CITC FX 100072, 100074, 100068 User Manual

JUNGLE MIST JUNIOR ANTI-DRIP

Operating Instructions

TM

110VAC P/N 100072

12VDC P/N 100068

230VAC P/N 100074 (w/transformer)

! Thank you for purchasing this Jungle Mist Junior Anti-Drip

TM

! As you will notice from the table of contents, the manual for your new

pump is quite extensive. To guarantee perfect and successful work with

this machine, please take time to read the manual carefully.

! Do not operate before changing oil cap!

! And finally, we believe you will enjoy many years of dependable, trouble

free service if you properly install and maintain your Jungle Mist Junior

Anti-DripTM

CITC

2100 196th St. S.W., Ste. 138

Lynnwood, WA 98036

(888) 786-CITC

www.citcfx.com

1

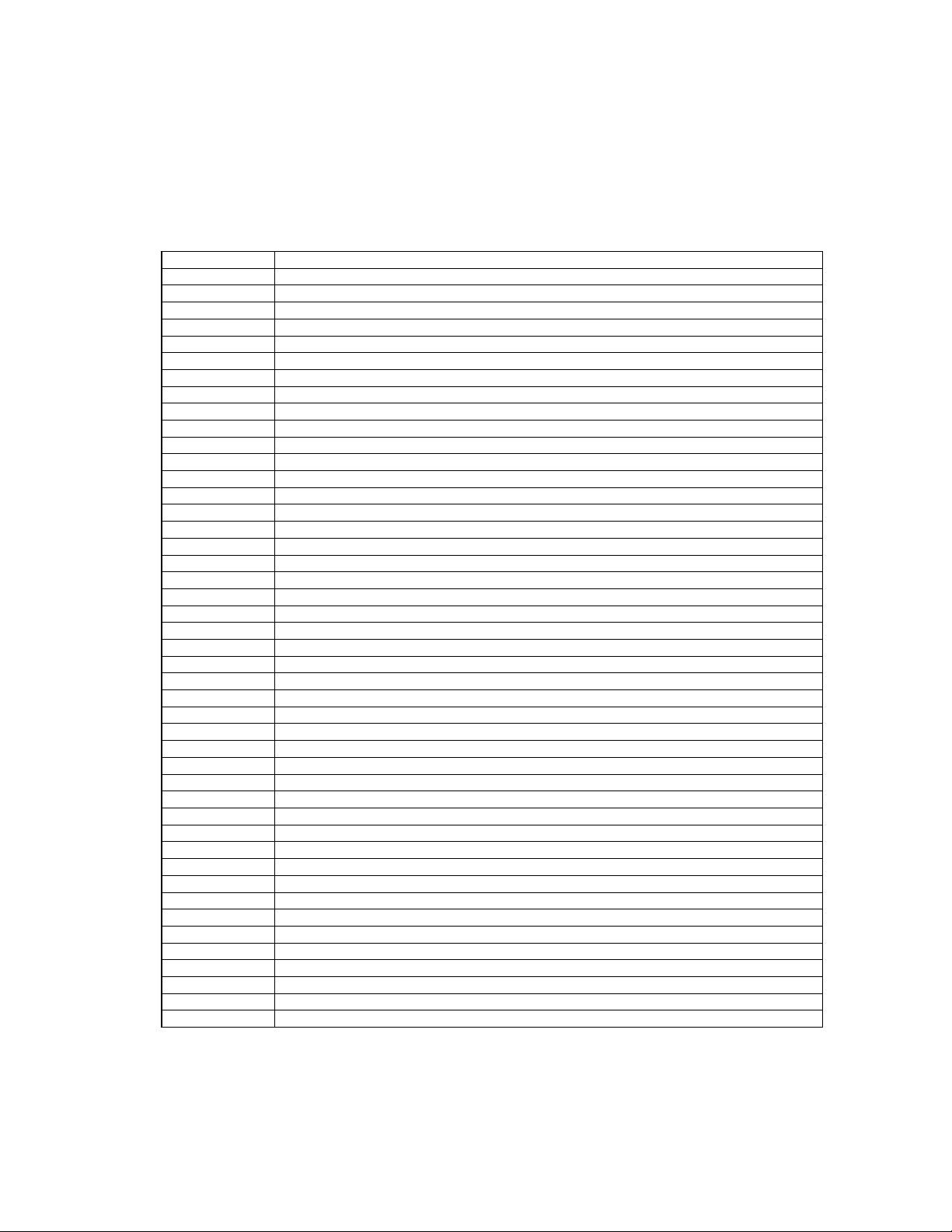

Contents

1. Equipment Supplied 3

2. Accessories and Parts 3

3. Safety information 4

4. Grounding Instructions 4

5. Receiving and Unpacking 5

5.1 Checking for Damage in Shipping

5.2 Checking Inventory of Parts

6. Hooking up the Pump 6

6.1 Installation of Pump

6.2 Water Supply

6.3 Water Filter Installation

6.4 Anti-Drip Extension

7. Mist Line Layout Strategies 7

7.1 Light, Medium or Heavy Haze

7.2 Indoor Fog Curtains

7.3 Raise Humidity to Keep Dust Down

7.4 Project Images and Lasers

8. Mist Line Assembly 8

8.1 Tubing Connection

8.2 Pre-Installation System Test

8.3 Pressure Regulation

8.4 Checking for Leaks

8.5 Adjusting the Fog Pattern

8.6 Mounting the Mist Line

9. Maintenance procedures 10

9.1 System Pressure

9.2 External Water Filter Inspection

10. Troubleshooting 10

10.1 Low Pressure

10.2 Water continues to run through pump

after pump is turned off

10.3 Pump stops running

10.4 Pulsation

10.5 Water leaking from under manifold

11. Technical Data 11

12. Warranty 12

2

1. Equipment Supplied

!

Jungle Mist Junior Anti-Drip System

(Please see section 5.2 for a complete checklist.)

2. Accessories and Parts

100068 10 Nozzle Anti-Drip Pump Kit 12 VDC

250042 Universal DMX Relay 3-pin XLR, Heavy Duty

600720 Filter Housing with Bracket Kit

600721 5-Micron Sediment Filter Cartridge

600722 1.5" Automatic Drain Valve

600723 .008 Nozzle with 10/24 Thread

600724 .012 Nozzle with 10/24 Thread

600725 Push Connector Quick Device - Tee Only (included)

600726 Push Connector Quick Device - Tee with Fine Nozzles (.008)

600727 Push Connector Quick Device - Tee with Heavy Nozzles (.012)

600728 Nylon Tubing 3/8" OD (price per foot)

600729 Nylon Tubing 3/8" OD (28" length) (included)

600730 Nylon Tubing 3/8" OD (50' roll)

600731 Nylon Tubing 3/8" OD (100' roll)

600732 Tubing Cutter

600733 Push Connector Quick Device - Brass Hose Adapter

600734 Push Connector Quick Device - End Plug (included)

600735 Push Connector Quick Device - 3/8" MIP Adapter (included)

600736 Push Connector Quick Device - Brass 90 Elbow (included)

600737 Push Connector Quick Device - Three-way Tee (included)

600738 Push Connector Quick Device - 4-Way Cross

600739 ½" Brass Nozzle Extension

600740 1½" Brass Nozzle Extension

600741 8 oz. Bottle of Nozzle Cleaner

600742 1 Gallon Bottle of Nozzle Cleaner

600743 Anti-Drip Extension with .008 (included)

600744 Anti-Drip Extension with .012

600746 3/8" Steel Clamp Vinyl-Coated Tie Wraps (included)

600747 10/24 Nozzle Plug

600748 .008 Nozzle O-Ring (Red) (included)

600749 .012 Nozzle O-Ring (Black)

600751 ¼" HP Solenoid Valve 110 N.O. with Setup

600752 Push Connector, coupling

600754 5-Nozzle Mist Pod without Nozzle

600755 Push-Connector Quick Device Brass Union

600756 2000psi Pressure Gauge

600759 10' Low-Pressure Tubing

600760 5' Low-Pressure Tubing with Hose Adapter

600761 3' Low-Pressure Tubing for Filter to Pump

600762 2' Low-Pressure Tubing for Drain to Bucket

600763 1 Gallon Bottle (Drain Container)

600765 Jungle Mist Instruction Booklet and Price Sheet

600768 2X Push-Connector Auto Drain-down (anti-freeze)

600780 5 head nozzle .008 w/ anti-drip adapter

600781 5 head nozzle .012 w/ anti-drip adapter

600782 Push-con Union

3

3. Safety Information

3.3 WARNING: Read through the entire instructions before attempting installation.

• Risk of electrical shock - This pump is supplied with a grounding conductor. To

reduce risk of electrical shock, connect only to a properly grounded, grounding type

receptacle.

• Plug the unit into a dedicated, fused circuit.

• Install pump on a flat, level, solid foundation. This pump is non-submersible.

4.4 CAUTIONS:

• Pump warranty is voided by failure to use factory- supplied filter on water

supply! Water filter is installed on water INLET line! (See section 5.3 for more

details.)

• To reduce risk of electric shock, disconnect power before servicing this pump.

• Maximum design pressure is 800 PSI (55 bar) continuous. Under no circumstances

should the pressure be allowed to go higher than 1000 PSI (69 bar).

• This pump has been evaluated for use with water only. Do not use with any other

liquids.

• To reduce risk of electric shock, install with all electrical components well-grounded

and dry.

4. Grounding Instructions

4.1 The pump should have a dedicated circuit

4.2 The pump MUST BE GROUNDED! In the event of a malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least resistance

for the electric current. Install electrical hookup in accordance with all local codes and

ordinances. Warning: Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. Check with a qualified electrician if you are in doubt

whether the pump is properly grounded. Never use a two-prong outlet or cut off the

third prong on the plug!

4

Loading...

Loading...