Page 1

GETTING STARTED GUIDE

Cisco 2500 Series Wireless Controller

May 2011

Revised June 2, 2011

1 About This Guide

2 Unpacking and Preparing the Controller for Operation

3 Installing the Controller

4 Running the Bootup Script and Power-On Self Test

5 Logging into the Controller

6 Connecting to the Network

7 What’s New in Cisco Product Documentation

8 Translated Safety Warnings

Page 2

1 About This Guide

This guide is designed to help you install and minimally configure your Cisco 2504 Wireless Controller

(2504 controller), which is part of the Cisco 2500 Series Wireless Controllers.

FCC Safety Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on.

Try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help. (cfr reference 15.105)

Safety Information

Safety warnings appear throughout this guide in procedures that may harm you if performed

incorrectly. A warning symbol precedes each warning statement. The warnings below are general

warnings that are applicable to the entire guide. Translated versions of the safety warnings in this guide

are provided in the “Translated Safety Warnings” section on page 38.

Warning

2

This warning symbol means danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical

circuitry and be familiar with standard practices for preventing accidents. Use the

statement number provided at the end of each warning to locate its translation in the

translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Statement 1071

Page 3

Warning

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery

only with the same or equivalent type recommended by the manufacturer. Dispose of

used batteries according to the manufacturer’s instructions.

Statement 1015

Warning

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the

equipment in the absence of a suitably installed ground conductor. Contact the

appropriate electrical inspection authority or an electrician if you are uncertain that

suitable grounding is available.

Ultimate disposal of this product should be handled according to all national laws and

regulations.

Statement 1040

Statement 1024

Safety Considerations

• Verify that the ambient temperature remains between 32 to 104° F (0 to 40° C), taking into

account the elevated temperatures when installed in a rack or enclosed space.

• When multiple 2504 controllers are mounted in an equipment rack, be sure that the power source

is sufficiently rated to safely run all the equipment in the rack (input: 100 to 240 VAC, 50–60 Hz,

output: 80 W per controller).

• Verify the integrity of the electrical ground before installing the controller.

Introduction to the Controller

The 2504 controller works in conjunction with Cisco lightweight access points and the Cisco Wireless

Control System (WCS) to provide system-wide wireless LAN functions. As a component of the Cisco

Unified Wireless Network (CUWN), the 2504 controller provides real-time communication between

wireless access points and other devices to deliver centralized security policies, guest access, Wireless

Intrusion Prevention System (WIPS), context-aware (location), award-winning RF management,

quality of services for mobility services such as voice and video, and OEAP support for the Teleworker

solution.

The 2504 controllers supports up to 50 lightweight access points in increments of 5 access points with

a minimum of 5 access points, making it a cost-effective solution for retail, enterprise branches, and

small and medium-sized businesses. The 2504 controller comes with four 4 Gigabit Ethernet ports.

