Page 1

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

First Published: August 13, 2014

Last Modified: February 01, 2016

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be determined by turning the equipment off and on, users are

encouraged to try to correct the interference by using one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•

Consult the dealer or an experienced radio/TV technician for help.

•

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED "AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2014-2016 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface

CHAPTER 1

CHAPTER 2

Preface vii

Audience vii

Documentation Conventions vii

Related Documentation viii

Documentation Feedback x

Obtaining Documentation and Submitting a Service Request x

Overview 1

Overview 1

Ports 2

Supported Transceivers and Cables 3

Fan Modules 3

Power Supply Modules 3

Preparing the Site 5

Temperature Requirements 5

Humidity Requirements 5

Altitude Requirements 6

Dust and Particulate Requirements 6

Minimizing Electromagnetic and Radio Frequency Interference 6

Shock and Vibration Requirements 7

Grounding Requirements 7

Planning for Power Requirements 7

Airflow Requirements 8

Rack and Cabinet Requirements 9

Clearance Requirements 10

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

iii

Page 4

Contents

CHAPTER 3

CHAPTER 4

Installing the Chassis 11

Preparing to Install the Switch 11

Installing a Rack or Cabinet 13

Unpacking and Inspecting the Switch 14

Installing the Chassis in a Four-Post Rack 15

Attaching the Bottom-Support Rails to the Rack 15

Attaching Front-Mount Brackets to the Chassis 17

Installing the Chassis in a Four-Post Rack 18

Grounding the Chassis 21

Powering Up the Switch 23

Connecting the Switch to the ACI Fabric 27

ACI Fabric Topology 27

Preparing to Connect to Other Devices 28

Connecting a Leaf Switch to an APIC 29

Connecting a Leaf Switch to a Spine Switch 30

CHAPTER 5

APPENDIX A

Setting Up an Optional Console or Optional Out-Of-Band Management Interface 32

Maintaining Transceivers and Optical Cables 32

Replacing Modules 33

Replacing a Fan Module During Operations 33

Replacing a Power Supply Module 35

Removing an HVAC/HVDC Power Supply 36

Removing an AC Power Supply 37

Removing a DC Power Supply 37

Installing an HVAC/HVDC Power Supply 38

Installing an AC Power Supply 39

Installing a DC Power Supply 40

Wiring a 48 V DC Electrical Connector Block 41

Rack Specifications 43

Overview of Racks 43

General Requirements for Cabinets and Racks 43

Requirements Specific to Standard Open Racks 44

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

iv

Page 5

Contents

Requirements Specific to Perforated Cabinets 44

Cable Management Guidelines 44

APPENDIX B

APPENDIX C

APPENDIX D

System Specifications 45

Environmental Specifications 45

Switch Dimensions 45

Switch and Module Weights and Quantities 46

Power Input Requirements 46

Transceivers, Connectors, and Cables 46

Transceiver and Cable Specifications 46

RJ-45 Connectors 47

Power Cord Specifications 47

LEDs 51

Switch Chassis LEDs 51

Fan Module LEDs 52

Power Supply LEDs 52

Accessory Kits 55

APPENDIX E

Accessory Kit Contents 55

Site Preparation and Maintenance Records 57

Site Preparation Checklist 57

Contact and Site Information 59

Chassis and Module Information 59

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

v

Page 6

Contents

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

vi

Page 7

Preface

Audience, page vii

•

Documentation Conventions, page vii

•

Related Documentation, page viii

•

Documentation Feedback, page x

•

Obtaining Documentation and Submitting a Service Request, page x

•

Audience

This publication is for hardware installers and network administrators who install, configure, and maintain

Cisco Nexus switches.

Documentation Conventions

Command descriptions use the following conventions:

DescriptionConvention

bold

Italic

[x | y]

{x | y}

Bold text indicates the commands and keywords that you enter literally

as shown.

Italic text indicates arguments for which the user supplies the values.

Square brackets enclose an optional element (keyword or argument).[x]

Square brackets enclosing keywords or arguments separated by a vertical

bar indicate an optional choice.

Braces enclosing keywords or arguments separated by a vertical bar

indicate a required choice.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

vii

Page 8

Related Documentation

Preface

DescriptionConvention

[x {y | z}]

variable

string

Examples use the following conventions:

italic screen font

Nested set of square brackets or braces indicate optional or required

choices within optional or required elements. Braces and a vertical bar

within square brackets indicate a required choice within an optional

element.

Indicates a variable for which you supply values, in context where italics

cannot be used.

A nonquoted set of characters. Do not use quotation marks around the

string or the string will include the quotation marks.

DescriptionConvention

Terminal sessions and information the switch displays are in screen font.screen font

Information you must enter is in boldface screen font.boldface screen font

Arguments for which you supply values are in italic screen font.

Nonprinting characters, such as passwords, are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

!, #

Related Documentation

The Application Centric Infrastructure documentation set includes the following documents that are available

on Cisco.com at the following URL:

http://www.cisco.com/c/en/us/support/cloud-systems-management/application-policy-infrastructure-controller-apic/tsd-products-support-series-home.html.

Web-Based Documentation

Cisco APIC Management Information Mode Reference

•

Cisco APIC Online Help Reference

•

Cisco APIC Python SDK Reference

•

Cisco ACI Compatibility Tool

•

Cisco ACI MIB Support List

•

An exclamation point (!) or a pound sign (#) at the beginning of a line

of code indicates a comment line.

viii

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

Page 9

Preface

Related Documentation

Downloadable Documentation

Knowledge Base Articles (KB Articles)are available at the following URL:

•

http://www.cisco.com/c/en/us/support/cloud-systems-management/application-policy-infrastructure-controller-apic/products-configuration-examples-list.html

Cisco Application Centric Infrastructure Controller Release Notes

•

Cisco Application Centric Infrastructure Fundamentals Guide

•

Cisco APIC Getting Started Guide

•

Cisco ACI Virtualization Guide

•

Cisco APIC REST API User Guide

•

Cisco APIC Command Line Interface User Guide

•

Cisco APIC Faults, Events, and System Messages Management Guide

•

Cisco ACI System Messages Reference Guide

•

Cisco APIC Layer 4 to Layer 7 Services Deployment Guide

•

Cisco APIC Layer 4 to Layer 7 Device Package Development Guide

•

Cisco APIC Layer 4 to Layer 7 Device Package Test Guide

•

Cisco ACI Firmware Management Guide

•

Cisco ACI Troubleshooting Guide

•

Cisco ACI Switch Command Reference, NX-OS Release 11.0

•

Cisco Verified Scalability Guide for Cisco ACI

•

Cisco ACI MIB Quick Reference

•

Cisco Nexus CLI to Cisco APIC Mapping Guide

•

Application Centric Inftrastructure Fabric Hardware Installation Guide

•

Cisco NX-OS Release Notes for Cisco Nexus 9000 Series ACI-Mode Switches

•

Cisco Nexus 9000 Series ACI Mode Licensing Guide

•

Cisco Nexus 93128TX ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9332PQ ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9372PX and 9372PX-E ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9372TX ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9396PX ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9396TX ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9504 ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9508 ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9516 ACI-Mode Switch Hardware Installation Guide

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

ix

Page 10

Documentation Feedback

Cisco Application Centric Infrastructure (ACI) Simulator Documentation

The following Cisco ACI Simulator documentation is available at

http://www.cisco.com/c/en/us/support/cloud-systems-management/application-centric-infrastructure-simulator/tsd-products-support-series-home.html.

Cisco Nexus 9000 Series Switches Documentation

The Cisco Nexus 9000 Series Switches documentation is available at

http://www.cisco.com/c/en/us/support/switches/nexus-9000-series-switches/tsd-products-support-series-home.html.

Cisco Application Virtual Switch Documentation

The Cisco Application Virtual Switch (AVS) documentation is available at

http://www.cisco.com/c/en/us/support/switches/application-virtual-switch/tsd-products-support-series-home.html.

Cisco ACI Simulator Release Notes

•

Cisco ACI Simulator Installation Guide

•

Cisco ACI Simulator Getting Started Guide

•

Preface

Documentation Feedback

To provide technical feedback on this document, or to report an error or omission, please send your comments

to apic-docfeedback@cisco.com. We appreciate your feedback.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, using the Cisco Bug Search Tool (BST), submitting a service

request, and gathering additional information, see What's New in Cisco Product Documentation, at: http://

www.cisco.com/c/en/us/td/docs/general/whatsnew/whatsnew.html.

