Page 1

Cisco 1.2 GHz GS7000 Node

Installation and Operation Guide

Page 2

Page 3

For Your Safety

You may find this symbol in the document that accompanies this product.

This symbol indicates important operating or maintenance instructions.

You may find this symbol affixed to the product. This symbol indicates a live

terminal where a dangerous voltage may be present; the tip of the flash points

to the terminal device.

You may find this symbol affixed to the product. This symbol indicates a

protective ground terminal.

You may find this symbol affixed to the product. This symbol indicates a

chassis terminal (normally used for equipotential bonding).

You may find this symbol affixed to the product. This symbol warns of a

potentially hot surface.

You may find this symbol affixed to the product and in this document. This

symbol indicates an infrared laser that transmits intensity-modulated light

and emits invisible laser radiation or an LED that transmits

intensity-modulated light.

Explanation of Warning and Caution Icons

Avoid personal injury and product damage! Do not proceed beyond any symbol

until you fully understand the indicated conditions.

The following warning and caution icons alert you to important information about

the safe operation of this product:

Important

Please read this entire guide. If this guide provides installation or operation

instructions, give particular attention to all safety statements included in this guide.

Page 4

Notices

Trademark Acknowledgments

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its

affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this

URL: http://www.cisco.com/go/trademarks.

Third party trademarks mentioned are the property of their respective owners.

The use of the word partner does not imply a partnership relationship between

Cisco and any other company. (1110R)

Publication Disclaimer

Cisco Systems, Inc. assumes no responsibility for errors or omissions that may

appear in this publication. We reserve the right to change this publication at any

time without notice. This document is not to be construed as conferring by

implication, estoppel, or otherwise any license or right under any copyright or

patent, whether or not the use of any information in this document employs an

invention claimed in any existing or later issued patent.

Copyright

© 2015 Cisco and/or its affiliates. All rights reserved. Printed in the United States of

America.

Information in this publication is subject to change without notice. No part of this

publication may be reproduced or transmitted in any form, by photocopy, microfilm,

xerography, or any other means, or incorporated into any information retrieval

system, electronic or mechanical, for any purpose, without the express permission of

Cisco Systems, Inc.

Page 5

iii

Contents

For Your Safety ......................................................................................................................... 3

Notices ....................................................................................................................................... 4

Important Safety Instructions.............................................................................................. vii

Laser Safety ............................................................................................................................xiii

Laser Warning Labels ............................................................................................................ xv

General Information 1

Equipment Description ........................................................................................................... 2

Theory of Operation 15

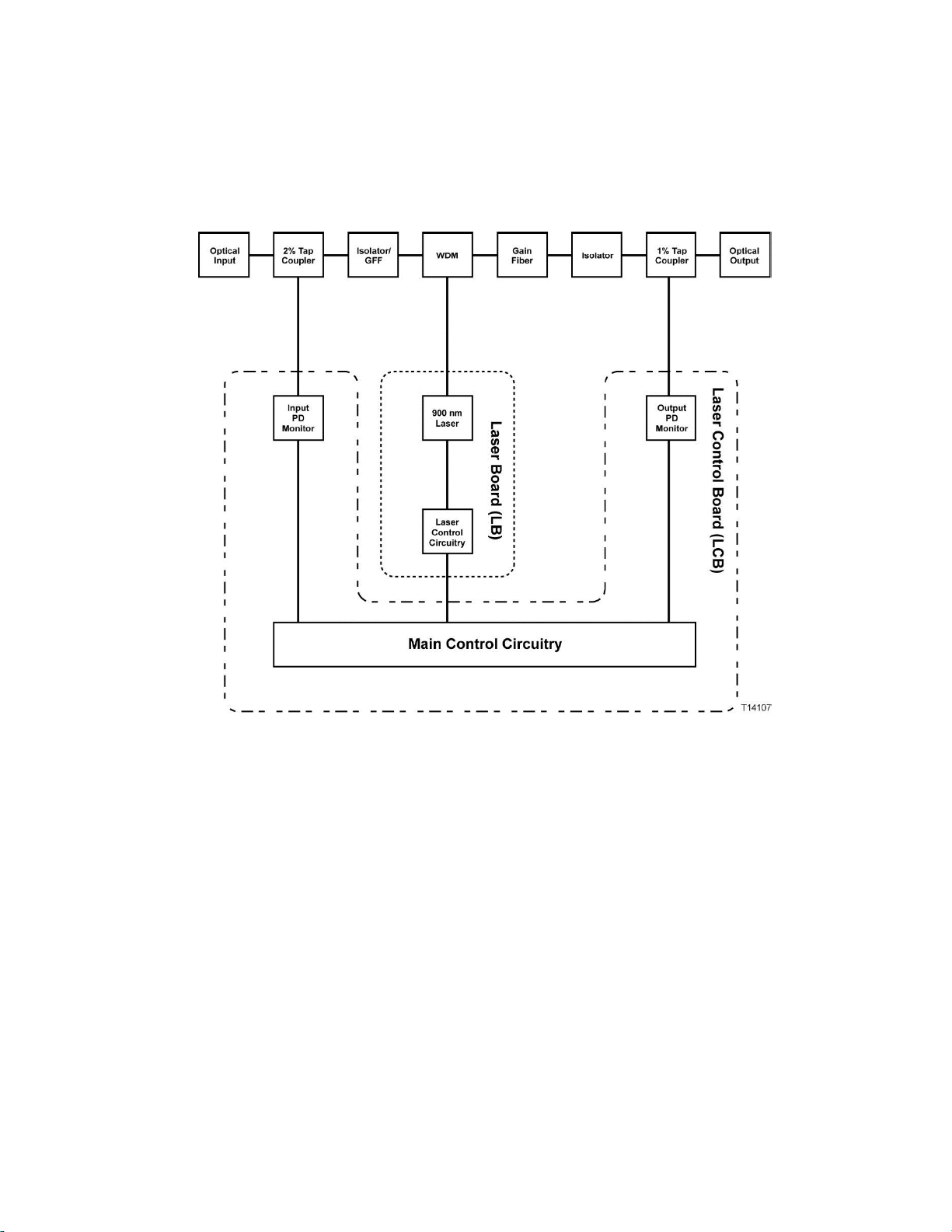

System Diagrams ................................................................................................................... 17

Forward Path .......................................................................................................................... 21

Reverse Path ........................................................................................................................... 22

Power Distribution ................................................................................................................ 23

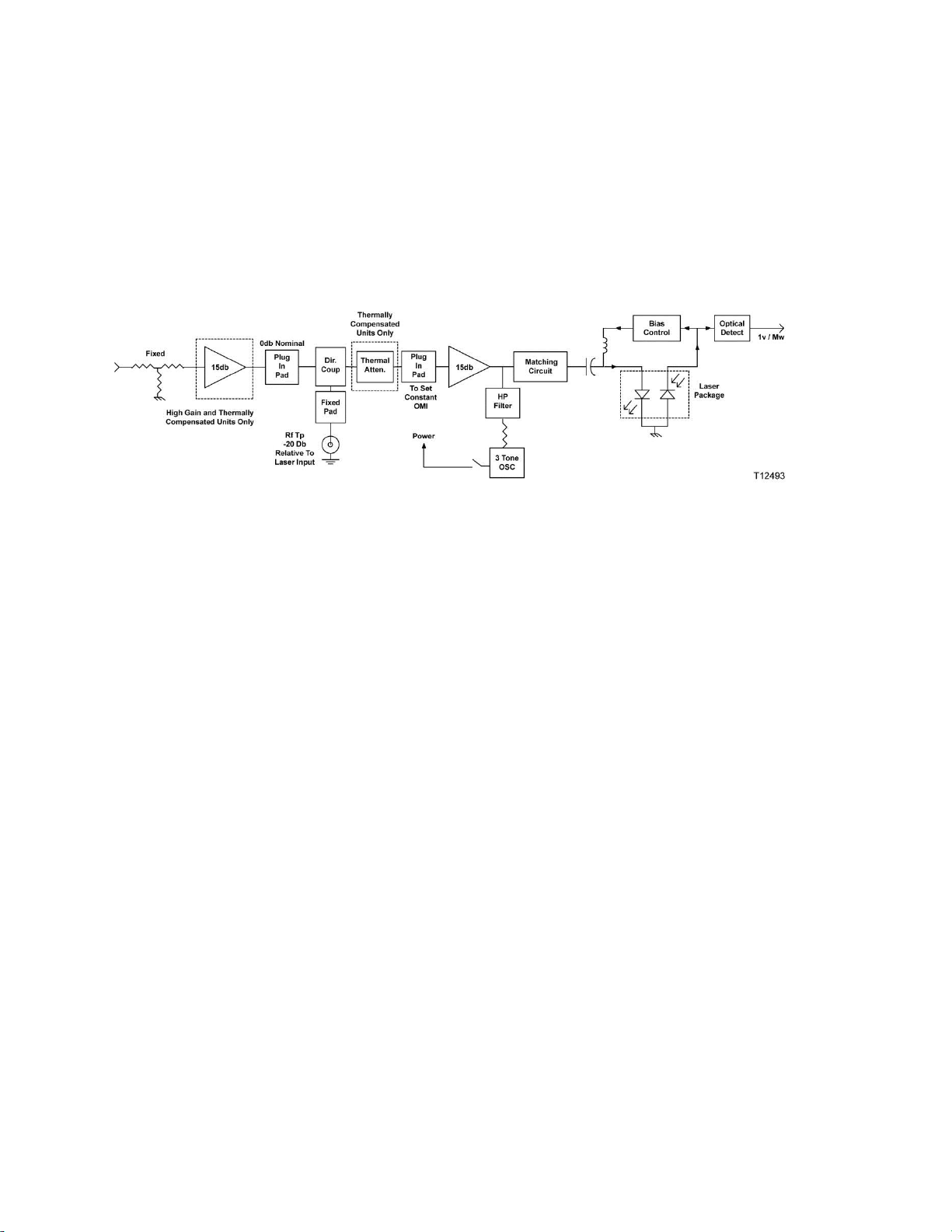

RF Amplifier Module ............................................................................................................ 24

Forward Configuration Module .......................................................................................... 29

Reverse Configuration Module ............................................................................................ 34

Optical Interface Board (OIB) ............................................................................................... 38

Optical Receiver Module ...................................................................................................... 39

Optical Analog Transmitter Modules ................................................................................. 43

Optical Amplifier (EDFA) Modules .................................................................................... 45

Optical Switch Module .......................................................................................................... 52

Local Control Module ........................................................................................................... 58

Power Supply Module .......................................................................................................... 61

Installation 65

Tools and Test Equipment .................................................................................................... 66

Node Housing Ports .............................................................................................................. 68

Strand Mounting the Node ................................................................................................... 69

Pedestal or Wall Mounting the Node ................................................................................. 72

Fiber Optic Cable Installation .............................................................................................. 74

RF Cable Installation ............................................................................................................. 82

Applying Power to the Node ............................................................................................... 85

Setup and Operation 89

Tools and Test Equipment .................................................................................................... 90

System Diagrams ................................................................................................................... 91

Forward Path Setup Procedure ............................................................................................ 97

Page 6

Contents

iv

Reverse Path Setup Procedure ........................................................................................... 101

Reconfiguring Forward Signal Routing ............................................................................ 103

Reconfiguring Reverse Signal Routing ............................................................................. 113

Maintenance 121

Opening and Closing the Housing .................................................................................... 122

Preventative Maintenance .................................................................................................. 124

Removing and Replacing Modules ................................................................................... 127

Care and Cleaning of Optical Connectors ........................................................................ 134

Troubleshooting 139

No RF Output at Receiver RF Test Point: Optical Power LED on Receiver Module is

off ........................................................................................................................................... 140

No RF Output: Fiber Optic Light Level is Good, Receiver Optical Power LED is on 142

Poor C/N Performance ....................................................................................................... 144

Poor Distortion Performance .............................................................................................. 146

Poor Frequency Response ................................................................................................... 148

No RF Output from Reverse Receiver .............................................................................. 150

Customer Support Information 151

Appendix A Technical Information 153

Linear Tilt Chart ................................................................................................................... 154

Forward Equalizer Chart .................................................................................................... 156

Appendix B Enhanced Digital Return Multiplexing Applications 158

Enhanced Digital Return System Overview .................................................................... 159

Enhanced Digital Return (EDR) System Installation ...................................................... 177

Transmitter Module Setup Procedure .............................................................................. 186

Reverse Balancing the Node with EDR ............................................................................ 189

Troubleshooting ................................................................................................................... 192

Appendix C Expanded Fiber Tray 197

Expanded Fiber Tray Overview......................................................................................... 198

Expanded Fiber Tray Installation ...................................................................................... 200

Fiber Management System ................................................................................................. 203

Configuration Examples ..................................................................................................... 209

Page 7

Contents

v

Glossary 213

Index 225

Page 8

Page 9

Important Safety Instructions

vii

Important Safety Instructions

WARNING:

To reduce risk of electric shock, perform only the instructions that are

included in the operating instructions. Refer all servicing to qualified service

personnel only.

Read and Retain Instructions

Carefully read all safety and operating instructions before operating this equipment,

and retain them for future reference.

Follow Instructions and Heed Warnings

Follow all operating and use instructions. Pay attention to all warnings and cautions

in the operating instructions, as well as those that are affixed to this equipment.

Terminology

The terms defined below are used in this document. The definitions given are based

on those found in safety standards.

Service Personnel - The term service personnel applies to trained and qualified

individuals who are allowed to install, replace, or service electrical equipment. The

service personnel are expected to use their experience and technical skills to avoid

possible injury to themselves and others due to hazards that exist in service and

restricted access areas.

User and Operator - The terms user and operator apply to persons other than service

personnel.

Ground(ing) and Earth(ing) - The terms ground(ing) and earth(ing) are synonymous.

This document uses ground(ing) for clarity, but it can be interpreted as having the

same meaning as earth(ing).

Electric Shock Hazard

This equipment meets applicable safety standards.

Electric shock can cause personal injury or even death. Avoid direct contact with

dangerous voltages at all times.

Know the following safety warnings and guidelines:

Only qualified service personnel are allowed to perform equipment installation

Page 10

Important Safety Instructions

viii

or replacement.

WARNING:

Avoid personal injury and damage to this equipment. An unstable mounting

surface may cause this equipment to fall.

CAUTION:

Be aware of the size and weight of strand-mounted equipment during the

installation operation.

Ensure that the strand can safely support the equipment’s weight.

WARNING:

Avoid the possibility of personal injury. Ensure proper handling/lifting

techniques are employed when working in confined spaces with heavy

equipment.

Only qualified service personnel are allowed to remove chassis covers and access

any of the components inside the chassis.

Equipment Placement

To protect against equipment damage or injury to personnel, comply with the

following:

Install this equipment in a restricted access location (access restricted to service

personnel).

Make sure the mounting surface or rack is stable and can support the size and

weight of this equipment.

Strand (Aerial) Installation

Pedestal, Service Closet, Equipment Room or Underground Vault

Installation

Ensure this equipment is securely fastened to the mounting surface or rack

where necessary to protect against damage due to any disturbance and

subsequent fall.

Ensure the mounting surface or rack is appropriately anchored according to

manufacturer’s specifications.

Ensure the installation site meets the ventilation requirements given in the

equipment’s data sheet to avoid the possibility of equipment overheating.

Ensure the installation site and operating environment is compatible with the

equipment’s International Protection (IP) rating specified in the equipment’s data

sheet.

