Citronix ci5200, ci5300, ci5500, ci5650 Technical & Service Manual

ci5000 Series Printer Technical Service Manual

Citronix ci5000 Series Printer

Technical Service Manual

Part Number:

ci5200

ci5300

ci5500

ci5650

Revision 0.1

012-1002-007

Version 0.1 1

ci5000 Series Printer Technical Service Manual

THIS PAGE INTENTIONALLY LEFT BLANK.

Version 0.1 2

ci5000 Series Printer Technical Service Manual

Preface

The Citronix team welcomes you to the ci5000 Series Continuous Inkjet Printer range. We are proud of

this product range and the features it has to offer and are confident that this product will exceed the high

expectations that you, our customers, have placed with us.

We have prepared this manual to provide comprehensive technical information on the ci5000s printers. It

contains important information on how to:

- Operate the equipment safely.

- Care for and maintain the printer.

- Use the day to day functionality of the printer.

- Calibration & troubleshooting.

All rights reserved. No part of this publication may be reproduced, stored on a retrieval system, or

transmitted in any form, or by any means, electronic, mechanical, photocopying, recording or otherwise,

without the prior permission of Citronix Inc.

To the best of our knowledge, the information contained in this guide was correct at the time of printing.

Continual enhancement of our products may result in some differences between instructions represented

in this guide and your ci5000 Series Printer.

Citronix and Codes of Excellence are trademarks of Citronix Inc.

This guide was written by:

Citronix Inc.

2241 S. Watson Road, Suite 111

Arlington, Texas 76010

United States of America

www.citronix.com

info@citronix.com

© Copyright Citronix Inc. 2003 – 2016

Version 0.1 3

EN55022:2011

Information Technology Equipment – Radio Disturbance Characteristics

– Limits and Methods of Measurement.

EN55024:2010 A1:2015

Information Technology Equipment – Immunity Characteristics – Limits

and Methods of Measurement.

IEC60950-1:2005(2nd ed)/

A1:2009/A2:2013

Information Technology Equipment - Safety - Part 1: General

Requirements.

2014/35/EU

Low Voltage Directive

2014/30/EU

EMC Directive

ci5000 Series Printer Technical Service Manual

DECLARATION of CONFORMITY

Issuer’s name: Citronix Inc.

Issuer’s Address: 2241 S. Watson Road, Suite 111, Arlington, Texas 76010, United States of America

Tel: +1-817-633-3200 Fax: +1-817-633-3207 Email: info@citronix.com

Declare under sole responsibility that the products identified herein, have been designed, manufactured

and tested in accordance with the following documents:

CE-Marked accordingly certification date May 20, 2016

Each product marketed, is identical to the representative unit tested and found to meet the standards.

Trade Name: Citronix

Type of Product: Continuous Ink Jet Printer

Model: ci5200, ci5300, ci5500, ci5650

Signed for and on behalf of

Citronix Inc.

2241 S. Watson Road, Suite 111

Arlington, Texas 76010

*Original signed and available from local distributor*

____________________

Michael Embree

Engineering Director

Signature Dated May 20, 2016

FCC Notice

Version 0.1 4

ci5000 Series Printer Technical Service Manual

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at own expense.

Any changes or modifications not expressly approved by the manufacturer could void the user's authority

to operate the equipment.

FCC/Industry Canada Statement

This device complies with FCC Part 15 and Industry Canada license exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may cause undesired operation of the device.

This device complies with Health Canada’s Safety Code. The installer of this device should ensure that

RF radiation is not emitted in excess of the Health Canada’s requirement.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

French Version:

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts

de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire

de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement

Cet appareil est conforme avec Santé Canada Code de sécurité 6. Le programme d’installation de cet

appareil doit s’assurer que les rayonnements RF n’est pas émis au-delà de I’exigence de Santé Canada.

Les changements ou modifications non expressément approuvés par la partie responsable de la

conformité pourraient annuler l'autorité de l'utilisateur à utiliser cet équipement.

European EMC Statement

This product may cause interference if used in residential areas. Such use must be avoided unless the

user takes special measures to reduce electromagnetic emissions to prevent interference to the

reception of radio and television broadcasts.

Version 0.1 5

ci5000 Series Printer Technical Service Manual

CONTENT

GENERAL INFORMATION SECTION 1:

GRAPHICAL USER INTERFACE SECTION 2:

PRINTER OPERATION SECTION 3:

INSTALLATION AND COMMISSIONING SECTION 4:

STATUS BAR/TROUBLESHOOTING SECTION 5:

CLEANING AND MAINTENANCE SECTION 6:

COMMUNICATIONS SECTION 7:

SPARES & ACCESSORIES SECTION 8:

CALIBRATION SECTION 9:

ci5650 AIR SYSTEM SECTION 10:

REFERENCE SECTION 11:

Version 0.1 6

ci5000 Series Printer Technical Service Manual

GENERAL INFORMATION SECTION 1:

CONTENTS

Introduction ............................................................................................................................ 1-3

Before You Begin ........................................................................................................................... 1-3

Safety Information ................................................................................................................. 1-3

Specific Warnings .......................................................................................................................... 1-4

Health and Safety .................................................................................................................. 1-4

Introduction .................................................................................................................................... 1-4

Basic Requirements ....................................................................................................................... 1-4

Page

Storage .......................................................................................................................................... 1-5

Fire Risk ........................................................................................................................................ 1-5

Printer Overview .................................................................................................................... 1-5

Controller Cabinet ................................................................................................................. 1-7

Hardware Specification: ................................................................................................................. 1-8

Interfaces: ...................................................................................................................................... 1-8

Inputs (opto-isolated, open collector or TTL type): ......................................................................... 1-8

Outputs: ......................................................................................................................................... 1-9

User Interface and Firmware Capabilities: ..................................................................................... 1-9

Operating Environment: ................................................................................................................. 1-9

Electrical Requirements: ................................................................................................................ 1-9

Controller and Printhead Physical Characteristics: ......................................................................... 1-9

Printhead and Umbilical....................................................................................................... 1-11

Printhead: .................................................................................................................................... 1-11

Umbilical: ..................................................................................................................................... 1-11

Printhead Dimension Drawings: ................................................................................................... 1-11

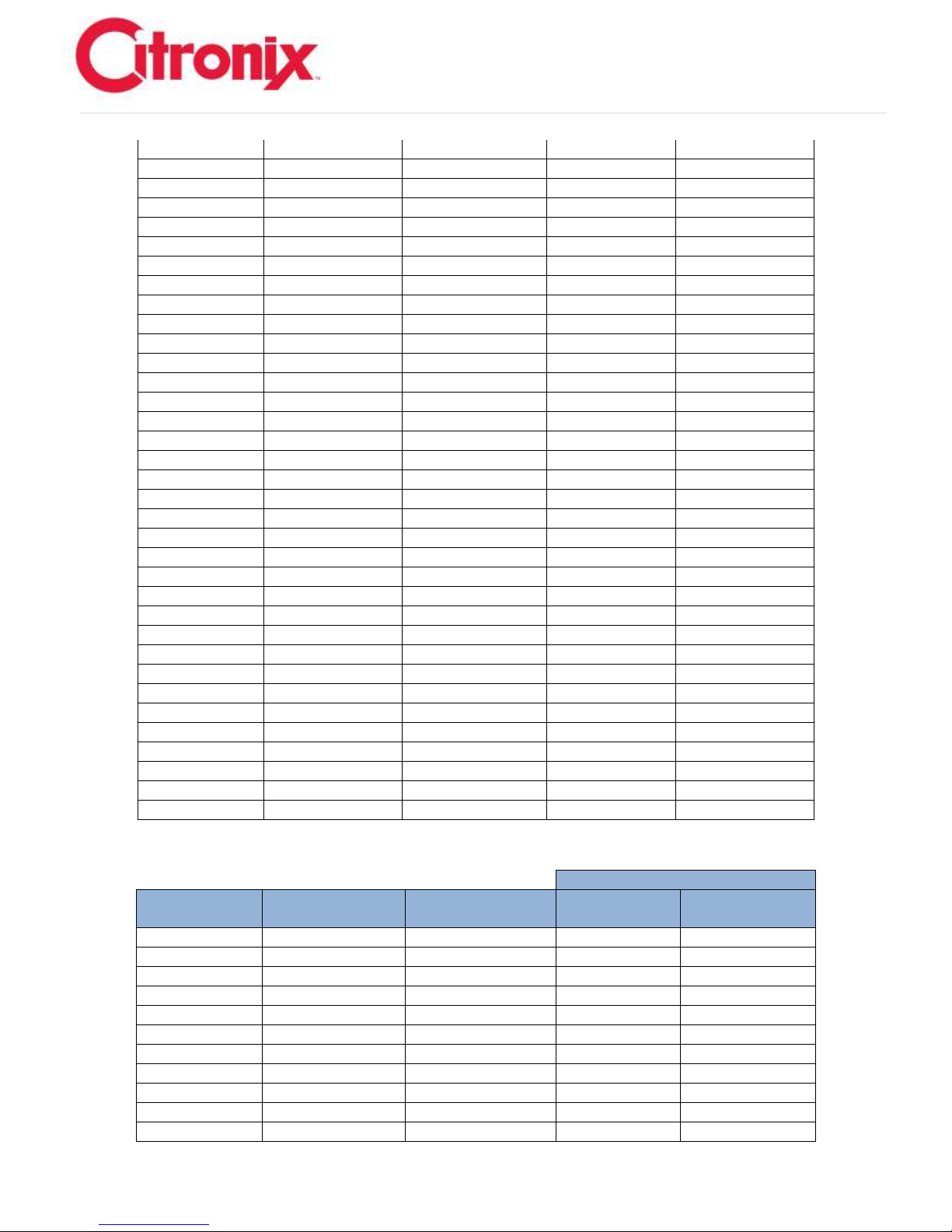

Print Speeds and Print Quality Charts ................................................................................. 1-13

Print Speed Chart - Drop Size: Normal/Internal Encoder.............................................................. 1-14

Print Speed Chart - Drop Size: Normal/External Encoder ............................................................ 1-14

Print Speed Chart - Drop Size: Macro/Internal Encoder ............................................................... 1-15

Version 0.1 1-1

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Macro/External Encoder .............................................................. 1-16

Print Speed Chart - Drop Size: Micro/Internal Encoder ................................................................ 1-17

Print Speed Chart - Drop Size: Micro/External Encoder ............................................................... 1-18

Print Speed Chart - Drop Size: HS50/Internal Encoder ................................................................ 1-19

Print Speed Chart - Drop Size: HS50/External Encoder ............................................................... 1-20

