Cissell WCS60 Installation Manual

Water Conservation System

Owners Manual

NGINEERED TO PERFORM. BUILT TO LAST.

E

Part No. C003021

Table of Contents

1. System overview & specifications 3

2. Installation instructions

a. Tools required 4

b. Supplies required 4

c. Prepare washing machine 5

d. Install control wiring 5

e. Install drain hose T 7

f. Position system and bolt down 7

g. Install pump 9

h. Plumb overflow hoses 10

i. Install control box 10

j. Connect wiring 11

k. Leak test 11

l. Functionality test 12

m. Return machine to service 13

3. Programming.

a. Machine setup 13

b. Programming basics 14

c. Tips and suggestions 15

d. Sample programs 15

4. Schematic 19

5. Drawings 20

6. Parts list 24

2

System Overview & Specifications

The Water Conservation System can be programmed to save up to four high level baths

to be used in subsequent cycles. This can reduce water usage and sewer output by up to

35%. The balanced design makes it impossible to accidentally overflow the tanks*. The

tanks are made of 304 stainless steel for maximum corrosion resistance and durability.

The system consists of a steel frame, two stainless steel tanks, one pump, two water

valves, hoses and a control box. This system is extremely robust yet simple to install and

operate with the benefit of easy installation on existing machines.

*Based on performance testing conducted with unrestricted open-trough drain system.

Water Savings per Year

Gallons

of Water

300000

250000

200000

150000

100000

50000

0

2000

Cycles/Yr

2500

3000

3500

4000

4500

NOTE: Water savings based on the capture and reuse of two high level baths on an IPH100.

WCS60 WCS80 WCS100 WCS140 Units

CAPACITY PER TANK 54 71.3 71.3 96 Gallons

NO. OF TANKS 2 2 2 2

MATERIAL 304 SST 304 SST 304 SST 304 SST

NET WEIGHT 625 733 733 820 Pounds

HEIGHT 86 94 94 102 Inches

WIDTH 43 1/4 51 1/4 51 1/4 59 Inches

DEPTH (includes machine) 59 67 67 71 Inches

OVERFLOW DIA. 2 3/8 2 3/8 2 3/8 2 3/8 Inches

NO. OF OVERFLOWS 2 2 2 2

FILL DIA. 1.5 1.5 1.5 1.5 Inches

NO. OF FILL LINES 1 1 1 1

PUMP CAPACITY 82 82 82 82 Gallons/Min.

PUMP PRESSURE 13.5 13.5 13.5 13.5 Lb/sq. in.

HIGH LEVEL FILL TIME 74 92 110 148 Sec.

HIGH LEVEL DRAIN TIME 23 28 34 47 Sec.

MED. LEVEL FILL TIME 55 68 80 105 Sec.

MED. LEVEL DRAIN TIME 20 25 30 39 Sec.

LOW LEVEL FILL TIME 40 47 54 71 Sec.

LOW LEVEL DRAIN TIME 17 20 23 30 Sec.

NO. OF PUMPS 1 1 1 1

NO. OF VALVES 2 2 2 2

VOLTAGE 110/60/1 110/60/1 110/60/1 110/60/1 Volts/Hz/Phase

Due to our policy of continuous quality improvements, specifications are subject to change without notification.

3

Installation Instructions

A. Tools Required

Tape measure

Razor knife or box cutter

Flat head screwdriver

Drill with concrete bit

5/16” nut driver or socket

9/16” wrench or socket

7/16” wrench or socket

Ratchet

#4 Phillips screwdriver (if tank removal is required)

B. Supplies Required

Concrete anchors

Material to plumb overflows into drain system

C. Prepare Washing Machine

Remove power from the washing machine.

Be sure to follow all lock-out/tag-out procedures for safety purposes. The machine must

be in a zero energy state prior to installing the Water Conservation System.