Page 11

Important Safety Instructions

ix

Connection to Network Power Sources

CAUTION:

RF connectors and housing seizure assemblies can be damaged if shunts are

not removed from the equipment before installing or removing modules from

the housing.

WARNING:

Avoid electric shock! Opening or removing this equipment’s cover may

expose you to dangerous voltages.

CAUTION:

These servicing precautions are for the guidance of qualified service

personnel only. To reduce the risk of electric shock, do not perform any

servicing other than that contained in the operating instructions unless you

are qualified to do so. Refer all servicing to qualified service personnel.

Refer to this equipment’s specific installation instructions in this manual or in

companion manuals in this series for connection to network ferro-resonant AC

power sources.

AC Power Shunts

AC power shunts may be provided with this equipment.

Important: The power shunts (where provided) must be removed before installing

modules into a powered housing. With the shunts removed, power surge to the

components and RF-connectors is reduced.

Equipotential Bonding

If this equipment is equipped with an external chassis terminal marked with the IEC

60417-5020 chassis icon ( ), the installer should refer to CENELEC standard EN

50083-1 or IEC standard IEC 60728-11 for correct equipotential bonding connection

instructions.

General Servicing Precautions

Be aware of the following general precautions and guidelines:

Servicing - Servicing is required when this equipment has been damaged in any

way, such as power supply cord or plug is damaged, liquid has been spilled or

objects have fallen into this equipment, this equipment has been exposed to rain

or moisture, does not operate normally, or has been dropped.

Page 12

Important Safety Instructions

x

Wristwatch and Jewelry - For personal safety and to avoid damage of this

equipment during service and repair, do not wear electrically conducting objects

such as a wristwatch or jewelry.

Lightning - Do not work on this equipment, or connect or disconnect cables,

during periods of lightning.

Labels - Do not remove any warning labels. Replace damaged or illegible

warning labels with new ones.

Covers - Do not open the cover of this equipment and attempt service unless

instructed to do so in the instructions. Refer all servicing to qualified service

personnel only.

Moisture - Do not allow moisture to enter this equipment.

Cleaning - Use a damp cloth for cleaning.

Safety Checks - After service, assemble this equipment and perform safety

checks to ensure it is safe to use before putting it back into operation.

Electrostatic Discharge

Electrostatic discharge (ESD) results from the static electricity buildup on the human

body and other objects. This static discharge can degrade components and cause

failures.

Take the following precautions against electrostatic discharge:

Use an anti-static bench mat and a wrist strap or ankle strap designed to safely

ground ESD potentials through a resistive element.

Keep components in their anti-static packaging until installed.

Avoid touching electronic components when installing a module.

Batteries

This product may contain batteries. Special instructions apply regarding the safe use

and disposal of batteries:

Safety

Insert batteries correctly. There may be a risk of explosion if the batteries are

incorrectly inserted.

Do not attempt to recharge ‘disposable’ or ‘non-reusable’ batteries.

Please follow instructions provided for charging ‘rechargeable’ batteries.

Replace batteries with the same or equivalent type recommended by

manufacturer.

Page 13

Important Safety Instructions

xi

Do not expose batteries to temperatures above 100°C (212°F).

Disposal

The batteries may contain substances that could be harmful to the environment

Recycle or dispose of batteries in accordance with the battery manufacturer’s

instructions and local/national disposal and recycling regulations.

The batteries may contain perchlorate, a known hazardous substance, so special

handling and disposal of this product might be necessary. For more information

about perchlorate and best management practices for perchlorate-containing

substance, see www.dtsc.ca.gov/hazardouswaste/perchlorate.

Modifications

This equipment has been designed and tested to comply with applicable safety, laser

safety, and EMC regulations, codes, and standards to ensure safe operation in its

intended environment. Refer to this equipment's data sheet for details about

regulatory compliance approvals.

Do not make modifications to this equipment. Any changes or modifications could

void the user’s authority to operate this equipment.

Modifications have the potential to degrade the level of protection built into this

equipment, putting people and property at risk of injury or damage. Those persons

making any modifications expose themselves to the penalties arising from proven

non-compliance with regulatory requirements and to civil litigation for

compensation in respect of consequential damages or injury.

Accessories

Use only attachments or accessories specified by the manufacturer.

Electromagnetic Compatibility Regulatory Requirements

This equipment meets applicable electromagnetic compatibility (EMC) regulatory

requirements. Refer to this equipment's data sheet for details about regulatory

compliance approvals. EMC performance is dependent upon the use of correctly

shielded cables of good quality for all external connections, except the power source,

when installing this equipment.

Ensure compliance with cable/connector specifications and associated

installation instructions where given elsewhere in this manual.

Page 14

Important Safety Instructions

xii

EMC Compliance Statements

Where this equipment is subject to USA FCC and/or Industry Canada rules, the

following statements apply:

FCC Statement for Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when this equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case users will be required to

correct the interference at their own expense.

Industry Canada - Industrie Canadiene Statement

This apparatus complies with Canadian ICES-003.

Cet appareil est confome à la norme NMB-003 du Canada.

CENELEC/CISPR Statement with Respect to Class A Information Technology Equipment

This is a Class A equipment. In a domestic environment this equipment may cause

radio interference in which case the user may be required to take adequate

measures.

Page 15

Laser Safety

xiii

Laser Safety

WARNING:

Avoid personal injury! Use of controls, adjustments, or procedures other

than those specified herein may result in hazardous radiation exposure.

Avoid personal injury! The laser light source on this equipment (if a

transmitter) or the fiber cables connected to this equipment emit invisible

laser radiation. Avoid direct exposure to the laser light source.

Avoid personal injury! Viewing the laser output (if a transmitter) or fiber

cable with optical instruments (such as eye loupes, magnifiers, or

microscopes) may pose an eye hazard.

WARNING:

Avoid personal injury! Qualified service personnel may only perform the

procedures in this manual. Wear safety glasses and use extreme caution when

handling fiber optic cables, particularly during splicing or terminating

operations. The thin glass fiber core at the center of the cable is fragile when

exposed by the removal of cladding and buffer material. It easily fragments

into glass splinters. Using tweezers, place splinters immediately in a sealed

waste container and dispose of them safely in accordance with local

regulations.

Introduction

This equipment contains an infrared laser that transmits intensity-modulated light

and emits invisible radiation.

Warning: Radiation

Do not apply power to this equipment if the fiber is unmated or unterminated.

Do not stare into an unmated fiber or at any mirror-like surface that could reflect

light emitted from an unterminated fiber.

Do not view an activated fiber with optical instruments (e.g., eye loupes,

magnifiers, microscopes).

Use safety-approved optical fiber cable to maintain compliance with applicable

laser safety requirements.

Warning: Fiber Optic Cables

Page 16

Laser Safety

xiv

Safe Operation for Software Controlling Optical Transmission

WARNING:

Ensure that all optical connections are complete or terminated before

using this equipment to remotely control a laser device. An optical or laser

device can pose a hazard to remotely located personnel when operated

without their knowledge.

Allow only personnel trained in laser safety to operate this software.

Otherwise, injuries to personnel may occur.

Restrict access of this software to authorized personnel only.

Install this software in equipment that is located in a restricted access area.

Equipment

If this manual discusses software, the software described is used to monitor and/or

control ours and other vendors’ electrical and optical equipment designed to

transmit video, voice, or data signals. Certain safety precautions must be observed

when operating equipment of this nature.

For equipment specific safety requirements, refer to the appropriate section of the

equipment documentation.

For safe operation of this software, refer to the following warnings.

Page 17

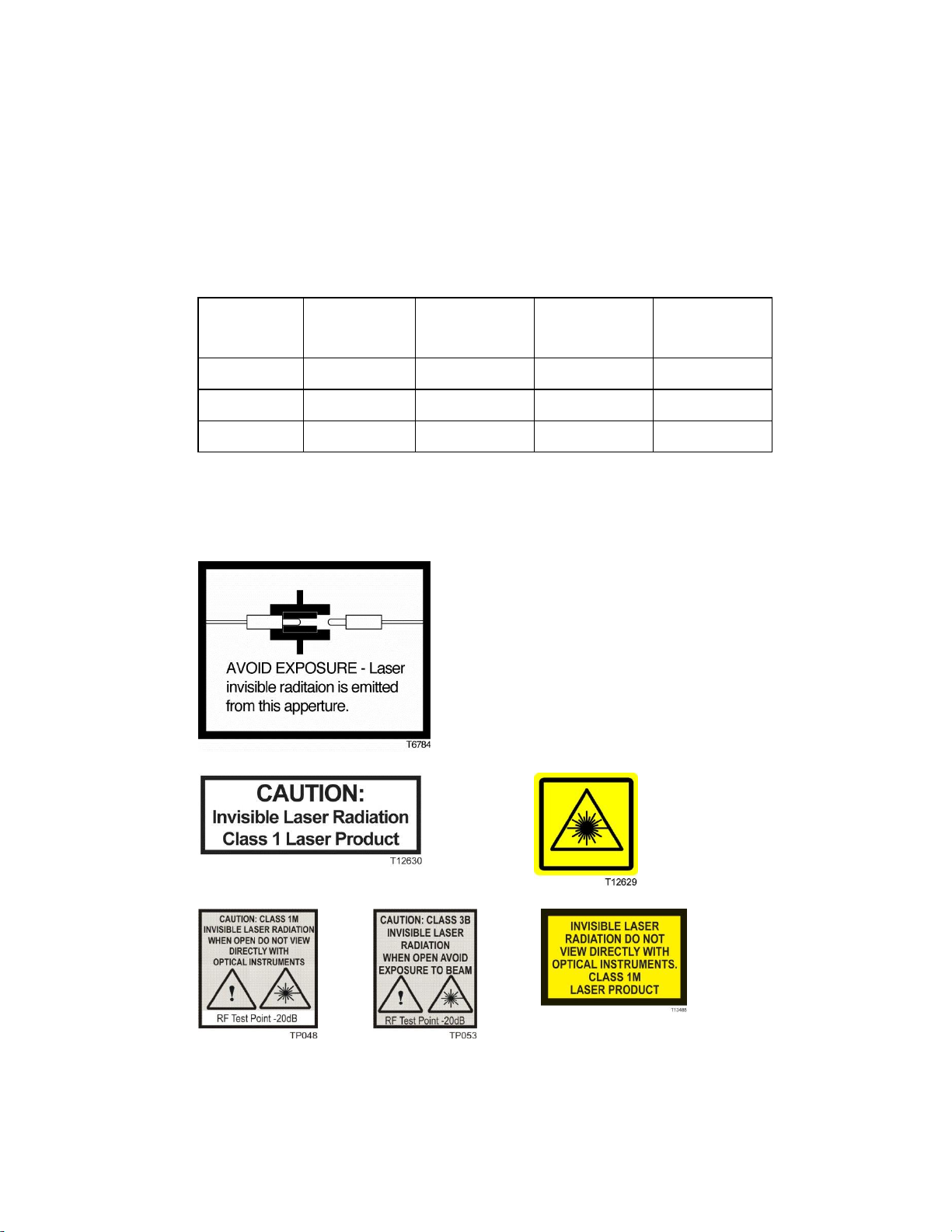

Laser Warning Labels

xv

Laser Warning Labels

Output

Power

Maximum

Output

CDRH

Classification

IEC 60825-1

Classification

IEC 60825-2

Hazard Level

17 dBm

17 dBm

1

1M

1M

20 dBm

20 dBm

1

1M

1M

22 dBm

22 dBm

1

1M

3B

Maximum Laser Power

The maximum laser power that can be expected from the EDFA optical amplifier for

various amplifier configurations is defined in the following table.

Warning Labels

One or more of the labels shown below are located on this product.

