Content

Contents

1 General safety instructions .............................................................. 3

2 Technical data and dimensions ....................................................... 4

Technical data ................................................................................ 4

Dimensions ..................................................................................... 5

3 Installation and connection ............................................................. 7

Ground ............................................................................................ 7

Anchoring ....................................................................................... 7

Water connection ............................................................................ 7

Water drain ..................................................................................... 8

Main power connection .................................................................... 8

Liquid soap connection ................................................................... 9

Connection of a central operating panel for coinmachines ............... 10

Steam connection ........................................................................... 11

4 Operating instructions ..................................................................... 12

Machine with start button ................................................................ 12

Machine with coin or token operation............................................... 21

5 Standard programs .......................................................................... 27

6 Technical remarks ............................................................................ 28

Internal connection of the electrical heating .................................... 28

Internal connections of the motor .................................................... 28

Thermo-magnetic motor protection .................................................. 29

Error messages .............................................................................. 29

7 Maintenance of the machine ........................................................... 31

Code: 249/00170/00

22/12/00

3

1

General safety instructions

Read the installation and instruction manual carefully before connecting the

machine.

It is recommended that the machine be installed by qualified technicians.

The machine should be installed according to the installation instructions.

(See chapter 4)

The machine should be grounded according to the instructions in order to

eliminate the risk of electrocution.

Do not expose the machine to high humidity or extreme high or low

temperatures.

Cut off all main water inlets, steam and electrical supplies at the end of each

operating day.

Before starting repairs or maintenance, shut off all power and water supplies.

To prevent fire and explosion:

Keep the area around the machine free from inflammable or combustible

products.

Do not put fabrics that are treated with inflammable products into the

machine. These fabrics should be hand-washed or air-dried first.

Always carefully read and follow the instructions on the packing of detergents. Store these products out of the reach of children.

Always take into account the instructions on the labels of clothes.

Never allow children to play in the surroundings of a machine.

S

S

These instructions surely cannot prevent all risks of accidents. It is up to the user to act with the

utmost precaution.

Do not hesitate to contact the dealer in case of a problem.

Ignoring any of the safety instructions can cause serious

personal injury and can also cause damage to the linen or the

machine

S

S

S

S

S

S

S

S

S

S

S

Remark:

4

2

Technical data and dimensions

Technical data

WE 176 WE 234

Capacity (dry weight)

1/11 16 kg 21,3 kg

1/10 17,6 kg 23,4 kg

1/9 16,1 kg 26 kg

Cylinder

Diameter 750 mm 750 mm

Depth 399 mm. 530 mm

Volume 176 Lit. 234 Lit.

Cabinet

Height 1505 mm 1505 mm

Width 900 mm 900 mm

Depth 800 mm 930 mm

Front loading

Diameter door opening 395 mm 395 mm

Door height 510 mm 510 mm

To center 750 mm 750 mm

Speed

Wash 45 rpm

Spin 425 rpm

G-force

Spin 76

Motor(3 phase)

Wash 18p. 290rpm 280 W 400 W

Spin 2p. 2900 rpm 1300 W 2000W

Drain valve

Depend-O-Drain 3"

Water supply

Hard, soft, warm water and cool-down 3/4"

Steam connection

Steam connection 3/8"