Access to the PS40 control enclosure and rear of the machine is required for installation

of the Water Conservation System. This can be accomplished by removing the top cover

(side cover on 140 & 175 lb. machines) and the lower rear panel from the machine.

4

Machines ordered with a Water Conservation System from the factory will have the

control wiring and drain hose T installed. Therefore, it will not be necessary to remove

the top (side) cover. Access to the rear of the machine is still required. Skip to step f:

“position machine and bolt down.”

D. Install Control Wiring

A 7/8” hole is required in the upper rear panel of the machine for installation. If there is

not a factory hole in the machine, the recommended location for this hole is near the top

middle of the upper rear panel. Avoid the area above the vacuum breaker the very top of

the panel where the top cover sits. Keep in mind that the control box cable is

approximately 2’ long.

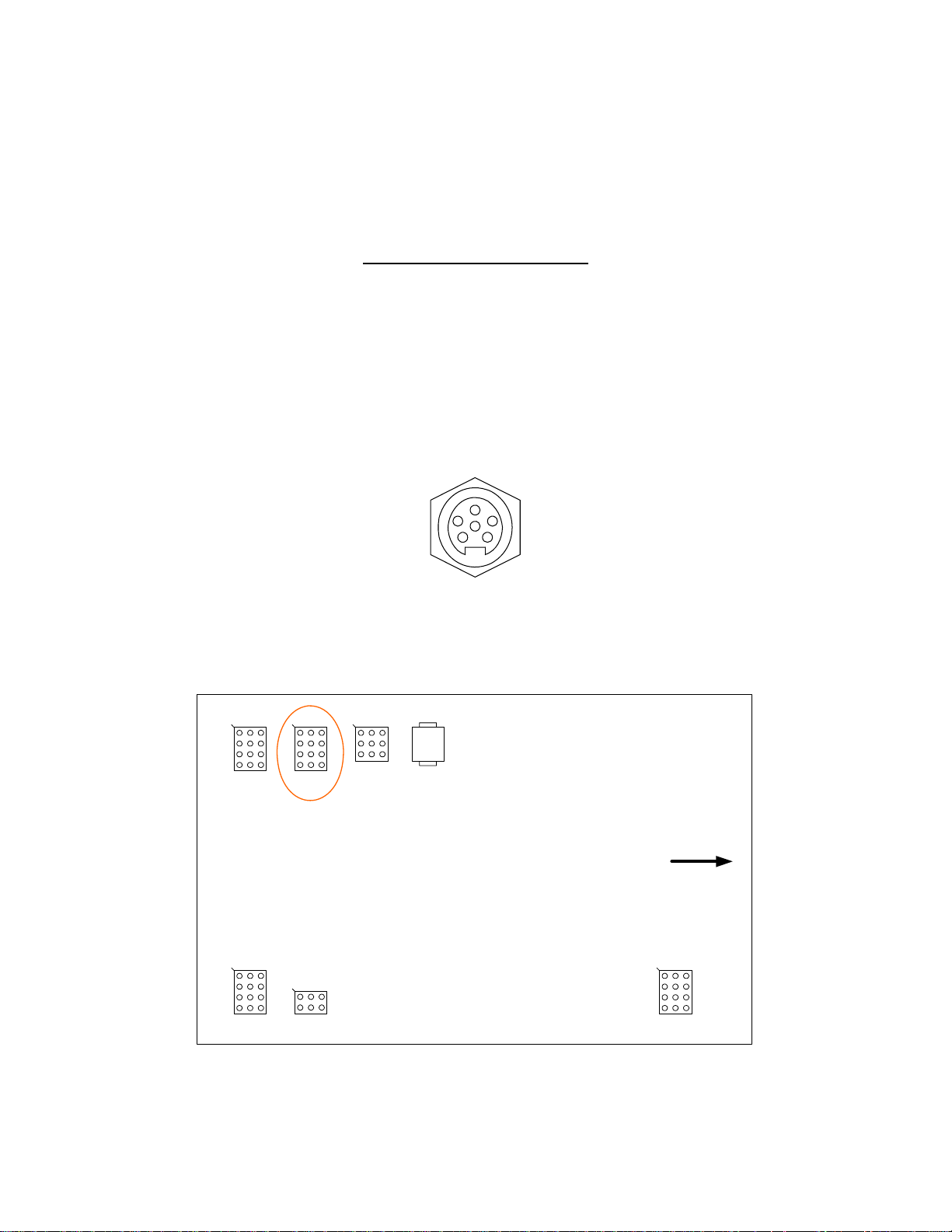

Thread the wires through the upper rear panel into the machine and secure with the

locknut. The connector in figure 1 should be visible when standing behind the machine.

Figure 1.

Figure 2 shows the location of the drain harness plug (E) when looking down on the

control box. Access inside this enclosure is not required.

D E

C

B

F

Front of Machine

A

Figure 2.

