Cisco 12016, 12416, 12816, GSR16-BLOWER=, 12000/10/16-BLWER= Replacement Instructions Manual

...

Cisco 12016, Cisco 12416, and Cisco 12816 Router

Blower Module and Air Filter

Replacement Instructions

Cisco Product Numbers: GSR16-BLOWER=, 12000/10/16-BLWER=, ACS-GSR16-FLTR=

This publication contains removal and replacement procedures for the blower module and chassis air

filter in Cisco 12016, Cisco 12416, and Cisco 128 16 routers. Unless otherwise noted, all information in

this publication applies to all router models.

Note The illustrations in this guide represent both the original and newer enhanced capacity blower modules,

and air filters for the Cisco 12016, Cisco 12416, and Cisco 12816 routers. Depending on your system,

these components may not look exactly like those in your chassis, but the removal and replacement

procedures are essentially the same. For clarity, most chassis covers are not shown in the illustrations.

Blower Module Compatibility

There are currently two types of blower modules in use for the Cisco 12016, Cisco 12416, and Cisco

12816 routers; blowers that shipped with original sy stems, and enhanced capacity blowers that ship wi th

current systems.

If you are replacing an:

• Original blower module (GSR16-BLOWER=)—Use an original blower module or enhanced

capacity blower modules as replacements.

Caution You cannot mix original and enhanced capacity blower modules in the same chassis. Both the upper and

lower blower modules must be identical.

• Enhanced capacity blower module (12000/10/16-BLWER=)—Use an enhanced capacity blower

module as a replacement.

Corporate Headquarters:

Cisco Systems, Inc., 170 West Tasman Drive, San Jose, CA 95134-1706 USA

Copyright © 2005 Cisco Systems, Inc. All rights reserved.

Contents

Contents

The following sections are included in this publication:

• Prerequisites and Preparation, page 2

• Installation Guidelines, page 4

• Removing and Replacing the Blower Modules, page 4

• Troubleshooting the Installation, page 7

• Cleaning or Replacing the Chassis Air Filter, page 7

• Regulatory, Compliance, and Safety Information, page 12

• Obtaining Documentation, page 14

• Obtaining Technical Assistance, page 15

• Obtaining Additional Publications and Information, page 16

Prerequisites and Preparation

Before you perform any of the procedures in this guide, we recommend that you:

• Read the safety and ESD-prevention guidelines in this section.

• Ensure that you have all of the necessary tool s and equip ment before b e ginning the installat ion (see

• Have access to the following documents during the installation:

For additional information about obtaining documentation see the “Obtaining Documentation” section

on page 14.

Safety Guidelines

Before you perform any procedure in this publication, review the safety guidelines in this section to

avoid injuring yourself or damaging the equipment.

Safety Warnings

Safety warnings appear throughout this publication in procedures that, if performed incorrectly, may

harm you. A warning symbol precedes each warning statement. The following warning is an example of

a safety warning. It identifies the wa rning sy mbol and associates it with a bodily injury hazard.

the “Installation Guidelines” section on page 4).

–

Regulatory Compliance and Safety Information for the Cisco 12016, Cisco 12416, and

Cisco 12816 Series Router publication that shipped with the router (PN 78-4347-xx)

–

Cisco 12016, Cisco 12416, and Cisco 12816 Router Installation and Configuration Guide

Warning

Cisco 12016, Cisco 12416, and Cisco 12816 Router Blower Module and Air Filter Replacement Instructions

2

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar

with standard practices for preventing accidents. To see translations of the warnings that appear in

this publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

78-16083-02

26208

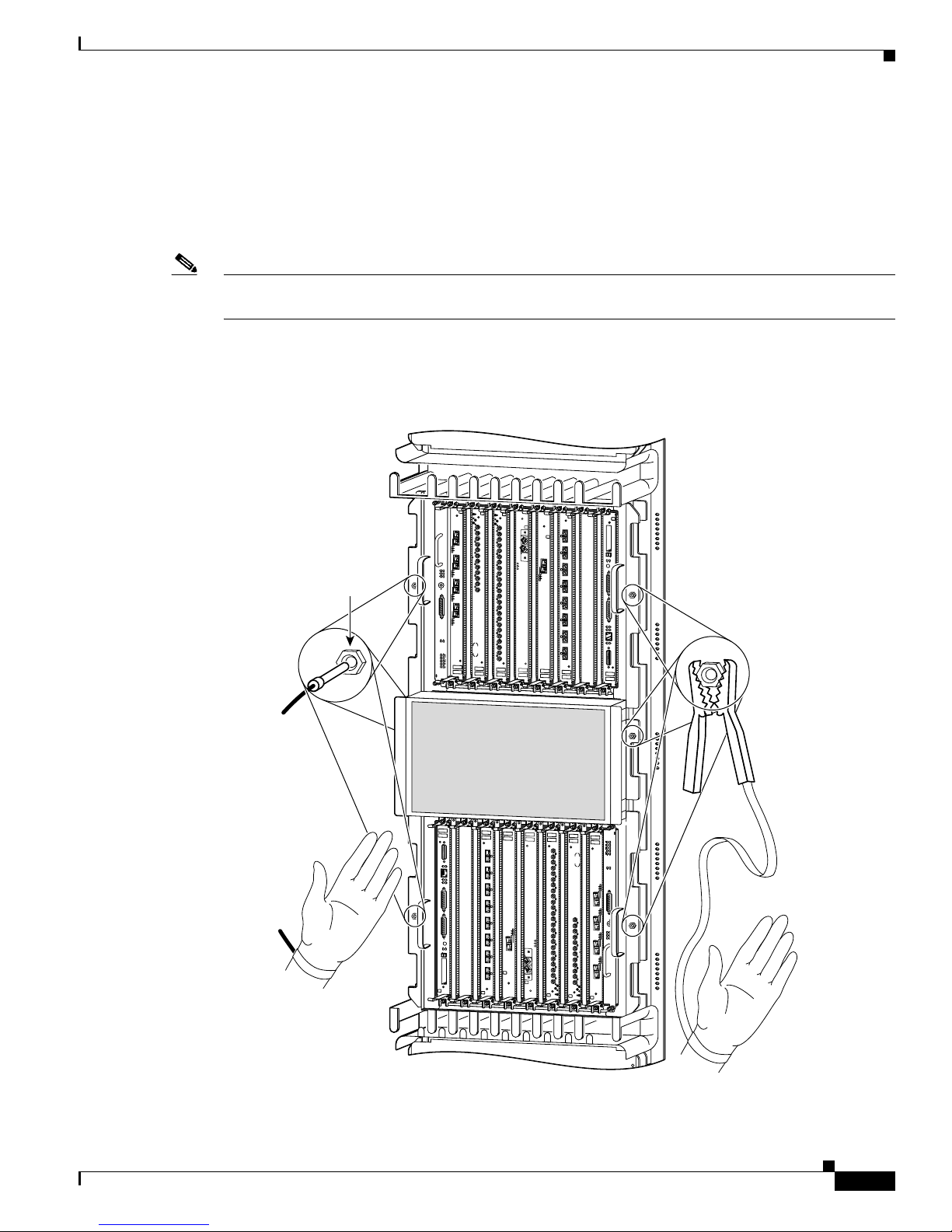

Preventing Electrostatic Discharge Damage

Many router components can be damaged by static electricity. Not exercising the proper electrostatic

discharge (ESD) precautions can result in intermittent or complete component f ailures. To minimize the

potential for ESD damage, always use an ESD-preventive antistatic wrist strap (or ankle strap) and

ensure that it makes good skin conta ct.

Note Y ou should periodically check the resistance value of the ESD-prev entive strap. Ensure the measurement

is between 1 and 10 megohms.

Before performing the procedures in this guide, att ach an ESD-preven tive strap to your wr ist and connect

the leash to the chassis or to another grounded, bare metal surface as shown in Figure 1.

Figure 1 Connecting an ESD-Preventive Wrist Strap to the Chassis

DOWN

LOOP RA LA

DOWN

LOOP RA LA

CDHNT CD

CDHNT CD

TX

TX

0

0

RX

RX

0

TX

TX

1

1

RX

RX

ACTIVE

CARRIER

TX

TX

RX PKT

2

2

RX

RX

TX

TX

ESD

connection

socket

1

3

ACTIVE

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Q OC-3/STM-POS

3

CARRIER

RX

RX

RX PKT

TX

TX

4

4

RX

RX

TX

TX

5

5

RX

RX

TX

6

RX

TX

7

RX

TX

8

RX

TX

9

RX

TX

10

RX

TX

11

OC-48/STM-16-SCPOS

RX

12DS3–SMB P

6DS3–SMB P

/

/

H

H

/

/

F

F

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM

ENABLED

FAIL

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

Prerequisites and Preparation

EJECT

SLOT-0

0

ACTIVE

CARRIER

RX CELL

OC-12/STM-4 ATM

FAST ETERNET

SLOT-1

RESET

AUX

CONSOLE

LINK

COLL

TX

RX

MII

RJ-45

ROUTE PROCESSOR

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

ROUTE PROCESSOR

FAST ETERNET

RJ-45

MII

RX

TX

COLL

LINK

CONSOLE

AUX

RESET

SLOT-1

SLOT-0

EJECT

RX CELL

CARRIER

ACTIVE

F

F

/

/

H

H

/

/

2

ALARM

SFC

1

OC-12/STM-4 ATM

12DS3–SMB P

RX

OC-48/STM-16-SCPOS

11

TX

RX

10

TX

RX

9

TX

RX

8

TX

RX

7

TX

RX

6

TX

RX

5

TX

RX

4

TX

RX PKT

RX

CARRIER

0

3

ACTIVE

TX

RX

2

TX

RX

1

TX

RX

0

TX

CDHNT CD

LOOP RA LA

DOWN

0

6DS3–SMB P

1

CSC

Q OC-3/STM-POS

0

FAIL

ENABLED

FAIL

ENABLED

RX PKT

CARRIER

ACTIVE

3

ALARM

RX PKT

CARRIER

ACTIVE

ACO/LT

RX

5

2

TX

RX

4

RX PKT

MINOR

CARRIER

TX

MAJOR

ACTIVE

CRITICAL

RX

3

1

TX

RX

2

RX PKT

TX

CARRIER

ACTIVE

RX

1

TX

0

RX

0

TX

CDHNT CD

LOOP RA LA

DOWN

Cisco 12016, Cisco 12416, and Cisco 12816 Router Blower Module and Air Filter Replacement Instructions

78-16083-02

3

Installation Guidelines

Installation Guidelines

The blower modules support online inser tion and remov al (O IR), so you can remo ve and install a b lower

module while the system remains powered on without presenting an electrical hazard or damage to the

system. Y ou can replace a blower module while the

session preservation.

Caution Although th e blower module support s OIR and can be replaced without interruption to system operation,

the system should not operate without a blower module for more than 3 minutes to prevent overheating.

Caution You cannot mix blower types within the chassis. If you are replacing a blower module from an old system

(GSR16-BLOWER=)

replacement blowers (12000/10/16-BLWER=). Although the blower modules can be replaced without

interruption to system operation, the system should not operate with mixed blower modules in the router

for more than 5 minutes.

system maintains all routing information and ensures

, you must replace both upper and lo wer bl ower mo dules with ne w, higher capacity

Required Tools and Equipment

You need the following tools and equipment to install the blower module:

• Number 2 Phillips screwdriver

• 3/16-inch flat-blade screwdriver

• An electrostatic discharge (ESD) preventive wrist or ankle strap with connection cord

• Vacuum cleaner (to clean the air filters)

Removing and Replacing the Blower Modules

This section contains the procedure to remove and replace the upper or lower blower modules from the

chassis. Before beginning either of these procedures, be sure to read the “Install ation Guidelines” se ction

on page 4.

Upper and Lower Blower Module Orientation

Illustrations in this procedure show the removal and replacement of the upper blower module. The

procedure to replace the lower blower module is the same except for the orientation of the blower

module.

• Heads-up orientation—Install the blo wer module in the upper bay in the “h eads-up” orientation with

the three fan air intake openings face down.

• Heads-down orientation—Install the blower module in the lower blower module bay in the

“heads-down” orientation with the three fan air intake openings face up.

Cisco 12016, Cisco 12416, and Cisco 12816 Router Blower Module and Air Filter Replacement Instructions

4

78-16083-02

Use the following procedure to remove and replace the blower modules.

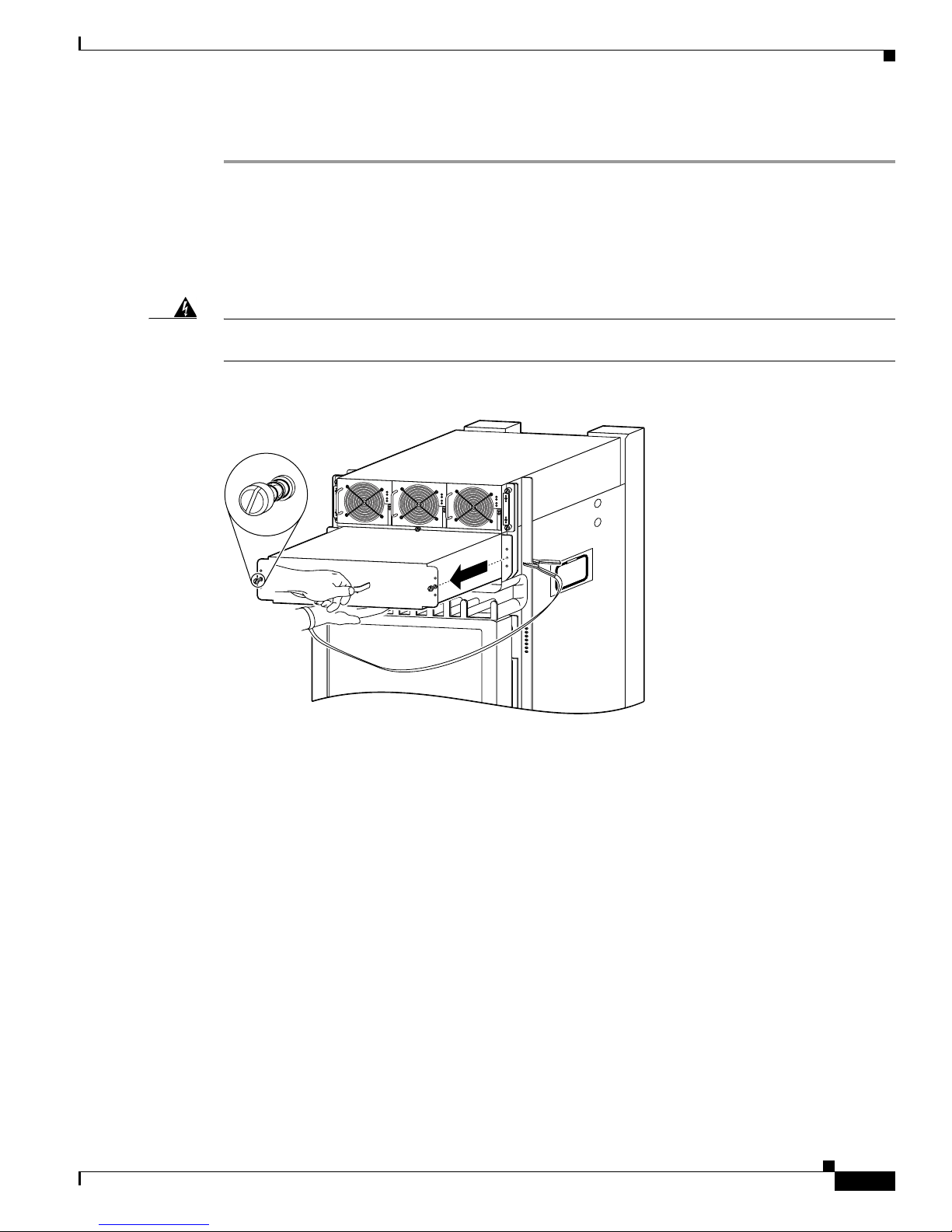

Step 1 Remove the blower module from the chassis (Figure 2):

a. Loosen the captive screw on each side of the blower module.

b. Pull out the blower module halfway from the module bay.

c. Slide out the blow er module completely from the module bay while supporting it with your other

hand.

Removing and Replacing the Blower Modules

Warning

The blower module weighs approximately 20 pounds (9 kg). Use two hands when handling the blowe r

module.

Figure 2 Removing the Upper Blower Module

PWR OK

FAULT

TEMP

I LIM

PWR OK

FAULT

TEMP

I LIM

PWR OK

FAULT

TEMP

I LIM

26213

Cisco 12016, Cisco 12416, and Cisco 12816 Router Blower Module and Air Filter Replacement Instructions

78-16083-02

5

Removing and Replacing the Blower Modules

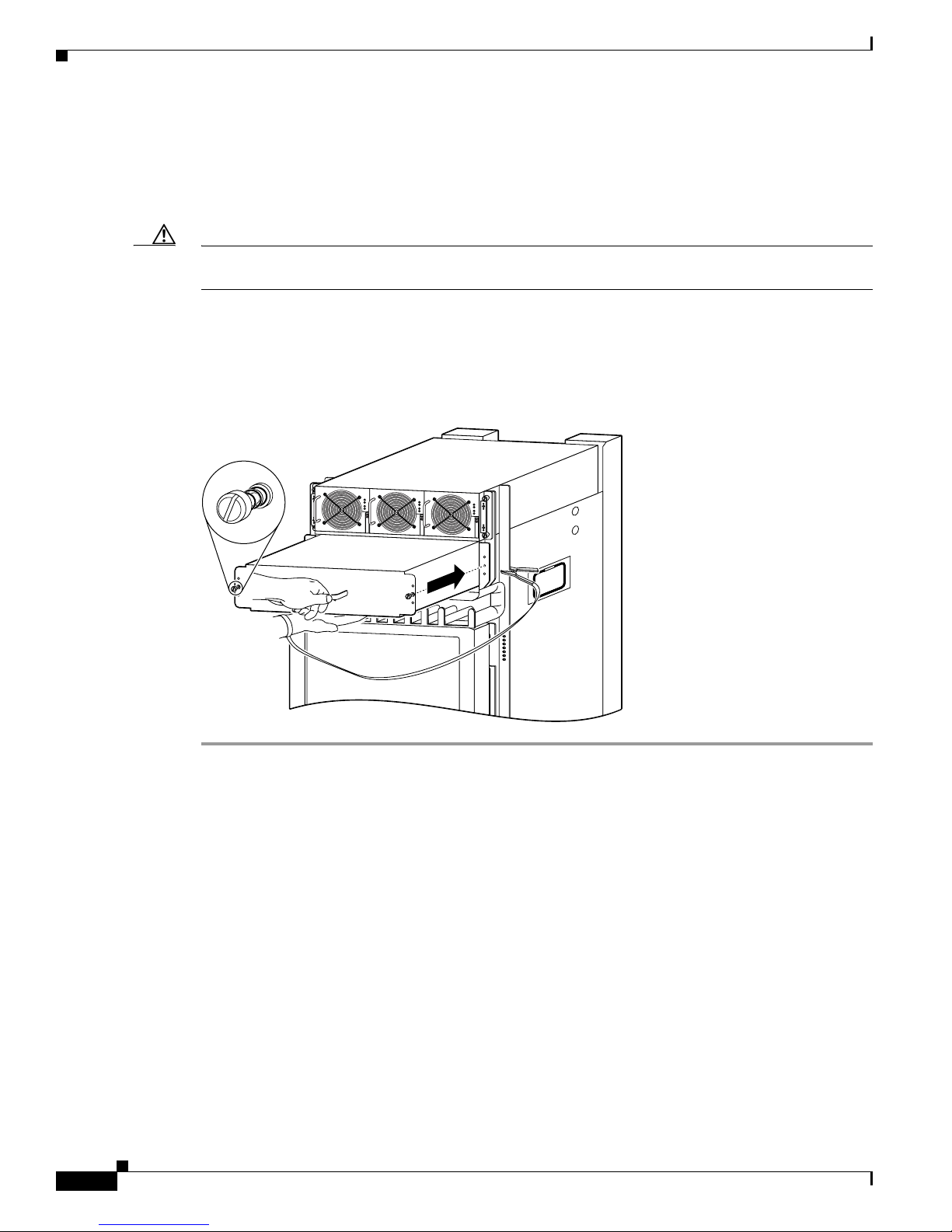

Step 2 Install the new blower module into the chassis (Figure 3):

a. Lift the blow er module (with two hands) and slide it halfway into the module bay.

b. Slowly push the blower module into the chassis until it mates with the backplane connector at the

back of the module bay.

Caution To prevent damage to the connectors, do not use excessive force when inserting the blower module into

the chassis.

c. Tighten the captive screws on the blower module to secure it to the chassis.

• The (green) OK status indicator on the front of the blower module should light. If the OK indicator

does not light, see the “Troubleshooting the Installation” section on page 7.

Figure 3 Installing the Upper Blower Module

PWR OK

FAULT

TEMP

I LIM

PWR OK

FAULT

TEMP

I LIM

PWR OK

FAULT

TEMP

I LIM

27218

Cisco 12016, Cisco 12416, and Cisco 12816 Router Blower Module and Air Filter Replacement Instructions

6

78-16083-02

Loading...

Loading...