Subscribe to What's New in Cisco Product Documentation, which lists all new and revised Cisco technical

documentation as an RSS feed and delivers content directly to your desktop using a reader application. The

RSS feeds are a free service.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

x

Page 11

Overview

CHAPTER 1

Overview

Overview, page 1

•

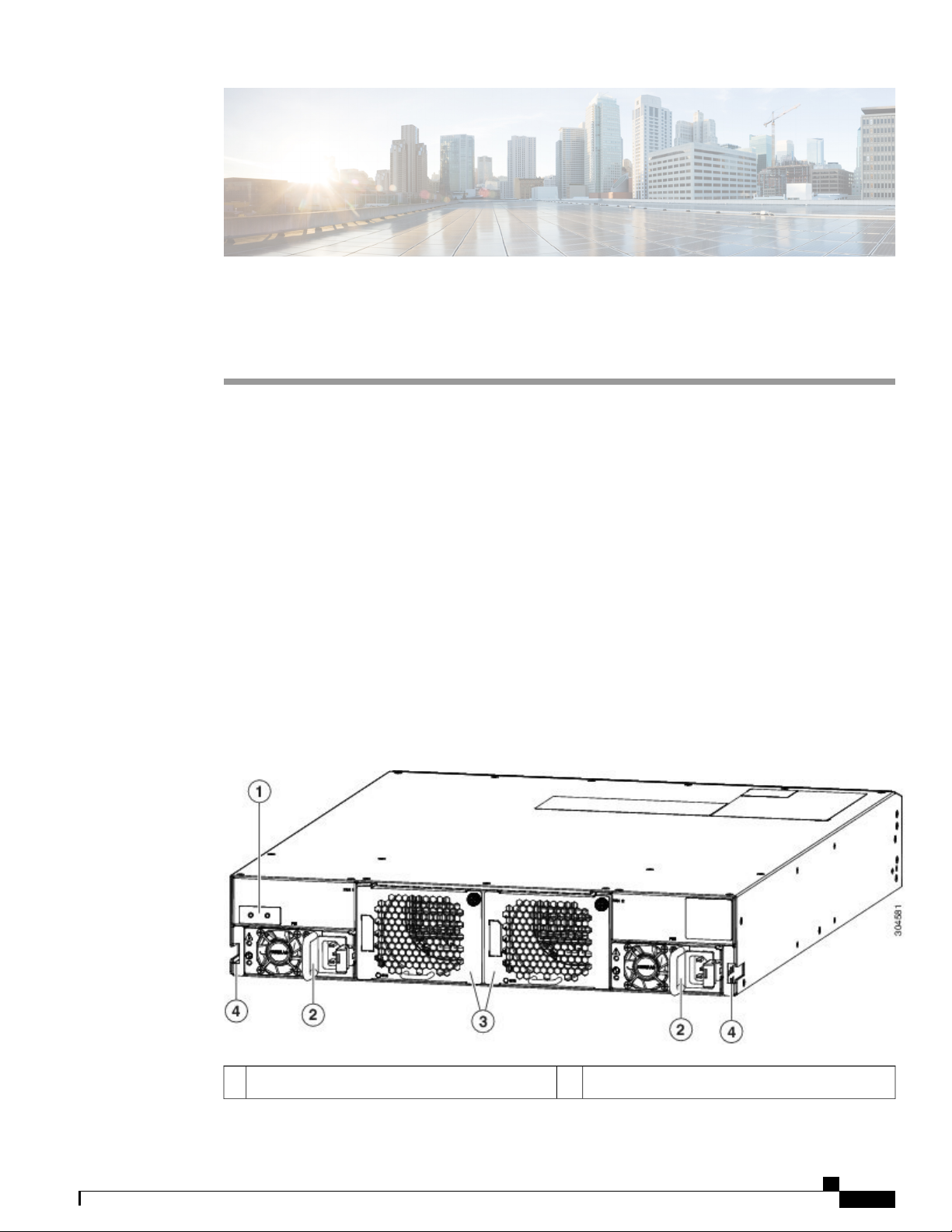

The Cisco Nexus 9336PQ ACI Spine Switch (N9K-C9336PQ) is a 2-rack-unit (RU) switch for the Cisco

Application-Centric Infrastructure (ACI). This switch includes the following components:

36 fixed 40-Gigabit Quad Small Form-factor Pluggable (QSFP+) ports

•

Console and out-of-band-management ports (one each)

•

• Power supplies (two—one required for operations and an optional one for redundancy)

Fan modules (two)

•

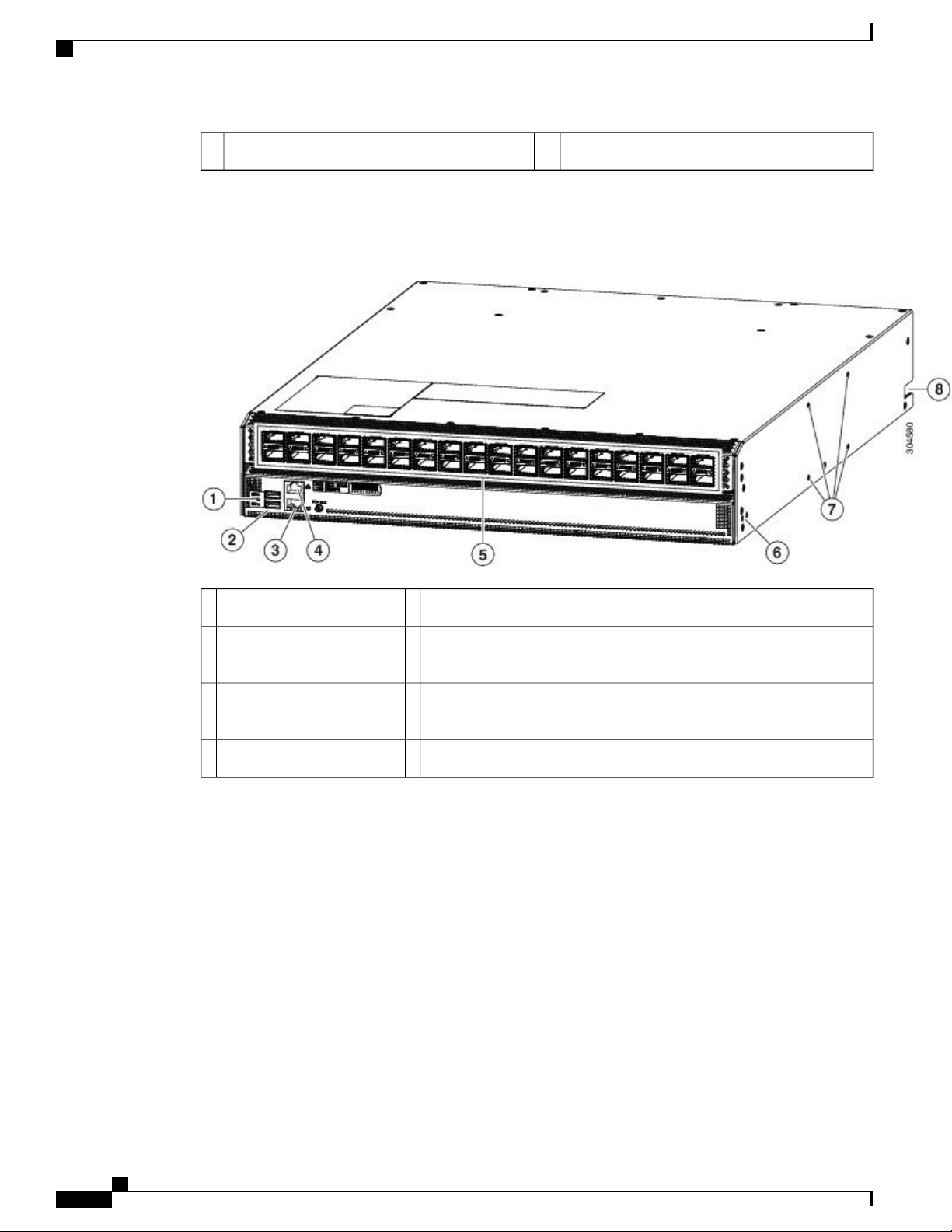

The following figure shows the hardware features seen on the power supply side of the chassis.