5

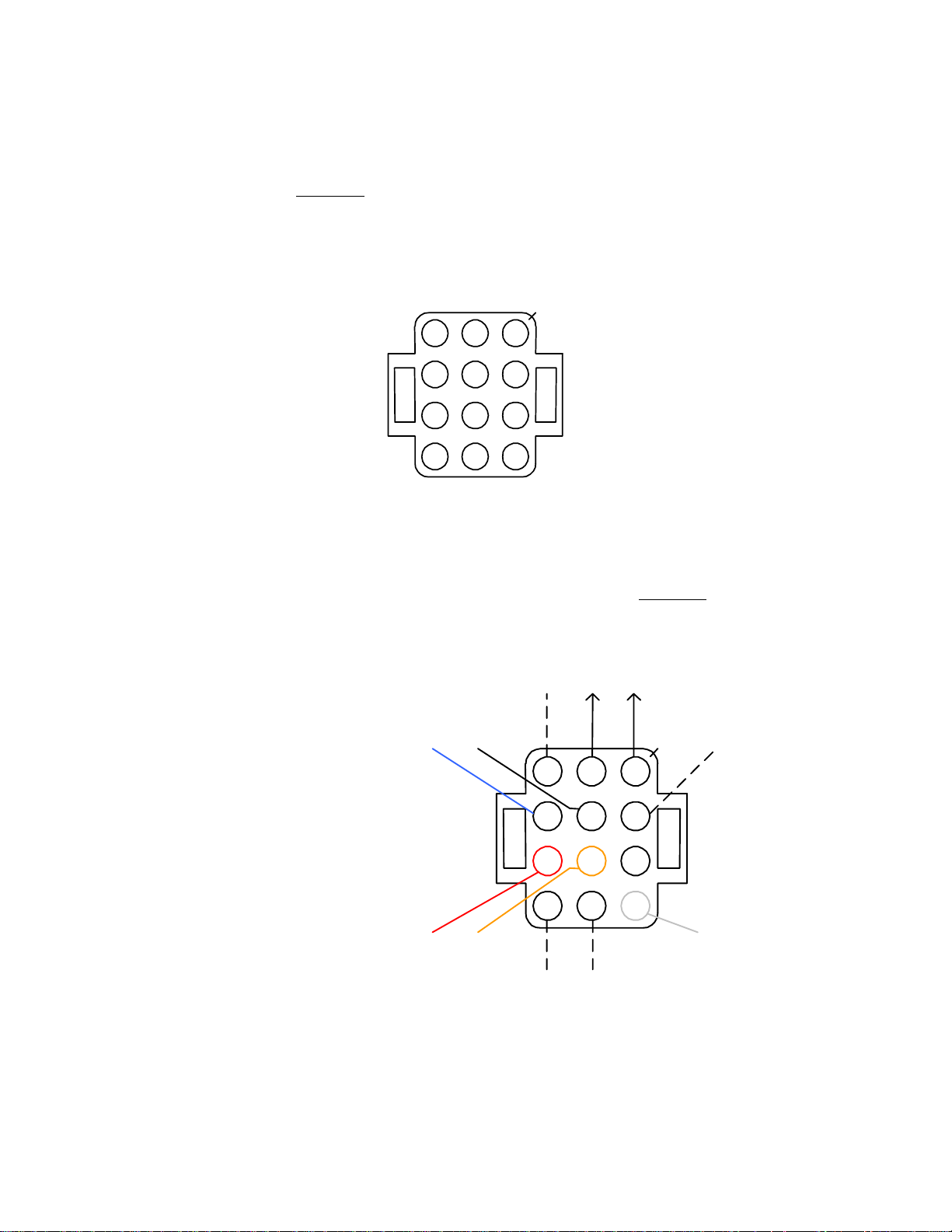

Remove the drain harness (E plug) connector from the underside of the PS40 control

enclosure.

When looking at the

wire side of the connector, pin 1 can be located by the tab protruding

from the corner of the connector, as in figure 3.

At a minimum, the drain harness connector will have wires in pins 1 and 2 for the drain

valve, but may also have wires in pins 3 and 4 for an optional second drain valve and pins

11 and 12 for motor cooling fans.

3 2 1

6 5 4

9 8 7

101112

Figure 3.

It is essential that the next step is done correctly otherwise a special pin extraction tool is

necessary to remove the pins without damage. Insert the wires in the following locations

as shown in figure 4. This is the view as seen when looking at the wire side of the

connector. Be sure the pins are securely locked in the connector by lightly pulling on the

wire after it is inserted.

Optional

to

drain

valve

Pin 5 – Black

Pin 6 – Blue

Pin 8 – Orange

BlackBlue

13 2

Optional

Pin 9 – Red

Pin 10 – White

6 5 4

9 8 7

101112

Red Orange White

Optional

Figure 4.

Connect the green/yellow ground wire to any ¼” bolt on the upper rear panel and fasten

with the supplied nut.

6

Re-attach the drain harness connector to the PS40 control enclosure. The plugs are keyed

so it will only attach if the connector is in the proper orientation (1-1, 2-2, etc).

Replace top or side cover with the appropriate fasteners. Access to the rear of the

machine is still necessary for plumbing connections.