Page 18

Laser Warning Labels

xvi

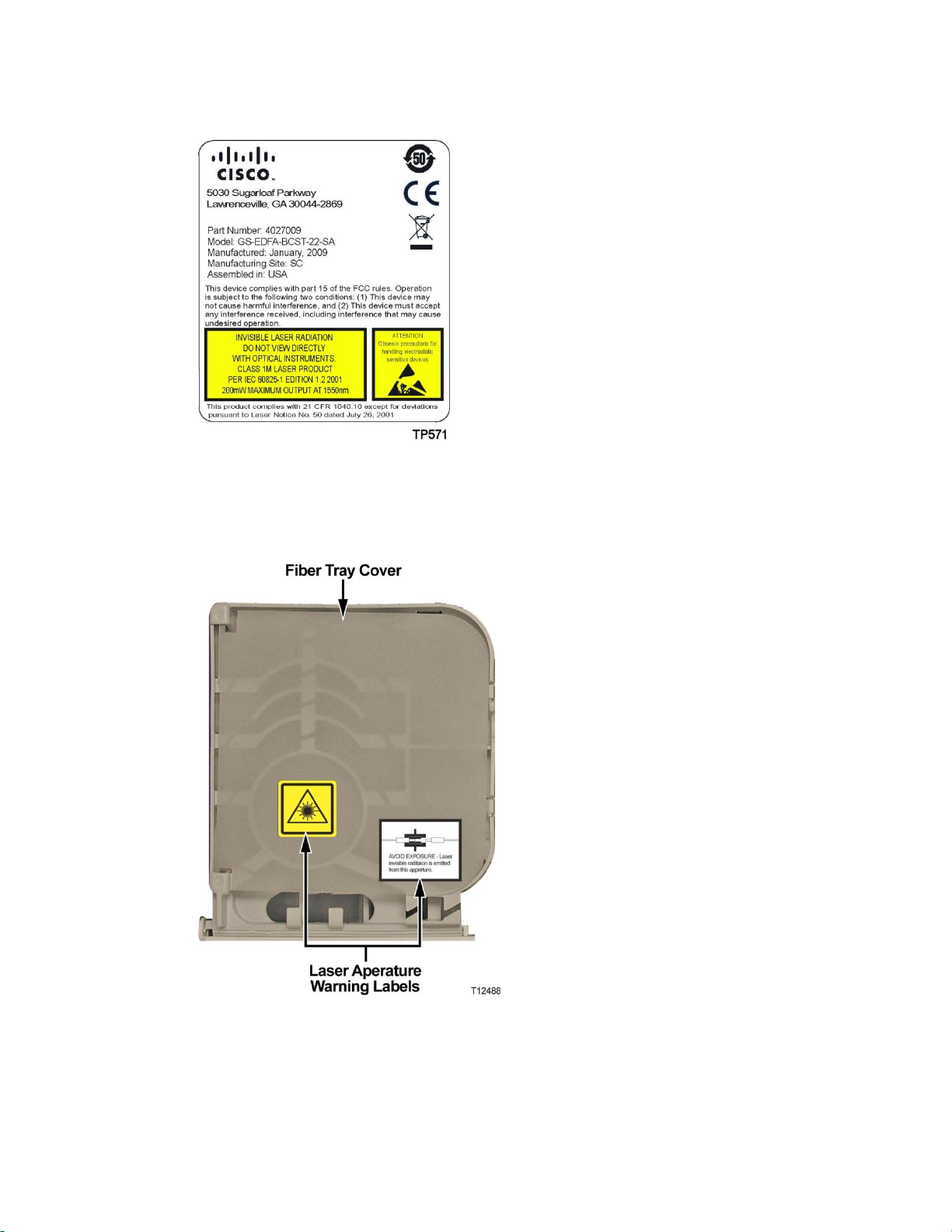

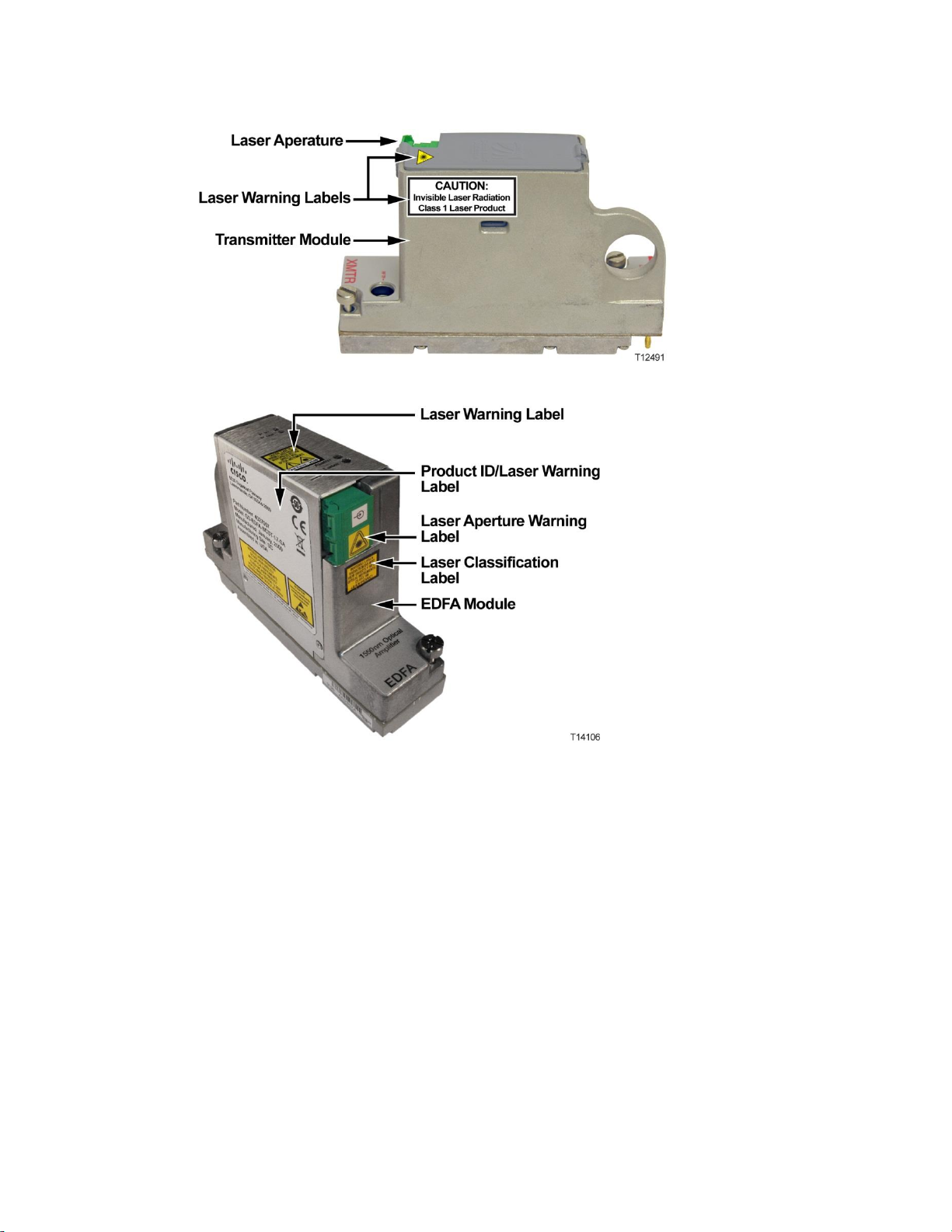

Location of Labels on Equipment

The following illustrations display the location of warning labels on this equipment.

Page 19

Laser Warning Labels

xvii

Page 20

Page 21

1

Introduction

This manual describes the installation and operation of the 1.2 GHz

GS7000 Node.

1 Chapter 1

General Information

In This Chapter

Equipment Description .......................................................................... 2

Page 22

Chapter 1 General Information

2

Equipment Description

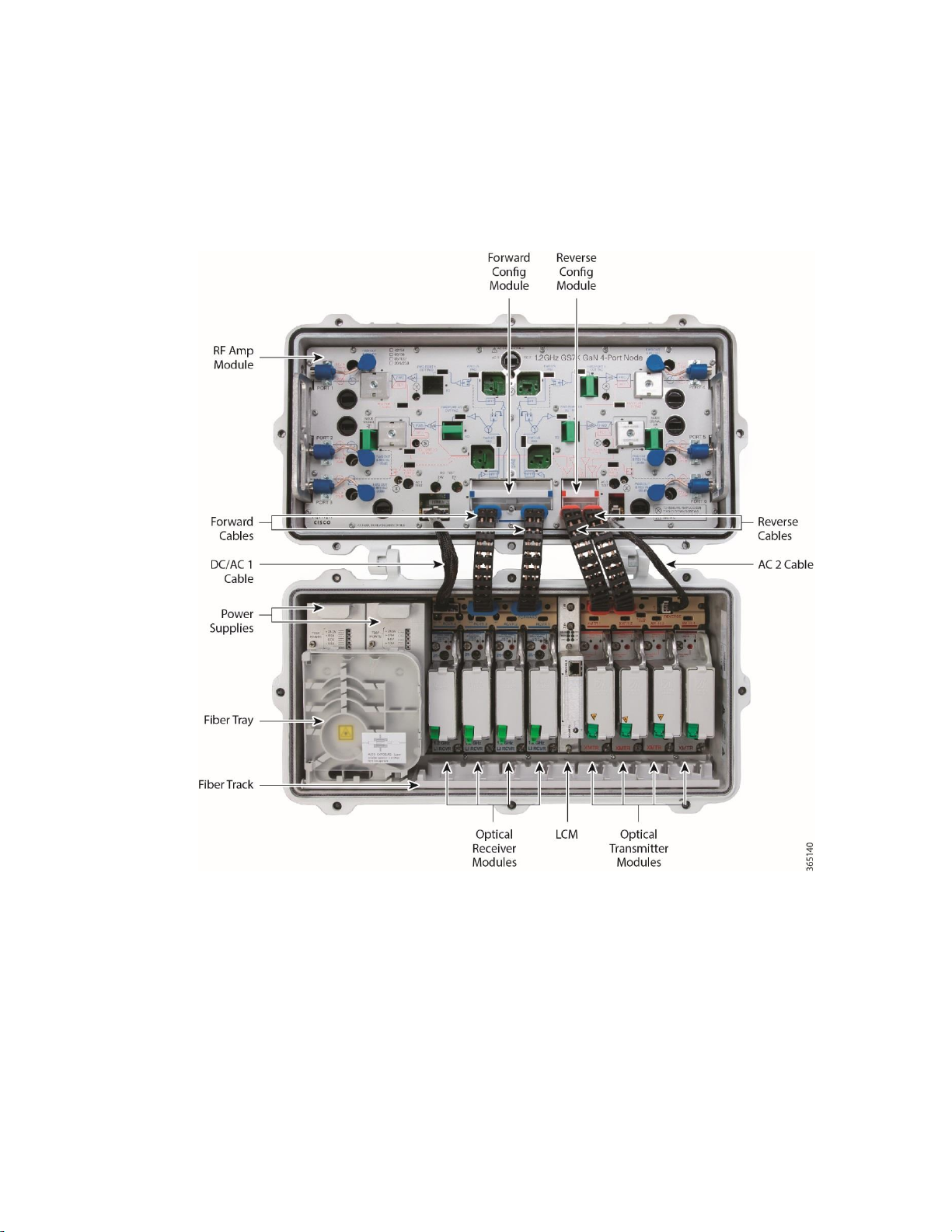

Overview

This section contains a physical and functional description of the 1.2 GHz GS7000

Node.

Physical Description

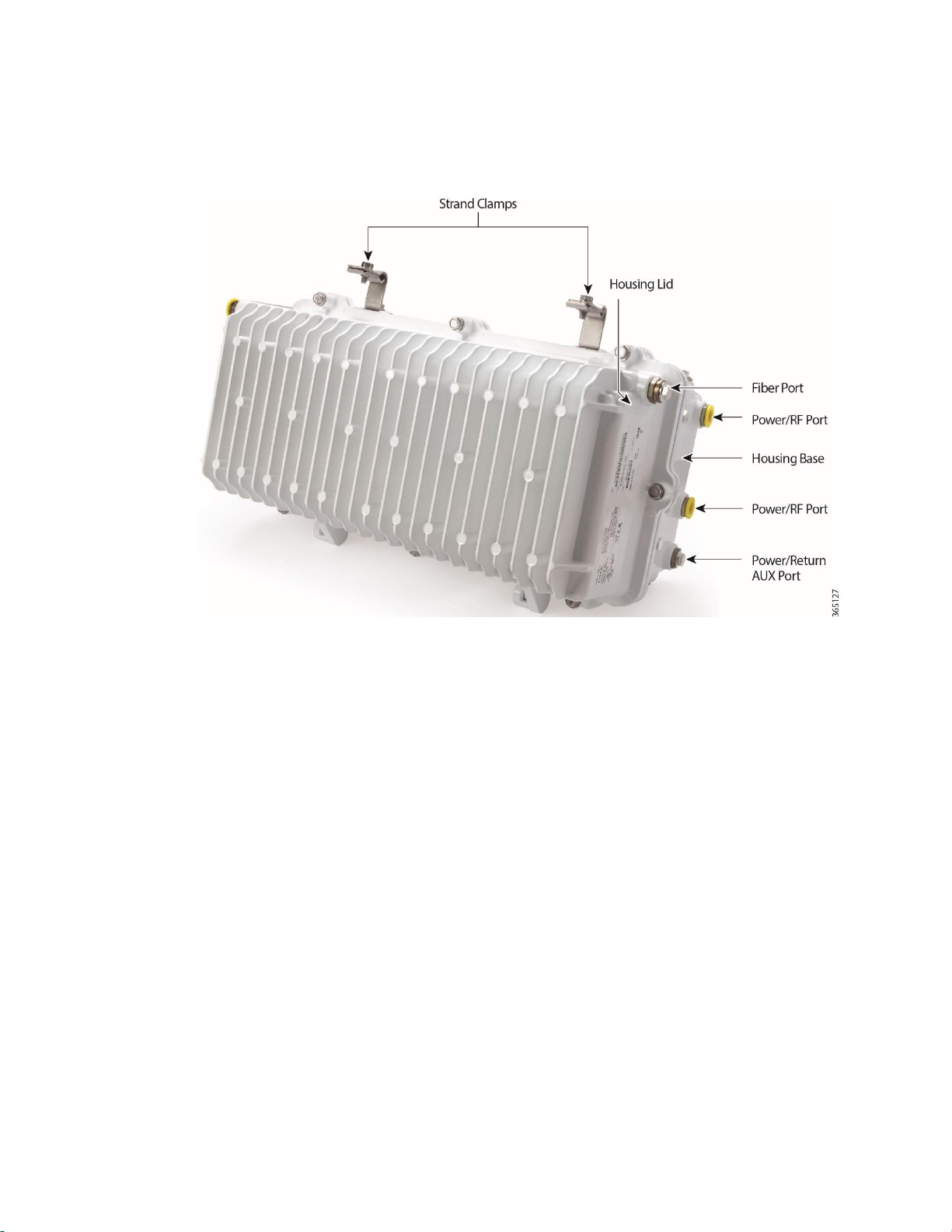

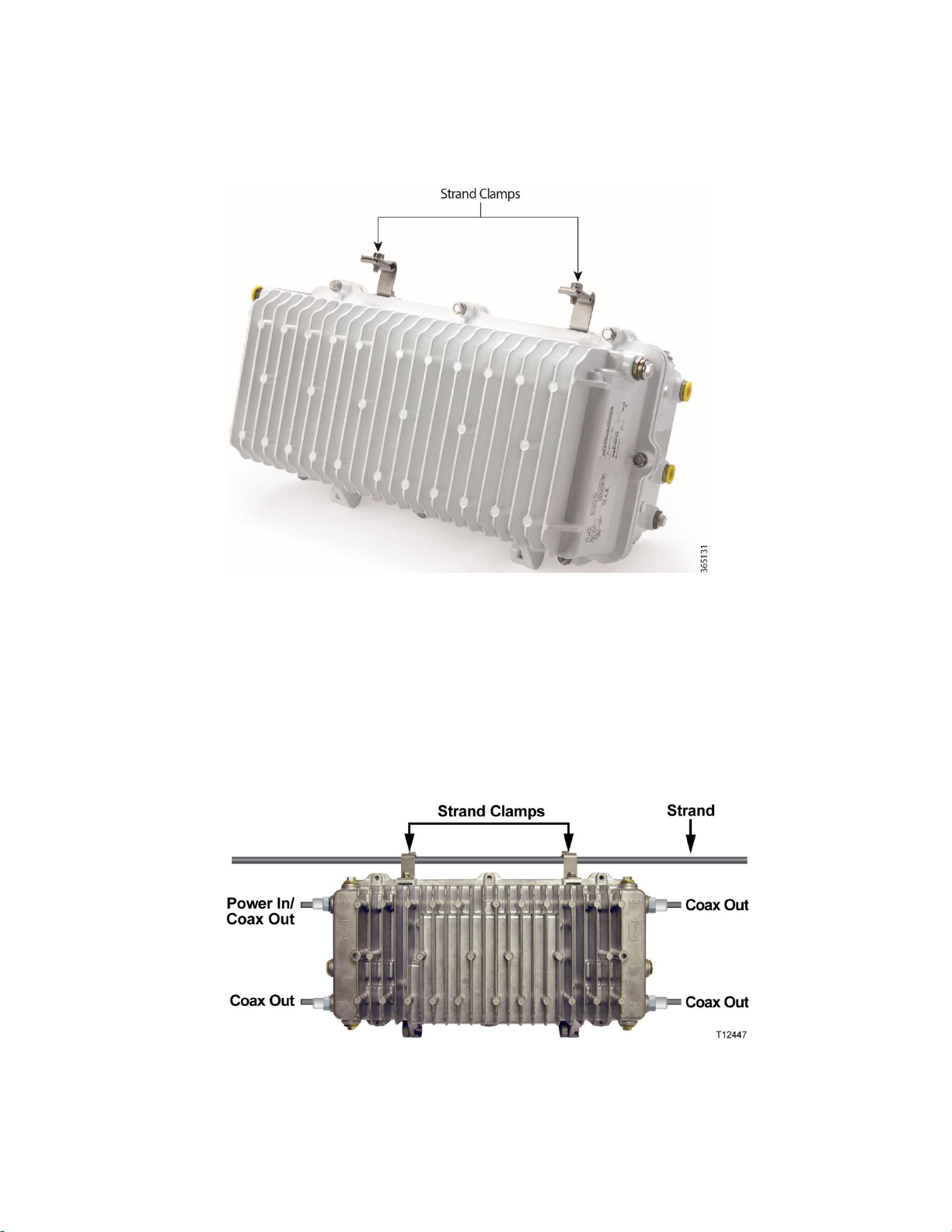

The 1.2 GHz GS7000 Node is the latest generation 1.2 GHz optical node platform

which uses the housing developed for the GS7000 Node Platform, but it has been

painted for improved thermal performance. The housing has a hinged lid to allow

access to the internal electrical and optical components. The housing also has

provisions for strand, pedestal, or wall mounting.

Note: The 1.2 GHz GS7000 node is painted white, and the pictures in this document

which use unpainted housings are used as references.