Heating

Electrical 220/380 V 12/15/18 kW

Electrical 380 V 12/15/18/21/24 kW

Steam X

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) 1105x975x1535 mm

Weight

Net 400 kg 435 kg

Gross 485 kg 500 kg

5

2

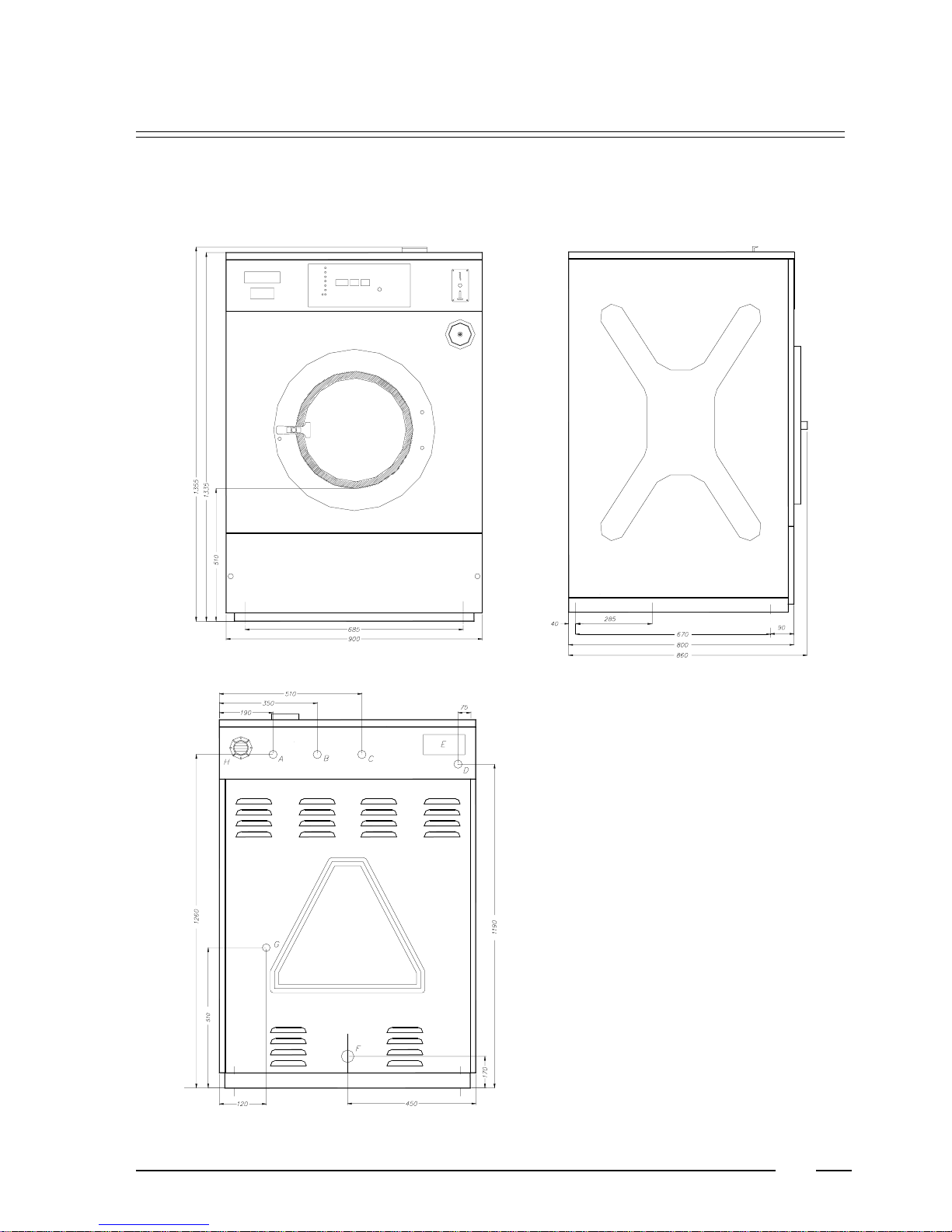

WE176

Dimensions

A. Hard water connection 3/4"

B. Warm water connection 3/4"

C. Soft water connection 3/4"

D. Electrical connection

E. Electrical connection clamps

F. Water drain

G. Steam connection

H. Ventilation soap dispenser

S

S

S

S

S

S

S

S

6

S

S

S

S

S

S

S

S

A. Hard water connection 3/4"

B. Warm water connection 3/4"

C. Soft water connection 3/4"

D. Electrical connection

E. Electrical connection clamps

F. Water drain

G. Steam connection

H. Ventilation soap dispenser

WE234

7

3

B

A

D

C

E

C

D

D

C

G

B

A

E

F

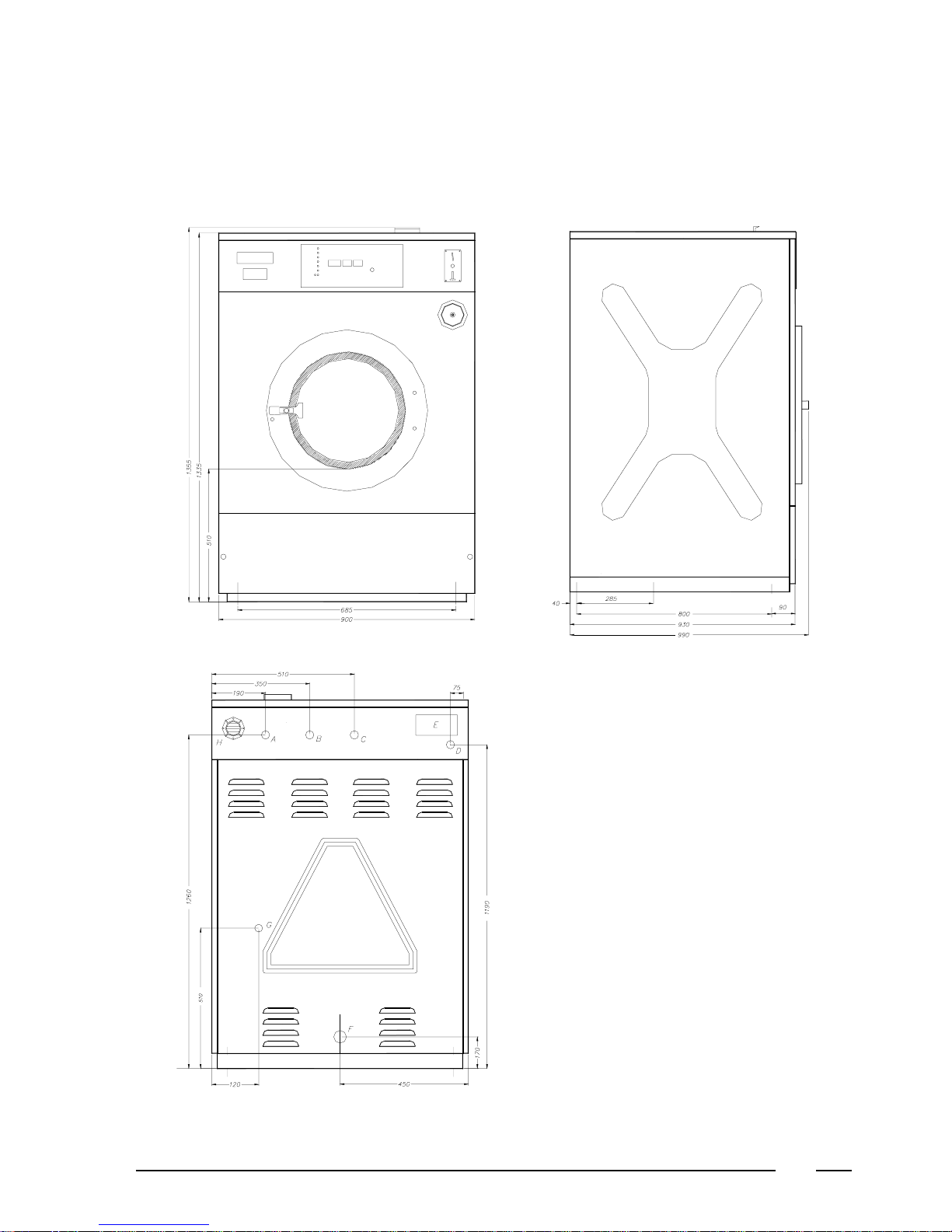

The machine must be securely fixed on a flat surface (metal base, concrete or

solid ground). The anchoring is to be done on the provided places (A) in the base.

(See Dimensions 2)

The machine must be placed entirely level. For easy maintenance it is recommended to keep a minimal distance of 600 mm between the wall and the back

of the machine.

If several machines are placed next to each another, there should be a minimal

distance of 30 mm between each machine.

Installation and connection

Surface

Anchoring

Water connection

The machine must be anchored directly on a concrete base.

Directly on the ground

The machines must be fixed on a metal base which is securely anchored on a

concrete base.

On a metal base

A: Bolt M16

B: Concrete base 40cm

C: Washer 40x17x4

D: Nut M16

E: Base of the machine

F: Metal base

A: Bolt M16

B: Concrete base 40cm

C: Washer 40x17x4

D: Nut M16

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet should

be between 0,5 and 10 kg/cm² (7 and 145 psi). If the pressure is too low, the cycle

time will increase considerably.

In case of boiler fed machines, a minimum of hot water of 90°C should be available.

For the WE 176: 125l.

For the WE 234: 150l.