Figure 1: Hardware Features on the Power Supply Side of the Chassis

Fan modules (2)3Grounding Pad1

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

1

Page 12

Ports

Overview

Power supplies (2) (AC power supply shown)2

The following figure shows the hardware features seen from the port side of the chassis.

Figure 2: Hardware Features on the Port Side of the Chassis

Ports

36 40-Gigabit QSFP+ ports5Chassis LEDs1

Screw holes (2) for attaching a front-mount bracket for four-post racks

6USB ports2

(one bracket on each of two sides)

Notch in both sides of the chassis for locking the power supply end of

3

port (RJ-45 port)

7Out-of-band management

the chassis to the bottom support brackets

Console port (RJ232 port)4

The switch chassis includes the following types of ports:

40-Gigabit QSFP+ interface ports (36)

•

Console port (1)

•

Out-of-band management port (1)

•

USB flash-memory ports (2)

•

The interface ports support QSFP+ transceivers and are numbered from left to right. You use these ports to

connect the switch to Cisco Nexus 9300 switches in the ACI network that this switch belongs to. These ports

are numbered 1 to 36 from left to right.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

2

Page 13

Overview

The console port enables you to perform the initial setup of the switch.

The out-of-band management port enables you to manage switch operations after you set up the switch.

If you need to download or upload switch configurations on a flash drive, you can use the flash drive in one

of the two USB ports.

Supported Transceivers and Cables

To determine which transceivers and cables are supported by this switch, see the Cisco Transceiver Modules

Compatibility Information document.

Fan Modules

The switch supports two fan modules, which provide port-side intake or port-side exhaust airflow for cooling.

You can hot swap one of the fan modules during operations but must replace it within one minute. If you

cannot replace the fan module within one minute, then it is best to leave the failed fan module in the chassis

until you are ready to replace it.

The fan modules are labeled FAN 1 on the left and FAN 2 on the right.

Supported Transceivers and Cables

Note

The switch must run with all of its power supply and fan modules taking in cooling air from a cold aisle

and exhausting to a hot aisle. If they take in air from the hot aisle, the switch can overheat and shut down.

All fan and power supply modules must use the same direction of airflow.

Power Supply Modules

The switch has two power supply slots labeled PS1 on the left and PS2 on the right. You can mix any of the

following power supplies in those slots:

1200-W HVAC/HVDC power supplies with white coloring for dual-directional airflow

•

(N9K-PUV-1200W)

1200-W port-side exhaust AC power supply with blue coloring and NEBS compliance

•

(NXA-PAC-1200W-PE)

1200-W port-side intake AC power supply with burgundy coloring and NEBS compliance

•

(NXA-PAC-1200W-PI)

1200-W port-side exhaust AC power supply with blue coloring (N9K-PAC-1200W-B)

•

1200-W port-side intake AC power supply with burgundy coloring (N9K-PAC-1200W)

•

930-W DC power supplies with green coloring for port-side intake airflow (UCSC-PSU-930WDC)

•

930-W DC power supplies with gray coloring for port-side exhaust airflow (UCS-PSU-6332-DC)

•

The switch requires one power supply for its operations and a second power supply for power redundancy.

You can hot swap one of the power supplies during operations but otherwise must always have two power

supplies (or one power supply and one blank faceplate) installed in the chassis to maintain the designed airflow.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

3

Page 14

Power Supply Modules

Overview

Caution

The switch must run with all of its power supply and fan modules taking in cooling air from a cold aisle

and exhausting to a hot aisle. If they take in air from the hot aisle, the switch can overheat and shut down.

All power supply and fan modules must use the same direction of airflow.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

4

Page 15

CHAPTER 2

Preparing the Site

Temperature Requirements, page 5

•

Humidity Requirements, page 5

•

Altitude Requirements, page 6

•

Dust and Particulate Requirements, page 6

•

Minimizing Electromagnetic and Radio Frequency Interference, page 6

•

Shock and Vibration Requirements, page 7

•

Grounding Requirements, page 7

•

Planning for Power Requirements, page 7

•

Airflow Requirements, page 8

•

Rack and Cabinet Requirements, page 9

•

Clearance Requirements, page 10

•

Temperature Requirements

The switch requires an operating temperature of 32 to 104° F (0 to 40° C). If the switch is not operating, the

temperature must be between –40 to 158° F (–40 to 70° C).

Humidity Requirements

High humidity can cause moisture to enter the switch. Moisture can cause corrosion of internal components

and degradation of properties such as electrical resistance, thermal conductivity, physical strength, and size.

The switch is rated to operate at 8 to 80 percent relative humidity, with a humidity gradation of 10 percent

per hour. For nonoperating conditions, the switch can withstand from 5 to 95 percent relative humidity.

Buildings in which the climate is controlled by air-conditioning in the warmer months and by heat during the

colder months usually maintain an acceptable level of humidity for the switch equipment. However, if the

switch is located in an unusually humid location, you should use a dehumidifier to maintain the humidity

within an acceptable range.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

5

Page 16

Altitude Requirements

Altitude Requirements

If you operate a switch at a high altitude (low pressure), the efficiency of forced and convection cooling is

reduced and can result in electrical problems that are related to arcing and corona effects. This condition can

also cause sealed components with internal pressure, such as electrolytic capacitors, to fail or to perform at a

reduced efficiency. This switch is rated to operate at altitudes from 0 to 13,123 feet (0 to 4,000 meters).

Dust and Particulate Requirements

Exhaust fans cool power supplies and system fans cool switches by drawing in air and exhausting air out

through various openings in the chassis. However, fans also ingest dust and other particles, causing contaminant

buildup in the switch and increased internal chassis temperature. A clean operating environment can greatly

reduce the negative effects of dust and other particles, which act as insulators and interfere with the mechanical

components in the switch.

In addition to regular cleaning, follow these precautions to avoid contamination of your switch:

Preparing the Site

Do not permit smoking near the switch.

•

Do not permit food or drink near the switch.

•

Minimizing Electromagnetic and Radio Frequency Interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) from the switch can adversely

affect other devices such as radio and television (TV) receivers operating near the switch. Radio frequencies

that emanate from the switch can also interfere with cordless and low-power telephones. Conversely, RFI

from high-power telephones can cause spurious characters to appear on the switch monitor.

RFI is defined as any EMI with a frequency above 10 kHz. This type of interference can travel from the switch

to other devices through the power cable and power source or through the air as transmitted radio waves. The

Federal Communications Commission (FCC) publishes specific regulations to limit the amount of EMI and

RFI that can be emitted by computing equipment. Each switch meets these FCC regulations.

To reduce the possibility of EMI and RFI, follow these guidelines:

Cover all open expansion slots with a blank filler plate.

•

Always use shielded cables with metal connector shells for attaching peripherals to the switch.

•

When wires are run for any significant distance in an electromagnetic field, interference can occur between

the field and the signals on the wires with the following implications:

Bad wiring can result in radio interference emanating from the plant wiring.

•

Strong EMI, especially when it is caused by lightning or radio transmitters, can destroy the signal drivers

•

and receivers in the chassis and even create an electrical hazard by conducting power surges through

lines into equipment.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

6

Page 17

Preparing the Site

Shock and Vibration Requirements

Note

Caution

To predict and prevent strong EMI, you might need to consult experts in radio frequency interference

(RFI).

The wiring is unlikely to emit radio interference if you use twisted-pair cable with a good distribution of

grounding conductors. If you exceed the recommended distances, use a high-quality twisted-pair cable with

one ground conductor for each data signal when applicable.

If the wires exceed the recommended distances, or if wires pass between buildings, give special

consideration to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by

lightning or other high-energy phenomena can easily couple enough energy into unshielded conductors

to destroy electronic switches. You might want to consult experts in electrical surge suppression and

shielding if you had similar problems in the past.

Shock and Vibration Requirements

The switch has been shock- and vibration-tested for operating ranges, handling, and earthquake standards.

