Page 1

CHA PT ER

2

Preparing for Installation

Before installing the router, consider power and cabling requirements that must

be in place at your installation site, special equipment for installing the router, and

the environmental conditions your installation site must meet to maintain normal

operation. This chapter guides you through the process of preparing for router

installation.

The shipping package for the router is engineered to reduce the chances of product

damage associated with routine material handling experienced during shipment.

• The router should always be transported or stored in its shipping package in

the upright position.

• Keep the router in the shipping container until you have determined the

installation site.

Use the unpacking instructions included with the router to unpack it and inspect

all items for shipping damage. If an item appears damaged, contact a Cisco

customer service representative immediately.

This chapter contains the following installation topics:

OL-17440-01

• Safety Guidelines, page 2-2

• Site Requirement Guidelines, page 2-7

• PRP Port Connection Guidelines, page 2-24

• Alarm Card Connection Guidelines, page 2-33

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-1

Page 2

Safety Guidelines

Safety Guidelines

Before you perform any procedure in this publication, review the safety

guidelines in this section to avoid injuring yourself or damaging the equipment.

In addition, be sure to review the safety warnings listed in the Regulatory

Compliance and Safety Information for Cisco 12000 Series Internet Routers

publication that accompanied your router before you begin router installation.

Note that the information in this section are guidelines and do not include every

potentially hazardous situation. When you install a router, always use common

sense and caution.

Safety with Equipment

• Cisco equipment operates safely when used in accordance with its

specifications and product-usage instructions.

• Never install equipment that appears damaged.

• Do not perform any action that creates a potential hazard to people or makes

the equipment unsafe.

• Never attempt to lift an object that might be too heavy for you to lift by

yourself.

• Do not wear loose clothing, jewelry, or other items that could get caught in

the router.

Chapter 2 Preparing for Installation

2-2

• Keep tools and assembly components away from walk areas.

• Do not work alone if potentially hazardous conditions exist.

• Keep the work area clear and dust-free during and after installation. Do not

allow dirt or debris to enter into any laser-based components.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 3

Chapter 2 Preparing for Installation

Safety with Electricity

• The installation shall be in compliance with national and local electrical

codes: in the United States, National Fire Protection Association (NFPA) 70,

United States National Electrical Code; in Canada, Canadian Electrical Code,

part I, CSA C22.1; in other countries, International Electrotechnical

Commission (IEC) 60364, part 1 through part 7.

• Before you begin any procedures requiring access to the interior of the router,

locate the emergency power-off switch for the room in which you are

working.

• Disconnect all power source cables before installing or removing a router.

• Never assume that power has been disconnected from a circuit; always check.

• Carefully examine your work area for possible hazards such as moist floors,

ungrounded power extension cables, and missing safety grounds.

• Only a DC power source that complies with the safety extra-low voltage

(SELV) requirements in UL60950, CSA-C22.2 No. 60950, EN60950,

ACATS001, AS/NZS 60950,and IEC60950 can be connected to the line card

chassis DC-input power system.

• A line card chassis configured with the DC-input power system shall have a

readily accessible two-poled disconnect device incorporated in the fixed

wiring.

Safety Guidelines

OL-17440-01

• The line card chassis requires short-circuit (overcurrent) protection to be

provided as part of the building installation.

• If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim. Disconnect power to the router.

–

If possible, send another person to get medical aid; otherwise, assess the

condition of the victim and then call for help.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-3

Page 4

Safety Guidelines

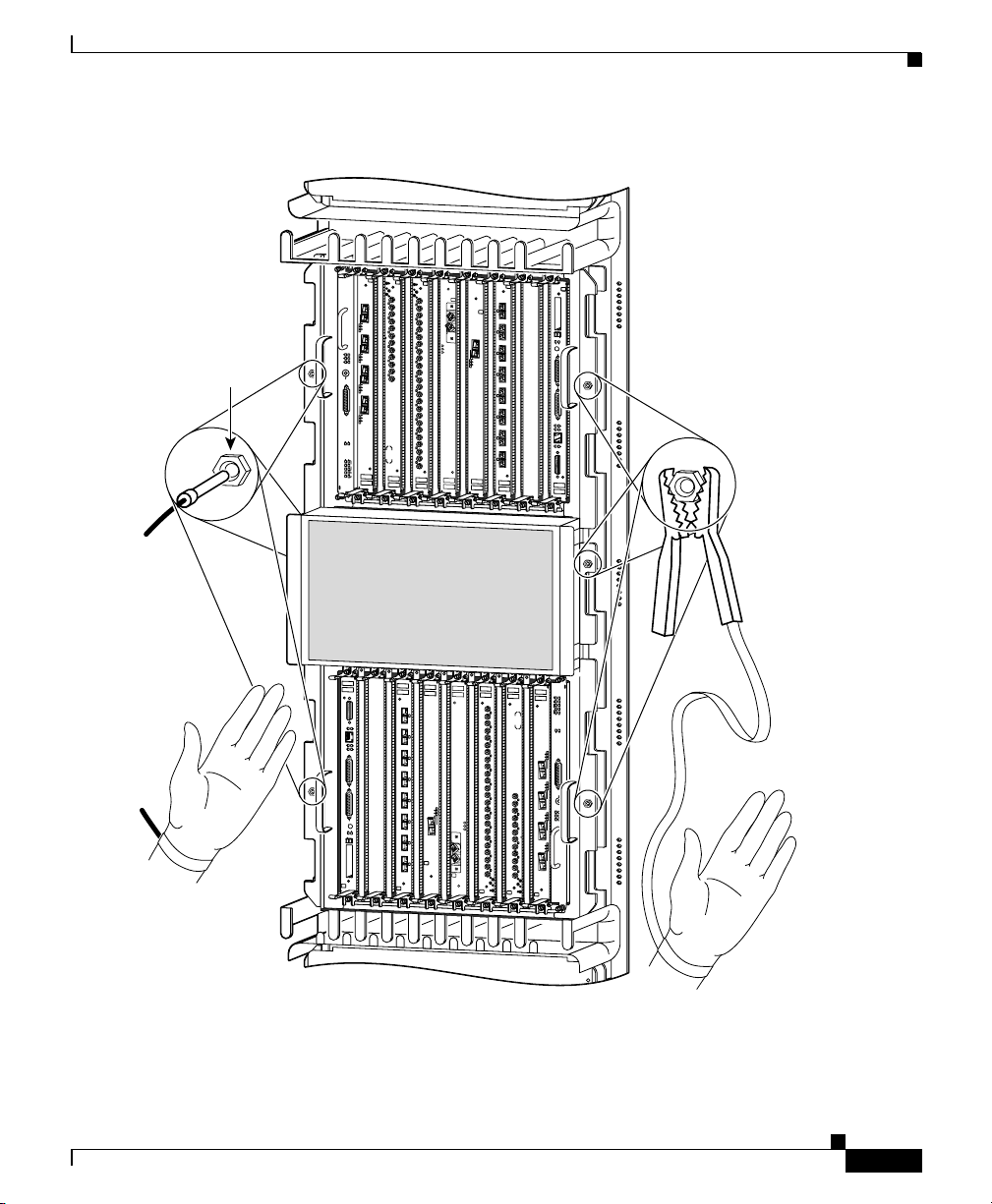

Preventing Electrostatic Discharge Damage

Many router components can be damaged by static electricity. Not exercising the

proper electrostatic discharge (ESD) precautions can result in intermittent or

complete component failures. To minimize the potential for ESD damage, always

use an ESD-preventive antistatic wrist strap (or ankle strap) and ensure that it

makes good skin contact.

Note Check the resistance value of the ESD-preventive strap periodically. The

measurement should be between 1 and 10 megohms.

Before you perform any of the procedures in this guide, attach an ESD-preventive

strap to your wrist and connect the leash to the chassis or to another grounded,

bare metal surface as shown in Figure 2-1.

Chapter 2 Preparing for Installation

2-4

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 5

Chapter 2 Preparing for Installation

Figure 2-1 Connecting an ESD-Preventive Strap to the Router Chassis

DOWN

LOOP RA LA

DOWN

LOOP RA LA

CDHNT CD

CDHNT CD

TX

TX

0

0

RX

RX

0

TX

TX

1

1

RX

RX

A

C

T

IV

C

E

A

TX

R

TX

R

R

IE

X

R

P

2

K

2

T

RX

RX

TX

TX

ESD

connection

socket

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

1

3

A

C

3

TI

V

CRITICAL

RX

MAJOR

A

C

T

TX

I

V

C

MINOR

E

A

R

R

R

4

I

X

E

R

P

K

T

RX

TX

2

5

RX

ACO/LT

A

C

T

IV

C

E

A

R

R

R

I

X

E

R

P

K

T

ALARM

3

A

C

T

IV

C

E

A

R

R

R

IE

X

R

P

K

T

ENABLED

FAIL

ENABLED

FAIL

0

Q OC-3/STM-POS

CSC

1

6DS3–SMB P

0

1

SFC

ALARM

2

/

H

/

F

ROUTE PROCESSOR

RJ-45

MII

RX

TX

COLL

LINK

CONSOLE

X

U

A

RESET

SLOT-1

SLOT-0

EJECT

RX

TX

4

RX

TX

5

RX

TX

6

RX

TX

7

RX

TX

8

RX

TX

9

RX

TX

10

RX

TX

11

RX

12DS3–SMB P

/

H

/

F

FAST ETERNET

0

E

C

A

R

R

IE

R

X

R

P

K

T

A

C

T

IV

C

E

A

R

R

R

IE

X

C

R

E

L

L

OC-48/STM-16-SCPOS

OC-12/STM-4 ATM

FAST ETERNET

F

/

H

/

OC-12/STM-4 ATM

12DS3–SMB P

RX

OC-48/STM-16-SCPOS

11

TX

RX

10

TX

RX

9

TX

RX

8

TX

RX

7

TX

RX

6

TX

RX

5

L

L

E

R

C

X

IE

R

R

R

A

E

C

IV

T

C

A

TX

RX

4

TX

T

K

X P

R

IER

R

R

RX

A

C

E

0

IV

T

3

C

A

TX

RX

2

TX

RX

1

TX

RX

0

TX

CDHNT CD

LOOP RA LA

DOWN

EJECT

SLOT-0

SLOT-1

RESET

A

U

X

CONSOLE

LINK

COLL

TX

RX

MII

RJ-45

ROUTE PROCESSOR

F

/

H

/

2

ALARM

SFC

1

0

6DS3–SMB P

1

CSC

Q OC-3/STM-POS

0

FAIL

ENABLED

FAIL

ENABLED

T

K

P

R

E

X

I

R

R

R

A

E

C

IV

T

C

A

3

ALARM

T

K

P

R

E

X

I

R

R

R

A

E

C

IV

T

C

A

ACO/LT

RX

5

2

TX

RX

T

K

P

R

E

X

I

4

R

R

R

MINOR

A

E

C

IV

TX

T

C

MAJOR

A

CRITICAL

RX

3

1

TX

RX

T

K

2

P

R

E

X

I

R

R

R

TX

A

E

C

IV

T

C

A

RX

1

TX

0

RX

0

TX

CDHNT CD

LOOP RA LA

DOWN

Safety Guidelines

OL-17440-01

26208

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-5

Page 6

Safety Guidelines

Lifting Guidelines

A fully configured router can weigh as much as 275 pounds (lb)

(124.74 kilograms (kg)), while an empty chassis weighs 125 lb (56.7 kg). These

systems are not intended to be moved frequently. Before you install the router,

ensure that your site is properly prepared so you can avoid having to move the

router later to accommodate power sources and network connections.

Use the following lifting guidelines to avoid injury to yourself or damage to the

equipment:

• Do not lift equipment alone; have another person help you to lift heavy

• Ensure that your footing is solid; balance the weight of the object between

• Lift the equipment slowly; never move suddenly or twist your body as you

• Keep your back straight and lift with your legs, not your back. When bending

Chapter 2 Preparing for Installation

equipment.

your feet.

lift.

down to lift equipment, bend at the knees (not at the waist), to reduce the

strain on your lower back muscles.

Caution To prevent equipment damage, never attempt to lift or tilt the router chassis using

the handles on the blower module or on line cards. These handles do not support

the weight of the chassis.

Compliance and Safety Information

The Cisco XR 12416 router is designed to meet the regulatory compliance and

safety approval requirements. Refer to the Regulatory Compliance and Safety

Information for the Cisco 12000 Series Router if you require additional

compliance information (see “Obtaining Documentation and Submitting a

Service Request” section on page -xiv for site information).

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-6

OL-17440-01

Page 7

Chapter 2 Preparing for Installation

Laser Safety

Some line cards are equipped with ports that can emit hazardous laser radiation

from the aperture when there is no cable connected to the port. This invisible

radiation can cause eye injury if you stare into the port.

Site Requirement Guidelines

Warning

To avoid eye injury, never stare into open line card ports.

Site Requirement Guidelines

This section provides the following site requirement guidelines that you must

consider before installing the router:

• Rack-Mounting Guidelines, page 2-7

• Air Flow Guidelines, page 2-14

• Temperature and Humidity Guidelines, page 2-16

• Power Connection Guidelines, page 2-16

• NEBS Supplemental Unit Bonding and Grounding Guidelines, page 2-21

• Site Wiring Guidelines, page 2-23

Rack-Mounting Guidelines

The router can be mounted in most 2-post, 4-post, or telco-type 19-inch

equipment racks that comply with the Electronics Industries Association (EIA)

standard for equipment racks (EIA-310-D). The rack must have at least two posts

with mounting flanges to mount the router chassis. The distance between the

center lines of the mounting holes on the two mounting posts must be 18.31 inches

± 0.06 inch (46.50 cm ± 0.15 cm). The rack-mounting hardware included with the

router is suitable for most 19-inch equipment racks or telco-style frames.

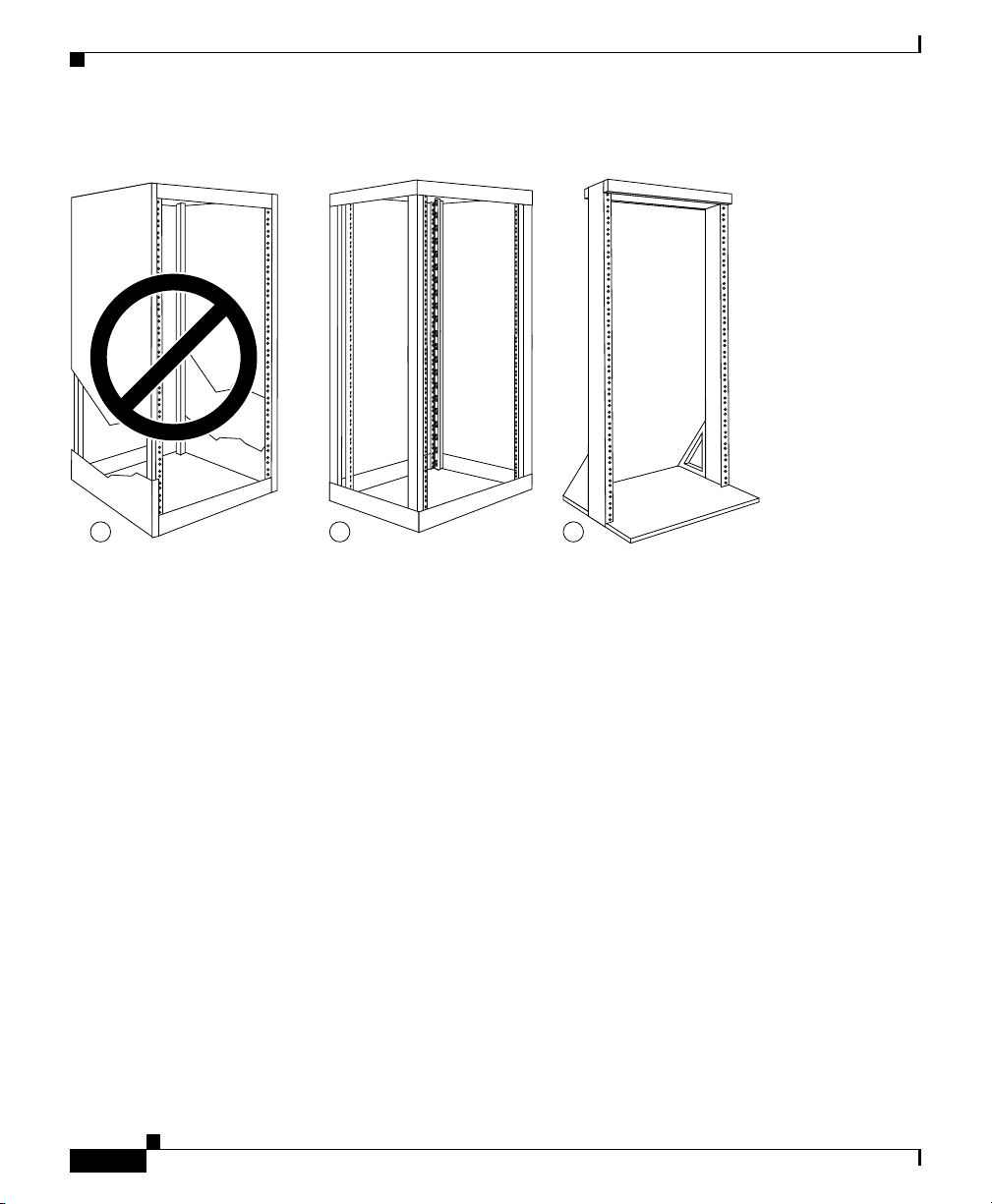

Figure 2-2 shows examples of typical 2-post, 4-post, and telco-type equipment

racks.

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-7

Page 8

Site Requirement Guidelines

Figure 2-2 Equipment Rack Types

a b c

Chapter 2 Preparing for Installation

27959

Enclosed Rack

Open Rack

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-8

Figure 2-2a shows a free-standing, enclosed rack with two mounting posts in the

front. The router should not be installed in this type of enclosed rack, because the

router requires an unobstructed flow of cooling air to maintain acceptable

operating temperatures for its internal components. Installing the router in any

type of enclosed rack—even with the front and back doors removed—could

disrupt the air flow, trap heat next to the chassis, and cause an overtemperature

condition inside the router.

Figure 2-2b shows a free-standing, 4-post open rack with two mounting posts in

the front and two mounting posts in the back. The mounting posts in this type of

rack are often adjustable so that you can position the rack-mounted unit within the

depth of the rack rather than flush-mount with the front of the rack.

OL-17440-01

Page 9

Chapter 2 Preparing for Installation

Telco Rack

Figure 2-2c shows a telco-type rack. The telco-type rack is an open frame

consisting of two posts tied together by a cross-bar at the top and a floor stand at

the bottom.

This type of rack is usually secured to the floor and sometimes to an overhead

structure or wall for additional stability. The router chassis can be installed in the

telco-type rack either in a front-mounted position or a center-mounted position

(Figure 2-3).

• In the front-mounted position, you secure the chassis rack-mounting brackets

• In the center-mounted position, you secure a set of optional center-mount

Site Requirement Guidelines

directly to the rack posts.

brackets to the rack posts. The chassis rack-mounting flanges are then

secured to the center-mount brackets. The center-mounted position moves the

center of gravity of the chassis closer to the vertical axis of the rack posts,

which adds to the stability of the rack installation.

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-9

Page 10

Chapter 2 Preparing for Installation

Site Requirement Guidelines

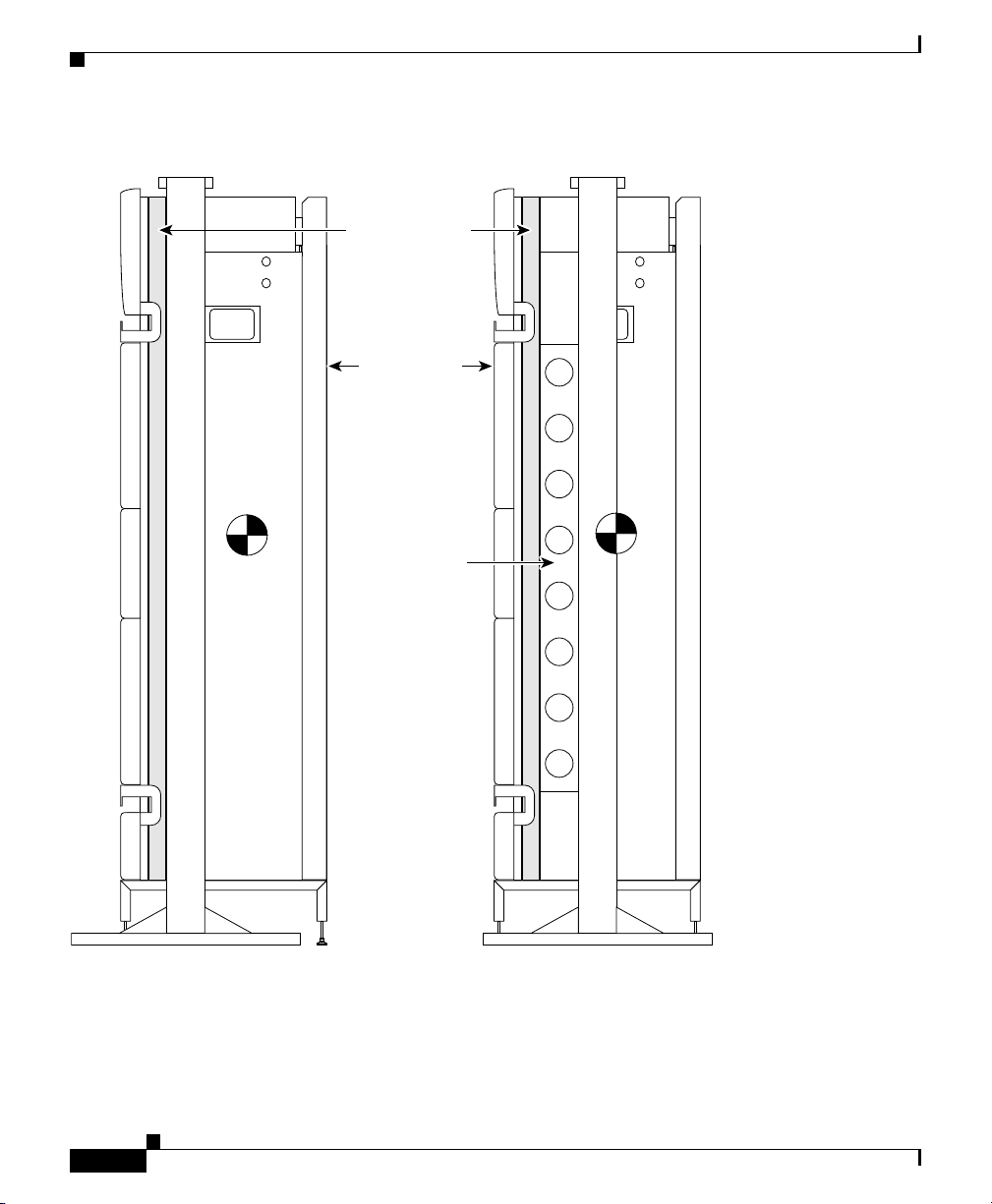

Figure 2-3 Front-Mounted and Center-Mounted Installation in a Telco Rack

Front-mount rail

Cisco 12016

chassis

Center-mount

bracket

Front-mounted chassis

in telco rack

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-10

Center-mounted chassis

27958

in telco rack

OL-17440-01

Page 11

Chapter 2 Preparing for Installation

Site Layout and Equipment Dimensions

To help maintain trouble-free operation, adhere to the following precautions when

planning your rack installation:

• Ensure the site of the rack includes provisions for source AC or DC power,

grounding, and network interface cables.

• Allow sufficient space to work around the rack during the installation. You

need:

–

At least 3 feet adjacent to the rack to move, align, and insert the chassis.

–

At least 2 feet in front of the power shelf to insert power entry modules.

• Maintain at least 24 inches (61 cm) of clearance in front of and behind the

chassis for maintenance after installation.

• To mount the router between two posts or rails, the usable aperture (the width

between the inner edges of the two mounting flanges) must be at least

17.7 inches (45.0 cm).

• When fully populated with cards, the router can weigh as much as 440 lb

(200 kg). Mount the router so that the bottom of the router chassis is no higher

than 10 inches (25.4 cm) from the floor to keep the center of gravity of the

rack as low as possible. To maintain equipment rack stability and to ensure

your safety, make sure you install any stabilizing devices provided before you

install the router.

• If you use a telco-style rack, the weight of the chassis is cantilevered off of

the two rack posts. Make sure that:

Site Requirement Guidelines

OL-17440-01

–

The weight of the router does not make the frame unstable.

–

The frame is bolted to the floor and is secured to the building structure

using either wall brackets or overhead brackets.

• When mounting the router in a telco-type rack or 4-post rack, be sure to use

all of the screws provided to secure the chassis to the rack posts.

• For theCisco XR 12416 router, the mounting rails on a 4-post rack must be

recessed no more than 1.5 inches for the front door to fully open and close

and to provide adequate room for cable routing.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-11

Page 12

Site Requirement Guidelines

• Install the cable-management brackets included with the router to keep cables

• To avoid noise interference in network interface cables, do not route them

Chapter 2 Preparing for Installation

organized. Be sure to:

–

Use appropriate strain-relief methods to protect cables and equipment

connections.

–

Make sure that cables from other equipment installed in the rack do not

restrict access to the card cages.

directly across or along power cables.

2-12

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 13

Chapter 2 Preparing for Installation

Figure 2-4 shows the footprint and outer dimensions of the of router chassis.

Figure 2-4 Router Chassis Footprint and Dimensions—Top View

17.963 in.

25.694 in.

Site Requirement Guidelines

17.3 in.

OL-17440-01

7.731 in.

18.950 in.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

57090

2-13

Page 14

Site Requirement Guidelines

Air Flow Guidelines

Cool air is circulated through the router chassis by two blower modules. The

blower modules maintain acceptable operating temperatures for the internal

components by drawing in cool air through the air filter in front of the switch

fabric card cage (middle), and circulating the air through both card cages

(Figure 2-5).

Each power supply is also equipped with a fan that draws cooler air into the front

of the power supply and forces warmer air out of the back of the chassis.

When selecting a site to install the router, observe the following guidelines:

• Dust free area—The site should be as dust free as possible. Dusty

environments can clog the air filter or power supply intake vents, reducing the

cooling air flow through the router. Clogged filters and vents can cause an

overtemperature condition in the router.

• Unrestricted air flow—Allow sufficient air flow by maintaining a minimum

of 6 inches (15.24 cm) of clearance at both the inlet and exhaust openings on

the chassis and the power modules. If the air flow is blocked or restricted, or

if the inlet air is too warm, an overtemperature condition can occur within the

router. Under extreme conditions, the environmental monitoring system will

power off the router to protect the components.

Chapter 2 Preparing for Installation

2-14

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 15

Chapter 2 Preparing for Installation

Figure 2-5 Air Flow Path through the Router - Side View

Site Requirement Guidelines

Power supply shelf

Top blower module

Air filter

Room air

Air exhaust

(Plenum)

Upper card cage

Middle card cage

Lower card cage

(Plenum)

OL-17440-01

Bottom blower module

Front Rear

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

Air exhaust

26204

2-15

Page 16

Site Requirement Guidelines

Temperature and Humidity Guidelines

The operating and nonoperating environmental site requirements are listed in

Table A-4 on page A-4. The router normally operates within the ranges listed in

the table, however, if a temperature measurement is approaching a minimum or

maximum parameter it indicates a potential problem. Maintain normal operation

by anticipating and correcting environmental anomalies before they approach

critical values by properly planning and preparing your site before you install the

router.

Power Connection Guidelines

You can configure the router with either an AC-input or DC-input power

subsystem, so the site power source requirements differ depending on the power

subsystem in your router. Ensure all power connection wiring conforms to the

rules and regulations in the National Electrical Code (NEC), as well as local

codes.

Chapter 2 Preparing for Installation

2-16

Caution Proper grounding is necessary to avoid damage from lightning and power surges.

See the “Router Bonding and Grounding Receptacles—Top Rear” section on

page 2-22 for grounding requirements.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 17

Chapter 2 Preparing for Installation

AC-Powered Routers

AC PEMs operate in the nominal range of 200 VAC to 240 VAC and require a

minimum service of:

• 20 A for operation in North America

• 16 A for international operation

• 13 A for operation in the UK

Each of the AC power inputs requires separate dedicated branch circuit. For a list

of the nominal and acceptable value ranges for source AC power, refer to

Table A-2 on page A-3.

Figure 2-6 shows different styles of AC power cords used to connect to the local

AC power source that are available for North America and various locales.

Figure 2-6 AC Power Cord Plugs and Appliance Coupler

Site Requirement Guidelines

North America

Rewirable twist-lock plug

NEMA L6-20P (20A)

Italy

1/3/16 plug

CEI 23-16 (16A)

OL-17440-01

Australia, New Zealand

SAA/3 plug

AS/NZZS 3112-1993 (15A)

United Kingdom

BS89/13

BS 1363/A

(13A; replaceable fuse)

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

Europe, Argentine, Brazil

VIIG plug

CEE (7) VII (16A)

Appliance coupler

C19W coupler

Hot EN60320/C19 (20A)

26044

2-17

Page 18

Site Requirement Guidelines

Table 2-1 lists power cord options. All AC-input power supply power cords

measure 14 feet (4.3 m).

Table 2-1 AC Power Cord International Options

Label Description Part Number

North America 20 A, 250 VAC CAB-GSR16-US=

Australia, New Zealand 15 A, 250 VAC CAB-GSR16-AU=

Europe, Argentina, Brazil 16 A, 250 VAC CAB-GSR16-EU=

Italy 16 A, 250 VAC CAB-GSR16-IT=

United Kingdom 13 A, 250 VAC

DC-Powered Routers

Connections to DC PEMs are rated at 60 amps maximum. A dedicated,

commensurately rated DC power source is required for each PEM connection.

For DC power cables, we recommend that you use a commensurately rated,

high-strand-count copper wire cable. Connection to the DC power shelf requires

one earth ground cable and two cable leads; a source DC (–) and source DC return

(+) for each PEM. The length of the cables depends on your router location from

the source power.

Chapter 2 Preparing for Installation

CAB-GSR16-UK=

(13 A replaceable fuse)

2-18

Note DC power cables are not available from Cisco, but are available from any

commercial cable vendor.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 19

Chapter 2 Preparing for Installation

You must terminate DC power cables using cable lugs at the power shelf end.

Ensure the lugs are dual-hole and that they are able to fit over M6 terminal studs

at 0.625-inch (15.88-mm) centers (for example, Panduit Part Number

LCD8-14A-L or equivalent).

Figure 2-7 shows the type of lug required for the DC-input cable connections.

Figure 2-7 DC Power Cable Lug

End View

Site Requirement Guidelines

All measurements in inches

2.24

0.48

Ø 0.267

2 holes

Crimp area

0.25 0.370.63

0.08

Figure 2-8 shows a source DC power distribution scheme for a DC-input power

shelf.

It shows two power cables attached to the DC-input power lugs for power shelf

bay B1 (far right bay of the DC-input power shelf when looking at the back panel).

The color coding of the source DC power cable leads depends on the color coding

of the site DC power source. Typically, green or green and yellow indicate that the

cable is a ground cable. Because there is no color code standard for the source DC

wiring, be sure that the power cables are connected to the DC-input power shelf

terminal studs using the proper positive (+) and negative (–) polarity.

• In some cases, the source DC cable leads might have a positive (+) or a

negative (–) label. This is a relatively safe indication of the polarity, but you

must verify the polarity by measuring the voltage between the DC cable leads.

When making the measurement, the positive (+) lead and the negative (–) lead

must always match the (+) and (–) labels on the power shelf.

• A green (or green and yellow) cable typically indicate that it is a ground

cable.

25527

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-19

Page 20

Chapter 2 Preparing for Installation

Site Requirement Guidelines

Figure 2-8 Typical Source DC Power Cabling Scheme for Power Shelf Bay B1

CO ground

Central

office

RectifiersAC

primary &

secondary

DC power

distribution

Plant

controls

Battery plant

Batteries

Ground

window

Central office

ground

+

+

–

–

Ground

Ground

2-20

27963

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 21

Chapter 2 Preparing for Installation

Site Requirement Guidelines

Caution DC PEMs contains circuitry to trip the breaker on the PEM if the PEM detects a

reverse polarity condition. No damage should occur from reverse polarity, but you

should correct a reverse polarity condition immediately.

For a list of the nominal and acceptable value ranges for source DC power, refer

to Table A-3 on page A-4.

NEBS Supplemental Unit Bonding and Grounding Guidelines

Although the router chassis requires a safety earth ground connection as part of

the power cabling to the power shelf, we also recommend that you connect the

central office ground system or interior equipment grounding system to the

supplemental bonding and grounding connections.

Supplemental connections are located at the top of the power interface panel on

the back of the chassis (Figure 2-9), and near the lower corners of the switch

fabric card cage on the front flanges of the chassis (Figure 2-10). The DC return

of this system should remain isolated from the system frame and chassis (DC-I).

This grounding points are also referred to as the network equipment building

system (NEBS) bonding and grounding connections.

OL-17440-01

Note These bonding and grounding connections satisfy the Telcordia NEBS

requirements for supplemental bonding and grounding connections. If you are not

installing the router in a NEBS environment, you can choose to bypass these

guidelines and rely on the safety earth ground connections to the AC and DC

power shelves.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-21

Page 22

Site Requirement Guidelines

Figure 2-9 Router Bonding and Grounding Receptacles—Top Rear

Supplemental

bonding and

grounding

receptacle

Figure 2-10 Router Bonding and Grounding Receptacles—Front

Q OC-3/STM-POS

6DS3–SMB P

/

H

/

F

RX

TX

11

RX

12DS3–SMB P

/

H

/

F

OC-48/STM-16-SCPOS

OC-12/STM-4 ATM

FAST ETERNET

ROUTE PROCESSOR

EN

ABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

Chapter 2 Preparing for Installation

29183

NEBS

supplemental

earth ground

receptacle

Air filter door

2-22

28022

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 23

Chapter 2 Preparing for Installation

To ensure a satisfactory supplemental ground connection to the router, use the

following parts:

Note These parts are not available from Cisco, but are available from commercial

vendors.

• Two grounding lugs, which have two M6 bolt holes with 0.625 to 0.75-inch

(15.86 to 19.05-mm) spacing between them, and a wire receptacle large

enough to accept a 6-AWG or larger, multistrand copper wire. This lug is

similar to those used for the DC-input power supply leads (see Figure 2-7).

• Two M6 hex-head nuts and locking washers (nickel-plated brass is ideal).

• Two grounding wires. Although we recommend at least 6-AWG multistrand

copper wire, the wire diameter and length depend on your router location and

site environment.

Site Wiring Guidelines

Site Requirement Guidelines

OL-17440-01

When planning the location of the router, consider distance limitations for

signaling, electromagnetic interference (EMI), and connector compatibility. If the

wiring is run for any significant distance in an electromagnetic field, interference

can occur between the field and the signals on the wires. Poor wiring can cause:

• Radio interference emanating from the wires.

• Strong EMI, especially when caused by lightning or radio transmitters. EMI

can destroy the signal drivers and receivers in the router, and can even create

an electrical hazard by conducting power surges through lines and into

equipment.

Note To predict and remedy strong EMI, you may need to consult with experts

in radio frequency interference (RFI).

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-23

Page 24

PRP Port Connection Guidelines

Site wiring is unlikely to emit radio interference if you use twisted-pair cable with

a good distribution of grounding conductors. Use a high-quality twisted-pair cable

with one ground conductor for each data signal, when applicable.

Give special consideration to the effect of a lightning strike in your vicinity,

especially if the wiring exceeds the recommended distances, or if it passes

between buildings. The electromagnetic pulse (EMP) caused by lightning or other

high-energy phenomena can easily induce enough energy into unshielded

conductors to destroy electronic devices. If you have experienced EMP problems

in the past, you may want to consult experts in electrical surge suppression and

shielding.

Most data centers cannot resolve the infrequent but potentially catastrophic

problems without pulse meters and other special equipment. In addition, these

problems can take a great deal of time to identify and resolve. We recommend that

you take the necessary precautions to avoid these problems by providing a

properly grounded and shielded environment, with special attention to issues of

electrical surge suppression.

PRP Port Connection Guidelines

Chapter 2 Preparing for Installation

This section contains detailed cabling and signal information for all interface and

port connections to the PRP. It also provides information for Ethernet routing and

equipment.

Caution Ports labeled Ethernet, 10BASE-T, Token Ring, Console, and AUX are safety

extra-low voltage (SELV) circuits. Only connect SELV circuits to other

SELV circuits.

PRP Auxiliary and Console Port Connection Guidelines

The PRP has two RJ-45 connection ports:

• Auxiliary port— DTE RJ-45 interface for connecting a modem or other

DCE device (such as a CSU/DSU or another router) to the PRP.

• Console port—DCE RJ-45 interface for connecting a data terminal device to

the router, which you need to perform the initial configuration of the router.

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-24

OL-17440-01

Page 25

Chapter 2 Preparing for Installation

Note The auxiliary and console ports are asynchronous serial ports. Ensure that

devices connected to these ports are capable of asynchronous

transmission.

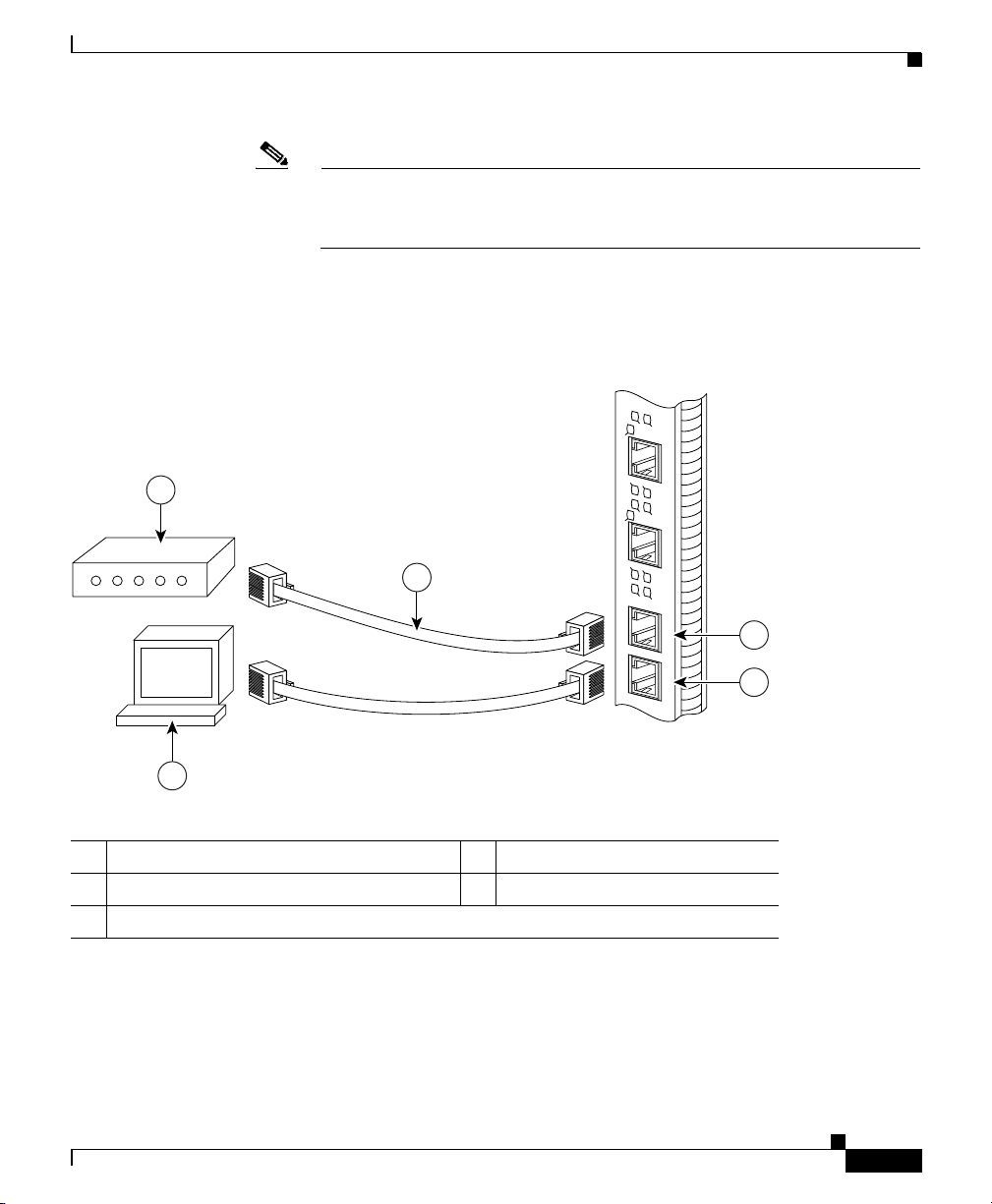

Figure 2-11 shows the auxiliary and console port connections from the PRP to the

associated devices.

Figure 2-11 PRP Auxiliary and Console Port Connections

1

3

PRP Port Connection Guidelines

S

L

S

O

L

O

T

PRIMARY

-0

T

-1

LIN

E

K

N

T

X

R

X

PRIMARY

ETH 1ETH 0 AUX

LIN

E

K

N

T

X

R

X

2

1 Modem 4 Auxiliary port

2 Console terminal 5 Console port

3 RJ-45 cables

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

4

CONSOLE

5

70692

2-25

Page 26

PRP Port Connection Guidelines

PRP Auxiliary Port Signals

The PRP auxiliary port is a DTE, RJ-45 interface for connecting a modem or other

DCE device (such as a CSU/DSU or another router) to the PRP. The auxiliary port

supports hardware flow control and modem control.

Table 2-2 lists the signals used on the auxiliary port.

Table 2-2 PRP Auxiliary Port Signals

Auxiliary Port Pin Signal Input/Output Description

1 RTS Output Request to send

2 DTR Output Data terminal ready

3 TxD Output Transmit data

4 GND — Signal ground

5 GND — Signal ground

6 RxD Input Receive data

7 DSR Input Data set ready

8 CTS Input Clear to send

Chapter 2 Preparing for Installation

2-26

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 27

Chapter 2 Preparing for Installation

PRP Console Port Signals

The PRP console port is a DCE RJ-45 interface for connecting a terminal to the

router. The console port does not support modem control or hardware flow control

and requires a roll-over RJ-45 cable.

Before connecting a terminal to the console port, check the terminal setting for

the data transmission rate, in bits per second (bps). The terminal transmission rate

setting must match the default rate of the PRP console port, which is 9600 bps.

Set the terminal to these operational values: 9600 bps, 8 data bits, no parity, 2 stop

bits (9600 8N2).

Table 2-3 lists the signals used on the console port.

Table 2-3 PRP Console Port Signals (with RJ45 roll-over cable)

Console Port Pin Signal Input/Output Description

1

1

2 DTR Output Data terminal ready

3 TxD Output Transmit data

4 GND — Signal ground

5 GND — Signal ground

6 RxD Input Receive data

7 DSR Input Data set ready

1

8

1. These pins are not connected.

PRP Port Connection Guidelines

—— —

—— —

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-27

Page 28

PRP Port Connection Guidelines

PRP Ethernet Connections

The PRP has two RJ-45 MDI Ethernet ports; ETH0 and ETH1 (Figure 2-12).

Figure 2-12 PRP Ethernet Connections

Chapter 2 Preparing for Installation

ETH 1ETH 0

SLOT-1

SLOT-0

PRIMARY

EN

LINK

RX

TX

PRIMARY

EN

LINK

RX

TX

70693

These connections support IEEE 802.3 and IEEE 802.3u interfaces compliant

with 10BASE-T and 100BASE-TX standards. The transmission speed of the

Ethernet ports is autosensing by default and is user configurable.

The PRP Ethernet port does not provide external routing functions. Its primary

roles are to act as a Telnet port into the router, and to boot or access Cisco IOS XR

software images over a network to which the PRP Ethernet port is directly

connected.

Caution Cisco Express Forwarding (CEF) functions on these ports are switched off by

default for security reasons. We strongly caution you to consider the security

implications of switching on CEF routing functions on these ports.

2-28

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 29

Chapter 2 Preparing for Installation

Figure 2-13 shows:

• You cannot access Network 2.0.0.0 from Ethernet port (E0) on the PRP in

Router A. You can only access Host A, Host B, and Router C, which are in

Network 1.0.0.0 (see dotted-line arrows).

• To access Network 2.0.0.0 from Router A, you must use an interface port on

one of the line cards (a POS line card in this example) in Router A. Data from

Router A is routed through Router B and Router C, to reach Network 2.0.0.0

(see solid-line arrows).

Figure 2-13 Using the Ethernet Port on the PRP

PRP Port Connection Guidelines

Router A

(Cisco 12000

series router)

POS

Router B

(Cisco 7500

series router)

EO

EO

Network 1.0.0.0

Host A

Host B

Router C

(Cisco 7500

series router)

Network 2.0.0.0

Host A

26196

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-29

Page 30

PRP Port Connection Guidelines

PRP RJ-45 Ethernet Connections

The RJ-45 Ethernet connection does not require an external transceiver.

Figure 2-14 shows the pin orientation of the RJ-45 Ethernet port and the modular

cable plug it accepts.

Figure 2-14 RJ-45 Receptacle and Plug

8 7 6 5 4 3 2 1

RJ-45 connector

Table 2-4 lists the RJ-45 pin signals used on the connector.

Table 2-4 PRP RJ-45 Ethernet Receptacle Pinout

Ethernet Port Pin Signal Description

1 TxD+ Transmit data +

2 TxD– Transmit data –

3 RxD+ Receive data +

4 Termination network No connection

5 Termination network No connection

6 RxD– Receive data –

7 Termination network No connection

8 Termination network No connection

Chapter 2 Preparing for Installation

210222

2-30

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 31

Chapter 2 Preparing for Installation

When connecting the RJ-45 port to a hub or repeater, use the straight-through

cable pinout shown in Figure 2-15.

Figure 2-15 Straight-Through Cable Pinout to Hub or Repeater

1 TxD+

2 TxD–

PRP Port Connection Guidelines

MDI-X wiringMDI wiring

1 RxD+

2 RxD–

3 RxD+

6 RxD–

3 TxD+

6 TxD–

H11007

When connecting two PRPs back-to-back, use the crossover cable pinout shown

in Figure 2-16.

Figure 2-16 Crossover Cable Pinout Between PRPs

PRP

1 TxD+

2 TxD–

3 RxD+

6 RxD–

PRP

1 TxD+

2 TxD–

3 RxD+

6 RxD–

75431

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-31

Page 32

PRP Port Connection Guidelines

Table 2-5 lists the cabling specifications for 100-Mbps transmission over

unshielded twisted-pair (UTP) cables.

Note The transmission speed of the Ethernet ports is autosensing by default and is user

configurable.

Table 2-5 Specifications and Connection Limits for 100-Mbps

Parameter RJ-45

Cable specification Category 5

Cable length (max) —

Segment length (max) 328 feet (100 m) for 100BASE-TX

Network length (max) 656 feet (200 m)

1. EIA/TIA-568 or EIA-TIA-568 TSB-36 compliant. Not supplied by Cisco.

2. AWG = American Wire Gauge. This gauge is specified by the EIA/TIA-568 standard.

3. Specifically, the length between any two stations on a repeated segment.

Transmission

Chapter 2 Preparing for Installation

1

UTP, 22 to 24 AWG

3

with 1 repeater

2

2-32

Table 2-6 lists IEEE 802.3u physical characteristics for 100BASE-TX.

Table 2-6 IEEE 802.3u Physical Characteristics

Parameter 100BASE-TX

Data rate (Mbps) 100

Signaling method Baseband

Maximum segment length 100 m between DTE and repeaters

Media Category 5 UTP

Topology Star/Hub

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Page 33

Chapter 2 Preparing for Installation

Alarm Card Connection Guidelines

The router is equipped with two alarm cards:

• One alarm card occupies the dedicated far left slot in the upper card cage

• The second alarm card occupies the dedicated far right slot in the lower card

cage

Each alarm card has one 25-pin D-subconnector (ALARM) on the front panel that

connects the router to an external site alarm maintenance system (Figure 2-17).

When a critical, major, or minor alarm is generated, it energizes the alarm relays

on the alarm card to activate the external site alarm.

Figure 2-17 Alarm Card Connector Location

Alarm Card Connection Guidelines

FAIL

ENABLED

CSC

FAIL

0

ENABLED

SFC

1

0

1

Critical, major, and

Handle

CRITICAL

MAJOR

minor alarm LEDs

MAJOR

CRITICAL

MINOR

MINOR

ACO/LT

Audio alarm

cutoff switch

Pin 25

ALARM

Pin 1

CSC

SFC

FAIL

ENABLED

FAIL

ENABLED

2

1

0

0

1

ALARM

Clock and scheduler card

and switch fabric card LEDs

The alarm relay contacts on the alarm card consist of standard common, normally

open, and normally closed relay contacts that are wired to the pins on the

connectors.

Caution Only safety extra-low voltage (SELV) circuits can be connected to the alarm

connector. Maximum rating for the alarm circuit is 2 A, 50 VA.

2

26867

OL-17440-01

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

2-33

Page 34

Alarm Card Connection Guidelines

Note To comply with the intrabuilding lightning surge requirements of

GR-1089-CORE, Issue II, Revision 01, February 1999, you must use a shielded

cable when connecting to the external alarm ports on the alarm card. The shielded

cable is terminated by shielded connectors on both ends, with the cable shield

material tied to both connectors.

Table 2-7 lists the pin-to-signal correspondence between the cable connector pins

and the alarm card relay contacts.

Table 2-7 Alarm Connector Pinout

Pin Group Common Normally Open Normally Closed

Critical audible alarm 2 1 14

Major audible alarm 16 3 15

Minor audible alarm 5 4 17

Critical visual alarm 19 6 18

Major visual alarm 8 7 20

Minor visual alarm 22 9 21

Alarm input 13 25 —

Chapter 2 Preparing for Installation

2-34

Cisco XR 12416 and Cisco XR 12816 Router Chassis Installation Guide

OL-17440-01

Loading...

Loading...