Citec DE38 Instruction Manual

DE38

Instruction Manual

Digital Differential Pressure Transmitter / Switch

Citec

Allée du plateau

Bât 2

ZI Nord

77200 TORCY

Tel : +33 (0) 1 60 37 45 08

Fax : + 33 (0) 1 64 80 45 18

Email : citec@citec.fr

www.citec.fr

1.2 Principles of Operation

The instrument uses a tough, flexible sensing diaphragm embedded between stiffening plates and

balanced by springs on either side. The diaphragm

is at zero position when pressures on either side of

the diaphragm are equal. Inequality of pressures

results in deflecting the diaphragm towards the lower pressure side until a new equilibrium determined

by the changed balance of forces is reached. Fastened to the center of the diaphragm is an axial rod,

the other end of which forms the moving core of an

inductive displacement transducer. The linear displacement of the core is proportional to the pressure difference across the diaphragm. This displacement is converted by the transmitter's electronic module to a standard electrical signal output.

An optional output signal can be slew rate limited,

spreaded, inverted and piecewise transformed nonlinearly by means of a table function.

2 Installation

The electronic module is mounted on a flat plate or

panel, for which it has 4 holes at the rear for selftapping screws 3.5mm.

A wall-mounting rear adaptor plate is available as

an option (s. Ordering Code).

The pressure transmitters are calibrated at the factory while mounted vertically, pressure ports downward. However, they can be mounted in any orientation. If they are installed with any orientation other

than vertical (pressure ports downward), the zero

point must be reset (s. section 5.3.2).

IP65 protection for the housing is guaranteed only if

suitable connecting cable is used.

If the instrument is intended for outdoor application,

we highly recommend using an adequate protective

housing (or at least a big enough shelter) as permanent protection against UV-radiation on the

membrane keyboard and against exposure of the

instrument to rain or snow.

1 Product Description and Functions

1.1 Block Schematic Diagram

NU 158

22/07/16

2.1 Process Connections

• Only qualified technicians authorized for this

type of work should undertake installation.

• Ensure that the mechanical configuration and

materials of construction of the instrument are

compatible with the process media.

• Ensure that process equipment and pressure

lines are at atmospheric pressure before making pressure connections.

• Pressure lines must have a downward gradient

throughout from the pressure instrument to the

process vessel/pipe. This is to prevent formation of air/gas pockets (for liquid applications) and liquid plugs (for air/gas applications).

• Pressure lines must be kept as short as possible and must not have short bends to avoid

measurement errors induced by pressure line

delays.

• The instrument should be provided with suitable

protection against pressure surges (e.g., snubber or pulsation damper).

• Ensure that process pressure is always less

than the specified safe pressure rating.

The instruments pressure ports are marked by ""

and "" symbols. For differential pressure applications the "" port must be connected to the higher

pressure and the "" port should be connected to

the lower pressure.

If the pressure transmitter is subjected to pressure

when it is started up, zero point checking and adjustment is not possible. In such cases, only electrical connections of the instrument should be made,

but not the pressure connections.

2.2 Elektroanschluss

• Only qualified technicians authorized for this

type of work should undertake installation.

• Switch off electrical power to the plant before

attempting electrical installation work of any

kind.

• Do not disconnect under voltage.

3-wire circuit

Connector 1: Supply voltage and output signal

For nominal supply voltage, the operating supply

voltage range and the maximum output signal loads

see chapter Specifications.

The signal ground line (-Sig) is internally connected

to the instrument ground (-Uo), and serves only as

an alternative ground connection for the output signal. This usually increases the noise margin.

Connector 2: Switch outputs

Switching output 1 (SP1) is configured by parameters R1A, R1E, R1D and R1F.

Switching output 2 (SP2) is configured by parameters R2A, R2E, R2D and R2F.

For more information see section 5.3.8.

SP1

no

SP2

com

SP2

no

SP1

com

Internally bridged

BN

WH

BU

BK

GN/YE

Signal -Sig

Supply –U

o

Signal +Sig

FE

Supply +U

o

p

Output

Evaluation

Input

+

-

-Sig /

+U

+Sig

-U

Output

230V

L

N

+Uo

-Uo

3 Starting Operation

All electrical supply, operating and measuring lines

and the pressure connections must have been correctly installed before commissioning. All supply

lines shall be arranged such that there are no mechanical forces acting on the device.

Check the leak-tightness of the pressure connections before commissioning.