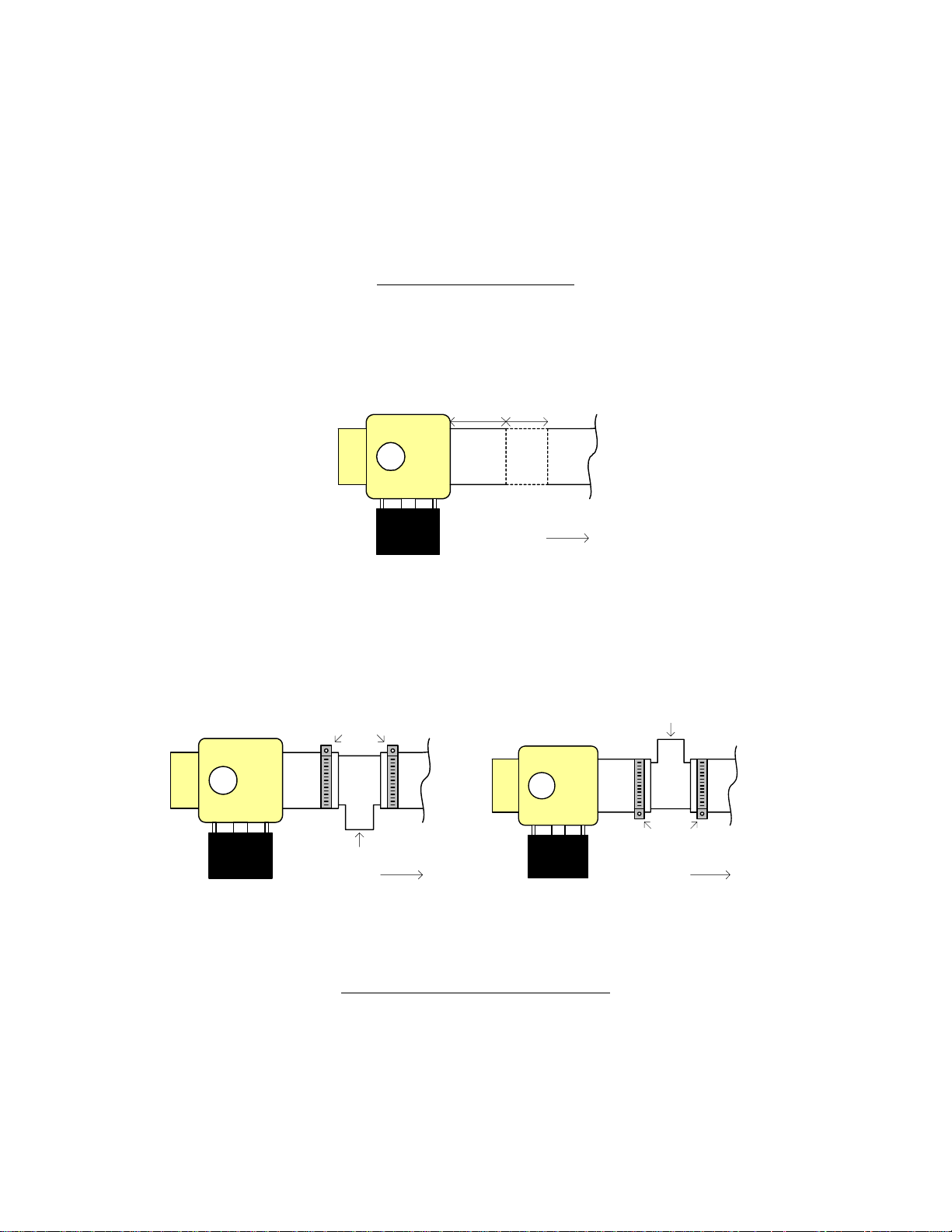

E. Install drain hose T

In order to install the T, the drain hose must be modified. As shown in figure 5, 2.0

inches of the hose needs to be cut out 4.5 inches from the drain valve. This can be

accomplished with a sharp knife or box cutter.

4.5

inches

2.0

inches

Front of Machine

Figure

5.

Install the clamps and T as shown in figure 6 for IPH60, IPH80, and IPH100’s. For

IPH140’s, the T must face in the opposite direction as in figure 7. Tighten clamps to

ensure leak-free operation.

Clamps

Drain T

Drain T

Front of Machine

Clamps

Front of Machine

Figure 6. Figure 7.

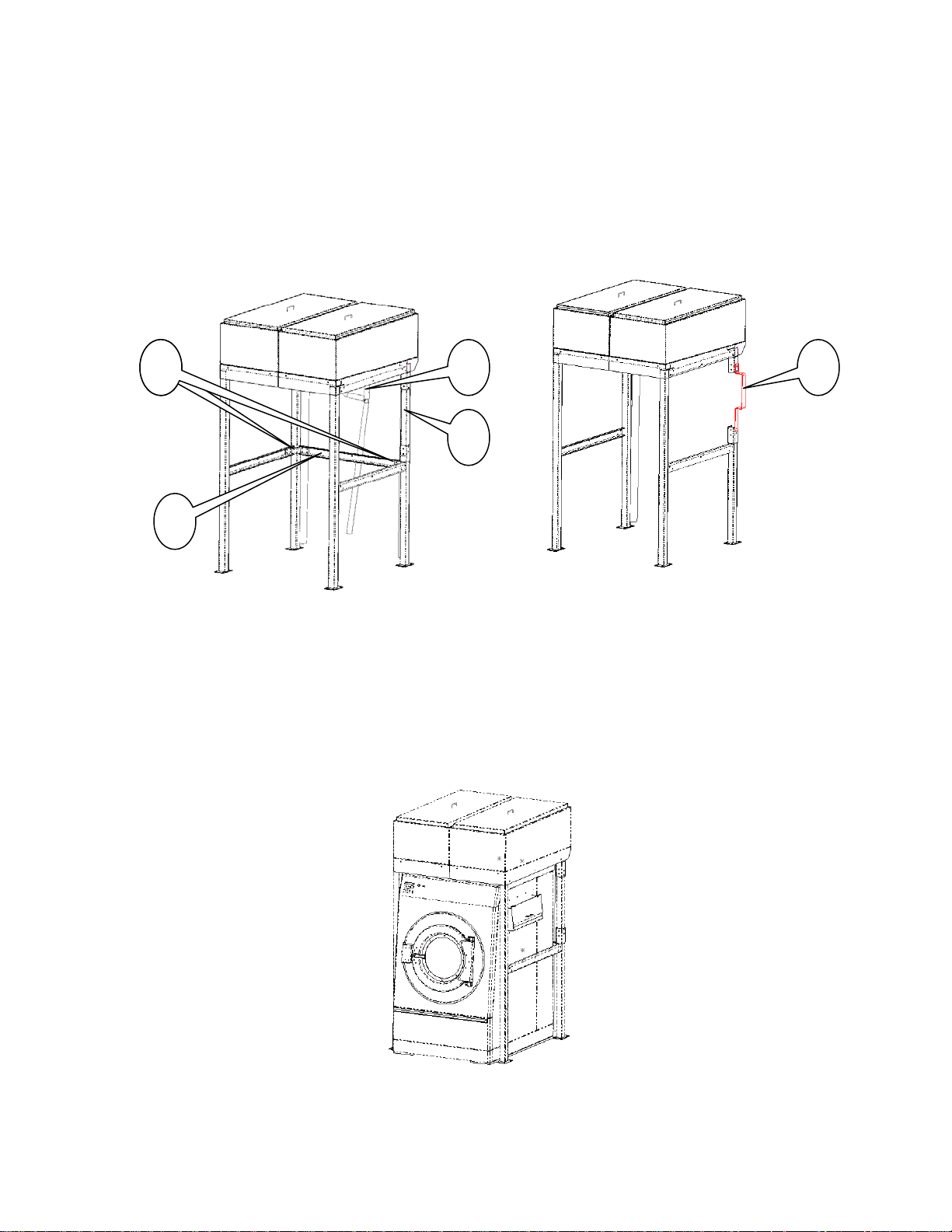

F. Position unit and bolt down

Remove the shipping pallet and position the system in front of the washing machine.

Due to the size of the unit, it may be necessary to remove the tanks or even breakdown

the frame to get the system through doorways. See Section 6 for exploded drawings.

7

Remove the hoses (1), the rear crossbar (2), and both crossbar mounting brackets (3). On

models WCS80, WCS100, and WCS140, remove the rear corner post insert (4) and insert

the installation support (5). This is necessary to get the rear leg past the side soap

dispenser on the washing machine. IPH60 washers do not have a side dispenser, so this

feature is not included on the WCS60. Figure 8 shows how the machine is shipped while

figure 9 shows the machine ready for positioning and installation over the washing

machine.

3 3

2

Slide the water conservation system into place over the washing machine. Watch the

overflow hoses; it is a tight fit. Position the front of the tanks flush with the front of the

washing machine control panel. Once the system is situated in the desired location,

remove the installation support (5) and reinstall the rear corner post insert (4). At this

time also reattach the rear crossbar brackets (3), the rear crossbar (2), and the hoses (1).

Figure 10 shows a correctly placed system ready to be bolted to the floor.

Figure 8. Figure 9.

1

4

Figure 10.

5

8

Loading...

Loading...