8

3

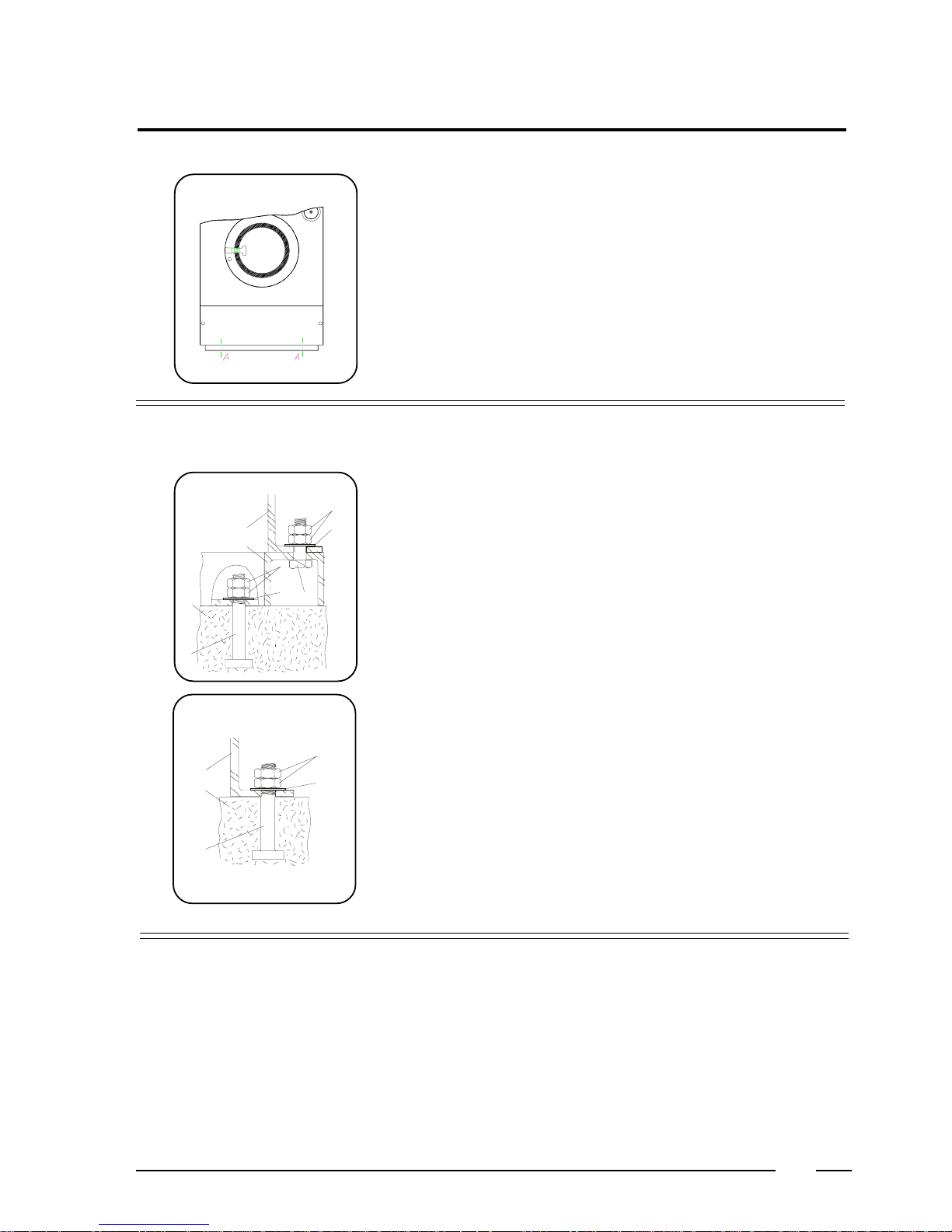

Remove the cover plate at the back of the machine. (See dimensions (E)).

Connect the power cable to the connectors.

220V 3AC

220V 3 phase (3AC) should be connected to the connectors “L1,L2,L3”.

The green/yellow grounding clamp has to be connected to the grounding

wire “PE”.

380 V 3AC + N

380 V 3 phase (3AC + N) has to be connected to the connectors

“L1,L2,L3”, the blue neutral to the “N” connector.

The green/yellow grounding clamp has to be connected to the grounding wire “PE”.

After connection, check the spin direction. The cylinder must spin in

the direction of the arrow, showed on the sticker on the door window

(clockwise).

A wrong spin direction can damage the motor, and can also cause water

to spurt from the soap dispenser.

In case of wrong spin direction: switch the terminal clamps of the motor

circuit “R” and “S” of the connecting cable.

The diameter of the main drain should be adapted to the water flow and

the number of machines. It should be sufficient to handle at least 160L/

min. per machine.

It is necessary to connect the main drain at least on one side to an open

air-brake to allow ventilation.

The machine is equipped with a drain valve with 3" outer diameter (80 mm).

This drain valve should be connected to the drain by means of the drain

elbow which is delivered with the machine.

S

S

Main power connection

Water drain

S

S

S

Power of the breaker plugs:

machine with steam heating or boiler fed machines without additional electrical heating