3

Page 4

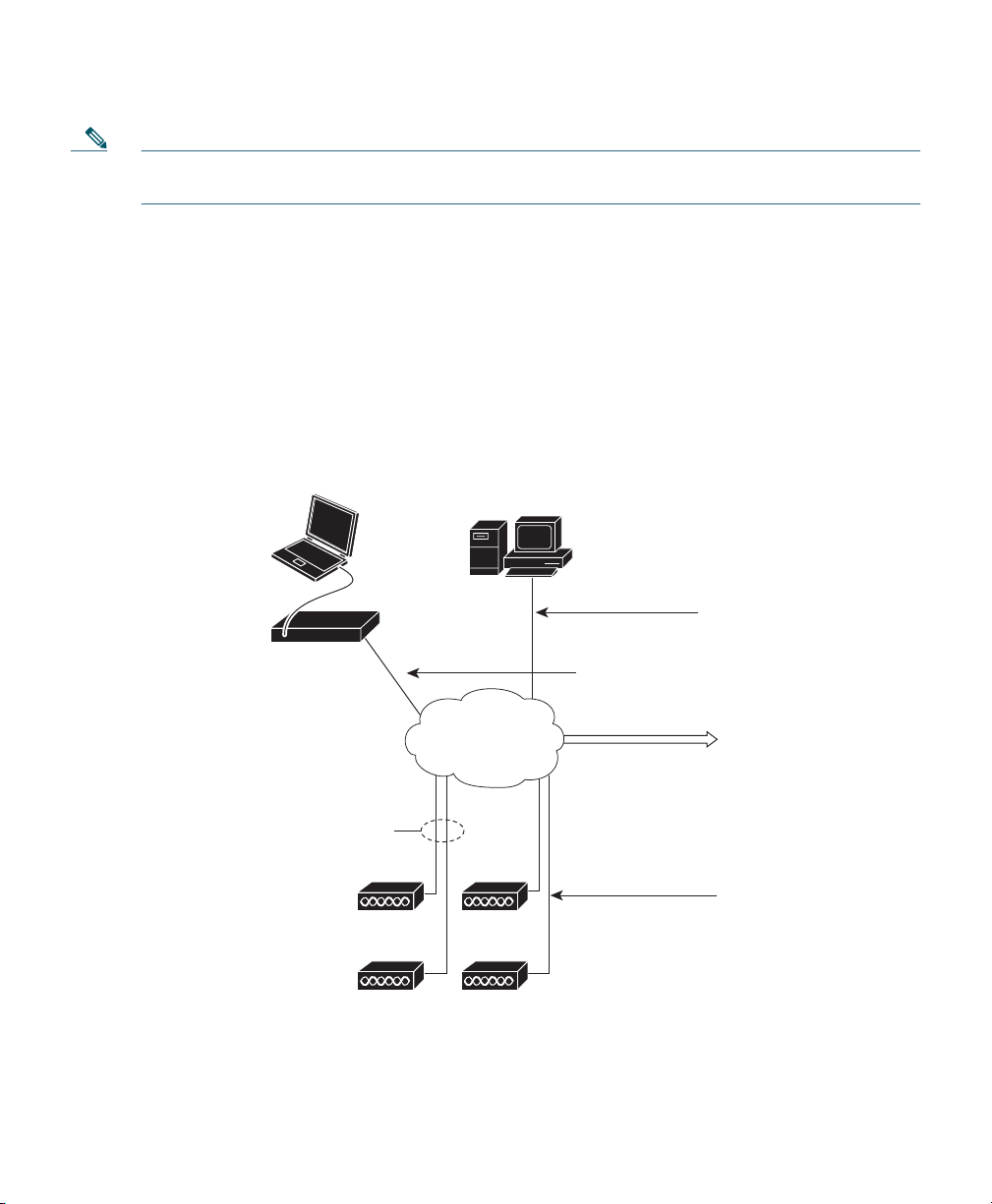

Note Direct connection of access points to Cisco 2500 Series Wireless Controllers are not currently

c

t

Console emulator

supported.

The 2504 controller offers robust coverage with 802.11 a/b/g and delivers unprecedented reliability

using 802.11n with Cisco Next-Generation Wireless Solutions and Cisco Enterprise Wireless Mesh.

To best use this guide, you should have already designed the wireless topology of your network and

have a working knowledge of how controllers function in a wireless LAN network.

Figure 1 shows a 2504 controller network topology and network connections, showing the medium

dependent interface (MDI) Ethernet cables required. The controller has an auto MDI feature, so you

can use straight-through or crossover cables.

Figure 1 Typical Controller Topology and Network Connections

for initial boot-up

Null modem serial

able (DB-9 -> RJ-45)