Grounding Requirements

The switch is sensitive to variations in voltage supplied by the power sources. Overvoltage, undervoltage,

and transients (or spikes) can erase data from the memory or cause components to fail. To protect against

these types of problems, ensure that there is an earth-ground connection for the switch. You can connect the

grounding pad on the switch either directly to the earth-ground connection or to a fully bonded and grounded

rack.

You must provide the grounding cable to make this connection, but you can connect the grounding wire to

the switch using a grounding lug that ships with the switch. Size the grounding wire to meet local and national

installation requirements. Depending on the power supply and system, a 12-AWG to 6-AWG copper conductor

is required for U.S. installations (for those installations, we recommend that you use commercially available

6-AWG wire). The length of the grounding wire depends on the proximity of the switch to proper grounding

facilities.

Note

You automatically ground the power supplies when you connect them to power sources. You must also

connect the chassis to the facility earth ground.

Planning for Power Requirements

The switch includes two power supplies (1-to-1 redundancy with current sharing) in one of the following

combinations (all power supplies must have the same airflow direction as the fan modules):

Two 1200-W HVAC/HVDC power supplies

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

7

Page 18

Airflow Requirements

Two 1200-W NEBS-compliant AC power supplies

•

Two 1200-W standard AC power supplies

•

Two 930-W DC power supplies

•

Any combination of the above power supplies

•

Preparing the Site

Note

Note

For n+1 redundancy, you must provide power to both power supplies. For n+n redundancy, you must

provide power to both power supplies and each power supply must be connected to a different power

source.

The power supplies are rated to output up to 1200 W (AC, NEBS-compliant AC, and HVAC/HVDC power

supplies) or up to 930 W (DC power supplies), but the switch requires less than those amounts of power from

the power supply. To operate the switch you must provision enough power from the power source to cover

the requirements of both the switch and a power supply. Typically, this switch and a power supply require

about 400 W of power input from the power source, but you must provision as much as 660 W power input

from the power source to cover peak demand.

To minimize the possibility of circuit failure, make sure that each power-source circuit used by the switch is

dedicated to the switch.

For the AC power cables that you can use with this switch, see Power Cord Specifications, on page 47.

For DC power cables, the recommended wire gauge is 8 AWG and the minimum wire gauge is 10 AWG.

Airflow Requirements

The switch is designed to be positioned with its ports in either the front or the rear of the rack depending on

your cabling and maintenance requirements. Depending on which side of the switch faces the cold aisle, you

must have fan and power supply modules that move the coolant air from the cold aisle to the hot aisle in one

of the following ways:

• Port-side exhaust airflow—Coolant air enters the chassis through the fan and power supply modules in

the cold aisle and exhausts through the port end of the chassis in the hot aisle.

• Port-side intake airflow—Coolant air enters the chassis through the port end in the cold aisle and exhausts

through the fan and power supply modules in the hot aisle.

• Dual-directional airflow—The airflow direction of the power supplies is determined by the airflow

direction of the fan modules.

You can identify the airflow direction of each fan and power supply module by its coloring as follows:

Blue coloring indicates port-side exhaust airflow.

•

Burgundy coloring indicates port-side intake airflow.

•

Gray coloring on DC power supplies indicates port-side exhaust airflow.

•

Green coloring on DC power supplies indicates port-side intake airflow.

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

8

Page 19

Preparing the Site

Rack and Cabinet Requirements

White coloring on HVAC/HVDC power supplies indicates dual direction airflow.

•

Note

To prevent the switch from overheating and shutting down, you must position the air intake for the switch

in a cold aisle, and all of the fan and power supply modules must have the same direction of airflow (even

if their coloring is different).

Rack and Cabinet Requirements

You can install the following types of racks or cabinets for your switch:

Standard perforated cabinets

•

Solid-walled cabinets with a roof fan tray (bottom-to-top cooling)

•

Standard open four-post Telco racks

•

To correctly install the switch in a cabinet that is located in a hot-aisle/cold-aisle environment, you should fit

the cabinet with baffles to prevent exhaust air from recirculating into the chassis air intake.

Work with your cabinet vendors to determine which of their cabinets meet the following requirements or see

the Cisco Technical Assistance Center (TAC) for recommendations:

Use a standard 19-inch (48.3-cm), four-post Electronic Industries Alliance (EIA) cabinet or rack with

•

mounting rails that conform to English universal hole spacing per section 1 of the ANSI/EIA-310-D-1992

standard.

The depth of a four-post rack must be 24 to 32 inches (61.0 to 81.3 cm) between the front and rear

•

mounting brackets.

Warning

Required clearances between the chassis and the edges of its rack or the interior of its cabinet are as

•

follows:

4.5 inches (11.4 cm) between the front of the chassis and the interior of the cabinet (required for

◦

cabling).

3.0 inches (7.6 cm) between the rear of the chassis and the interior of the cabinet (required for

◦

airflow in the cabinet if used).

No clearance is required between the chassis and the sides of the rack or cabinet (no side airflow).

◦

Additionally, you must have power receptacles located within reach of the power cords used with the switch.

For the power cord specifications, see the Power Cord Specifications.

Statement 1048—Rack Stabilization

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor

before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

9

Page 20

Clearance Requirements

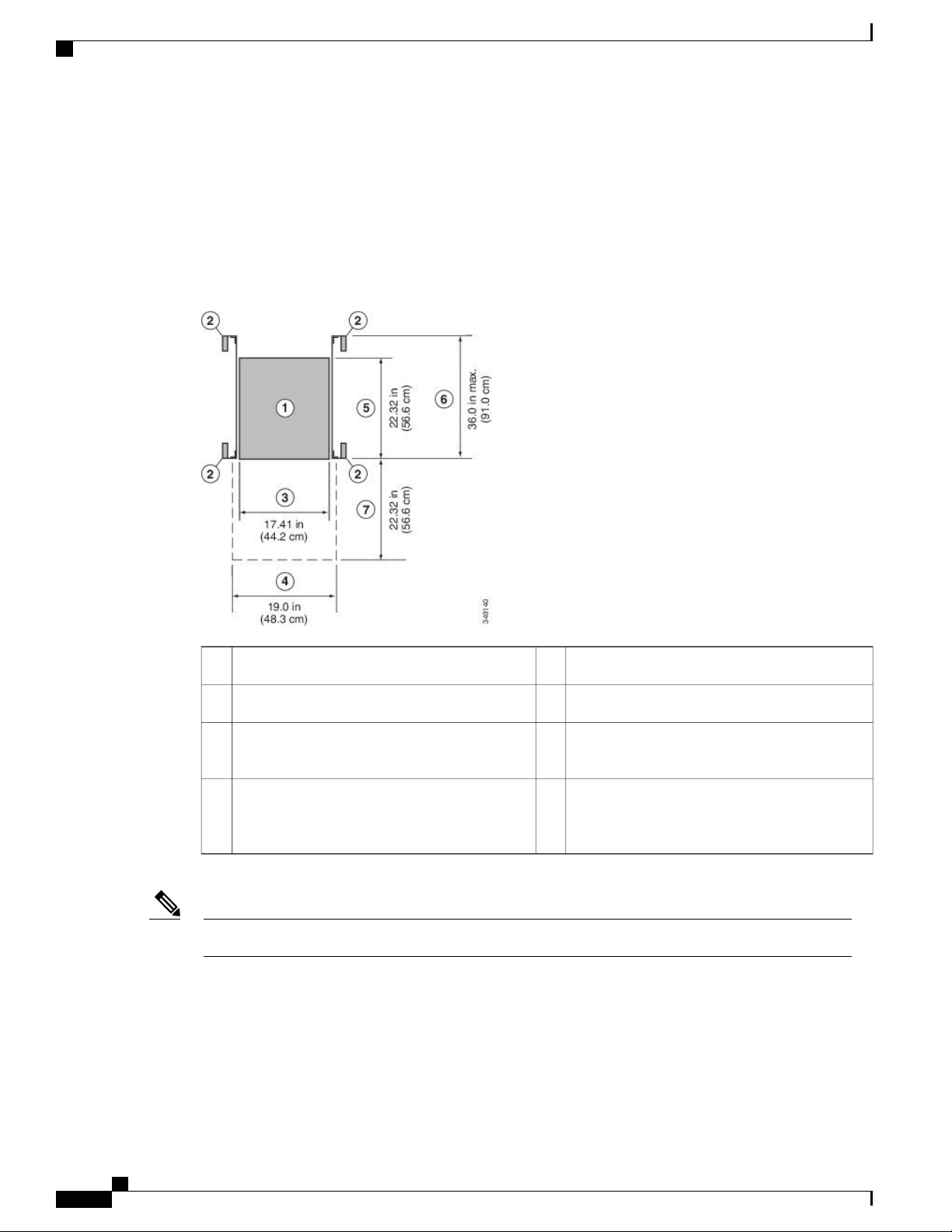

Clearance Requirements

You must provide the chassis with adequate clearance between the chassis and any other rack, device, or

structure so that you can properly install the chassis, route cables, provide airflow, and maintain the switch.