Heating: 220V 3AC 380V 3AC + N

12 kW 40 A 20 A

15 kW 50 A 25 A

18 kW 50 A 32 A

21 kW ---- 40 A

24 kW ---- 40 A

machine with electrical heating

220V 3AC 380V 3AC + N

16 A 16 A

S

9

3

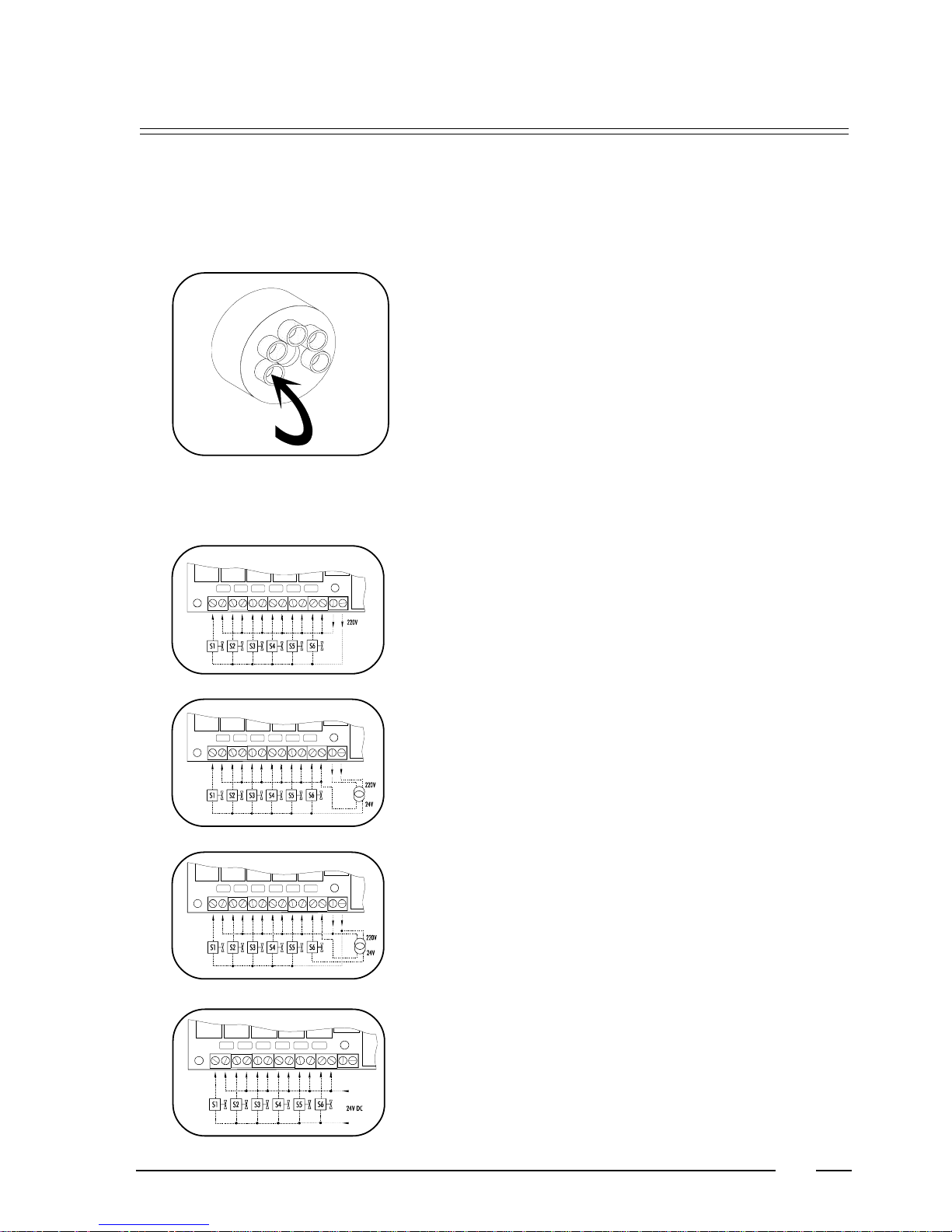

With an external tension 24V DC

Electrical connection of

the liquid soap pumps

On machines equipped with a liquid soap connection, connect the wires

directly on the print board next to the ground wire connection (option).

Connect as indicated on the wiring diagram.

The two connectors on the right give a tension of 220V ~ (max. 4A) which

can be applied to drive 220V ~ soap pumps. If more than 4A is required,

an external tension will have to be used. 6 connections have been

provided, of which one (S6) can be used to drive a waterproofing pump

(e.g. for rain coats, etc.).

The 220V can be transformed to other values to drive other type soap

pumps.

Example: pumps 24V ~.

Also, pumps with different operating tension can be combined.

Example: 5 pumps 220V ~ and 1 pump 24V ~.

A rubber connection has been placed over the air break opening at the back

of the machine. There are 5 holes in this rubber connection, through each

of which a liquid soap hose can be driven (S1...S5). Press the hoses until

they appear well inside the soap dispenser.

The central gap in the rubber connection remains and serves as air breaker.

Liquid soap connection (option)

Connection of the liquid soap

hoses

10

3

A

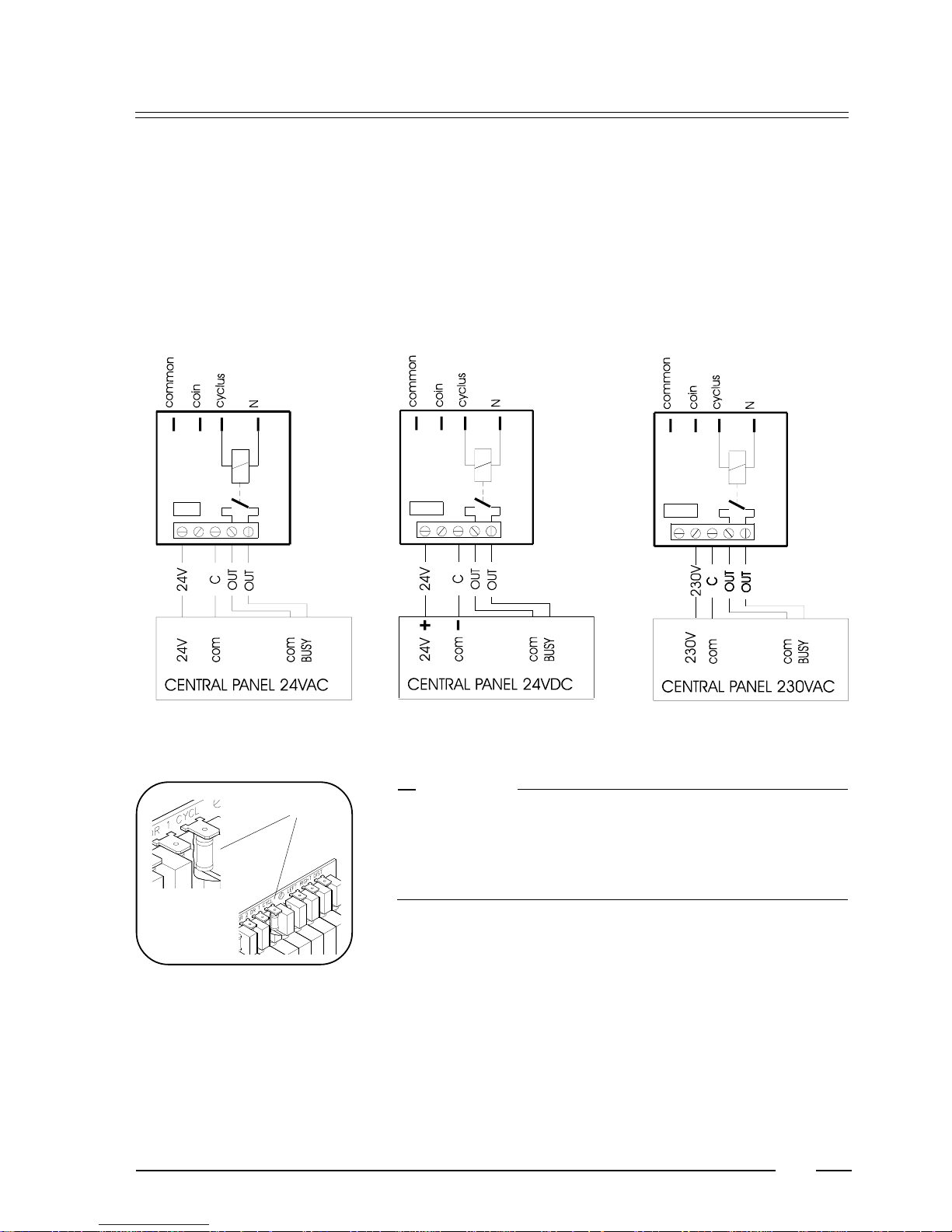

Connection of a central operating

panel for coinmachines (option)

At the backside above the main connectors, you find a printboard, to which the

central operating panel for coinmachines can be connected.

The right connectors form a potential free output contact as a result of which the

operating

panel detects when the machine is activated or not.

The left connectors receive the signal, by means of which a machine is chosen

through the operating panel.

There are 3 different variations possible according to the output voltage of the

operating panel.

Remark :

If a machine is equipped with this kind of printboard or if a printboard

has been built in, the resistance of the cycle contact (A) may no longer

be present on the main printboard.

When this resistance is present, it has to be cut out of the main

printboard.

11

3

Steam connection

With direct steam injection into the machine

1. Steam pipe

2. Steam cut-off valve 3/8"

3. Pipe coupling 3/8"

4. Steam filter 3/8"

5. Magnetic steam valve 3/8"

6. Curve MF 3/8"

7. Steam hose with appropriate pipe coupling 3/8"

The manufacturer is not responsible for damage or accidents

caused by not following the installation instructions!