o console connection

10/100/1000BASE-T

10/100/1000BASE-T

MDI cables

Cisco Access Points

MDI cable

Network

Cisco WCS software,

web user interface

LAN link for

management software

Distribution

system

connection

connections

WAN or LAN

connection to

main office

Access

point

connections

282297

4

Page 5

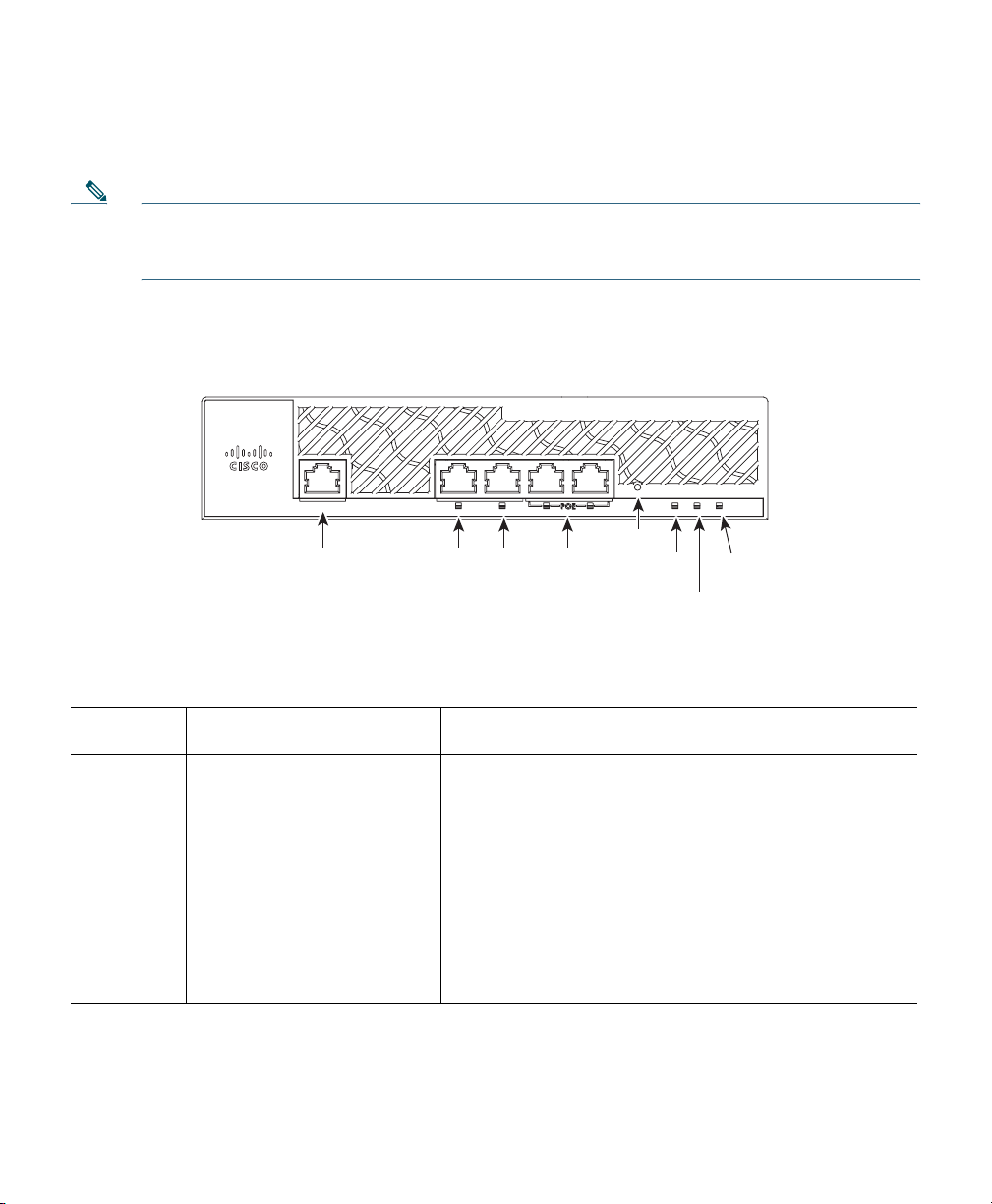

Figure 2 shows the front panel and location of the ports and light-emitting diodes (LEDs) for the 2504

controller. Table 1 describes the components of the front panel.

Note It is expected that there will be small variations in LED color intensity and hue from unit to

unit. This is within the normal range of the LED manufacturer’s specifications and is not a

defect.

Figure 2 Front Panel and LEDs

CISCO 2500 Series WIRELESS CONTROLLER

CONSOLE

1234

1CONSOLE 2 3-4 POE

Ta b l e 1 WLC2504 Front Panel Component Descriptions

Callout Port and LEDs State and Description

CONSOLE

CPU console port The CPU console port is an RS-232 port that supports

a RJ-45 connector. At boot-up the controller configures

the RS-232 port as a console port with default settings

of 9600, N, 8, 1. The boot-loader supports baud rates

of 1200, 2400, 4800, 9600, 19200, 38400, 57600, and

115200. A default baud-rate recovery mechanism is not

available; however the bootloader ensures that the

stored baud rate setting matches one of the allowed

values before setting the baud rate. If a nonstandard

value is detected the baud rate will default to 9600.

