Cissell PANTOPAMAN39, A Owner's Manual

PP

P

PP

antsants

ants

antsants

TT

T

TT

Model Model

Model

Model Model

OWNER’S MANUOWNER’S MANU

OWNER’S MANU

OWNER’S MANUOWNER’S MANU

opperopper

opper

opperopper

AA

A

AA

ALAL

AL

ALAL

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANY

CISSELL MANUFACTURING COMPANYCISSELL MANUFACTURING COMPANY

HEADQUARTERSHEADQUARTERS

HEADQUARTERS PHONE: (502) 587-1292

HEADQUARTERSHEADQUARTERS

831 SOUTH FIRST ST. SALES FAX: (502) 585-3625

P.O. BOX 32270 SERVICE/PARTS FAX: (502) 681-1275

LOUISVILLE, KY 40232-2270

THIS MANUTHIS MANU

THIS MANU

THIS MANUTHIS MANU

MAN39MAN39

MAN39

MAN39MAN39

9/989/98

9/98

9/989/98

AL MUST BE GIVEN AL MUST BE GIVEN

AL MUST BE GIVEN

AL MUST BE GIVEN AL MUST BE GIVEN

2C WB2C WB

2C WB

2C WB2C WB

Page 1Page 1

Page 1

Page 1Page 1

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

T

O

THE EQUIPMENT OWNER.

TT

O O

THE EQUIPMENT OWNER.THE EQUIPMENT OWNER.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

The Cissell Manufacturing Company (Cissell) warrants all new equipment (and the original parts thereof)

to be free from defects in material or workmanship for a period of one (1) year from the date of sale thereof

to an original purchaser for use, except as hereinafter provided. With respect to non-durable parts normally

requiring replacement in less than one (1) year due to normal wear and tear, including, but not limited to,

cloth goods, valve discs, hoses, and iron cords, and with respect to all new repair or replacement parts for

Cissell equipment for which the one (1) year warranty period has expired, or for all new repair or

replacement parts for equipment other than Cissell equipment, the warranty period is limited to ninety (90)

days from date of sale. The warranty period on each new replacement part furnished by Cissell in fulfillment

of the warranty on new equipment or parts shall be for the unexpired portion of the original warranty period

on the part replaced.

With respect to electric motors, coin meters and other accessories furnished with the new equipment, but

not manufactured by Cissell, the warranty is limited to that provided by the respective manufacturer.

Cissell's total liability arising out of the manufacture and sale of new equipment and parts, whether under

the warranty or caused by Cissell's negligence or otherwise, shall be limited to Cissell repairing or replacing,

at its option, any defective equipment or part returned f.o.b. Cissell's factory, transportation prepaid, within

the applicable warranty period and found by Cissell to have been defective, and in no event shall Cissell be

liable for damages of any kind, whether for any injury to persons or property or for any special or

consequential damages. The liability of Cissell does not include furnishing (or paying for) any labor such

as that required to service, remove or install; to diagnose troubles; to adjust, remove or replace defective

equipment or a part; nor does it include any responsibility for transportation expense which is involved

therein.

The warranty of Cissell is contingent upon installation and use of its equipment under normal operating

conditions. The warranty is void on equipment or parts; that have been subjected to misuse, accident, or

negligent damage; operated under loads, pressures, speeds, electrical connections, plumbing, or conditions

other than those specified by Cissell; operated or repaired with other than genuine Cissell replacement

parts; damaged by fire, flood, vandalism, or such other causes beyond the control of Cissell; altered or

repaired in any way that effects the reliability or detracts from its performance, or; which have had the

identification plate, or serial number, altered, defaced, or removed.

No defective equipment or part may be returned to Cissell for repair or replacement without prior written

authorization from Cissell. Charges for unauthorized repairs will not be accepted or paid by Cissell.

CISSELL MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY, STATUTORY OR OTHERWISE,

CONCERNING THE EQUIPMENT OR PARTS INCLUDING, WITHOUT LIMITATION, A WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OR A WARRANTY OF MERCHANTABILITY. THE

WARRANTIES GIVEN ABOVE ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED. CISSELL NEITHER ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT,

ANY OTHER WARRANTY OR LIABILITY IN CONNECTION WITH THE MANUFACTURE, USE OR SALE

OF ITS EQUIPMENT OR PARTS.

For warranty service, contact the Distributor from whom the Cissell equipment or part was purchased. If

the Distributor cannot be reached, contact Cissell.