For the clearances required for an installation of this chassis in a four-post rack, see the following figure.

Figure 3: Clearances Required for a Four-Post Rack Installation

Preparing the Site

Width of the front clearance area (this equals

4

the width of the chassis with two rack-mount

brackets attached to it)

Both the front and rear of the chassis must be open to both aisles for airflow.Note

Depth of the chassis5Chassis1

Maximum extension of the bottom-support rails6Vertical rack-mount posts and rails2

Depth of the front clearance area (this equals the

7Chassis width3

depth of the chassis)

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

10

Page 21

Installing the Chassis

Preparing to Install the Switch, page 11

•

Installing a Rack or Cabinet, page 13

•

Unpacking and Inspecting the Switch, page 14

•

Installing the Chassis in a Four-Post Rack, page 15

•

Grounding the Chassis, page 21

•

Powering Up the Switch, page 23

•

Preparing to Install the Switch

Before you install, operate, or service the switch, see the Regulatory, Compliance, and Safety Information for

the Cisco Nexus 9000 Series for important safety information.

CHAPTER 3

Warning

Statement 1071—Warning Definition

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

The switch can be installed in the following types of racks using a rack-mount kit shipped with the switch:

Open EIA rack

•

Perforated EIA cabinet

•

The rack or cabinet that you use must meet the requirements listed in Rack Specifications, on page 43.

You can order the switch chassis with port-side-intake or port-side exhaust airflow. Port-side intake airflow

enters the chassis through the port side (I/O module side) of the chassis and exhausts through the fan and

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

11

Page 22

Preparing to Install the Switch

power supply modules on the opposite end of the chassis. Port-side exhaust airflow enters the chassis through

the fan modules and exhausts through the port side of the chassis.

When lifting the chassis, use each of the following guidelines:

Disconnect any cables attached to the switch.

•

Ensure that your footing is solid and the weight of the switch is evenly distributed between your feet.

•

Lift the switch slowly, keeping your back straight. Lift with your legs, not with your back. Bend at the

•

knees, not at the waist.

When installing the switch, follow these guidelines:

Record switch and installation information in Site Preparation and Maintenance Records, on page 57

•

as you install and configure the switch.

Ensure that there is adequate space around the switch to allow for servicing the switch and for adequate

•

airflow (see Clearance Requirements, on page 10 for the switch specifications).

Ensure that the switch is going to be positioned with its air intake side positioned in the cold aisle and

•

its air exhaust positioned in the hot aisle. This enables the switch to be cooled properly. If the air intake

is positioned in a hot aisle, the switch can overheat and shutdown.

Installing the Chassis

Ensure that the rack or cabinet meets the requirements listed in Rack Specifications, on page 43.

•

Jumper power cords are available for use in a cabinet.Note

Ensure that the chassis can be adequately grounded. If the switch is not mounted in a grounded rack,

•

we recommend connecting both the system ground on the chassis and the power supply ground directly

to an earth ground.

Ensure that the site power meets the power requirements listed in System Specifications. If available,

•

you can use an uninterruptible power supply (UPS) to protect against power failures.

Caution

Avoid UPS types that use ferroresonant technology. These UPS types can become

unstable with switches that have substantial current draw fluctuations because of

fluctuating data traffid patterns.

Ensure that circuits are sized according to local and national codes and meet the requirements of the

•

switch (see Planning for Power Requirements, on page 7 for the switch requirements).

Caution

To prevent loss of input power, ensure that the total maximum loads on the circuits

supplying power to the switch are within the current ratings for wiring and breakers.

Depending on your power redundancy needs, have outlets or terminals for one or two power sources

•

close to the rack as follows:

For no power redundancy, have one power source.

◦

For n+1 redundancy, have one or two power sources.

◦

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

12

Page 23

Installing the Chassis

Installing a Rack or Cabinet

For n+n redundancy, have two power sources.

◦

Use the following screw torques when installing the switch:

•

Captive screws: 4 in-lb (0.45 N·m)

◦

M3 screws: 4 in-lb (0.45 N·m)

◦

M4 screws: 12 in-lb (1.36 N·m)

◦

M6 screws: 40 in-lb (4.5 N·m)

◦

10-32 screws: 20 in-lb (2.26 N·m)

◦

12-24 screws: 30 in-lb (3.39 N·m)

◦

Before beginning the installation, ensure that you have the following items available in addition to the switch

and accessory kit:

Eight customer supplied 12-24 or 10-32 screws (required for attaching slider rails and mounting brackets

•

to the mounting rails)

Number 1 and number 2 Phillips screwdrivers with torque capability

•

3/16-inch wide flat screwdriver

•

Tape measure and level

•

ESD wrist strap or other grounding device

•

Antistatic surface

•

Grounding cable (6 AWG recommended), sized according to local and national installation requirements;

•

the required length depends on the proximity of the switch to proper grounding facilities

Crimping tool large enough to accommodate the girth of the grounding lug

•

Wire-stripping tool

•

Installing a Rack or Cabinet

Before you install the switch, you must install a standard four-post, 19-inch (48.3-cm) EIA data center rack

(or a cabinet that contains such a rack) that meets the requirements listed in Rack and Cabinet Requirements,

on page 9.

Warning

Statement 1048—Rack Stabilization

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor

before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

13

Page 24

Unpacking and Inspecting the Switch

Installing the Chassis

Step 1

Step 2

Step 3

Warning

Bolt the rack to the subfloor before moving the chassis onto it.

If the rack has bonded construction, connect it to the earth ground. This action enables you to easily ground the switch

and its components and to ground your electrostatic discharge (ESD) wrist strap to prevent discharge damage when you

handle ungrounded components during installation.

If you need access to the source power at the rack, include one of the following:

Note

Statement 1018—Supply Circuit

Take care when connecting units to the supply circuit so that wiring is not overloaded.

For AC power, include an AC circuit that meets the power specifications of the switch (see Planning for Power

•

Requirements, on page 7). This circuit must include receptacles that match your local and national requirements

and match the needs of the power cable used with the power supply unit.

For DC power, include a DC circuit that meets the power specifications of the switch (see Planning for Power

•

Requirements, on page 7). This circuit must include a circuit breaker so that you can safely connect the power

cables to the power supply.

If you are using the combined mode or n+1 redundancy mode, you need only one power source. If you are using

the n+n redundancy mode, you need two power sources (one power source for each power supply).

Unpacking and Inspecting the Switch

The switch is thoroughly inspected before shipment. If any damage occurred during transportation or any

items are missing, contact your customer service representative immediately.

Keep the shipping container in case the chassis requires shipping in the future.Note

Before You Begin

To protect the electrical components in the switch, you must wear a grounded ESD strap and handle modules

by only their handles and carrier edges. To ground the ESD strap, make sure that it is attached to an earth

ground, a grounded chassis, or grounded rack.

Step 1

Compare the shipment to the equipment list provided by your customer service representative and verify that you have

received all items, including the following:

Grounding lug kit

•

Rack-mount kit

•

ESD wrist strap

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

14

Page 25

Installing the Chassis

Cables with connectors

•

Any optional items ordered

•

Installing the Chassis in a Four-Post Rack

Step 2

Step 3

Check for damage and report any discrepancies or damage to your customer service representative. Have the following

information ready:

Invoice number of shipper (see packing slip)

•

Model and serial number of the damaged unit

•

Description of damage

•

Effect of damage on the installation

•

Check to be sure that all of the fan and power supply modules have the expected direction of airflow. Burgundy coloring

on fan and AC power supply modules indicates port-side intake airflow, and blue coloring indicates port-side exhaust

airflow. DC power supply modules have either port-side intake airflow (green coloring) or port-side exhaust (grey

coloring). HVAC/HVDC power supply modules have white coloring to indicate that they automatically use the same

airflow direction used by the fan modules.