RESET

RESET

Model 2504

PWR SYS ALM

PWR ALM

SYS

282249

5

Page 6

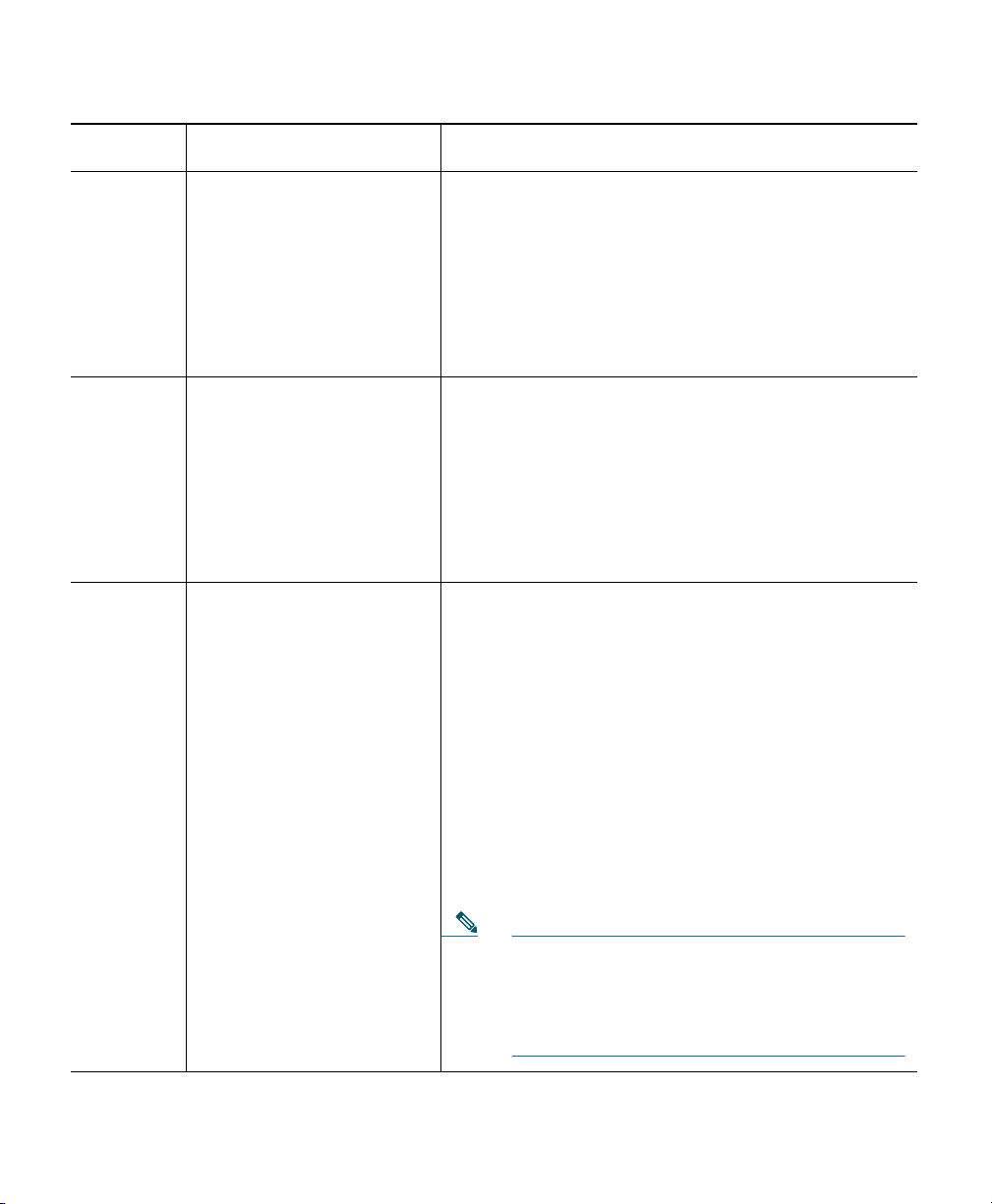

Callout Port and LEDs State and Description

1

2

3 & 4 POE

GigE port and LED The Gigabit Ethernet port is an RJ-45 connector

form-factor. This port is designed so that 1500 VAC rms

isolation (per the 802.3 specification) is met between

chassis ground and any 48V/Ethernet signal.

LED description:

• Green or Blinking Green—Link activity

• Off—No link

GigE port and LED The Gigabit Ethernet port is an RJ-45 connector

form-factor. This port is designed so that 1500 VAC rms

isolation (per the 802.3 specification) is met between

chassis ground and any 48V/Ethernet signal.

LED description:

• Green or Blinking Green—Link activity

• Off—No link

GigE Power-over-Ethernet

(POE) ports

The Gigabit POE ports are RJ-45 connector

form-factor. They provide a I2C communications

channel between the PSE controller and host CPU TWSI

bus #1. This interface supports the proper voltage

isolation as defined by 802.3. The POE controller is

configured to I2C address 0x40/41 (0100 000r/w).

The POE controller reset is driven from system reset. If

software needs to reset the POE controller, it can do so

over I2C.

LED description:

• Green or Blinking Green—Link activity

• Off—No link

Note Ports 3 and 4 are PoE only ports; do not

connect access point devices to these ports. The

ports can be used for infra-switch connection

using multiple an AP-Manager or data

interface.

6

Page 7

Callout Port and LEDs State and Description

RESET

PWR

SYS

ALM

Reset button Pushing the Reset button reboots the system.

Power LED The power LED light is on when all the power

conversion circuits are running normally.

LED description:

• Green—Power is on

• Off—No power to the system

System LED The system LED determines if the system is powered up.

LED description:

• Blinking Amber—Boot-loader is active and waiting

for user input from the system console.

• Blinking Green—Boot-loader or booting.

• Green—Normal System Operation.

• Amber—System failed the bootup process or an

error caused the system to halt. A status or error

message is posted on the console screen.

• Off—System not receiving power.

Alarm LED The alarm LED determines a status or error occurred.

The status or error is posted on the console screen.

LED description:

• Blinking Green—Controller image upgrading.

• Amber—Controller status activity, such as

firmware upgrade.

• Blinking Amber—Controller error. For example, a

temperature error exists.

Caution Do not connect a Power over Ethernet (PoE) cable to the console port. Doing so will

damage the controller.

7

Page 8

Note Wait at least 20 seconds before reconnecting an access point to the controller. Otherwise, the

controller may fail to detect the device.