Page 2Page 2

Page 2

Page 2Page 2

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

———————————————————————————————————————————

Warranty ....................................................................................................................2

Specifications, General Information .........................................................................4

Dimension Drawings .................................................................................................5

Electrical Connections, Steam Connections .............................................................6

Steam Connections Illustration ................................................................................7

Operating Instructions .......................................................................................... 8-9

Air Pressure Control Operation ..............................................................................10

Installation of Bag and Boots..................................................................................11

Pleat Setter Cover Assembly and Adjustment.......................................................12

Pants Topper Bag, Sealing Steam Leaks................................................................13

Plastic Sleeve, Bearing Adjustment........................................................................14

Motor and Blower Assembly Removal....................................................................15

Belt T ension Adjustment, Pulley Alignment ..........................................................15

Control Switches Replacement, Knob Adjustment ................................................16

Maintenance Instructions .......................................................................................17

Simplified Wiring Diagram .....................................................................................18

Wiring Diagram .......................................................................................................1 9

Trouble Shooting Service Charts ...................................................................... 20-21

ILLUSTRAILLUSTRA

ILLUSTRA

ILLUSTRAILLUSTRA

Overall View.............................................................................................................23

Overall View.............................................................................................................24

Control Switches, Track Assembly..........................................................................25

Motor and Blower Assembly ...................................................................................26

Piping and Tubing ...................................................................................................27

Solenoid V alve Parts ................................................................................................28

Electric Control Box.................................................................................................29

Water Spray Gun, Pistol Type.................................................................................30

Spray Gun, Piping, and Condenser Parts...............................................................3 1

Condenser Parts.......................................................................................................32

TED PTED P

TED P

TED PTED P

ARTSARTS

ARTS

ARTSARTS

Page 3Page 3

Page 3

Page 3Page 3

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

Electric Motor........................................ 1/3 H.P., 115V. or 230V., 60 Cycle, AC, 1 Phase

........................................................... 220V., 50 Cycle, AC, 1 Phase

Operating Steam Pressure..................... 100 P.S.I.G. (5.8 Bars) Maximum

Boiler Horsepower (Approx.).................. 3/4 (7.3 kw)

Steam Supply Line................................. 1/2" Pipe (1.3 cm)

Steam Return Line................................. 1/2" Pipe (1.3 cm)

Net Weight............................................ 230 Pounds (104.5 kg)

Note: Specifications are subject to change without prior notice.

TIONSTIONS

TIONS

TIONSTIONS

GENERAL INFORMAGENERAL INFORMA

GENERAL INFORMA

GENERAL INFORMAGENERAL INFORMA

IMPORTIMPORT

IMPORT

IMPORTIMPORT

air line filter to the regulator as shown in the “Air Line Assenbly” drawing in the Parts section of this manual.

UNCRAUNCRA

UNCRA

UNCRAUNCRA

PROPRO

PRO

PROPRO

installed and is ready for operation.

AA

UTUT

A

UT

AA

UTUT

factory for 4 seconds normal steaming. Adjust as required.

AA

UTUT

A

UT

AA

UTUT

seconds for normal drying. Adjust as required.

ANT:ANT:

ANT: The air line filter was removed from the machine for shipping. When installing the unit, fasten the

ANT:ANT:

TING:TING:

TING: Set crate upright, remove sides and top. Remove the two rear base bolts and lift from crate.

TING:TING:

TECTIVE PLASTIC COVER:TECTIVE PLASTIC COVER:

TECTIVE PLASTIC COVER: Do not remove plastic cover from the nylon pants topper bag until machine is

TECTIVE PLASTIC COVER:TECTIVE PLASTIC COVER:

OMAOMA

TIC STEAM TIC STEAM

OMA

TIC STEAM

OMAOMA

TIC STEAM TIC STEAM

OMAOMA

TIC TIC

OMA

TIC

OMAOMA

TIC TIC

AIR AIR

AIR

AIR AIR

TIMER:TIMER:

TIMER: The Automatic Steam Timer (A) is adjustable from 0 to 60 seconds, and is set at the

TIMER:TIMER:

TIMER:TIMER:

TIMER: The Automatic Air Timer (B) is adjustable for 0 to 60 seconds and is factory set for 25

TIMER:TIMER:

TIONTION

TION

TIONTION

Page 4Page 4

Page 4

Page 4Page 4

PP

ANTS ANTS

P

ANTS

PP

ANTS ANTS

TT

OPPER - MODEL OPPER - MODEL

T

OPPER - MODEL

TT

OPPER - MODEL OPPER - MODEL

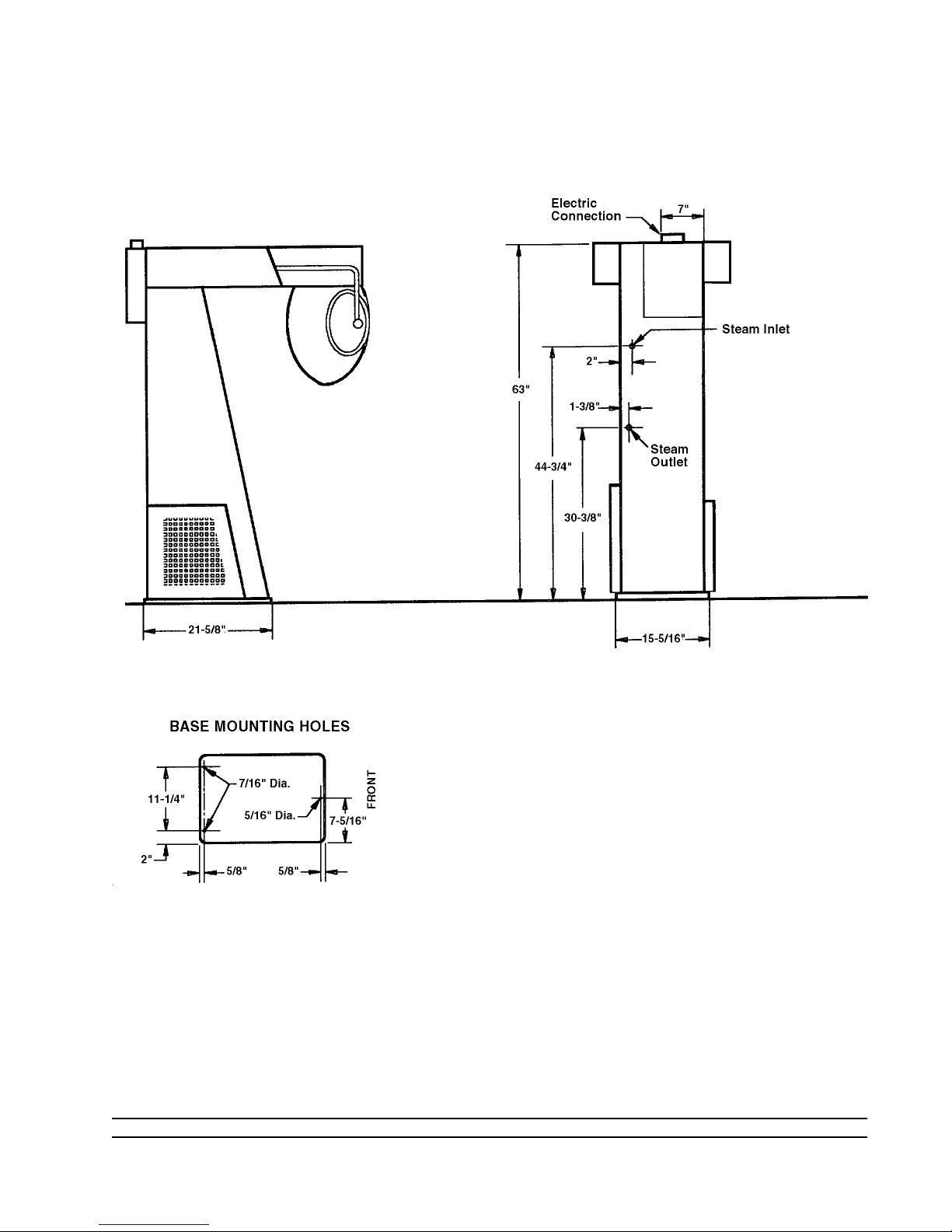

A - DIMENSION DRAA - DIMENSION DRA

A - DIMENSION DRA

A - DIMENSION DRAA - DIMENSION DRA

WINGSWINGS

WINGS

WINGSWINGS

Dimensions given in inches plus/minus 1/2" and are subject to change without prior noticeDimensions given in inches plus/minus 1/2" and are subject to change without prior notice

Dimensions given in inches plus/minus 1/2" and are subject to change without prior notice

Dimensions given in inches plus/minus 1/2" and are subject to change without prior noticeDimensions given in inches plus/minus 1/2" and are subject to change without prior notice

Page 5Page 5

Page 5

Page 5Page 5

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

IMPORTANT: Consult your local electrical codes before making any connections, and be certain that the connections

conform with all applicable codes.

The standard Pants Topper has single phase motors. Before installation, check nameplates on motor and control box

for rated voltage and current specifications. Make electrical connections as indicated on the wiring diagram attached to machine.

For single phase current, connect power leads, L1 and L2, to an approved fused disconnect switch in power line.

For standard, single phase machine to three phase current, connect power leads, L1 and L2, to any two terminals of

an approved fused disconnect switch in the three phase power line.

For three phase current, connect power leads L1, L2, and L3 to the three terminals of an approved fused disconnect

switch in the three phase power line. The motor must rotate clockwise when facing the belt and pulley. If rotation is

incorrect, transpose any two leads connecting the power line, and rotation of motor will reverse.

STEAM CONNECTIONSSTEAM CONNECTIONS

STEAM CONNECTIONS

STEAM CONNECTIONSSTEAM CONNECTIONS

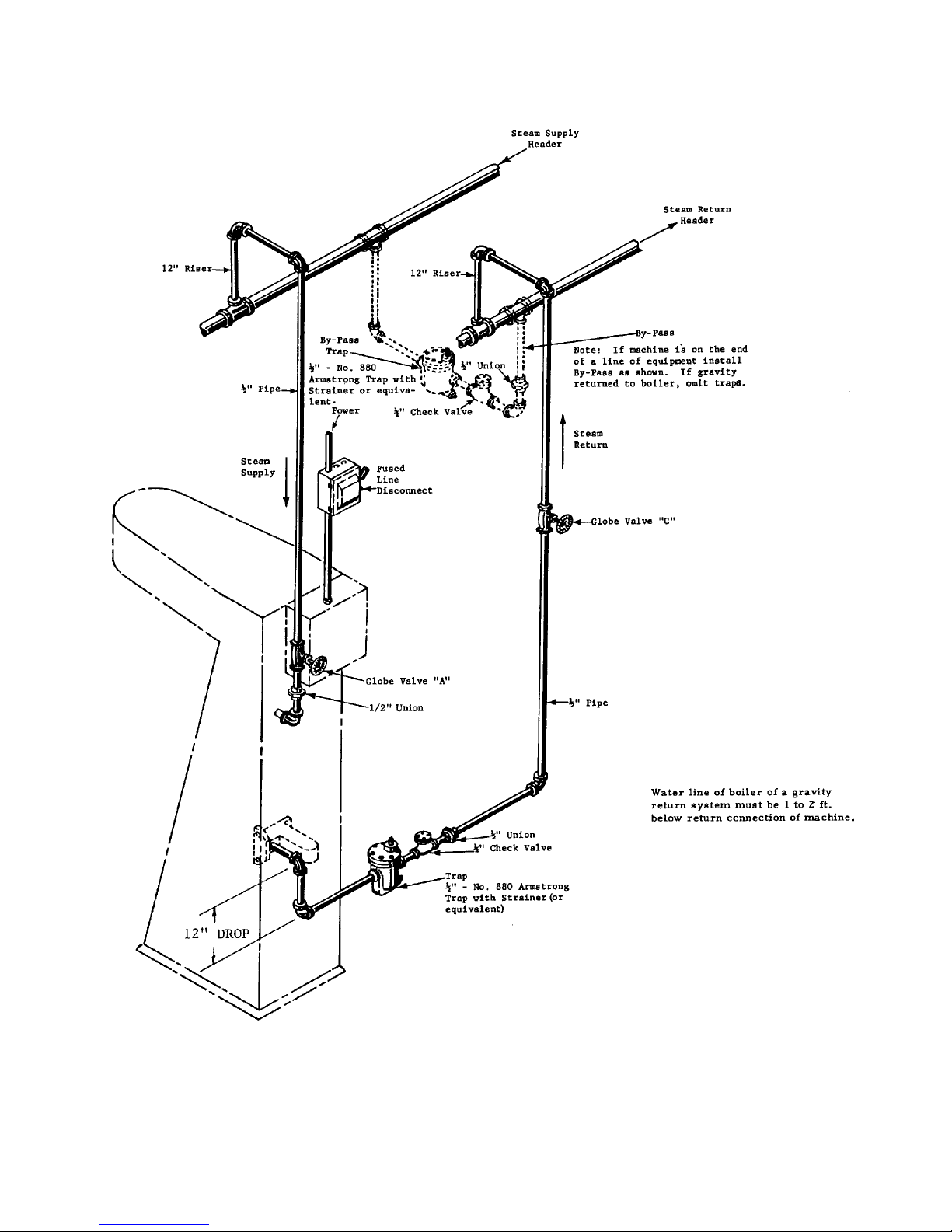

Refer to drawing on opposite page for steam supply and return connections.

All horizontal runs must drain by gravity to respective steam header. Portions that cannot drain to header must

drain by gravity to machine, without water pockets. Each steam header must drain, by gravity, to boiler or condensate return tank.

To prevent condensate draining from steam headers to machine, make steam connections (to each respective header)

with a 12 inch or more, vertical riser. Do not make steam connections to a header with a horizontal or downwardly

facing tee or elbow.

Water pockets or an improperly drained steam line (or header) will provide wet steam, causing unnecessary wettingout of buck padding.

Before installing check valve, trap and strainer, connect steam supply to machine from globe valve (A). Open globe

valve (A) to flush any foreign matter that may be in castings or pipes. Open globe valve (C) to flush foreign matter

from return connections, then connect steam return from valve (C) to machine with check valve, trap, and strainer as

shown. If steam is gravity returned to boiler, omit trap.

NOTE: For successful operation of machine, install trap as close to floor and as near machine as possible. Inspect

trap carefully for inlet and outlet marks and install according to manufacturer’s instructions.

IMPORTANT: A separate steam trap must be used with each machine.

CAUTION: Before operating Pants Topper, open globe valves in steam lines. Check carefully for steam leaks and see

that trap is operating properly. Under no circumstances should machine be operated until hot. Operating the

machine cold will wet the nylon bag and padding. To dry a wet bag or pad, depress the ON manual Air switch. Air

will operate continously until OFF Air switch is pressed.