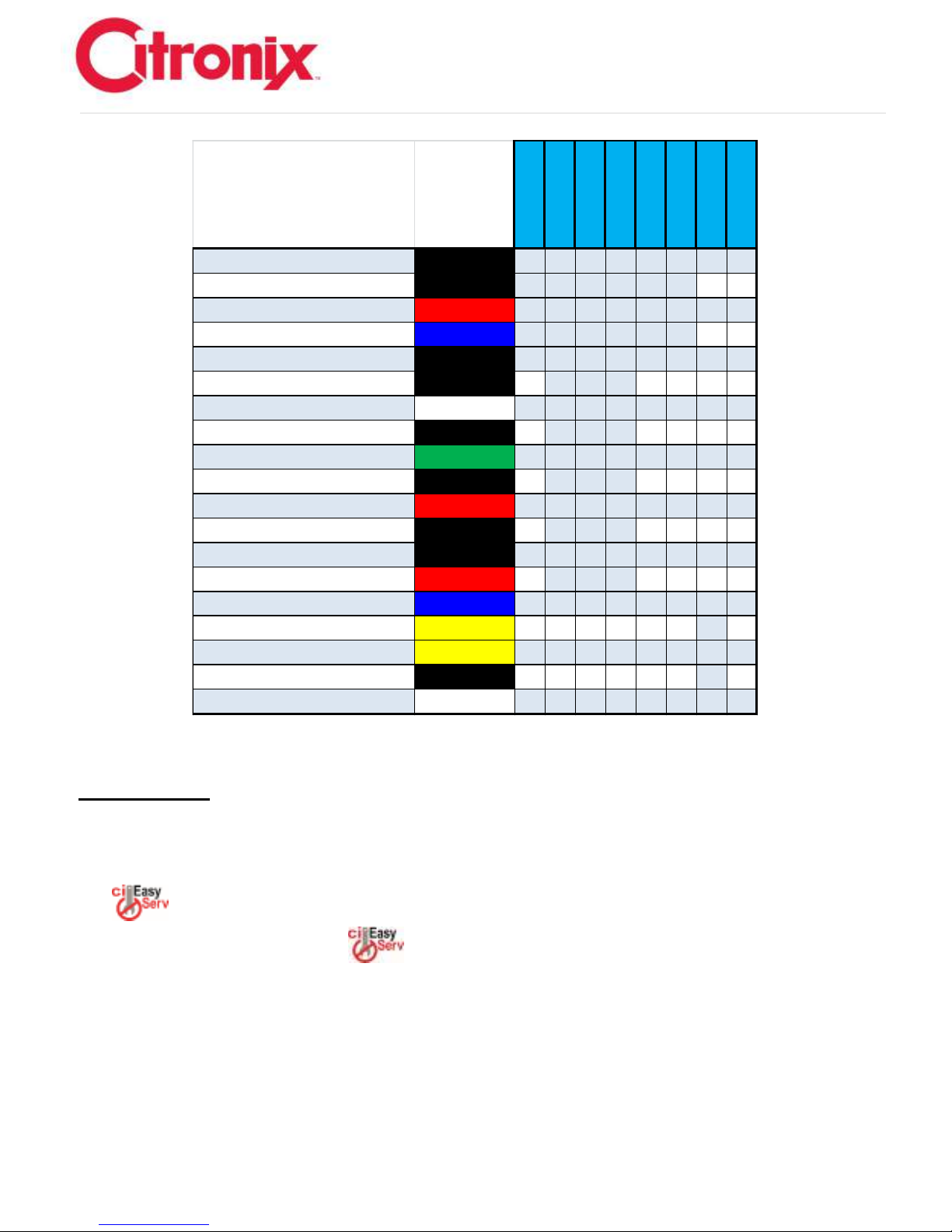

Consumables and Delivery .................................................................................................. 1-21

Ink System ........................................................................................................................... 1-22

Ink and Makeup Tanks ................................................................................................................. 1-24

Ink Pump ..................................................................................................................................... 1-24

Ink System Valves & Manifold ...................................................................................................... 1-24

Pressure Transducer ................................................................................................................... 1-26

Viscometer ................................................................................................................................... 1-26

The ciEasyServ Filter Module ...................................................................................................... 1-26

Ink System Diagram ..................................................................................................................... 1-28

Print Head ........................................................................................................................... 1-29

Drop Generator ............................................................................................................................ 1-30

Nozzle .......................................................................................................................................... 1-30

Charge Electrode and Strobe ....................................................................................................... 1-30

Phase Detector ............................................................................................................................ 1-30

Deflector Plates ........................................................................................................................... 1-30

Gutter........................................................................................................................................... 1-30

Printhead Valve ........................................................................................................................... 1-30

Phase Circuit Board ..................................................................................................................... 1-31

Printhead Cover Sensor ............................................................................................................... 1-31

Printhead Temperature Sensor .................................................................................................... 1-31

Version 0.1 1-2

ci5000 Series Printer Technical Service Manual

Introduction

The Citronix ci5000 Series Continuous Ink Jet Printer applies identifying marks such as “best before”

dates, traceability codes, logos and batch codes onto almost any kind of material or surface. The printers

comprise of hardware, software, and printing fluids that work seamlessly together to provide reliable, high

quality, product coding.

This guide applies to all ci5000 Series Printers, namely ci5200, ci5300, ci5500 and ci5650 as well as

specialty Printers (micro, HS50, Pigment and Heavy Pigment). Any differences between product variants

are identified or highlighted.

It is intended for use by Maintenance and Distributor Service Department technicians and contains

important information on how to:

- Operate the equipment safely.

- Care for and maintain the printer.

- Use the day to day functionality of the printer.

- Calibration & troubleshooting

- Component replacements

Before You Begin

Before printing, make sure:

1. All warnings and notes have been read and understood.

2. The ci5000 Series Printer is correctly installed and integrated with your production line.

3. At least one message has been created, programmed and saved (refer to Section 3 Printer

Operation) or select the default message.

Safety Information

The following symbols are used in this manual. Where they appear next to a procedure or instruction,

they have the significance and importance of written warnings and cautions. WARNINGS, CAUTIONS

and NOTES are provided to avoid hazards and to safely operate the Printer.

A WARNING symbol identifies an operating procedure that if not strictly followed could

result in injury or death. Warnings will be identified by a general warning symbol or a

specific warning symbol.

A CAUTION symbol identifies an operating procedure that if not strictly followed could

result in equipment damage.

Version 0.1 1-3

ci5000 Series Printer Technical Service Manual

Specific Warnings

The following Warnings should be read and understood by all personnel involved in the operation and

maintenance.

PERSONAL INJURY: The Printer uses extremely high voltages. Only trained and

authorized personnel are allowed to perform maintenance work.

PERSONAL INJURY: Use safety goggles or a face mask when using Ink, Make-up or

Cleaning Solvents to prevent fluids from entering the eyes.

FIRE HAZARD: The Ink, Make-up and Cleaning Solvents are flammable; do not smoke or

use a flame in the vicinity of the Printer, servicing area or chemical storage.

PERSONAL INJURY: Wear protective gloves and clothing when handling Ink, Makeup or

Cleaning Solvent.

Health and Safety

Introduction

Citronix supplies Safety Data Sheets (SDS) giving specific safety information with each of its ink, makeup and wash fluids. There are also warnings on each container. The following notes are for general

guidance only.

Basic Requirements

When used correctly, printing inks do not cause problems. However, everybody using them should be

familiar with the appropriate safety standards and be aware of the precautions that should be taken. The

following are basic requirements:

Proper standards of industrial practice relating to cleanliness and tidiness must be maintained.

Inks and their containers must be stored and handled with care.

Smoking or the use of open flames (or other sources of ignition) in the vicinity of any inks or

solvents is highly dangerous and therefore strictly inadvisable.

All who come into contact with inks must be properly instructed in their use.

Directions for safe working practices vary according to the environment. The following are broad

principles so that necessary precautions may be taken:

Contact with the mouth must be avoided. Therefore, eating, drinking or smoking, or any personal

habits or actions which may transfer ink to the mouth, must be avoided.

Contact with the eyes must be avoided. Suitable eye protection must always be worn whenever

there is any risk of splashing or misting. If ink does get into the eyes, first aid treatment is to flood

the affected eye for 15 minutes with saline solution, (or clean water if saline solution is not

Version 0.1 1-4

ci5000 Series Printer Technical Service Manual

available), taking care not to allow the water to run into an unaffected eye. Medical aid must be

obtained immediately.

After exposure to ink, all possible traces must be washed off as soon as possible at the nearest

washing facility.

Most inks contain solvents which may injure the skin. Good working practice must always be

employed and risk assessments carried out. Safety Data Sheets are available that give advice on

personal protective equipment. Most gloves only offer limited and short term exposure protection

and must be changed after any splashing and on a frequent basis.

Many inks contain materials which vaporize easily and can be inhaled. Good ventilation is

necessary.

Any used cleaning materials, e.g. rags, paper wipes, are a potential fire hazard. They must be

collected for safe disposal after use.

Certain inks are allowed for use where they can be in indirect contact with food. In these cases,

the following precautions must be observed in addition to those appropriate to hygiene:

The inks must only be used in printers supplied from new for use with these inks. Any repairs and

replacements must use genuine, new and unused spare parts.

The inks must not be used in printers which have previously been used, at any time, for any other

purpose.

Storage

Printing inks must be stored in well-ventilated buildings, in areas set aside for the purpose, chosen for

safety in case of fire. Materials based on volatile, flammable solvents must be stored in accordance with

local regulations.

Fire Risk

For an electrical fire, do not use water. If water must be used, such as in the case of a Nitro-cellulose ink

fire (see below) the power MUST BE REMOVED first.

Many inks contain Nitro-cellulose as the binder and remain highly flammable when dry. Observe all

warnings given on the machine and the following safety instructions:

If there has been an accumulation of dried ink, do not use metal scrapers to remove it, as they

can produce sparks.

If dry Nitro-cellulose based ink ignites, it will generate its own oxygen and can only be

extinguished by lowering the temperature with water.

If a Nitro-cellulose fire occurs, ENSURE THAT THE ELECTRICAL POWER IS IMMEDIATELY

REMOVED FROM THE PRINTER BEFORE water is used to extinguish the fire. Fire risk is a

most important consideration where printing inks are stored and used. The degree of fire hazard

will vary considerably from one type of ink or wash to another. Solvent-based inks offer a greater

degree of hazard depending on the particular solvent or solvent combination. When there is a

particular hazard the appropriate information is given on the SDS.