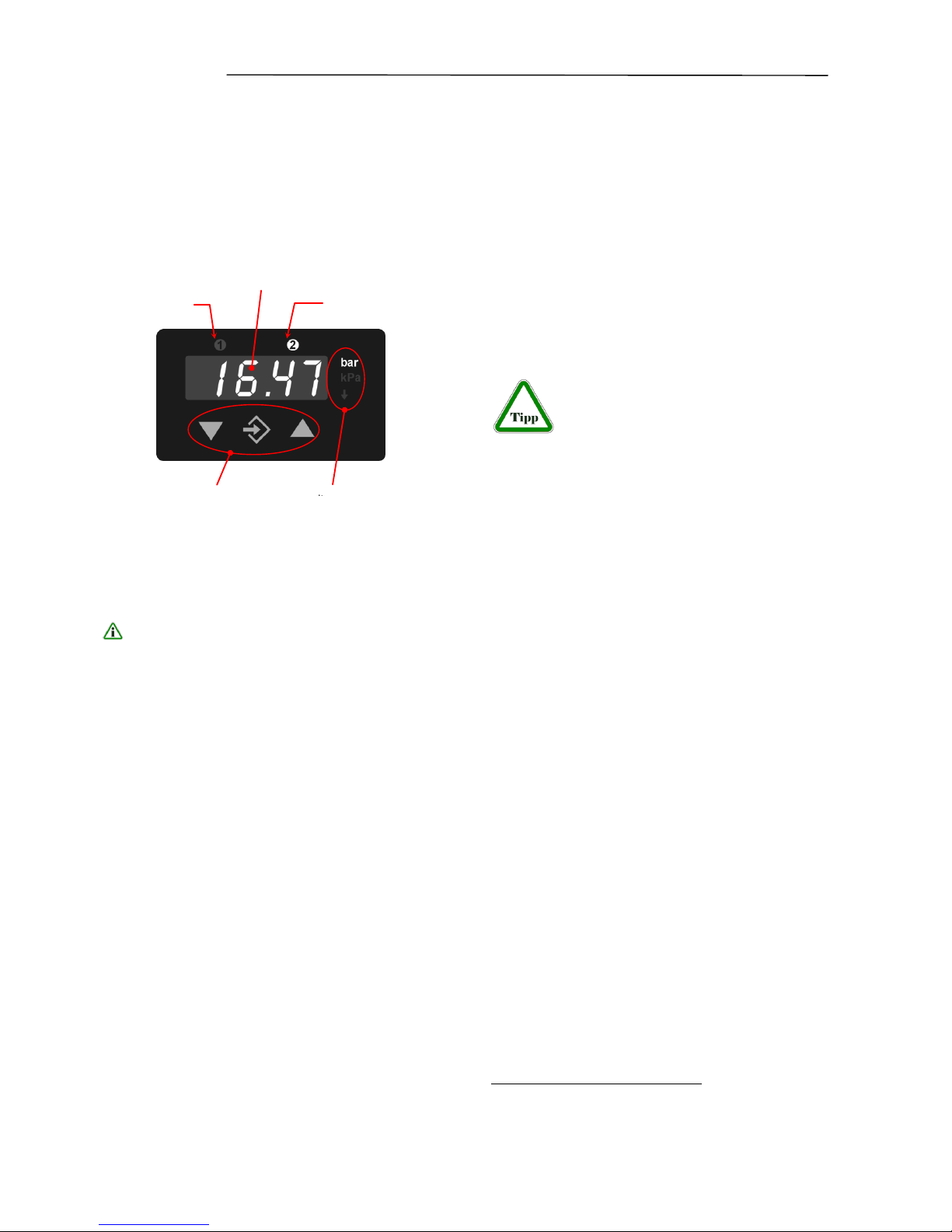

• The 3½ character LED display presents the

current differential pressure in normal operating

mode.

• The selected measuring unit is highlighted at

the right of the display.

The units represented on the screen may deviate from the actual design.

• Above the display, two LEDs symbolise

the condition of the switching outputs. As soon

as the switch is closed, the applicable LED

lights up.

3.2 Control keys

The control keys have the following functions:

ÿ

Menu down

Decrease value

û

Enter key

þ

Menu up

Increase value

By using the middle û key on the membrane keypad you can access the parameter menu (settings

mode). The display now shows the text ESc.

By using the right þ key you can move up within the

menu and can now select numerous parameters.

By pressing the left ÿ key, you can move down-

wards in the menu and finally get back to the ESC

parameter.

By pressing the middle û key you can call up a parameter.

Using the ÿ and þ keys, you can then set the parameter value.

In order to take on the adjusted parameter value,

press the û key.

All adjusted parameters are first then saved if you

leave the menu via the ESC parameter.

3.3 Configuration

For commissioning there is a multitude of setting

options for optimum adaptation of the device to the

measuring point and task at hand. This section covers these options step by step.

Depending on the device design available,1 some

menu points are not available. For example, all

characteristic curve functions are masked from the

menu if the device does not have a signal output.

The device can be completely set conveniently on the PC using a PC adaptor.

There all parameters are immediately

visible and accessible. In addition, the

complete configuration can be loaded, saved and

documented as a control print-out. Further guidelines on this program can be found in the documentation for this program (see accessories).

3.3.1 General

Put the device electrically into operation and ensure

that the device is initially depressurised (if necessary, disconnect the pressure connection lines).

In order to set a parameter, proceed as follows:

• Press the Enter û key in order to switch into the

menu. ESc will appear on the display.

• Use the ÿ þ arrow keys in order to select a pa-

rameter from the list.

• Press the Enter û key in order to call up the pa-

rameters.

• Use the ÿ þ arrow keys to set the required val-

ue.

• Use the Enter û key to save the value.

After you have set all the parameters, leave the

menu as follows:

2

• Using the ÿ þ arrow keys, set the ESc parame-

ter. You can find this both at the start and at the

end of the parameter list.

• Use the Enter û key to leave the menu.

3.3.2 Selection of pressure unit

First select the required pressure measuring unit.

The unit currently valid is highlighted on the right

next to the figure display. For setting, use the middle û key and then look using the right þ key for

1

With reference to the transmitter signal, voltage output, current

output etc.

2

Only when you leave the menu via the ESC parameter are the

set parameters valid.

3.1

Display Switching

Output1

Switching Output 2

3½ digits LED Display

Control keys

Measuring

Loading...

Loading...