Installing the Chassis in a Four-Post Rack

Before you install the chassis, be sure that the rack is fully secured to the data center floor.

You must attach the bottom support rails to the rack and attach the mounting brackets to the chassis before

mounting the chassis in the rack.

Attaching the Bottom-Support Rails to the Rack

The switch chassis that you are installing ships with two adjustable bottom-support rails that you can attach

to a four-post rack to hold the chassis. Each of these bottom-support rails has two pieces—one that slides into

the other so that you can adjust them to fit racks with front and rear mounting posts that are spaced less than

36 inches (91 cm). On each bottom-support rail, the rail half that slides into the other rail includes a chassis

stop that fits into the module end of the chassis. Depending on direction of the chassis airflow, you need to

position the rail half with the chassis stop so that the fan and power supply modules end up in the appropriate

aisle as follows:

Port-side intake (burgundy coloring for fan modules) airflow requires that the bottom-support rail with

•

the chassis stop be located on the hot aisle side of the rack.

Port-side exhaust (blue coloring for fan modules) airflow requires that the bottom-support rail with the

•

chassis stop be located on the cold aisle side of the rack.

Warning

Statement 1074—Comply with Local and National Electrical Codes

Installation of the equipment must comply with local and national electrical codes.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

15

Page 26

Attaching the Bottom-Support Rails to the Rack

Before You Begin

Before you can install the bottom support rails for the chassis, you must do the following:

Verify that a four-post rack or cabinet is installed.

•

If any other devices are stored in the rack or cabinet, verify that the heavier switches are installed below

•

lighter switches and that there is at least rack units open to install the switch.

Verify that the bottom-support rails kit is included in the switch accessory kit.

•

Verify that you have 8 screws for attaching the bottom support brackets to the racks (typically M6 x 10

•

mm screws or the screw appropriate for the vertical mounting rails on the rack.

Installing the Chassis

Step 1

Step 2

Step 3

Step 4

Step 5

Warning

Statement 1006—Chassis Warning for Rack-Mounting and Servicing

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with

•

the heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Look at the fan and power supply modules installed in the chassis to determine how you must position the bottom-support

rails on the rack.

If the fan modules have blue coloring (port-side exhaust modules), you must position the bottom support rails so

•

that the chassis stop is positioned by the cold aisle.

If the fan modules have burgundy (port-side intake modules), you must position the bottom support rails so that

•

the chassis stop is positioned by the hot aisle.

Separate the two sliders that make up one bottom-support rail and position the half with the chassis stop by the appropriate

aisle for the fan and power supply modules. Also make sure that there is at least rack units open above the bottom-support

rails so that you can easily install the chassis.

Use two customer-supplied screws (typically M6 x 10 mm screws) to attach the bottom-support rail half to the vertical

mounting rails on the rack post. Tighten each screw to the appropriate torque setting for the screws (for M6 x 10 mm

screws, use 40 in. lbs [4.5 N·m] of torque).

Slide the other half of the bottom-support rail onto the attached half of the rail set and use two customer supplied screws

(typically M6 x 10 mm screws) to secure that portion to the vertical mounting rails on the rack. Tighten each screw to

the appropriate torque setting for the screws (for M6 x 10 mm screws, use 40 in. lbs [4.5 N·m] of torque).

Repeat Steps 2 and 3 to attach the other expanding bottom-support rails to the other side of the rack.

Note

Check the two installed bottom support rails to be sure that both have their chassis stops by the same aisle (either

both by the hot aisle or both by the cold aisle) and that both rails are level and level with each other. If they are

not level, adjust the higher rail down to the level of the lower rail.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

16

Page 27

Installing the Chassis

What to Do Next

You are ready to install two front-mount brackets on the chassis.

Attaching Front-Mount Brackets to the Chassis

You need to attach a right-angled bracket to each side of the chassis. This bracket holds the chassis in place

on a four-post rack.

If you are installing the chassis in a two-post rack, see Attaching Center-Mount Brackets to the ChassisNote

Before You Begin

You must have the following tools and equipment:

•

Attaching Front-Mount Brackets to the Chassis

Step 1

Manual Phillips-head torque screwdriver

◦

Front-mount brackets (2) and screws (4) (found inside the switch accessory kit)

◦

Align the two holes in one side of one of two front-mount brackets to two holes on the left or right side of the chassis

(see the following figure).

Be sure that the other side of the bracket is facing toward the front (port end) of the chassis.

Figure 4: Aligning and Attaching Front-Mount Brackets to the Sides of the Chassis

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

17

Page 28

Installing the Chassis in a Four-Post Rack

1

two screw holes in the chassis and one screw hole

facing the front (port side) of the chassis.

Installing the Chassis

Two M4 x 6 mm screws used to fasten the bracket to

2Front-mount bracket with two screw holes aligned to

the chassis.

Step 2

Step 3

Use two M4 x 6 mm screws to attach the bracket to the chassis. Tighten each screw to 11 to 15 in-lb (1.2 to 1.7 N·m).

Repeat Steps 1 and 2 to attach the second center-mount bracket to the other side of the chassis.

What to Do Next

You are ready to mount the chassis to the four-post rack.

Installing the Chassis in a Four-Post Rack

You need to slide the chassis onto the bottom-support rails so that the power supply end locks onto the chassis

stops at the end of the rails and so that the front-mount brackets on the chassis come into contact with the

front-mount rails on the rack.

Warning

Warning

Statement 1074—Comply with Local and National Electrical Codes

Installation of the equipment must comply with local and national electrical codes.

Statement 1032—Lifting the Chassis

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the

handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to

support the weight of the unit.

Before You Begin

Make sure that the four-post rack is properly installed and secured to the concrete subfloor.

•

Make sure that the bottom-support rails are installed so that the fan modules will be in the appropriate

•

aisle as follows:

Burgundy (port-side intake airflow) fan modules are positioned in a hot aisle (the chassis stop on

◦

the bottom-support rails is positioned by the hot aisle).

Blue colored (port-side exhaust airflow) fan modules are positioned in a cold aisle (the chassis

◦

stop on the bottom-support rails is positioned by the cold aisle).

Make sure that two front-mount brackets are securely fastened to the sides of the chassis at the port end.

•

Make sure that you have two customer-supplied rack-mount screws (M6 x 10 mm or appropriate screw

•

for the vertical mounting rails on the rack).

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

18

Page 29

Installing the Chassis

Installing the Chassis in a Four-Post Rack

Step 1

Warning

Statement 1006—Chassis Warning for Rack-Mounting and Servicing

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with

•

the heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Slide the power supply end of the chassis onto the bottom-support rails that are installed on the rack.

Be sure that the sides of the chassis by the power supplies clips into the chassis stops on the bottom-support rails and

the front-mount brackets come in contact with the rack (see the following figure).

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

19

Page 30

Installing the Chassis in a Four-Post Rack

Installing the Chassis

Note

If the bottom-support rails are extended a long distance, they can bend outwards slightly when you install the

chassis and the chassis stops at the far end of the rails might not fit into the end of the chassis. If this happens,

press the side rails toward the sides of the chassis so that the chassis stops can go inside the chassis and hold it

in place on the rack.

Figure 5: Sliding the Chassis onto the Bottom-Support Rails

Receiving hole on each side of the chassis for the

1

bottom-support rails so that the chassis locks onto the

3Slide the power-supply end of the chassis onto the

chassis stops on the bottom-support rails.

chassis stops at the end of the rails.

Customer-supplied rack-mount screw (M6 x 10 mm

2

the aisle required for the fan and power supply

modules).

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

20

4Chassis stops for holding the chassis (positioned by

screw or other screw appropriate for the rack) used

to secure each side of the chassis to the rack.

Page 31

Installing the Chassis

Grounding the Chassis

Step 2

Use a customer-supplied rack-mount screw (an M6 x 10 mm screw or other appropriate screw for the rack) to attach

each of the two mounting brackets on the chassis to the rack and tighten each screw to the appropriate torque setting for

the screw (for M6 x 10 mm screws, use 40 in-lbs [4.5 N·m] of torque).