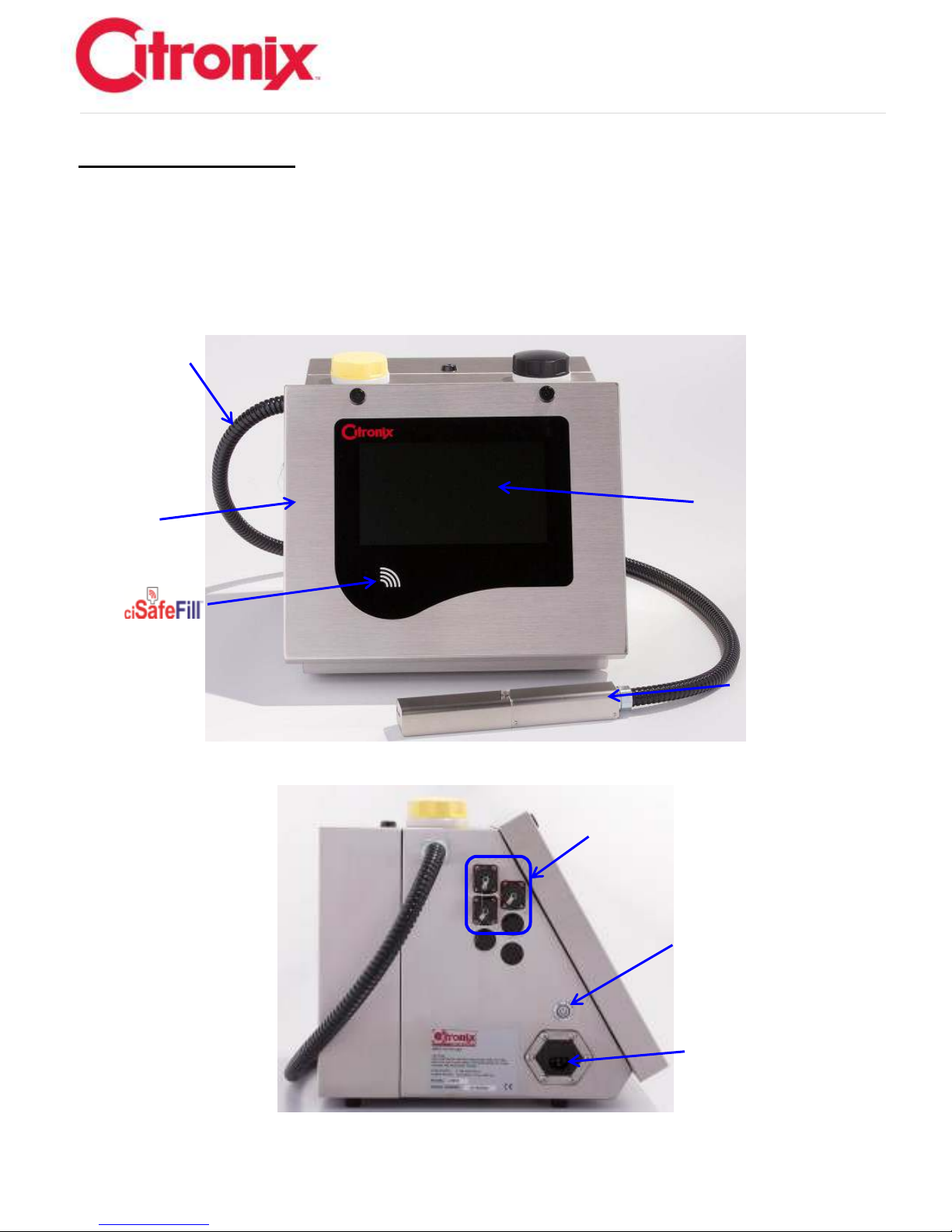

Printer Overview

The Printer consists of a Controller cabinet and a print head that are connected by a Flexible conduit.

They work seamlessly together to create reliable product coding. The cabinet is split into an electronics

compartment and a fluid compartment. The electronics compartment houses the controller PCB, has the

Version 0.1 1-5

ci5000 Series Printer Technical Service Manual

touch screen interface and all interfacing connectors, Low & High voltage power supplies, Pump Motor,

and the power switch.

The fluids compartment houses the ink system, filter module and the ink and make up tanks. These

tanks are filled using their respective fill ports located on the top of the printer.

Version 0.1 1-6

Power On/Off

Button.

Flexible conduit

Touch Screen

Print Head

Reader

Tablet

External Interface

Connectors

Power Cord

Socket

ci5000 Series Printer Technical Service Manual

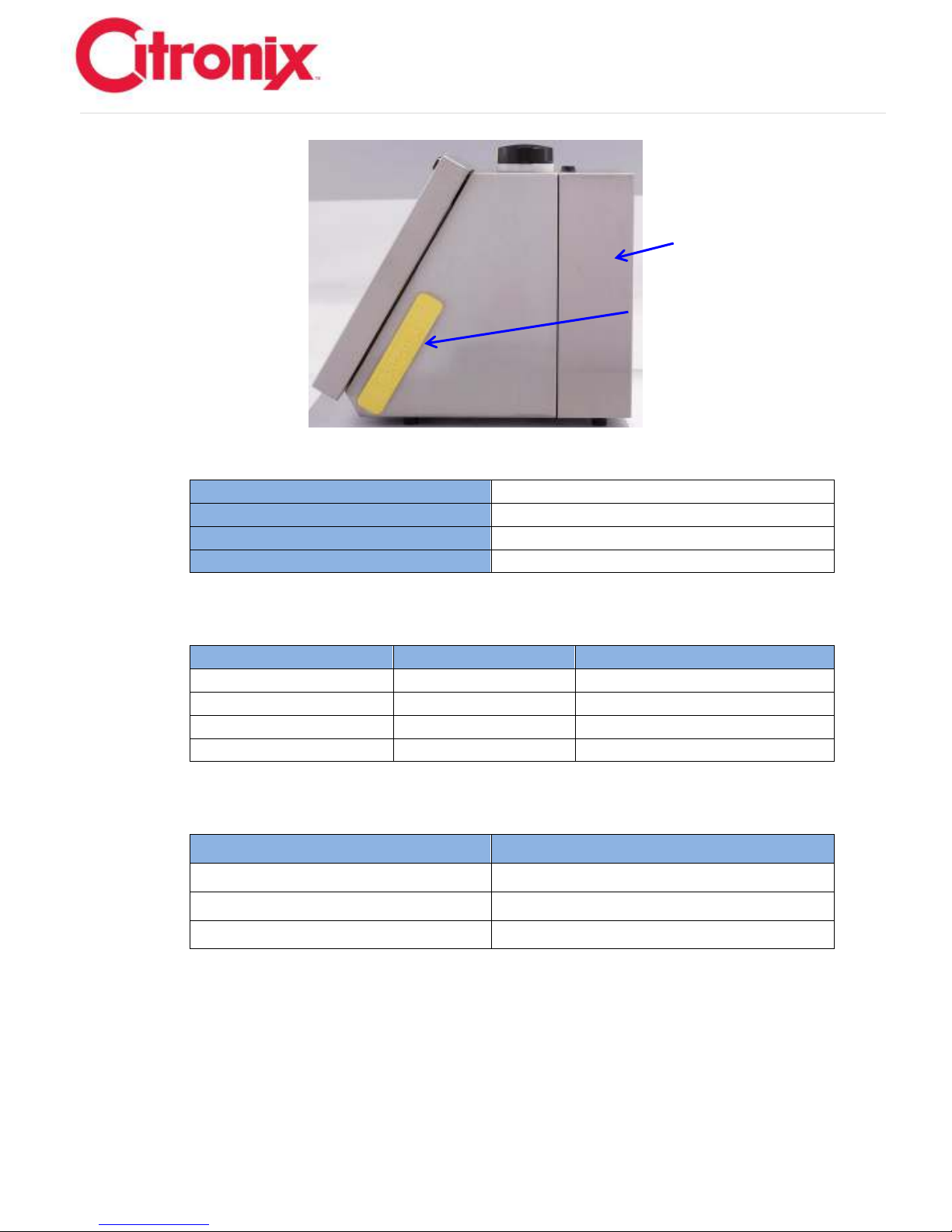

Controller Cabinet

The front half of the controller cabinet consists of the electronics compartment. The cover, also known as

the tablet has the touchscreen display, ciSafeFill Reader and controller PCB. The right hand side of the

electronics cabinet houses the air filter. The left side has the accessory connectors (Beacon, Photocell

and encoder) power plug and the power on/off button.

Version 0.1 1-7

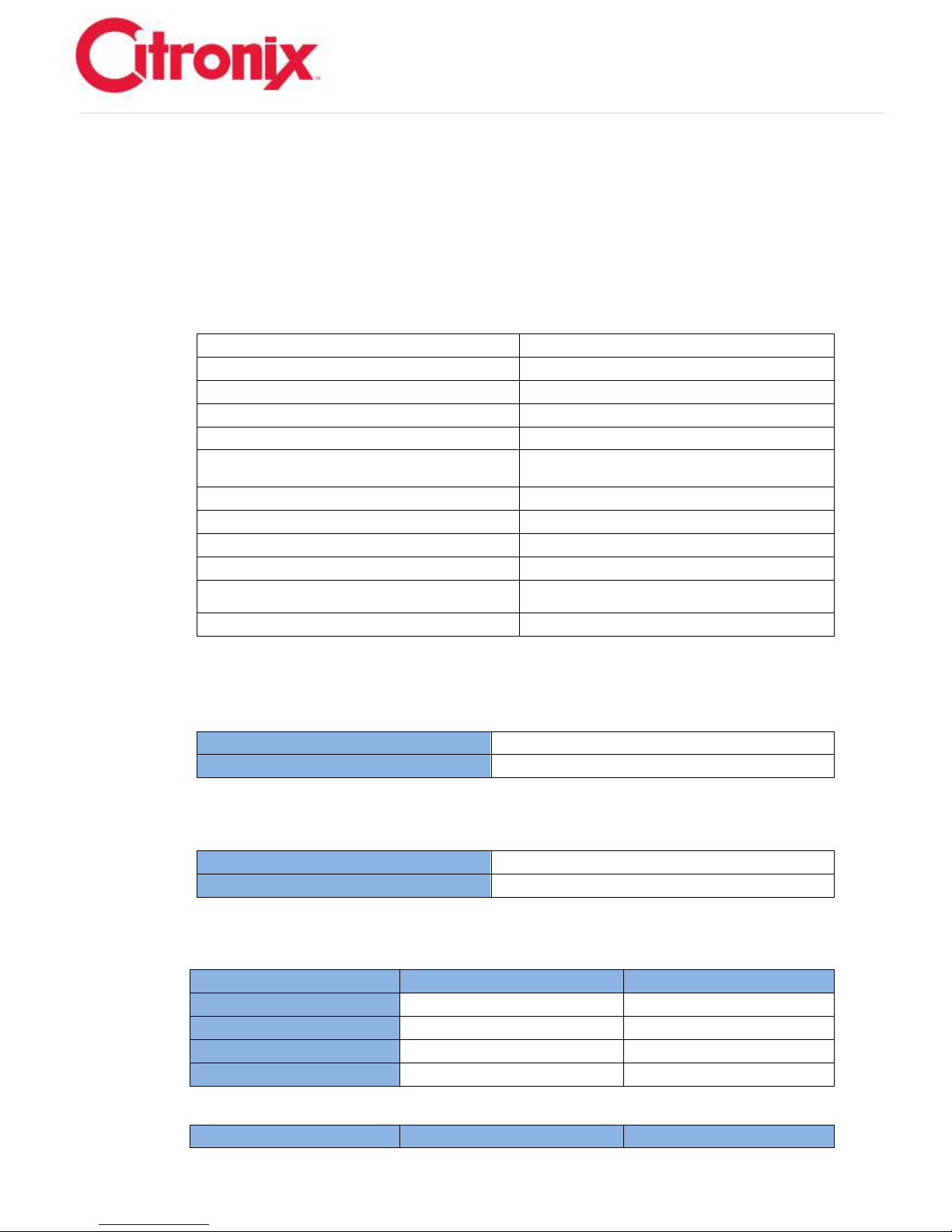

Single Printhead Control

55-88 KHz

Processor

Cold Fire V4

Speed

250Mhz

Memory

256Mb Flash and 256Mb RAM

ci5200

Ci5300

Ci5500/ci5650

1 RS232

1 RS232

1 Ethernet

1 RS232 (1200 up to 115.2KB)

USB

USB

USB

SB Card

SB Card

SB Card

ci5200

ci5300/ci5500/ci5650

1 photocell

2 photocell*

1 shaft encoder

1 shaft encoder

6 programmable**

Air Filter

Ink System

Cover

Hardware Specification:

ci5000 Series Printer Technical Service Manual

Interfaces:

Inputs (opto-isolated, open collector or TTL type):

*Programmable options for Photocell 2

**Remote message selection – 255 possible selections

Version 0.1 1-8

Color Capacitance touch screen

Graphic downloadable

On board Help/Diagnostics

Integrated graphic creator / editor

Intuitive icon based operation

Automatic diagnostics

WYSIWYG message editing

Event log

Pick and place by pixel field based formatting

Service reminders

Message/Graphic Storage – up to 1000

messages*

Tower Printing Functions

Single button start and stop operation

Continuous print capability

Programmable Password security

Backup / restore functions

Real and expiration time and date coding

Multiple operator languages

Shift and rollover time and date coding

Multi-national character printing (Unicode)

Product and batch counting coding

Downloadable firmware updates (Ethernet or

USB)

Internet browser interface for ci5500/ci5650

Temperature

35° – 113° F (5° – 45° C)

% Relative Humidity

10-90% (non-condensing)

Auto Ranging

90-260VAC (3 Amp)

Frequency

50-60 Hz

ci5200

ci5300

Enclosure

Black Powder Coated Steel

304 grade Stainless Steel

Environmental

IP55

IP55

Printer Weight

38.4 lbs.*

38.4 lbs.*

Weight Printhead*

2 lbs.

2 lbs.

ci5500

ci5650

ci5000 Series Printer Technical Service Manual

Outputs:

3 programmable alarms – Warning, Failure, Print Ready (Open Collector, 150mA

sinking)

Programmable dry contact relay

External Power (+24VDC 500mA)

User Interface and Firmware Capabilities:

*Depending on the size of the messages

Operating Environment:

Electrical Requirements:

Controller and Printhead Physical Characteristics:

Version 0.1 1-9

Enclosure

304 grade Stainless Steel

316 grade Stainless Steel

Environmental

IP55

Designed to IP65

Printer Weight

38.4 lbs.*

40.3 lbs.*

Weight Printhead *

2 lbs.

2 lbs.

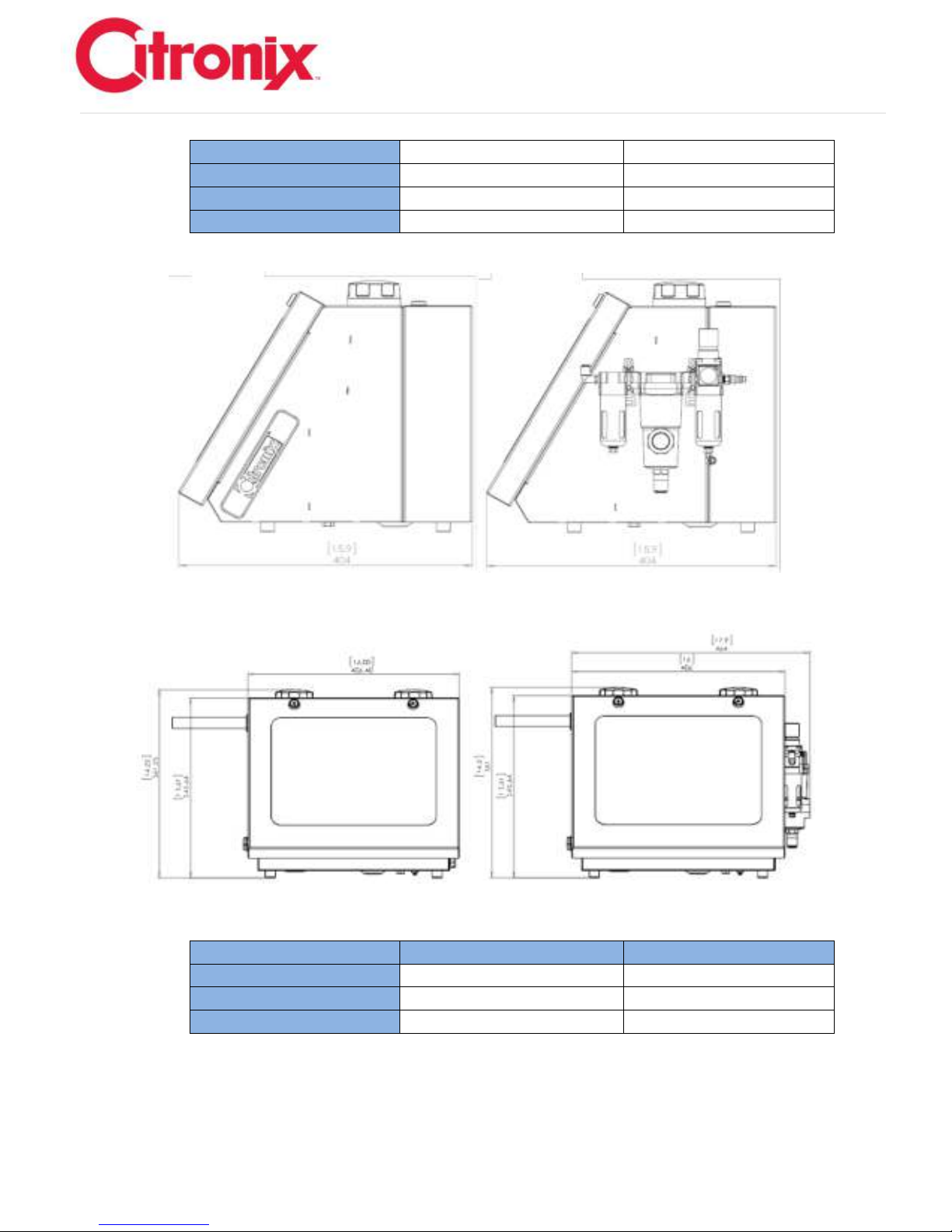

Cabinet Dimensions

ci5200, ci5300 & ci5500

ci5650

Height

14.2 inches (361mm)

14.2 Inches (361mm)

Width

16 inches (406mm)

17.7 inches (450mm)

Depth

15.9 inches (404mm)

15.9 inches (404mm)

ci5000 Series Printer Technical Service Manual

* The weight of the Printhead and conduit is included in the Printer weight.

Ci5200/ci5300/ci5500 Side View ci5650 Side View

Ci5200/ci5300/ci5500 Front View ci5650 Front View

Version 0.1 1-10

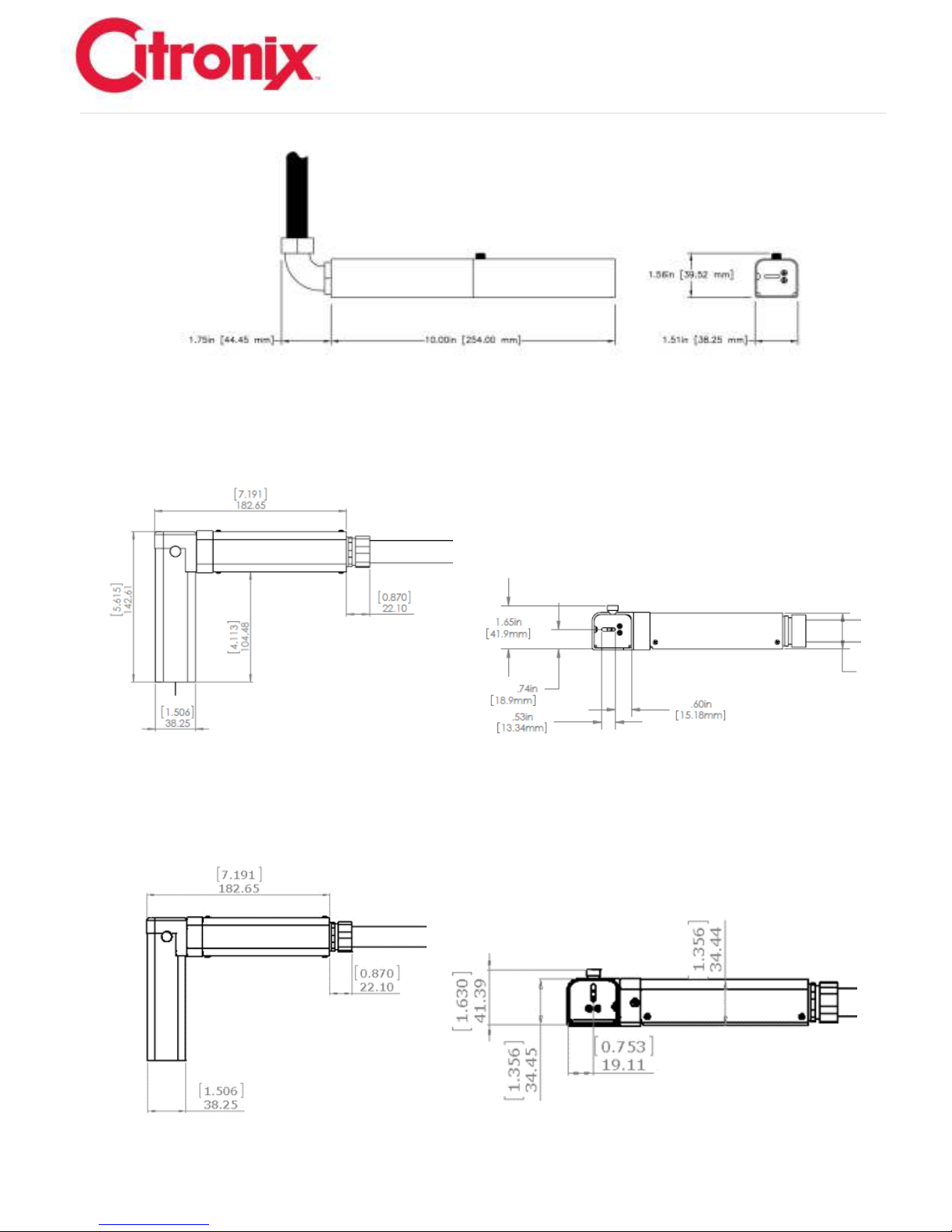

Technology

Continuous Ink Jet (CIJ)

Print

Text, Graphics, Bar codes, Autocodes

Printhead Orientation

Omni-directional

ci5000 Series Printer Technical Service Manual

Printhead and Umbilical

Printhead:

Umbilical:

Three Umbilical lengths are available on all printer types; 9 feet (2.7 meters), 15 feet (4.5 meters), or 20

feet (6 meters).

IP55 – Protected against dust and has limited ingress (no harmful deposit). Protected against low-

pressure Jets of water from all directions; limited ingress permitted.

IP65 – Totally protected against dust. Protected against low-pressure Jets of water from all directions;

limited ingress permitted.

Printhead Dimension Drawings:

Straight Printhead Umbilical Fitting

Access for Straight Printhead Umbilical Fitting

(ci5200/ci5300/ci5500/ci5650)

(ci5200/ci5300/ci5500/ci5650)

Version 0.1 1-11

ci5000 Series Printer Technical Service Manual

90 Degree Printhead Umbilical Fitting

(ci5500/ci5650 option)

Right Angle Printhead

(ci5500/ci5650 option)

Version 0.1 1-12

ci5000 Series Printer Technical Service Manual

In-Line Right Angle Printhead

(ci5500/ci5650 option)

Print Speeds and Print Quality Charts

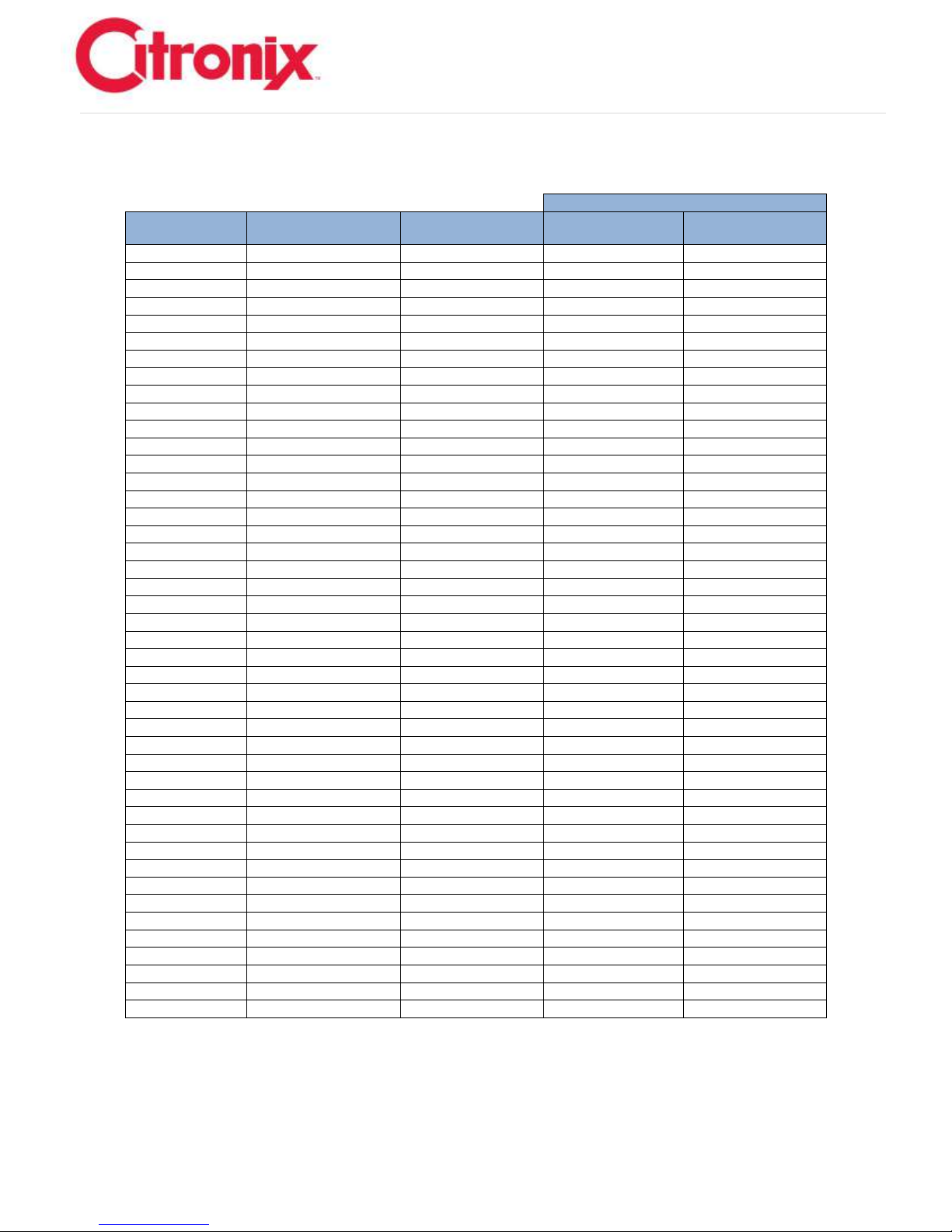

The line speed at which the product passes the Printhead will affect print quality. The following pages

show how to determine the maximum line speeds for each print quality setting. These speeds charts are

calculated at 50 dpi (dots per inch).

When determining the Print settings for the application, the following factors need to be considered:

• Line Speed

• Pixel Setting (vertical resolution)

• Print Resolution or dpi (horizontal resolution or raster pitch)

• Whether an external or internal encoder is used

*For more details reference Section 3 Printer Operation

NOTE: Print Quality/Speed may be selected in increments of 20 to optimize for each application.

300 is the best quality; 0 is the fastest speed. The Speed Chart shows speeds at 0, 100, 200 and

300.

NOTE: ci5200 is available only in Macro mode. Micro and HS50 models are available only with

ci5500 and ci5650.

NOTE: In the following Charts the Characters per second are based on 50 dpi.

Version 0.1 1-13

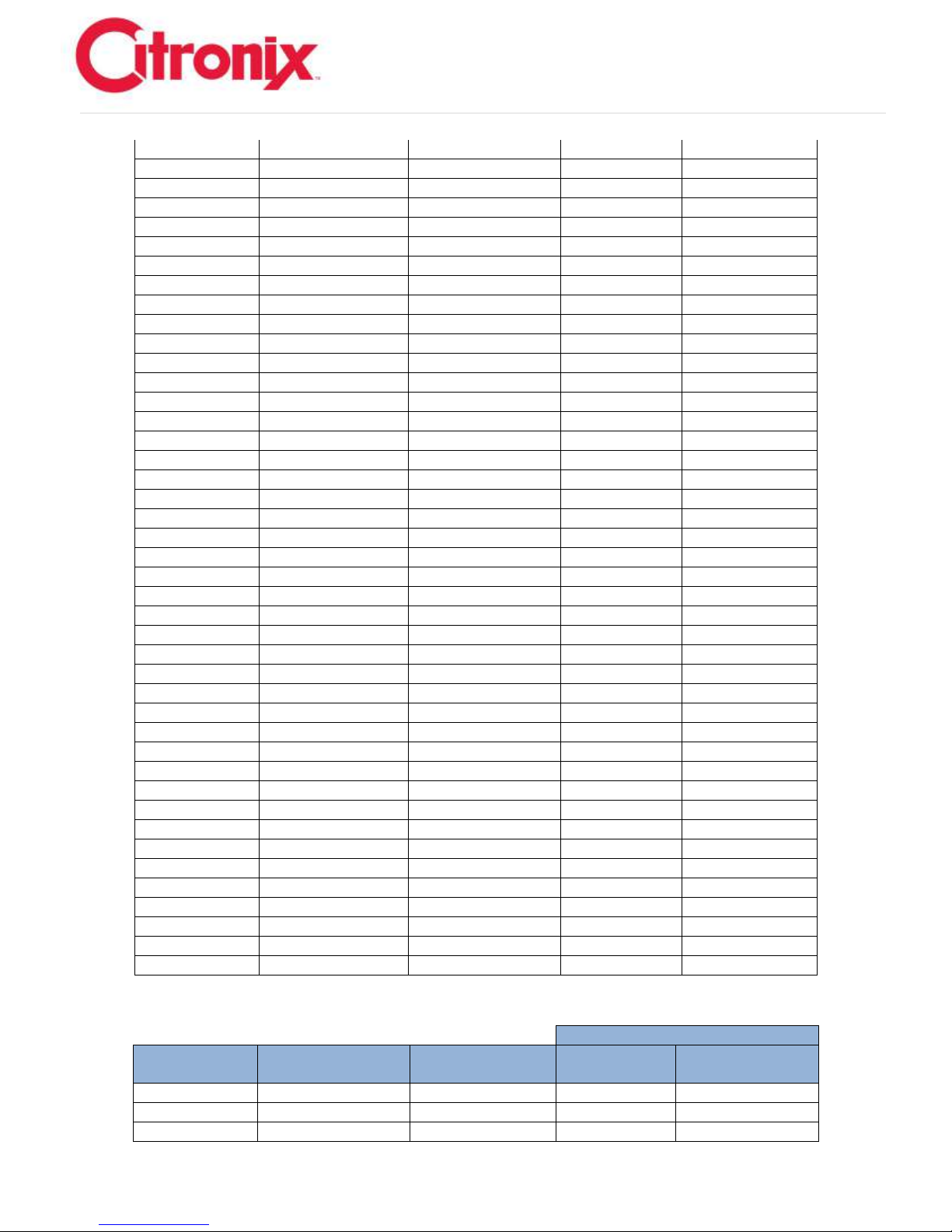

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per

second

Feet per minute

Meters per minute

1L5

0

3213

1928

588

1L5

100

1428

857

261

1L5

200

989

593

181

1L5

300

756

454

138

1L7

0

2142

1285

392

1L7

100

989

593

181

1L7

200

676

406

124

1L7

300

514

308

94

1L9

0

1224

857

261

1L9

100

648

454

138

1L9

200

441

308

94

1L9

300

334

234

71

1L12

0

876

701

214

1L12

100

419

335

102

1L12

200

283

227

69

1L12

300

214

171

52

1L16

0

292

350

107

1L16

100

178

214

65

1L16

200

126

151

46

1L16

300

97

117

36

2L7

0

1285

771

235

2L7

100

756

454

138

2L7

200

494

297

90

2L7

300

330

198

60

1L19

0

237

308

94

1L19

100

145

188

57

1L19

200

101

131

40

1L19

300

77

100

31

1L25

0

104

188

57

1L25

100

71

129

39

1L25

200

51

92

28

1L25

300

40

71

22

3L7

0

559

335

102

3L7

100

494

297

90

3L7

200

313

188

57

3L7

300

207

124

38

1L31

0

56

157

48

1L31

100

37

104

32

1L31

200

26

74

23

1L31

300

21

58

18

4L7

0

476

286

87

4L7

100

389

234

71

4L7

200

214

129

39

4L7

300

143

86

26

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Normal/Internal Encoder

Print Speed Chart - Drop Size: Normal/External Encoder

Version 0.1 1-14

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per second

Feet per minute

Meters per minute

1L5 0 3083

1850

564

1L5

100

1370

822

251

1L5

200

949

569

173

1L5

300

725

435

133

1L7 0 2055

1233

376

1L7

100

949

569

173

1L7

200

649

389

119

1L7

300

493

296

90

1L9 0 1174

822

251

1L9

100

622

435

133

1L9

200

423

296

90

1L9

300

320

224

68

1L12 0 841

673

205

1L12

100

402

322

98

1L12

200

272

218

66

1L12

300

206

164

50

1L16 0 280

336

103

1L16

100

171

206

63

1L16

200

121

145

44

1L16

300

93

112

34

2L7 0 1233

740

226

2L7

100

725

435

133

2L7

200

474

285

87

2L7

300

316

190

58

1L19 0 228

296

90

1L19

100

139

180

55

1L19

200

96

125

38

1L19

300

74

96

29

1L25 0 100

180

55

1L25

100

69

123

38

1L25

200

49

88

27

1L25

300

38

69

21

3L7 0 536

322

98

3L7

100

474

285

87

3L7

200

301

180

55

3L7

300

199

119

36

1L31 0 54

151

46

1L31

100

36

100

30

1L31

200

25

71

22

1L31

300

20

55

17

4L7 0 457

274

84

4L7

100

374

224

68

4L7

200

206

123

38

4L7

300

137

82

25

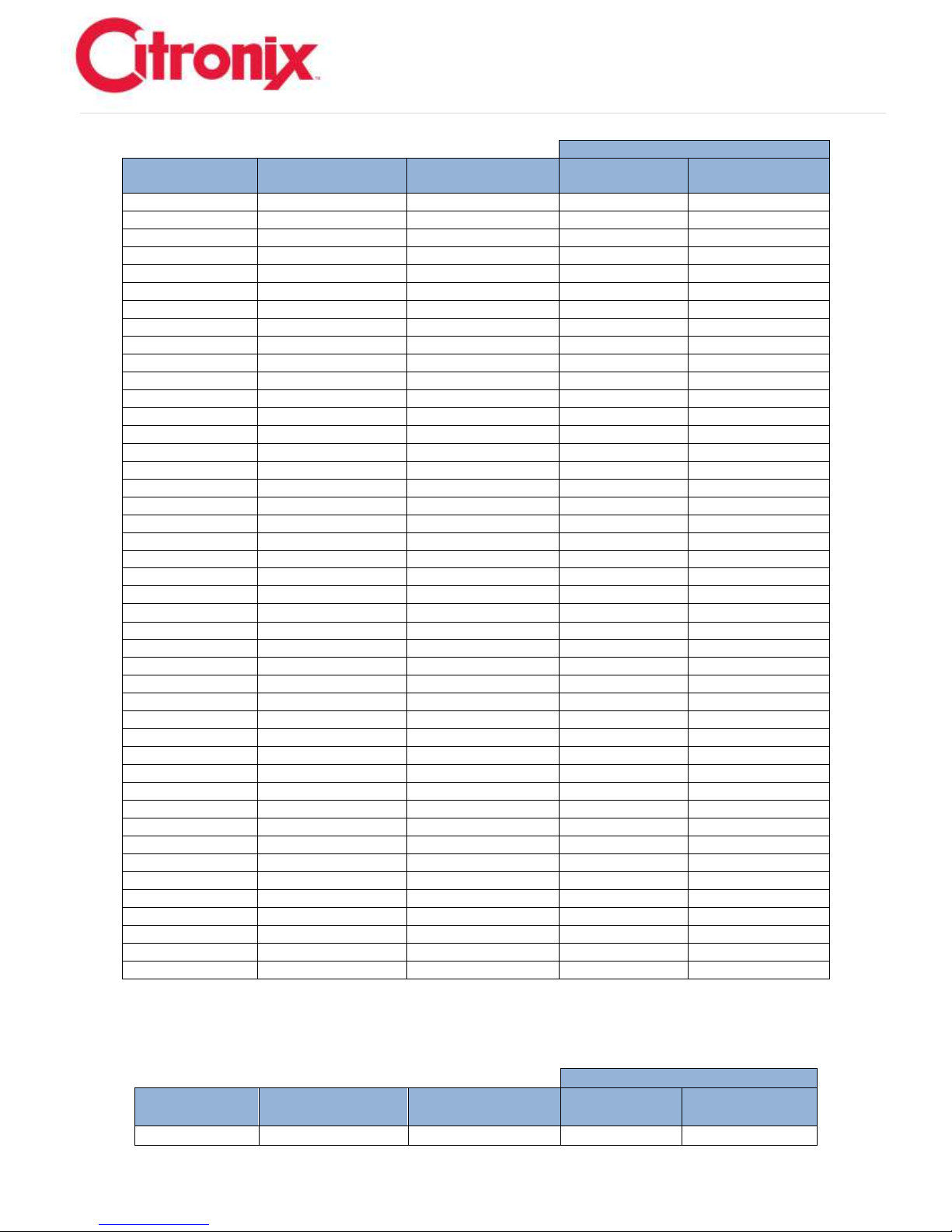

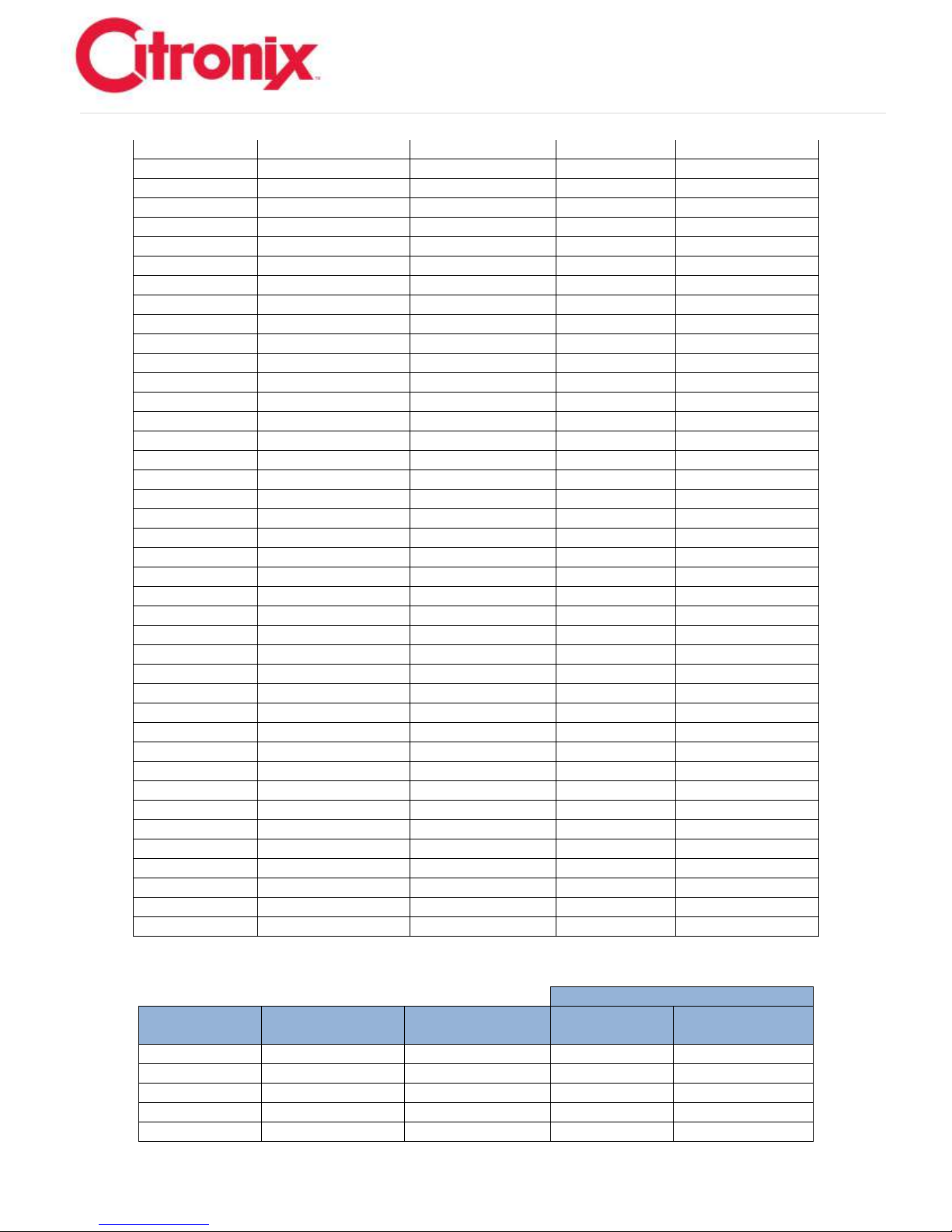

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per second

Feet per minute

Meters per minute

1L5

0

2277

1366

416

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Macro/Internal Encoder

Version 0.1 1-15

1L5

100

1012

607

185

1L5

200

700

420

128

1L5

300

536

321

98

1L7

0

1518

911

278

1L7

100

700

420

128

1L7

200

479

288

88

1L7

300

364

219

67

1L9

0

976

683

208

1L9

100

459

321

98

1L9

200

312

219

67

1L9

300

237

166

50

1L12

0

525

420

128

1L12

100

285

228

69

1L12

200

195

156

48

1L12

300

148

119

36

1L16

0

285

341

104

1L16

100

126

152

46

1L16

200

89

107

33

1L16

300

69

83

25

2L7

0

911

546

167

2L7

100

536

321

98

2L7

200

350

210

64

2L7

300

233

140

43

1L19

0

168

219

67

1L19

100

103

133

41

1L19

200

71

93

28

1L19

300

55

71

22

1L25

0

74

133

41

1L25

100

51

91

28

1L25

200

36

64

20

1L25

300

29

52

16

3L7

0

396

238

72

3L7

100

350

210

64

3L7

200

222

133

41

3L7

300

147

88

27

1L31

0

43

121

37

1L31

100

27

77

23

1L31

200

20

55

17

1L31

300

15

42

13

4L7

0

314

188

57

4L7

100

260

156

48

4L7

200

152

91

28

4L7

300

101

61

19

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per second

Feet per minute

Meters per minute

1L5

0

2185

1311

400

1L5

100

971

583

178

1L5

200

672

403

123

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Macro/External Encoder

Version 0.1 1-16

1L5

300

514

308

94

1L7

0

1456

874

266

1L7

100

672

403

123

1L7

200

460

276

84

1L7

300

350

210

64

1L9

0

936

655

200

1L9

100

441

308

94

1L9

200

300

210

64

1L9

300

227

159

48

1L12

0

504

403

123

1L12

100

273

218

67

1L12

200

187

150

46

1L12

300

142

114

35

1L16

0

273

328

100

1L16

100

121

146

44

1L16

200

86

103

31

1L16

300

66

79

24

2L7

0

874

524

160

2L7

100

514

308

94

2L7

200

336

202

61

2L7

300

224

134

41

1L19

0

161

210

64

1L19

100

98

128

39

1L19

200

68

89

27

1L19

300

52

68

21

1L25

0

71

128

39

1L25

100

49

87

27

1L25

200

34

62

19

1L25

300

28

50

15

3L7

0

380

228

69

3L7

100

336

202

61

3L7

200

213

128

39

3L7

300

141

85

26

1L31

0

42

117

36

1L31

100

26

74

23

1L31

200

19

52

16

1L31

300

14

40

12

4L7

0

301

181

55

4L7

100

250

150

46

4L7

200

146

87

27

4L7

300

97

58

18

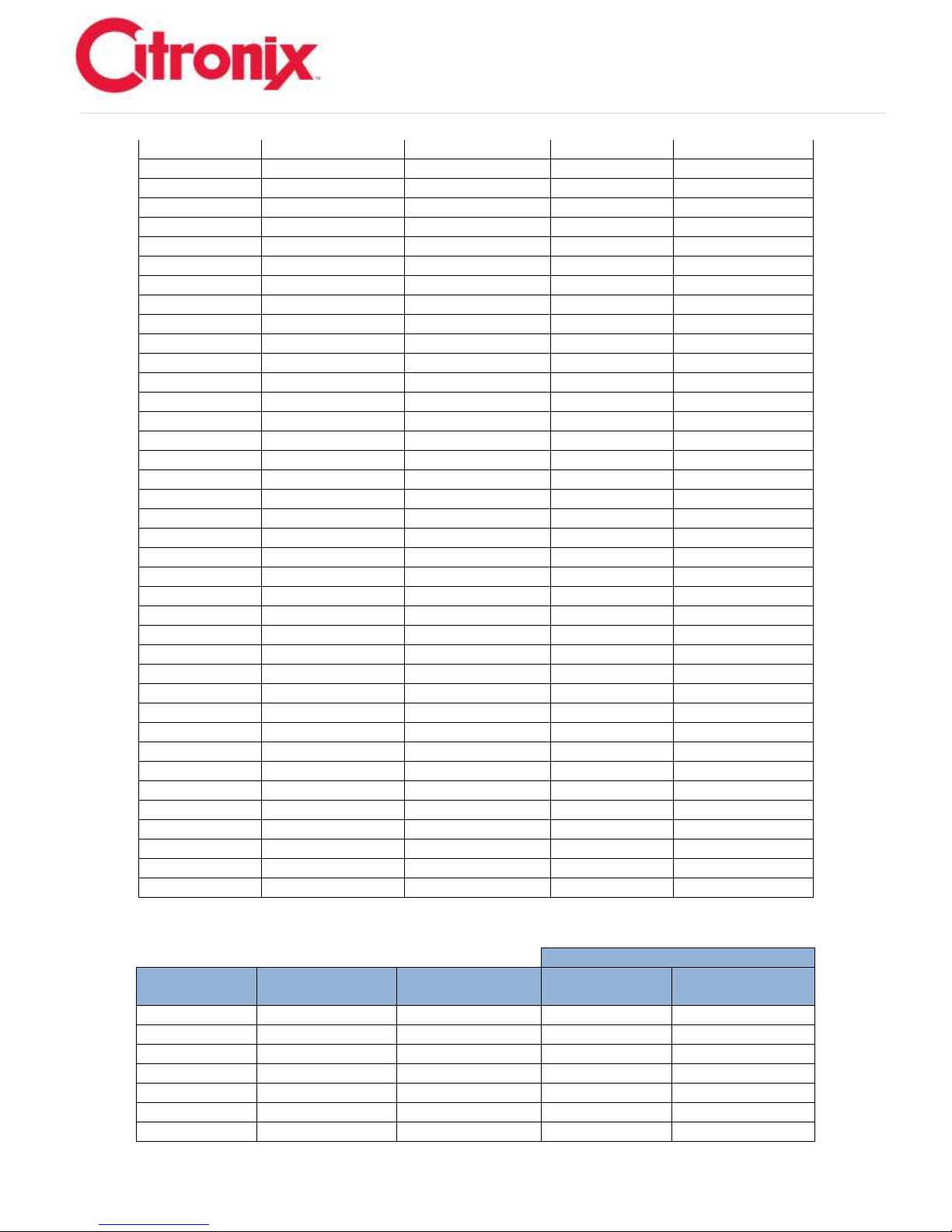

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per second

Feet per minute

Meters per minute

1L5

0

3370

2022

616

1L5

100

1498

899

274

1L5

200

1037

622

190

1L5

300

793

476

145

1L7

0

2247

1348

411

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Micro/Internal Encoder

Version 0.1 1-17

1L7

100

1037

622

190

1L7

200

709

426

130

1L7

300

539

324

99

1L9

0

1444

1011

308

1L9

100

680

476

145

1L9

200

462

324

99

1L9

300

350

245

75

1L12

0

266

213

65

1L12

100

169

135

41

1L12

200

125

100

30

1L12

300

96

77

23

1L16

0

153

184

56

1L16

100

96

116

35

1L16

200

67

81

25

1L16

300

52

62

19

2L7

0

1498

899

274

2L7

100

843

506

154

2L7

200

518

311

95

2L7

300

355

213

65

1L19

0

259

337

103

1L19

100

152

197

60

1L19

200

105

137

42

1L19

300

81

105

32

1L25

0

76

213

65

1L25

100

48

135

41

1L25

200

34

96

29

1L25

300

27

75

23

3L7

0

613

368

112

3L7

100

518

311

95

3L7

200

329

197

60

3L7

300

221

133

40

1L31

0

61

172

52

1L31

100

39

109

33

1L31

200

28

78

24

1L31

300

22

60

18

4L7

0

499

300

91

4L7

100

408

245

75

4L7

200

225

135

41

4L7

300

150

90

27

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per

second

Feet per minute

Meters per minute

1L5

0

3234

1940

591

1L5

100

1437

862

263

1L5

200

995

597

182

1L5

300

761

457

139

1L7

0

2156

1293

394

1L7

100

995

597

182

1L7

200

681

408

124

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: Micro/External Encoder

Version 0.1 1-18

1L7

300

517

310

95

1L9

0

1386

970

296

1L9

100

652

457

139

1L9

200

443

310

95

1L9

300

336

235

72

1L12

0

255

204

62

1L12

100

162

129

39

1L12

200

120

96

29

1L12

300

92

74

23

1L16

0

147

176

54

1L16

100

92

111

34

1L16

200

65

78

24

1L16

300

50

60

18

2L7

0

1437

862

263

2L7

100

808

485

148

2L7

200

497

298

91

2L7

300

340

204

62

1L19

0

249

323

99

1L19

100

146

189

58

1L19

200

101

132

40

1L19

300

78

101

31

1L25

0

73

204

62

1L25

100

46

129

39

1L25

200

33

92

28

1L25

300

26

72

22

3L7

0

588

353

108

3L7

100

497

298

91

3L7

200

315

189

58

3L7

300

212

127

39

1L31

0

59

165

50

1L31

100

37

105

32

1L31

200

27

75

23

1L31

300

21

58

18

4L7

0

479

287

88

4L7

100

392

235

72

4L7

200

216

129

39

4L7

300

144

86

26

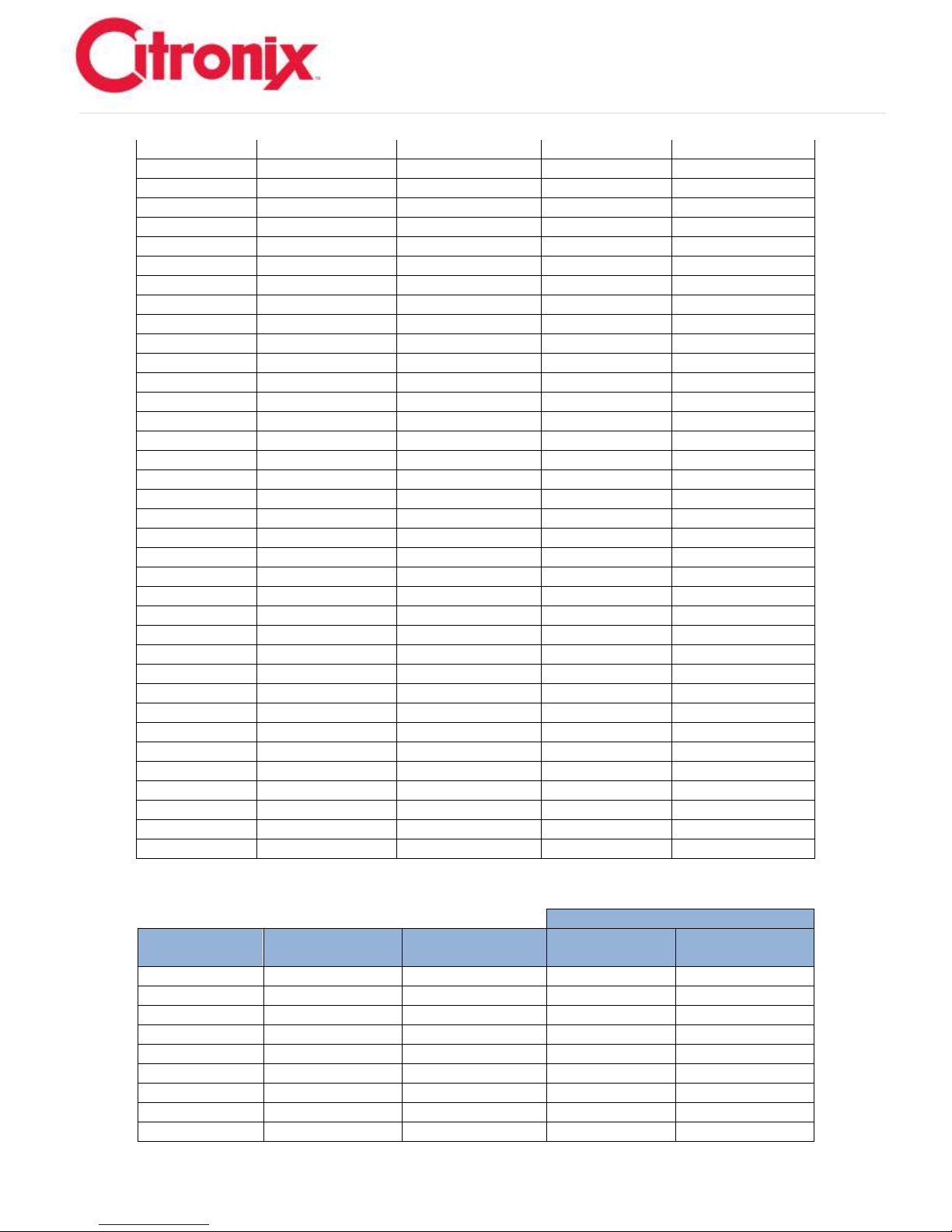

Maximum Line Speed

Pixel Setting

Print Speed /

Quality Selection

Characters per

second

Feet per minute

Meters per minute

1L5

0

3472

2083

635

1L5

100

1543

926

282

1L5

200

1068

641

195

1L5

300

817

490

149

1L7

0

2315

1389

423

1L7

100

1068

641

195

1L7

200

731

439

134

1L7

300

556

333

102

1L9

0

1323

926

282

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: HS50/Internal Encoder

Version 0.1 1-19

1L9

100

700

490

149

1L9

200

476

333

102

1L9

300

361

253

77

1L12

0

947

758

231

1L12

100

453

362

110

1L12

200

306

245

75

1L12

300

231

185

56

1L16

0

316

379

115

1L16

100

193

231

71

1L16

200

136

163

50

1L16

300

105

126

38

2L7

0

1389

833

254

2L7

100

817

490

149

2L7

200

534

321

98

2L7

300

356

214

65

1L19

0

256

333

102

1L19

100

156

203

62

1L19

200

109

141

43

1L19

300

83

108

33

1L25

0

73

203

62

1L25

100

50

139

42

1L25

200

35

99

30

1L25

300

28

77

24

3L7

0

604

362

110

3L7

100

534

321

98

3L7

200

339

203

62

3L7

300

228

137

42

1L31

0

61

170

52

1L31

100

40

113

34

1L31

200

29

80

24

1L31

300

22

62

19

4L7

0

514

309

94

4L7

100

421

253

77

4L7

200

231

139

42

4L7

300

154

93

28

Maximum Line Speed

Pixel Setting

Print Speed / Quality

Selection

Characters per second

Feet per minute

Meters per minute

1L5

0

3332

1999

609

1L5

100

1481

888

271

1L5

200

1025

615

187

1L5

300

784

470

143

1L7

0

2221

1333

406

1L7

100

1025

615

187

1L7

200

701

421

128

1L7

300

533

320

97

1L9

0

1269

888

271

1L9

100

672

470

143

1L9

200

457

320

97

ci5000 Series Printer Technical Service Manual

Print Speed Chart - Drop Size: HS50/External Encoder

Version 0.1 1-20

1L9

300

346

242

74

1L12

0

909

727

222

1L12

100

435

348

106

1L12

200

294

235

72

1L12

300

222

178

54

1L16

0

303

363

111

1L16

100

185

222

68

1L16

200

131

157

48

1L16

300

101

121

37

2L7

0

1333

800

244

2L7

100

784

470

143

2L7

200

513

308

94

2L7

300

342

205

62

1L19

0

246

320

97

1L19

100

150

195

59

1L19

200

104

136

41

1L19

300

80

104

32

1L25

0

70

195

59

1L25

100

48

133

41

1L25

200

34

95

29

1L25

300

26

74

23

3L7

0

579

348

106

3L7

100

513

308

94

3L7

200

325

195

59

3L7

300

218

131

40

1L31

0

58

163

50

1L31

100

39

108

33

1L31

200

27

77

23

1L31

300

21

60

18

4L7

0

494

296

90

4L7

100

404

242

74

4L7

200

222

133

41

4L7

300

148

89

27

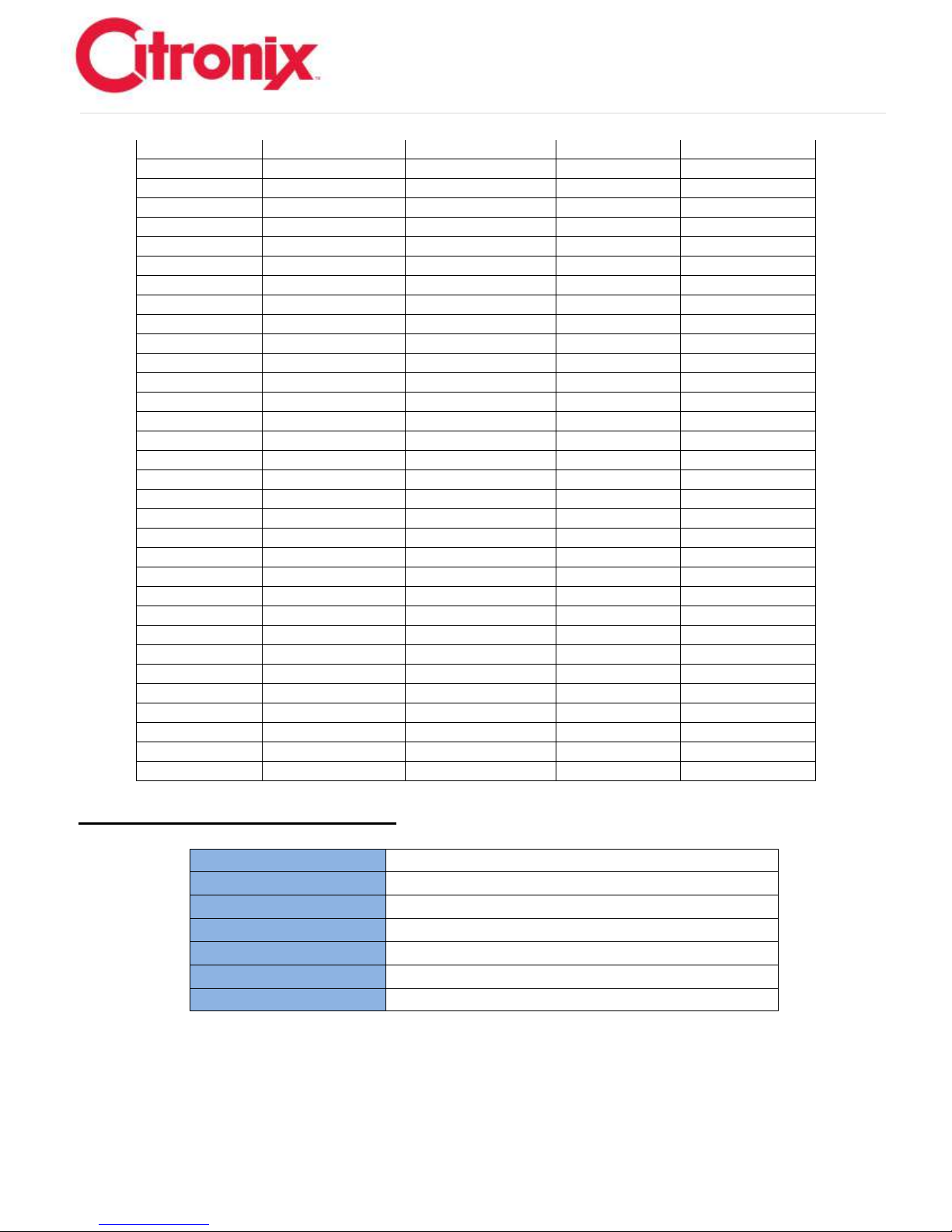

Ink/Makeup Types

Full range – MEK, Acetone, Ethanol

Ink/Makeup Colors

Black, Red, Blue, Yellow, Green, White, UV Readable

Dry Time

Quick dry to immediate

Ink Bottles

750 ml (25.4 oz)

Makeup Bottles

750 ml (25.4 oz)

Ink Tank

1.9 L (64 oz)

Makeup Tank

2.25 L (76 oz)

ci5000 Series Printer Technical Service Manual

Consumables and Delivery

Ink/Makeup options for all Printers are shown in the following table.

Version 0.1 1-21

ci5200

ci5300

ci5500

ci5650

Micro

HS50

Pigment

Heavy Pigment

MEK Black Black ● ● ● ● ● ●

Ethanol Black

Black ● ● ● ● ● ●

MEK Red Red ● ● ● ● ● ●

MEK Blue Blue ● ● ● ● ● ●

Acetone Black

Black ● ● ● ●

MEK Plastic

Black ● ● ●

MEK UV Readable UV Readable ● ● ●

MEK Alcohol Resistant

Black ● ● ●

MEK Caustic Washable Green Green ● ● ●

MEK Caustic Washable

Black ● ● ●

MEK Thermotropic BLK-Red Black to Red ● ● ●

MEK Plastic Plus

Black ● ● ●

Acetone/Ethanol Black

Black ● ● ●

Red Food Grade Red ● ● ●

Blue Food Grade Blue ● ● ●

Acetone Yellow Pigment Yellow ●

MEK Yellow Pigment Yellow ●

MEK Black Pigment

Black ●

Acetone Heavy Pig White White ●

ci5000 Series Printer Technical Service Manual

Ink System

The inks system keeps the ink optimally conditioned for reliable printing and cleaning/flushing of the

printhead.

The filter module conditions the ink for optimal performance. It comes in a clean, quick, easy to

replace quick connect module. The filter module and air filter are the only two items that require

periodic servicing.

The Ink and Make-up tanks are topped up using their respective fill ports located on the top of the printer.

The following components are housed within the Ink system enclosure:

Version 0.1 1-22

Ink and Make-up Fill Ports

Ink and Makeup Tanks

Ink Manifold

Ink Fill Port

Viscometer

Ink Tank

Make-up

Fill Port

Filter Module

Make-up Tank

Make-up

Manifold

(behind bracket)

Ink Pump

Pressure

Transducer

Module Base

ci5000 Series Printer Technical Service Manual

Ink Pump

Ink System Valves and Manifold

Pressure Transducer

Viscometer

Filter Module

Fluid Level Sense

Version 0.1 1-23

ci5000 Series Printer Technical Service Manual

Ink and Makeup Tanks

The Ink tank holds 1.9 liters of Ink and the Makeup tank holds 2.25 liters of Makeup.

Ink Pump

The pump motor is on the electrical side of the enclosure, and the Ink pump is on the fluidic side of the

enclosure isolated through a Teflon seal. The motor is magnetically coupled to the pump.

NOTE: Further troubleshooting/testing and adjustments explained in SECTION 5 Status Bar &

Troubleshooting

CAUTION: Dry Ink residue in the Ink pump may cause pump to de-couple from the

motor. If the Printer is left idle for more than two weeks, ensure the Printer is

flushed completely of all Ink residues. To remedy, squirt Cleaning Solvent directly

into the pump head (using a Squirt Bottle) via the inlet or outlet and allow to sit with

solvent in the pump for 2 minutes to loosen dried ink. Repeat until the pump is free,

or replace if not free after 10 repeated steps.

Ink System Valves & Manifold

The Ink System Valves control the various Ink and Makeup supplies.

Version 0.1 1-24

Loading...

Loading...