Added parts for steam heating with heat exchanger

3. Double pipe coupling 1/2"

9. Condensation accumulator with filter 1/2"

10. Conical coupling MM 1/2"

11. Single window 1/2"

12. One-way valve 1/2"

M = inner wire, F = outer wire

Machines with steam heating must have a steam valve between the steam

installation and the machine.

12

4

Operating instructions

Machine with start button

Sort the linen according to the type and required temperature of the linen. Empty

all pockets of the garments so that no garments can be damaged and no left articles

can cause damage to the machine. Turn sleeves of shirts, blouses inside out. It is

recommended to mix small and large items to enhance the drop of the linen during

the wash cycle and hence improve the wash quality. Wash loads of below 80%

of machine capacity can obstruct the proper functioning of the machine and can

damage the machine. Overloading the machine can also lead to a bad wash result.

It is recommended to only use detergents with a “foam-breaker”. These are often

found in the launderette or laundry or can easily be found in retail stores.

Recommended doses are mentioned on the detergent packing.

Overdosing of detergents can lead to reduced wash results and “overfoaming”

which can damage the machine.

Close the door

Fill the drum

On machines with a start button, the programmer can contain up to 100 programs

(0-99). The program number is displayed on the right display.

By pressing the SELECT-button (P), the next program will be displayed.

By pressing the ECO-button (E), the previous program will be displayed. By

keeping this button pressed, this function will be accelerated.

Remark

Select program “0” by keeping the SELECT-button pressed continuously for more

than 5 seconds.

Add detergent

Left compartment A: Prewash (1st wash)

Central compartment B: Main Wash (2nd wash)

Right compartment C: Final Rinse (fabric softener)

Bottom compartment D: Direct access to tub

Moderately soiled linen can be washed using the Economy Wash function, which

reduces the water level of washes and rinses by 20%, allowing savings of water

and energy.

Press the ECO-button during the wash cycle to activate the economy wash

function. The ECO-LED will light up.

At the end of the program the ECO-function will be automatically eliminated. If

the ECO-function is required in the following wash cycle as well, reactivate this

function by repeating the actions described above.

Economy Wash

Opening the door

Push the red button on the door handle to open the door.

Select program

13

4

Start the wash-cycle by pressing the Start button (S) and releasing it immediately.

The door is sealed and the cycle-LED lights up.

During the first 2 minutes after starting, the program number is blinking and you

can change the program in case of a possibly wrong selection.

To do so, select another program with the SELECT button (P). This new program

will start immediately.

Start the machine

Display information

The left display will indicate the temperature of the wash bath - in °C or °F (on

machines where this function has been selected).

The central display shows the remaining time to the end of the wash cycle.

Indications of program

sequence

For programs which are being run for the first time, the machine will take a

theoretical time estimate. If this time indication does not correspond to the real

cycle time, the cycle time will be corrected from the second cycle onwards

(Self-Teaching function of the machine).

This correction will have to be preprogrammed and is not activated on

program numbers higher than 20. The corrected time will also be lost when

the power has been cut from the machine for more than 24 hours.

The right display will continue to show the selected program number.

If a Level-stop was programmed (which halts the programmer during the filling

of the cylinder) and/or a Heat-stop (which stops the programmer during the

heating up of the wash bath, then the respective LED’s light up in the display.

Once the required water level and/or temperature have been reached, the LED

is turned off and the internal programmer advances again.

Wash cycle-LED’s

Each program segment has a corresponding LED. Each of these 6 LED’s light up

when the appropriate segment is executed. This way, the program sequence can

be accurately followed.

When a LED blinks, the machine is taking up water.

When a LED blinks slowly, the machine is heating up the water.

Spin-LED’s

When the water is drained at the at the end of a program segment and the machine

spins if so desired, the left spin-LED (intermediate spin) will light up together with

the cycle-LED.

- Functioning of the spin-LED’s during intermediate spin:

- Functioning of the spin-LED’s during gentle-intermediate spin:

LED drain/distribution low spin coast

Interm. spin blinking rapidly blinking slowly blinking slowly

LED drain/distribution low spin coast

Interm. spin blinking rapidly continuously continuously

14

4

During final spin, both the left spin-LED (intermediate spin) will light up together

with the right spin-LED (final spin).

- Functioning of the spin-LED’s during final spin:

LED drain/distribution low spin high spin coast tumble

Interm. spin blinking rapidly continuously slowly continuously off

Final spin continuously continuously slowly continuously rapidly

- Functioning of the spin-LED’s during gentle-final spin:

LED drain/distribution low spin high spin coast tumble

Interm. spin blinking rapidly slowly ---- slowly of f

Final spin continuously continuously ---- continuously rapidly

Manual interventions during

the program

Following functions can be activated during the program:

F1 = Time stop

To increase the duration of a program segment beyond its originally programmed duration.

F2 = Soak

To soak heavily soiled linen

F3 = Reduced wash action

To avoid wear of delicate garments

F5 = Rapid advance

To skip certain program segments

F6 = No spin

To give total protection to delicate garments

Selecting a function

Push the SELECT-button (P) at the time the special function needs to be activated

and keep the button depressed.

Now push the START-button (S) simultaneously and release same. Only now

release the SELECT-button (P).

The central display now shows F1 and this function is now active.

By pressing the SELECT-button (P) the next function will appear on the central

display. And so on up to F8.

To return to normal operation, press the START-button (S) and release.

A function is also terminated by selecting another function. Functions are also

automatically ended and switched off at the end of the each program.

15

4

Function F1 (Time stop)

During the wash cycle:

The wash time is stopped. The temperature, water level and wash action remain

the same as programmed.

During the wash cycle, this function remains active until the START button (S)

is pressed again.

During intermediate spin :

The intermediate spin normally lasts 1 minute.

By activating function F1, the machine will spin for nine minutes unless the

START button (S) is pressed earlier.

During final spin :

At final spin, you have high spin after low spin.

By activating F1 during low spin, this low spin will be extended to15 minutes

unless the START button (S) is pressed earlier.

If the 15 minutes of low spin have been completed, the high spin is automatically

canceled.

By activating F1 after the preprogrammed low spin, you will have a maximum of

14 minutes of high spin unless the START button (S) is pressed earlier.

Adjustable stop time :

Here you can program a certain stop time. The display shows the countdown

of this extra time. When this time is expired, the function will appear automatically

and the program will continue.

Select F1 (see above).

The stop time can be programmed by means of the ECO button (E). By pressing

it once, the stop time is programmed for 10 minutes. From now onwards, “F1”

and “10” appear by turns on the middle display.

By pressing the ECO button (E) once more, you add each time 10 minutes.

After 50 minutes, 1.0, 1.1, 1.2, etc... appear with a maximum of 4.0 hours.

By means of the START button (S), you can each time reduce 10 minutes.

