Cissell SFBMAN99, A Owner's Manual

Steam

Finishing

Board

Model A

OWNERS MANUAL

CISSELL MANUFACTURING COMPANY

HEADQUARTERS PHONE: (502) 587-1292

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUAL MUST BE GIVEN TO THE EQUIPMENT OWNER.

MAN99 3/98

Page 1

WARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 2

TABLE OF CONTENTS

Warranty ...................................................................................................................................... 1

Specifications .......................................................................................................................... 3-4

Installation Instructions........................................................................................................... 5

Operating Instructions.............................................................................................................. 6

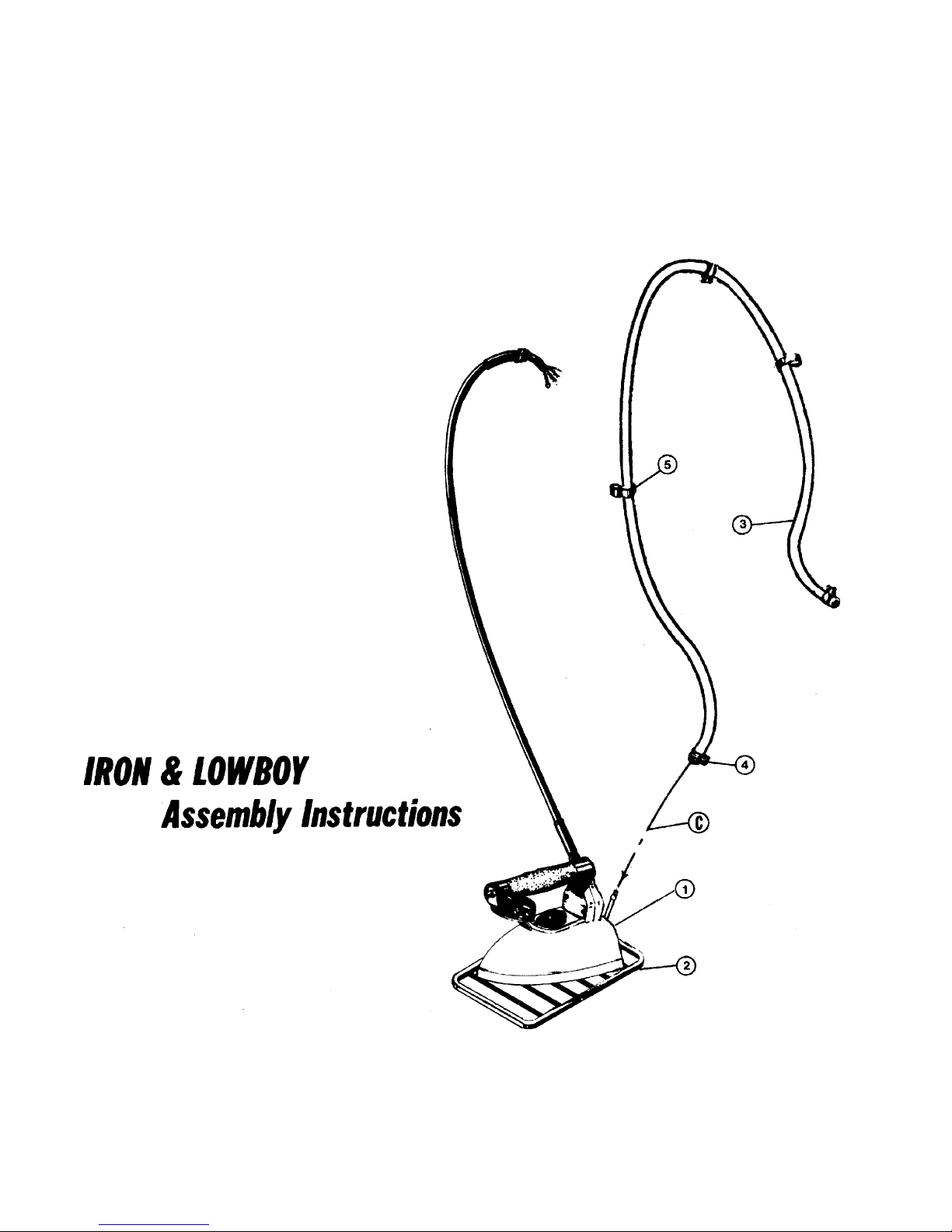

Iron & Lowboy Assembly Instructions .............................................................................. 7-8

Overall View of Parts................................................................................................................. 9

Type D Lowboy Assembly & Installation...................................................................... 10-11

Lowboy Assembly Instructions.............................................................................................. 12

PARTS LISTS

Type P ......................................................................................................................................... 13

Steam Finishing Board..................................................................................................... 14-15

Base Assembly........................................................................................................................... 16

Top Assembly............................................................................................................................. 17

Chamber & Valve Assembly...................................................................................................17

Air Vacuum Valve ..................................................................................................................... 18

Steam Vacuum Valve ...............................................................................................................1 8

Pleat Setter Rack................................................................................................................ 19-20

Two in One Sleeve Board .......................................................................................................2 1

Installation of FB-154 Cover Assembly...............................................................................2 2

Head Valves ...............................................................................................................................23

Trouble-Shooting...................................................................................................................... 24

Page 3

STEAM FINISHING BOARD - MODEL A

The Cissell Steam Finishing Board comes complete with one 12 and one 18 Pleat

Setter, Pleat Setter Rack, Cover and Padding for Board and Tray Assembly. Other

equipment, such as Irons and Lowboys, is optional and must be ordered separately.

