Cissell PROHC, Professional Humidity Control System Instruction Manual

Instruction Manual

for the

Professional Humidity Control System

MANPROHC - 5/02

Table of Contents

1 PRO/HC control system............................................................................ 3

2 Setting menu........................................................................... 4

Structure of setting menu....................................................... 4

Selection of setting menu .................................................... 4

Selection of submenus............................................................... 5

Technical menu ................................................................................ 7

Program menu ................................................................................. 1 1

Display menu..................................................................................... 2 2

3 Operating instructions.............................................................. 2 8

Selecting a program .................................................................... 2 8

Weighing of dry linen.................................................................. 2 8

Loading of the drum................................................................... 2 8

Starting the program .................................................................. 2 8

Program course............................................................................... 3 0

4 Technical remarks......................................................................... 3 4

Gas failure .......................................................................................... 3 4

Error messages................................................................................ 3 4

Serial error.......................................................................................... 3 5

Sale switch.......................................................................................... 3 5

Power breakdown ............................................................................ 3 5

Direct access to the program menu............................... 3 5

2

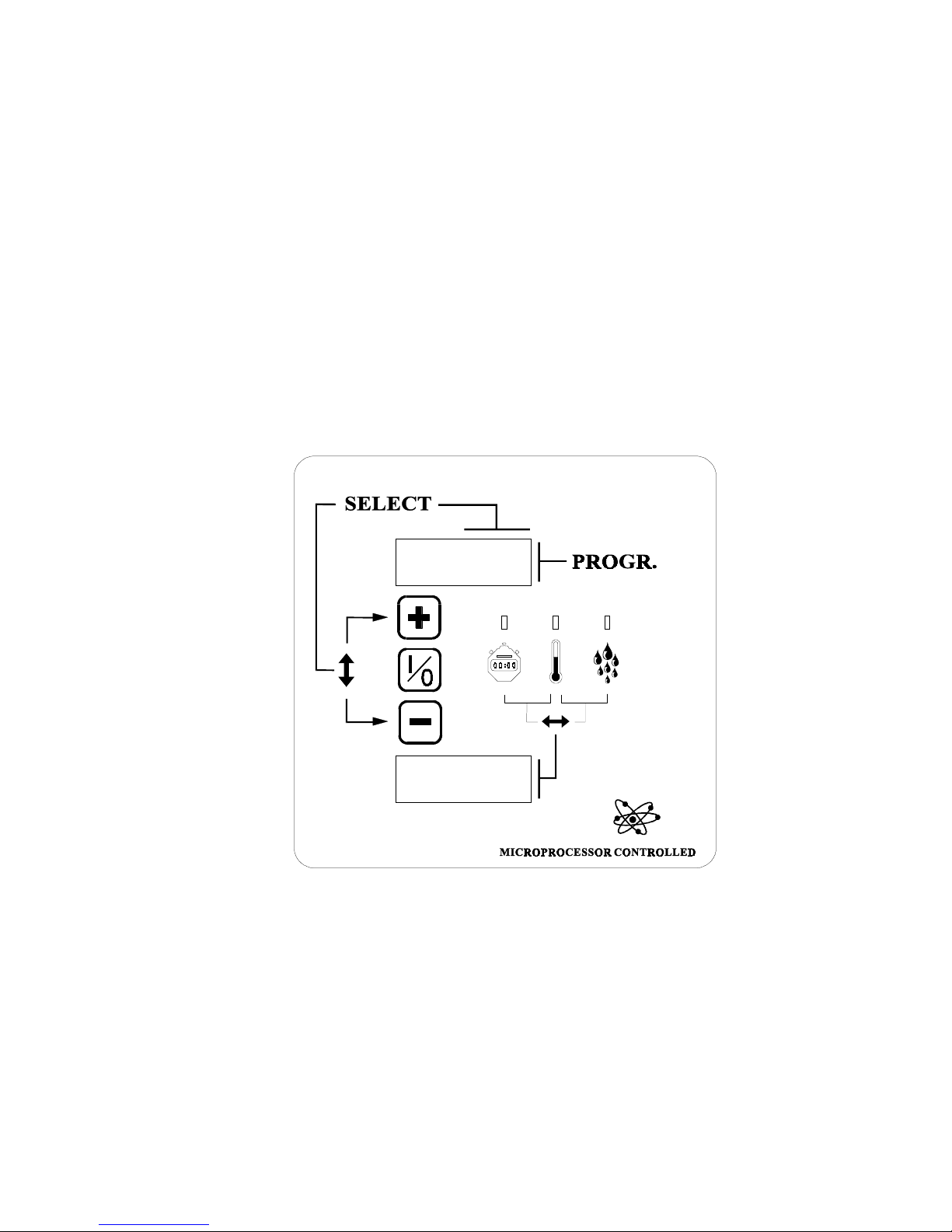

"PRO/HC" control system

The “PRO/HC” is a very powerful control system by means of which you can obtain

perfect drying results, especially when using the humidity control sensors (option).

It is possible to preprogram 30 fixed drying programs. They can be selected and started

directly by the user.

1

Furthermore, you can also preprogram two variable programs - one manual (MANU) and

one automatic program (SEnS), where the user himself can easily put in certain parameters

such as drying temperature, drying time or residual moisture level before starting the

program.

There are also 10 standard programs (31 to 40) available. Those standard programs can

be started directly, but cannot be changed. However it is possible to copy them to another

program number and then change them. This way they can thus serve as a base for another

program.

3

Setting menu

2

Structure of setting

menu

The setting menu is subdivided in three submenus.

Technical menu.

A dryer can be configurated according it’s own technical characteristics.

For example, is it a dryer with reversing of the drum, is the dryer equipped with a residual moisture measuring system etc...

This menu is programmed by the manufacturer and does usually not have to be

modified.

Programming menu.

To program the programs.

Display menu.

To recall data such as supplied labor time of a dryer.