Description of the

functions

Function F2 (soak)

This function can only be chosen during prewash, main wash and first rinse.

The cycle time is stopped. The bath is filled till high water level and heated up

to 40 °C (if a higher temperature was programmed, this will be followed).

As long as this temperature is not reached, the machine makes a reduced wash

action ( shorter action time and longer pause time). When the bath has reached

its temperature, the drum will make one left/right rotation every 4 minutes. Should

the temperature fall, the water will be heated again, during which the action will

be reduced again.

This function remains active until the START button (S) is pressed again.

Programmable soak time :

In the same way as for the stop time, you can program the soak time (see

programmable stop time).

The programmed stop time is executed after the decimal point in the right

display has extinguished.

The stop time cannot be programmed during spin.

Remark :

16

4

Function F3 (reduced wash action):

By selecting F3, the wash action time and pause time will be reversed;

unless the wash action time was programmed to be shorter than the pause

time.

Example: 12 sec. action/3 sec. pause becomes: 3 sec. action/12 sec. pause

6 sec. action/9 sec. pause remains: 6 sec. action/9 sec. pause

This function does not influence the cycle time - the program continues

normally - and remains active until the START-button (S) is pressed.

Function F5 (rapid advance):

This function is mostly used by technicians and maintenance staff. It allows

to the program.

By pressing and releasing the ECO-button (E), the programs skips to the

next segment.

Attention!

If F5 is activated during final spin, this segment of the program will be

skipped as described above. It is however followed by a coast and tumble

time to disentangle the linen. This special function prevents the user from

opening the machine while the drum is still rotating and represents an

important safety feature.

To return to normal operation, press the START-button (S).

Function F6 (no spin):

This function eliminates all spin action.

Intermediate spin is replaced by a regular wash action. During final spin, only

the programmed low spin time will be completed as regular wash action. High

spin is skipped in its entirety.

This function influences the cycle time - the program continues normally - and

remains active until the START-button (S) is pressed.

17

4

End of a program

At the end of a program, while the door is being released, the left display shows

End; and the Start-LED is switched off.

After that only the right display will continue to show the program number. This

is the end of the program.

Premature ending of the program

By pressing the START-button (S) during the program, the Start-LED is

switched off and the water is drained from the machine. As long as the water has

not reached the safety level, the door will remain sealed and the display will show

“SLE” (Safety Level) on the left display. Afterwards the display will temporarily

show “End” on the same display and the Start-LED will be switched off. After

that only the right display will continue to show the program number. This is the

end of the program.

Remark:

If any attempt is made to interrupt the program prematurely during a spin

phase of the program, all functions on the display will be temperary

replaced by blinking horizontal dashes. After that only the right display

will continue to show the program number and the door will be released.

This is the end of the program.

18

4

Remarks:

Freely programmable stop-function

Before starting a program it is possible to preprogram a time stop in every

program segment. This function permits special additional functions like adding

bleach or extra detergent to the wash bath.

Programming:

After selecting the program, press the ECO-button (E) and keep it depressed.

Now push the START-button (S) simultaneously and release same. Only now

release the ECO-button (E).

The left display now shows “StO” (Stop) and the right display shows the program

number. The first program sequence LED is switched on.

Confirm by pressing the START-button (S) if a time stop is required in this phase

of the program. If no time stop is needed, press the ECO-button (E) to move on

to the next segment of the program. Run through the entire program in this way.

If needed, return to previous segments by pressing the SELECT-button (P).

Errors can be corrected by returning to the erroneously programmed time stop

in the segment and correcting by pressing the START-button (S).

After the final program segment all programmed time stops will be displayed and

the left display will show “End”. Confirm this program by pressing the STARTbutton (S) again. Now start the program.

Operation:

When a stop is reached during the run of the program, the time will be stopped.

The wash bath will be filled to the appropriate level and temperature and the

programmed wash action is executed.

The left display will alternately show temperature and “StO”, while the central

display is showing “F1”. Now, if so desired, additional detergents can be added.

When this has been done, press the START-button (S) to continue the run of

the program. To remove any possible remains of corrosive products in the tub,

the machine will rinse an additional 2 seconds.

Programmable automatic start

By using this function a program can be started up to 99 hours later.

Programming:

After selecting the program, press the SELECT-button (P) again and keep it

depressed.

Now push the START-button (S) simultaneously and release same. Only now

release the SELECT-button (P).

The left display now shows “DEL” (Delay). The central display shows “10”

(minutes). Every push on the SELECT-button (P) will add 10 minutes to the

delayed start time. Hours and minutes are separated by a decimal point: 1.5 stands

for 1 hour and 50 minutes. After 10, the counting is done by hours.

By pressing the ECO-button (E), the delay time can be counted down.

Operation:

After having set the desired delay time, the count-down can be started by

pressing the START-button (S). During the count-down the displays blink and

the remaining time is counted down. In the last hour the displays blink faster.

When the delay time has elapsed, the program is started automatically.

19

4

Linking 2 programs

It is possible to run 2 programs automatically in sequence. This can be handy

to perform very special functions (like waterproofing outerwear) and add these

to the wash program.

Programming:

First select the program which will be run last.

Now, press the START-button (S) and keep it depressed for at least 5 seconds.

The left display now shows “Add”. Now select the program which will be run

first.

The right display now shows both linked programs alternately: the first to be

run program during the longer time span alternating with the following program

displayed during the shorter time span.

This function is canceled by pressing the START-button (S) again for at least

5 seconds.

This function can be combined with an economy wash, with the functions F1

to F6 and with a programmed start. The freely programmable stop-function can

however only be executed during the first program.

Operation:

Press the START-button (S) to start the programs. The central display will show

the remaining time per program. The total time of both programs together is not

displayed.

The right display alternately shows the program in operation (during a longer

time span) and the second program to be executed (during the shorter time span).

After the first program has been run, only the second program number will be

displayed.

20

B

A

Before opening the door, check that all the water has been drained from the

tub and that the cylinder has come to a complete stop.

Important:

Remote stop function

By means of this function, no cycles can be selected anymore during a certain

period of time (e.g. between 10 p.m. and 7 a.m.). This time is determined by an

extern timer. As soon as the last cycle is finished,

“ OFF “ (blinking) appears on the left display as long as this function is

activated.

Cool down

This function allows to gradually lower the temperature of the wash bath to

prevent creasing of the linen.

During a cool down, the remaining program time on the central display will be

replaced by “cd”.

Power Failure

Should the power fall out during the program, the water will be drained and the

door can be opened after maximum 3 minutes. When the door remains locked,

and the power comes back up within 24 hours, the program will continue from

there, where it was at the time of the power failure.

If due to breakdown, the door is not unlocked automatically, you have to remove

the service panel (A) below and pull the ring (B), suspended on the left side, while

opening the door.

