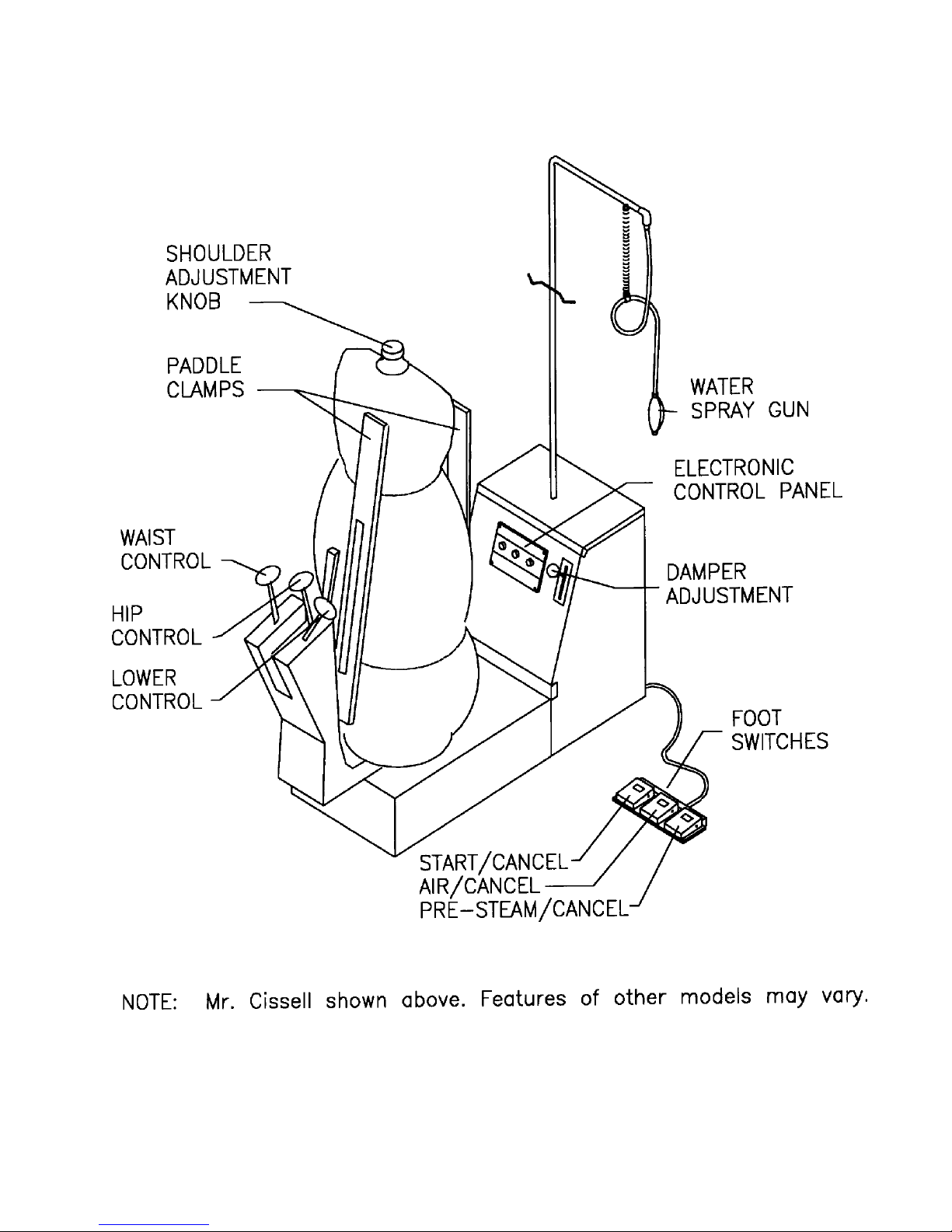

Cissell MANCONS, Suzie II, Mr. Cissell, Ms. Cissell, Sensi-Form User Manual

Form

Finishers

Models:

Suzie II

Mr. Cissell

Ms. Cissell

Sensi-Form

CISSELL MANUFACTURING COMPANY

HEADQUARTERS PHONE: (502) 587-1292

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUAL MUST BE GIVEN TO THE EQUIPMENT OWNER.