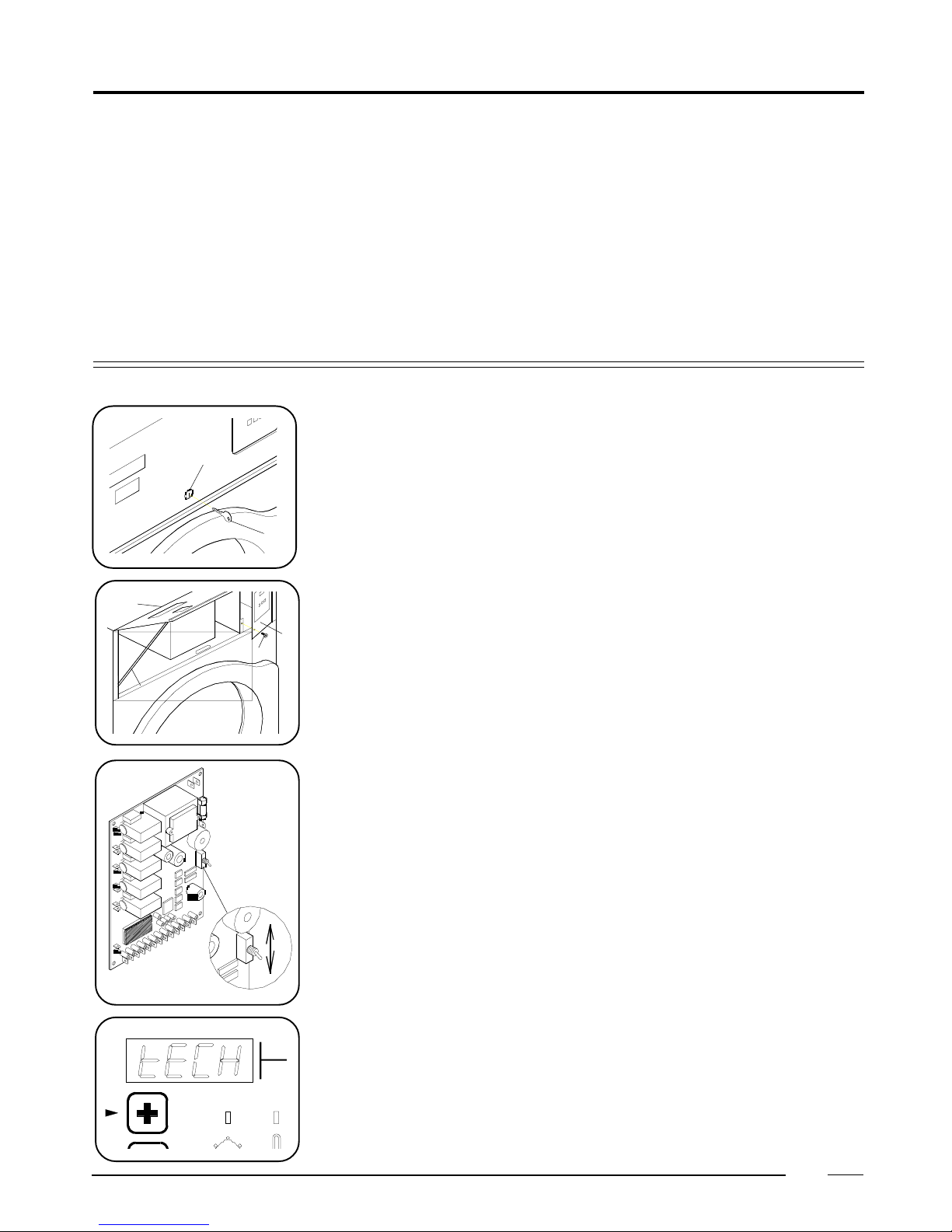

Selection of setting menu

In order to select the setting menu, the switch at the back of the printplate has to be pulled.

A

B

To reach the switch :

- Turn the lock (A) with the delivered key (B) 90°counter-clockwise.

- Open the top front panel (C) and put the support (D) at the left side under this panel in

C

F

E

D

the provided clamp.

- Remove the screw (E) in the operating door (F).

- Then open this door.

Behind this, at the backside of the printplate you find the switch.

By pulling the switch downwards, you reach the setting menu.

When pulling the selection switch in the upper position, “IPSO” appears and afterwards

“TECH” on the upper display.