Thermo-magnetic motor protection

If the program switches off due to overheating of the motors and the thermomagnetic protection shuts them down, the left display will alternately show

“Mot” and the temperature of the wash bath. This can occur during:

washing

All movement is halted but the water remains in the tub. When the motors switch

back on again, the program will continue to run where it left of.

spinning

All movement is halted and the water is drained. When the motors are switched

on again, the spinning phase will be skipped.

Remark

If the thermo-magnetic motor-protection switches on for the fifth time during

the same program, this program will be immediately terminated.

21

4

Machine with coin or token operation

Push the red button on the door handle to open the door.

Opening the door

Fill the drum

Sort the linen according to the type and required temperature of the linen. Empty

all pockets of the garments so that no garments can be damaged and no left

articles can cause damage to the machine. Turn sleeves of shirts, blouses inside

out. It is recommended to mix small and large items to enhance the drop of the

linen during the wash cycle and hence improve the wash quality. Wash loads

of below 80% of machine capacity can obstruct the proper functioning of the

machine and can damage the machine. Overloading the machine can also lead

to a bad wash result.

On machines with a coin or token meter, the programmer can contain up to 20

programs (0-19). The program number is displayed on the right display.

By pressing the SELECT-button (P), the next program will be displayed.

The price will be displayed on the left display. The display will count down

every time a coin is introduced into the coin meter. When the total price has been

introduced into the machine, the display will be switched off and the machine

will start.

During the first 2 minutes after starting, the program number is blinking and you

can change the program in case of a possibly wrong selection.

To do so, select another program with the SELECT button (P). The new program

will be started immediately.

If a more expensive program has been selected, the price difference with the

previous program will be displayed. The new program will only start after this

price difference has been introduced. If this has not been done within two

minutes of selecting the new program, the machine will switch back to the

original program and continue operating.

Close the door

Select program

It is recommended to only use detergents with a “foam-breaker”. These are

often found in the launderette or laundry or can easily be found in retail stores.

Recommended doses are mentioned on the detergent packing.

Overdosing of detergents can lead to reduced wash results and “overfoaming”

which can damage the machine.

Add detergent

Start the machine

Left compartment A: Prewash (1st wash)

Central compartment B: Main Wash (2nd wash)

Right compartment C: Final Rinse (fabric softener)

Bottom compartment D: Direct access to tub

22

4

Display information

The left display will indicate the temperature of the wash bath - in °C or °F (on

machines where this function has been selected).

The central display shows the remaining time to the end of the wash cycle.

For programs which are being run for the first time, the machine will take a

theoretical time estimate. If this time indication does not correspond to the real

cycle time, the cycle time will be corrected from the second cycle onwards (Self-

Teaching function of the machine).

This function has to be specified during preprogramming.

The right display will continue to show the selected program number.

If a "Level-stop" was programmed (which halts the programmer during the filling

of the cylinder) and/or a "Heat-stop" (which stops the programmer during the

heating up of the wash bath, then the respective LED’s light up in the display.

Once the required water level and/or temperature have been reached, the LED

is turned off and the internal programmer advances again.

Wash cycle-LED’s

Each program segment has a corresponding LED. Each of these 6 LED’s light up

when the appropriate segment is executed. This way, the program sequence can be

accurately followed.

When a LED blinks, the machine is taking up water.

When a LED blinks slowly, the machine is heating up the water.

Spin-LED’s

When the water is drained at the at the end of a program segment and the machine

spins if so desired, the left spin-LED (intermediate spin) will light up together with

the cycle-LED.

- Functioning of the spin-LED’s during intermediate spin:

LED drain/distribution low spin coast

Interm. spin blinking rapidly continuously continuously

- Functioning of the spin-LED’s during gentle-intermediate spin:

LED drain/distribution low spin coast

Interm. spin blinking rapidly blinking slowly blinking slowly

During final spin, both the left spin-LED (intermediate spin) will light up together with

the right spin-LED.

- Functioning of the spin-LED’s during final spin:

LED drain/distribution low spin high spin coast tumble

Interm. spin blinking rapidly continuously slowly continuously off

Final spin continuously continuously slowly continuously rapidly

- Functioning of the spin-LED’s during gentle-final spin:

LED drain/distribution low spin high spin coast tumble

Interm. spin blinking rapidly slowly ---- slowly o ff

Final spin continuously continuously ---- continuously rapidly

Indications of program

sequence

23

4

At the end of a program, while the door is being released, the left display shows End

and the Start-LED is switched off. After that only the right display will continue

to show the program number. This is the end of the program.

End of a program

Rapid advance

This function allows to skip the rest or certain segments of the program. This

function has to be specified during preprogramming and is mostly used by

technicians and maintenance personnel.

Selection

Push the SELECT-button (P) at the time the special function needs to be

activated and keep the button depressed.

Now push the upper hidden button simultaneously and release same. Only

now release the SELECT-button (P).

The central display now shows F5 and this function is now active.

Operation

By pressing and releasing the lower hidden button and releasing it again, the

programs skips to the next segment (if necessary, the program can be advanced

to the end).

To return to the original wash program, press the upper hidden button.

Attention!

If F5 is activated during final spin, this segment of the program will be skipped

as described above. It is however followed by a coast and tumble time to

disentangle the linen. This special function prevents the user from opening the

machine while the drum is still rotating and represents an important safety

feature.

Premature ending of the program

By using the rapid advance function during the program, a program can be

prematurely ended. When the end of a program is reached using this function,

and as long as the water has not reached the safety level, the door will remain

sealed and the display will show “SLE” (Safety Level) on the left display.

Afterwards the display will temporarily show “End” on the same display. After

that only the right display will continue to show the program number. This is

the end of the program.

Remarks

Hidden buttons

If any attempt is made to interrupt the program prematurely during a spin

phase of the program, all functions on the display will be temperary

replaced by blinking horizontal dashes. After that only the right display

will continue to show the program number and the door will be released.

This is the end of the program.

Remark:

24

4

B

A

Cool down

This function allows to gradually lower the temperature of the wash bath to

prevent creasing of the linen.

During a cool down, the remaining program time on the central display will be

replaced by “cd”.

Power Failure

Should the power fall out during the program, the water will be drained and the

door can be opened after maximum 3 minutes. When the door remains locked,

and the power comes back up within 24 hours, the program will continue from

there, where it was at the time of the power failure.

If due to breakdown, the door is not unlocked automatically, you have to remove

the service panel (A) below and pull the ring (B), suspended on the left side, while

opening the door.

Important:

Central panel control (Option)

Here payment is done through the central panel and not directly into the

machine. As soon as the payment is done, and a machine has been selected

normally, “STA” appears blinking on the left display. The machine can be

started by pressing the START button or the special START button, which has

been built in on the spot of the coin meter (option).

Before opening the door, check that all the water has been drained from

the tub and that the cylinder has come to a complete stop.

Remark :

This option can only be used, when it has actually been programmed as such

in the programmation.(REMOTE START).

For certain versions, PAY can appear on the left display when this operation

is not active.