MANCONS 8/00 IH

WARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 1

TABLE OF CONTENTS

Cissell Equipment Warranty ................................................................................................. 1

Specifications and Dimensions ............................................................................................. 3

Installation Instructions......................................................................................................... 4

Operation and Safety Precautions ....................................................................................... 5

Operation-Controls........................................................................................................6

Service Chart and Maintenance ......................................................................................... 7-8

Revolving Form Adjustment.........................................................................................8

Instructions for Removing and Replacing Bag............................................................9

Instructions for Tying Lower Tie String ............................................................................ 1 0

Replacement Form Bags ........................................................................................................ 1 1

Instructions for Adjsting Height of Revolving Form...................................................12

Mr. Cissell Form Assembly Parts ...................................................................................... 13-14

Waist, Hip, and Lower Control Parts .................................................................................. 15

Base and Blower Parts ........................................................................................................... 16

Ms. Cissell and Sensi Form Parts ..................................................................................... 17-18

Suzie II Parts................................................................................................................19

Front and Rear Paddle Assembly.................................................................................20

Steam Column and Piping Parts ......................................................................................... 21

Condenser and Spray Gun Parts ...................................................................................... 22-23

Damper Assembly Parts......................................................................................................... 2 4

Control Panel and Electrical Parts...................................................................................... 2 5

Wiring Diagrams.................................................................................................................. 26-28

Page 2

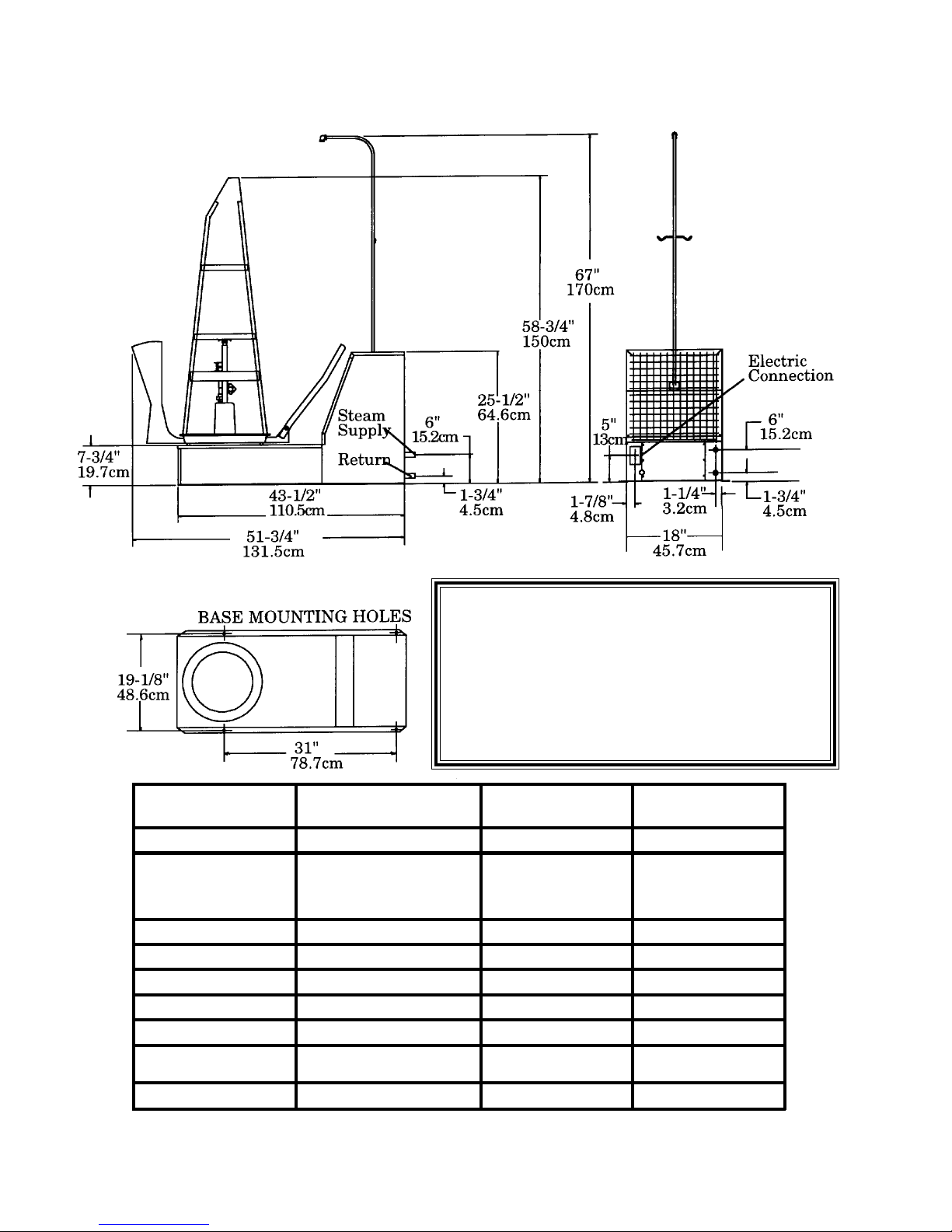

OVERALL DIMENSIONS

NOTE:

Shown with Mr. Cissell Form. To figure the height from

floor, add 7-3/4 (19.7cm) to the form heights listed

below.