4

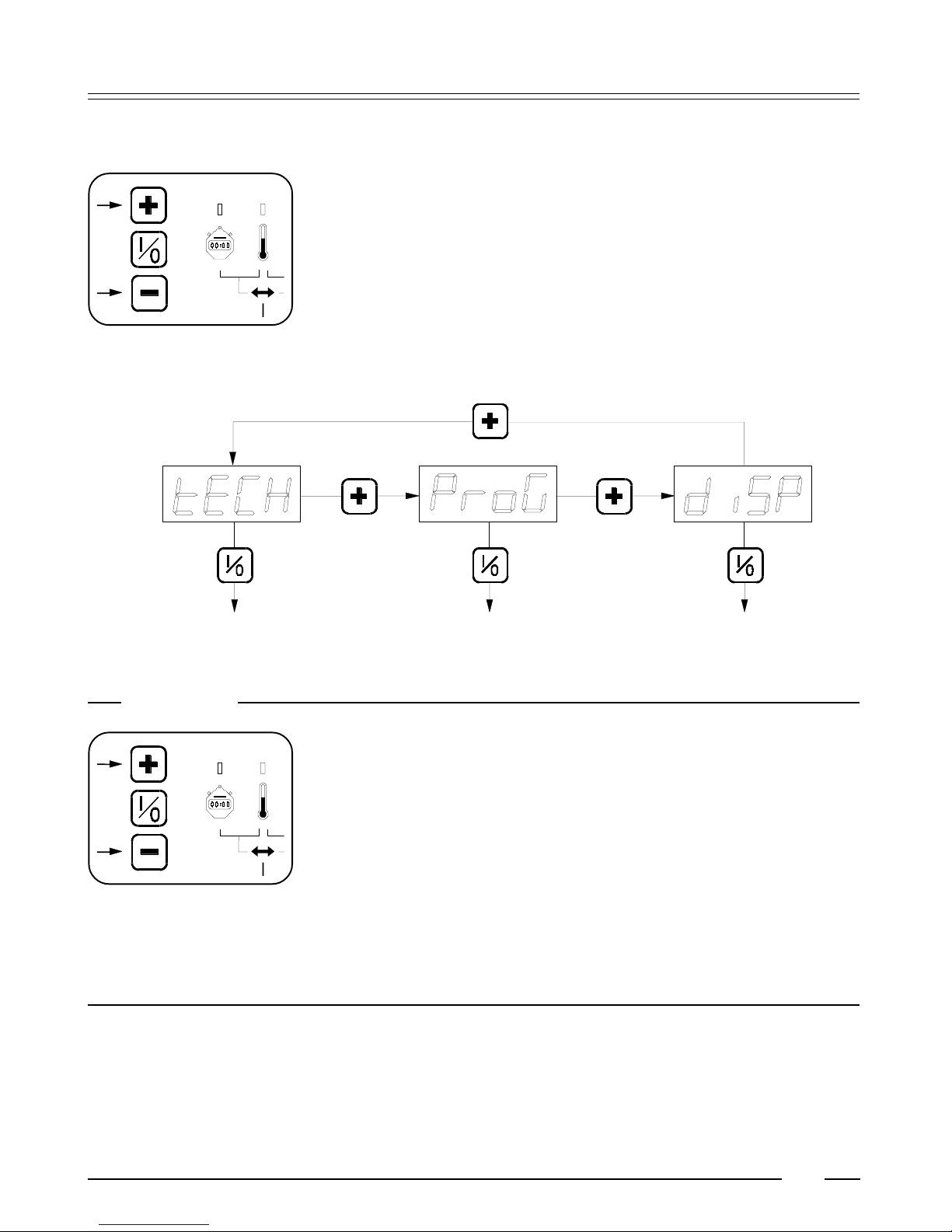

Selection of submenus

2

Selection of submenus or programming parameters in these submenus is done by

means of the three push buttons in front of the operating panel.

Select with the “+” button one of the submenus and then push the middle button in

order to confirm the selection.

XX

If necessary, change this value (default 5 seconds) by means of the + or - button between

5 and 99 seconds.

TECHNICAL MENU PROGRAMMING MEMU DISPLAY MENU

Remark

Operation of the push buttons.

Only when a button is pushed and released afterwards, the action is done.

Extremely hard or long pressing the buttons is totally useless. A light or short push

gives a correct operation.

Return to selection or programming

With the following action, it is always possible to return to the previous step of

selection or to program.

- Push the middle button and keep it pressed.

- Then push (while the middle button is still pressed) shortly the lower button.

- Next release the middle button and the previous step is shown.

