Cissell TURN OUT DRYING CABINET, CTGC User Manual

Firemen’s Turn-out

Exceptional Choices

Gear Drying Cabinet

EXCEPTIONAL CHOICES

For more than half a century, Cissell has been an industry leader

in the design and innovation of laundry equipment. That's just

the history built into its Firemen’s Turn-out Gear Drying Cabinet.

The result of years of research and development, the cabinet

provides an ideal combination of efficiency in design and

durability in construction.

The Cabinet Features:

• Gently dries garments to prevent excessive wear

and tear. Prevents shrinkage and damage.

• Solid construction with electrostatically applied

powder paint, inside and out, for rust inhibition.

• Removable hangers for easier handling.

• Two independent heating and fan systems.

• Short drying times.

• Drain for excessive water drippings.

EXCEPTIONAL CAPACITY

Cissell’s Firemen’s Turn-out Gear Drying Cabinet

can handle from one to six fire suits at a time.

Included with the cabinet is a unique rack

design that allows boots, gloves, and

other items to be dried.

Cissell’s Firemen’s Turn-out Gear Drying Cabinet operates with

two separate heated air systems. One system dries the turnout

gear by blowing warm air through the hangers into the garments

and out the arms and legs, thus drying from the inside. The other

system blows warm air from the side of the cabinet around the

outside of the garments.

With several turnout gear manufacturers advising against

tumble drying of their protective clothing, Cissell’s gentle

drying process offers a safe alternative. Cissell’s dryer will

help return gear to service faster than air drying alone,

and without risking damage to the protective qualities

of the high-tech fibers.

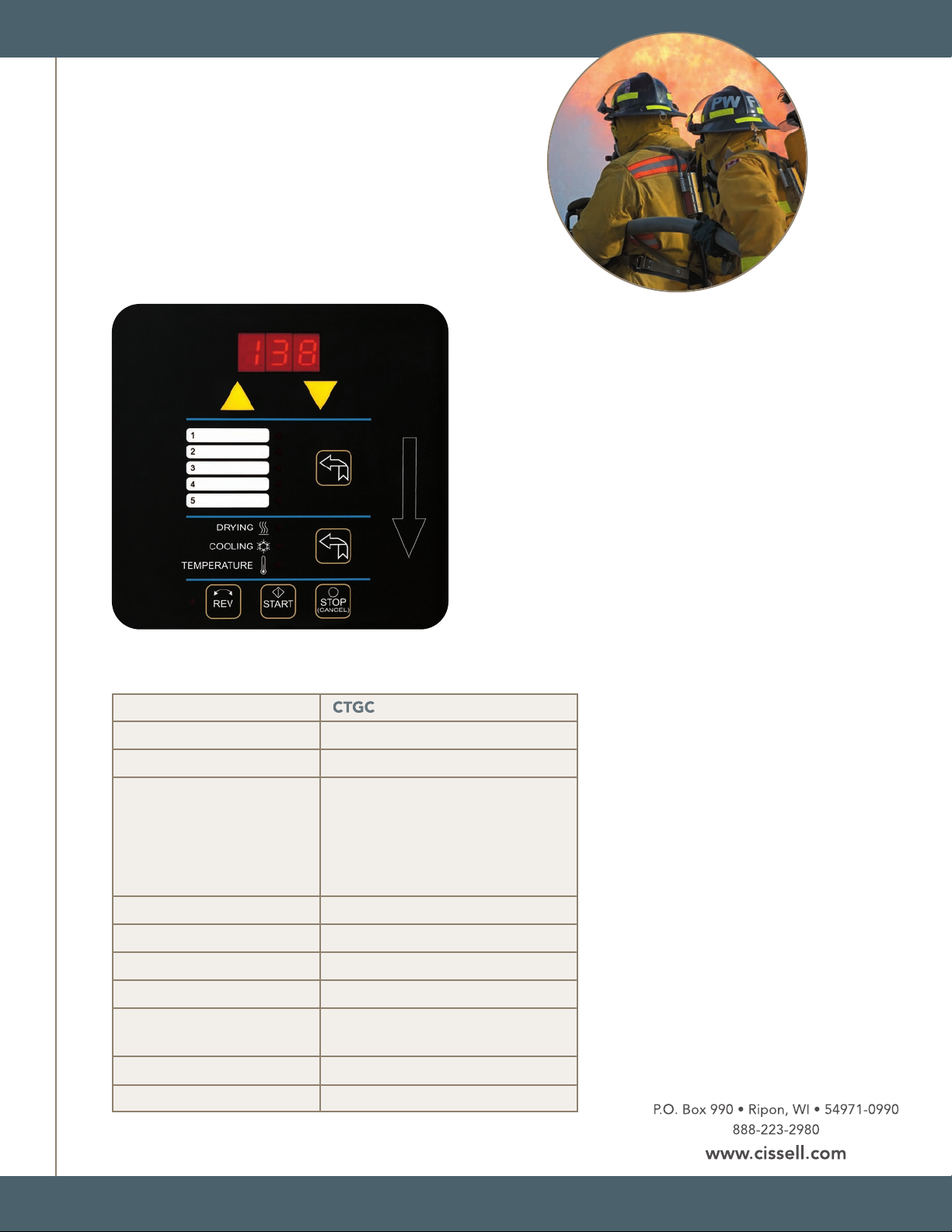

EXCEPTIONAL CONTROL

Cissell’s Microprocessor Control is designed to manage the

drying and cooling cycles of the gear cabinet. The controller

is pre-programmed with five different default programs or

the operator may modify the default programs. The operator

has the flexibility to select the time for the drying and cooldown cycles and the drying temperature.

The Control Features:

• Drying Time: 0 - 555 minutes.

• Cooling Time: 2 - 60 minutes.

• LED display of cycle time, set temperature,

• Thermistor controlled temperature.

• Buzzer for end of cycle, audible alarm.

• Five user-programmable programs.

Specifications

• Monitors the thermistor for operation.

and actual temperature.

Capacity Six Full Sets of Turn-out Gear

Electric Heating 12 kW

Electric Connection

208 V - 50/60 Hz 1 - Ph • 60 amp breaker

208 V - 50/60 Hz 3 - Ph • 35 amp breaker

240 V - 50/60 Hz 1 - Ph • 70 amp breaker

240 V - 50/60 Hz 3 - Ph • 40 amp breaker

380-415 V - 50 Hz 3 - Ph • 25 amp breaker

Exhaust Diameter - in (mm) 6" (152)

Outlet Airflow - cfm (m3/h) 300 (510)

Width - in (mm) 61 1/8" (1553)

Depth - in (mm) 32 3/4" (832)

Height - in (mm) Outer: 79 1/2" (2019)

Inner: 60" (1524)

Net Weight - lb (kg) 534 (242)

Shipping Weight - lb (kg) 594 (270)

For the most accurate information, the installation guide should be used for all design and construction

purposes. Due to continuous product improvements, design and specifications subject to change without

notice. The quality management system of Alliance Laundry Systems’ Ripon facility has been registered to

ISO 9001:2000.

Printed in the U.S.A.

AL11-0119

©Copyright 2011 Alliance Laundry Systems LLC

Loading...

Loading...