Page 1

2002

CAR 050013

«The technical information contained in this document is intended for the exclusive use of the trained personnel of the

motor vehicle repair trade. In some instances, this information could concern the security and safety of the vehicle. The

information is to be used by the professional vehicle repairers for whom it is intended and they alone would assume full

responsibility to the exclusion of that of the manufacturer».

«The technical information appearing in this brochure is subject to updating as the characteristics of each model in the

range evolve. Motor vehicle repairers are invited to contact the CITROËN network periodically for further information and

to obtain any possible updates».

Page 2

PRESENTATION

THIS HANDBOOK summarises the specifications, adjustments, checks and special features of the CITROEN C8.

The handbook is divided into the following sections representing the main functions :

GENERAL - ENGINE - INJECTION - IGNITION - CLUTCH - GEARBOX - DRIVESHAFTS - AXLES - SUSPENSION - STEERING - BRAKES - HYDRAULICS ELECTRICAL - AIR CONDITIONING.

Page 3

GENERAL

1

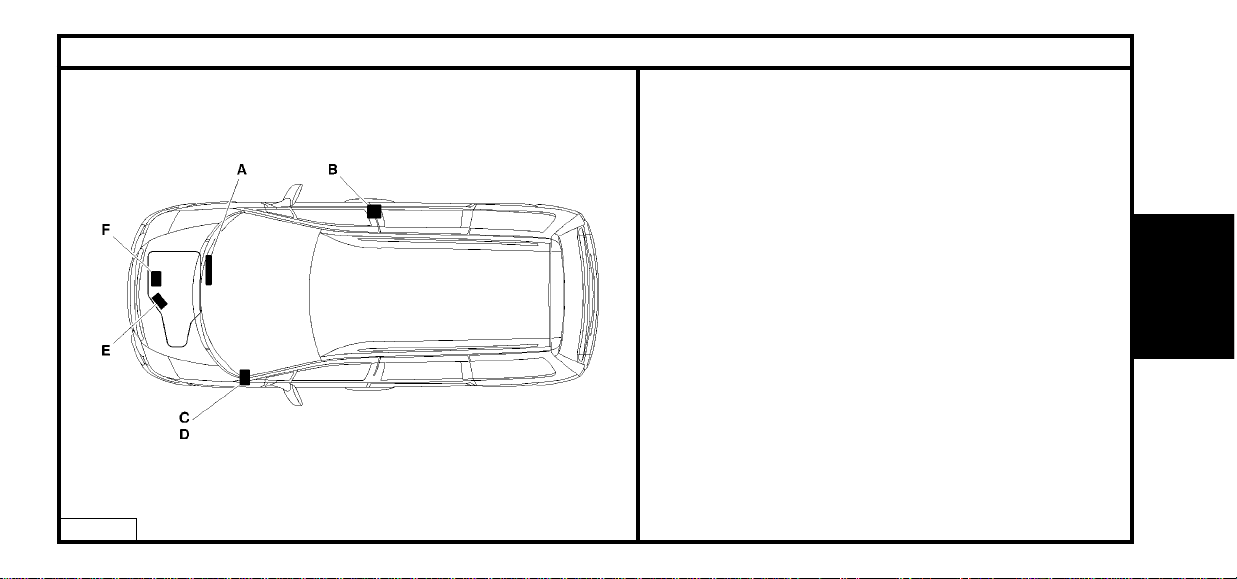

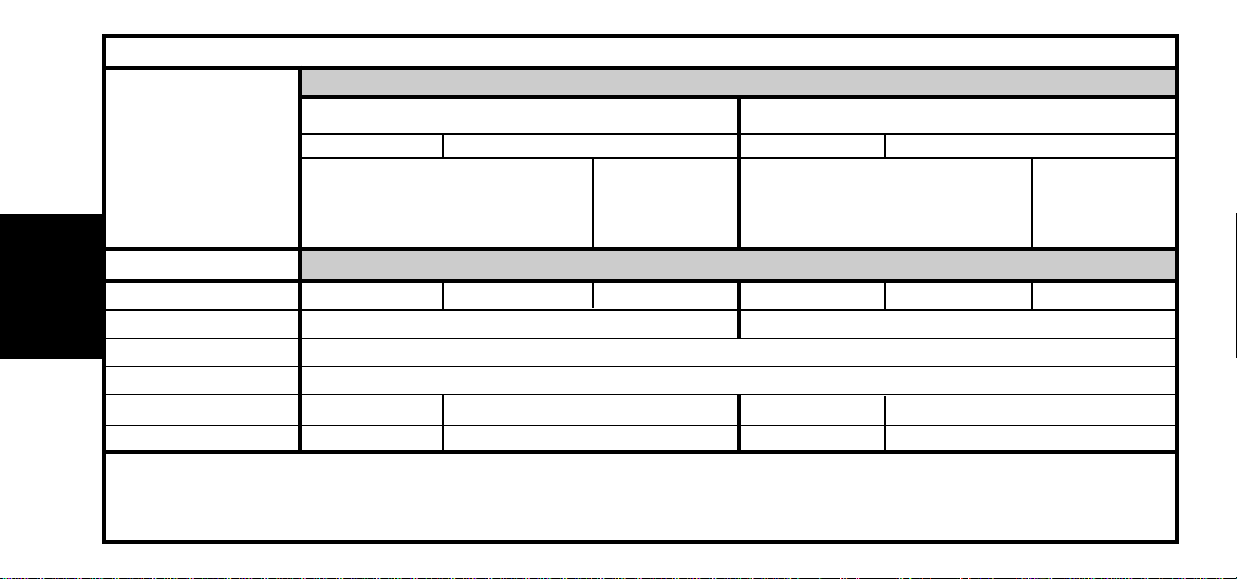

IDENTIFICATION OF VEHICLES

E1AP0A2D

(A) Chassis stamp (cold stamp on bodywork).

(B) Manufacturer’s data plate (under RH centre pillar).

(C) A-S / RP No. and RP paint code

(label on front pillar).

(D) Inflation pressures and tyre references.

(label on front pillar)

(E) Gearbox reference – Factory serial no.

(F) Engine legislation type – Factory serial no.

GENERAL

Page 4

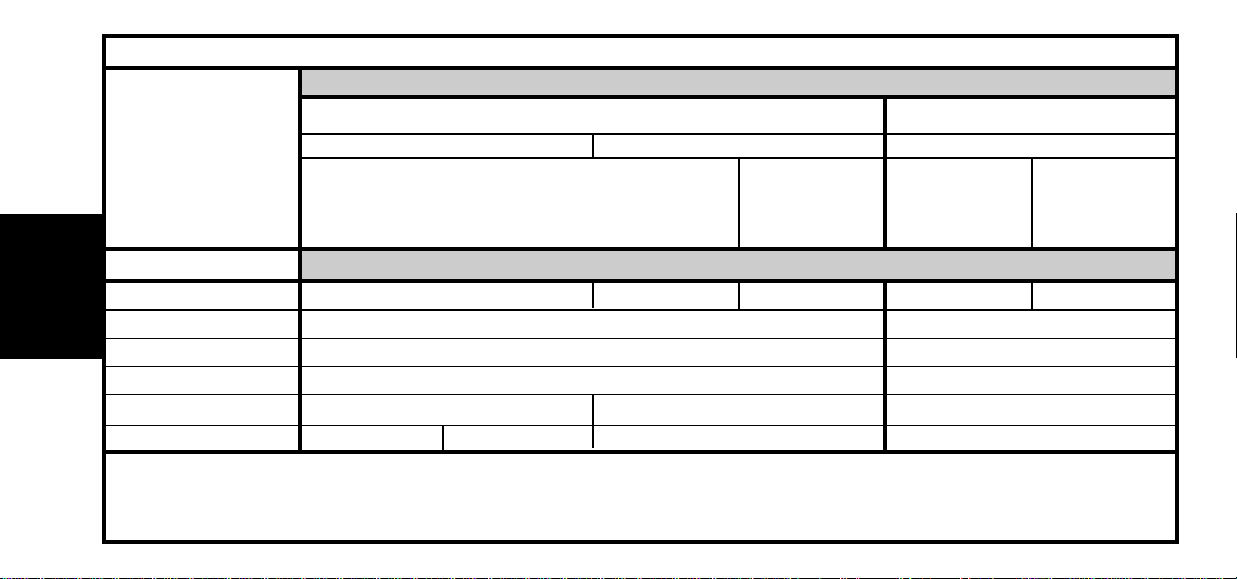

2

GENERAL

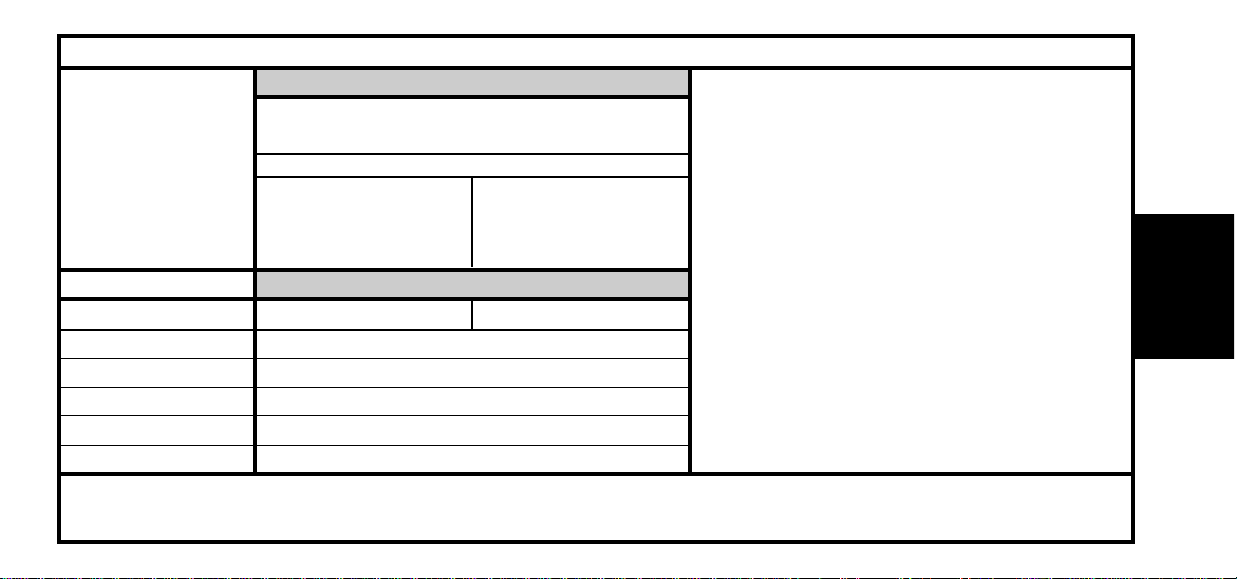

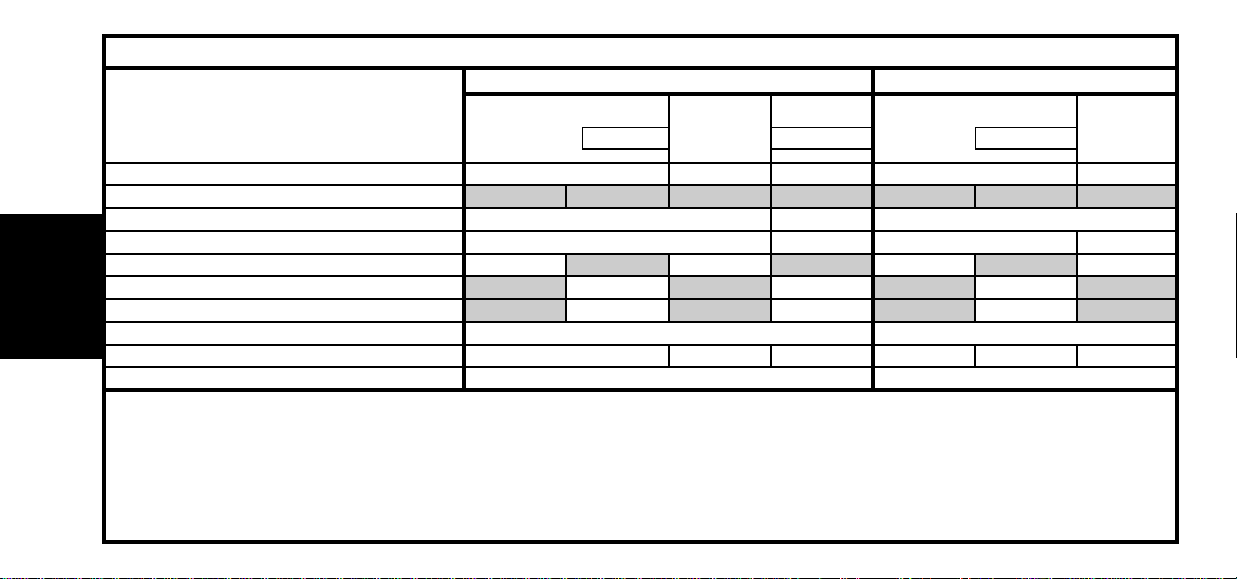

Emission standard IFL5

Type code EB RFNC/IF EB RFNF/IF EA RFNF/IF EB 3FZC/IF EA 3FZC/IF

Engine type RFN 3FZ

Cubic capacity (cc) 1998 2230

Fiscal rating (hp) 911

Gearbox type BE4/5 AL4 ML5C

Gearbox ident. plate 20 DL 27 (1) 20 DL 26 (2) 20 TP 74 20 LM 09

IDENTIFICATION OF VEHICLES

Petrol

2.0i 16V

2.2i 16V

X – SX

Exclusive

SX

Captain Chair

SX

Captain Chair

Exclusive

Captain Chair

Automatic

ManualManual

X - SX

(1) = Right hand drive

(2) = Left hand drive.

Page 5

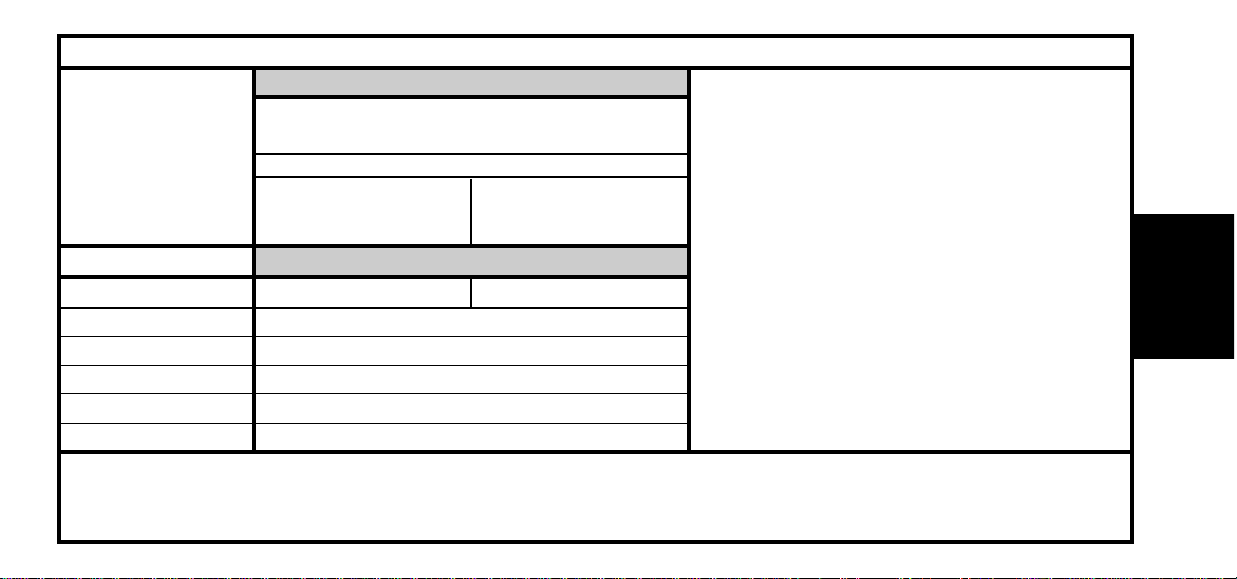

3

GENERAL

Automatic

Emission standard IFL5

Type code SEB XFWF/IF EA XFWF/IF

Engine type XFW

Cubic capacity (cc) 2946

Fiscal rating (hp) 14

Gearbox type 4 HP 20

Gearbox ident. plate 20 HZ 27

IDENTIFICATION OF VEHICLES

Petrol

3.0i V6 S24

Exclusive

Captain Chair

Exclusive

Page 6

4

GENERAL

Emission standard L4

Type code EB RHTB EB RHTE EA RHTE EB RHWB EB RHWE EA RHWE

Engine type RHT RHW

Cubic capacity (cc) 1997

Fiscal rating (hp) 7

Gearbox type ML5C AL4 ML5C AL4

Gearbox ident. plate 20 LM 05 20 TS 04 20 LM 05 20 TS 04

IDENTIFICATION OF VEHICLES

Diesel

2.0 HDi (*)

2.0 HDi (**)

X – SX – Exclusive

SX

Captain Chair

Automatic

Manual AutomaticManual

SX

Captain Chair

X – SX – Exclusive

(*) = With particle filter.