The base of the housing contains:

an RF amplifier module

AC power routing

forward and reverse configuration modules (configuration will vary)

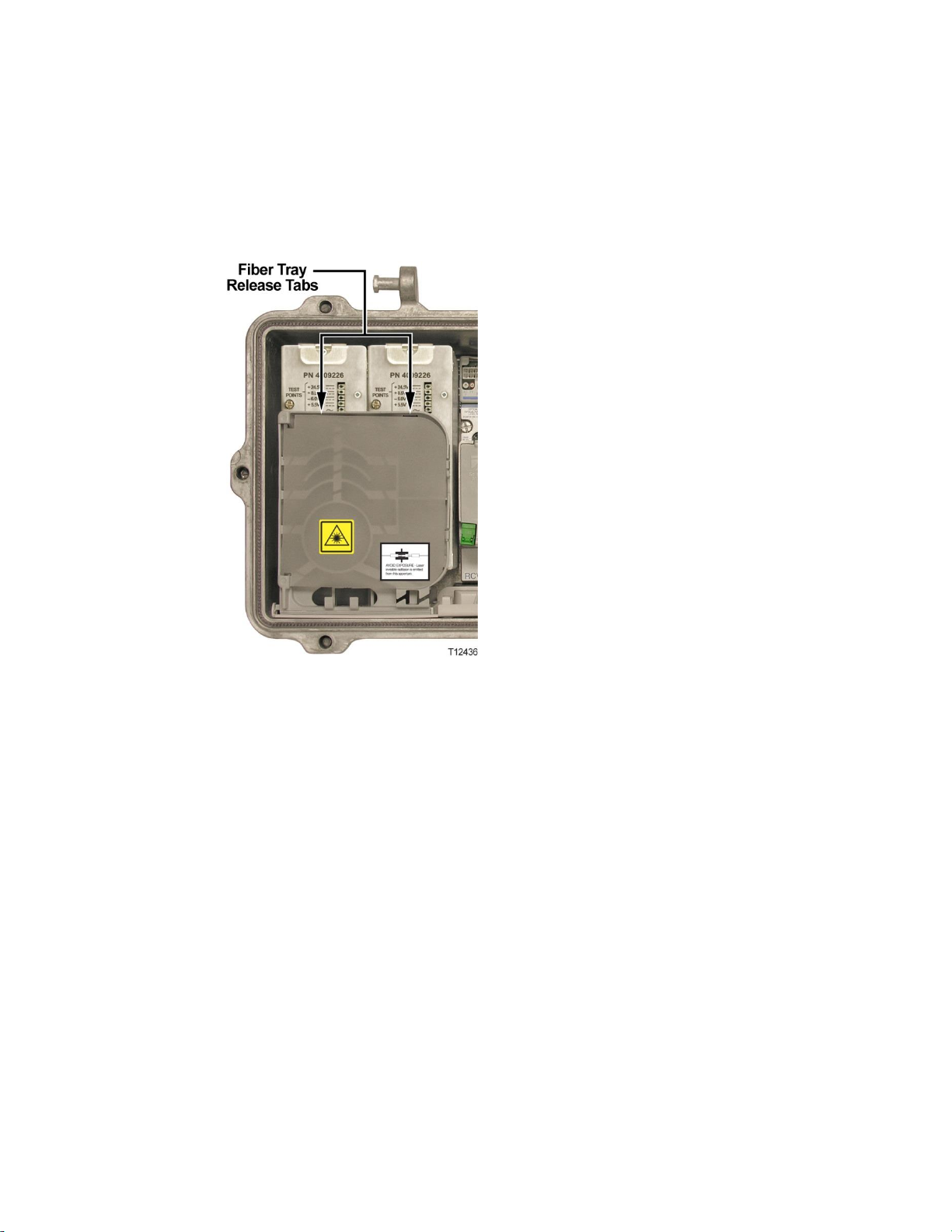

The lid of the housing contains:

a fiber management tray and track (included in all nodes)

optical receiver and transmitter modules (configuration will vary)

EDFA (erbium-doped fiber amplifier) modules and optical switch modules

(for hub node application)

power supplies (one or two)

a status monitor/local control module (optional)

Not every 1.2 GHz GS7000 Node contains all of these modules. The 1.2 GHz GS7000

Node is a versatile node that can be configured to meet various network

requirements.

Page 23

Equipment Description

3

The following illustration shows the external housing of the 1.2 GHz GS7000 Node.

Page 24

Chapter 1 General Information

4

The following illustration shows the 1.2 GHz GS7000 Node internal modules and

components.

Functional Description

Node

The 1.2 GHz GS7000 Node is used in broadband hybrid fiber/coax (HFC) networks.

It is configured with the receivers, transmitters, configuration modules, and other

modules to meet your unique network requirements. This platform allows

independent segmentation and redundancy for both the forward and reverse paths

in a reliable, cost-effective package.

Page 25

Equipment Description

5

The 1.2 GHz GS7000 Node receives forward optical inputs, converts the input to an

electrical radio frequency (RF) signal, and outputs the RF signals at up to six ports.

The forward bandwidth is from 54 MHz (or 86, 102, 258 MHz) to 1218 MHz. The

lower edge of the passband is primarily determined by the diplex filter and the

reverse amplifier assembly. Diplex filter choices are 54 MHz, 86 MHz, 102 MHz, and

258 MHz.

The forward path of the 1.2 GHz GS7000 Node can be deployed with a broadcast

1310/1550 nm optical receiver with common services distributed to either four

output ports (all high level) or six output ports (two high level and four lower level).

The forward path can also be segmented by using one optical receiver that feeds all

output ports, two independent optical receivers that each feed half of the node’s

output ports (left/right segmentation) or four independent optical receivers that

feed four independent forward paths. Forward optical path redundancy is

supported via the use of optional local control module. The type of forward

segmentation and/or redundancy is determined by the type of RF amplifier

assembly and Forward Configuration Module installed in the node.

The 1.2 GHz GS7000 Node’s reverse path is equally flexible. Reverse traffic can be

segmented or combined and routed to up to four DFB reverse optical transmitters, or

up to four Enhanced Digital Return reverse optical transmitters as part of our EDR

system. Redundant (back-up) transmitters may be utilized. In addition, an auxiliary

input path is provided for reverse signal injection (5 - 210 MHz). Reverse

segmentation and/or redundancy are determined by the type of Reverse

Configuration Module installed in the node.

The 1.2 GHz GS7000 Node accepts Optical Transmitter Modules based on the

existing 694x/GainMaker optical transmitters. Reverse optical transmitters can be

installed to transmit data, video, or both. Reverse bandwidth is determined by the

diplex filter and the reverse amplifier assembly. Diplex filter choices are 42/54 MHz,

65/86 MHz, 85/102 MHz, and 204/258 MHz.

The 1.2 GHz GS7000 Node utilizes the transmitter and receiver module covers that

have been designed to allow fiber pigtails storage within them, providing improved

fiber management within the node.

Up to four optical receivers and up to four analog or two digital transmitters can be

installed in the 1.2 GHz GS7000 Node.

45 - 90 V AC input power is converted to +24.5, +8.5, -6.0, and +5.5 V DC by an

internal power supply to power the 1.2 GHz GS7000 Node.

Hub Node

The GS7000 Hub Node performs the same functions as the GS7000 Node with the

added benefit of also providing optical gain and optical switching capability. The

hub node allows you to push fiber deeper into your network while taking advantage

Page 26

Chapter 1 General Information

6

of the RF plant that is already in place.

The GS7000 Node can be upgraded to a GS7000 Hub Node in the field. This is

accomplished by the installation of optical amplification (EDFA) modules, optical

switching modules, and the Status Monitor/Local Control Module in the node lid.

The GS7000 Hub Node can then serve as a traditional node feeding the local HFC

plant and as an optical hub with the optical amplifiers. The node hub with the

amplifiers can service up to 32 nodes at a distance of 50 km with only three fibers.

EDFAs are available in 17 dBm, 20 dBm, and 22 dBm for broadcast constant output

power. A 17 dBm, 20 dBm and 21 dBm narrowcast constant gain EDFA version is

available to fit any architecture for requirements like DWDM narrowcasting.

The optical switch module is used for switching the input of an EDFA module from

a primary signal to a backup or secondary signal. The switch is monitored and

controlled by the Status Monitor/Local Control Module (SM/LCM) in the node.

A specific model of the SM/LCM is required for use in the hub node. This SM/LCM

model monitors and controls several EDFA and optical switch parameters and

functions while continuing to monitor the standard node components.

Features

The 1.2 GHz GS7000 Node has the following features:

Six port 1.2 GHz RF platform

Uses rugged GaN Technology on the output stage

Uses standard GainMaker style accessories (i.e., attenuator pads, equalizers,

diplexers and crowbar)

Field accessible plug-in Forward Interstage Linear Equalizers,

Forward/Reverse Configuration Modules, and Node Signal Directors

3-state reverse switch (on/off/-6 dB) allows each reverse input to be isolated

for noise and ingress troubleshooting (status monitor or local control module

required)

Auxiliary reverse injection (5 - 210 MHz) configurable on up to 2 ports (port 3

or port 6)

Positions for up to 4 optical receivers and 4 optical transmitters in housing lid

Provides hub node functionality with addition of available optical amplifier

and optical switch modules

Optional low-cost Local Control Module may be installed in conjunction with

a Redundant Forward Configuration Module to allow optical forward path

Page 27

Equipment Description

7

redundancy when no status monitor is present

Fiber entry ports on both ends of housing lid

Fiber management tray and track provides easy access to fiber connections

Primary and redundant power supplies with passive load sharing

Spring loaded seizure assemblies allow coax connectors to be installed or

removed without removing amplifier chassis or spring loaded mechanism

from the rear of the housing base

Dual/Split AC powering

Space provided for mounting WDM modules inside the housing lid.

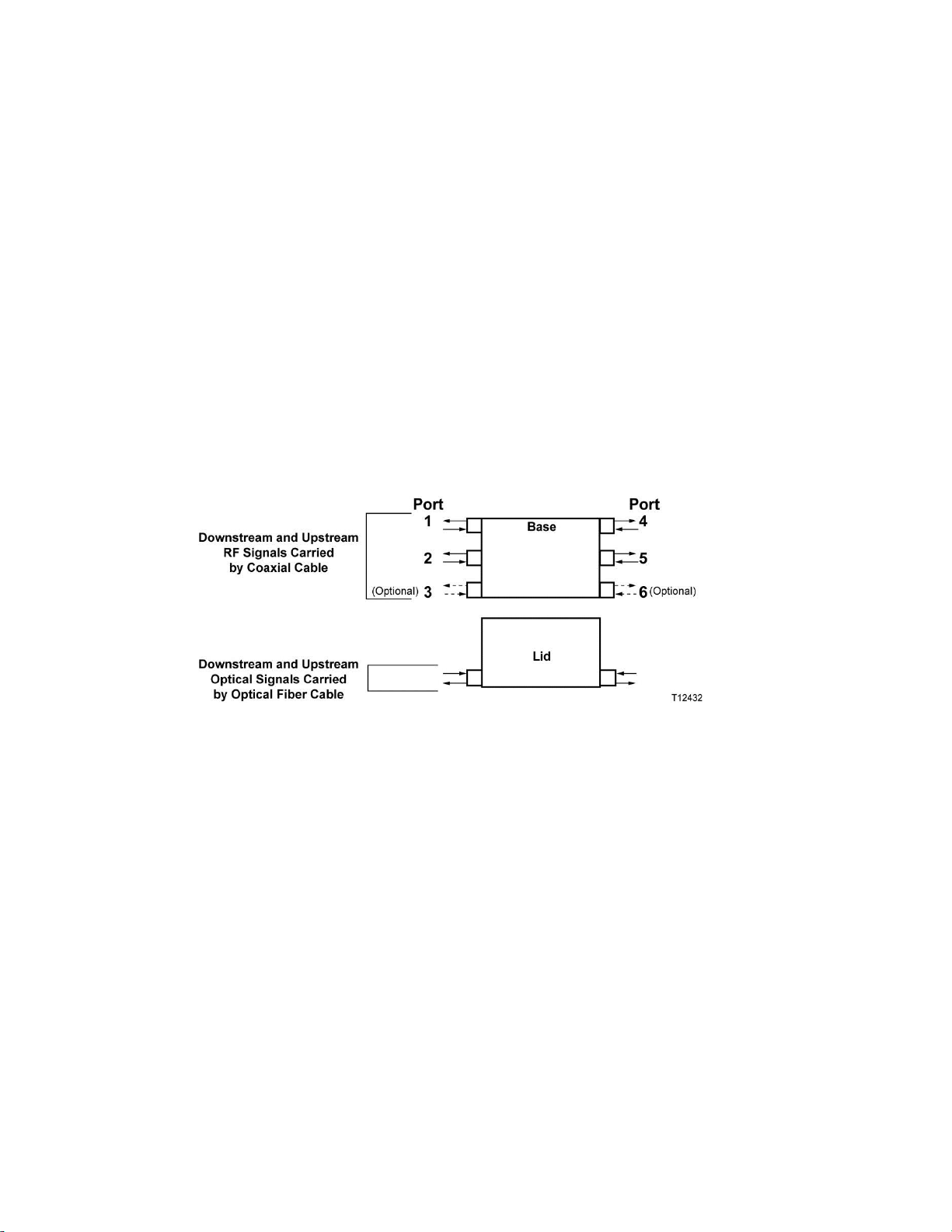

Node Inputs/Outputs Diagram

The following diagram shows the system-level inputs and outputs of the 1.2 GHz

GS7000 Node.

The AC can be applied to any RF port and routed, if required, to the other

ports.

The DC power supply modules can be fed by any RF port (1 through 6).

Modules Functional Descriptions

This table briefly describes each module. The 1.2 GHz GS7000 Node may not contain

all these modules. See Theory of Operation (on page 15) for detailed descriptions of

the modules.

Page 28

Chapter 1 General Information

8

Module

Description

RF Amplifier

The RF Amplifier Module includes:

four separate and independent forward amplification paths, each

having one or two RF outputs.

four independent reverse inputs.

forward and reverse bandwidths that are established by diplexer

and reverse amplifier assembly selection.

Forward

Configuration

There are several types of this module.

The 1x4 Forward Configuration Module (FCM) is used when the 1.2

GHz GS7000 Node is configured with a single optical receiver routed

to all four outputs of the amplifiers. This module splits the signals

equally to the inputs of the RF amplifier module. The 1x4 Forward

Configuration Modules with forward RF injection are similar to the

1x4 Forward Configuration Modules, but are used with the Forward

Local Injection (FLI) Module. The FLI Module routes an RF signal

from an external source to the Forward Configuration Module which

is then coupled with other inputs from an optical receiver.

The 1x4 Redundant Forward Configuration Module is used when the

1.2 GHz GS7000 Node is configured with two optical receivers routed

to all four outputs of the amplifiers in a redundant configuration.

Receiver 1 is the primary receiver and Receiver 2 is the backup. The

active receiver is selected with a status monitor or local control

monitor.

Page 29

Equipment Description

9

Module

Description

Forward

Configuration

(cont'd)

The 1x4 Redundant Forward Configuration Modules with forward RF

injection are similar to the 1x4 Redundant Forward Configuration

Modules, but are used with the Forward Local Injection (FLI) Module.

The FLI Module routes an RF signal from an external source to the

Forward Configuration Module which is then coupled with other

inputs from an optical receiver.

The 2x4 Forward Configuration Module is used when the 1.2 GHz

GS7000 Node is configured with two optical receivers, each feeding

two/three outputs of the amplifier module. In this configuration, the

node serving area is divided in half in the forward direction. Receiver

1 is routed to RF amplifier Ports 4 and 5/6, while Receiver 3 is routed

to RF amplifier Ports 1 and 2/3.

The 2x4 Redundant Forward Configuration Module is used when the

GS7000 Node is configured with four optical receivers with each pair

feeding two/three RF outputs of the amplifier module in a redundant

configuration. In this configuration, the node serving area is divided

in half, with redundancy, in the forward direction. Receivers 1

(primary) and 2 (redundant) are routed to RF amplifier Ports 4 and

5/6, while Receivers 3 (primary) and 4 (redundant) are routed to RF

amplifier Ports 1 and 2/3. The active receiver is selected with a status

monitor or local control monitor.

The 3x4 Forward Configuration Module is used when the 1.2 GHz

GS7000 Node is configured with three receivers each feeding

one/two/three/four outputs of the amplifier module. Two versions of

this module are available. In one version Receiver 1 is routed to RF

amplifier ports 4/5/6, Receiver 3 is routed to port 1, and Receiver 4 is

routed to ports 2/3. In the other version Receiver 1 is routed to RF

amplifier ports 5/6, Receiver 2 is routed to port 4, and Receiver 4 is

routed to ports 1/2/3. (Note that the 3x4 FCM can only be used with

the 4-way RF amplifier module.)

The 4x4 Forward Configuration Module is used when the 1.2 GHz

GS7000 Node is configured with four optical receivers with each

feeding separate RF outputs of the amplifier module. Receiver 1 is

routed to RF amplifier Ports 5/6. Receiver 2 is routed to RF amplifier

Port 4. Receiver 3 is routed to RF amplifier Port 1. Receiver 4 is routed

to RF amplifier Ports 2/3. (Note that the 4x4 FCM can only be used

with the 4-way RF amplifier module.)

Page 30

Chapter 1 General Information

10

Module

Description

Reverse

Configuration

There are several types of this module.

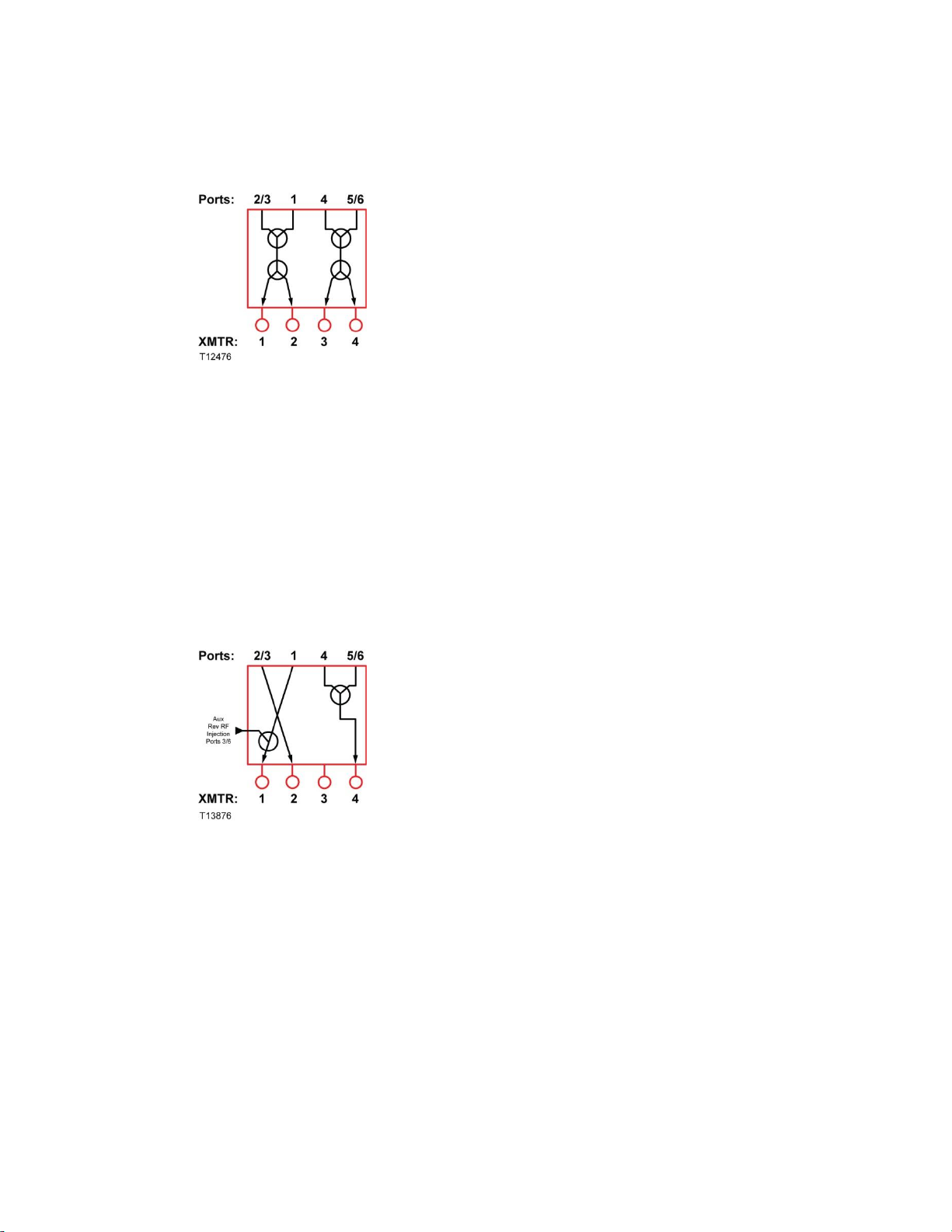

The 4x1 Reverse Configuration Module (RCM) with auxiliary

reverse RF injection combines all four reverse RF inputs (Ports 1, 2/3,

4, and 5/6) of the node and routes the signal to Transmitter 1. An RF

signal from an external source can optionally be injected and coupled

with the reverse RF inputs on Ports 3/6 and routed to Transmitter 1.

The 4x1 Redundant Reverse Configuration Module combines all four

reverse RF signals (Ports 1, 2/3, 4 and 5/6) together, splits this RF

signal and routes it to Transmitters 1 and 2.

The 4x2 Reverse Configuration Module with auxiliary reverse RF

injection combines reverse inputs from Ports 1 and 2/3 and routes

them to Transmitter 1; it also combines reverse inputs from Ports 4

and 5/6 and routes them to Transmitter 3. An RF signal from an

external source can optionally be injected and coupled with reverse RF

inputs from Ports 3/6 and routed to Transmitter 1.

The 4x2 Redundant Reverse Configuration Module combines reverse

inputs from Ports 1 and 2/3 and routes them to Transmitters 1 and 2;

it also combines reverse inputs from Ports 4 and 5/6 and routes them

to Transmitters 3 and 4.

The 4x3 Reverse Configuration Module with auxiliary reverse RF

injection is available in two types. The

left-combined/right-segmented version combines reverse inputs from

Ports 1 and 2/3 and routes them to Transmitter 1; it also routes reverse

inputs from Port 4 to Transmitter 3 and from Ports 5/6 to Transmitter

4. An RF signal from an external source can optionally be injected at

Ports 3/6 and coupled with the reverse RF input from Port 1 and

routed to Transmitter 1. The left-segmented/right-combined version

combines reverse inputs from Ports 4 and 5/6 and routes them to

Transmitter 4; it also routes reverse inputs from Port 1 to Transmitter 1

and from Ports 2/3 to Transmitter 2. An RF signal from an external

source can optionally be injected at Ports 3/6 and coupled with the

reverse RF inputs from Ports 2/3 and 1 and routed to Transmitter 1.

Page 31

Equipment Description

11

Module

Description

Reverse

Configuration

(cont'd)

The 4x4 Reverse Configuration Module with auxiliary reverse RF

injection routes reverse inputs from Port 1 to Transmitter 1, from Port

2/3 to Transmitter 2, from Port 4 to Transmitter 3, and from Port 5/6

to Transmitter 4. An RF signal from an external source can optionally

be injected and coupled with reverse RF inputs from Ports 3/6 and

routed to Transmitter 1. (Note that this module is typically installed

when using EDR multiplexing digital reverse modules. Since the

digital reverse module occupies the physical space that transmitters 3

and 4 normally occupy in the node base, this reverse configuration

module is typically used with a 6-port optical interface board.)

Optical Receiver

This module converts an optical signal from the headend into a

forward path RF signal. An SC/APC fiber connector is standard.

Optical power, test points, and status LEDs are provided.

Optical

Transmitter

This module converts reverse path RF signals from the network into

an optical signal. An SC/APC fiber connector is standard. Multiple

transmitter options are available such as uncooled DFB, 1550 ITU, and

EDR. EDR uses the included LC/APC connector that jumps over to an

SC/APC bulkhead. Optical power, test points, and status LEDs are

provided.

Optical

Amplifier

(EDFA)

Erbium-doped fiber amplifier modules are available in two categories:

broadcast and narrowcast (gain-flattened). EDFAs are available in 17

dBm, 20 dBm, and 22 dBm for broadcast constant output power. A 17

dBm, 20 dBm and 21 dBm narrowcast constant gain EDFA version is

available to fit any architecture for requirements like DWDM

narrowcasting. EDFA modules are single-wide, single-output devices.

The modules mount in receiver or transmitter slots on the optical

interface board in the node lid using a reversible pin adapter. The

EDFA is monitored and controlled by the Status Monitor/Local

Control Module in the node.

Optical Switch

The optical switch module is used for switching the input of an EDFA

module from a primary signal to a backup or secondary signal. The

module mounts in receiver or transmitter slots on the optical interface

board in the node lid using a reversible pin adapter. The switch is

monitored and controlled by the Status Monitor/Local Control

Module in the node.

Page 32

Chapter 1 General Information

12

Module

Description

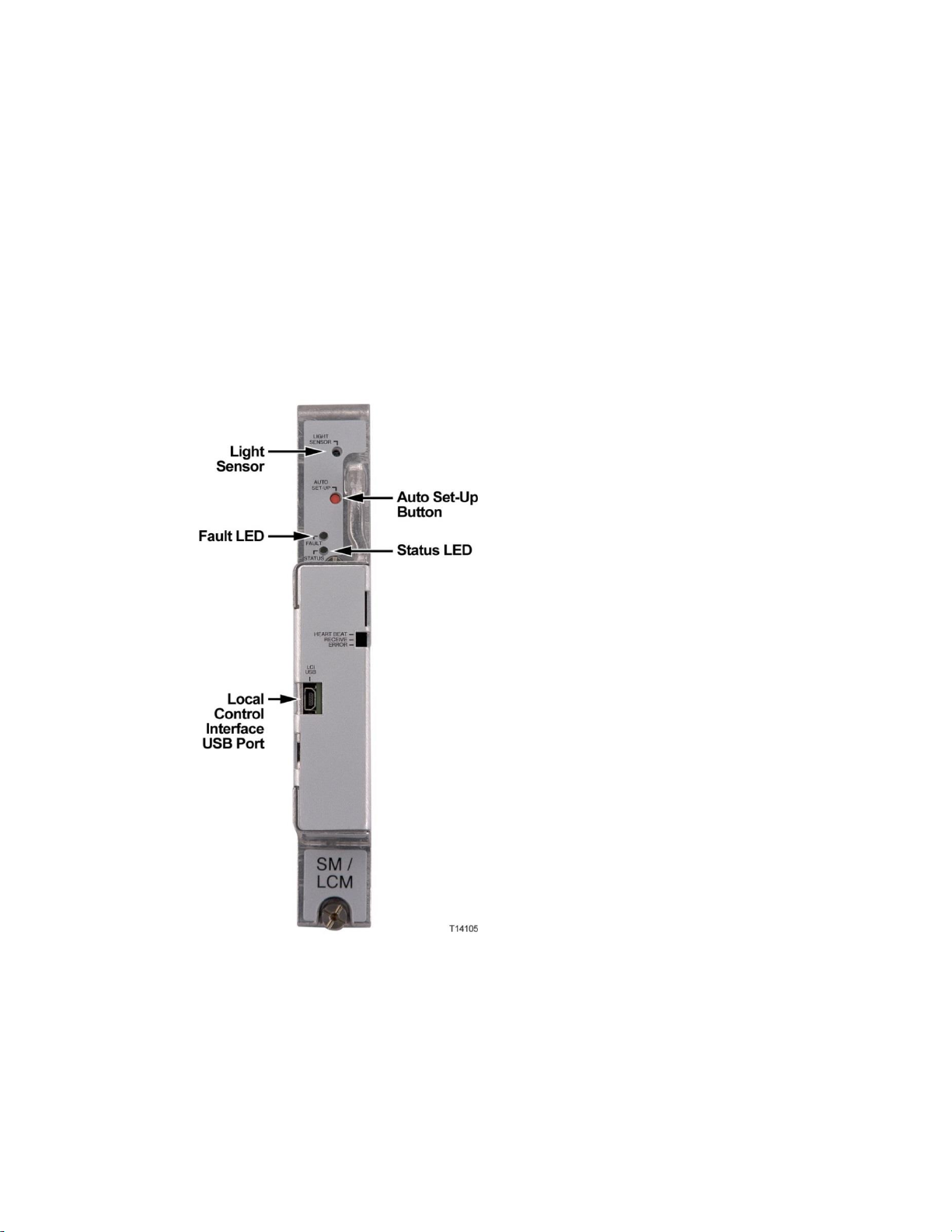

Status Monitor/

Local Control

Module

(SM/LCM)

The local control module monitors the input optical power of up to

four receivers and four transmitters, plus AC power entry and power

supply voltage rails. It also provides local reverse path wink and

shutdown capabilities through the PC-based GS7000 ViewPort

software. It can be upgraded to a status monitor which provides node

monitoring and control capability at the cable plant's headend. This

module is not required for normal operation of the node. In a hub

node application the SM/LCM also monitors and controls the

operation of the EDFAs and optical switches.

Power Supply

The 1.2 GHz GS7000 power supply module has multiple output

voltages of +24.5, +8.5, -6.0, and +5.5 V DC. A second power supply

can be installed in the node for redundancy or load sharing.

The 1.2 GHz GS7000 Node can be set up in the following powering

configurations:

two power supplies powered by different AC sources

two power supplies using the same AC source

a single supply using a single AC source

Fiber

Management

Tray and Track

The fiber management system secures and protects the optical fiber

inside the node housing.

Optical Interface

Board

The Optical Interface Board (OIB) provides all interconnections

between the modules in the housing lid of the 1.2 GHz GS7000 Node.

Each module in the lid plugs directly into the OIB through a connector

header or row of sockets. Input attenuator pads are provided on the

OIB for each optical receiver in the housing lid. Output attenuator

pads are provided on the OIB for each optical transmitter in the

housing lid.

Page 33

Equipment Description

13

Ordering Information

The 1.2 GHz GS7000 Node is available in a wide variety of configurations. Please

refer to the 1.2 GHz GS7000 Node Data Sheet for a full listing of the configured node,

components, and accessories that are available.

Note: Please consult with your Account Representative, Customer Service

Representative, or System Engineer to determine the best configuration PID for your

particular application.

Note: Please consult with your Account Re presentative, Customer Service Representative, or System Engineer to determi ne the best configuration for your particular application.

Page 34

Page 35

15

Introduction

This chapter describes the theory of operation for the 1.2 GHz GS7000

Node, including functional descriptions of each module in the node.

The 1.2 GHz GS7000 Node is comprised of two parts, the lid and the

base.

The lid houses an optical interface board (OIB), and some of the

following products: one to four optical receivers, one to four optical

transmitters, one digital return module with one or two digital

transmitters, EDFA (optional), optical switch (optional), a status

monitor (optional) or a local control module (optional), one or two

power supplies, and a fiber management tray/track.

The base houses the RF amplifier module and the accessories that plug

into it. These accessories include a forward configuration module, four

forward band linear equalizer modules, multiple attenuator pads, two

node signal director jumper or splitter modules, and two auxiliary

reverse injection director modules. Also contained within the launch

amplifier module are a reverse auxiliary

jumper/combiner/amplifier/termination module and a reverse

configuration module.

2 Chapter 2

Theory of Operation

Page 36

Chapter 2 Theory of Operation

16

In This Chapter

System Diagrams .................................................................................. 17

Forward Path ......................................................................................... 21

Reverse Path .......................................................................................... 22

Power Distribution ............................................................................... 23

RF Amplifier Module ........................................................................... 24

Forward Configuration Module ......................................................... 29

Reverse Configuration Module .......................................................... 34

Optical Interface Board (OIB) .............................................................. 38

Optical Receiver Module ..................................................................... 39

Optical Analog Transmitter Modules ................................................ 43

Optical Amplifier (EDFA) Modules ................................................... 45

Optical Switch Module ........................................................................ 52

Local Control Module .......................................................................... 58

Power Supply Module ......................................................................... 61

Page 37

System Diagrams

17

System Diagrams

F2F1

P4

P5

P6

P1

P2

P3

Optical

Interface Board

Power

Supply #1

Power Dire ctor

FWD

REV

FWD

REV

Aux. Rever se Injection

Director

Node

Signal Dir ector

Jumper

Pad

Crowbar

Power Dire ctor

Power Dire ctor

FWD

REV

FWD

REV

(to RCM)

5

-210 MHz

Reverse In jection

Option

Aux. Rever se Injection

Director

Aux. Rev

RF

Injection

Node

Signal Dir ector

Splitter

Pad

Crowbar

Power Dire ctor

EQ

AC

Byp ass

AC

Byp ass

AC

Byp ass

AC

Byp ass

AC

Byp ass

RS = rever se switch

X

M

T

R

L

a

s

e

r

D

i

o

d

e

TP

P

R

C

V

R

P

h

o

t

o

D

i

o

d

e

P

S

t

a

t

u

s

M

o

n

i

t

o

r

/

L

o

c

a

l

C

o

n

t

r

o

l

M

o

d

u

l

e

1x4

Forward Configuration

Module

4x1 Reverse

Configuration Module

w/Aux Reverse

RF Injection

Fiber Tray

Power

Supply #2

RCVR

# 1

XMT R

# 1

Pad

Pad

Pad

Pad

Pad Pad Pad Pad PadPadPad

Pad

Pad

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

Thermal

Thermal

PadPad

Thermal

EQ

Pad

EQ

Pad

Pad

Pad

EQ

Pad

Pad

Thermal

RF Switch

RF Switch

RF Switch

RF Switch

(to RCM)

5

-210 MHz

Reverse In jection

Option

External

-20 dB TP

-20 dB

Fwd. TP

External

-20 dB TP

-20 dB

Fwd. TP

Power Dire ctor

Power Dire ctor

-20 d

B

Fwd. TP

-20 d

B

Fwd. TP

-20 d

B

Fwd. TP

External

-20 dB TP

External

-20 dB TP

External

-20 dB TP

External

-20 dB TP

-20 dB

Fwd. TP

AC

Byp ass

3

6

4

7

4

3

RS RS

RS

RS

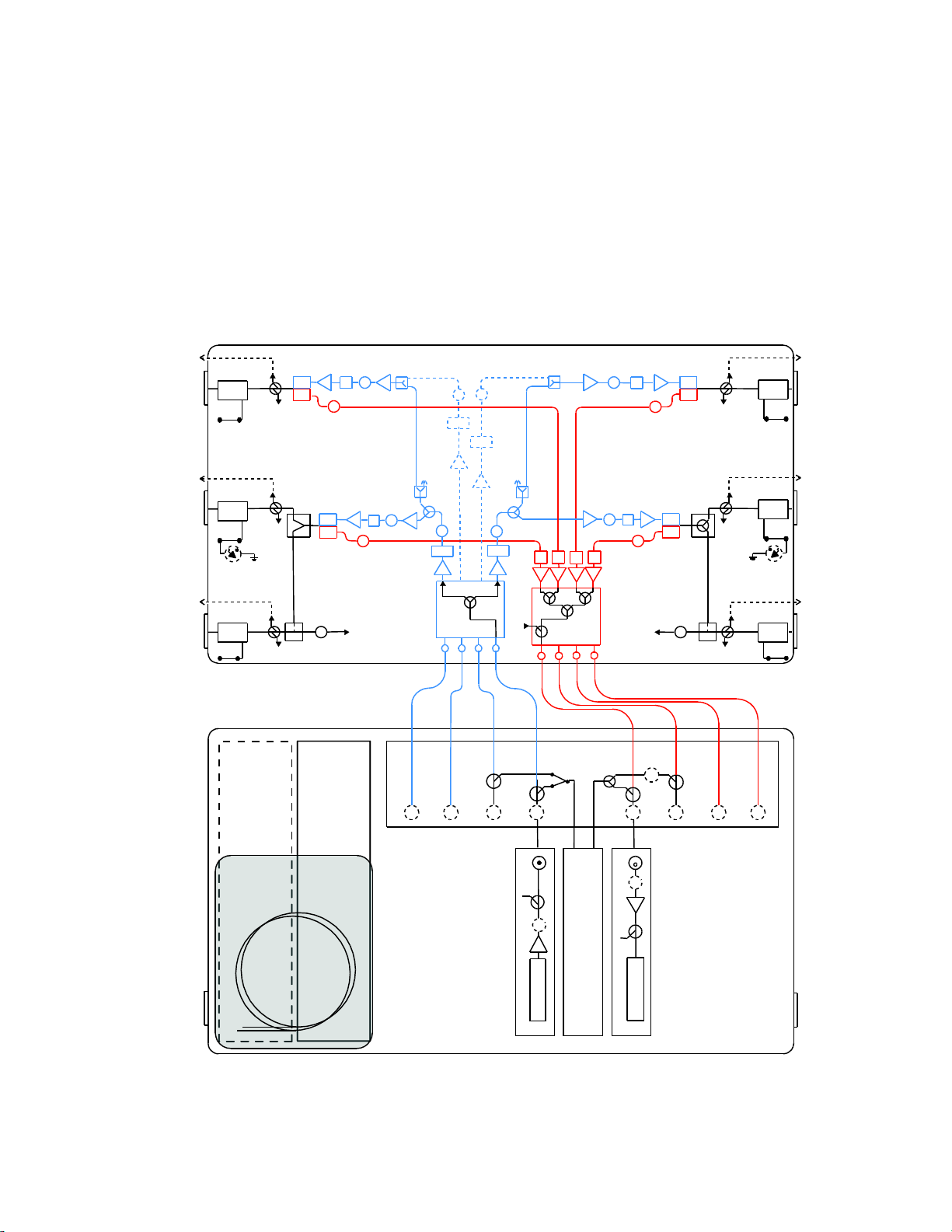

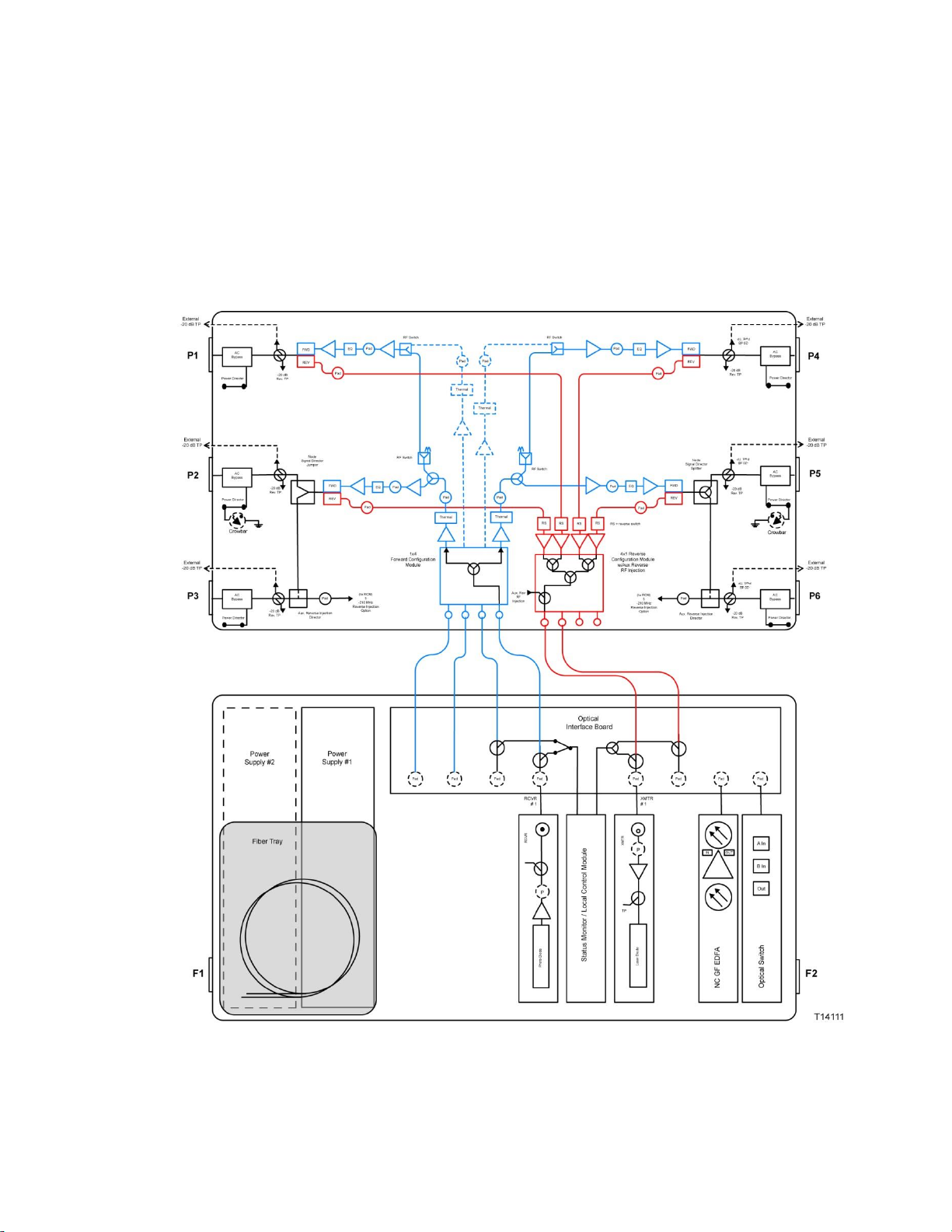

Functional Diagrams: 4-Way Forward Segmentable Node

The following diagrams show the signal flow through the 4-way forward

segmentable node.

Non-Segmented

Page 38

Chapter 2 Theory of Operation

18

Left-Right Segmented

Page 39

System Diagrams

19

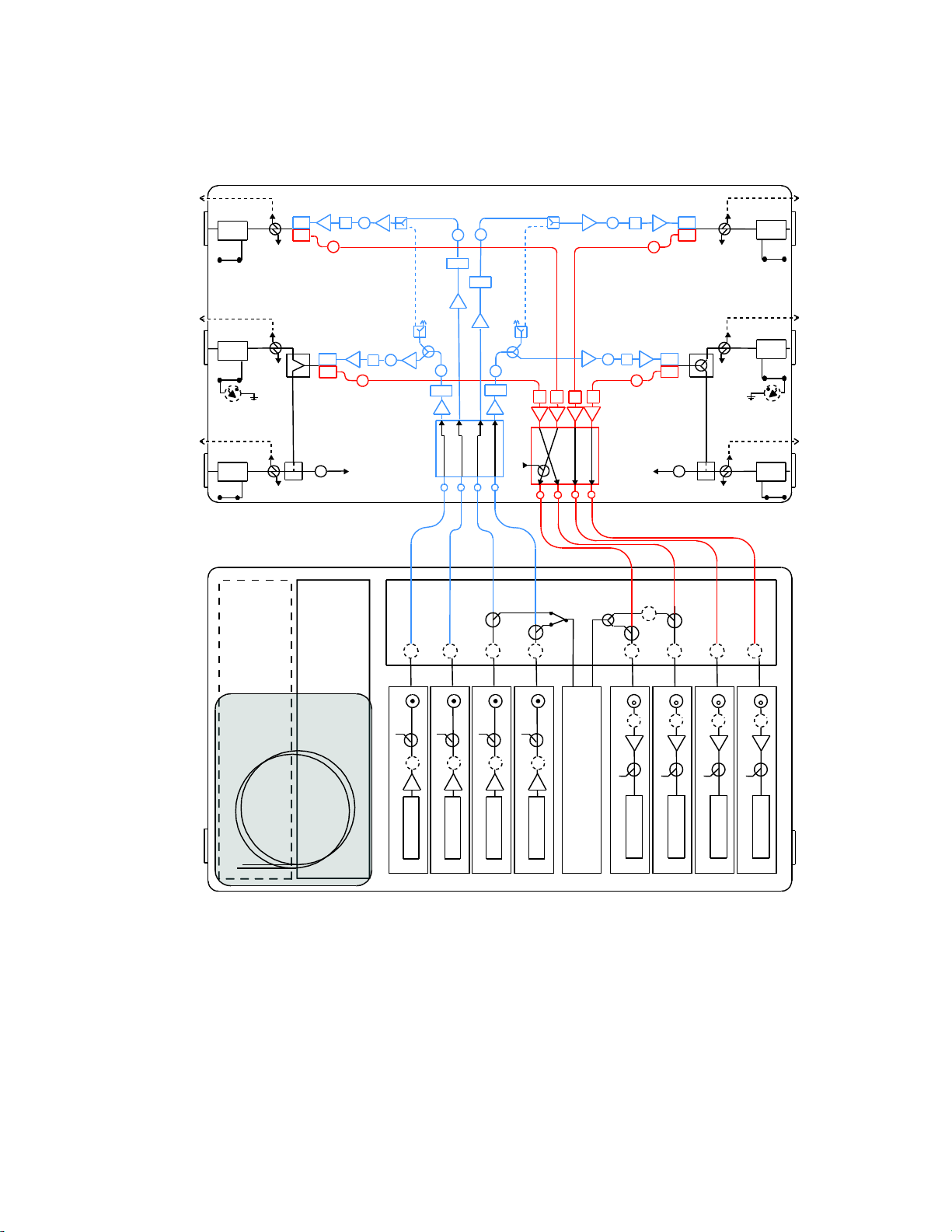

Fully Segmented

F2F1

P4

P5

P6

P1

P2

P3

Optical

Interface Board

Power

Supply #1

Power Dire ctor

FWD

REV

FWD

REV

Aux. Rever se Injection

Director

Node

Signal Dir ector

Jumper

Pad

Crowbar

Power Dire ctor

Power Dire ctor

FWD

REV

FWD

REV

(to RCM)

5

-210 MHz

Reverse In jection

Option

Aux. Rever se Injection

Director

Aux. Rev

RF

Injection

Node

Signal Dir ector

Splitter

Pad

Crowbar

Power Dire ctor

EQ

AC

Byp ass

AC

Byp ass

AC

Byp ass

AC

Byp ass

AC

Byp ass

RS = rever se switch

X

M

T

R

L

a

s

e

r

D

i

o

d

e

TP

P

R

C

V

R

P

h

o

t

o

D

i

o

d

e

P

S

t

a

t

u

s

M

o

n

i

t

o

r

/

L

o

c

a

l

C

o

n

t

r

o

l

M

o

d

u

l

e

4x4

Forward Configuration

Module

4x4 Reverse

Configuration Module

w/Aux Reverse

RF Injection

Fiber Tray

Power

Supply #2

RCVR

# 1

R

C

V

R

P

h

o

t

o

D

i

o

d

e

P

RCVR

# 2

R

C

V

R

P

h

o

t

o

D

i

o

d

e

P

RCVR

# 3

R

C

V

R

P

h

o

t

o

D

i

o

d

e

P

RCVR

# 4

XMT R

# 1

X

M

T

R

L

a

s

e

r

D

i

o

d

e

TP

P

XMT R

# 2

X

M

T

R

L

a

s

e

r

D

i

o

d

e

TP

P

XMT R

# 3

X

M

T

R

L

a

s

e

r

D

i

o

d

e

TP

P

XMT R

# 4

Pad

Pad

Pad

Pad

Pad Pad Pad Pad PadPadPad

Pad

Pad

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

-20 dB

Rev. TP

Thermal

Thermal

PadPad

Thermal

EQ

Pad

EQ

Pad

Pad

Pad

EQ

Pad

Pad

Thermal

RF Switch

RF Switch

RF Switch

RF Switch

(to RCM)

5

-210 MHz

Reverse In jection

Option

External

-20 dB TP

-20 dB

Fwd. TP

External

-20 dB TP

-20 dB

Fwd. TP

Power Dire ctor Power Dire ctor

-20 d

B

Fwd. TP

-20 d

B

Fwd. TP

-20 d

B

Fwd. TP

External

-20 dB TP

External

-20 dB TP

External

-20 dB TP

External

-20 dB TP

-20 dB

Fwd. TP

AC

Byp ass

3

6

4

7

4

2

RS RS

RS

RS

Page 40

Chapter 2 Theory of Operation

20

Functional Diagram: Hub Node

The following diagram shows the signal flow through a 4-way non-segmented hub

node.

Page 41

Forward Path

21

Forward Path

Stage

Description

1

1310 nm or 1550 nm optical signals from the headend are applied to receiver

module 1 (and/or modules 2, 3, and 4, if used) in the 1.2 GHz GS7000 Node.

2

The receiver module detects the signal on the optical carrier applied to it and

outputs an electrical RF signal to the node Optical Interface Board (OIB).

3

The RF signals travel across the OIB and cables to the Forward Configuration

Module (FCM). The FCM determines how RF signals from the different receiver

modules are routed to the four independent forward amplification paths in the

RF amplifier module. The 1X4 FCM splits the RF signals entering it equally

between the four forward amplification paths in the RF amplifier module.

4

Each of the forward amplification paths in the RF amplifier module is composed

of one input amplification stage and one interstage amplification stages in series

followed by a power doubler output amplification stage. This topology

provides one driven output port for each of the forward amplification paths in

the RF amplifier module, for a total of four driven node output ports.

5

Each of the forward amplification paths in the RF amplifier module also

contains padding, trimming, thermal compensation, equalization, and filtering

circuitry.

6

Node signal directors are present at two of the nodes forward output ports and

allow the signals at those ports to be redirected to the nodes auxiliary output

ports or split equally between the primary and auxiliary node output ports. In

this way, the node can be configured to have up to six output ports.

Introduction

Forward path refers to signals received by the node from the headend. These signals

are amplified in the node and routed to subscribers through the cable distribution

network.

4-Way Forward Path Signal Routing

1.2 GHz GS7000 Node 4-way forward path signal routing functions are described

below.

Page 42

Chapter 2 Theory of Operation

22

Reverse Path

Stage

Description

1

Reverse path RF signals are applied to node output ports 1, 2, 4, and 5. A fifth

reverse path RF signal can be applied to node auxiliary output port 3 or 6 if the

node is configured for local reverse path injection.

2

The RF signals from each of the four node output ports are amplified

independently in the RF amplifier module and routed to the Reverse

Configuration Module (RCM).

3

Each of the reverse amplification paths in the RF amplifier module also contains

padding, trimming, filtering, -6 db wink, and RF On/Off switch circuitry.

4

The RCM determines how RF signals from the different node output ports are

combined and routed to the four transmitter module paths on the Optical

Interface Board (OIB). The 4X1 RCM combines the reverse path signals from the

four node output ports together and directs them to the transmitter module 1

path on the OIB. (Note that other RCMs combine and direct signals to OIB

transmitter module paths 2, 3, and 4 differently.)

5

The RF signals travel across the OIB to transmitter module 1 (and/or modules 2,

3, and 4, if used and proper RCM is installed.) The transmitter modulates the RF

signals entering it onto an optical carrier and routes it through the fiber portion

of the network back to the headend.

Introduction

Reverse path refers to signals received by the node from the cable distribution

network. These signals are amplified in the node and returned to the headend

optically through the fiber portion of the network. The reverse path is not used in all

networks.

Reverse Path Signal Routing

1.2 GHz GS7000 Node reverse path signal routing functions are described below.

Note: Node output ports 3 and 6 can be configured as primary reverse ports. See

Reconfiguring Reverse Signal Routing (on page 113) for further details on this configuration.

Page 43

Power Distribution

23

Power Distribution

Stage

Description

1

45 to 90 V AC is applied to one or two power supply modules in the 1.2 GHz

GS7000 Node.

2

The power supply module(s) convert(s) the AC input to +24.5, +8.5, -6.0, and

+5.5 V DC.

3

The +24.5, +8.5, -6.0, and +5.5 V DC lines are routed to 1.2 GHz GS7000 Node

internal modules.

4

If two power supplies are installed and both are active, the load is shared

equally between them.

5

An AC segmentable shunt is available to separate the AC connection to ports

1-3 from that of ports 4-6. This allows the node to be configured where one

power supply is powered from ports 1-3 and a second power supply is powered

from ports 4-6.

Introduction

The 1.2 GHz GS7000 Node is powered by one or two power supplies.

Power Distribution

1.2 GHz GS7000 Node power distribution functions are described below.

Page 44

Chapter 2 Theory of Operation

24

RF Amplifier Module

Port 3

Port 2

Port 1

1.2GHz GS7000 Node

4 Way Forward Segmentable Launch Amplifier Module

Digital

Control

Pre

Amp

Forward Configuration

Module

Forward Input

R1R2R4

Digital

Control

R3

G

Pre

Amp

AC 2

Power

Surge

Protection

Rev. TP

Fwd. TP

Rev. TP

Fwd. TP

Fwd. TP

Port 6

Rev. TP

Port 5

AC

Port 4

AC

AC

Output

GaN

Gain Block

Aux. Reverse

Injection

Director

Node Signal

Director

Splitter

Interstage

GaAs

Gain Block

Output

GaN

Gain Block

Tilt Pad EQ

Pad

Pad

Pad

EQPad

Pad

Pad

Ther

Ther

Interstage

GaAs

Gain Block

RF

Switch

RF

Switch

E

Pad

D

210 MHz Aux.

Reverse Injection

Option

F

DC

Switch

G

J

Surge

Protection

AC 1

Power

Rev. TP

Fwd. TP

Rev. TP

Fwd. TP

Fwd. TP

Rev. TP

AC

AC

AC

Aux. Reverse

Injection

Director

Node Signal

Director

Jumper

Output

GaN

Gain Block

Pad

Pad B

Tilt

EQ

Pad

Ther

Pad

210 MHz Aux.

Reverse Injection

Option

C

A

Output

GaN

Gain Block

Pad

Pad

EQ PadPad

Ther

DC

Switch

Interstage

GaAs

Gain Block

J

RF

Switch

RF

Switch

Pre

Amp

Interstage

GaAs

Gain Block

TrimTrim

Trim

Trim

Field Accessable

Plug-In

Factory

Plug-In

Field Accessable

Split Upgrade

Low

High

Low

High

Low

High

Low

High

Low

High

Introduction

This section describes the RF amplifier module. The RF amplifier module contains

the forward band and the reverse band amplifiers.

Functional Diagrams

The following diagrams show how the RF amplifier functions.

Page 45

RF Amplifier Module

25

Reverse Amplifier PWB

Reverse Amplifier IC

with Integrated Attenuator

Digital Att

(Off - 0 - 6 dB)

Trim

RF

Switch

Trim

RF

Switch

Trim

RF

Switch

Trim

RF

Switch

Reverse Amplifier

Digital Control Circuitry

Digital Control

Digital Control

Parallel

Output

Digital Control

Digital Control

Reverse

Aux.

Jumper/

Comb./

Amp./

Term./

Module

LPF

LPF

LPF

LPF

Serial

Input

T4

T2

T1

T3

. . .

Optical Interface PWB

Status Monitor or

Local Control Module

Receiver 1

Receiver 2

Receiver 3

Receiver 4

Power Supply 1

Power Supply 2

Pad

Pad

Pad

Pad

R1

R2

R3

R4

RF

Switch

To Forward

Amplifier

Reverse

Config.

Module

Control

Digital Att

(Off - 0 - 6 dB)

Digital Att

(Off - 0 - 6 dB)

Digital Att

(Off - 0 - 6 dB)

EN

EN

EN

EN

Transmitter 4

Transmitter 3

Transmitter 2

Transmitter 1

Pad

Pad

Pad

T4

T2

T3

T1

Pad

Pad

Field Accessable

Plug-In

Field Accessable

Split Upgrade

Forward Band Amplification 4-Way Path Description

The RF amplifier module provides all forward signal amplification outside the

optical receiver modules in the GS7000 Node.

The 4-way segmentable launch amplifier contains four independent forward

amplification paths, each having one input near the center of the amplifier module

and one, two or three outputs at one end of the amplifier module. Each of the

forward paths is comprised of the forward configuration module, an input gain

block, a frequency response trim circuit, a thermal compensation circuit, an

inter-stage pad, a 2-way splitter or RF switch circuit, an inter-stage gain block, a

plug-in forward band linear equalizer, an output pad, an output gain block, a diplex

filter, a bi-directional 20 dB down forward test point, and finally an AC bypass

circuit.

The thermal circuit on the RF amplifier module is designed to compensate for the RF

forward path thermal movement of the entire node RF station. This includes the

forward path amplifier module circuitry, RF cables, and optical interface board

Page 46

Chapter 2 Theory of Operation

26

circuitry. It does not include the thermal movement of the optical receivers.

Forward Configuration Module

The forward configuration module determines the forward path topology in the RF

amplifier module and the 1.2 GHz GS7000 Node. The output signals from one to

four optical receivers enter the forward configuration module where they are

combined and or directed to the two or four independent forward paths in the RF

amplifier module. Forward path segmentation and/or redundancy are set by

plugging the appropriate forward configuration module into the RF amplifier

module. The forward configuration module is a plug-in, field accessible module. See

Forward Configuration Module (on page 29) for more information.

Forward Band Linear Equalizer Module

The forward band linear equalizer module sets the overall forward path tilt of the RF

amplifier module and the 1.2 GHz GS7000 Node. The 1.2GHz GS7000 Node launch

amplifier is shipped with four 18.0 dB linear equalizers installed in the RF amplifier

module. One equalizer is installed in each of the four amplifier module forward

paths. This sets the nodes forward path tilt to 17.5 dB linear. Forward band linear

equalizer modules of other values are available. This allows the nodes forward path

tilt to be adjusted as needed. The forward band linear equalizer module is a plug-in,

field accessible module. See the equalizer charts in Appendix A - Technical

Information.

Node Signal Director Jumper/Splitter Module

The node signal director jumper/splitter module is a plug-in, field accessible module.

It is present on the center output ports on either end of the RF amplifier module. The

orientation of these modules determines where the RF amplifiers center output port

signals are directed. The node signal director jumper allows the center output port

signals to be routed to either the amplifiers primary center output port or to its

auxiliary corner output port. The node signal director splitter module splits the

center output port signals equally between the primary and auxiliary output ports.

Auxiliary Reverse Injection Director Module

The auxiliary reverse injection director module is a plug-in module. It is accessible

only after the RF amplifier modules cover has been removed. Auxiliary reverse

injection director modules are present on the auxiliary corner output ports on either

end of the RF amplifier module. The orientation of these modules determine if the

nodes auxiliary output ports are configured to be primary or split node output ports,

or local reverse injection ports.

Page 47

RF Amplifier Module

27

Reverse Band Amplification Path Description

The RF amplifier module provides all reverse signal amplification outside the optical

transmitter modules in the 1.2 GHz GS7000 Node. It contains four independent

reverse paths comprised of an AC bypass circuit, a bi-directional 20 dB down reverse

test point, a diplex filter, an input pad, a low pass filter, a 6 dB switched attenuator, a

16 dB gain block, a second low pass filter, an RF on/off switch, a frequency response

trim circuit, and a reverse configuration module. The 6 dB switched attenuator and

RF on/off switch circuits allow each reverse path to have 6 dB (wink) and on/off

capabilities. These circuits are controllable from the headend via the status monitor

or locally via the local control module and a hand held controller. A serial

communication link is provided between status monitor or local control module and

the reverse band launch amplifier. Circuitry on the amplifier converts the serial

communications to parallel control signals and routes them as needed.

The RF amplifier module also provides the routing for the auxiliary ports, 5 to 210

MHz reverse band local injection signals. Each of the two auxiliary port reverse band

local injection paths is comprised of an AC bypass circuit, a bi-directional 20 dB

down reverse test point, an input pad, and a reverse auxiliary

jumper/amplifier/termination module. Signals from port 3 or port 6 of the nodes

auxiliary path are directed by the reverse auxiliary/jumper/amplifier/termination

module to the reverse configuration module.

Reverse Configuration Module

The reverse configuration module determines the reverse path topology in the RF

amplifier module and 1.2 GHz GS7000 Node. The input signals from four

independent amplifier module output ports and possibly the auxiliary reverse

injection amplifier module port enter the reverse configuration module where they

are combined and/or directed to one to four optical transmitters. Reverse path

segmentation and or redundancy as well the ability to locally inject signals into the

reverse path of the amplifier is set by plugging the appropriate reverse configuration

module into the RF amplifier module. The reverse configuration module is a plug-in,

field accessible module. See Reverse Configuration Module (on page 34) for more

information.

Reverse Auxiliary Jumper/Combiner/Amplifier/Termination Module

The reverse auxiliary jumper/combiner/amplifier/termination module determines

how reverse band signals, locally injected into the RF amplifier modules auxiliary

ports, are routed within the amplifier module. The reverse auxiliary jumper module

directs signals for one of the RF amplifiers auxiliary ports to the reverse

configuration module.

The reverse auxiliary amplifier module amplifies signals for one or both of the RF

Page 48

Chapter 2 Theory of Operation

28

amplifiers auxiliary ports and directs them to the reverse configuration module. The

reverse auxiliary termination module terminates both auxiliary port reverse injection

signal paths in 75 ohms as well as the path to the reverse configuration module.

Page 49

Forward Configuration Module

29

Forward Configuration Module

Introduction

The forward configuration module determines the forward path topology in the RF

amplifier module and the 1.2 GHz GS7000 Node. The output signals from one to

four optical receivers enter the forward configuration module where they are

combined or directed to the four independent forward paths in the RF amplifier

module. The various types of the forward configuration module are described

below.

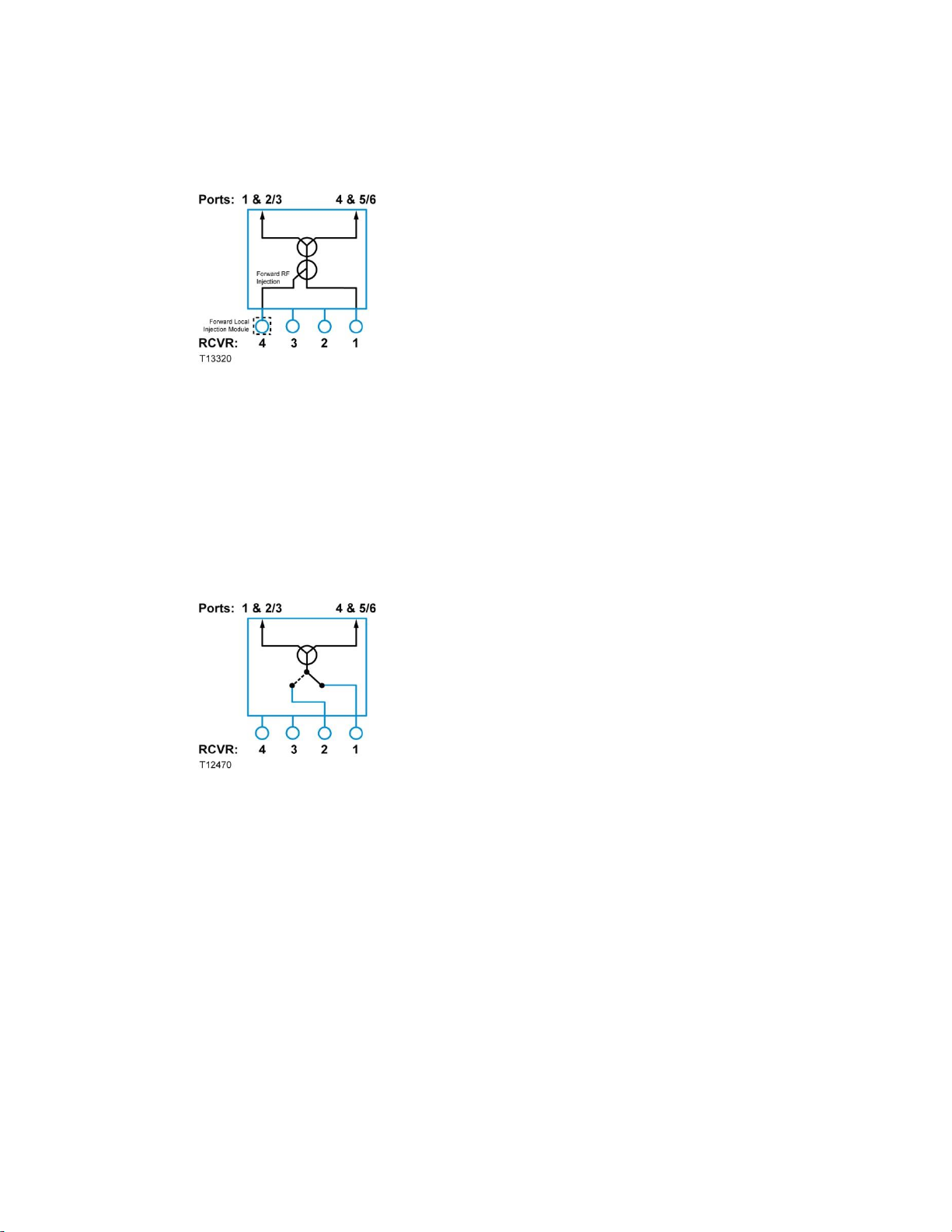

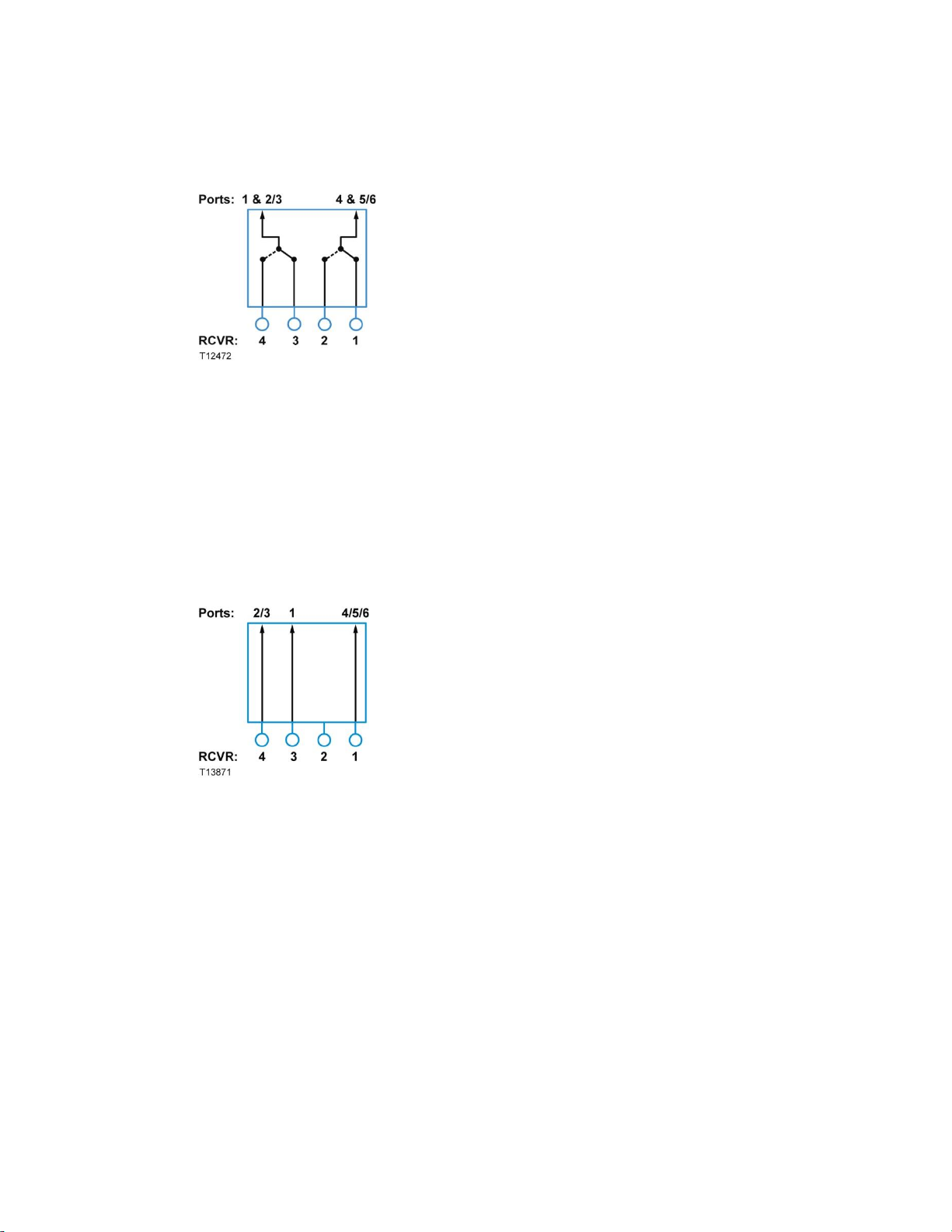

1x4 Forward Configuration Modules Description

The 1x4 Forward Configuration Module is used when the 1.2 GHz GS7000 Node is

configured with a single optical receiver routed to all four outputs of the RF

amplifier module. This module splits the signals equally to the inputs of the RF

amplifier module.

The following diagram shows how this module functions.

1x4 Forward Configuration Modules with Forward RF Injection

Description

The 1x4 Forward Configuration Modules with forward RF injection are similar to the

1x4 Forward Configuration Modules, but are used with the Forward Local Injection

(FLI) Module. The FLI Module routes an RF signal from an external source to the

Forward Configuration Module which is then coupled with other inputs from an

optical receiver.

The following diagram shows how this module functions.

Page 50

Chapter 2 Theory of Operation

30

1x4 Redundant Forward Configuration Modules Description

The 1x4 Redundant Forward Configuration Module is used when the 1.2 GHz

GS7000 Node is configured with two optical receivers routed to all four outputs of

the amplifiers in a redundant configuration. Receiver 1 is the primary receiver and

Receiver 2 is the backup. The active receiver is selected with a digital signal from the

status monitor/local control module.

The following diagram shows how this module functions.

1x4 Redundant Forward Configuration Modules with Forward RF

Injection Description

The 1x4 Redundant Forward Configuration Modules with forward RF injection are

similar to the 1x4 Redundant Forward Configuration Modules, but are used with the

Forward Local Injection (FLI) Module. The FLI Module routes an RF signal from an

external source to the Forward Configuration Module which is then coupled with

other inputs from an optical receiver.

The following diagram shows how this module functions.

Page 51

Forward Configuration Module

31

2x4 Forward Configuration Modules Description

The 2x4 Forward Configuration Module is used when the 1.2 GHz GS7000 Node is

configured with two optical receivers, each feeding two outputs of the amplifier

module. In this configuration, the node serving area is divided in half in the forward

direction. Receiver 1 is routed to RF amplifier Ports 4 and 5/6, while Receiver 3 is

routed to RF amplifier Ports 1 and 2/3.

The following diagram shows how this module functions.

2x4 Redundant Forward Configuration Modules Description

The 2x4 Redundant Forward Configuration Module is used when the 1.2 GHz

GS7000 Node is configured with four optical receivers with each pair feeding two RF

outputs of the amplifier module in a redundant configuration. In this configuration,

the node serving area is divided in half for redundancy in the forward direction.

Receivers 1 (primary) and 2 (redundant) are routed to RF amplifier Ports 4 and 5/6,

while Receivers 3 (primary) and 4 (redundant) are routed to RF amplifier Ports 1 and

2/3. The active receiver is selected with digital signal from the status monitor/local

control module.

The following diagram shows how this module functions.

Page 52

Chapter 2 Theory of Operation

32

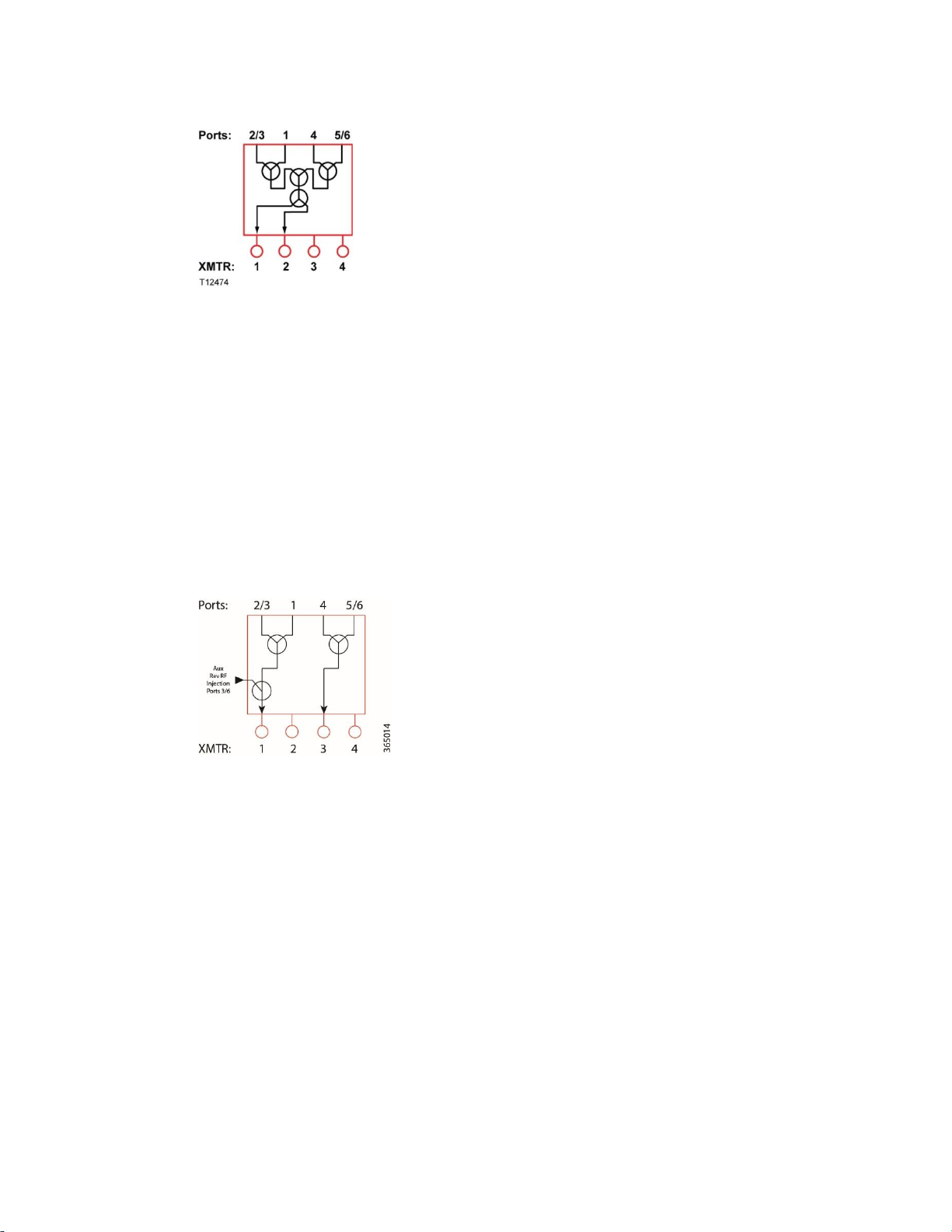

3x4-1, 3, 4 Forward Configuration Module Description

The 3x4-1, 3, 4 Forward Configuration Module is used when the 1.2 GHz GS7000

Node is configured with three receivers each feeding one/two/three/four outputs

of the amplifier module. Receiver 1 is routed to RF amplifier ports 4/5/6, Receiver 3

is routed to port 1, and Receiver 4 is routed to ports 2/3.

Note: The 3x4-1, 3, 4 FCM can only be used with the 4-way RF amplifier module.

The following diagram shows how this module functions.

3x4-1, 2, 4 Forward Configuration Module Description

The 3x4-1, 2, 4 Forward Configuration Module is used when the 1.2 GHz GS7000

Node is configured with three receivers each feeding one/two/three/four outputs

of the amplifier module. Receiver 1 is routed to RF amplifier ports 5/6, Receiver 2 is

routed to port 4, and Receiver 4 is routed to ports 1/2/3.

Note: The 3x4-1, 2, 4 FCM can only be used with the 4-way RF amplifier module.

The following diagram shows how this module functions.

Page 53

Forward Configuration Module

33

4x4 Forward Configuration Module Description

The 4x4 Forward Configuration Module is used when the 1.2 GHz GS7000 Node is

configured with four optical receivers with each feeding separate RF outputs of the

amplifier module. Receiver 1 is routed to RF amplifier Ports 5/6. Receiver 2 is routed

to RF amplifier Port 4. Receiver 3 is routed to RF amplifier Port 1. Receiver 4 is

routed to RF amplifier Ports 2/3.

Note: The 4x4 FCM can only be used with the 4-way RF amplifier module.

The following diagram shows how this module functions.

Page 54

Chapter 2 Theory of Operation

34

Reverse Configuration Module

Introduction