5

2

6

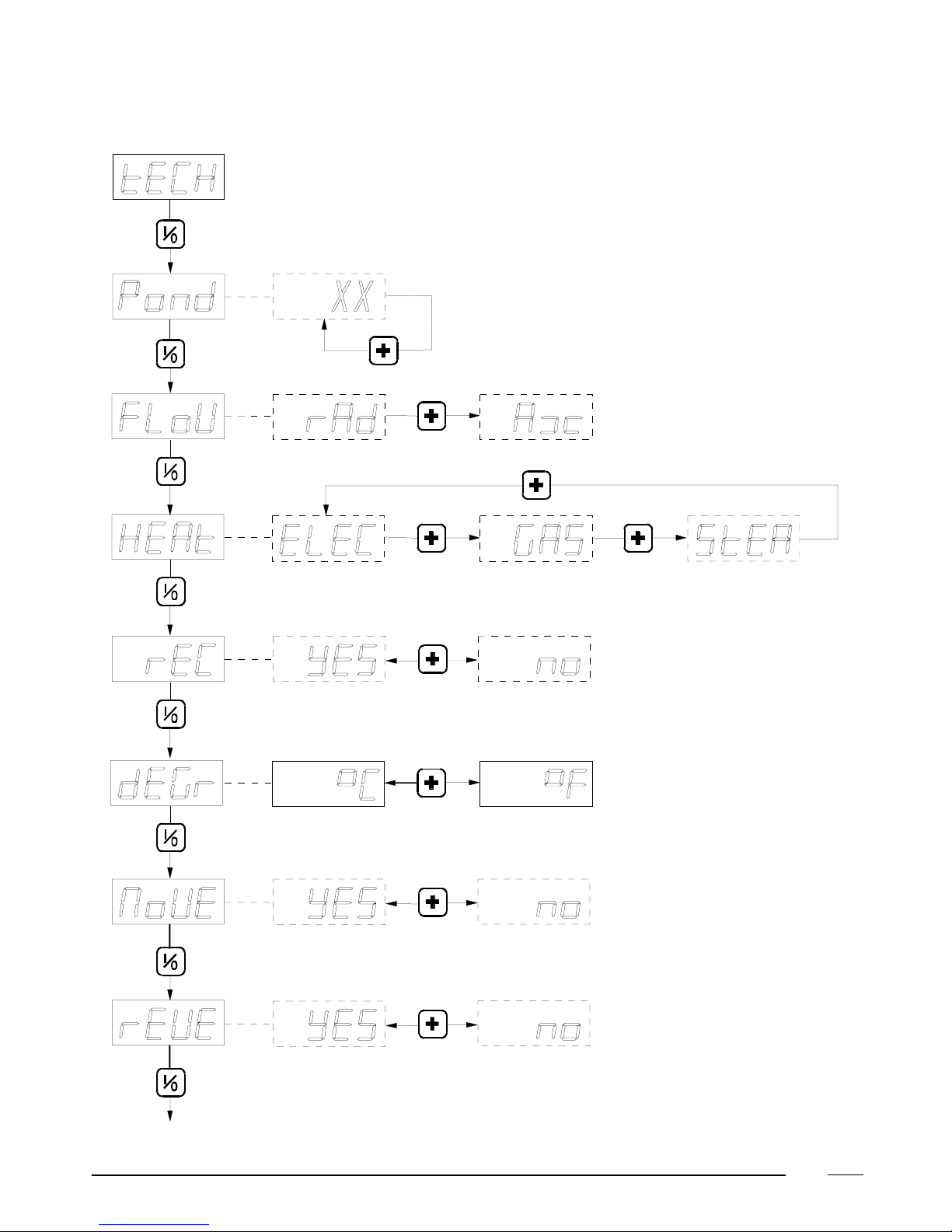

Technical menu

TECH

Press the middle button to continue.

Pond

The lower display shows the drum capacity of the dryer.

If necessary, select another value with the upper button.

Press the middle button to continue.

FloW

To program whether the dryer operates with radial or axial airflow in the drum.

- rAd: Radial current of air means that the air flows from the top to the bottom of the drum.

- Ax : Axial current of air means that the air flows from the back to the front of the drum.

If necessary, change this program with the upper button.

Press the middle button to continue.

HEAt

The lower display shows the kind of heating system that is built in.

- ELEC: electric heating.

- GAS: gas heating

- STEA: steam heating

If necessary, change this program with the upper button.

Press the middle button to continue.

2

rEC

Now the lower display shows (with YES or no) whether the dryer is equipped with heat reclaimer.

If necessary, change this program with the upper button.

Press the middle button to continue.

dEGr

The lower display shows whether the temperature indication will be in °C or °F.

If necessary, change this program with the upper button.

Press the middle button to continue.

MoVE

The lower display shows (with YES or no) whether the rotating detection is built in.

If necessary, change this program with the upper button.

Press the middle button to continue.

rEVE

Now the lower display (YES or no) shows whether the dryer can operate reversing (left-right movement).

If necessary, change this program with the upper button.

Press the middle button to continue.

When “no” was selected, you proceed to "bEEP "

7

2

8

SEnS

Now it is shown on the bottom display (YES or no) whether the dryer is equipped with a residual moisture system with humidity

sensors.

Change this setting, if necessary, with the top button.

Press the middle button to continue.

If “no” was selected, then the display switches immediately to “bEEP”

SE.LE

The bottom display indicates the calibration of the humidity sensors (Sensor level). This is normally set at 5. If the drying results

are continuously too dry or too humid, then this value can be changed between 0 and 10. The lower this factor is set, the dryer

are the drying results. Is this value higher, then the drying results are more humid.

If this factor is changed, then this will automatically have an influence on all drying programs with residual moisture control.

It is normally not necessary to change this factor. It is only meant to give the technicians the possibility to optimize the

drying results when the dryer is used in rather unusual environments.

Change this setting, if necessary, with the top button.

Press the middle button to continue.

St.Pr

Now the bottom display indicates (YES or no) whether the standard programs (31-40) should be shown.

Change this setting, if necessary, with the top button.

Press the middle button to continue.

2

Pr.CY

Here the bottom display indicates (YES or no) whether the cycle contact needs to be programmable. If yes, then the cycle contact

will during the cycle close and open again alternately (pulsating function). If "no" is selected, then the contact will be closed during

the entire drying cycle.

Change this setting, if necessary, with the top button.

Press the middle button to continue.

bEEP

The bottom display indicates (YES or no) whether a buzzer will sound at the end of the cycle.

Change this setting, if necessary, with the top button.

Press the middle button to continue.

tMP.1

The bottom display indicates the temperature inside the cylinder. This is meant as a test of the temperature sensor.

Press the middle button to continue.

If “no” was selected with “SEnS”, then the display will automatically go on to “End”

HuM.1

The bottom display now indicates the humidity inside the cylinder. This is meant as a test of the humidity sensor.

Press the middle button to continue.

tMP.2

The bottom display now indicates the temperature in the room. This is meant as a test of the temperature sensor.

Press the middle button to continue.

HuM.2

The bottom display now indicates the humidity in the room. This is meant as a test of the humidity sensor.

Press the middle button to continue.

End

This is the end of the technical menu

Press the middle button to continue.

Now the display shows IPSO for a while and then goes back to the beginning of the technical menu.

9

10

Programming menu

2

Structure

With the “PRO”, 2 variable and 3 fixed programs can be preprogrammed.

The variable programs "MAnU " and "AutO "

At the start, the user will have to program himself some data such as drying temperature,

drying time or residual moisture and cooldown time.

The fixed programs "1- 30 "

The user will be able to start these programs immediately after the selection. They can be

built up in different parts. This way, for example, the temperature can be programmed

higher at the start of a program in order to obtain a quicker drying - and decreased at the end,

to avoid shrinking.

Remark :

If the residual moisture control system is not used, then there is only 1 variable program

available.

The programs can be programmed according to 2 kinds of drying systems.

Manual drying system

Drying by means of setting the drying time.

Automatic drying system

Drying by means of setting the residual moisture of the linen.

Remark :

If the residual moisture control system is not used, then it is not possible to use the automatic

drying system.

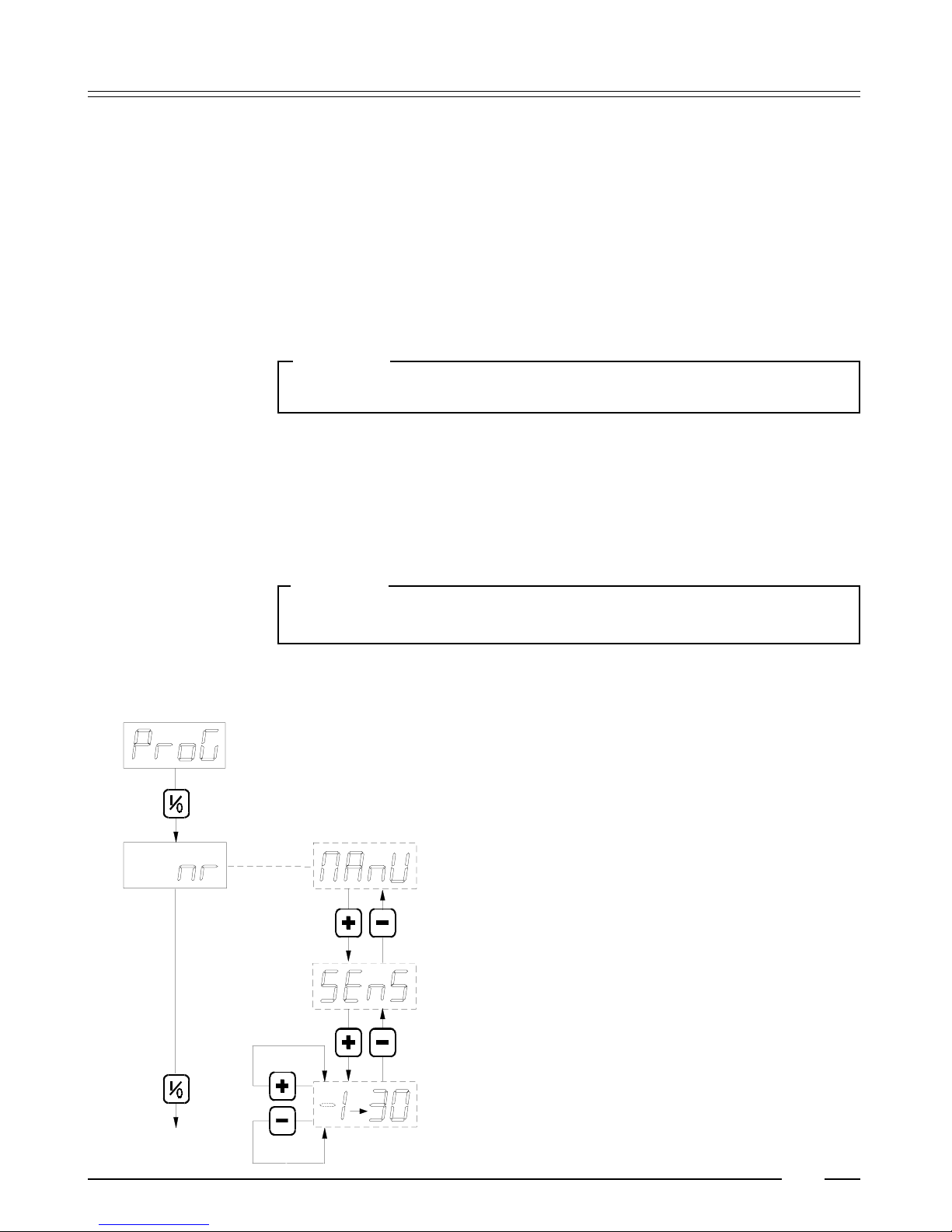

Selection of the

programs

Press the middle button.

" nr " appears on the upper display while the lower display shows the name or number of the

program to be programmed.

With the upper or lower button you have to select now :

MAnU: This is the variable program for manual drying.

SEnS: This is the variable programme for automatic drying.

This program is not shown if the humidity sensors are not

connected.

1-30: These are the fixed programs.

When a program was not programmed, a - sign is placed

before this program number.

Confirm the selection with the middle button.

11

Loading...

Loading...