Grounding the Chassis

The switch is grounded when you connect the chassis and the power supplies to the earth ground in both of

the following ways:

You connect the chassis (at its grounding pad) to the data center ground. If the rack is fully-bonded and

•

grounded, you can ground the switch by connecting it to the data center ground indirectly through the

rack. Otherwise, you must connect the chassis directly to the data center ground.

Note

You connect each power supply to the data center ground.

•

The chassis ground connection is active even when the power supply modules have not

been grounded or connected to the switch.

AC power supplies are automatically grounded when you connect the power supply to an AC

◦

power source (see Powering Up the Switch, on page 23).

Warning

Warning

DC power supplies are grounded when you connect the ground cable to the power source ground

◦

terminal while also connecting the positive and negative wires to their power source terminals (see

Powering Up the Switch, on page 23).

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available.

Statement 1046—Installing or Replacing the Unit

When installing or replacing the unit, the ground connection must always be made first and disconnected

last.

Before You Begin

Before you can ground the chassis, you must have a connection to the earth ground for the data center building.

If you installed the switch chassis into a bonded rack (see the rack manufacturer's instructions for more

information) that now has a connection to the data center earth ground, you can ground the chassis by connecting

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

21

Page 32

Grounding the Chassis

its grounding pad to the rack. Otherwise, you must connect the chassis grounding pad directly to the data

center ground.

Installing the Chassis

Step 1

Step 2

Use a wire-stripping tool to remove approximately 0.75 inch (19 mm) of the covering from the end of the grounding

wire.

Insert the stripped end of the grounding wire into the open end of the grounding lug, and use a crimping tool to crimp

the lug to the wire (see Callout 2 in the following figure). Verify that the ground wire is securely attached to the grounding

lug by attempting to pull the wire out of the crimped lug.

Figure 6: Grounding the Chassis

Step 3

Step 4

Two M4 screws used to secure the grounding lug to

3Chassis grounding pad1

the chassis

Grounding cable, with 0.75 in. (19 mm) of insulation

2

stripped from one end, inserted into the grounding

lug and crimped in place

Secure the grounding lug to the chassis grounding pad with two M4 screws (see Callouts 1 and 3 in the previous figure),

and tighten the screws to 11 to 15 in-lb (1.24 to 1.69 N·m) of torque.

Prepare the other end of the grounding wire and connect it to an appropriate grounding point in your site to ensure an

adequate earth ground for the switch. If the rack is fully bonded and grounded, connect the grounding wire as explained

in the documentation provided by the vendor for the rack.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

22

Page 33

Installing the Chassis

Powering Up the Switch

To power up the switch, you must connect one or two power supplies to one or two power sources. The number

of power supplies and power sources used depends on the type of power redundancy that you require as

follows:

For no power redundancy, connect only one power supply to a power source.

•

For n+1 redundancy, connect two power supplies to one or two power sources.

•

For n+n redundancy, connect two power supplies to two different power sources.

•

Powering Up the Switch

Warning

Warning

Warning

Warning

Statement 7012—Equipment Interfacing with AC Power Ports

This equipment shall be connected to AC mains provided with a surge protective device (SPD) at the

service equipment complying with NFPA 70, the National Electrical Code (NEC).

Statement 1004—Installation Instructions

Read the installation instructions before connecting the system to the power source.

Statement 1018—Supply Circuit

Take care when connecting units to the supply circuit so that wiring is not overloaded.

Statement 1029—Blank Faceplates and Cover Panels

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous

voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt

other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system

unless all cards, faceplates, front covers, and rear covers are in place.

Before You Begin

Step 1

Switch installed in a rack and connected to an earth ground

•

Recommended power cable for your nation or region

•

Power source with the required amperage located within reach of the power cable being used

•

Connect each power supply to a power source as follows:

Connecting an AC power supply:

•

Using the recommended power cable for your country or region (see Power Cord Specifications, on page 47),

1

connect the C13 plug on the power cable to the power receptacle on the power supply.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

23

Page 34

Powering Up the Switch

Rotate the cable retention clip on the power supply over the C13 plug to prevent accidental unplugging of the

2

cable.

Connect the other end of the power cable to the AC power source.

3

4

Verify that the LED is on and green.

If the LED is off, check the AC power source circuit breaker to be sure that it is turned on.

Connecting a DC power supply:

•

Verify that the circuit breaker for the DC power source you are connecting is turned off.

1

Remove the DC power connector block from the power supply by doing the following:

2

a

b

Strip 0.6 inches (15 mm) of insulation off the DC wires that you are using.

3

Installing the Chassis

Push the orange plastic button on the top of the connector block inward toward the power supply.

Pull the connector block out of the power supply.

Orient the connector as shown in the following figure with the orange plastic button on top.

4

Figure 7: Wiring a 930W -48VDC Power Supply Connector Block

-48V (-DC) cable4Wire retainer lever1

Grounding cable (8 AWG recommended)5Orange plastic button on top of the connector2

-48V Return (+DC) cable3

Use a small screwdriver to depress the spring-loaded wire retainer lever on the lower spring-cage wire connector.

5

Insert your green (ground) wire into the aperture and then release the lever.

Use a small screwdriver to depress the spring-loaded wire retainer lever on the middle spring-cage wire connector.

6

Insert your black (DC negative) wire into the aperture and then release the lever.

Use a small screwdriver to depress the spring-loaded wire retainer lever on the upper spring-cage wire connector.

7

Insert your red (DC positive) wire into the aperture and then release the lever.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

24

Page 35

Installing the Chassis

8

Connecting an HVAC/HVDC power supply:

•

1

2

Powering Up the Switch

Insert the connector block back into the power supply. Make sure that your red (DC positive) wire aligns with

the power supply label, "+ DC".

Note

If you require n+n redundancy, be sure that each power supply is powered by a different power source.

Using the recommended power cable for your country or region (see Power Cord Specifications, on page 47),

insert the Saf-D-Grid connector on the power cable to the power receptacle on the power supply until it clicks

in place.

Connect the other end of the power cable to the power source.

If connecting to an AC power source, plug the cable into the receptacle for the power source.

•

If connecting to a DC power source, do the following:

•

Verify that the power source is turned off at the circuit breaker located between the power source and

1

the terminals where you will connect the power cable.

Step 2

Connect each of the three wires in the power cable to the three terminals for the power source and

2

secure them with the terminal nuts. Make sure that the positive wire is attached to the positive terminal,

the negative wire is attached to the negative terminal, and the ground wire is attached to the ground

terminal.

If there is a safety cover for the terminals, place it over the terminals to prevent people from accidentally

3

touching the terminals when the power is on.

Turn the power on at the circuit breaker.

4

3

Verify that the LED is on and green.

If the LED is off, check the AC power source circuit breaker to be sure that it is turned on.

If you are connecting only one power supply, be sure that there is a blank faceplate in the open power supply slot.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

25

Page 36

Powering Up the Switch

Installing the Chassis

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

26

Page 37

Connecting the Switch to the ACI Fabric

ACI Fabric Topology, page 27

•

Preparing to Connect to Other Devices, page 28

•

Connecting a Leaf Switch to an APIC, page 29

•

Connecting a Leaf Switch to a Spine Switch, page 30

•

Setting Up an Optional Console or Optional Out-Of-Band Management Interface, page 32

•

Maintaining Transceivers and Optical Cables, page 32

•

ACI Fabric Topology

The ACI fabric topology includes the following major components:

Application Centric Infrastructure Controller (APIC) appliance (cluster of APICs)

•

CHAPTER 4

Leaf switches (Cisco Nexus 93120TX, 93128TX, 9332PQ, 9372PX, 9372PX-E, 9372TX, 9396PX, and

•

9396TX switches)

Spine switches (Cisco Nexus 9336PQ, 9504, 9508, and 9516 switches)

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

27

Page 38

Preparing to Connect to Other Devices

As shown in the following figure, each spine switch is connected to a downlink port on a leaf switch, which

is in turn uplinked to one or more APICs.