(**) = Without particle filter.

Page 7

5

GENERAL

(*) = With particle filter.

Manual

Emission standard L4

Type code EB 4HWB EA 4HWB

Engine type 4HW

Cubic capacity (cc) 2179

Fiscal rating (hp) 8

Gearbox type ML5C

Gearbox ident. plate 20 LM 01

IDENTIFICATION OF VEHICLES

Diesel

2.2 HDi (*)

SX

Captain Chair

Exclusive

Captain Chair

SX

Captain Chair

Page 8

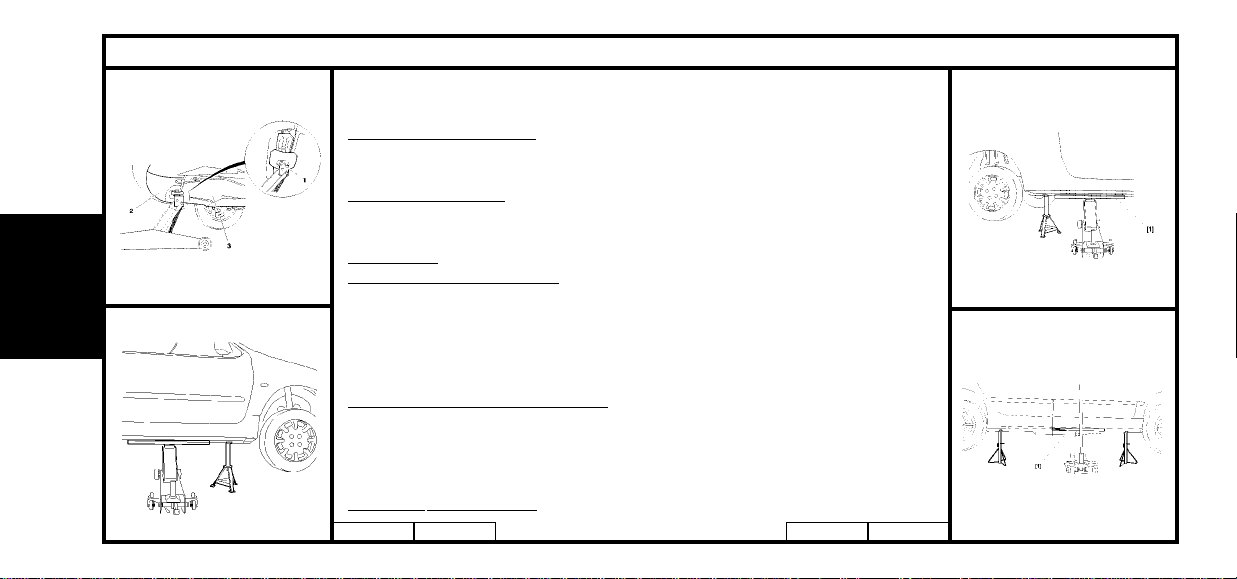

GENERAL SPECIFICATION: LIFTING AND SUPPORTING THE VEHICLE

6

GENERAL

Tooling.

[1] Crossbeam : (-). 0010.

Front lifting on one side.

Position the jack (4) at the strongpoints provided for this purpose on each side

of the front crossmember between the bumper (2) and the engine (3).

Front central lifting.

Using a jack equipped with a crossbeam (sufficiently rigid) take the weight at the

two strongpoints on the front crossmember.

Side lifting.

At the front and at the rear

Take the weight at the sill, by means of the crossbeam [1], as close as possible

to the jacking point.

Position a stand at the jacking point provided for the purpose of lifting the

vehicle with the jack.

WARNING : Avoid the battery tray on the right hand side.

Side lifting at both front and rear

Take the weight at the sill, by means of the crossbeam [1].

Position stands at the jacking points provided for the purpose of lifting the

vehicle with the jack.

WARNING : Lifting at the rear of the vehicle using the crossbeam is

STRICTLY PROHIBITED.

E2AK02ZD E2AF006C E2AK030D E2AK031D

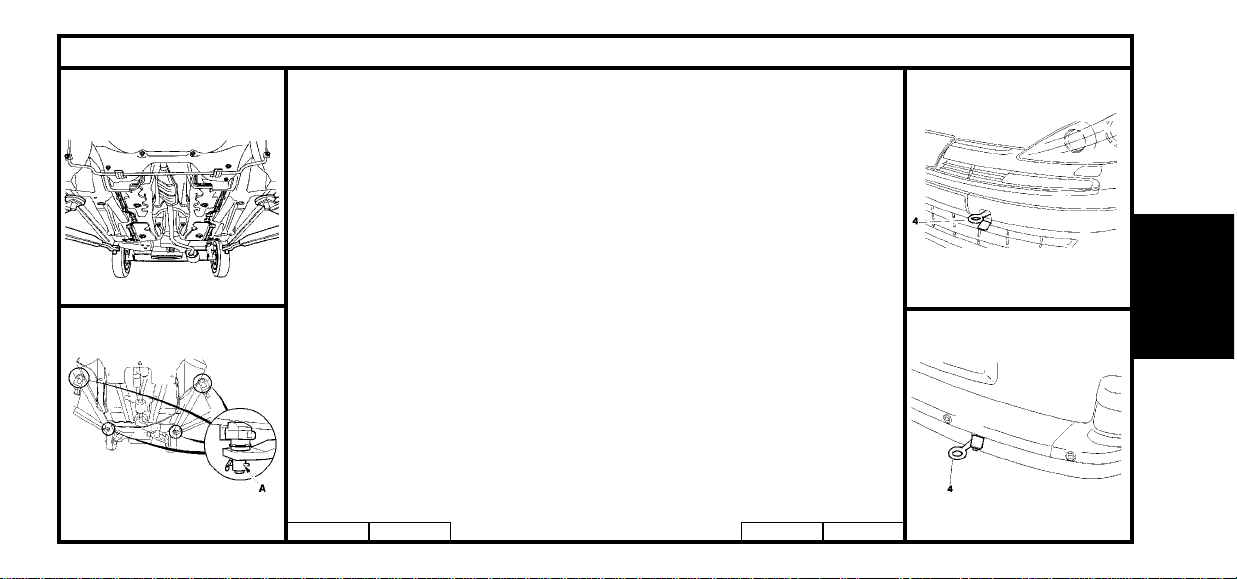

Page 9

7

GENERAL SPECIFICATION: LIFTING AND SUPPORTING THE VEHICLE

GENERAL

Lifting by means of a two-column workshop lift

WARNING : The removing of components such as the engine/gearbox, rear sub-

frame etc, can cause a displacement of the centre of gravity: Use a lift equipped

with retaining devices to keep the body stable on the lift.

Without body clamps.

Place the lift’s guide pads at each jacking point.

WARNING : To prevent any risk of the vehicle toppling, it is prohibited to

remove mechanical components.

With body clamps

WARNING : These clamps are fitted only on FOG lifts.

Position the clamps at the sill in the jacking points provided, screw heads oriented

towards the outside of the vehicle. Tighten the clamps using the gudgeon pin and,

after tightening, engage the pin in the hole (A).

Towing (front).

Lift the blank with the aid of the flat part of the towing eye (1) and then screw the

eye home.

NOTE : The towing eye is to be found on the front panel inside the engine compartment.

Towing (rear).

Lift the blank (1) and screw the towing eye home.

E2AF004D E5AF022D E2AK02YD E2AK02XD

Page 10

8

GENERAL

Engine type RFN 3FZ XFW RHT - RHW 4HW

Engine angle

Engine with filter change 4.25 5.25 4.75

Between Min. and Max. 1.7 2 1.9 1.5

5-speed gearbox 1.8 2 2 2

Automatic gearbox 6 8.3 6

After oil change 3 5.3 3

Hydraulic or brake circuit 0.66 0.66

Cooling system 7 7.2 10.5 10 10.2 11.3

Fuel tank capacity 80 80

CAPACITIES (in litres)

Petrol Diesel

Auto.

Auto. Auto.

2.0i 16V 2.2i 16V 3.0i 24V 2.0 HDi 2.2 HDi

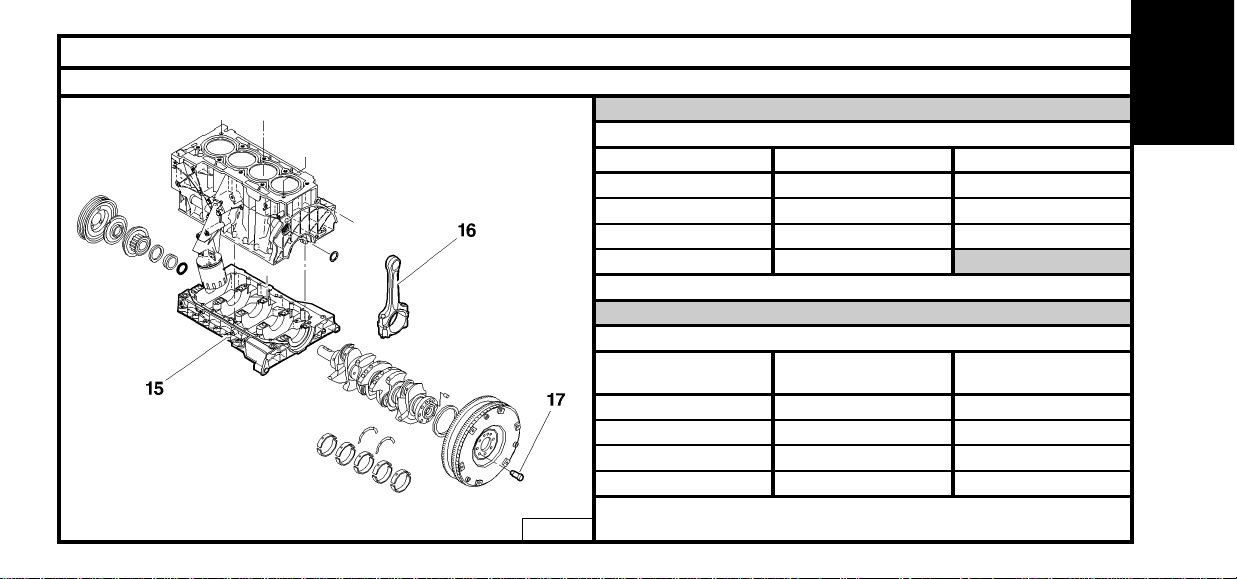

Page 11

9

ENGINE SPECIFICATIONS

Diesel

Engines : RFN - 3FZ - XFW - RHW - RHT - 4HW

Petrol

All Types

2.0i 16V 2.2i 16V 3.0i 24V 2.0 HDi 2.2 HDi

Engine type

Cubic capacity (cc)

Bore / Stroke

Compression ratio

Power ISO or EEC KW - rpm

Power DIN (HP - rpm)

Torque ISO or EEC (m.daN - rpm)

RFN 3FZ XFW RHT- RHW 4HW

1997 2230 2946 1997 2179

85/88 86/96 87/82.6 85/88 85/96

10.8/1 10.9/1 17.3/1 17.6/1

100-6000 116-5650 150-6000 79-4000 94-4000

138-6000 160-5650 204-6000 109-4000 130-4000

19-4100 21.7-3900 28.5-3750 27-1750 31.4-2000

ENGINE

Page 12

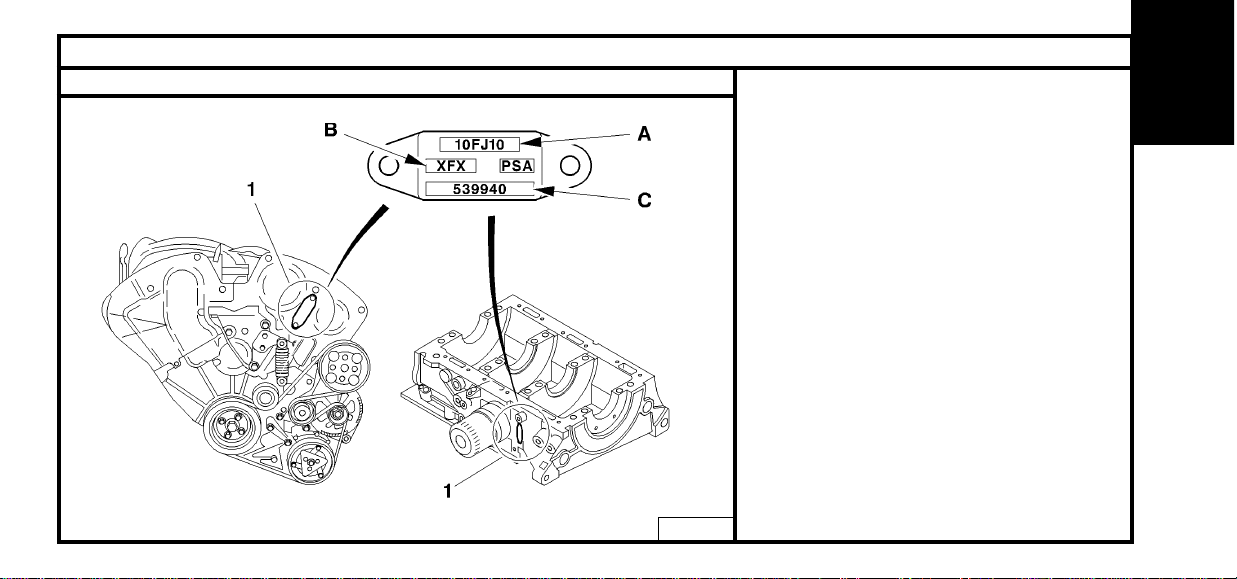

10

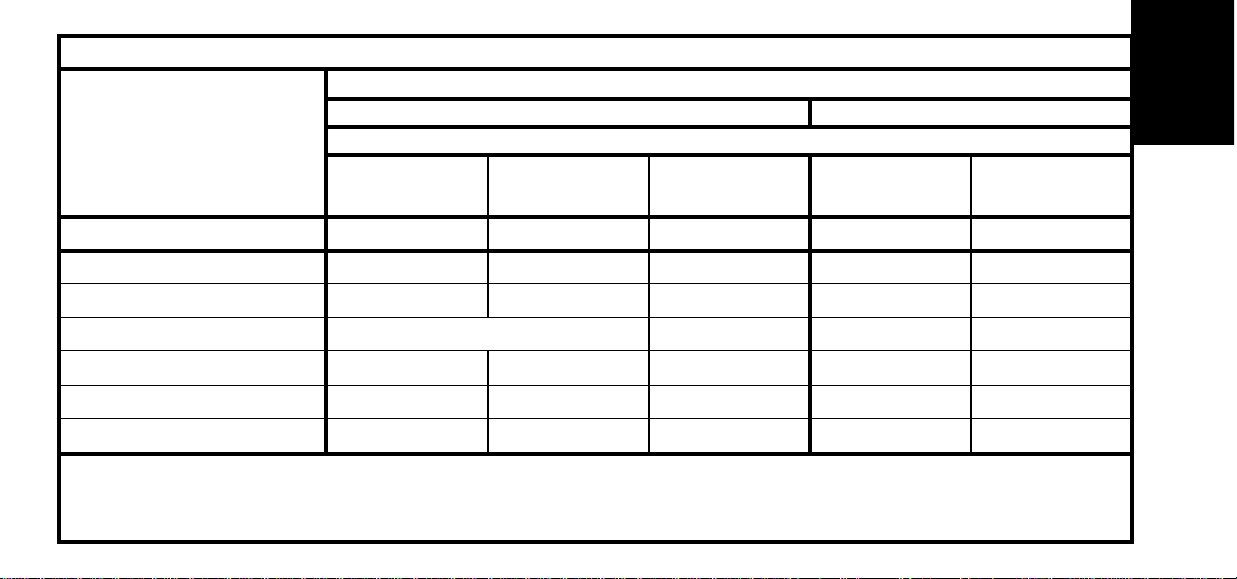

ENGINE SPECIFICATIONS

Engines : RFN – 3FZ

(1) Compulsory engine plate :

(A) Engine legislation type.

(B) Component reference.

(C) Factory serial no.

B1BB010D

ENGINE

Page 13

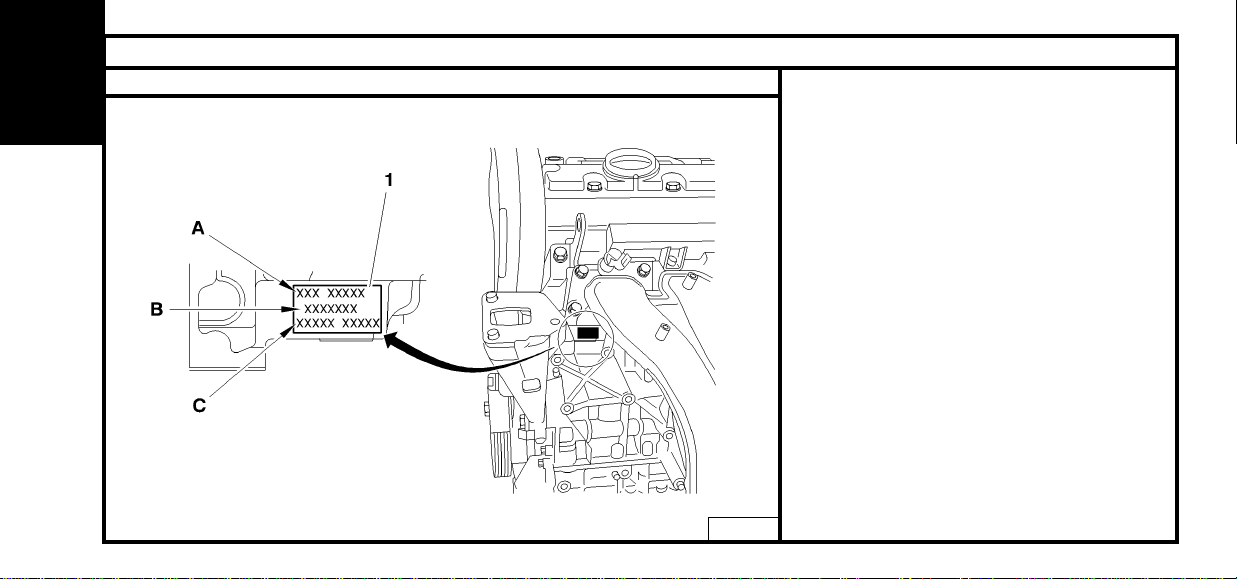

11

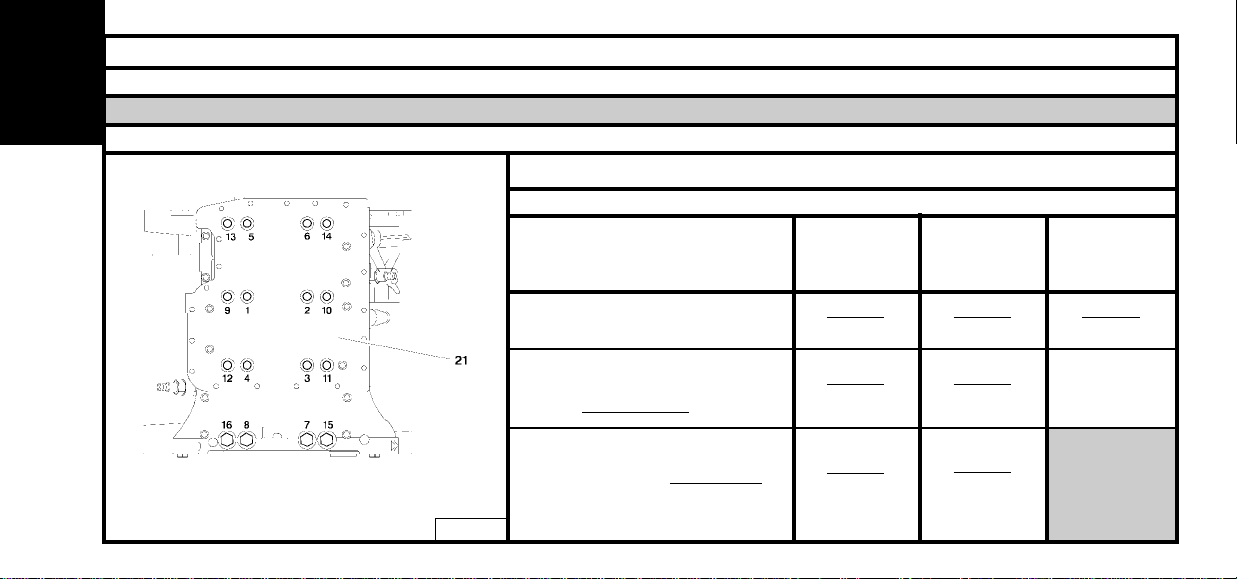

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engines : RFN – 3FZ

Crankshaft

Crankshaft bearing cap cover (15)

Description M11 M6

Pre-tightening 1 ± 0.1 0.5

Slackening Yes No

Re-tightening 1 ± 0.1 puis 2 ± 0.2 1 ± 0.1

Angular tightening 70° ± 5°

B1BK1X8D

Description

(16) Con-rod caps

(17) Flywheel/

crankshaft fixing

Pre-tightening 1 ± 0.1 2.5 ± 0.2

Slackening Yes 18°± 1°

Re-tightening 2.5 ± 0.2 1 ± 0.1

22°±2°Angular tightening 46° ± 5°

ENGINE

Page 14

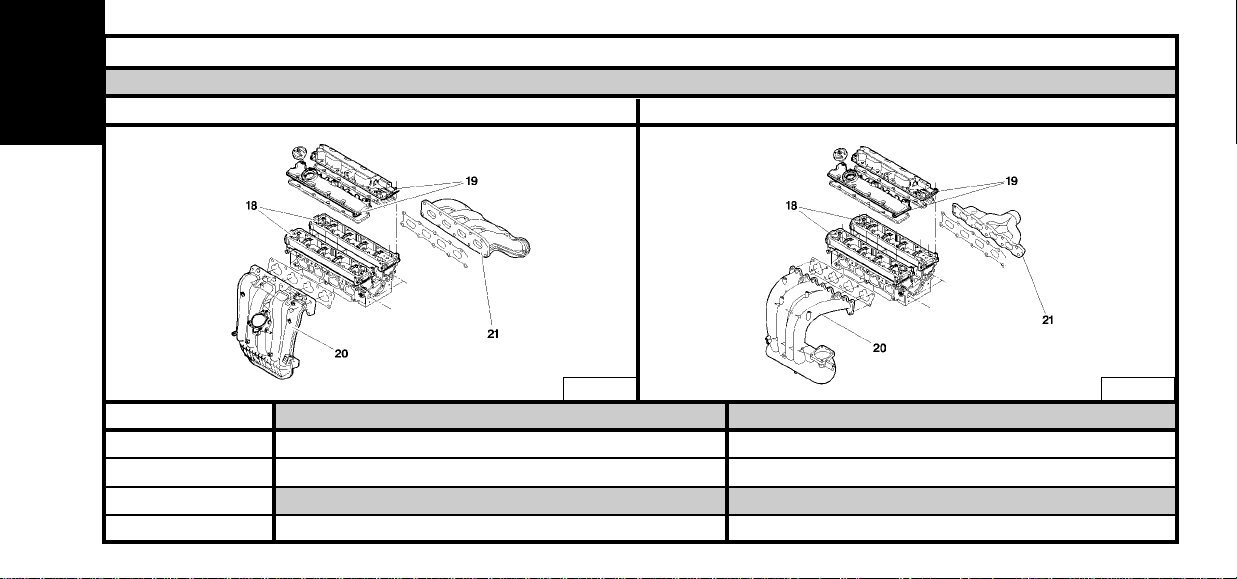

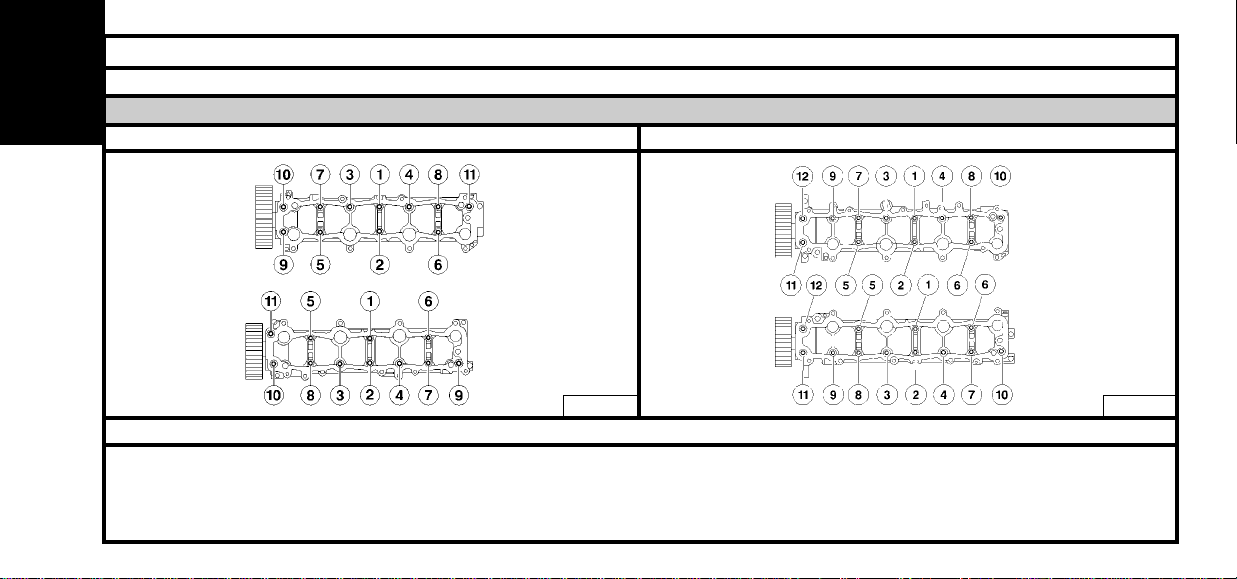

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Equipment on cylinder head

Engine : RFN Engine : 3FZ

12

B1BK1X9D B1BK1XAD

Description (18) Camshaft bearing cap covers (19) Valve covers

0.5 0.5

1 ± 0.1 1.5 ± 0.1

(20) Inlet manifold (21) Exhaust manifold

1 ± 0.1 3.5 ± 0.3

Pre-tightening

Tightening

Description

Tightening

ENGINE

Page 15

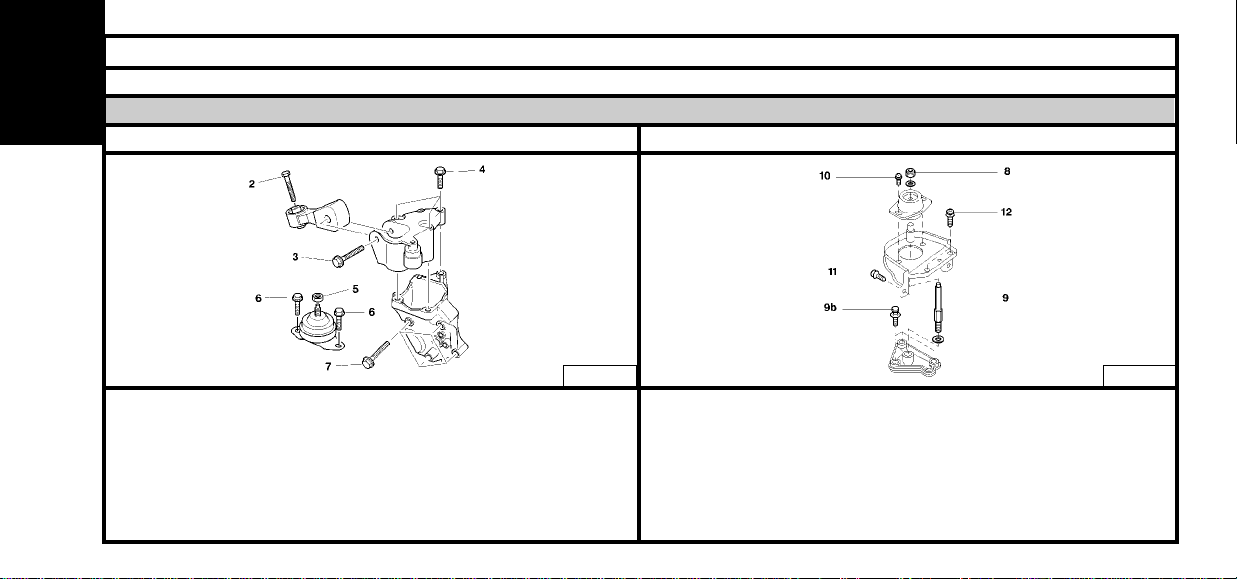

13

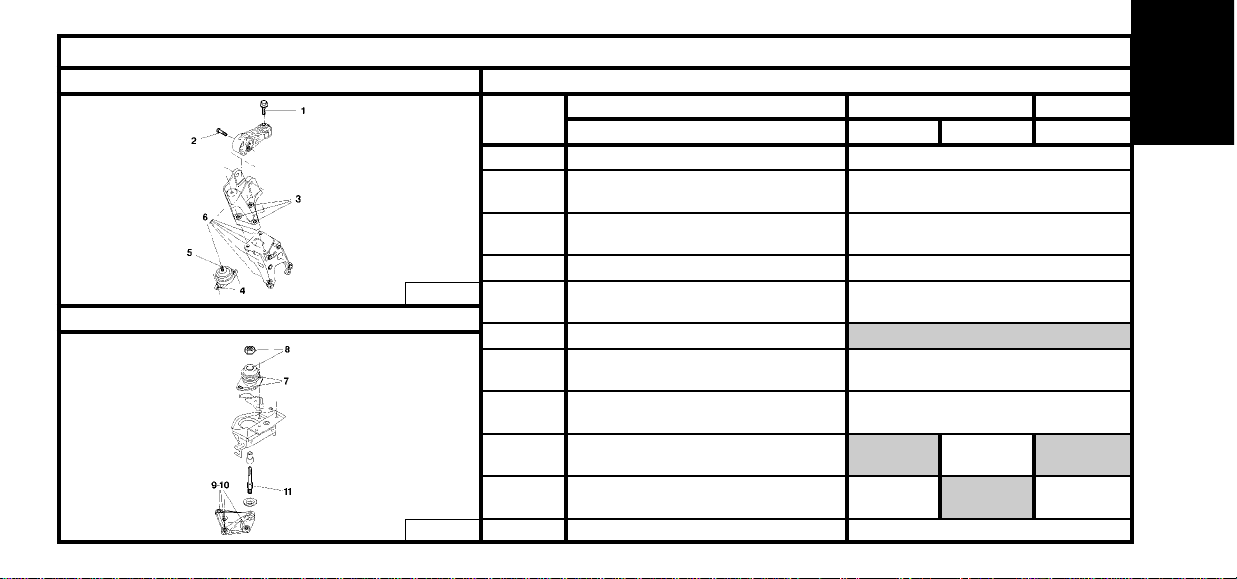

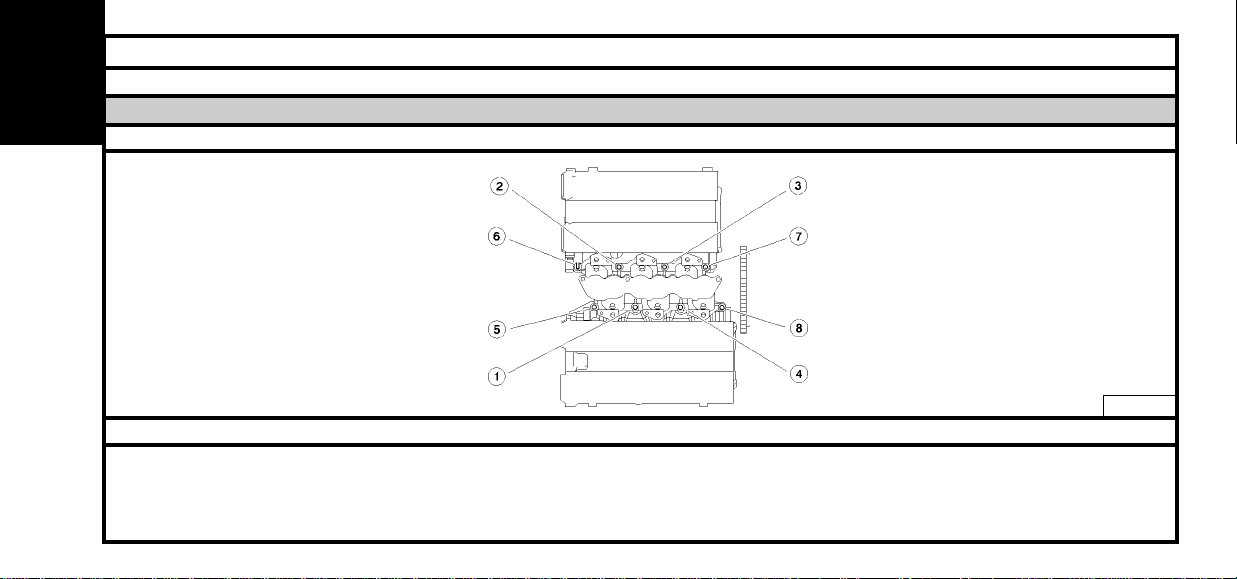

SPECIAL FEATURES: POWER UNIT SUSPENSION

Upper RH engine support Engines : RFN – 3FZ

Description RFN 3FZ

Gearbox type

Rod/body fixing screw..(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Engine support/torque reaction rod

flexible stop pin

Upper support/intermediate

support fixing screw.

Upper support/body fixing screw

Upper support/flexible

support fixing nut.

Support

LH flexible support/LH engine

support fixing nut.

LH flexible support/body

fixing screw.

Intermediate engine support/gearbox

casing fixing screw.

LH intermediate support/gearbox

fixing screw.

Flexible support pin.

BE4/5 AL4

5 ± 0.5

4.5 ± 0.4

6.5 ± 0.6

3 ± 0.3

4.5 ± 0.4

6.5 ± 0.6

3 ± 0.3

4.5 ± 0.4

5 ± 0.5

6 ± 0.6 4.5 ± 0.4

ML5C

Intermediate engine support

B1BK1X5D

B1BK1X6D

Ref.

ENGINE

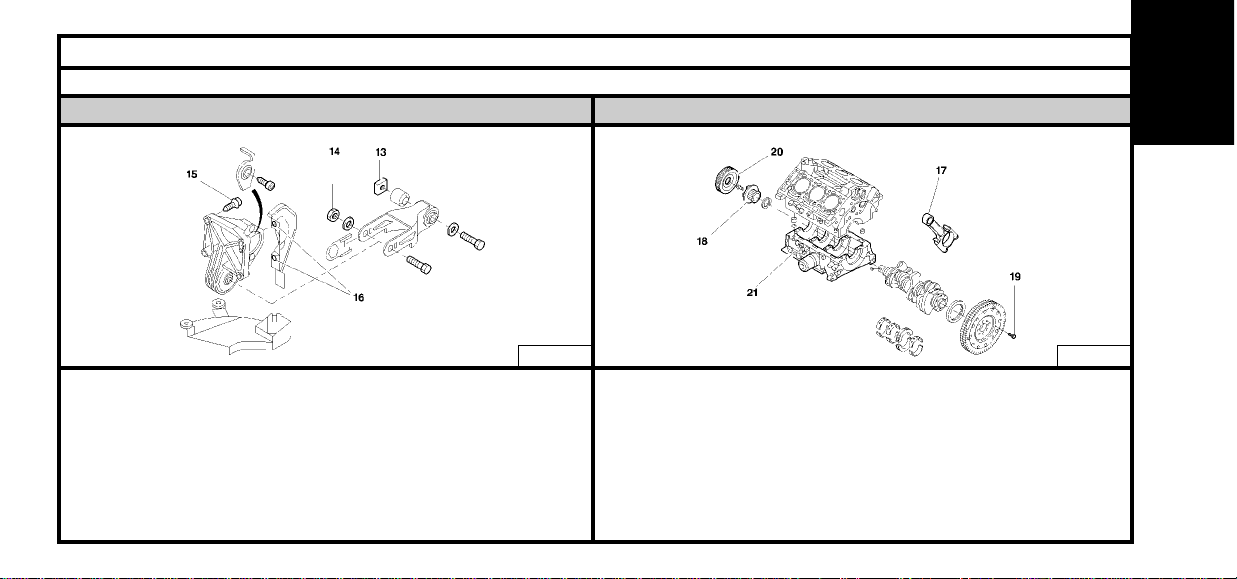

Page 16

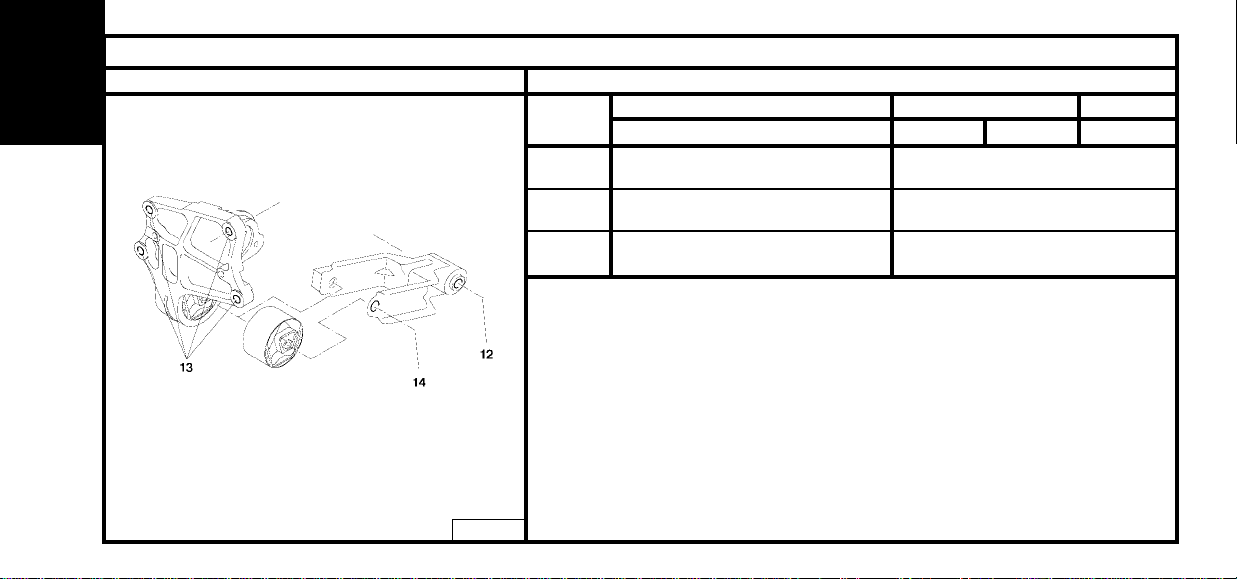

14

SPECIAL FEATURES: POWER UNIT SUSPENSION

Intermediate engine support Engines : RFN – 3FZ

Description RFN 3FZ

Gearbox type

(12)

(13)

(14)

Lower RH rod/subframe

fixing screw.

Lower RH engine support/cylinder

block fixing screw.

Lower rod/lower RH engine

support fixing screw

BE4/5 AL4

9 ± 0.9

4.5 ± 0.4

6.5 ± 0.6

ML5C

B1BK1X7D

Ref.

ENGINE

Page 17

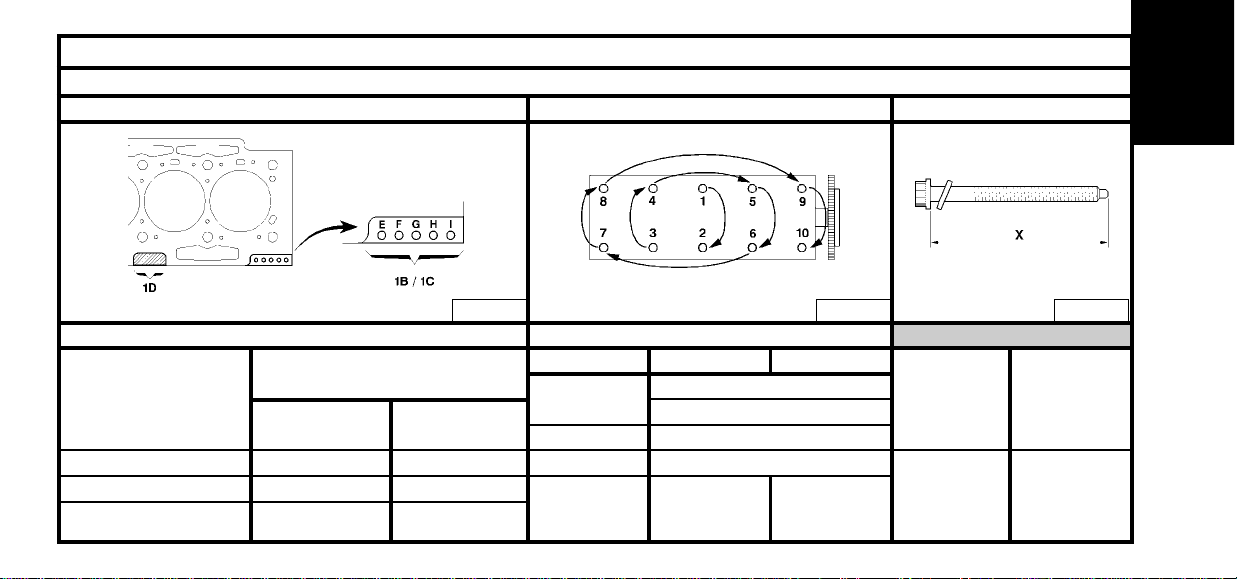

15

CYLINDER HEAD

Engines : RFN – 3FZ

Cylinder head gasket identification Cylinder head tightening (m.daN) Cylinder head bolts

(1D) : Manufacturer

identification.

Angular

tightening

Tightening

Slackening

Pre-tightening

285°

2

360°

2/ : 5

1/ : 1.5

3FZ

RFN

RFN

Tighten in the order indicated

X = MAXI re-usable

270°

(1C) : Repair dimension

E – F – H =0.99 E – F – G sans

E – H = 0.8 E – G = 0.8

RFN 3FZ

Cylinder head gasket thickness

(mm)

Ref.

Multi-layer metallic gasket.

(1B) : Nominal dimension

3FZ

144.5 mm 127.5 mm

B1BK24QD B1DK001C B1DB002C

ENGINE

Page 18

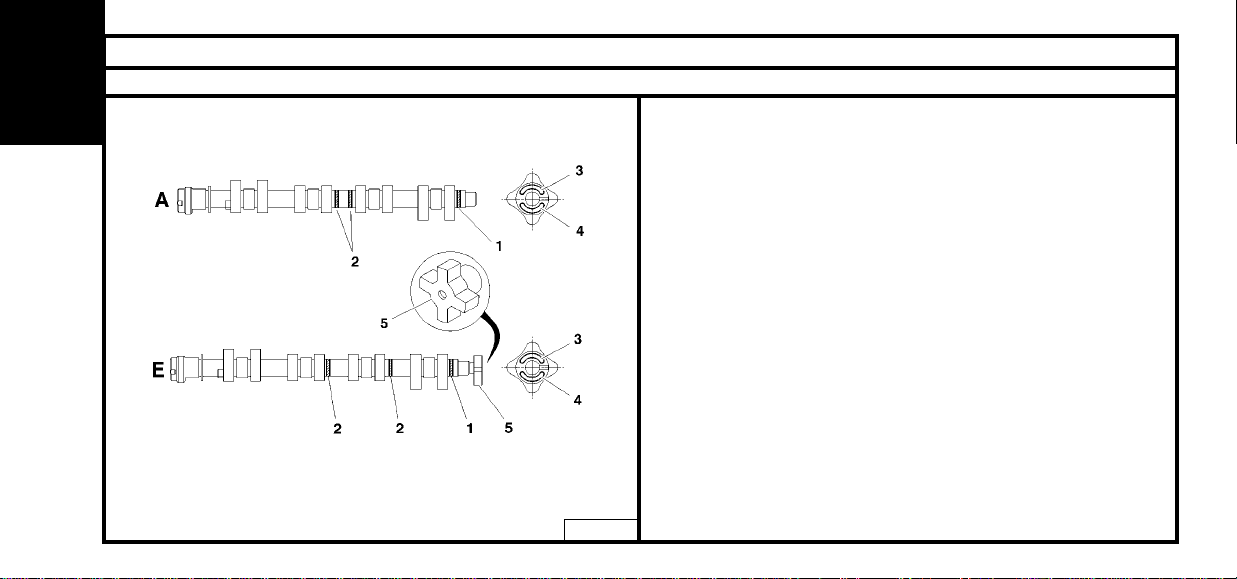

SPECIAL FEATURES: VALVE TIMING

Engines : RFN - 3FZ

The camshafts are referenced following two methods.

- (1) Marking position (2) Paint rings.

- (3) Marking position (4) Marking at end of shaft.

- (5) Target for camshaft position sensor.

Marking position:

(1) Paint ring : Repair reference.

(2) Green paint ring : Factory reference.

(3) Inlet D1309 : Exhaust D1348.

(4) Inlet 96 332 713 99 : Exhaust 96 3425433 99.

Timing belt.

Width : 25.4 mm

Number of teeth : 153

Material : HSN

Valve clearances when cold

Inlet (A) : NON adjustable

Exhaust (E) : NON adjustable

16

B1EK1UCD

ENGINE

Page 19

17

ENGINE SPECIFICATIONS

Engine : XFW

(A) Component reference.

(B) Engine legislation type.

(C) Factory serial no.

B1BK1JWD

ENGINE

Page 20

18

ENGINE

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Power unit suspension

Gearbox suspensionRH engine support (Suspension)

(2) Link rod fixing : 5 ± 0.5

(3) Link rod fixing : 4.5 ± 0.4

(4) Fixing of upper RH engine support on intermediate engine

support flexible mounting : 6 ± 0.6

(5) Fixing of RH engine support on flexible mounting : 4.5 ± 0.4

(6) Fixing of flexible mounting : 3 ± 0.3

(7) Fixing of RH intermediate engine support on cylinder block : 6 ± 0.6

(8) Fixing of gearbox support on LH flexible mounting : 6.5 ± 0.6

(9) Shaft : 6.5 ± 0.6

(10) Fixing of flexible mounting on support : 3 ± 0.3

(11) Fixing of flexible mounting support on body : 2.5 ± 0.2

(12) Fixing of flexible mounting support on body : 2.5 ± 0.2

B1BK24RD B1BK24SD

Page 21

19

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

CrankshaftPower unit suspension – Engine support (Lower)

(13) Torque reaction link rod fixing : 9 ± 0.9

(14) Fixing of link rod on torque reaction flexible mounting : 6.5 ± 0.6

(15) Fixing of torque reaction flexible mounting : 4.5 ± 0.4

(16) Fixing of heat shield on torque reaction flexible mounting : 1 ± 0.1

(17) Bearing cap Tightening : 2 ± 0.2

+ Angular tightening : 74° ± 7°

(18) Timing pinion Tightening : 4 ± 0.4

+ Angular tightening : 80° ± 8°

(19) Fixing of starter gear support flange, plus crankshaft

converter support Tightening : 2 ± 0.2

Angular tightening : 60° ± 6°

(20) Accessory pulley on timing pinion : 2.5 ± 0.2

B1BK24TD B1BK24UD

ENGINE

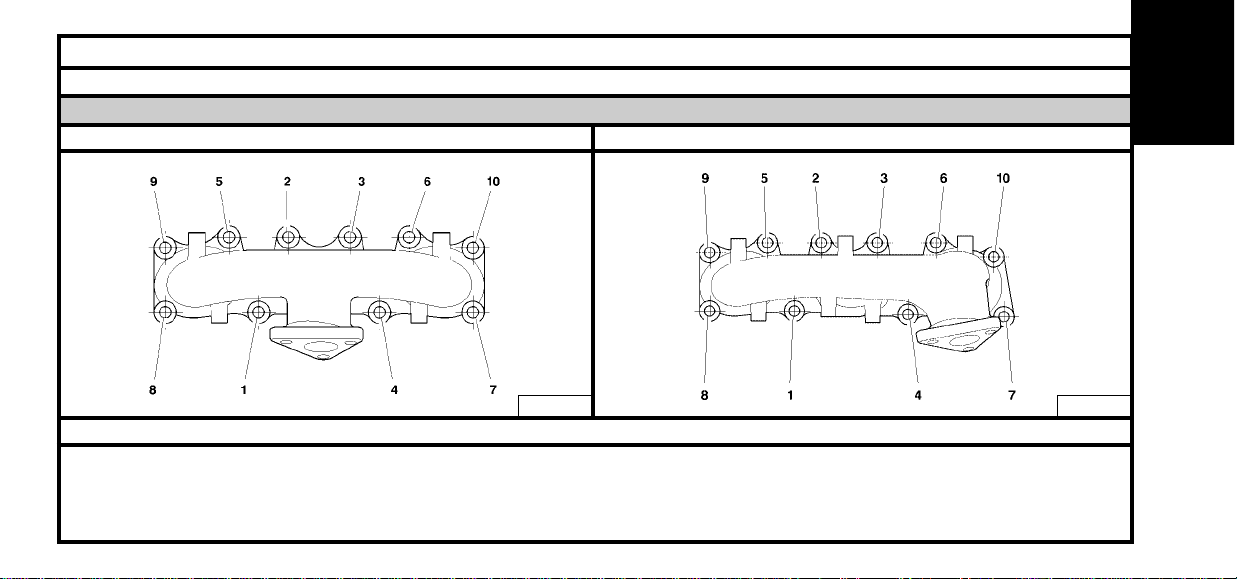

Page 22

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder block

Bearing cap cover

Respect the sequence of stages and the order of tightening

Reference/description

(21) Fixings of bearings/cap covers or

bearings/caps

21) Fixings of bearings/cap covers or

bearings/caps

(Slacken to zero torque

.)

(21) Fixings of bearing cap cover or

bearing caps (Tighten bolt by bolt

)

Tightening

+ Angular tightening

M11

Bolts from 1

to 8

Stage 1

3 ± 0.3

Stage 2

1 ± 0.1

Stage 3

1 ± 0.1

Stage 4

YES

Stage 4

YES

Stage 5

3 ± 0.3

180°

Stage 6

1 ± 0.1

180°

NO

M8

Bolts from 9

to 16)

M6

20

B1BK24VD

ENGINE

Page 23

21

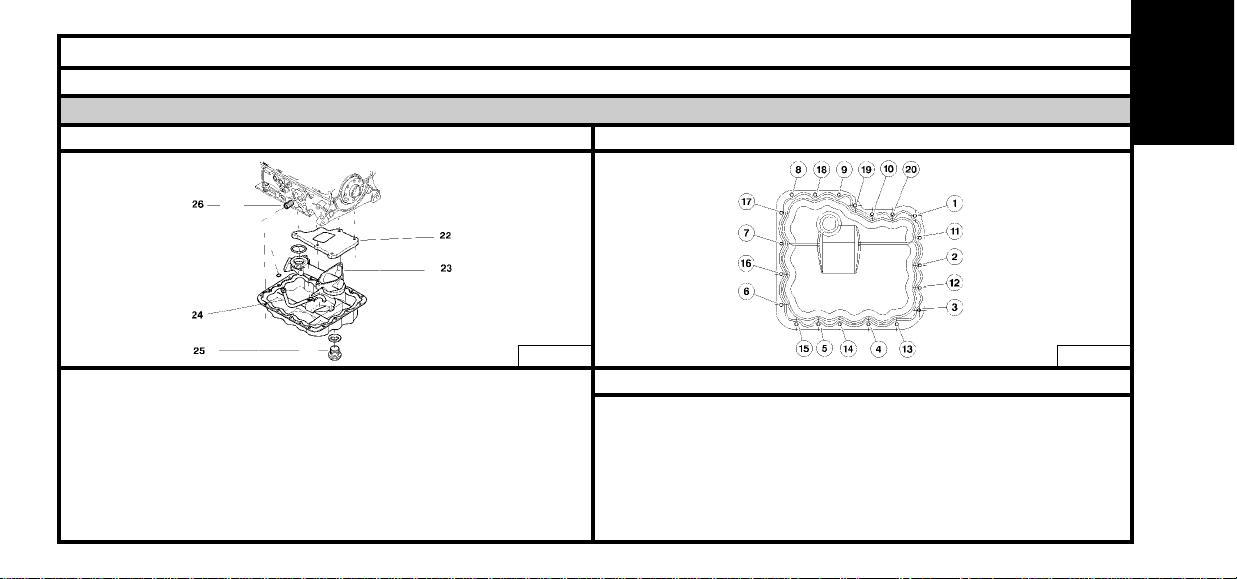

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Lubrication circuit

Oil sumpLubrication circuit.

(22) Oil separator : 0.8

(23) Strainer : 0.8

(24) Induction pipe : 0.8

(25) Drain plug : 3 ± 0.3

(26) Oil filter sleeve (with coolant/oil exchanger) : 0.5

Oil filter : 0.2

Stage 1 : Do up bolts 13,15 and 17.

Stage 2 : Tighten bolts 13,15 and 17 to : 0.2

Stage 3 : Do up the 17 remaining bolts.

Stage 4 : Tighten the remaining bolts to : 0.5

Stage 5 : Tighten all the bolts : 0.8

Stage 6 : Repeat the tightening a few times in the same order to obtain

a tightening torque of 0.8 m.daN on all the bolts.

B1BK24WD B1BK24XD

ENGINE

Respect the sequence of stages and the order of tightening

Page 24

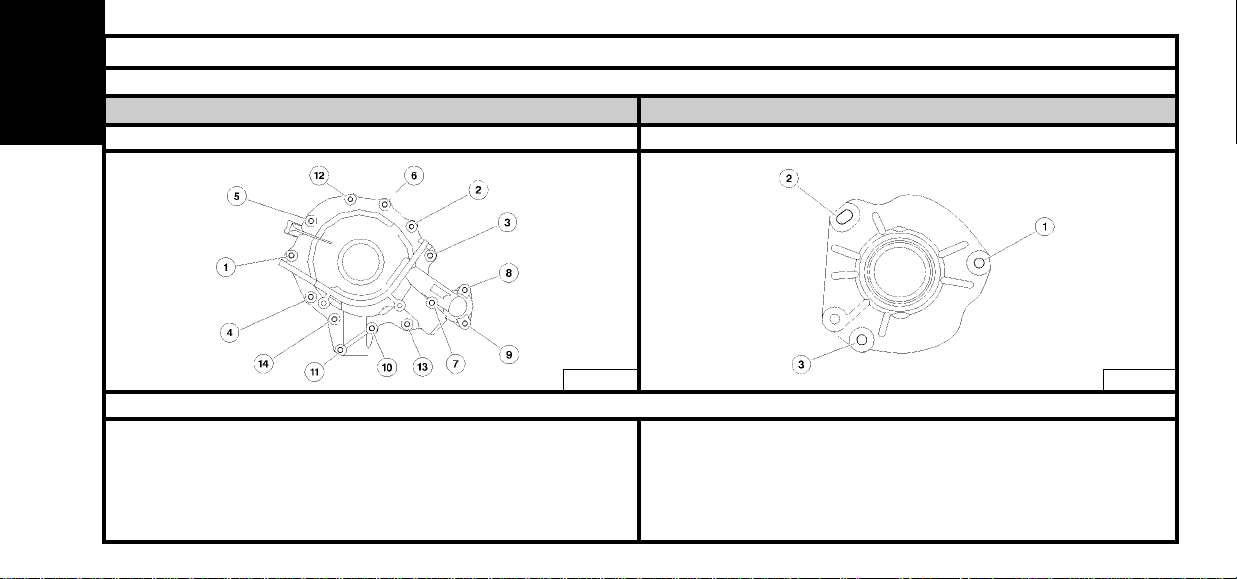

22

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cooling circuitLubrication circuit

Coolant pumpOil pump

Stage 1 : Position the screws and do them up by hand.

Stage 2 : Pre-tighten the screws : 0.5

Stage 3 : Tighten the screws : 0.8

Stage 4 : Repeat the tightening a few times in the same order to obtain

a tightening torque of 0.8 m.daN on all the screws.

Stage 1 : Position the screws and do them up by hand.

Stage 2 : Pre-tighten the screws : 0.5

Stage 3 : Tighten the screws : 0.8

Stage 4 : Repeat the tightening a few times in the same order to obtain a

tightening torque of 0.8 m.daN on all the screws.

B1BK3B6D B1BK3B7D

Respect the sequence of stages and the order of tightening

ENGINE

Page 25

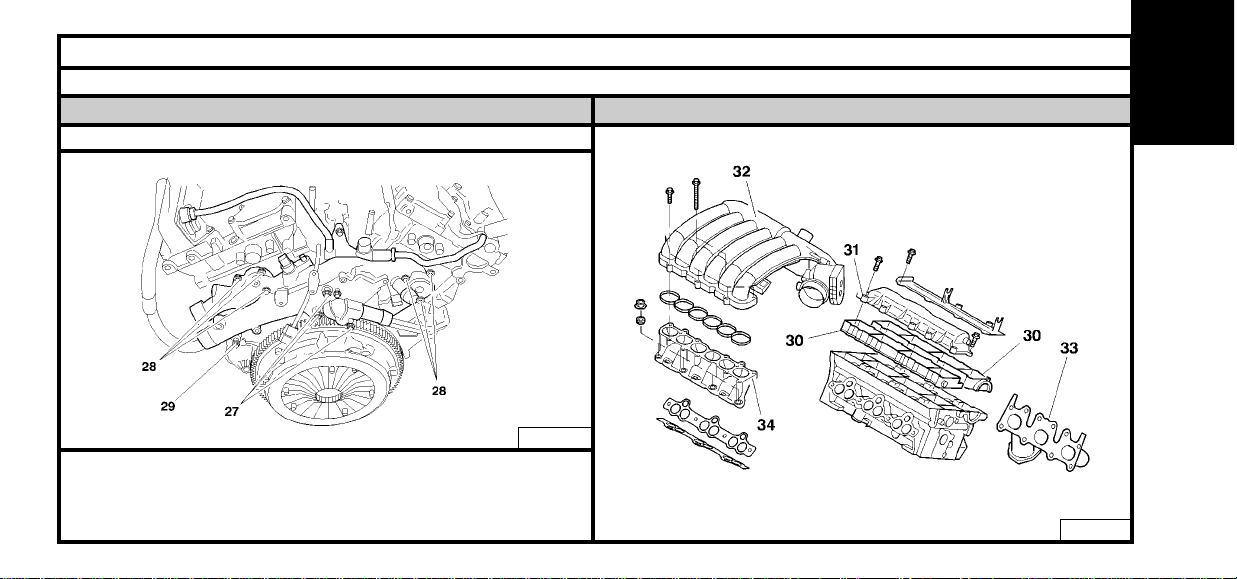

23

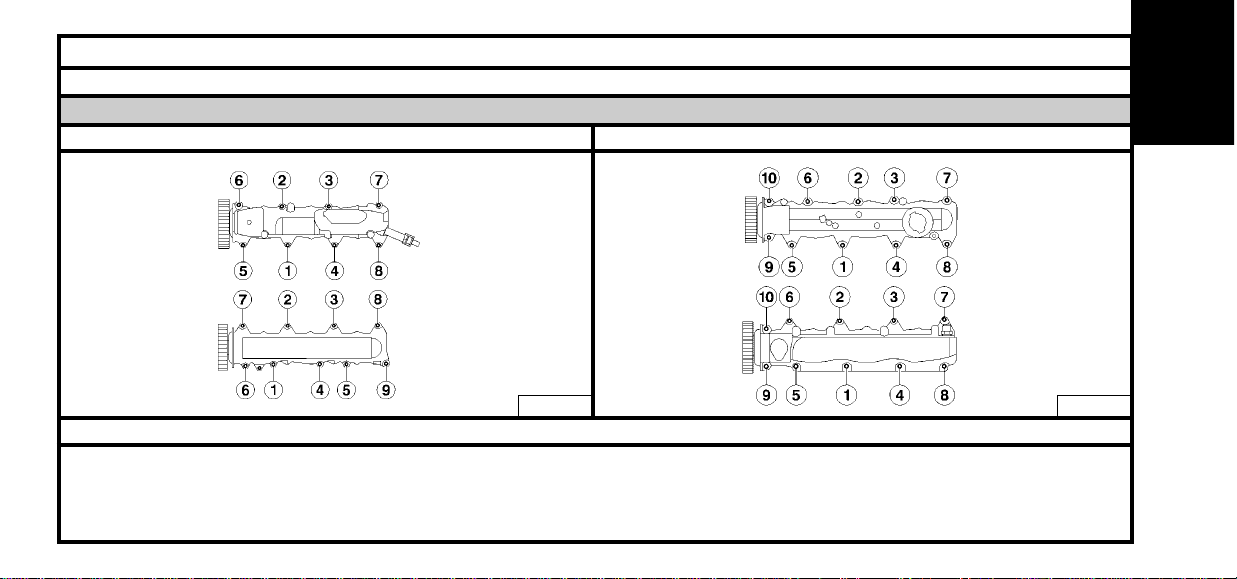

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipmentLubrication circuit

Coolant manifold

(27) Screws : 2.5 ± 0.2

(28) Screws : 0.8

(29) Screws : 0.8

B1BK24YD

B1BK24ZD

ENGINE

Page 26

24

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipment

Camshaft bearing cap cover (left hand side)Camshaft bearing cap cover (right hand side)

(30) Camshaft bearing cap cover or camshaft bearing:

Pre-tighten to : 0.2

Tighten to : 1

B1EK0GCC B1BK3B8D

Respect the sequence of stages and the order of tightening

ENGINE

Page 27

25

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipment

Valve covers (left hand side)Valve covers (right hand side)

(31) Valve cover :

Pre-tighten to : 0.5

Tighten to : 0.8

B1EK0GEC B1EK0GFC

Respect the sequence of stages and the order of tightening

ENGINE

Page 28

26

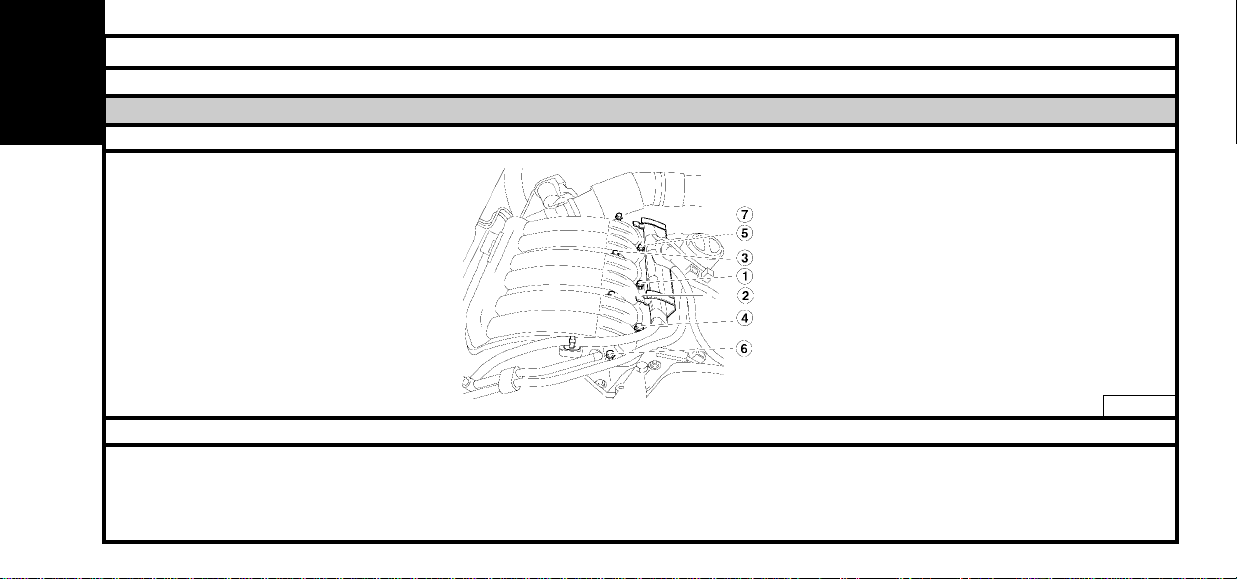

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipment

Inlet manifold

(32) Inlet manifold:

Pre-tighten to : 0.4

Tighten to : 0.8

B1BK251D

Respect the sequence of stages and the order of tightening

ENGINE

Page 29

27

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipment

Exhaust manifold (left hand side)Exhaust manifold (right hand side)

(33) Exhaust manifold:

Pre-tighten to : 1

Tighten to : 3 ± 0.3

B1JK03ND B1JK03LD

Respect the sequence of stages and the order of tightening

ENGINE

Page 30

28

SPECIAL FEATURES : TIGHTENING TORQUES (m.daN)

Engine : XFW

Cylinder head equipment

Inlet distributor

(34) Inlet distributor:

Pre-tighten to : 0.4

Tighten to : 0.8

B1BK252D

Respect the sequence of stages and the order of tightening

ENGINE

Page 31

29

ENGINE

CYLINDER HEAD

Engine : XFW

Identification of cylinder head gaskets

The RH and LH cylinder head gaskets are specific, of multilayer metallic type.

Cylinder head gasket thicknesses

(1A) : Engine ref : G-H

(1B) : Nominal dimension: Without marking = 0.75 mm

(1C) : CRepair dimension : E (1st repair dimension R1) = 0.95 mm

(1C) : Repair dimension: E-F (2nd repair dimension R2) = 1.15 mm

(a) : RH cylinder head gasket.

(b) : LH cylinder head gasket.

V : Engine flywheel side.

B1DK0QKD B1DK0QLD

Respect the sequence of stages and the order of tightening

Page 32

B1DK0QPD

30

CYLINDER HEAD

Engine : XFW

Cylinder head tightening (m.daN) Cylinder head bolts

X = MAX. re-usable

Pre-tightening : 2

Slackening : YES

Tightening : 1.5

Angular tightening : 225°

NOTE : Grease the bolts on the

threads and under the heads,

using engine oil or Molykote G

plus).

149.5 mm

B1EK0XAD

ENGINE

Page 33

31

ENGINE

CYLINDER HEAD

Engine : XFW

Identification of camshafts

The camshafts are identified by the following references:

(1) Exhaust camshaft E389 (Front)

(2) Inlet camshaft. A423 (Front)

(3) Inlet camshaft. A422 (Rear)

(4) AExhaust camshaft E388 (Rear)

A=Inlet camshaft

E = Exhaust camshaft

B1EK0WVD

Timing belt

Width: 32 mm Number of teeth: 259

Page 34

32

CYLINDER HEAD

Engines : RHT – RHW - 4HW

Identification of cylinder head gasket Cylinder head tightening (m.daN) Cylinder head bolts

X = MAX. re-usable

Tighten in the order indicated

Pre-tightening : 1/ 2

2/ 6

Slackening : 360°

Tightening : 1/ 2

2/ 6

Angular tightening : 220°

B1DK1M6D

RHT - RHW 4HW

134 mm 134.5 mm

B1DK00SCB1DK0Q6C

ENGINE

NOTE : Grease the bolts on

the threads and under the

heads, using engine oil or

Molykote G plus).G Plus)

0.55 to 0.60 1.25 ± 0.04 0 1 1

0.61 to 0.65 1.30 ± 0.04 0 1 2

0.66 to 0.70 1.35 ± 0.04 0 1 3

0.71 to 0.75 1.40 ± 0.04 0 1 4

Piston

stand-proud

(mm)

Thickness

(mm)

RHT

RHW

4HW

Hole at

G

Hole at F

Page 35

33

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engines : RFN-3FZ

Tools

[1] Peg for dynamic tensioner roller (-).0189-E

Removing.

Remove:

The front RH wheel.

The front RH splash-shield.

Detension the auxiliary drive belt by actioning the screw (1).

Peg the dynamic tensioner roller (2), using tool [1].

Remove the auxiliary drive belt.

ESSENTIAL : Check that the rollers (3) and (4) turn freely (no tight spot).

Refitting.

Refit the auxiliary drive belt.

Check that the auxiliary drive belt is correctly positioned in the grooves of the various pulleys.

Remove tool [1].

Continue the refitting operations in reverse order to removal.

BXXK08DD

BXXK0AUD

Page 36

34

AUXILIARY EQUIPMENT DRIVE BELT

Engine : XFW

Tools

[1] Ratchet spanner FACOM (1/2" square).

[2] Reduction box FACOM S.230 (1/2" - 3/8" square).

Removing.

Move aside the power steering oil low pressure pipe flange.

Pivot the support (1) of the tensioner roller clockwise, as far as it will go, using tools [1] and [2].

Remove the auxiliary drive belt.

IMPERATIVE : Check the operation of the rollers (no play, no tight spot).

Refitting.

Position the auxiliary drive belt.

Commence with the crankshaft pulley (2).

Finish with the tensioner roller (3).

Free the support (1) of the tensioner roller, pivoting it anti-clockwise, using tools [1] and [2].

ESSENTIAL : Check that the belt is correctly positioned in the grooves of the various pulleys.

Continue the refitting operations in reverse order to removal.

B1EK0VAD

B1EK0VBD

ENGINE

Page 37

35

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine : RHT - RHW

Tools.

[1] Tensioning lever : (-).0188-J2.

[2] Peg for dynamic roller Ø 4 mm : (-) 0188-Q1.

[3] Peg for dynamic roller Ø 2 mm : (-).0188-Q2.

[4] Dynamic roller compression lever : (-).1888-Z.

(A) Pegging hole.

(B) Belt wear check mark (fixed on engine).

(C) Zero wear mark.

(D) Maximum wear mark.

This marking system permits checking of the belt wear; if the marks (D) and (B) coincide, it implies that the belt

requires replacing.

Tighten the screw (1) to 4.5 ± 0.4 m.daN.

Removing

Remove:

- The front RH wheel.

- The front RH splash-shield.

- The under-engine shield.

IMPERATIVE : Mark the direction of rotation of the belt if to be re-used.

E5AK0E9C

B3EK0DHD

Page 38

36

AUXILIARY EQUIPMENT DRIVE BELT

Engine : RHT - RHW

Removing (continued).

Slacken the fixing (2).

Action the roller (3), using tool [1], until the tool [2] is positioned in the pegging hole (A).

Bring the roller (3) back towards the rear.

Gently tighten the screw (2).

Remove the belt.

ESSENTIAL : Check that the rollers (3) and (4) turn freely (no play, no tight spot).

Refitting.

IMPERATIVE: If re-using the belt, refit it respecting the direction of rotation marked on removal.

Refit the belt, finishing with the tensioner roller (4).

Action the roller (3), using tool [1] (clockwise) to free the tool [2].

Tighten the fixing (2) to 4.5 ± 0.5 m.daN, without altering the position of the roller.

ESSENTIAL : Check that the belt is correctly positioned in the grooves of the various pulleys.

Remove the tool [1].

Rotate the engine four times.

Check that the marks (B) and (C) coincide.

Tool [3] should be able to engage freely, if not, repeat the adjustment.

Complete the refitting.

B1BK1A4C

ENGINE

Page 39

37

AUXILIARY EQUIPMENT DRIVE BELT

Engine : 4HW

Tools.

[1] Peg for dynamic roller : (-) 0188-Q1

[2] Dynamic roller compression lever : (-).1888-Z.

(A) Pegging hole.

(B) Belt wear check mark (fixed on engine).

(C) Zero wear mark.

(D) Maximum wear mark.

This marking system permits checking of the belt wear; if the marks (D) and (B)

coincide, it implies that the belt requires replacing.

Tighten the screw (1) to 4.5 ± 0.4 m.daN.

Removing.

Remove:

- The front RH wheel.

- The front RH splash-shield.

- The under-engine shield.

IMPERATIVE : Mark the direction of rotation of the belt if to be re-used.

E5AK0EDC

E5AK0E8C

B3EK09PC

ENGINE

Page 40

38

AUXILIARY EQUIPMENT DRIVE BELT

Engine : 4HW

Removing (continued).

Action the roller (3), using tool [2], until the tool [1] is positioned in the pegging hole (A).

Remove the belt.

ESSENTIAL : Check that the rollers (3) and (4) turn freely (no play, no tight spot).

Refitting.

IMPERATIVE: If re-using the belt, refit it respecting the direction of rotation marked on removal.

Refit the belt, finishing with the tensioner roller (3).

ESSENTIAL : Check that the belt is correctly positioned in the grooves of the various pulleys.

Rotate the engine four times.

Complete the refitting.

B1BK1IWD

ENGINE

Page 41

39

ENGINE

Tools

BELT TENSION/SEEM UNITS CORRESPONDENCE TABLE

! 4099-T (C.TRONIC.105)

4122-T (C.TRONIC.105.5)

!

!

!

B1EP135D

Page 42

40

AUXILIARY EQUIPMENT DRIVE BELT

Engines : All Types Petrol and Diesel

TOOLS

Belt tension measuring instrument : 4122 - T .(C.TRONIC 105.5)

WARNING : If using tool 4099-T (C.TRONIC 105), refer to the correspondence table on page 39.

ESSENTIAL:

Before refitting the auxiliary equipment drive belt, check that:

- 1 / The roller(s) rotate freely (no play or stiffness)

- 2 / The belt is correctly engaged in the grooves of the various pulleys.

ENGINE

Page 43

41

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Tools.

[1] Crankshaft setting peg : (-).0189-B

[2] Camshaft hub setting pegs : (-).0189-AZ

[3] Belt retaining pin : (-).0189-K

[4] Positioning peg : (-).0189-J

[5] Tool for immobilising hub : (-).6310-T

Removing.

Disconnect the battery.

Remove:

- The under-engine shield.

- The auxiliary drive belt (see corresponding operation).

Move aside:

- The fuel delivery pipe.

- The canister purge electrovalve.

- The expansion chamber.

Remove:

- The screws (1) and (2).

- The torque reaction rod (3).

- The screws (4), plus the auxiliary drive pulley.

- The timing covers (5) and (6).

WARNING : Do not slacken the fixing screws (A).

B1EK1UDD

B1EK1T7D

B1EK0V7D

Page 44

42

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Removing (continued).

Peg :

- The camshafts, using tool [2].

- The crankshaft, using tool [1].

Slacken the screw (7) while holding tool [4].

Using the hexagonal recess (C), turn the eccentric hub (8) of the tensioner roller

(9) (clockwise), to detension the belt. The cursor (10) moves against the tool [4].

Remove the timing belt.

B1EK1UED

B1EK1UFD

ENGINE

Page 45

43

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Refitting.

Systematically replace the timing belt.

IMPERATIVE : Check that the rollers (9) and (11), as well as the coolant pump (12) turn freely (no

tight spot).

When replacing the belt (11), tighten the fixing to 3.5 ± 0.3 m.daN.

Position the belt on the crankshaft pinion (13), respecting its direction of fitting.

Immobilise the belt, using tool [3].

Refit the timing belt, well-tensioned, in the following sequence:

- Guide roller (11).

- Pinions (14) and (15).

- Coolant pump (12).

- Tensioner roller (9).

B1EK1T8D

ENGINE

Page 46

44

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Tensioning the timing belt.

Remove tool [3].

(D) : Max. position.

(E) : Nominal tension position.

Using the hexagonal recess (C), turn the roller hub (anti-clockwise), to bring the index (10) to position (D) to

tension the belt to the maximum.

Turn the eccentric hub (8) of the roller (9) (clockwise), to bring the cursor (10) into light contact with the peg [4].

IMPERATIVE : Never make a complete rotation of the eccentric hub (8) when tool [4] is in position.

NOTE : This operation places the index (10) in the nominal position (E).

Tighten the screw (7) to 2 ± 0.2 m.daN while holding the roller by means of the hexagonal recess (C).

Remove the pegs [1], [2] and [4].

Checks.

Make two rotations of the crankshaft (direction of rotation of the engine).

IMPERATIVE : Never turn the crankshaft backwards.

Make sure that the timing is correctly set, by refitting the pegs [1] and [2].

Remove the pegs [1] and [2].

Make ten rotations of the crankshaft (direction of rotation of the engine).

Check the position of the index (10).

If the tensioner index is not in its adjustment position (E), recommence the operations to tension the timing belt.

B1EK1T9D

B1EK1TAD

ENGINE

Page 47

45

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Positioning the crankshaft.

NOTE : This operation positions all the pegs in their respective pegging points.

Peg:

- The camshaft pulleys, using tool [2].

- The crankshaft, using tool [1].

If this is not possible, reposition the flange (17).

IMPERATIVE : This operation guarantees the setting of the timing for subsequent operations.

Slacken the screw (16) so as to free the crankshaft pinion (17).

Bring the flange (17) to the pegging point, using tool [5].

Position tool [1].

Tightening of screw (16) (Tool FACOM D360).

Tighten to : 4 ± 0.4 m.daN

Angular tighten to : 53°±5°.

Remove tools [1], [2] and [5].

IMPERATIVE : When tightening screw (16), hold the pulley (17) in position, using tool [5].

B1EK1TBD

B1EK1TCD

ENGINE

Page 48

46

CHECKING AND SETTING THE VALVE TIMING

Engine : RFN

Refitting (continued).

Refit:

- The timing cover (6).

- The auxiliary drive pulley.

- The screws (4), tighten to 2.1 ± 0.2 m.daN.

- The timing cover (5).

- The torque reaction rod (3).

- The screws (1) and (2), tighten to 4.5 ± 0.4 m.daN.

Refit the auxiliary drive belt (see corresponding operation).

Continue the refitting operations in reverse order to removal.

B1EK0V7D

B1EK1T7D

ENGINE

Page 49

47

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

Tools.

[1] Crankshaft setting peg : (-).0189-B

[2] Exhaust camshaft setting peg : (-).0189-AZ

[3] Inlet camshaft setting peg : (-).0189-L

[4] Positioning peg : (-).0189-J

[5] Tool for immobilising hub : 6310-T

[6] Belt retaining pin : (-).0189.K

[7] Engine support crossmember : 4090-T

Removing.

Disconnect the battery.

Remove:

- The under-engine shield.

- The auxiliary drive belt (see corresponding operation).

Uncouple the exhaust line (to avoid damaging the flexible pipe).

Position the tool [7].

Move aside:

- The fuel delivery pipe.

- The canister purge electrovalve.

- The expansion chamber.

B1EK0V1D

B1EK1SJD

B1EK1SLD

ENGINE

Page 50

48

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

Remove:

- The screws (1) and (2).

- The torque reaction rod (3).

- The nut (4).

- The 3 screws (5).

- The RH engine support (6).

- The screws (7), plus the auxiliary drive pulley.

- The timing covers (8) and (9).

WARNING : Do not slacken the fixing screws (A).

IMPERATIVE : Do not slacken the fixing screws (B).

Peg:

- The exhaust camshaft, using tool [2].

- The inlet camshaft, using tool [3].

- The crankshaft, using tool [1].

B1EK1SUD

B1EK1SKD

B1EK1SMD

ENGINE

Page 51

49

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

Position tool [4].

Slacken the screw (10) while holding tool [4].

Using the hexagonal recess (D), turn the eccentric hub (11) of the tensioner roller (12) (clockwise), to detension

the belt. The cursor (13) moves against the tool [4].

Remove the timing belt.

Refitting.

Systematically replace the timing belt.

IMPERATIVE : Check that the rollers (12) and (14), as well as the coolant pump (15) turn freely (No play,

no tight spot).

When replacing the belt (14), tighten the fixing to 3.5 ± 0.3 m.daN.

Position the belt on the crankshaft pinion (16), respecting its direction of fitting.

Immobilise the belt, using tool [6].

Refit the timing belt, well-tensioned, in the following sequence:

- Guide roller (14).

- Pinion (17).

- Pinion (18).

- Coolant pump (15).

- Tensioner roller (12).

B1EK1SMD

B1EK1SND

ENGINE

Page 52

50

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

Tensioning the timing belt.

Remove tool [6].

(E) : Max. position.

(F) : Nominal tension position.

Using the hexagonal recess (D), turn the roller hub (anti-clockwise), to bring the index (13) to position (E) to tension the belt to the maximum.

Turn the excentric hub (11) of the roller (12) (clockwise), to bring the cursor (13) into light contact with the tool [4].

IMPERATIVE : Never make a complete rotation of the eccentric hub (11) when tool [4] is in tension.

NOTE : This operation places the index (13) in the nominal position (F).

Tighten the screw (10) to 2 ± 0.2 m.daN while holding the roller by means of the hexagonal recess (D).

Remove the tools [1], [2], [3], and [4].

Checks.

Make two rotations of the crankshaft (direction of rotation of the engine).

IMPERATIVE : Never turn the crankshaft backwards.

Make sure that the timing is correctly set, by refitting the camshaft and crankshaft setting pegs.

Remove the pegs.

Make ten rotations of the crankshaft (direction of rotation of the engine).

Check the position of the index (13).

If the tensioner index is not in its adjustment position (F), recommence the operations to tension the timing belt.

B1EK1SPD

B1EK1SQD

ENGINE

Page 53

51

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

Positioning the crankshaft.

NOTE : This operation positions all the pegs in their respective pegging points.

Peg:

- The inlet camshaft pulley, using tool [3].

- The crankshaft, using tool [1].

If this is not possible, reposition the flange (20).

IMPERATIVE : This operation guarantees the setting of the timing for subsequent operations.

Immobilise the crankshaft, using tool [5].

Slacken the screw (19) so as to free the crankshaft pinion (16).

Bring the flange (20) to the pegging point, using tool [5].

Position tool [1].

Tightening of screw (19) (Tool FACOM D360).

Tighten to : 4 ± 0.4 m.daN

Angular tighten to : 53°±5°.

Remove tools [1], [3] and [5].

B1EK1SRD

B1EK1SSD

ENGINE

Page 54

52

CHECKING AND SETTING THE VALVE TIMING

Engine : 3FZ

B1EK1STD

B1EK1SUD

ENGINE

Refitting (continued).

Refit:

- The timing cover (9).

- The auxiliary drive pulley.

- The screws (7), tighten to 2.1 ± 0.2 m.daN.

- The timing cover (8).

- The RH engine support (6).

- The torque reaction rod (3).

Tighten:

- Screws (5) to 6 ± 0.6 m.daN

- Nut (4) to 4.5 ± 0.4 m.daN

- Screws (1) and (2) to 4.5 ± 0.4 m.daN

Refit the auxiliary drive belt (see corresponding operation).

Continue the refitting operations in reverse order to removal.

Page 55

53

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

Tools.

[1] Camshaft setting pegs : (-).0187-B

[2] Crankshaft setting peg : (-).0187-A

[3] Belt retaining pin : (-).0187-J

[4] Peg for checking camshaft settings : (-).0187-CZ

[5] Tool for immobilising inlet camshaft hubs : (-).0187-C

[6] Tool for immobilising exhaust camshaft hubs : (-).0187-F

[7] Instrument for measuring belt tension : (-).0192

Removing.

Remove:

The front RH wheel

The RH wheelarch.

The front RH tie-bar.

The auxiliary drive belt (see corresponding operation).

The tensioner roller assembly (1).

The crankshaft pulley (2).

Support the engine using a stand.

Remove:

The upper RH torque reaction rod.

The RH engine support.

B1EK004D

ENGINE

Page 56

54

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

Removing (continued).

Remove:

The twelve screws (3) (6 mm external hexagonal adaptor).

The seven screws (4) (7 mm external hexagonal adaptor).

The two covers (5).

The cover (6).

The fixing screws of the power steering pump, then suspend the latter.

The support (7).

NOTE : The camshaft pegging operation can be performed without slackening the

pinion screws or rotating the camshafts (using tools [5] and [6]; lightly oil the pegs

[1] and [2] prior to fitting.

Peg in the sequence:

Camshafts, using tool [1].

Crankshaft, using tool [2].

B1EK005D

B1EK006D

B1EK007D

ENGINE

Page 57

55

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

Removing (continued).

Remove screw (8).

Slacken screws (9) and (10) and nut (11).

Pivot the tensioner roller eccentric (clockwise), using tool FACOM R 161 at «B».

Remove the guide roller (12).

Remove the timing belt, commencing with the tensioner roller and the coolant pump.

Refitting.

Make sure that the camshafts, as well as the crankshaft, are correctly pegged.

Check that the rollers (13) and (14), as well as the coolant pump (15) turn freely (no tight

spots).

If replacing the belt, tighten the rollers (13) and (14) to 8 ± 0.8 m.daN.

Slacken screws (16) by a 1/4 turn.

Ensure that the camshaft pinions rotate freely on their hubs.

Turn the four camshaft pinions (clockwise), to end of slots.

Engage the timing belt on the crankshaft pinion.

Immobilise the belt, using tool [4].

B1EK009D

B1EK008D

ENGINE

Page 58

56

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

Refitting (continued).

Position the belt on the guide roller (13), belt at (C) well tensioned.

NOTE : Carefully turn the camshaft pinion in the opposite direction to the rotation of the

engine in order to engage the belt on the pinion.

Engage the belt on the LH exhaust camshaft pinion (17).

IMPERATIVE : The angular displacement value of the pinion relative to the timing

belt should not be greater than the width of one tooth.

Engage the belt on the LH inlet camshaft pinion (18), as before.

Refit the roller (12), tighten to 8 ± 0.8 m.daN.

B1EK00BD

B1EK00AD

ENGINE

Page 59

57

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

Refitting (continued).

Engage the belt on:

The roller (13).

The camshaft pinions, inlet (19) then RH exhaust (20), as before for the camshafts.

Simultaneously engage the belt on:

The roller (21).

The pump (15).

The roller (14).

Using tool FACOM S.161, at «A», pivot the plate to be able to engage the screw (8).

Tighten screws (8), (9) and (10) to 2.5 ± 0.2 m.daN.

Pivot the tensoner roller to tension the belt to the maximum (anti-clockwise), using tool FACOM R.161 at «B» :

- SEEM CTI 901-1 : 440 ± 15 SEEM units,

- SEEM CTG 105.5 : 83 ± 2 SEEM units,

- SEEM CTG 105.6 : 86 ± 2 SEEM units.

Tighten the nut (11) of the tensioner roller to 1 ± 0.1 m.daN.

IMPERATIVE : Check that the camshaft pinions are not at end of slots (by removing a screw).

If they are, repeat the operation to refit the belt.

B1EK00CD

B1EK00DD

ENGINE

Page 60

58

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

B1EK0VRD

B1EK00ED

ENGINE

Refitting (continued).

Tighten at least two screws (16) per hub to 1 ± 0.1 m.daN, in the order indicated (17),(18),

(19) and (20).

Remove tools [4], [7], [1] and [2].

Effect two rotations of the crankshaft (direction of rotation of the engine).

WARNING : Never rotate the engine backwards.

Peg the crankshaft, using tool [2].

Slacken the nut (11) a 1/4 turn.

Align the marks (D) and (E) of the tensioner roller, using tool FACOM R.161.

Tighten the nut (11) to 2.5 ± 0.2 m.daN, without altering the position of the roller.

Remove the crankshaft setting peg [2].

Effect two rotations of the crankshaft.

WARNING : Never rotate the engine backwards.

Peg the crankshaft, using tool [2].

Check the position of the tensioner roller.

If the marks are not aligned, recommence the alignment of the marks (D) and (E) of the

tensioner roller.

Page 61

59

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

B1EK00HD

B1EK00GD

Refitting (continued).

Peg the camshaft hubs, starting with LH exhaust (17) then (18), (19) and (20), using tool

[1], proceeding in the following way:

- The peg goes in: slacken by 45° the fixing screws of the pinion on the camshaft hub,

- The peg does not go in: slacken by 45° the fixing screws of the pinion on the camshaft

hub until the peg will go in.

ESSENTIAL : Check that the camshaft pinions are not at end of slots (by removing

a screw).

If they are, repeat the operation to refit the belt.

Tighten the pinions in the sequence below:

Pinions (17), (18), (19), (20) tighten to 1 ± 0.1 m.daN.

Remove tools [1] and [2]

Checking the setting of the timing.

Effect two rotations (Normal direction of rotation of the engine).

IMPERATIVE : Never turn the engine backwards.

Refit the crankshaft peg [2].

Check that the peg for checking the camshaft settings [4] engages freely in the cylinder

heads (J), as far as the camshaft pinions.

ENGINE

Page 62

60

CHECKING AND SETTING THE VALVE TIMING

Engine : XFW

B1EK00JD

ENGINE

Checking the setting of the timing (continued).

Should this not be the case, repeat the operation to refit the belt.

Remove the crankshaft peg [2].

Refitting (continued).

Refit:

The power steering pump.

The support (7).

The tensioner roller assembly (1).

Tighten:

Screw (22) to 2.5 m.daN + LOCTITE FRNETANCH.

Screw (23) to 4.0 m.daN + LOCTITE FRNETANCH.

Screw (24) to 2.5 m.daN + LOCTITE FRNETANCH.

Screw (25) to 6.0 m.daN + LOCTITE FRNETANCH.

Tighten the crankshaft pulley screws to 2.5 ± 0.2 m.daN.

Refit the auxiliary drive belt (see corresponding operation).

Complete the refitting operations in the opposite order to removal.

Page 63

61

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

Tools :

[1] Instrument for measuring belt tension SEEM C.TRONIC : (-).0192

[2] Crankshaft setting peg (engine DW12TED4) : (-).0188-X

[3] Camshaft peg : (-).0188-M

[4] Belt retaining pin : (-).0188-K

[5] Engine flywheel stop : (-).0188-F

[7] Tensioning lever : (-).0188-J2

[8] Pulley extractor : (-).0188-P

[9] Crankshaft setting peg (engine DW10ATED4) : (-).0188-Y

[10] Crossmember : 4090-T

[11] Tie-bar support : 4176-T

[12] Retaining support : (-).0911-J

[13] Support with adjustable screw : (-).0911-H

[14] Set of plugs : (-).0188-T

Removing.

Remove:

- The front RH splashshield.

- The under-engine shield.

- The auxiliary drive belt (see corresponding operation).

ENGINE

Page 64

62

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

Removing.

Remove:

- The closing panel of the clutch casing (block the engine flywheel, tool [5]).

- The auxiliary drive pulley screw.

Refit the screw without the washer.

Remove:

- The auxiliary drive pulley, using tool [8].

- The tool [5].

Turn the crankshaft.

Peg:

- The engine flywheel, tool [2] (engine DW12TED4).

- The engine flywheel, tool [9] (engine DW10ATED4).

B1EK0TVC

B1EK1T4D

B1EK0TUC

ENGINE

Page 65

63

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

Removing (continued).

Disconnect the battery.

Move aside the header tank.

Position the tools for supporting the engine [10], [11], [12] and [13].

Remove:

- The scuttle panel grille.

- The torque reaction rod (1).

- The fuel unions (2).

IMPERATIVE : Plug the apertures using tool [13].

Protect the radiator harness with strong cardboard cut out to the dimensions of the radiator.

Remove:

- The RH engine support (4).

- The timing covers (3).

- The lower timing cover.

Peg the camshaft pulley, using tool [3].

Slacken the tensioner roller fixing (5).

Retighten the fixing to the position of maximum de-tension. (Tighten to 0.1 m.daN).

Remove the timimg belt.

B1EK1TTD

B1EK1T2D

ENGINE

Page 66

64

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

Refitting.

IMPERATIVE : Check that the rollers (5) and (6) as well as the coolant pump (7) turn freely (no play, no tight

spot), check also that these rollers are not noisy and/or that they are not throwing out grease.

In the event of replacement, tighten the roller (6) to 4.3 ± 0.4 m.daN.

Slacken the screws (8).

Check that the pulley (9) turns freely on its hub.

Tighten the screws (8) by hand.

Slacken the screws (8) by a 1/6 turn.

Turn the pulley (9) (clockwise), to end of slots.

Refit the timing belt, well tensioned, in the following order:

- Crankshaft (immobilise the belt, using tool [4]).

- Guide roller (6).

Engage the timing belt on the pulley (10).

Carefully turn the camshaft pinion in the opposite direction to the rotation of the engine in order to engage the belt

on the pinion.

WARNING : The angular displacement «a» of the pulley relative to the belt should not be greater than the width of

one tooth.

Engage the belt on the tensioner roller (5) and on the coolant pump pinion (7).

Turn the tensioner roller (5) (anti-clockwise), so as to put the tensioner roller (5) in contact with the belt.

Pre-tighten the fixing screw of the tensioner roller to 0.1 m.daN.

Remove the tool [4].

B1EK0TXC

B1EK0TYC

ENGINE

Page 67

65

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

B1EK1TSD

Pre-tensioning the timing belt.

Position the tool [1].

NOTE : Check that the tool is not in contact with anything else around it.

Turn the roller (5) (anti-clockwise), using tool [7] to obtain a tension of:

98 ± 2 SEEM units.

Tighten the screw (11) to 2.3 ± 0.2 m.daN (without modifying the position of the roller).

Remove the tool [1].

IMPERATIVE : By removing one of the screws (8) on the pulley (9), make sure that

these screws (8) are not at end of slots. (If they are, repeat the operation to refit the

timing belt).

Bring the screws (8) into contact with the pulleys.

Tighten the screws (8) to 2 ± 0.2 m.daN.

Remove the setting pegs [3] and [2].

Effect eight turns of the engine in the normal direction of rotation.

IMPERATIVE : Never turn the crankshaft backwards.

ENGINE

Page 68

66

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

B1EK1T1D

Tensioning the timing belt.

Refit the pegs [2] and [3].

Slacken the screws (8).

Tighten the screws (8), by hand.

Slacken the screws (8) by a 1/6 turn.

Slacken screw (11).

Place tool [1] on the belt at (A).

Turn the roller (anti-clockwise),using tool [7] to obtain a tension of:

51 ± 2 SEEM units.

Tighten screw (11) to 2.3 ± 0.2 m.daN. (without modifying the position of the roller).

Tighten the screws (8) to 2 ± 0.2 m.daN.

Remove tool [1] to release the internal forces.

Refit the tool [1].

The tension value should be between 48 and 55 SEEM units.

IMPERATIVE : Value noted outside the tolerance: detension the belt and recommence the operation

Remove tools [1], [2] and [3].

ENGINE

Page 69

67

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

B1EK1T0D

Checking the timing setting.

Effect two turns of the engine in the normal direction of rotation, without turning the engine

backwards.

Refit the peg [2].

IMPERATIVE : Check visually that the offset between the hole in the camshaft hubs

and the corresponding pegging hole is not more than 1 mm.

Remove the peg [2].

Refit:

- The lower timing cover.

- The elements (3) of the timing cover.

- The engine support (4).

- The screws (13), tighten to 6.1 ± 0.6 m.daN.

- The nut (12), tighten to 4.5 ± 0.4 m.daN.

IMPERATIVE : Apply an opposite torque at (A).

Refit:

- The torque reaction rod (1).

- Screw (14), tighten to 5 ± 0.5 m.daN.

- Screw (15), tighten to 5 ± 0.5 m.daN.

ENGINE

Page 70

68

CHECKING AND SETTING THE VALVE TIMING

Engines : RHT-4HW

B1EK0TVC

Refit:

- The tool [5].

- The auxiliary drive pulley

Clean the threads of the pulley screw going into the crankshaft, (Tap M16x150).

Brush the screw threads.

Nettoyer le taraudage de la screws de poulie dans le vilebrequin. (Taraud M16x150).

Brosser le filetage de la screws.

Tightening torque for the screw:

Tighten to : 7 ± 0.7 m.daN (+ LOCTITE FRENETANCH)

Angular tighten : 60° ± 6° (Outil FACOM D360).

Check the tightening: 26 ± 2.6 m.daN

Refit the auxiliary drive belt (see corresponding operation).

Remove tool [5].

Refit the closing plate, tighten to 0.7 m.daN.

Tighten the wheel bolts to 10 m.daN.

Complete the refitting in reverse order to removal.

Initialise the various ECUs.

ENGINE

Page 71

69

RFN 3FZ XFW RHT - RHW 4HW

7 litres 7.2 litres 10.5 litres 10 litres (*) 11.3 litres

25 dm

3

1.4 Bar

89°C 78°C 89°C

1x350W (**) 1x350W 1x350W +1x300W 1x400W +1x300W (***) 1x460 + 1x300W

97°C or 10 Bars 97°C or 10 Bars

in aircon circuit in aircon circuit

101°C or 17 Bars 97°C or 10 Bars 101°C or 17 Bars 105°C or 22 Bars

in aircon in aircon in aircon in aircon

circuit circuit circuit

105°C or 22 Bars

in aircon circuit

115°C 112°C 115°C

118°C

No

COOLING SYSTEM SPECIFICATIONS

Vehicle with air conditioning

Engines : RFN – 3FZ – XFW – RHT – 4HW

Engine type

Circuit capacity

Radiator surface

Pressurisation

Opening of thermostatic

regulator

Cooling fan

1st speed

2nd speed

3rd speed

Aircon cut-out

Warning

Post-cooling

2.0i 16V 2.2i 16V 3.0i 24V 2.0 HDi 2.2 HDi

ENGINE

(*) = (*) = With automatic gearbox : 10.2 litres ; (**) = With automatic gearbox = 1x460W ; (***) = With automatic gearbox = 1x350W+1x300W

Page 72

70

EXHAUST SPECIFICATIONS

B1JP02JC

ENGINE

Petrol engines all types

Repair

Respect the precautions to be taken when operating on a vehicle.

The flexible pipe must not come into contact with corrosive products.

Do not distort the flexible pipe by more than 20° angular (X), 20mm axial, 25 mm shear (Y)

(flexible pipe not fitted).

Do not distort the flexible pipe by more than 3° angular (X), 0 mm axial, 3 mm shear (Y)

(flexible pipe in place).

WARNING : Non-respect for these precautions will result in a reduction in the lifetime of

the flexible pipe. It is thus essential to disconnect or remove the exhaust line in any operation necessitating the lifting of the power unit.

Page 73

71

EXHAUST SPECIFICATIONS

Engines : RFN-3FZ

B1JK05YD

Tightening torques (m.daN)

(1) Bicone collar Ø 74.5 mm

Fixing of catalytic converter/manifold pipework : 2.5 ± 0.4

(2) Flexible metallic pipe

(3) Lambda probes take-off : 4.7 ± 0.7

(4) Catalytic converter

(5) Intermediate silencer

(6) Rear silencer

A and A’ : After sales cutting zones.

Connecting sleeve Ø 55 mm : 5.2 ± 0.7

ENGINE

Page 74

72

EXHAUST SPECIFICATIONS

Engine : XFW

B1JK05ZD

Tightening torques (m.daN)

(1) Front precatalyser

(2) Flexible metallic pipe

(3) Bicone collar Ø 66 mm

(front/rear precatalyser assembly) : 2.5 ± 0.4

(4) Rear precatalyser

(5) Flexible metallic pipe

(6) Catalytic converters

(7) Intermediate silencer

(8) Rear silencer

(9) Upstream lambda probe take-off : 4.7 ± 0.7

(10) Downstream lambda probe take-off : 4.7 ± 0.7

A and A’After sales cutting zones.

Connecting sleeve Ø 55 mm : 5.2 ± 0.7

ENGINE

Page 75

73

EXHAUST SPECIFICATIONS

Engines : RHT-4HW

With particle filter

B1JK060D

Tightening torques (m.daN)

(1) Ball-joint front fixing bracket : 4.5 ± 0.7

(2) Precatalyser

(3) Catalytic converter

(4) Particle filter

(5) Bicone collar Ø 74.5 mm : 2.5 ± 0.4

(6) Rear silencer

(7) Catalytic converter bracket (P. filter) : 3.3 ± 0.5

(8) C. converter and p. filter pressure take-off : 1.7 ± 0.1

ENGINE

Page 76

74

EXHAUST SPECIFICATIONS

Engine : RHW

Without particle filter

B1JK061D

Tightening torques (m.daN)

(1) Ball-joint front fixing bracket : 4.5 ± 0.7

(2) Precatalyser

(3) Catalytic converter

(4) Intermediate silencer

(5) Rear silencer

A and A’ After sales cutting zones.

Connecting sleeve Ø 55 mm : 5.2 ± 0.7

ENGINE

Page 77

75

CHECKING THE OIL PRESSURE

Engine type

Temperature (°C)

Pressure (Bars)

Rpm

Engine type

Diesel engines

2.0i 16V

RFN 3FZ XFW

80°C

1.5

5 3.4 6.3 6.9 1.2 2 5

1000

3000 1000 2000 4000 650 900 3000

2.2i 16V

3.0i 24V

2.0 HDi 2.2 HDi

RHT- RHW

80°C

4HW

Petrol engines

Temperature (°C)

Pressure (Bars)

Rpm

Tools (Toolkit 4103-T).

[1] Pressure gauge

[2] Flexible pipe

[3] Union 4202-T

ESSENTIAL : Respect the safety and cleanliness recommendations.

WARNING : Checking the oil pressure should be done when the engine is hot, after having checked the oil level.

ENGINE

2.0 4.0 2.0 4.0

1000 2000 1000 2000

Page 78

76

ENGINE

OIL FILTERS

PURFLUX

LS 880

LS 923

Specifications

Ø (mm)

Height (mm)

LS 923

LS 880

140

86

X

2.0i 16V – 2.2i 16V 3.0i 24V 2.0 HDi – 2.2 HDi

X

X

To be read together with the Petrol and Diesel correspondence tables

Page 79

77

CLUTCH

GEARBOX

DRIVESHAFTS

DieselPetrol

2.2i 16V 2.0 HDi 2.2 HDi2.0i 16V

CLUTCH SPECIFICATION

Engine type RFN 3FZ RHT - RHW 4HW

Gearbox type BE4/5 ML5C

Feature «Push» clutch «Pull» clutch

Supplier VALEO LUK

Mechanism / type 230 DNG 4700 230 DNG 5100 225 T 5700 242 T 6500

Clutch disc 11 R 14 X Clutch with double damping flywheel (DVA)

No. of splines

Ø of lining. Ext/Int 228/155 225/150 242/162

Quality of lining F 808

Page 80

78

CLUTCH

GEARBOX

DRIVESHAFTS

CLUTCH SPECIFICATION

Engines: RFN – 3FZ – RHT – RHW – 4HW

«Push» clutch

«Pull» clutch

«Push» clutch and «Pull» clutch.

(1) Clutch disc.

(2) Clutch plate.

(3) Clutch bearing.

B2BK22WD

B2BB000D

Page 81

79

HYDRAULIC CLUTCH CONTROL SPECIFICATION

CLUTCH

GEARBOX

DRIVESHAFTS

Engines : RFN-3FZ-RHT-RHW-4HW

Bleeding the hydraulic clutch control.

Composition of the hydraulic circuit.

- Brake fluid reservoir located on the master cylinder.

- Hydraulic control sender located in the passenger compartment and fixed on the pedal gear.

- Clutch pedal.

- Hydraulic control receiver fixed on or inside the clutch housing, depending on gearbox type.

Bleed.

IMPERATIVE : Use only new, clear brake fluid, avoid entry of any foreign bodies or impurities into the hydraulic circuit.

Use only hydraulic fluid that is approved and recommended : DOT4.

IMPERATIVE : Do not use any automatic bleed apparatus (risk of the fluid emulsifying in the reservoir).

Remove:

- The pollen filter and its support (see corresponding operation in chapter on aircon).

- The air filter and its union.

- The under-engine sound-deadening.

Refill the brake fluid reservoir to the maximum of its capacity.

Page 82

HYDRAULIC CLUTCH CONTROL SPECIFICATION

80

CLUTCH

GEARBOX

DRIVESHAFTS

Engines : RFN-3FZ-RHT-RHW-4HW

B2BK22XD

B2BK064C

Bleeding the hydraulic clutch control.

Couple a transparent pipe onto the bleed screw (1).

Submerge the end of the pipe in a receptacle containing brake fluid, situated lower than

the clutch slave cylinder (2).

Create a syphon at «A» above the clutch slave cylinder, using the transparent pipe.

Open the bleed screw (1).

Action the clutch pedal (3) manually through all its travel, with seven rapid down-up

movements.

On the final movement, hold the clutch pedal (3) at the end of its travel.

Reclose the bleed screw (1).

Allow the clutch pedal (3) to rise back up again.

Fill the brake fluid reservoir to the maximum of its capacity.

NOTE : For new bleed operations: open the bleed screw (1).

If necessary, repeat the operation.

Page 83

81

HYDRAULIC CLUTCH CONTROL SPECIFICATION

CLUTCH

GEARBOX

DRIVESHAFTS

Engines : RFN-3FZ-RHT-RHW-4HW

B2BK065C

Bleeding the hydraulic clutch control (continued).

T op up the brake fluid level to the MAXIMUM of the brake fluid reservoir capacity.

Declutch and clutch rapidly 40 times.

Start the engine.

Apply the handbrake.

Engage a gear.

Check that the clutch starts to engage at a dimension (X) greater than or equal to 35 mm

(Dimension (X) is given as a guide).

NOTE : If incorrect, repeat the bleed operations.

Tighten the bleed screw (1) to 0.75.m.daN.

Page 84

82

CLUTCH

GEARBOX

DRIVESHAFTS

RFN 3FZ XFW

205/65 R 15 – 1.973 m 215/65 R15-2.016 m 215/60 R16-2.025 m

BE4/5 AL4 ML5C 4 HP 20

20 DL 26 (*) 20 DL 27 (**) 20 TP 74 20 LM 09 20 HZ 27

14x62 21 x 73 14x65 19 x 73

18x14 20 x 16 25x20 –

Diesel

2.0 HDi 2.2 HDi

Auto.

RHT - RHW RHT 4HW

215/65 R 15 - 2.016 M

ML5C AL4 ML5C

20 LM 05 20 TP 74 20 LM 01

15x67 21 x 73 16x69

27x21 20 x 16 27x21

GEARBOX AND TYRE SPECIFICATIONS

Engine type

Tyres-Rolling circumference

Speedometer ratio

Gearbox type

Gearbox ident. plate

Reduction box torque

Engine type

Tyres-Rolling circumference

Speedometer ratio

Gearbox type

Gearbox ident. plate

Reduction box torque

Petrol

2.0i 16V 2.2i 16V 3.0i 24V

Auto. Auto.

Page 85

83

BE4/5 GEARBOX SPECIFICATION

CLUTCH

GEARBOX

DRIVESHAFTS

Engine : RFN

(A) Marking zone including:

- Component reference.

- Factory serial no.

B2CKU3PD

Page 86

84

CLUTCH

GEARBOX

DRIVESHAFTS

BE4/5 GEARBOX SPECIFICATION

Engine : RFN

Tightening torques m.daN.

(1) Gearbox rear casing : 1.5 ± 0.1

(2) Gearbox casing / clutch casing fixings : 1.5 ± 0.1

(3) Reverse gear rocker shaft fixing nut : 4.5 ± 0.4

(4) Breather pipe : 1.5 ± 0.1

(5) Reverse gear switch : 2.5 ± 0.2

(6) Drain plug : 3.5 ± 0.2

(7) Top-up plug : 2 ± 0.2

(8) Speedo drive support : 1.5 ± 0.1

(9) Differential housing fixings (M7) : 1.5 ± 0.1

(10) Differential housing fixings (M10) : 5 ± 0.5

(11) Clutch bearing guide fixing screw : 1.5 ± 0.1

(12) Differential extension fixing : 1.5 ± 0.1

B2CKUB0D

Page 87

85

CLUTCH

GEARBOX

DRIVESHAFTS

BE4/5 GEARBOX SPECIFICATION

Engine : RFN

Tightening torques m.daN.

(13) Primary shaft nut : 7.5 ± 0.7

(14) Secondary shaft nut : 6.5 ± 0.6

(15) Bearing retaining screw : 1.5 ± 0.1

(16) Differential gearwheel screw : 6 ± 0.6

(17) Gear control support screw : 1.5 ± 0.1

B2CKUB1D

Page 88

86

CLUTCH

GEARBOX

DRIVESHAFTS

ML5C GEARBOX SPECIFICATION

Engines : 3FZ – RHT – RHW – 4HW

(A) Label.

(B) Gearbox reference.

(C) Sequence no.

(D) Bar code.

(E) Marking zone:

Gearbox reference.

Sequence no.

B2CKUC2D

B2CKUCAD

Page 89

87

CLUTCH

GEARBOX

DRIVESHAFTS

ML5C GEARBOX SPECIFICATION

Engines : 3FZ – RHT – RHW – 4HW

Gearbox lubrication.

Oil type: ESSO 75W80 EZL 848 or TOTAL 75W 80W H 6965

Oil capacity: 2.1 litres.

Lubricated for life.

NOTE : If the gearbox is drained, refilling of the gearbox is via the venting hole.

Tightening torques m.daN.

(1) Differential housing fixing (M8 L45) : 1,8 ± 0,1

(2) Differential housing fixing (M8 L70) : 1,8 ± 0,1

(3) Differential housing fixing (M10 L70) : 4 ± 0,4

(4) Differential housing fixing (M10 L50) : 4 ± 0,4

(5) Differential housing fixing (M10 L85) : 4 ± 0,4

(6) Drain plug : 3 ± 0,3

(7) Speedo control support : 1 ± 0.1

WARNING : Do not use the plug on the differential housing, this does not

allow the gearbox oil level to be checked.

B2CKUC4D

Page 90

88

CLUTCH

GEARBOX

DRIVESHAFTS

ML5C GEARBOX SPECIFICATION

Engines : 3FZ – RHT – RHW – 4HW

Tightening torques m.daN.

(8) Fixing of gearbox cover on gearbox casing : 2 ± 0,2

(9) Bearing stop plate : 2 ± 0,2

(10) Vent hole.

(11) Reverse gear switch : 2,5 ± 0,2

(12) Fixing of gearbox casing on clutch casing : 2 ± 0.2

B2CKUC4D

Page 91

89

CLUTCH

GEARBOX

DRIVESHAFTS

ML5C GEARBOX SPECIFICATION

Engines : 3FZ – RHT – RHW – 4HW

Tightening torques m.daN..

(13) Flange fixing screws : 2 ± 0,2

(14) Secondary shaft nut : 17 ± 1,7

(15) Gear control support screw : 1,5 ± 0,1

(16) Differential gearwheel screw : 7.7 ± 0.7

B2CKUC5D

B2CKUC6D

Page 92

90

CLUTCH

GEARBOX

DRIVESHAFTS

AL4 AUTOMATIC GEARBOX SPECIFICATION

Engines : RFN - RHT

The automatic gearbox is identified by a self-adhesive label (A) or, failing that,

by a marking (B).

(1) Component reference.

(2) Serial no.

B2CA085D

Page 93

91

CLUTCH

GEARBOX

DRIVESHAFTS

AL4 AUTOMATIC GEARBOX SPECIFICATION

Engines : RFN - RHT

Tightening torques m.daN.

(1) Converter:

Pre-tightening : 1 ± 0.1

Tightening : 3 ± 0.3

(2) Fixing of gearbox on cylinder block : 5,2 ± 0,5

(3) Speedometer drive : 0,8

(4) Electrovalve and/or regulators on hydraulic block : 0,9

(5) Hydraulic block : 0,8

(6) Hydraulic block casing : 0,8

(7) Automatic gearbox input speed sensor : 1 ± 0,1

(8) Automatic gearbox input speed sensor : 1 ± 0,1

(9) Line pressure sensor : 0,9

B2CKU7AD

B2CKU7BD

B2CKU7CD

Page 94

92

CLUTCH

GEARBOX

DRIVESHAFTS

AL4 AUTOMATIC GEARBOX SPECIFICATION

Engines : RFN - RHT

Tightening torques m.daN.

(10) Electrovalve controlling flow into the exchanger : 1 ± 0,1

(11) Multifunction switch : 1,5 ± 0,1

(12) Sleeve stop : 1,5 ± 0,1

(13) Automatic gearbox heat exchanger : 5 ± 0,5

(14) Filler cap : 2,4 ± 0,2

(15) Top-up plug : 2,4 ± 0,2

(16) Gearbox drain plug : 4 ± 0,4

(17) Gearbox support : 4,5 ± 0,4

Driveshaft nut (M24x150) : 32,5 ± 3

B2CKU7AD

B2CKU7BD

Page 95

93

DRAIN / REFILL /TOP-UP : 4 HP 20 GEARBOX

CLUTCH

GEARBOX

DRIVESHAFTS

Engine : XFW

Preliminary conditions:

Checks there are no faults , using the diagnostic tool.

Place the vehicle on a lift, keep vehicle horizontal.

Gear lever in position «P», without applying the handbrake.

Heavy electrical consumers disconnected.

Connect the diagnostic tool.

Select the parameter measures function.

Make starting this operation, make sure that the oil temperature is well

below 55°C; if it is not, allow the oil to cool.

Press the brake pedal.

Start the engine and allow it to run at idling speed, engage all the gears

using the gear selector. Return to «P».

Tools.

[1] Filling kit : (-).0341

[1a] Filling cylinder : (-).0341-A

[1b] 4 HP 20 adaptor without gauge : (-).0341-B

NOTE :

- The 4 HP 20 automatic gearbox is lubricated for life.

- Check the level every 20 000 miles.

Checks

IMPERATIVE : Use only ESSO LT 71141.

Page 96

94

CLUTCH

GEARBOX

DRIVESHAFTS

DRAIN / REFILL /TOP-UP : 4 HP 20 GEARBOX

Engine : XFW

Checks (continued)

With the engine running at the temperature 55°±1°C, open the top-up plug (3).

Wait for the temperature to reach 60°±1°C.

1st possibility :

- Oil flows out, the level is correct.

- Refit the top-up plug (3), tighten to 2,5 ± 0,2 m.daN.

2nd possibility :

- Oil does not flow out.

- Refit the top-up plug (3).

- Add 0,5 litres of oil. (Refer to the chapter on refilling).

Repeat the procedure of checking the oil level.

Refit the metallic part of the vent plug (2), using an 18mm dia. punch and a mallet.

Clip the plastic part of the vent plug (2).

B2CK0JQC

Page 97

95

CLUTCH

GEARBOX

DRIVESHAFTS

DRAIN / REFILL /TOP-UP : 4 HP 20 GEARBOX

Engine : XFW

Draining.

Preliminary conditions:

- Draining should be carried out with the engine hot, to eliminate impurities in

suspension in the oil.

The draining is partial since the converter cannot be totally emptied.

In draining, approx. 3 litres is removed.

Tighten the cap (1) to 4,5 ± 0,4 m.daN.

Filling.

IMPERATIVE : Use only ESSO LT 71141.

Place the vehicle on a lift.

Move aside the air filter assembly.

ESSENTIAL : Leave the air temperature sensor connected.

Remove the air vent assembly (2).

Raise the vehicle.

Remove the top-up plug (3).

Using tool [1], pour new oil through the air vent aperture, until oil flows out via the top-up hole.

Start the engine and allow it to run at idling speed (applying the brake pedal) and

engage all the gears using the gear selector. Return to «P».

Add oil until it flows out via the top-up hole.

Reclose the top-up hole.

Stop the engine.

IMPERATIVE : Check the oil level.

B2CK17KC B2CK0JPC B2CK0JQC

Page 98

96

CLUTCH

GEARBOX

DRIVESHAFTS

1.0

DRIVESHAFTS - GEARBOX

Tightening torques (m.daN)

Driveshaft

bearing

EnginesVehicles Gearbox

Right Left Tool kit

Gearbox oil seal mandrels

10 + 60°

7114-T.X

9017-T.C

(-).0338.J1

(-).0338.J3

(-).8010-T.D

(-).8010-T.K1

7114-T.W

5701-T.A

(-).0338.H1

(-).0338.H2

(-).8010-T.J

(-).8010-T.K2

7116-T

9017-T

(-).0338

(-).8010-T

Driveshaft

nut

RFN

3FZ

RHT - RHW

4HW

RFN

RHT

XFW

BE4/5

ML5C

AL4

4 HP 20

C8

Tightening torques (m.daN) for the wheel bolts

CITROËN C8

Steel

Light alloy

10 ± 0.5

Page 99

97

AXLES

SUSPENSION

STEERING

Engine type

Tyre

circumference

Wheel

Pressure Front/ Rear

(Bars)

Front/ Rear

Tyre

circumference

Wheel

Pressure (Bars)

Electronic under-inflation

detection

WHEELS AND TYRES

Symbols and abbreviations used : S = Standard fitting T = Alu-steel wheel. A = Alloy wheel (*) = Option fitting

(1) = Normal operating pressure (Max. 4 persons and 40 kg in the boot).

(2) = Pressure under load (More than 4 persons and «MAX» load in the boot).

Winter fitting : NOTE : All the above tyres can take chains on the front wheels. (Snow chain for 205/65/15 = KOeNIG Ref : 9410.26).

Vehicles equipped with the under-inflation detection system are identifiable by the presence of aluminium valves.

The under-inflation detection option can only be fitted on vehicles equipped with light alloy wheels.

2.0i 16V

RFN 3FZ XFW RHT - RHW 4HW

MICHELIN XH1

205x65 R 15 94 H

1.973 m

S

T

A

(1)

(2)

6.5 J 15-5-27

CHARMES

6.5J15-5-27 (*)

DOUGLAS

7J16-5-27

CHARMES

6.5J15-5-27 (*)

Non 6.5 J 15-5-27

MICHELIN

PRIMACY

215x65 R 15 96 H

2.016 m

MICHELIN

HX MXM

215x60 R16 99H

2.025 m

MICHELIN XH1

205x65 R 15 94 H

1.973 m

MICHELIN XH1

205x65 R 15 94 H

1.973 m

2.2i 16V 3.0i 24S 2.0 HDi 2.2 HDi

Spare

wheel

2.5/2.5 2.4/2.4 2/2 2.4/2.4

2.5/3.2 2.4/3 2/3

This tyre is the same size as the tyres fitted on the wheels.

3.2 3 3

2.4/3

Page 100

98

AXLES

SUSPENSION

STEERING

WHEELS AND TYRES

Inflation pressures

The label giving the recommended inflation pressures is affixed to one of the front door pillars.

a: Type of tyre.

b: Tyre specifications.

c: Recommended tyre inflation pressures (unladen and laden).

d: Recommended tyre inflation pressures for the spare wheel.

Tightening torque: 10 m.daN.

B2GP00ND

Loading...

Loading...