Available for steam or central air vacuum.

Specifications

Floor Space ............................................................................. 17 x 53 (43.2 cm x 134.6 cm)

Table Height ......................................................................................................... .37 (93.9 cm)

Length of Working Surface .............................................................................. 46 (116.4 cm)

Width of Front End or Working Surface ............................................................9 (22.9 cm)

Width of Rear End of Working Surface ........................................................... 14 (35.6 cm)

Net Weight ....................................................................................................... 260 lbs. (118 kg)

Domestic Shipping Weight ........................................................... Approx. 300 lbs. (136 kg)

Export Shipping Weight ............................................................ Approx. 475 lbs. (215.7 kg)

Export Shipping Dimensions...................... 61 x 26 x 49 (155 cm x 66 cm x 124.5 cm)

Cubic Feet Export Crating ........................................................................ 45 cu. ft. (1.26 m3)

Boiler Horsepower Required........................................................... Approx. 1 1/4 (.931 kw)

Operating Steam Pressure........................................................................... 100 P.S.I.G. Max

Steam Supply Connection ........................................................................ 1/2 Pipe (1.27 cm)

Steam Return Connection ........................................................................ 1/2 Pipe (1.27 cm)

Steam Vacuum Exhaust Connection................................................ 1 1/4 Pipe (3.175 cm)

Central Air Vacuum Connection ....................................................... 1 1/4 Pipe (3.175 cm)

Specifications with Lowboy & Steam Electric Iron

Overall Height .................................................................................................... 75 (190.5 cm)

Net Weight ....................................................................................................285 lbs. (129.4 kg)

Domestic Shipping Weight ........................................................ Approx. 330 lbs. (149.8 kg)

Export Shipping Weight ............................................................ Approx. 475 lbs. (215.7 kg)

Specifications for Two-In-One Swinging Sleeve Board Assembly (Optional)

Length of Boards .................................................................................................. 23 (58.4 cm)

One Board 6 (15.2 cm) wide at rear end, tapering to 2 1/2 (6.35 cm) at front end.

Other Board 4 7/8 (11.75 cm) wide at rear end, tapering to 2 1/2 (6.35 cm) at

front end.

Net Weight .........................................................................................Approx. 12 lbs. (5.45 kg)

Domestic Shipping Weight .............................................................Approx. 16 lbs. (7.26 kg)

Page 4

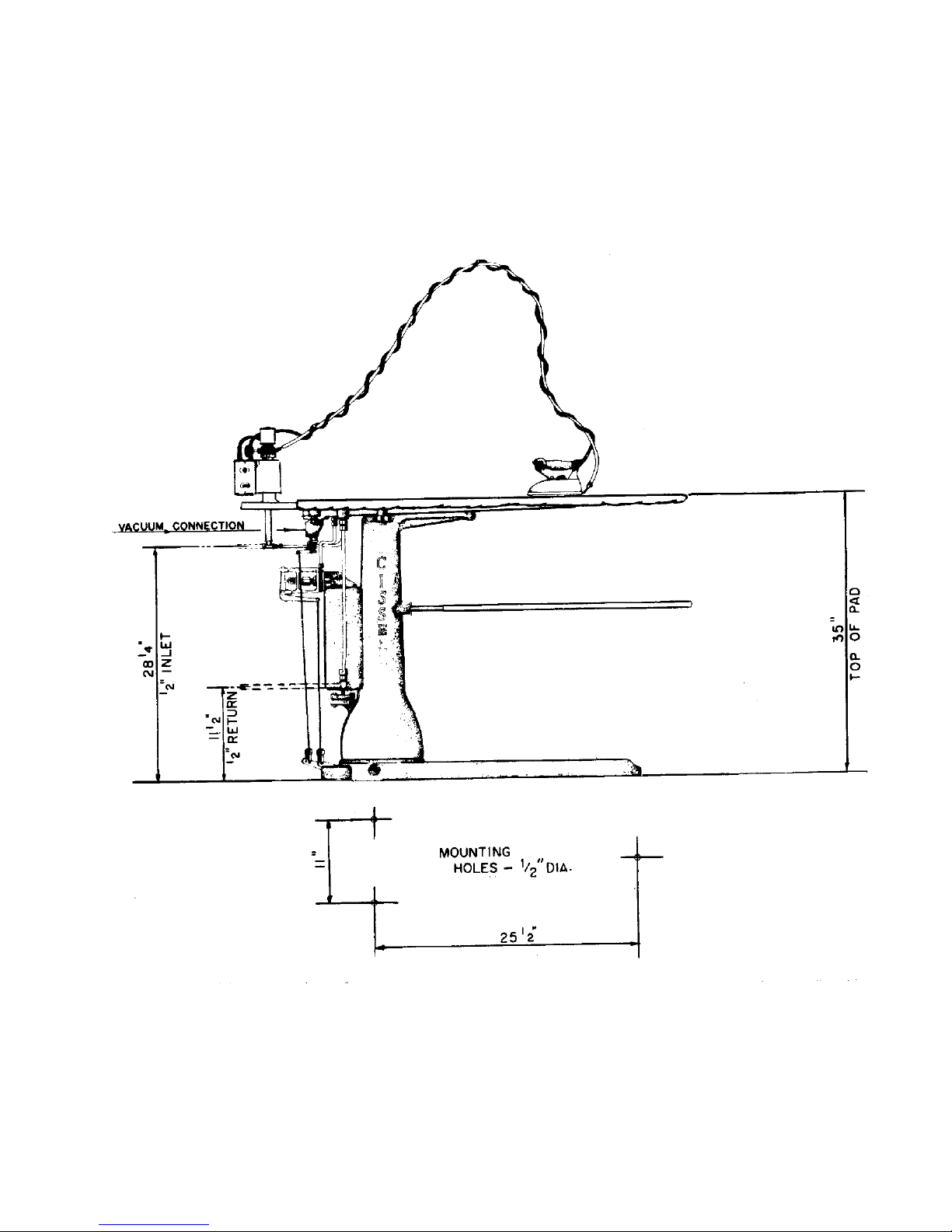

Page 5

SPECIFICATIONS

Boiler Horsepower................. Approx. 1 1/4

Operating Steam Pressure.. 60 to 100

Steam Supply ......................... 1/2 Pipe

Steam Return ......................... 1/2 Pipe

INSTALL STEAM PIPING IN ACCORDANCE WITH

ALL LOCAL REGULATIONS AND REQUIREMENTS

Installation Instructions

Make Steam Supply and

Steam Return Connections

as Illustrated

Whenever possible, horizontal

runs of steam connections must

drain by gravity to respective

Steam Holder. Portions that

drain by gravity, to machine,

without pockets.

Each Steam Holder must drain,

by gravity, to boiler or condensate return tank.

To prevent condensate draining

from Steam Holders to machine,

make steam connections to each

respective Header with a 12 Inch

(or more) vertical riser. Do not

make steam connections to a

Header with a horizontal or

downwardly facing tee or elbow.

Y STRAINER & THERMODYNAMIC TRAP

MAY BE SUBSTITUTED.

Before installing check valve and trap w/built-in strainer, open globe valve in the supply line and allow to flush out any foreign matter that may be in the casting and pipes.

This will help assure proper operation of trap when installed. If steam is gravityreturned to boiler, omit trap but install check valve in return line near machine.

NOTE: For successful operation of machine, install trap as close to floor and as near

machine as possible. Inspect trap carefully for inlet and outlet marks and install according to manufacturers instructions.

IMPORTANT: A separate steam trap should be used with each machine.

Water pockets, or an improperly

drained steam line (or header)

will provide wet steam, causing

unnecessary wetting-out of buck

padding and improper operation

of steam iron.

Page 6

OPERATING INSTRUCTIONS

1. Make certain that steam supply, steam return, and electrical connections have been

made per installation instructions.

2. Open steam supply and return valves for the finishing board. If iron lowboy has a

separate steam supply and return valves, open them also. Allow finishing board to

preheat for at least 15 minutes. (30 minutes preheating time will ensure a hot

buck).

3. Turn on the electrical switch for the iron and lowboy, so the iron can be heating

also.

4. After preheating, if the board is hooked into a central vacuum system, make

certain that it is operating. If the board is provided with steam vacuum, make

certain that it is operating.

5. Depress the iron thumb switch and observe the steam flow through the iron lowboy.

Open or close the steam valve until desired flow is achieved.

6. Place garment to be finished on the buck. Vacuum or upstream may be applied to

the entire buck surface immediately by depressing the appropriate foot pedal.

(Although both foot pedals can be depressed together, the vacuum is inoperative

when upsteaming is being performed). Iron garment using vacuum and/or up

stream as required, until desired garment finish is achieved.

7. The swinging sleeve board (if so equipped) may be used in any position over the

buck.

Page 7

Remove iron (1), iron rest (2) and

steam hose (3) from carton.

A. Unwind iron cord which is wrapped

around iron handle.

B. Set iron on iron rest.

C. Slip steam hose (3) over iron steam

tube and tighten hose clamp (4).

D. Take steam hose (3) in one hand and

iron cord in other and wrap iron cord

around steam hose at least twelve

times. (see illustration on next page).

E. Press hose cord spring clip (5) around

iron cord to help hold cord in position.

Page 8

Loading...

Loading...