Page 1

Installation

This chapter contains the following sections:

Installation Notes and Warnings for the Cisco UCS 5108 Server Chassis, page 1

•

Installing the Chassis, page 7

•

Repacking the Chassis, page 23

•

SFP+ Transceivers, page 23

•

Installation Notes and Warnings for the Cisco UCS 5108 Server Chassis

The following notes and warnings apply to all installation tasks:

Note

Warning

Warning

OL-20035-05 1

Before you install, operate, or service the system, see the Regulatory Compliance and Safety Information

for Cisco UCS for important safety information.

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device. Statement 1071

SAVE THESE INSTRUCTIONS

This unit is intended for installation in restricted access areas. A restricted access area can be accessed

only through the use of a special tool, lock and key, or other means of security. Statement 1017

Cisco UCS 5108 Server Chassis Installation Guide

Page 2

Rack Requirements

Installation

Warning

Only trained and qualified personnel must be allowed to install, replace, or service this equipment.

Statement 1030

Rack Requirements

This section provides the requirements for installing in a standard open rack, assuming an external ambient

air temperature range of 50 to 95°F (10 to 35°C):

Note

Do not use racks that have obstructions. These obstructions could impair access to field-replaceable units

(FRUs).

The Cisco R Series Racks are an ideal choice. If other racks will be used, the rack must be of the following

type:

Standard 19-inch (48.3 cm) four-post EIA rack, a minimum of 39.4 inches (100 cm) deep, with mounting

•

rails that conform to English universal hole spacing per section 1 of ANSI/EIA-310-D-1992.

The mounting holes of the rails in the rack must be square (unless the optional round hole adapter kit is

•

used).

The tool-less rack-mount kit shipped with the chassis is required. The adjustable rack rails shipped with

•

each enclosure extend from 29 inches (73.66 cm) to 35 inches (88.9 cm)

• Front and rear doors—If your server rack includes closing front and rear doors, the doors must have 65

percent open perforated area evenly distributed from top to bottom to permit adequate airflow.

Caution

The rack must also meet the following requirements:

The minimum available vertical rack space per chassis must be six RU (rack units), equal to 10.5 inches

•

(26.7 cm).

Cable Management

To help with cable management, allow additional space in the rack above and below the chassis to make it

easier to route copper cables (plus up to eight copper cables per Cisco UCS 5108 server chassis) through the

rack.

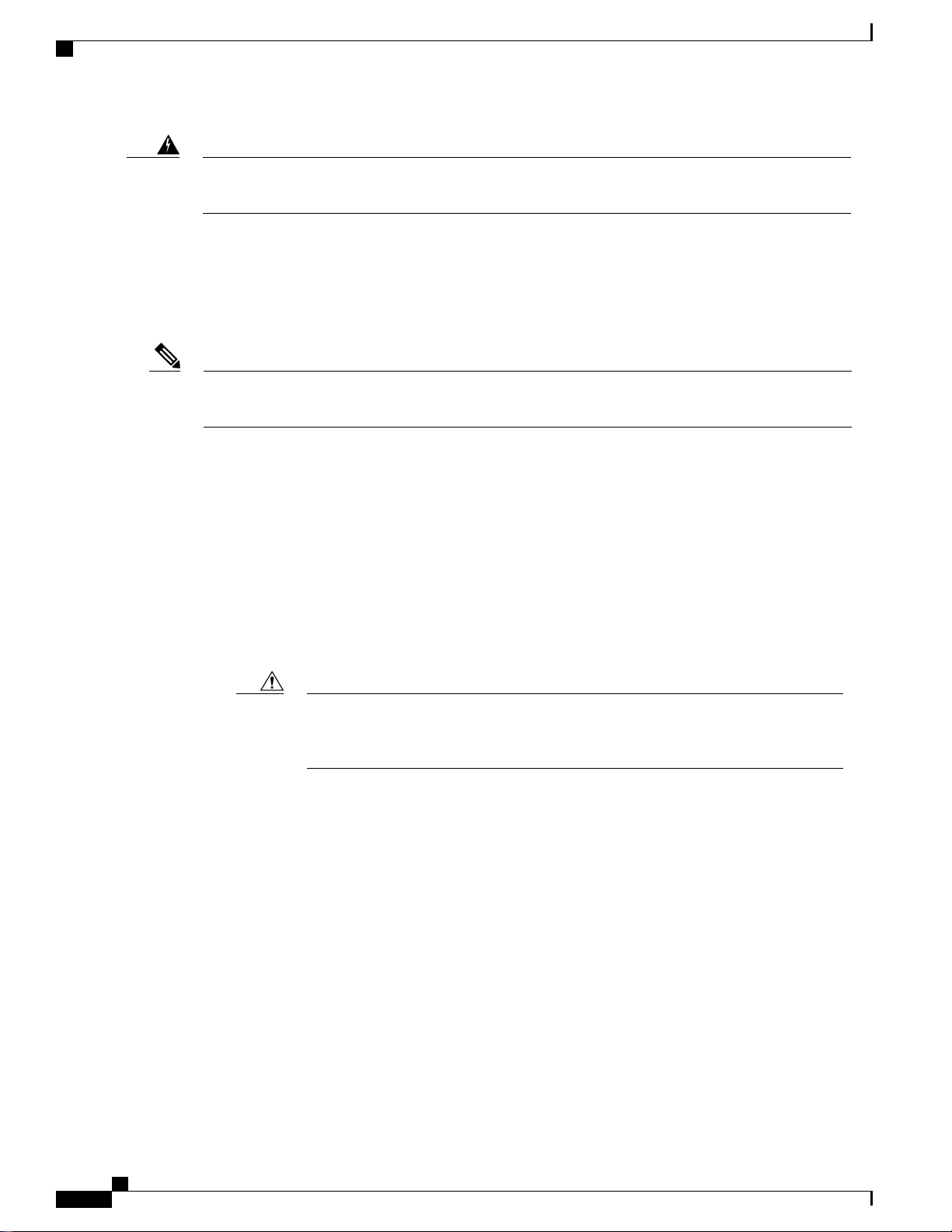

Cable management can be an important factor in preventing overheating issues. In the following figure, the

“before“ illustration shows cables blocking the rear of the chassis, and preventing the fans from exhausting

warm air from the chassis. This situation causes failed DIMMs in the blade servers, and seemingly random

Always use blanking panels to fill all remaining empty front panel U-spaces in the rack.

This arrangement ensures proper airflow. Using a rack without blanking panels results

in improper cooling that can lead to thermal damage.

Cisco UCS 5108 Server Chassis Installation Guide

2 OL-20035-05

Page 3

253898

Before

After

Installation

Airflow Considerations

server shutdowns when internal temperatures exceed specification. Use cable ties and other wiring practices

to keep the rear of the chassis unobstructed as shown in the “after“ illustration.

Figure 1: Cable Management

Airflow Considerations

Airflow through the chassis is from front to back. Air enters the chassis through the blade servers and power

supply grills at the front of the chassis and exits through the fan modules on the back of the chassis. To ensure

proper airflow, follow these guidelines:

Maintain ambient airflow throughout the data center to ensure normal operation.

•

Consider the heat dissipation of all equipment when determining air-conditioning requirements. Do not

•

allow the exhaust of one system to be the intake for another system.

When evaluating airflow requirements, take into consideration that the hot air generated by equipment

•

at the bottom of the rack can be drawn in the intake of the equipment above.

Make sure that the exhaust at the rear of the chassis is unobstructed for at least 24 in. (61 cm). This

•

includes obstruction due to messy cabling practices.

Some blade servers ship with internal shrouds that are placed over the DIMMs and CPUs. They are used

•

to channel airflow to where it is needed the most. If a shroud can be used a given model, it should be

used.

If an enclosed rack is used, the front door must be 65 percent perforated to ensure adequate airflow to

•

the servers.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 3

Page 4

Moving Server Chassis

Moving Server Chassis

When lifting the chassis, be aware of its weight, and follow these guidelines:

Installation

Caution

Do not try to lift the chassis using the handles on the side. These handles are intended only for moving

and adjusting the chassis position.

• Never lift the chassis alone—Always use two people to lift the chassis. If available, use a scissor jack

or other lifting device designed for installing heavy equipment into data center racks.

Disconnect all power and external cables before lifting the chassis.

•

Remove all FEXes, power supplies, fans, and servers from the chassis before lifting.

•

Ensure that your footing is solid and the weight of the system is evenly distributed between your feet.

•

Lift the system slowly, keeping your back straight. Lift with your legs, not with your back. Bend at the

•

knees, not at the waist.

Do not remove the Power Distribution Unit (PDU) located at the back of the chassis.Caution

Installation Guidelines

When installing the chassis, follow these guidelines:

Plan your site configuration and prepare the site before installing the chassis. See Site Planning and

•

Maintenance Records for the recommended site planning tasks. Further detail is provided in the Cisco

UCS Site Preparation Guide.

Record the information listed in Site Planning and Maintenance Records as you install and configure

•

the chassis.

Ensure that there is adequate space around the chassis to allow for servicing the chassis and for airflow.

•

Ensure that the air-conditioning meets the heat dissipation requirements listed in Technical Specifications

•

Ensure that the cabinet or rack meets the requirements listed in Rack Requirements, on page 2.

•

Note

Ensure that the site power meets the power requirements listed in Technical Specifications. If available,

•

you can use an uninterruptible power supply (UPS) to protect against power failures.

Avoid UPS types that use ferroresonant technology. These UPS types can become unstable with systems

such as the Cisco UCS, which can have substantial current draw fluctuations due to fluctuating data

traffic patterns.

Cisco UCS 5108 Server Chassis Installation Guide

4 OL-20035-05

Jumper power cords are available for use in a rack. See Specifications for the Cisco

UCS 5108 Blade Server Chassis Power Supply Units.

Page 5

Installation

Ensure that circuits are sized according to local and national codes. For North America, the power supply

•

requires a 20 A circuit.

To prevent loss of input power, ensure that the total maximum loads on the circuits supplying power to

the chassis are within the current ratings for the wiring and breakers.

Use the following torque values when installing the chassis:

•

Required Equipment

Before you begin the installation, ensure that you have the following items:

Number 1 and number 2 Phillips-head screwdrivers with torque measuring capabilities

•

Tape measure and level

•

ESD wrist strap or other grounding device

•

10-32 screws: 20 in-lb

◦

Required Equipment

Antistatic mat or antistatic foam

•

Unpacking and Inspecting the Chassis

When handling chassis components, wear an ESD strap and handle modules by the carrier edges only.Caution

Keep the shipping container in case the chassis requires shipping in the future.Tip

Note

Step 1

Step 2

The chassis is thoroughly inspected before shipment. If any damage occurred during transportation or any

items are missing, contact your customer service representative immediately.

Procedure

Remove the chassis from its cardboard container. Save all packaging material.

Compare the shipment to the equipment list provided by your customer service representative and verify that

you have received the following items:

Any printed documentation

•

• Tool-less rack-mount kit (N20-CRMK2=)—mounting rails can be installed in a rack without the use of

tools. The optional round hole adapter kit (N20-CRMK2-RHA=) does require tools.

ESD wrist strap

•

Cables with connectors (including the N20-BKVM=, which is the KVM/local I/O console dongle)

•

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 5

Page 6

279771

1

2

3

Attaching the Round Hole Adapter Kit to the Rails (Optional)

Any optional items ordered

•

Installation

Step 3

Verify that all unused blade slots and power supply bays have blank covers.

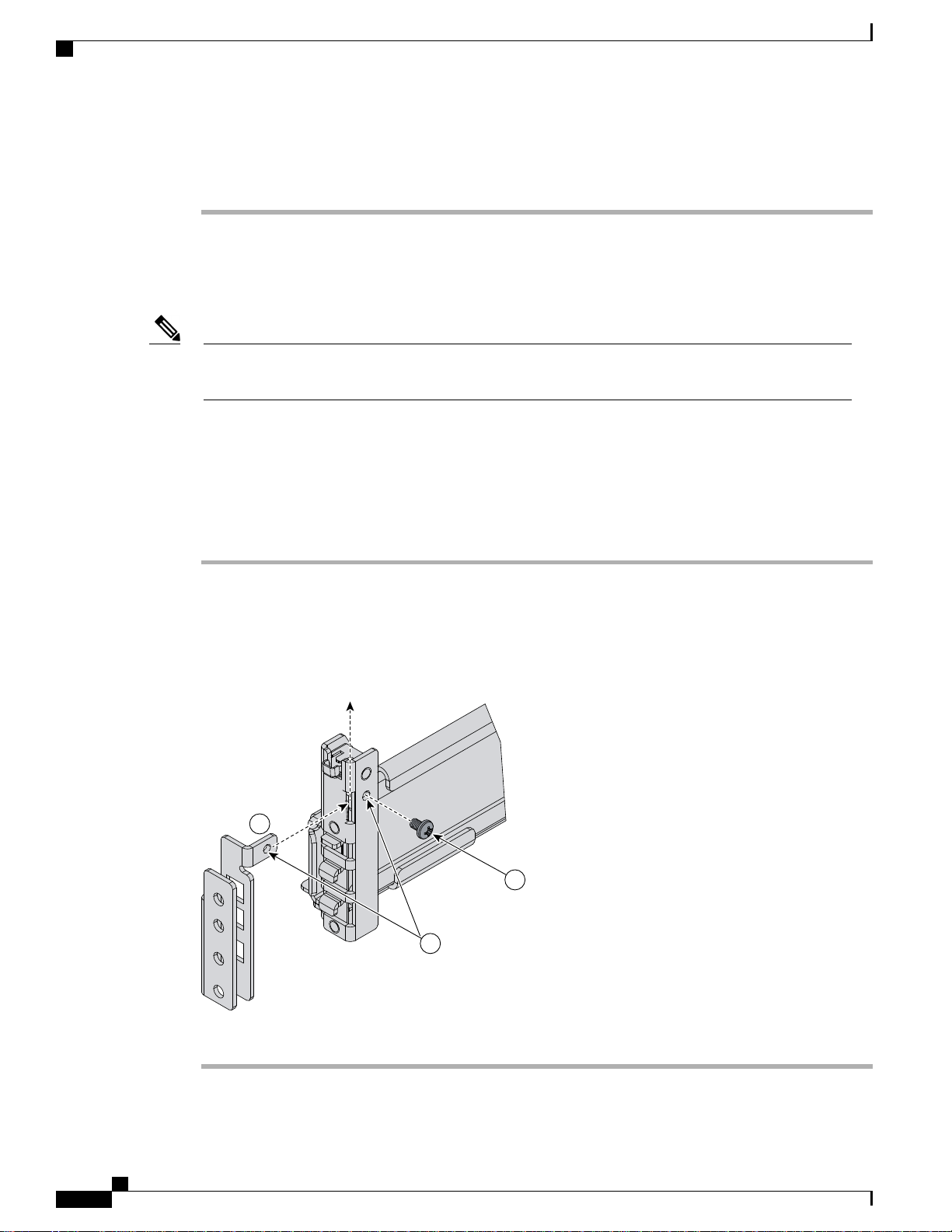

Attaching the Round Hole Adapter Kit to the Rails (Optional)

Note

Step 1

Step 2

Step 3

The chassis tool-less rails are designed for racks that have square mounting holes. You must use the round

hole adapters (N20-CRMK2-RHA=) to install the chassis in racks that have round mounting holes.

This round hole adapter kit allows you to adapt the rail kit (N20-CRMK2=) to install into rack (front and/or

rear) posts that use either threaded or non-threaded round holes. Four adapters in the kit are for adapting the

rail kit to install into rack posts with threaded round holes, and the other four adapters in the kit are for adapting

the rail kit to install into rack posts with non-threaded round holes. You can use a combination of adapters

based on the type of holes in the rack posts. Various sizes and lengths of screws are also included in the kit.

Procedure

Insert the adapter tab into the mounting rail as shown in callout 1.

Slide the adapter up to lock it into position as shown in callout 2.

Secure the adapter into place using the provided pan-head screw as shown in callout 3.

Figure 2: Attaching the Round Hole Adapter (Optional)

Step 4

Repeat steps 1to 3 for the other three adapters.

Cisco UCS 5108 Server Chassis Installation Guide

6 OL-20035-05

Page 7

Installation

Installing the Chassis

This section describes how to install the chassis. This two part process consists of installing the rails into the

rack and then installing the chassis into the rack and on to the rails.

Installing the Chassis

Caution

Caution

Never attempt to lift the chassis by using an installed module’s handle as a grip point. only use the handles

on the sides of the chassis.

If the rack has wheels, ensure that the brakes are engaged, the stabilizing pads are extended, or that the

rack is otherwise stabilized.

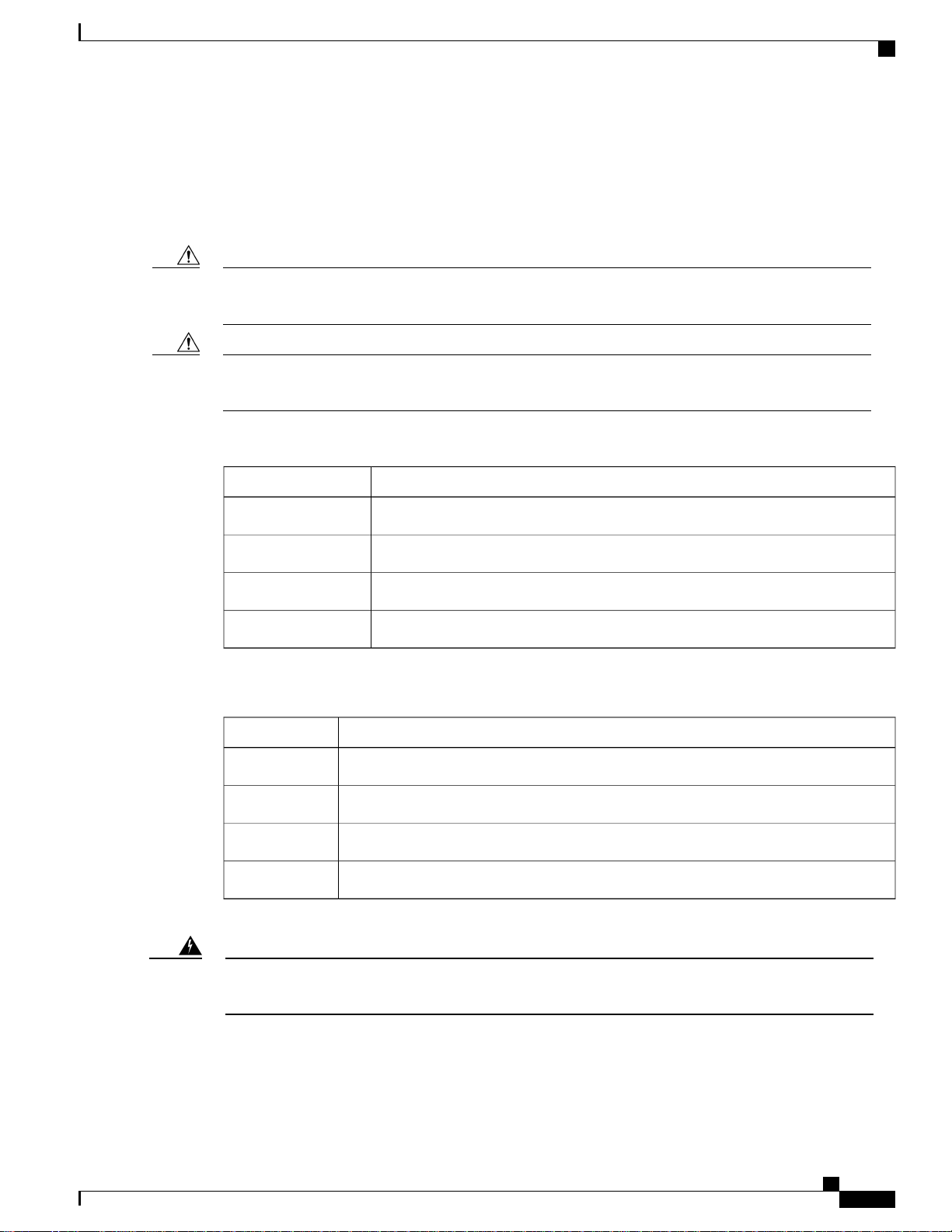

Table 1: Contents of the Cisco UCS 5108 Server Chassis Rack-Mount Kit (N20-CRMK2=)

Part DescriptionQuantity

Left tool-less rack mount rail1

Right tool-less rack mount rail1

10-32 X 0.75 Phillips round washer head screws6

10-32 X 0.125 cage nuts6

Table 2: Contents of the Cisco UCS 5108 Server Round Hole Adapter Kit (N20-CRMK2-RHA=)

Part DescriptionQuantity

Round hole adapters (threaded)4

Round hole adapters (un-threaded)4

Adapter securing screws4

Phillips head screws for securing the rails to the rack16

Warning

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device. Statement 1019

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 7

Page 8

192517

Sl

i

de-adjust

192731

.250

.625

.625

.500

Installing the Rails

Installing the Rails

Procedure

Installation

Step 1

Step 2

Step 3

Remove the mounting template (Cisco 78-19093-01) from the accessory box. The template is designed to

show you the proper holes within which the rails and cage nuts should be placed. Once the rack holes line up

with the template, you should mark the holes so that their position is known after removing the template.

Adjust the length of the rail by sliding the ends of the rail back and forth until they match the depth of the

rack.

Figure 3: Adjusting the Tool-less Rack Mount Rail

Place the two hooks at each end of the rail into the first two holes at a rack unit boundary.

Figure 4: Hole Spacing for the Tool-less Rails in Relationship to a Rack Unit

Cisco UCS 5108 Server Chassis Installation Guide

8 OL-20035-05

Page 9

192518

Installation

Installing the Rails

The following figure shows a rail mounted into a rack in the proper position with respect to a rack-unit

boundary. Measurements are in inches between the centers of the holes.

Figure 5: Installing Tool-less Chassis Support Rails into the Rack

Step 4

Step 5

Step 6

Step 7

Press down firmly on the rail until the hooks seat firmly and securely into the holes, and the spring clip latches

into place.

Follow the same procedure to install the other rack rail.

Use a tape measure and level to verify that the rack rails are horizontal and at the same height.

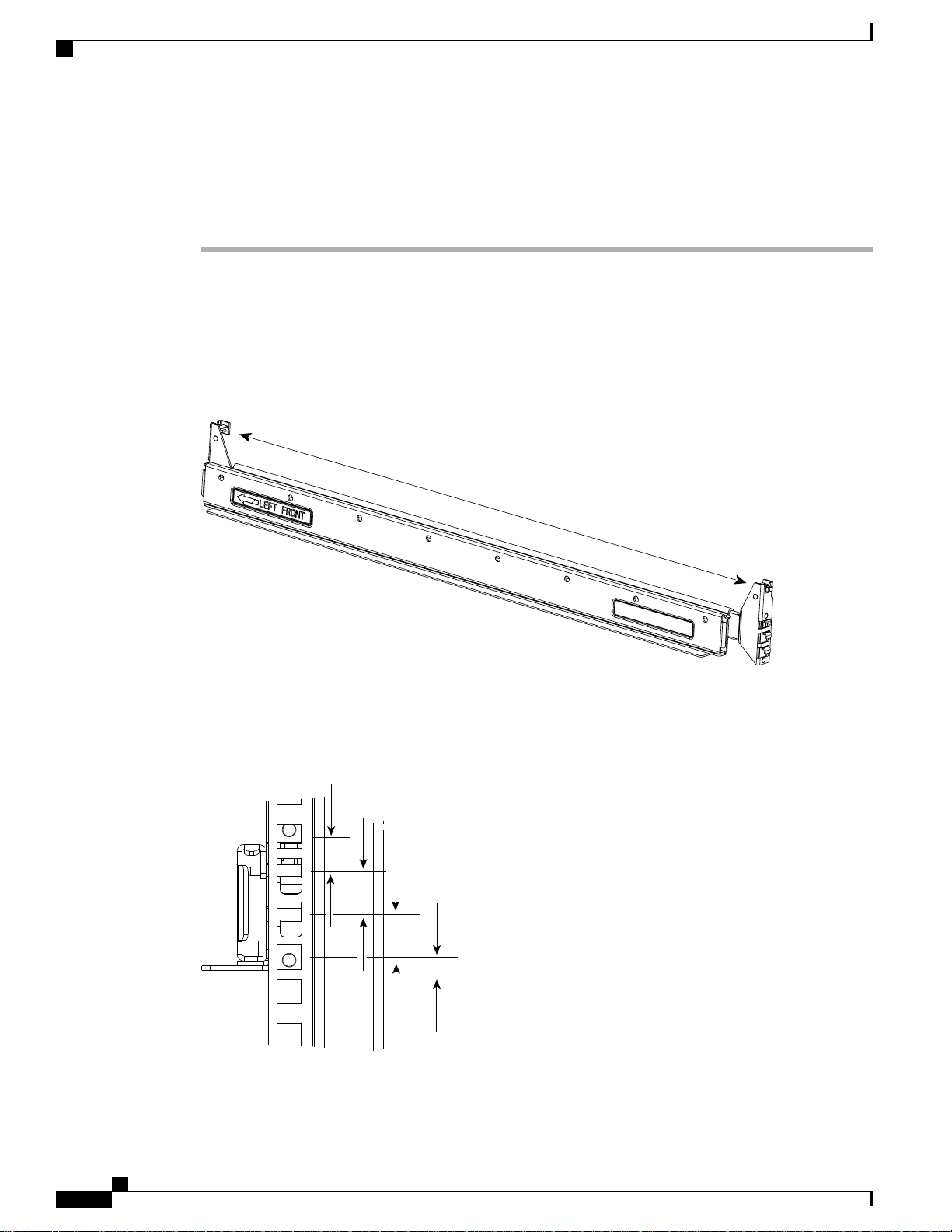

Insert the cage nuts on to the rack in the needed square holes as shown below. When the rails are installed on

a rack unit boundary, the first two cage nuts are installed into the seventh holes above the rails’ horizontal

OL-20035-05 9

Cisco UCS 5108 Server Chassis Installation Guide

Page 10

192824

4

5

7

Lower rack unit

reference boundry

Installing the Rails

Installation

plates. The next two cage nuts are installed into the fifth holes above the first cage nut. Finally, the two cage

nuts are installed into the fourth holes above the second cage nuts.

Figure 6: Placement of Rails and Cage Nuts with Respect to the Rack Unit Boundary

Figure 7: Proper Placement for the Rails and Cage Nuts

Cisco UCS 5108 Server Chassis Installation Guide

10 OL-20035-05

Page 11

.250

.625

.625

.500

.

Left rail

Right rail

Cage nuts

192730

Installation

Installing the Round Hole Adapter Kit

Step 8

Remove all power supplies, fan assemblies, server blades, and fabric extenders to lighten the chassis. Even

with devices removed, the chassis weighs 90 lbs (40.83 kg).

Installing the Round Hole Adapter Kit

Before installing the chassis in a round hole rack, prepare the rails by adding the adapter kit according to the

instructions in Attaching the Round Hole Adapter Kit to the Rails (Optional), on page 6.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 11

Page 12

279772

Installing the Round Hole Adapter Kit

Procedure

Installation

Step 1

Step 2

Step 3

Step 4

Remove the mounting template (Cisco 78-19093-01) from the accessory box. The template is designed to

show you the proper holes within which the rails and cage nuts should be placed. Once the rack holes line up

with the template, you should mark the holes so that their position is known after removing the template.

Adjust the length of the rail by sliding the ends of the rail back and forth until they match the depth of the

rack.

Place the adapters and rails even with a rack boundary at each end of the rail.

Secure the rail to the rack with the provided pan head screws as shown below.

Figure 8: Attaching the Mounting Brackets to a Round Hole Rack

Cisco UCS 5108 Server Chassis Installation Guide

12 OL-20035-05

Page 13

279774

Installation

Installing the Round Hole Adapter Kit

Step 5

Follow the same procedure to install the other rack rail as shown below.

Figure 9: Round Hole Adapter and Rails Installed in a Rack

Step 6

Step 7

Use a tape measure and level to verify that both rack rails are horizontal and at the same height.

Remove all power supplies, fan assemblies, server blades, and I/O modules to lighten the chassis. Even with

devices removed, the chassis weighs 90 lbs (40.83 kg).

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 13

Page 14

192518

Weight bearing surface.

Chassis should be riding

on this surface.

NON-WEIGHT BEARING SURFACE-

CHASSIS SHOULD NOT BE RIDING

ON THIS SURFACE

Inserting the Chassis into the Rack

Inserting the Chassis into the Rack

Procedure

Installation

Step 1

With the help of another person (or special lifting equipment), lift the chassis and place it on the mounting

rail as shown.

Figure 10: Mounting Rail Weight Distribution (Square Hole Mount Shown)

Caution

The mounting rails may come loose and cause the chassis to fall if the weight is resting on the

wrong surface. Make sure that the bottom of the chassis is resting on the correct rail surface.

14 OL-20035-05

Cisco UCS 5108 Server Chassis Installation Guide

Page 15

192519

Installation

Inserting the Chassis into the Rack

Step 2

Step 3

Slide the chassis into the rack until the front flange is flat against the cage nuts. (Cage nuts are not needed in

round hole racks.)

Using the six Phillips round washer head screws and the cage nuts (used in square hole installations), secure

the chassis by its flanges to the rack as shown.

Figure 11: Securing the Chassis Into the Rack

Step 4

Step 5

Replace all servers, fans, and power supplies back into their respective chassis slots.

To power up the chassis, connect the appropriate AC power cables to the inlet connector corresponding to

each installed power supply, and then connect the other end of the cables to the power source. For a DC

installation, see Connecting a DC Power Supply, on page 16.To determine the number of power supplies

needed for a given configuration, use the Cisco UCS Power Calculator tool.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 15

Page 16

PS 1

PS 2

PS 3

PS 4

Server Slot 1

Server Slot 2

Server Slot 3

Server Slot 5

Server Slot 7

Server Slot 4

Server Slot 6

Server Slot 8

Front

Fan 1

Fan 2

I/O Module Slot 1

I/O Module Slot 2

Connector

PS 4

Connector

PS 3

Connector

PS 2

Connector

PS 1

Fan 6

Fan 5

Fan 4

Fan 3

Fan 8

Fan 7

Rear

279770

Connecting a DC Power Supply

Installation

Step 6

Note

Both grids in a power redundant system should have the same number of power supplies. If your system is configured for grid redundancy,

slots 1 and 2 are assigned to grid 1 and slots 3 and 4 are assigned to grid 2. If only two power supplies (PS) are in a redundant- mode

chassis, they should be in slots 1 and 3. Slot and cord connection numbering is shown below.

Figure 12: Power Supply Bay and Connector Numbering

Connect the server chassis to the fabric interconnect as described in Proper FEX and Fabric Interconnect Port

Connectivity, on page 20.

Connecting a DC Power Supply

This section describes how to connect power to the rear PDU terminals on the DC version chassis

(UCSB-5108-DC) corresponding to a UCS 5108 DC power supply (UCSB-PSU-2500DC48).

Required Tools

You must have the following tools to perform this procedure:

A Phillips screwdriver

•

A 10-mm wrench or socket

•

Connectors and wire for the DC circuit or circuits

•

DC Power Installation Procedure

Warning

When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type

with upturned lugs. These terminations should be the appropriate size for the wires and should clamp both

the insulation and conductor. Statement 1002

Cisco UCS 5108 Server Chassis Installation Guide

16 OL-20035-05

Page 17

Installation

Connecting a DC Power Supply

Warning

Warning

Warning

Warning

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1003

A readily accessible two-poled disconnect device must be incorporated in the fixed wiring. Statement

1022

Use copper conductors only. Statement 1025Warning

This product requires short-circuit (overcurrent) protection, to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations. Statement 1045

When installing or replacing the unit, the ground connection must always be made first and disconnected

last. Statement 1046

Installation of the equipment must comply with local and national electrical codes. Statement 1074Warning

Warning

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Hazardous voltage or energy may be present on DC power terminals. Always replace cover when terminals

are not in service. Be sure uninsulated conductors are not accessible when cover is in place. Statement

1075

Procedure

Install the DC power supply in the chassis, making note of the bay number, so you are sure to connect the

wiring to the appropriate terminals on the DC PDU at the chassis rear.

Verify that power is off to the DC circuit or circuits on the power supply that you are installing.

Ensure that all site power and grounding requirements have been met.

Remove the plastic cover from the DC terminals by squeezing the flanges at the top and bottom of the cover.

Connect the ground wires to the power supply terminal block, shown as a green wire below. Only one ground

connection is required, though there may be up to four DC connections.

Connect the DC-input wires to the power supply terminal block. The proper wiring sequence is positive to

positive (red wire), and negative to negative (black wire). The figure below shows a connection to terminal

1.

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 17

Page 18

237204

Connecting a DC Power Supply

Installation

Note

The positive and negative wires can be installed pointing either to the right or to the left as long as

the terminal cover is used. The figure below shows them pointed to the right. Panduit LCD4-14A-L

connectors may be used for the supply and return wires, and Panduit LCD4-14AF-L or equivalent

connectors may be used for the 90-degree ground lug wire. Both connections have double lugs with

.25 inch holes measuring .625 inches from center to center.

Figure 13: Connecting DC Power to the Chassis (shows DC PDU only, Chassis is Omitted)

Cisco UCS 5108 Server Chassis Installation Guide

18 OL-20035-05

Page 19

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31

26 28 30 3218 20 22 2410 12 14 162 4 6 8

1 3 5 7 9 11 13 15

10 12 14 162 4 6 8

1 2 3 4 5 6

330345

Installation

Cabling Considerations for Fabric Port Channels

Step 7

Replace the terminal cover as shown. This cover should always be in place when power is applied to the

terminals.

Step 8

Step 9

Connect the other end of the power wires to a DC-power input source.

Set the DC disconnect switch in the circuit to ON.

Caution

In a system with multiple power supplies, connect each power supply to a separate DC power

source. In the event of a power source failure, if the second source is still available, it can maintain

system operation.

Step 10

Step 11

Verify power supply operation by checking the power supply's front-panel LEDs. You should see the following:

The LED labeled INPUT OK is green.

•

The LED labeled OUTPUT FAIL is not lit.

•

Check the power supply and system status from the UCS console by entering the show system command or

the show power command, do using the GUI. For more information on these commands, refer to the command

reference for your software.

Cabling Considerations for Fabric Port Channels

When you configure the links between the Cisco UCS 2200 Series FEX and a Cisco UCS 6200 series fabric

interconnect in fabric port channel mode, the available VIF namespace on the adapter varies depending on

where the FEX uplinks are connected to the fabric interconnect ports.

Inside the 6248 fabric interconnect there are six sets of eight contiguous ports, with each set of ports managed

by a single chip. When uplinks are connected such that all of the uplinks from an FEX are connected to a set

of ports managed by a single chip, Cisco UCS Manager maximizes the number of VIFs used in service profiles

deployed on the blades in the chassis. If uplink connections from an IOM are distributed across ports managed

by separate chips, the VIF count is decreased.

Figure 14: Port Groups for Fabric Port Channels

Caution

Adding a second link to a fabric port channel port group is disruptive and will automatically increase the

available amount of VIF namespace from 63 to 118. Adding further links is not disruptive and the VIF

namespace stays at 118.

OL-20035-05 19

Cisco UCS 5108 Server Chassis Installation Guide

Page 20

Proper FEX and Fabric Interconnect Port Connectivity

Installation

Caution

Linking a chassis to two fabric port channel port groups is disruptive and does not affect the VIF namespace

unless it is manually acknowledged. The VIF namespace is then automatically set to the smaller size fabric

port channel port group usage (either 63 or 118 VIFs) of the two groups.

For high availability cluster mode applications, symmetric cabling configurations are strongly recommended.

If the cabling is asymmetric, the maximum number of VIFs available is the smaller of the two cabling

configurations.

For more information on the maximum number of VIFs for your Cisco UCS environment, see the configuration

limits document for your hardware and software configuration.

Proper FEX and Fabric Interconnect Port Connectivity

Note

The following illustrations are for example only; you do not need to skip available ports to provide future

expansion room. See the UCS Manager configuration guide for FI port configuration considerations and

limitations.

Observe the following guidelines:

When you connect the server chassis to the fabric interconnect, do not connect the FEXes to the fabric

•

interconnect’s expansion modules. While similar in appearance to the other ports on the fabric interconnect,

the expansion modules are never used for direct chassis connections. They are typically used for SAN

connectivity or network uplink.

All ports of a FEX must be connected to only one fabric interconnect. You must connect each fabric

•

interconnect to the chassis through its own FEX.

If you need to connect to a second fabric interconnect, do the following:

•

The chassis must have a second FEX installed.

◦

All ports of the second FEX must be connected to the second fabric interconnect only because the

◦

FEX is a fabric extender, which can only be connected to a single switch, or in this case, a fabric

interconnect.

Cisco UCS 5108 Server Chassis Installation Guide

20 OL-20035-05

Page 21

I/O Module Slot1 I/OModule Slot 2I/O Module Slot 1 I/OModule Slot 2

Chassis 1 rear

Port 1

Port 2

Port 3

Port 4

Port 1

Port 2

Port 3

Port 4

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31

26 28 30 3218 20 22 2410 12 14 162 4 6 8

1 3 5 7 9 11 13 15

10 12 14 162 4 6 8

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31

26 28 30 3218 20 22 2410 12 14 162 4 6 8

1 3 5 7 9 11 13 15

10 12 14 162 4 6 8

Fabric Interconnect A Rear

Fabric Interconnect B Rear

192748

Installation

Proper FEX and Fabric Interconnect Port Connectivity

The following figure shows an invalid connection from a FEX to two separate fabric interconnects.

Figure 15: Invalid Connection for the Server Chassis and two Cisco UCS 6120XP Fabric Interconnects

Both fabric interconnects should be wired identically: if port 1 on FEX 1 for a chassis goes to FI-A

◦

port 5, then port 1 on FEX 2 goes to FI-B port 5.

The following figure shows valid connections from FEXes in two chassis to two separate fabric

interconnects. When you connect the server chassis to the fabric interconnect do not connect the

FEXes to the fabric interconnect's expansion modules. While similar in appearance to the other

Cisco UCS 5108 Server Chassis Installation Guide

OL-20035-05 21

Page 22

I/O Module Slot 1 I/OModule Slot 2I/O Module Slot 1 I/OModule Slot 2

Chassis 1 rear

Port 1

Port 2

Port 3

Port 4

Port 1

Port 2

Port 3

Port 4

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31

26 28 30 3218 20 22 2410 12 14 162 4 6 8

1 3 5 7 9 11 13 15

10 12 14 162 4 6 8

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31

26 28 30 3218 20 22 2410 12 14 162 4 6 8

1 3 5 7 9 11 13 15

10 12 14 162 4 6 8

Fabric Interconnect A Rear

Fabric Interconnect B Rear

I/O Module Slot 1 I/OModule Slot 2I/O Module Slot 1 I/OModule Slot 2

Chassis 2 rear

Port 1

Port 2

Port 3

Port 4

Port 1

Port 2

Port 3

Port 4

192749

Removing the Chassis from a Rack

Installation

ports on the fabric interconnect, the expansion modules are never used for direct chassis connections,

they are used for uplink or SAN connections.

Figure 16: Proper Connection for the Server Chassis and two Cisco UCS 6120XP Fabric Interconnects

Removing the Chassis from a Rack

If you plan to remove a chassis from a UCS system and then from a rack you should first:

1

Use Cisco UCS Manager to shut down the OS on all blade servers in the chassis. Graceful shutdown of a

blade server is discussed in the “System Management“ section, “Managing Blade Servers” chapter of the

Cisco UCS Manager configuration guide for your software release. The related CLI commands are as

follows:

UCS-A# scope org

UCS-A /org # scope service-profile service-profile-name

Cisco UCS 5108 Server Chassis Installation Guide

UCS-A /org/service-profile # power down

22 OL-20035-05

Page 23

Installation

Repacking the Chassis

2

Disable the Smart Call Home feature, as mentioned in the “System Monitoring” section, “Configuring Call

Home” chapter of the Cisco UCS Manager configuration guide for your software release. The related CLI

commands are:

UCS-A# scope monitoring

UCS-A /monitoring # scope callhome

UCS-A /monitoring/callhome # disable

3

Decommission the chassis as described in the “System Management“ section, “Managing the Chassis“

chapter of the UCS Manager configuration guide for your software release. The related CLI command is

decommission-chassis chassis-num.

Procedure

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Disconnect the power cords and networking cables from the chassis.

Remove all modules and blades from the chassis to lighten its weight.

Remove the screws holding the front rack-mount flange to the rack.

With two people holding the chassis, make sure that its weight is fully supported.

Gently slide the chassis off the rails, and out of the rack.

Replace the modules and blades in the server chassis.

Repacking the Chassis

If you need to repack the chassis, remove it from the rack by reversing the steps in the Removing the Chassis

from a Rack, on page 22 section, and then pack it for shipment. If possible, use the original packing materials

and container to pack the chassis. If you are returning the chassis to Cisco, contact your Cisco customer service

representative to arrange for return shipment to Cisco.

SFP+ Transceivers

Each FEX within the chassis supports Small Form-Factor Pluggable (SFP+) copper or optical transceivers.

Each transceiver runs at 10 Gb.

SFP+ Twinax Copper Transceivers

The FEX also supports Twinax copper transceivers. The enhanced SFP+ 10-Gb Ethernet transceiver is a

bidirectional device with a transmitter and receiver in the same physical package. It has a 20-pin connector

on the electrical interface.

Table 3: SFP+ 10 Gb Ethernet Transceiver

DescriptionModel

SFP-H10GB-CU1M

OL-20035-05 23

10-Gb Ethernet—copper SFP+ (1 m, 3.28 ft.)

Cisco UCS 5108 Server Chassis Installation Guide

Page 24

187492

Optical SFP+ Transceivers

Installation

DescriptionModel

SFP-H10GB-CU3M

SFP-H10GB-CU5M

SFP-H10GB-ACU7M

SFP-H10GB-ACU10M

10-Gb Ethernet—copper SFP+ (3 m, 9.84 ft.)

10-Gb Ethernet—copper SFP+ (5 m, 16.4 ft.)

10-Gb Ethernet—copper SFP+ (7 m, 22.9 ft.)

10-Gb Ethernet—copper SFP+ (10 m, 32.8 ft.)

The figure below shows the SFP-H10GB-CU5M transceiver. The rubber loop is used for removing the SFP+

from its port on the I/O module.

Figure 17: SFP+ 10 Gb Twinax Copper Transceiver

Optical SFP+ Transceivers

If distances greater than 10 meters (33 feet) must be spanned, the FEX also supports the substitution of the

copper SFP+ by optical SFP+ transceivers. The SFP+ 10-Gb Ethernet optical transceiver is a bidirectional

device with a transmitter and receiver in the same physical package. It has a duplex LC connector on the

optical interface.

DescriptionModel

SFP-10G-SR

SFP-10G-LR

1

While the SFP-10G-LR is supported by both the fabric interconnect and I/O module, the maximum distance will introduce latency issues that will affect overall

performance.

1

Documentation for SFP+ 10-Gb Ethernet optical transceivers is at

http://www.cisco.com/en/US/docs/interfaces_modules/transceiver_modules/installation/note/78_15160.html

Cisco UCS 5108 Server Chassis Installation Guide

24 OL-20035-05

Short–range optical SFP+ (up to 300 m/ 984 feet)

Long–range optical SFP+ (up to 10 km/6.2 miles)

Page 25

192627

192666

Installation

Replacing a Copper Twinax SFP+ Transceiver with an Optical SFP+ Transceiver

Replacing a Copper Twinax SFP+ Transceiver with an Optical SFP+ Transceiver

Procedure

Step 1

Step 2

Step 3

Remove the copper Twinax SFP+ from the FEX port by pulling gently on the rubber loop. The cable and

SFP+ transceiver come out as a single unit, leaving the FEX port empty.

Figure 18: Removing a Twinax Copper SFP+ Transceiver

Insert the optical SFP+ transceiver into the FEX port. Make sure that it clicks firmly into place.

Plug the fiber-optic cable into the optical SFP+ transceiver.

Figure 19: Replacing a Copper SFP+ Transceiver with an Optical SFP+ Transceiver

OL-20035-05 25

Cisco UCS 5108 Server Chassis Installation Guide

Page 26

Replacing a Copper Twinax SFP+ Transceiver with an Optical SFP+ Transceiver

Installation

Cisco UCS 5108 Server Chassis Installation Guide

26 OL-20035-05

Loading...

Loading...