Mr. Cissell - 51 (130cm)

Ms. Cissell - 58-7/8 (150cm)

Sensi-Form - 58-7/8 (150cm)

Suzie II - 59-1/4 (150.49 cm)

SPECIFICATIONS

Electrical

Maxi m um Op er at i ng P re ss ure 100 P.S.I. (6.9 Bars) 100 P.S.I. (6.9 Bars) 100 P.S.I. (6.9 Bars)

Boiler Horsepower Required 2.5 H.P. ( 1.9 kw ) 2 H .P. (1. 5 kw) 2 H .P. (1. 5 kw)

Stea m Supp ly & R etur n Line s 1/2" (1 . 27 cm) 1/ 2" (1 . 27 cm) 1/ 2" (1 . 27 cm)

Net Weight 220 lb s . (1 00 kg ) 220 lb s . (1 00 kg ) 220 lb s . (1 00 kg )

Ship ping Weight 250 lbs . (113 kg ) 250 lbs. (113 kg) 250 lbs . (113 kg )

Export Sh ipp ing Dimens io ns

Export Crate Volu me 61 Cubic Feet (1.73 m

MS. CISSELL, SENSI- FORM

CF600

1 H. P. Moto r

115V, 50/60 Hz., 1 Ph, 12 Amps

230V, 50 /6 0 Hz . , 1 Ph , 6 Am ps

61" x 25" x 69"

(155 cm x 64 cm x 175 cm)

3

) 61 Cu bic Fe et ( 1.7 3 m 3) 61 C u bic Fe et (1. 7 3 m 3)

MR. CISSELL

CF100

1 H.P. Motor

115V, 60 Hz. , 1 Ph , 6 Am ps

230V, 60 Hz. , 1 Ph , 3 Am ps

230V, 50 Hz. , 1 Ph , 3 Am ps

61" x 25" x 69"

(155 cm x 64 cm x 175 cm)

SUZIE II

1 H. P. Moto r

115V, 6 0 Hz. , 1 Ph , 6 Amps

230V, 6 0 Hz. , 1 Ph , 3 Amps

115V, 5 0 Hz. , 1 Ph . 3 Amps

61" x 25" x 69"

(155 cm x 64 cm x 175 cm)

Page 3

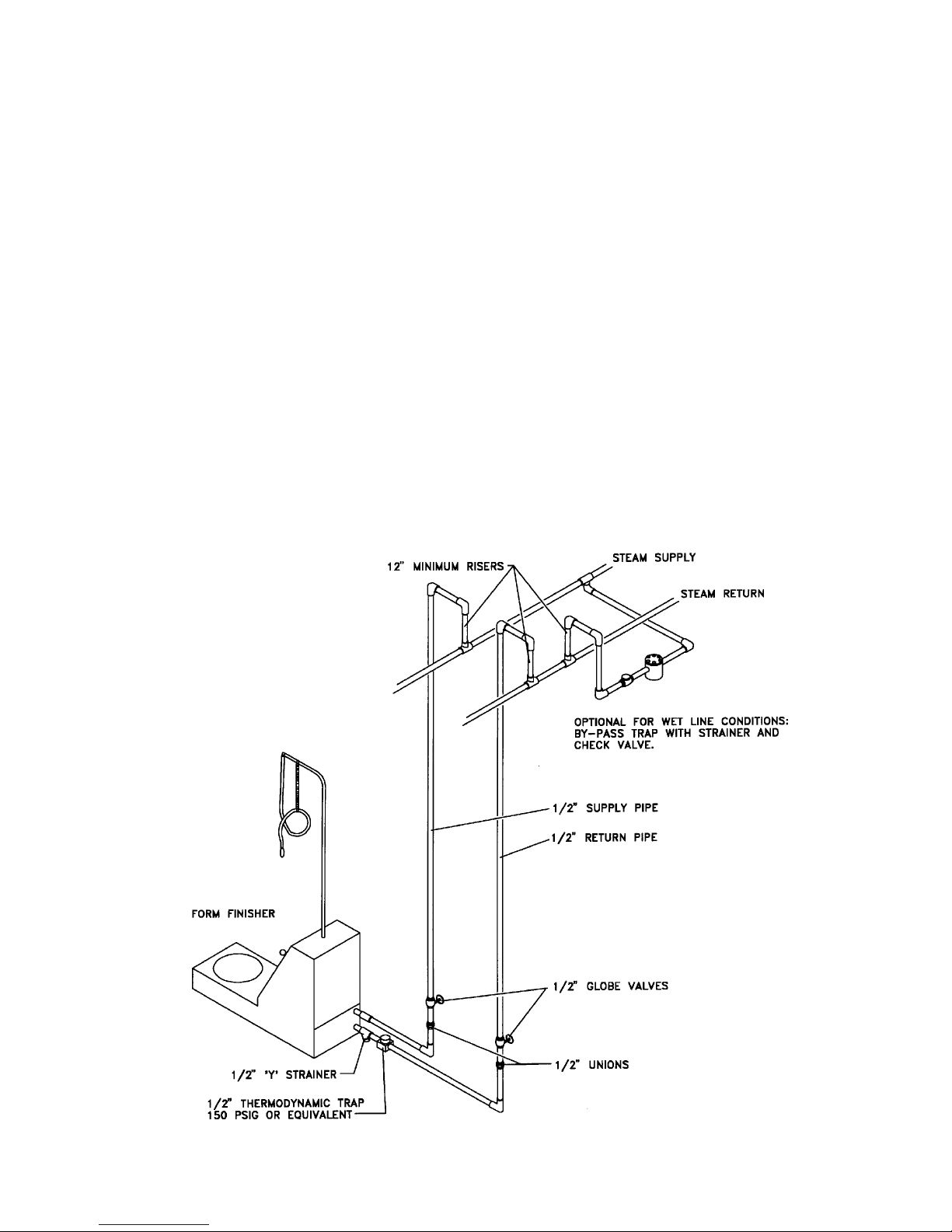

INSTALLATION INSTRUCTIONS

NOTE: This machine should be installed by qualified service personnel only.

1. Uncrate the machine. Check the nameplate voltage and current; match it with the power

being connected.

2. Set the machine in position and bolt to floor.

3. Connect Water Spray Gun to machine. Remove the Lint Screen to access the connection.

Open the valve on the Condenser and replace the Lint Screen.

4. Connect steam supply line as shown in illustration.

5. Connect steam return line as shown. NOTE: Before final return line connection is made,

open the steam supply valve and blow all foreign matter out of the steam lines. Failure to

do so will cause trap to leak.

6. Make electrical connections in junction box on rear of machine, following applicable electric

codes. Include a fused disconnect switch or circuit breaker with slow-blow characteristics

and be capable of carrying 15 amps, 115 volts or 8 amps, 230 volts.

7. Install the revolving form on the machine.

8. Turn on the electric power to machine. Remove the plastic cover from the bag. Open the

steam lines.

9. Test the machine, following the OPERATING INSTRUCTIONS in this manual.

Page 4

SAFETY PRECAUTIONS

Please read these warnings before operating or servicing machine.

CAUTION: This machine emits hot steam. To prevent burns, avoid contact with hot steam. Before

service machine, close steam supply valve and purge lines.

CAUTION: Shut off electrical supply before servicing to avoid electrical shock.

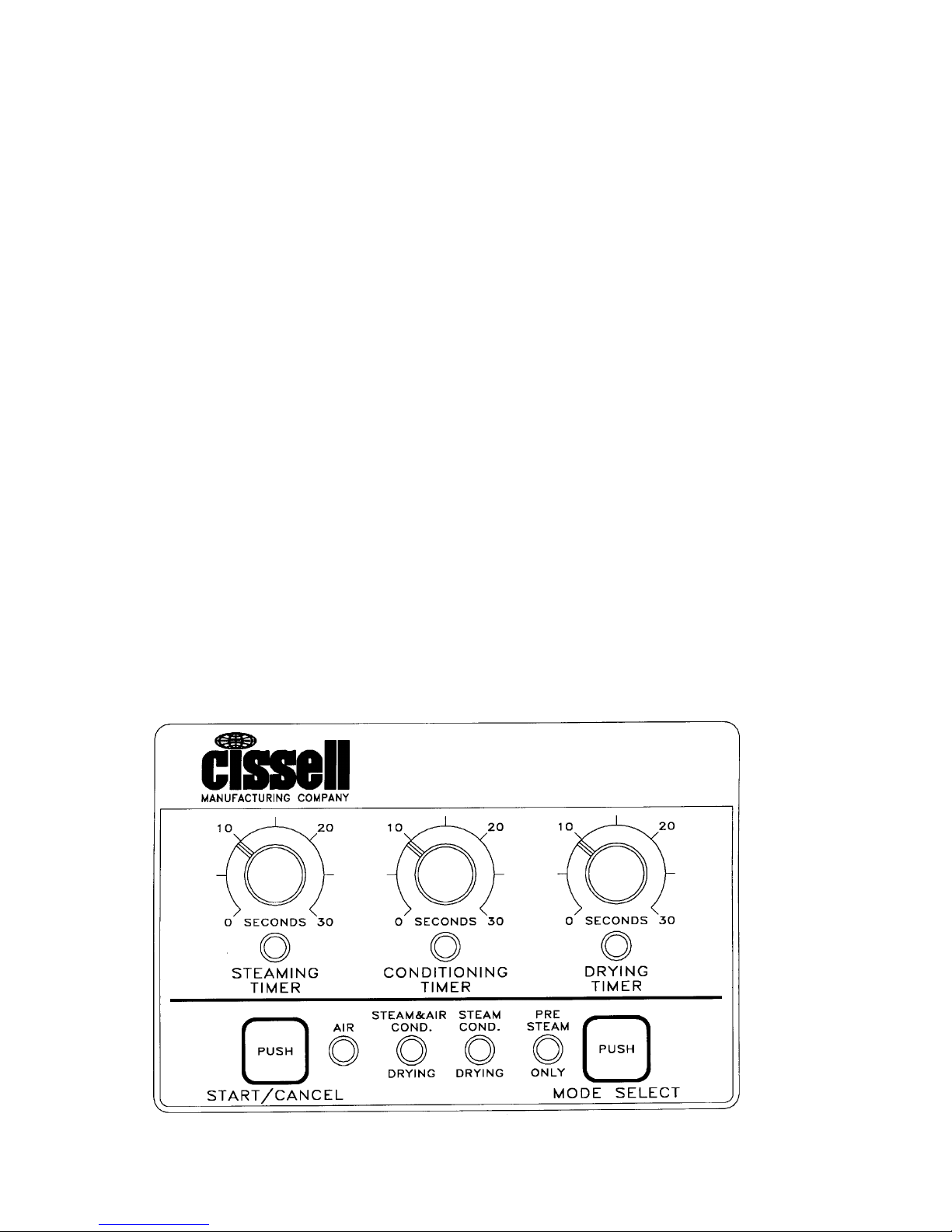

OPERATING INSTRUCTIONS

1. Machine can be operated from any side. Position foot switches at convenient location.

2. Place garment on form. Adjust shoulder form width by turning knob in either direction. The Mr.

Cissell form requires adjustment of the Waist, Hip and Lower control knobs. After adjusting lock

the controls by twisting the knobs clockwise.

3. Press the AIR foot switch to operate the blower for sizing the form bag. Size the bag by adjusting

the DAMPER CONTROL. Using the Control Panel, press the MODE SELECT until the AIR light

glows and press START/CANCEL to operate the blower, then proceed with sizing the bag.

4. Set the three control timers to the recommended settings:

Steaming: 6-9 seconds

Conditioning: 4-9 seconds

Drying: 12-16 seconds

These settings should be fine-tuned to the particular garment, steam pressure and ambient

conditions. The recommended cycle is the steam/air conditioning and the drying. The control will

power up in this cycle.

5. This machine has the ability to pre-steam a garment prior to the automatic finishing cycle. To

actuate this cycle, press the MODE SELECT pad until the PRE-STEAM LIGHT glows, then press

START. Using the foot switch, press PRE-STEAM.

6. If a cycle is operating, it can be cancelled at any time by pressing any foot switch or control panel

pads.

Control Panel

Page 5

OPERATION - CONTROLS

Page 6

SERVICE CHART

CAUTION: BEFORE SERVICEING MACHINE, SHUT OFF ELECTRICAL POWER TO

AVOID POSSIBLE ELECTRICAL SHOCK. SHUT OFF STEAM SUPPLY AND PURGE

PRESSURE FROM STEAM LINES TO AVOID BURNS FROM HOT STEAM.