Figure 8: ACI Fabric Topology

Connecting the Switch to the ACI Fabric

Preparing to Connect to Other Devices

When preparing to connect the switch to leaf switchesspine switches and one or more APICs, consider the

following for each type of interface, and gather all of the required equipment before making the connections:

Cabling type required for each interface type

•

Distance limitations for each signal type

•

Additional interface equipment required

•

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

28

Page 39

Connecting the Switch to the ACI Fabric

Connecting a Leaf Switch to an APIC

Note

When running power and data cables in overhead or subfloor cable trays, we strongly recommend that

you locate power cables and other potential noise sources as far away as practical from network cabling

that terminates on Cisco equipment. In situations where long parallel cable runs cannot be separated by

at least 3.3 feet (1 meter), we recommend that you shield any potential noise sources by housing them in

a grounded metallic conduit.

The optical transceivers that are not already assembled to their cables come separate from their cables. To

prevent these transceivers and their cables from being damaged, we recommend that you keep the transceivers

disconnected from their cables when installing them in ports and then insert the optical cable into the transceiver.

When removing transceivers from ports, remove their cables before removing the transceivers.

To maximize the effectiveness and life of your transceivers and optical cables, do the following:

Wear an ESD-preventative wrist strap that is connected to an earth ground whenever handling transceivers.

•

The switch is typically grounded when you install transceivers and provides an ESD port to which you

can connect your wrist strap. If you cannot find an ESD port, connect the wrist strap to an earth ground

(such as the grounding connection for the chassis).

Do not remove or insert a transceiver more often than necessary. Repeated removals and insertions can

•

shorten its useful life.

Keep the transceivers and fiber-optic cables clean and dust free to maintain high signal accuracy and to

•

prevent damage to the connectors. Attenuation (loss of light) increases with contamination and should

be kept below 0.35 dB.

Clean these parts before installing them to prevent dust from scratching the fiber-optic cable ends.

◦

Clean the connectors regularly; the required frequency of cleaning depends upon the environment.

◦

In addition, clean connectors if they are exposed to dust or accidentally touched. Both wet and dry

cleaning techniques can be effective; refer to your site's fiber-optic connection cleaning procedures.

Do not touch the ends of connectors. Touching the ends can leave fingerprints and cause other

◦

contamination.

Inspect routinely for dust and damage. If you suspect damage, clean and then inspect fiber ends under

•

a microscope to determine if damage has occurred.

Connecting a Leaf Switch to an APIC

You must downlink one or two (recommended for redundancy) Cisco Nexus 93120TX, 93128TX, 9332PQ,

9372PX, 9372PX-E, 9372TX, 9396PX, or 9396TX leaf switches running in ACI mode to each Application

Policy Infrastructure Controller (APIC) in your ACI fabric (each leaf switch can be connected to multiple

APICs). The type of interface cables and leaf switches that you connect to are determined by the type of virtual

interface card (VIC) installed on the APIC as follows:

The VIC1225 module supports optical transceivers, optical cables, and the Cisco Nexus 9396PX leaf

•

switch.

The VIC1225T module supports copper connectors, copper cables, and the Cisco Nexus 93128TX and

•

9396TX leaf switches.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

29

Page 40

Connecting a Leaf Switch to a Spine Switch

Before You Begin

The switch and APIC must be fully installed in their racks.

•

The switch and APIC must be grounded and powered up.

•

Connecting the Switch to the ACI Fabric

Step 1

Step 2

Connect an interface cable to one of the two ports on the virtual interface card (VIC) installed on the APIC. If the cable

is not already assembled to its transceivers, insert the transceiver into the VIC port and then connect the optical interface

cable to the transceiver.

For a VIC1225 optical module, use one of the following sets of transceivers and cables:

•

Cisco 10GBASE-LR transceivers (SFP-10G-LR) supporting a link length of up to 6.1 miles (10 km)

◦

Cisco 10GBASE-SR transceivers (SFP-10G-SR) supporting the following link lengths:

◦

Using 2000 MHz MMF (OM3) for up to 984 feet (300 m)

◦

Using 4700 MHz MMF (OM4) for up to 1312 feet (400 m)

◦

Cisco SFP+ Active Optical Cables (SFP-10G-AOCxM [where x=1, 2, 3, 5, 7, or 10 for lengths in meters])

◦

For transceiver specifications, see http://www.cisco.com/c/en/us/support/interfaces-modules/transceiver-modules/

products-installation-guides-list.html.

For a VIC1225T 10GBASE-T copper module, use 10GBASE-T cables with RJ-45 connectors.

•

Connect the other end of the interface cable to a downlink port on a leaf switch.

For a Cisco 10GBASE-LR or -SR transceiver and cable, insert the transceiver into a downlink optical port on a

•

leaf switch before connecting the cable to the transceiver.

For Cisco SFP+ Active Optical Cables, insert the transceiver on the cable into a downlink optical port on a leaf

•

switch.

For a 10GBASE-T copper cable, insert the RJ-45 connector on the cable into a downlink BASE-T port on a leaf

•

switch.

What to Do Next

If the APICs are also connected to the leaf switches, then the ACI fabric is ready to be automatically initiated.

Connecting a Leaf Switch to a Spine Switch

You must connect each Cisco Nexus 93120TX, 93128TX, 9332PQ, 9372PX, 9372PX-E, 9372TX, 9396PX,

or 9396TX leaf switch to every Cisco Nexus 9336PQ, 9504, 9508, or 9516 spine switch in the same ACI

fabric. The Cisco Nexus 93128TX allows for 8 connections (uplink ports 1 through 8) to spine switches, the

Cisco Nexus 9396PX and 9396TX switches allow up to 12 connections to spine switches, and the Cisco Nexus

93120TX, 9332PQ, 9372PX, 9372PX-E, 9372TX, and 9372TX-E switches allow up to 6 connections to spine

switches. To determine which transceivers and cables are supported by this switch, see http://www.cisco.com/

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

30

Page 41

Connecting the Switch to the ACI Fabric

c/en/us/support/interfaces-modules/transceiver-modules/products-device-support-tables-list.html. To see the

transceiver specifications and installation information, see http://www.cisco.com/c/en/us/support/

interfaces-modules/transceiver-modules/products-installation-guides-list.html.

Connecting a Leaf Switch to a Spine Switch

Warning

Warning

Warning

Statement 1053—Class 1M Laser Radition

Class 1M laser radiation when open. Do not view directly with optical instruments.

Statement 1055—Class I and Class 1M Laser

Class I (CDRH) and Class 1M (IEC) laser products.

Statement 1056—Unterminated Fiber Cable

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not

view directly with optical instruments. Viewing the laser output with certain optical instruments (for

example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard.

Before You Begin

The leaf and spine switches must be fully installed in their racks.

•

The leaf and spine switches must be grounded and powered up.

•

If you are using a Cisco Nexus 9504, 9508, or 9516 spine switch in the ACI fabric, it must have only

•

the 36-port 40-Gigabit ACI-spine I/O modules (N9K-X9736PQ). You cannot mix other I/O modules in

the same chassis when running in ACI mode.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

For the transceivers with removable cables, make sure that the transceivers are separated from their interface cables.

Insert the appropriate transceiver into an active uplink port on the leaf switch.

Insert the same type of transceiver in the spine switch port on a X9736PQ I/O module.

For transceivers with removable cables, insert the interface cable into the open end of each of those transceivers.

Repeat Steps 1 through 4 for each spine switch in the ACI fabric.

The leaf switch is connected to each spine switch in the ACI fabric.

Repeat Steps 1 through 5 for each leaf switch in the ACI fabric.

Each leaf switch in the ACI fabric is connected to each spine switch in the network,

What to Do Next

If the APICs are also connected to the leaf switches, then the ACI fabric is ready to be automatically initiated.

Cisco Nexus 9336PQ ACI-Mode Switch Hardware Installation Guide

31

Page 42

Connecting the Switch to the ACI Fabric

Setting Up an Optional Console or Optional Out-Of-Band Management Interface

Setting Up an Optional Console or Optional Out-Of-Band

Management Interface

You can optionally set up a console or out-of-band management interface for monitoring and troubleshooting

purposes. For information on how to set up a console or out-of-band management interface, see the Cisco

ACI Getting Started Guide.

Maintaining Transceivers and Optical Cables

Transceivers and fiber-optic cables must be kept clean and dust free to maintain high signal accuracy and

prevent damage to the connectors. Attenuation (loss of light) is increased by contamination and should be

below 0.35 dB.

Consider the following maintenance guidelines: