 Refit the camshaft sprocket so that the

location peg enters the cut-out. Insert and

tighten the bolt while holding the sprocket

stationary, using the method described in

paragraph 1.

15 Engine reassembly - general

information

Refer to Section 14 in Part A of this Chapter.

16 Engine - preparation for

reassembly

3

Refer to Section 15 in Part A of this Chapter.

17 Cylinder liners - checking

protrusion

3

Refer to Section 16 in Part A of this Chapter.

18 Engine - complete reassembly

4

Note: Maintain conditions of absolute

cleanliness when reassembling the engine

Crankshaft

1 With the cylinder block upside-down on the

bench, press the main bearing upper shells

into position. Note that the grooved bearings

are fitted to positions No 2 and 4.

2 Smear a little grease on the thrustwashers

and locate them each side of No 2 bearing

with their grooves facing outwards.

3 Oil the bearings and lower the crankshaft

into position (see illustration).

4 Check that the crankshaft endfloat is as

given in the Specifications, using a feeler

blade between a thrustwasher and the

crankshaft web. The thrustwashers are

available in four thicknesses.

5 Fit the oil pump sprocket and chain to the

front of the crankshaft, locating the sprocket

on the Woodruff key.

6 Press the main bearing lower shells into

position in the main bearing cap casting,

noting that the grooved bearings are fitted to

positions No 2 and 4.

7 Apply jointing compound to the mating

face, then lower the main bearing cap casting

into position over the crankshaft (see

illustrations). At the same time, feed the oil

pump chain through the aperture.

8 Insert the main bearing bolts dry, then

tighten them evenly to the initial torque

wrench setting. Angle-tighten the bolts by a

further 45º (see illustration)

9 Refit the bolts securing the main bearing

cap casting to the block, and tighten them to

the specified torque.

2C•12 K1G engine

14.3b . . . and withdraw camshaft 14.4a Compress valve spring and remove

split collets . . .

14.4b . . . the retainer . . .

18.3 Oiling main bearing shells

14.4c . . . the spring . . . 14.4d . . . the spring seat . . . 14.4e . . . and the valve

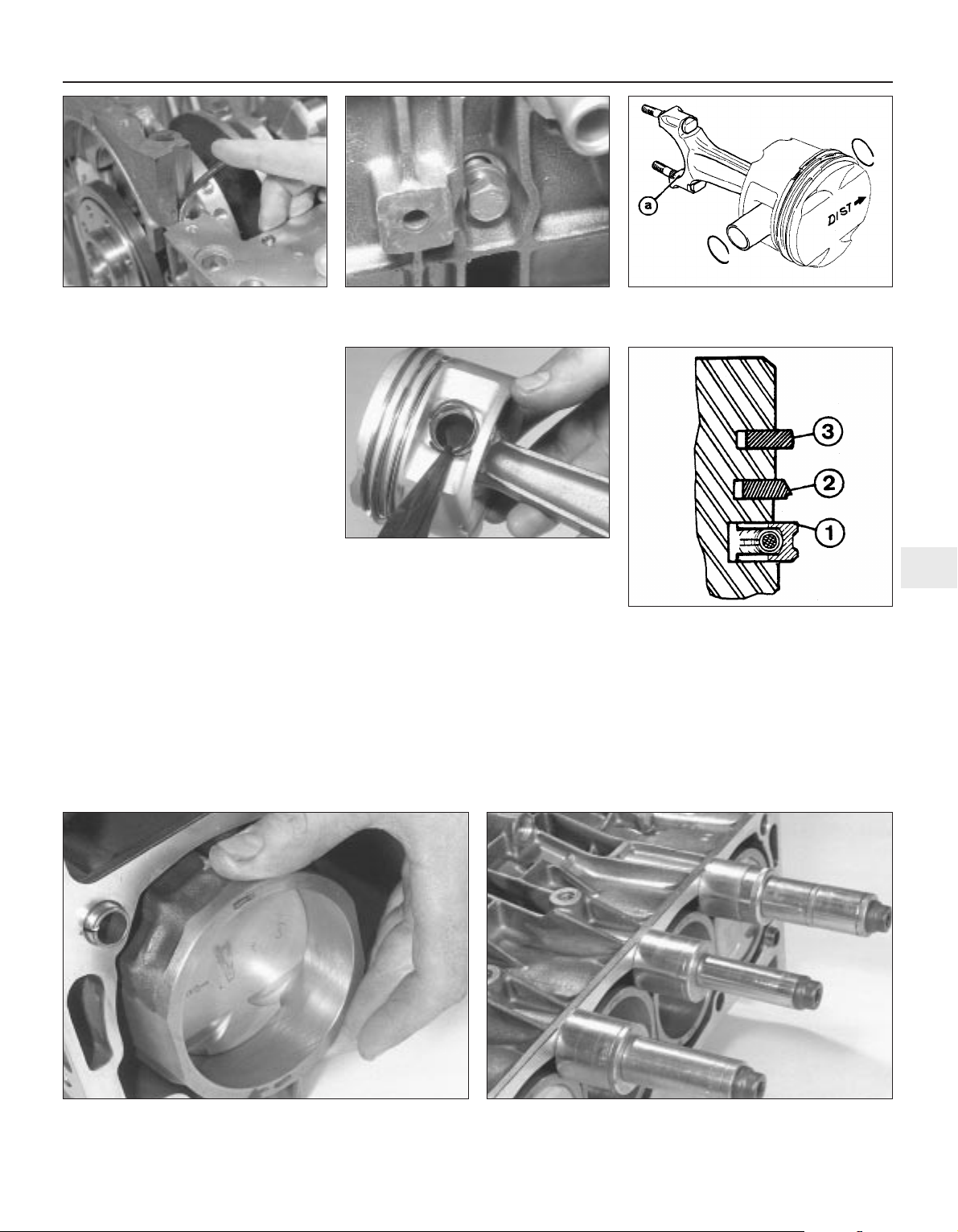

Pistons and liners

10 Support the cylinder block on its flywheel

end.

11 Check that the lower big-end bearing

shells are fitted to the big-end caps and the

upper shells to the connecting rods.

12 Oil the liner bores and piston rings.

13 Position the piston ring end gaps at 120º

from each other, so that none is in line with

another.

14 Fit a piston ring compressor to each

piston in turn and push the pistons in their

respective liners using a hammer handle (see

illustrations). Make sure that the arrows on

the piston crowns face the front (timing belt

end) of the liners.

15 Fit the bottom O-rings to the liners, taking

care not to twist them.

16 Check that the crankshaft rotates freely,

then position Nos 1 and 4 crankpins at bottom

dead centre (BDC). Oil the crankpins.

17 Insert No 1 liner/piston into the block and

guide the connecting rod big-end onto the

crankpin. Refit the big-end bearing cap and

tighten the nuts evenly to the specified torque

(see illustration).

18 Check that the crankshaft rotates freely

while holding the liner in position with a

clamp. Temporarily refit the crankshaft

sprocket bolt to turn the crankshaft.

19 Repeat the procedure to fit the remaining

pistons and liners.

Oil pump

20 Support the block upside-down on the

bench.

21 Check that the oil pump location pin is

fitted to the main bearing casting, then refit

the oil pump, tilting it to engage the drive

sprocket with the chain. Insert and tighten the

bolts.

Sump

22 Apply jointing compound to the mating

faces of the sump and main bearing casting.

Refit the sump, insert the bolts and tighten

them to the specified torque.

Crankshaft rear oil seal

23 Dip the new crankshaft rear oil seal in

clean engine oil and locate it over the rear of

the crankshaft (see illustration).

24 Citroën dealers use a special tool (0132U)

to fit the seal but it can be fitted by using the

flywheel. Temporarily locate the flywheel on

the crankshaft using four bolts, then tighten

the bolts evenly until the flywheel contacts the

rear flange. Remove the flywheel and use a

metal tube or block of wood to drive the oil

seal fully into position.

K1G engine 2C•13

2C

18.14b Using a hammer handle to push a

piston into its liner

18.17 Tightening a big-end bearing cap

nut

18.8 Angle-tightening main bearing cap

bolts

18.14a Fitting a piston ring compressor

18.23 Crankshaft rear oil seal located over

rear of crankshaft

18.7a Apply jointing compound to crankcase mating face . . . 18.7b . . . then lower main bearing cap casting into position

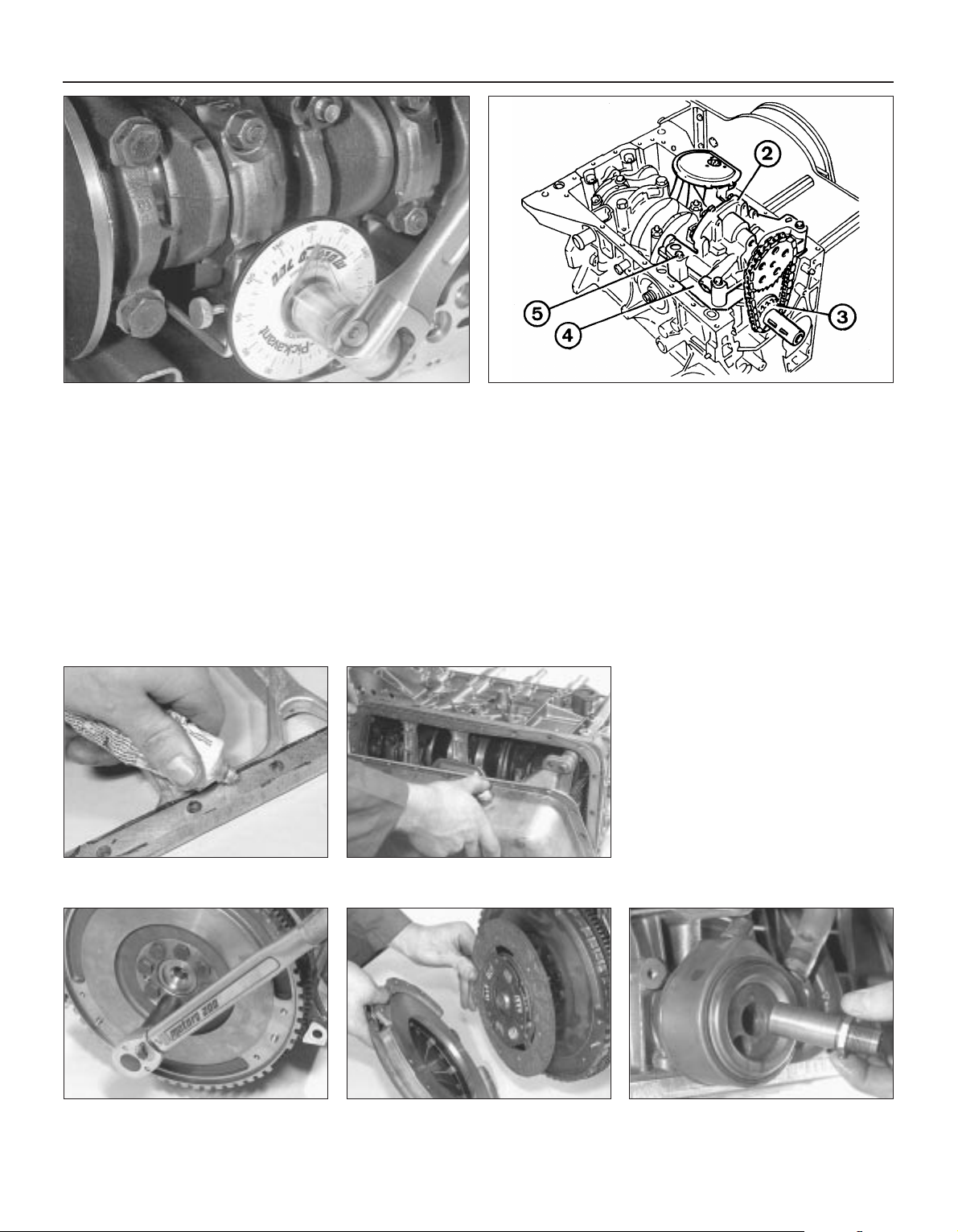

Flywheel

25 Apply locking fluid to the threads of the

flywheel bolts. Locate the flywheel on the

crankshaft dowel then insert the bolts and

tighten them to the specified torque while

holding the flywheel stationary with a

wide-bladed screwdriver inserted between

the starter ring gear teeth (see illustration).

Crankshaft front oil seal

26 Support the engine upright.

27 Dip the crankshaft front oil seal in clean

engine oil, locate it over the front of the

crankshaft and drive it in flush with the front of

the block using a metal tube or socket (see

illustration). There is no seating, so take care

not to drive it in too far.

28 Fit the oil seal flange, followed by the

hub/sprocket. Insert the sprocket bolt and

spacer, and tighten the bolt to the specified

torque while holding the flywheel stationary

(see illustration).

Coolant pump housing

29 Refit the coolant pump housing, together

with a new O-ring, and tighten the bolts to the

specified torque.

Clutch friction disc and pressure

plate

30 Locate the clutch friction disc and

pressure plate on the flywheel with the dowels

engaged. Insert the bolts finger-tight.

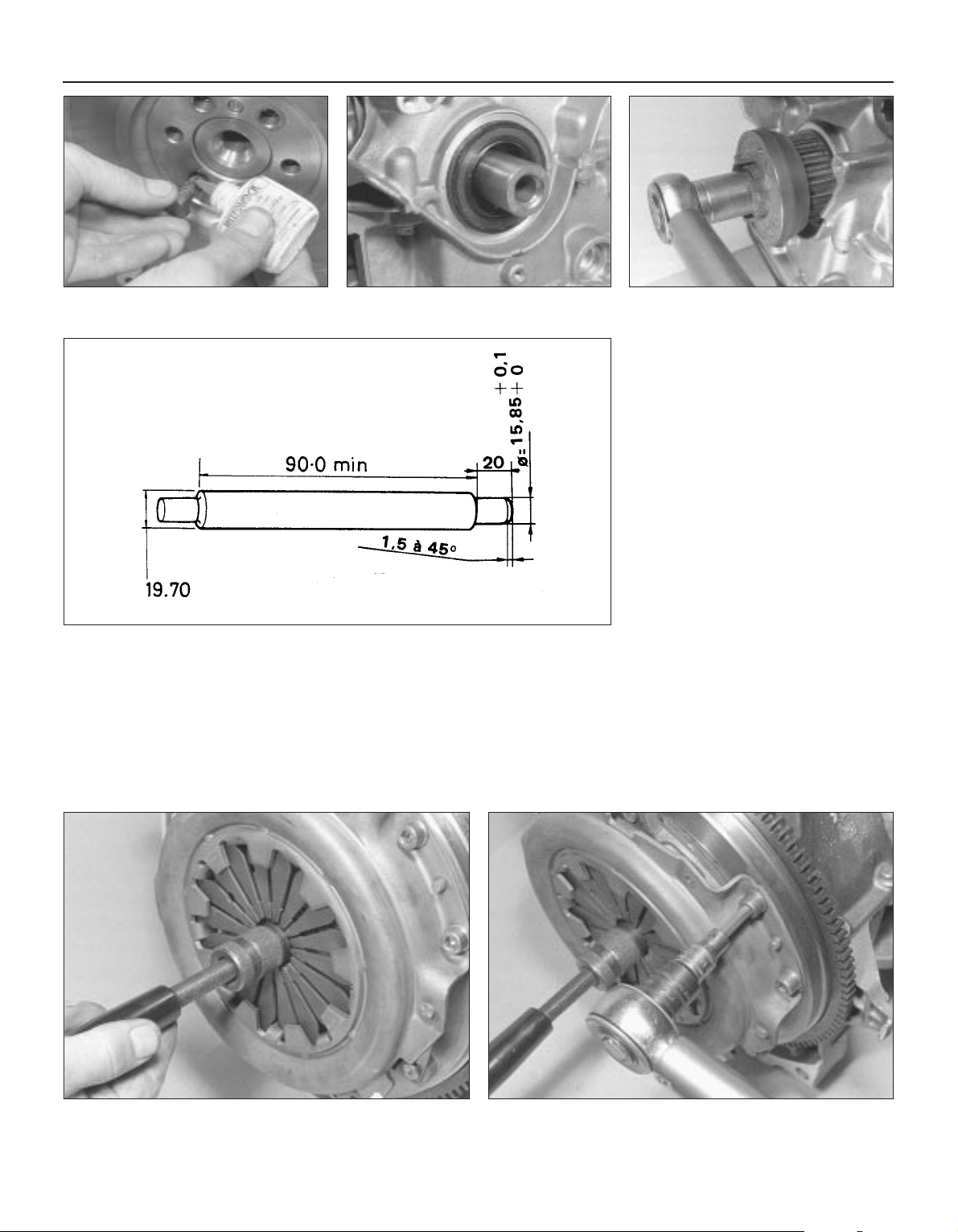

31 Centralise the friction disc using a

universal tool, or by making a wooden adapter

to the dimensions shown (see illustrations).

32 Tighten the pressure plate bolts evenly to

the specified torque (see illustration).

Cylinder head

33 Clean the cylinder head and block joint

faces thoroughly. Also clean the cylinder head

bolt holes.

2C•14 K1G engine

18.25 Applying locking fluid to a flywheel

bolt

18.27 Crankshaft front oil seal located

over front of crankshaft

18.28 Tightening crankshaft sprocket bolt

18.31a Clutch centralising tool dimensions

Dimensions in mm

18.31b Centralising clutch friction disc using a universal tool 18.32 Tightening a clutch pressure plate bolt

34 Locate the new cylinder head gasket on

the block dowels, with the manufacturer’s

name uppermost.

35 Align the TDC holes in the flywheel and

block rear flange, then insert a twist drill or

long bolt.

36 Align the small hole in the camshaft

sprocket with the hole in the cylinder head,

then insert a twist drill or bolt.

37 Lower the cylinder head onto the block so

that it engages the two dowels.

38 Refit the rocker arm assembly.

39 Lubricate the cylinder head bolt threads

and heads with molybdenum disulphide

grease. Insert them and tighten to the initial

torque using the sequence shown (see

illustration 7.40).

40 Using the same sequence, angle-tighten

the bolts through the specified angle.

Timing belt and covers

41 Refit the timing belt tensioner roller, turn it

clockwise and tighten the nut.

42 Engage the timing belt with the crankshaft

sprocket then, keeping it taut, feed it onto the

camshaft sprocket, around the tensioner

pulley, and onto the coolant pump sprocket.

43 Loosen the nut and turn the tensioner

roller anti-clockwise by hand. Tighten the nut.

44 Citroën dealers use the special tool

shown (see illustration 6.12) to tension the

timing belt. A similar tool may be fabricated

using an 8.0 cm long arm and a 1.5 kg (3.3 lb)

weight. The torque applied to the roller will

approximate 12 kgf cm (10.5 lbf in).

Pre-tension the timing belt with the tool and

tighten the nut, then remove the timing pins

and rotate the crankshaft through two

complete turns. Loosen the nut and allow the

roller to re-position itself. Tighten the nut.

45 If the special tool is not available, an

approximate setting may be achieved by

turning the roller hub anti-clockwise, until it is

just possible to turn the timing belt through

90º by finger and thumb midway between the

crankshaft and camshaft sprockets. The

square in the roller hub should then be directly

below the adjustment nut, and the deflection

of the belt in the midway position should be

approximately 6.0 mm. If using this method,

the tension should be re-checked by a Citroën

dealer at the earliest opportunity.

46 Refit the lower, intermediate and upper

timing covers, then tighten the bolts.

Remaining components

47 Adjust the valve clearances.

48 Refit the baffle plate with its edges

pointing downwards, followed by the two

spacers.

49 Fit the rubber gasket to the rocker cover,

locate the cover in position and tighten the

nuts.

50 Apply a little sealant to the end of the

engine oil dipstick holder and insert it in the

main bearing cap casting. Insert and tighten

the mounting bolt.

51 Insert and tighten the oil pressure switch.

52 Smear a little oil on the sealing ring and

tighten the oil filter into position by hand only.

53 Refit the timing plate and tighten the

bolts.

54 Refit the TDC sensor and tighten the bolt.

Fix the lead in the plastic clip on the timing

plate. Note that the main body of the TDC

sensor should be 1.0 mm from the flywheel.

55 Apply jointing compound to the distributor

mounting flange, then refit it to the cylinder

head and tighten the bolts.

56 Apply jointing compound to the

thermostat housing, then refit it to the cylinder

head and tighten the bolts to the specified

torque.

57 Refit the thermostat.

58 Refit the distributor.

59 Refit the exhaust manifold together with

new gaskets. Refit the nuts and washers and

tighten securely.

60 Refit the exhaust manifold hot air shroud

and tighten the bolts.

61 Locate the coil and bracket over the

distributor and tighten the bolts.

62 Position the pulley on the front of the

crankshaft. Insert and tighten the bolts.

63 Refit the alternator and insert the pivot

and adjustment bolts. Slip the drivebelt onto

the pulleys and tighten the tension bolt until

the deflection of the belt midway between the

pulleys is approximately 6.0 mm under firm

thumb pressure. Tighten the pivot and

adjustment bolts.

64 Refit the fuel pump with a new gasket and

tighten the bolts.

65 Thoroughly clean the mating faces of the

inlet manifold and cylinder head and apply

jointing compound.

66 Refit the inlet manifold complete with

carburettor and tighten the nuts.

67 Reconnect the hose between the fuel

pump and carburettor and tighten the clips.

68 Reconnect the vacuum hose between the

distributor and carburettor.

69 Refit and tighten the spark plugs.

70 Refit the HT leads and distributor cap.

19 Engine - reconnection to

transmission

4

Refer to Section 18 in Part A of this Chapter.

20 Engine - initial start-up after

overhaul

3

1 Refer to Section 19 in Part A of this

Chapter.

2 Note that the cylinder head bolts of this

engine do not require re-tightening and the

timing belt does not require re-tensioning.

3 If new bearings and/or pistons have been

fitted, treat the engine as new, and run it in at

reduced speeds. Also change the engine oil at

1000 miles (1500 km).

K1G engine 2C•15

2C

2D

Chapter 2 Part D:

D6C engine

Specifications are as for the type 159 engine (see Chapter 2B) except for the following:

General

Model application:

BX 19 GTi 16 valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D6C (XU9J4)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4:1

Maximum power DIN (BHP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 at 6500 rpm

Maximum torque DIN (lbf ft) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133 at 5000 rpm

Valves

Head diameter:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.7 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.7 mm

Cam followers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic (valve clearance adjustment not required)

Valve timing

Valve lift 9.2 mm

Inlet opens* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1º 35’ BTDC

Inlet closes* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45º 50’ ABDC

Exhaust opens* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47º 0’ BBDC

Exhaust closes* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0º 30’ ATDC

*With valve clearance of 1.0 mm

Crankshaft

Endfloat thrustwasher thicknesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33 to 2.53 mm (in increments of 0.05 mm)

Crank journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59.7 to 60.0 mm

Crankpin diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49.7 to 50.0 mm

Lubrication system

Oil pressure:

At 850 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 bar

At 3000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8 bar

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion F104

Oil capacity (with filter change) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3 litres (9.3 pints)

Dipstick minimum to maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 litres (2.6 pints)

Cylinder head - removal, overhaul and refitting . . . . . . . . . . . . . . . . . 6

Cylinder liners - checking protrusion . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine - complete dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Engine - complete reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine dismantling - ancillary items . . . . . . . . . . . . . . . . . . . . . . . . . 9

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . . 8

Engine - examination and renovation . . . . . . . . . . . . . . . . . . . . . . . . 12

Engine - initial start-up after overhaul . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine - preparation for reassembly . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . . 13

Engine - reconnection to transmission . . . . . . . . . . . . . . . . . . . . . . . 17

Engine - separation from transmission . . . . . . . . . . . . . . . . . . . . . . . 10

Engine/transmission - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Engine/transmission - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Major operations possible with engine in vehicle . . . . . . . . . . . . . . . 3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . 4

Oil filter - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Timing belt - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2D•1

Specifications

Contents

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

5

4

3

2

1

Torque wrench settings Nm lbf ft

Camshaft bearing cap Allen screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Main bearing cap bolts and nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 37

Centre main bearing cap side bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Sump pan bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Big-end bearing cap nuts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 30

Stage 2: slacken, then tighten to . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Stage 3: then immediately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten a further 70º

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 37

Clutch cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Crankshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 82

Coolant pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11

Camshaft sprocket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Timing belt tensioner locking screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Engine mounting bracket at timing cover end:

Larger bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 53

Smaller bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Crankshaft damper bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Camshaft rear pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Inlet manifold bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Exhaust manifold bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 43

Stage 2: slacken, and then tighten each bolt in turn to . . . . . . . . . . . 20 15

Stage 3: then immediately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten a further 300º

1 General information and

precautions

General information

The D6C engine is fitted to all BX 19 GTi 16

valve models and is a development of the D6A

engine, which itself is based upon the 159A

engine dealt with in Chapter 2B.

Introduced in July 1987, the essential

difference is the 16 valve double overhead

camshaft cylinder head, the camshafts being

driven by a toothed belt tensioned by two idler

rollers.

The need for valve clearance adjustment is

eliminated by the incorporation of Hydraulic

tappets (cam followers).

The pistons have been re-designed, with

valve head recesses machined in the piston

crown and the gudgeon pins are now of the

“floating” type, secured by circlips in the

piston. The undersides of the pistons are

cooled by oil jets located in lubrication pipes

within the crankcase.

The crankshaft has lighter balancing

counterweights with a damper fitted to the

sprocket end.

Pressurised oil is supplied by an oil pump

located within the sump pan, the pump being

driven by chain from the crankshaft.

Due to an oil cooler being fitted, oil capacity

has increased. The oil filter is of disposable

screw-on canister type, mounted on the oil

cooler housing. The oil filler pipe is an

independent assembly, remote from the engine,

in order to provide a reasonable position for

pouring oil into the steeply-canted engine.

Precautions

Because of the unusual layout of the engine

and transmission systems, extra care and

attention are necessary during maintenance

and overhaul procedures which, in many

instances, differ from more conventional

systems.

Read through the various Sections

concerned before tackling any job, and

analyse the instructions, so that any snags or

possible difficulties can be noted in advance.

Because the sub-assembly castings are made

from aluminium alloy it is of utmost

importance that, where specified, all

fastenings are tightened to the correct torque

and, in some instances, in the correct

sequence.

2 Oil filter - removal and refitting

2

Refer to Chapter 1, Section 9.

3 Major operations possible

with engine in vehicle

The following items can be removed and

refitted with the engine in the vehicle:

a) Timing belt and camshafts.

b) Cylinder head.

c) Sump pan

d) Oil pump.

e) Engine mountings.

4 Major operations requiring

engine removal

The engine must be removed for the

following operation:

a) Removal of the crankshaft and main

bearings

5 Timing belt - removal and

refitting

3

Note: If there is the slightest doubt about the

condition of the timing belt then it must be

renewed.

Note: The following operation was carried out

with the engine in the vehicle.

Note: Accurate adjustment of the timing belt

entails the use of Citroën special tools. An

approximate setting can be achieved using

the method described in this Section but is

essential that the tension is checked by a

dealer on completion.

Removal

1 Disconnect the battery.

2 Remove the front right-hand roadwheel,

then unclip and remove the wheel arch

blanking panel to provide access to the timing

cover, the crankshaft sprocket and damper

(see illustration).

3 Loosen the alternator mounting bolts and

the belt adjuster link, then remove the

alternator drivebelt.

2D•2 D6C engine

4 Pull out the keyhole slot-type spring clips

from the front face of the timing belt cover

(see illustration).

5 Extract the screws and remove the timing

belt cover.

6 Using the centre bolt in the crankshaft

damper, turn the crankshaft until the slot in

the crankshaft sprocket is aligned with the

one on the oil pump cover, and the pin holes

in the camshaft sprockets are aligned with the

holes in the cylinder head.

7 Unscrew the bolts and take off the damper

from the front end of the crankshaft.

8 Remove the timing belt lower cover.

9 Using an Allen key, release the belt

tensioner locking screws.

10 Remove the timing belt.

Refitting

Caution: Take care not to kink or

contaminate the timing belt with oil

11 Setting tools will be required when fitting

the new belt. In the absence of Citroën special

tools (01 53M and 01 53G), make up two

stepped pins as shown (see illustration).

Obtain a short length of rod which will be a

snug fit in the cut-outs of the crankshaft

sprocket and the oil pump cover.

12 Insert the camshaft sprocket stepped pins

and the crankshaft rod (see illustrations).

13 Fit the new timing belt in a clockwise

direction, following the numerical sequence

shown (see illustration). Adjust the

tensioning pulleys on both sides to make the

belt taut. Check that the longest run of the

belt can be twisted through 45º when gripped

between the finger and thumb. Tighten the

tensioner screws to the specified torque. Note

that in this application, the tensioners serve

two purposes, both to tension the belt and to

provide fine adjustment of the valve timing.

14 Remove the two stepped pins and the

rod.

15 Turn the crankshaft through two complete

revolutions. Fit the crankshaft sprocket

locking rod.

16 The two stepped pins should now slide

smoothly through the holes of the camshaft

sprockets into the holes in the cylinder head.

Even the slightest misalignment will require

re-adjustment of the tensioner pulleys to

provide perfect alignment.

17 Remove the pins and rod, and recheck

after turning the crankshaft through two more

complete revolutions. It is strongly

recommended that the belt tension should be

checked by your Citroën dealer using the

special tensioner device (Seemtronic 87).

18 Fit the timing belt lower cover, the

crankshaft damper and the belt main cover

(see illustrations).

19 Refit and reconnect all the other

components in reverse order of removal,

referring to the Specifications for the

appropriate torque wrench settings.

6 Cylinder head - removal,

overhaul and refitting

4

Note: The following operation was carried out

with the engine in the vehicle.

Removal

1 Drain the engine cooling system and

disconnect the battery.

D6C engine 2D•3

2D

5.2 Removing front right-hand wheel arch

blanking panel

5.4 Removing a timing belt cover spring

clip

5.11 Stepped pin fabrication

a 8.43 mm b 6.38 mm

5.12a Camshaft sprocket locking pins in

position

5.12b Crankshaft sprocket locking rod in

position

5.13 Fit timing belt in clockwise direction,

starting at No 1

5.18a Timing belt lower cover refitted 5.18b Fitting a crankshaft damper bolt

2 Release the screws and remove the cover

plate from the centre of the camshaft cover

(see illustration).

3 Disconnect the spark plug leads from the

spark plugs and disconnect the coolant

temperature sender lead.

4 Extract the screws and remove the

distributor cap, complete with leads.

5 Disconnect the fuel hose from the fuel rail.

6 Disconnect the fuel injector wiring plugs

and then unbolt the fuel rail and remove

complete with injectors.

7 Disconnect the coolant hoses from their

cylinder head connections.

8 Extract the screws and take off the

camshaft cover and the timing belt cover (see

illustrations).

9 Using the centre bolt in the crankshaft

damper, turn the crankshaft until the slot in

the crankshaft is aligned with the one on the

oil pump cover and the pin holes in the

camshaft sprockets are aligned with the holes

in the cylinder head. Use two stepped pins to

lock the sprockets in this position as shown in

illustration 5.12a.

10 Release the tension of the timing belt by

slackening the Allen screws in the two

tensioner rollers. Mark the direction of rotation

on the belt then slip the belt from the

camshaft sprockets.

11 Pull the lubrication pipes from the

camshaft bearing caps. The camshafts can be

removed independently of the cylinder head if

required, or the complete cylinder head can

be removed and then dismantled.

12 Assuming that the cylinder head is to be

removed complete, release and remove the

high pressure pump drivebelt from the end of

the exhaust valve camshaft.

13 Note that the camshaft bearing caps are

numbered 1 to 5 from the flywheel end of the

engine and are doweled so that they can only

be fitted one way.

14 Progressively unscrew the Allen screws in

the reverse order to that shown for tightening.

Remove the camshaft bearing caps in the

following order - No 4 first, then Nos 2, 3, 1

and 5.

15 Lift out the camshafts, labelling them

“Exhaust” and “Inlet”.

16 Disconnect the air inlet duct from the air

cleaner and the hoses, control cables and

leads from the inlet manifold and throttle

housing.

17 Unscrew the inlet manifold nuts and lift

the manifold from the cylinder head.

18 Unscrew the exhaust manifold nuts and

pull it away from the cylinder head. The lower

nuts are more accessible from underneath.

19 Using a TX55 Torx bit, unscrew and

remove the cylinder head bolts in the reverse

order to that shown for tightening.

20 Remove the cylinder head. If it is stuck,

rock it using pieces of wood inserted in the

inlet ports. Discard the cylinder head gasket.

21 As soon as the head is removed, fit liner

clamps to prevent the liner base seals being

disturbed.

Overhaul

22 Remove the hydraulic tappets (cam

followers), keeping them in order of

installation.

23 Removal of the valves and decarbonising

are as described in Section 13 in Part A of this

Chapter but the valves must be identified as

to original location (see illustrations).

24 When refitting a valve, some difficulty may

be experienced in inserting the split collets.

Use of a pencil magnet or a dab of thick

grease will help.

25 The valve stem oil seals can be removed

with a pair of long-nosed pliers. Fit the new

ones using a piece of tubing of suitable bore.

Refitting

26 Ensure that all components are clean and

new gaskets are to hand. Remember that as

refitting proceeds, all nuts and bolts must be

tightened to the torque wrench settings given

in the Specifications. Remove the liner clamps.

27 Smear the hydraulic tappets (cam

followers) with grease, then refit them in their

original locations.

28 Place a new cylinder head gasket on the

top of the cylinder block (see illustration).

29 Lower the cylinder head onto the

positioning dowels.

30 Lightly oil the cylinder head bolts, then

insert and tighten them in the order shown to

the torque wrench settings given in

Specifications (see illustrations).

31 Locate the camshafts with new oil seals.

Assuming that the crankshaft has not been

moved from its position aligned with the oil

pump housing, the camshafts should be set

with the keyways at the 3 o’clock position. This

is so that when the camshaft sprockets are

fitted, the pin holes will be in alignment with the

corresponding holes in the cylinder head.

2D•4 D6C engine

6.2 Removing camshaft centre cover plate 6.8a Extracting a camshaft cover screw 6.8b Extracting a timing belt cover screw

6.23a View of combustion chamber showing

inlet valves (1) and exhaust valves (2)

6.23b Valve components 6.28 Fitting a new cylinder head gasket

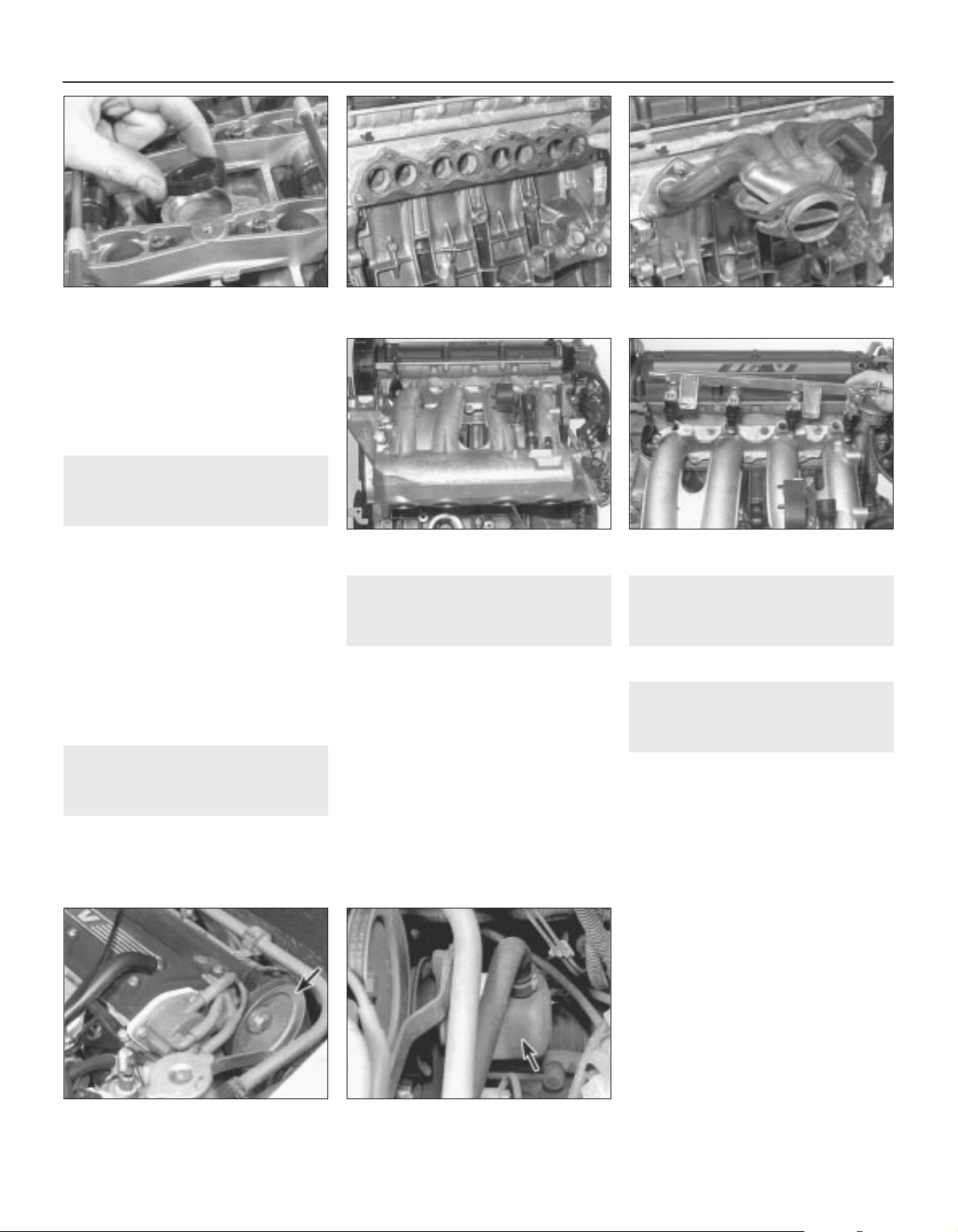

32 Fit the camshaft bearing caps and tighten

the bolts to the specified torque in the

sequence shown (see illustrations).

33 Fit the camshaft lubrication pipes (see

illustration).

34 Fit the timing belt rear cover and the

camshaft sprockets, ensuring that the

alignment is correct by using the stepped pins

described earlier. Use an open-ended

spanner on the flats of the camshaft to hold it

whilst tightening the sprocket bolt to the

specified torque (see illustrations).

35 Refit the timing belt.

36 Fit the timing belt cover. Check that the

spark plug hole oil seals are in position (see

illustration) and then fit the cam cover.

37 Fit the distributor cap and connect the

spark plug leads.

38 Using new gaskets, reconnect the inlet

and exhaust manifolds to the cylinder head

(see illustrations).

39 Reconnect and tension the drivebelts,

then connect the air cleaner inlet.

D6C engine 2D•5

2D

6.33 Camshaft lubrication pipe - note seal

on spigot

6.34a Timing belt rear cover correctly

refitted

6.34b Fitting a camshaft sprocket bolt

6.30a Angle-tightening a cylinder head bolt 6.30b Cylinder head bolt tightening sequence

6.32a Fitting a camshaft bearing cap 6.32b Camshaft bearing cap bolt tightening sequence

40 Reconnect the electrical leads to the

cylinder head switches and then reconnect

the coolant hoses and control cables.

41 Reconnect the fuel hoses, fuel rail and

injectors (see illustration).

42 Reconnect the battery.

43 Refill the cooling system.

7 Engine/transmission -

removal

4

1 This operation is essentially as described in

Part B of this Chapter. The connections for

the Motronic engine management system

must be taken into account and any

references to a carburettor ignored.

2 The pressure regulator for the hydraulic

system (located on the forward-facing side of

the crankcase) must be withdrawn and tied

aside.

3 The hydraulic pump (driven by the exhaust

camshaft pulley) must be removed from its

drivebelt and mounting and tied to one side

(see illustrations).

8 Engine dismantling - general

information

Refer to Section 8 in Part A of this Chapter.

9 Engine dismantling - ancillary

items

The extent of engine ancillary items to be

removed is dependent on the extent to which

the engine is to be dismantled and repaired.

Refer to Section 9 in Part A of this Chapter

and remove those items listed which are

applicable, ignoring references to the coolant

pump and, if the cylinder head is to be

removed, the exhaust manifold. These two

items are best removed later during the

engine dismantling procedures.

Note that the clutch unit is removed after

the engine and gearbox are separated.

10 Engine - separation from

transmission

4

Refer to Section 12 in Part B of this Chapter.

11 Engine - complete dismantling

4

Note: As dismantling of the engine requires

the timing belt to be removed, it is advisable

to read the procedure for timing belt removal

and refitting before starting work.

1 Support the engine on a clean bench or

strong table.

2 Clean away all external dirt using

water-soluble solvent or paraffin and a stiff

brush.

3 Unbolt the ignition coil from the inlet

manifold.

4 Withdraw the engine oil dipstick.

5 Remove the oil filler pipe assembly.

6 Unplug the fuel injectors, release the fuel

rail (two screws) and withdraw the rail/injector

assembly.

7 Remove the cover plate from the centre of

the cam cover then remove the cam cover

itself. Disconnect and withdraw the spark plug

HT leads.

8 Unscrew and remove the spark plugs.

9 Disconnect the hoses and remove the

coolant distribution pipe.

2D•6 D6C engine

6.36 Spark plug hole oil seal 6.38a Exhaust manifold gasket correctly

located

6.38b Exhaust manifold fitted

6.38c Inlet manifold fitted 6.41 Fitting fuel rail and injectors

7.3b Hydraulic pump (arrowed)7.3a Hydraulic pump drive pulley

(arrowed)

10 Unbolt and remove the inlet manifold

complete with throttle housing. Discard the

gasket.

11 Unbolt and remove the thermostat

housing.

12 Unbolt the exhaust manifold and discard

its gasket.

13 Unbolt and remove the coolant

multi-union from the exhaust side of the

crankcase.

14 Unbolt and remove the mounting bracket

from the front of the cylinder block.

15 Remove the distributor and drive flange.

16 Remove the pulley and plastic guard from

the rear end of the exhaust camshaft. The

camshaft may be held against rotation using

the spanner flats on the camshaft.

17 Unscrew and remove the oil pressure,

temperature and level switches.

18 Remove the oil filter.

19 If necessary, remove the oil cooler by

disconnecting the hoses and then unscrewing

the large fixing nut.

20 Extract the Allen screws, slide the timing

belt cover upwards and remove it.

21 Remove the timing belt.

22 Hold the flats on the camshafts with an

open-ended spanner, unscrew the bolts

which secure the camshaft sprockets, then

remove the sprockets.

23 Unbolt and remove the crankshaft

sprocket. Take out the Woodruff key (see

illustrations).

24 Remove the timing belt guide plate from

the crankshaft.

25 Remove the timing belt upper cover

backplate.

26 Remove the coolant pump.

27 Pull off the camshaft lubrication pipes.

28 Remove the cylinder head.

29 Unbolt and remove the clutch assembly.