Page 6Page 6

Page 6

Page 6Page 6

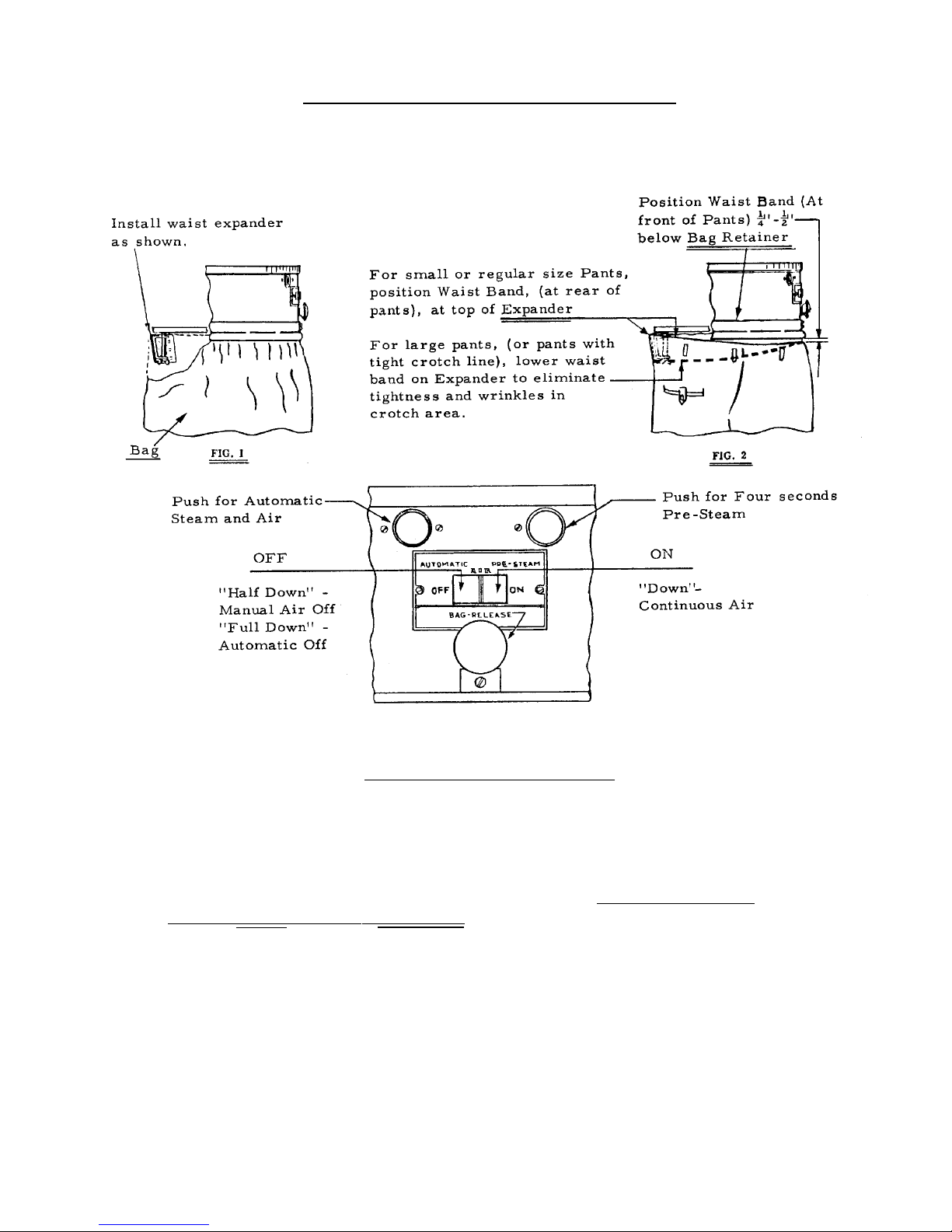

Fig. 2

Page 7Page 7

Page 7

Page 7Page 7

OPERAOPERA

OPERA

OPERAOPERA

CAUTION: Timer Adjustments

STEAM: Must not be greater than 6 seconds AIR: Must not be less than 20 seconds

(Average setting 4-5 Seconds) (Average Setting 25 Seconds)

NOTE: Straighten Pockets; Button Pocket Flaps; Button or Snap front of

Waist Band, But Do Not Close Zipper.

1. Grip rear top portion of bag and puff waist expander forward until it locks.

2. Lift trousers onto form, placing back center of waist band high onto waist expander.

Pull trousers forward; hook, button or snap front of waist band.

Do not close zipper of pants.

3. Continue to hold forward tension on trousers and push “bag release” knob. Allow automatic tension of waist

expander to draw front of trousers onto face of buck.

4. Adjust and center pants to highest position on buck. Align crotch; do not raise pants too high as crotch must

remain loose in buck opening to prevent wrinkling of crotch area.

5. To soften pleats (Before making respective pleat lays), push PRE-STEAM BUTTON. Steam Timer controls

pre-steaming automatically.

NOTE: Excessive moisture will de-lusterize Rayon acetates. This may be minimized by

using “air” while steaming; or shortening of steam cycle by depressing fully “off”

air switch. Do not use the pre-steaming operation on rayon acetates.

TING INSTRUCTIONSTING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONSTING INSTRUCTIONS

6. Smooth out material and lay each pleat separately, working from fly toward pleat being layed. Align pleat

with leg crease; close pleat holder. If too much material is encountered during laying of pleats, trousers are

too high on the buck and too low on the rear expander. If too little material is available to lay the pleat

properly, the trousers may be too low on the buck and too high on the expander.

7. Push AUTOMATIC Button. Steam and Air Timers control steam followed by air automatically.

Leg-out during the final phase of the automatic cycle of the Topper.

8. Place creased trousers on hanger and make necessary touch-ups on Puff Iron before placing pants on finish

rail.

Page 8Page 8

Page 8

Page 8Page 8

POSITIONING PANTS ON TOPPER

(A) At “Start-Up” (or after “Idle Periods” of operation) preheat before operating:

a. Lower pleat clamps onto padded buck; Operate Topper on “Manual Air”

continuously for about one (1) minute.

(B) Either PRE-STEAM or AUTOMATIC Steam-Air cycle may be cancelled by

pushing “OFF” Air Switch fully down.

(C) For Suede, Chamois or leather trimmed trousers, use manual air switch to provide

air “while steaming”, as full air pressure is required to hold pants taut during steaming

cycle.

(D) Tops Trousers, slacks, shorts (Lightweight or Heavyweight) sizes 28 to 50.

NOTE: Top small sizes, (including boys pants and small size ladies

slacks) on 1M Puff Iron.

Top large sizes on end of utility press.

OPERATING INSTRUCTIONS

Page 9Page 9

Page 9

Page 9Page 9

Loading...

Loading...