Therefore, “Remote PAY” was programmed in the programmation.

Thermo-magnetic motor protection

If the program switches off due to overheating of the motors and the thermomagnetic protection shuts them down, the left display will alternately show

“Mot” and the temperature of the wash bath. This can occur during:

washing

All movement is halted but the water remains in the tub. When the motors switch

back on again, the program will continue to run where it left of.

spinning

All movement is halted and the water is drained. When the motors are switched

on again, the spinning phase will be skipped.

Remark

If the thermo-magnetic motor-protection switches on for the fifth time during

the same program, this program will be immediately terminated.

25

4

The price is set according to the specifications at the time of ordering the

machine. If no prices were specified, some standard amounts have been preset.

Every program can be priced differently. These prices can also be modified

easily.

Accessing the price setting mode

Remove the coin box from its house. Certain machines have a press button inside

the coin box house at the left upper part. Access to the price setting mode is

obtained using this button.

If there is no press button, remove the top panel of the machine.

At the back of the coin meter, a switch-lever can be found. Access is obtained

using this switch-lever.

If the machine is equipped with a double coin meter, access is obtained using

the left switch-lever.

Press the button or pull the switch-lever down for 5 seconds.

The central display will show the letter “c”. Release the button or switch .

When the letter “o” appears on the display, press the button are pull the switchlever back down again for 5 seconds.

Now the display will show the letters “co”. From now on the price can be set.

Setting the prices

The right display will show the program number “0”, while the left display will

show the price for this program.

To increase the price: push the upper hidden button.

To decrease the price: push the lower hidden button.

When the price has been adjusted to requirements and no more adjustments are

necessary to this program price, press the SELECT-button (P) again. The

machine moves automatically onto the next program.

Repeat the previous actions if the price of this program has to be modified as

well. When all program prices have been properly set, exit the price setting mode

by pressing the button or pushing the coin meter switch-lever back down again

once more.

Setting the price

Hidden buttons

26

5

After programming the price for the last program, there are still the following

parameters :

A : Eco - price

This is the decrease in value of the price for economical wash. In other words, the

amount that the customer is saving by using economic wash.

B : Number of coin insertions COIN 1 (up to 60.000)

This parameter is only indicated if it has been programmed as such in the programmation (COIN COUNT).

C : Number of coin insertions COIN 2 (up to 60.000)

This parameter is only indicated if it has been programmed as such in the programmation (COIN COUNT).

D : Info manufacturer or technician

TMP T/N : Info manufacturer or technician.

Here you can program the temperature to appear on display in case this has not been

done at the programmation.

When all desired programs are provided with the right price, end the operation by

pressing the push button or pulling over the coin meter switch-lever.

27

5

The machine is standard equipped with 10 programs (0+9). These have been

designed in cooperation with specialized detergent manufacturers to obtain the

best possible wash results using the most frequently used detergents.

Program 0 (starching) is mostly used in very special applications and is therefore

not displayed on the front panel.

0. Starching 1 RINSE COLD

1. HOT WASH 2 BATHS 40°/90°C

2. HOT WASH 1 BATH 90°C

3. COLOUREDS 2 BATHS 40°/60°

4. COLOUREDS 1 BATH 60°C

5. SYNTHETICS 2 BATHS 40°/40°C

6. SYNTHETICS 1 BATH 40°C

7. WOOL 2 BATHS 30°/30°C

8. WOOL 1 BATH 30°

9. CURTAINS 1 BATH COLD

Standard programs

28

V

+

6

3x220V R5 3x380V R5

12kW 3x2kW V LC1D253 + LC1D0901

3x2kW

15kW 3x2kW V LC1D253 + LC1D1810

3x3kW

18kW 3x3kW V LC1D323 + LC1D1810

3x3kW

21kW 3x3kW ------ ------ + LC1D1810

3x4kW ------ ------ V LC1D1810

24kW 3x4kW ------ ------ V LC1D1810

3x4kW ------ ------ V LC1D1810

Heating

Technical remarks

Internal connections of the electrical heating

B = Black Br = Brown

Gy = Grey Bu = Blue

R = Red W = White

PU = Purple W/B = White/black

Remark:

Other executions are available as options.

Internal connections of the motors

220V 380V

Low speed High speed Low speed High speed

29

6

Autom. reset

Man. reset

The thermic overload relay turns off in case of overloading. Because this relay

is installed on automatical reset, after a while the motors are switched back on

automatically.

Installation and type of overload relay

220V

Type value installation

LR2D13149 7-10A 8A

380V

Type value installation

LR2D13109 4-6A 4A

Thermo-magnetic motor protection

When one of the following malfunctions occurs during a program, the central

display will communicate the appropriate error message at the end of the cycle.

E3 (Eprom)

The Eprom is wrong, replace it by another.

Error messages

Remark :

For coin op machines, it is possible that a program number appears on the

right display in combination with E3.

This indicates a wrong price adjustment for this program. A coin value “0”

or bigger than “1000” was programmed.

Example : wrong price adjustment for program 5.

E4 (water level)

The appropriate water level was not reached after 15 minutes.

E5 (Heating)

The wash bath did not reach the required temperature after 80 minutes of

30

6

E7 (safety level)

The water was insufficiently drained, the machine did not spin and the water is

possibly still inside the tub.

E8 (temperature sensor)

The temperature sensor is probably broken or malfunctioning.

E9 (motor protection)

The thermo-magnetic protection was activated 5 times.

Remark

When a malfunction occurs during a program, the central display will communicate

the appropriate error message at the end of the cycle. When this malfunction has

been removed and a new program has been selected, this error message also

disappears.

When malfunctions E6, E7 or E9 are detected at the start of the wash cycle, the

program will not be started and the error message will remain on the display.

E6 (door lock)

The door lock was released during the wash cycle.

31

7

Clean the entire cabinet of the machine regularly and remove all traces of soap,

etc....

Remove all detergent residue in the soap dispenser with hot water.

Clean the door gasket and remove all detergents and other products.

Shut off the main water, steam and power connections at the end of each day.

Do not change the setting of the water inlet taps on boiler fed machines once

these have been installed.

It is recommended to leave the door and the soap dispenser open after use, to

ventilate the machine.

S

Maintenance of the machine

General maintenance

S

S

S

S

Check regularly if the filters of the water inlet are not blocked by calcification.

Periodical maintenance

S

S

Repair and after-sales

service

In case of important malfunctions and deficiencies which you cannot resolve

yourself, do not hesitate to contact the technical service of your distributor.

Data machine:

Type: .....................................................................................

Program: ...............................................................................

Date of installation: ...............................................................

Installed by: ..........................................................................

Serial number: .......................................................................

Operation voltage and frequency: ..........................................

Data distributor: Name: ...................................................................................

Address: ...............................................................................

Tel.: ......................................................................................

The manufacturer reserves the right to change the content of this instruction manual, at all times and without previous notice.

Loading...

Loading...