REFER TO PARTS SHEETS FOR CORRECT REPLACEMENT PARTS.

PROBLEM

(1) No Steam

(2) No Air

(3) Steam Valve Leaks

(4) Wet Steam

CAUSE

A. Steam supply valve closed.

B. Electric power off.

C. Bad solenoid valve coil.

D. Steam timer may slip on shaft

and be set on 0.

See item 11.

A. Damper closed.

B. Drying timer slipping.

C. Defective motor relay.

D. Blower wheel stuck.

E. Defective motor.

F. Defective motor capacitor.

See items 1B and 11.

A. Defective steam valve.

A. Trap not operating.

B. Check valve problem.

C. Strainer clogged.

D. Return line closed.

E. Steam cycle set too long.

F. Steam lines installed wrong.

G. Heavy condesate in supply.

H. Units not trapped correctly.

I. Back pressure in return line.

Page 7

REMEDY

Open valve in steam supply line.

Check for blown fuse, tripped

circuit breaker or loose wire

connection. Tighten wire nuts and

restore power.

Disconnect power and measure coil

resistance. A good coil should be

between 50-125 hms. Replace coil if

not within these parameters.

Loosen set screw and remove knob

shaft. Turn shaft to maximum

counter-clockwise position. Attach

knob to shaft pointing to 0 and

tighten set screw.

Open damper.

See item 1D.

Disconnect and measure resistance

of relay coil. A good coil should be

between 240-360 ohms. Replace

coil if not within these parameters.

Check wheel by moving by hand. If

wheel rubs or is stuck, loosen the

set screws and align the wheel on

the shaft. Tighten set screws.

Measure the resistance of the black

and white wires on the motor

terminal board. They should be

between 5-20 ohms. Replace motor

if not within these parameters.

If relay, blower wheel, and motor

are good, replace motor.

Replace valve.

Check size and operation of trap.

Refer to the Installation Instructions and make corrections in

installation if needed. Replace trap

if defective.

Check for proper installation.

Replace if bad.

Clean or replace as needed.

Open return line.

Reduce steam timer setting.

Refer to steam line Installation

Instructions.

Install by-pass from supply header

to return line.

Each machine needs separate trap.

Check trap installation. Return

lines must be gravity fed to condensate tank. Properly vent the

condensate tank.

SERVICE CHART

PROBLEM

(5) Water inthe base.

(6) Noisy or vibration.

(7) Not enough steam.

(8) Too much steam.

(9) Too much air.

(10)Form will not inflate.

(11)Timer control does not

function.

CAUSE

A. Wet steam.

B. Steam leak in machine.

See items 3, 4, and 8.

A. Foreign object in blower.

B. Wheel out of balance.

C. Wheel loose on shaft.

D. Motor mount bent.

E. Motor bearings bad..

See items 1A, 1D, or 11.

Timer set too long.

See item 11.

Timer set too long.

See item 11.

A. Damper is closed.

See items 2 and 11.

A. No power on control.

B. Moisture accumulated.

C. Timer control bad.

REMEDY

See item 4.

Inspect and repair or replace

leaking part.

Remove foreign object.

Inspect wheel for loose weights, out

of round or damage. Repair or

replace as needed.

Tighten set screws on wheel hub.

Repair or replace as needed.

Repair or replace as needed.

Reset timer.

Reset timer.

Open damper; check damper

control linkage and reapir or

replace as needed.

Check fuse on back of control,

replace if needed.

Check for steam or water leaks.

Dry out control.

Replace timer control.

REVOLVING FORM ADJUSTMENT

If the Revolving Form drags on the base rather than turning freely, it must be raised. First remove

the form by lifting it straight up off the base. Then loosen the Bearing Locknut and turn the Bearing

Adjustment Screw counter-clockwise. Check adjustment by replacing form and rotate. Repeat

adjustment if needed.

If Revolving Form is too high above base, steam will escape from between the base and the bottom of

the form. To correct, first remove form from the base. Then loosen the Bearing Locknut and turn the

Bearing Adjustment Screw clockwise. Replace form on the base and check adjustment. Repeat if

needed.

MAINTENANCE RECOMMENDATION

Change the air filter located on the rear of the machine at least every six months depending on the use

and environmental conditions. See the parts section of this manual for the replacement part number.

Page 8