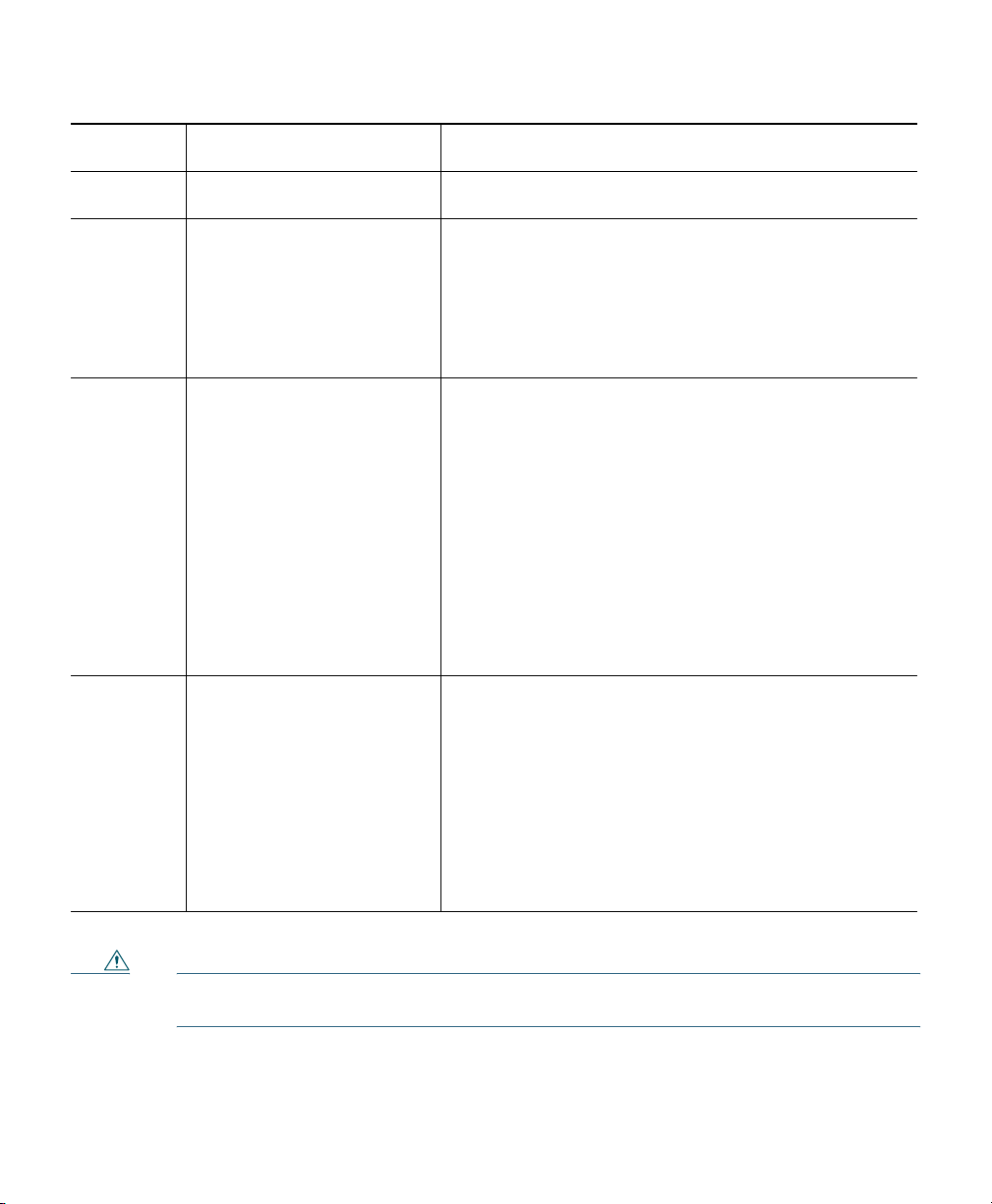

Figure 3 shows the back panel and identifies its components. Table 2 describes the back panel

components.

Figure 3 Controller Back Panel and Components

282250

Cable Lock

POWER 48VDC

Ta b l e 2 Controller Back Panel and Component Descriptions

Slot

Ports and Slots State and Description

POWER 48VDC The 48 V input power is provided via an external

AC/DC adapter. Power is provided to the system board

from the 48 VDC input. There is enough power

available to power the system board plus two 802.3af

PoE devices.

Note The Cisco 2106 power adapter is not

compatible with a 2504 controller.

Cable Lock slot Security locking slot.

8

Page 9

2 Unpacking and Preparing the Controller for Operation

Follow these steps to unpack the 2504 controller and prepare it for operation:

Step 1 Open the shipping container and carefully remove the contents.

Step 2 Return all packing materials to the shipping container and save it.

Step 3 Ensure that all items listed in the “Package Contents” section are included in the shipment.

Check each item for damage. If any item is damaged or missing, notify your authorized Cisco

sales representative.

Package Contents

Each 2504 controller package contains the following items:

• One Cisco 2504 Wireless Controller.

• One Power supply and power cord (power cord option configurable).

• Cisco 2504 Wireless Controller software pre-loaded on the controller (software option

configurable).

• Optional licenses will be pre-installed on controller at factory, if selected.

• Two Number 6 Phillips pan-head screws for mounting the controller on a desk, shelf, or wall.

• Two wall anchors.

• Strain relief clip and screw.

• Optional hardware will be included, if selected.

Required Tools and Information

You will need the following tools and information before you can install the controller:

• Wireless controller hardware

–

Controller with factory-supplied power cord and mounting hardware

–

Network, operating system service network, and access point cables as required

• Command-line interface (CLI) console

–

VT-100 terminal emulator on CLI console (PC, laptop, or palmtop)

–

Null modem serial cable to connect CLI console and controller

9

Page 10

• Local TFTP server (required for downloading operating system software updates). Cisco uses an

integral TFTP server. This means that third-party TFTP servers cannot run on the same

workstation as the Cisco WCS because Cisco WCS and third-party TFTP servers use the same

communication port.

Initial System Configuration Information

Obtain the following initial configuration parameters from your wireless LAN or network

administrator:

• A system (controller name), such as controller. The system name can contain up to 32 printable

ASCII characters.

• An administrative username and password, which can contain up to 24 printable ASCII

characters.

Note You must enter a username and password and the configured username and password cannot

be the same.

• A management interface (DS Port or network interface port) IP address, such as 10.40.0.4.

• A management interface netmask address, such as 255.255.255.0.

• A management interface default router IP address, such as 10.40.0.5.

• A VLAN identifier if the management interface is assigned to a VLAN, such as 40 or 0 for an

untagged VLAN.

• A management interface port, such as 1.

• A management interface DHCP server IP address, such as 10.40.0.6 (the IP address of the default

DHCP server that will supply IP addresses to clients and the management interface.

• A virtual gateway IP address (a fictitious, unassigned IP address, such as 1.1.1.1, used by all Cisco

wireless controller Layer 3 security and mobility managers).

• A Cisco wireless controller mobility or RF group name, such as rfgrp40 if required. An RF group

name can contain up to 19 printable ASCII characters.

• An 802.11 network name (SSID), such as wlan1. An SSID can contain up to 32 printable,

case-sensitive ASCII characters.

• DHCP bridging

• Whether or not to allow static IP addresses from clients, either Yes or No.

–

Yes is more convenient, but has lower security (session can be hijacked).

–

No is less convenient, but has higher security and works well for Windows XP devices.

10

Page 11

• RADIUS server IP address, communications port, and secret if you are configuring a RADIUS

server, such as 10.40.0.3, 1812, and mysecretcode.

• The country code for this installation. Enter help to see a list or refer to the Cisco Wireless LAN

Controller Configuration Guide for country code information. This guide is available at

cisco.com.

• Status of the 802.11a, 802.11b, 802.11g, or 802.11n networks, either enabled or disabled.

• Status of Radio Resource Management (RRM), either enabled or disabled.

Choosing a Physical Location

You can install the controller almost anywhere, but it is more secure and reliable if you install it in a

secure equipment room or wiring closet. For maximum reliability, mount the controller while

following these guidelines:

• Make sure you can reach the controller and all cables attached to it.

• Make sure that water or excessive moisture cannot get into the controller.

• Make sure that airflow through the controller is not obstructed. Leave at least 4 in. (10 cm) clear

on both sides and rear of the controller.

• Verify that the ambient temperature remains between 32 to 104° F (0 to 40° C).

• Make sure that the controller is within 328 ft. (100 m) of equipment connected to the 10/100/1000

Mb/s Ethernet ports.

• Make sure that the power cord can reach a 100 to 240 VAC grounded electrical outlet.

3 Installing the Controller

This section includes the following installation procedures:

• Mounting the Controller, page 11

• Connecting the Controller Console Port, page 21

• Securing the Power Adapter Cable, page 21

• Installing a Security Lock, page 23

Mounting the Controller

This section includes the following mounting procedures:

• Mounting the Controller on a Desktop or Shelf

11

Page 12

• Mounting the Controller on a Wall (Rack-Mount Brackets)

• Mounting the Controller on a Wall (Mounting Screws)

• Mounting the Controller in a Rack

Mounting the Controller on a Desktop or Shelf

Before mounting the controller on a desktop or shelf, install the rubber feet located in accessory kit

shipped with the controller.

To install the rubber feet to the controller, follow these steps:

Step 1 Locate the adhesive strip with the rubber feet in the mounting-kit envelope.

Step 2 Remove the four rubber feet from the adhesive strip and attach the feet to the recessed areas

on the bottom of the unit as shown in

Note We strongly recommend that you attach the rubber feet. Doing so helps prevent airflow

restriction and overheating.

Figure 4 Installing the Rubber Feet on the Bottom of the Controller

Figure 4.

282084

12

Page 13

Step 3 Place the switch on the table or shelf near an AC power source.

Note Allow 3 inches of space around the controller ventilation openings to prevent airflow

restriction and overheating.

Step 4 After the controller is mounted on a shelf or desk, perform the following tasks to complete

the installation:

• Connecting the Controller Console Port

• Securing the Power Adapter Cable

• Connecting to the Network

Step 5 For configuration instructions about using the CLI setup program, see the “Running the

Bootup Script and Power-On Self Test” section on page 23.

Mounting the Controller on a Wall (Rack-Mount Brackets)

The controller can be mounted on a wall using an optional rack-mount bracket kit that is not included

with the controller. You can order a kit with 19-inch rack mounting brackets and hardware from

Cisco. The kit part number is AIR-CT2504-RMNT.

Warning

To mount the controller on a wall using rack-mount brackets, follow these steps:

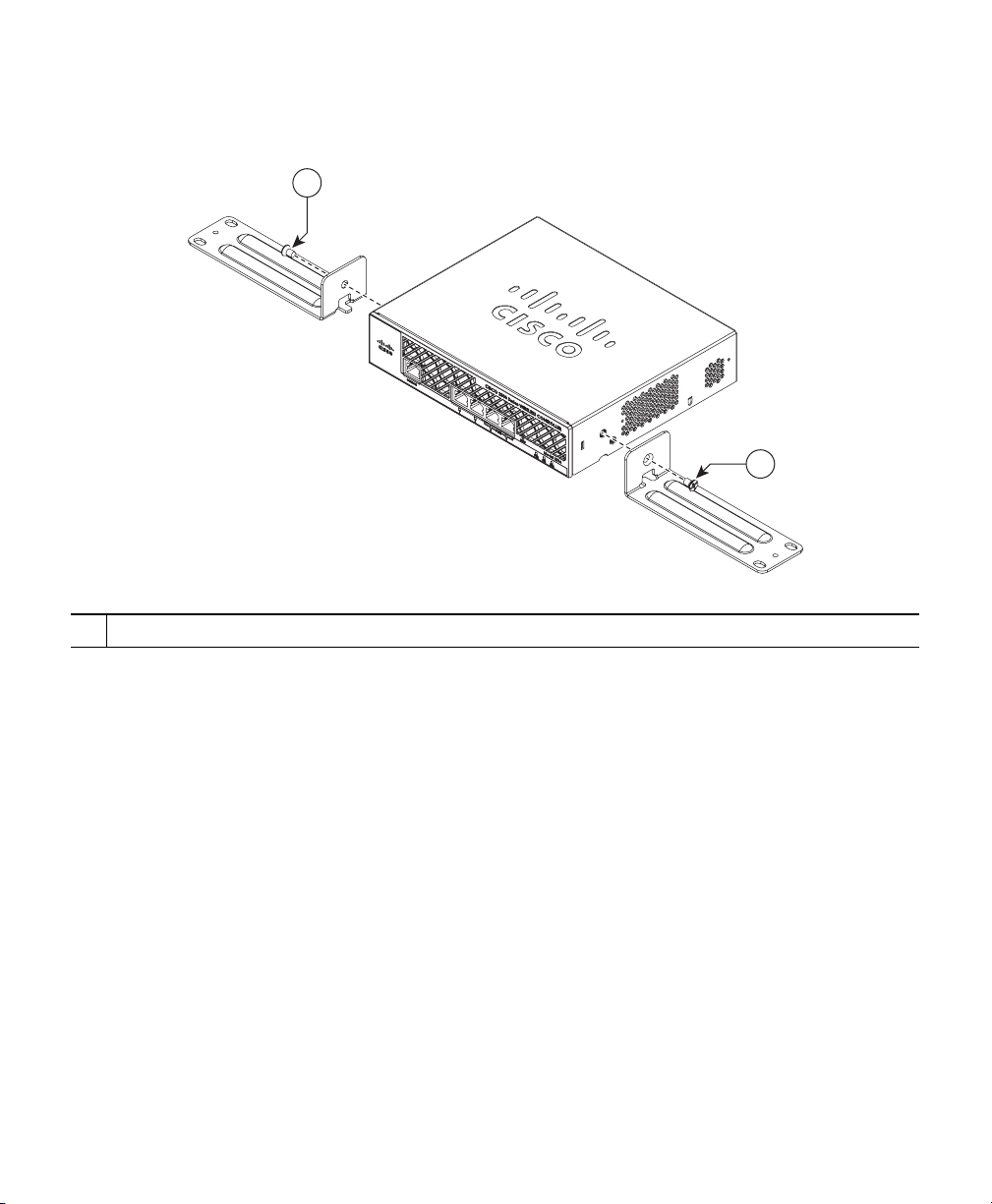

Step 1 Attach the 19-inch brackets to each side of the 2504 controller as shown in Figure 5 with

Read the wall-mounting carefully before beginning installation. Failure to use the

correct hardware or to follow the correct procedures could result in a hazardous

situation to people and damage to the system.

#10-32 flat head screws provided in the kit.

Statement 378

13

Page 14

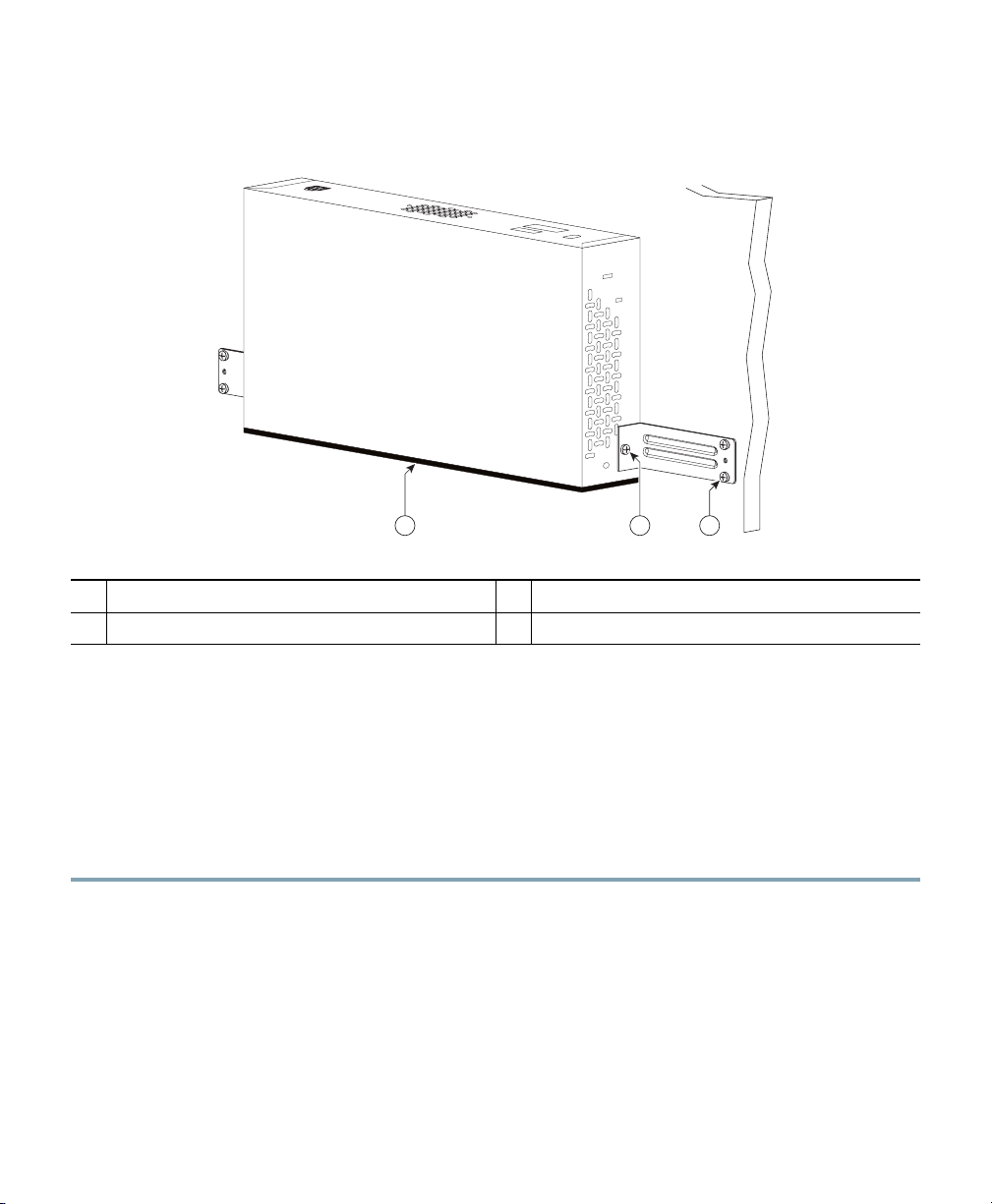

Figure 5 Installing the Rack-Mount Brackets to the Sides of the Controller

1

282083

BASE MOUNT

#10-32 flat head screws (mounting screws for each side of the controller)

1

1

Step 2 Mount the 2504 controller on the wall with the front panel facing down, as shown Figure 6.

For the best support of the controller and cables, make sure the controller is attached securely

to wall studs or to a firmly attached plywood mounting backboard.

14

Page 15

Figure 6 Mounting the Controller on the Wall

282085

Front panel (facing down)

1

#10-32 flat head screws

2

Wall mounting screws

3

2

31

Step 3 After the controller is mounted on the wall, perform the following tasks to complete the

installation:

• Connecting the Controller Console Port

• Securing the Power Adapter Cable

• Connecting to the Network

Step 4 For configuration instructions about using the CLI setup program, see the “Running the

Bootup Script and Power-On Self Test” section on page 23.

Mounting the Controller on a Wall (Mounting Screws)

When mounting the 2504 controller on a wall using mounting screws, always mount the controller

with the front panel facing down.

15

Page 16

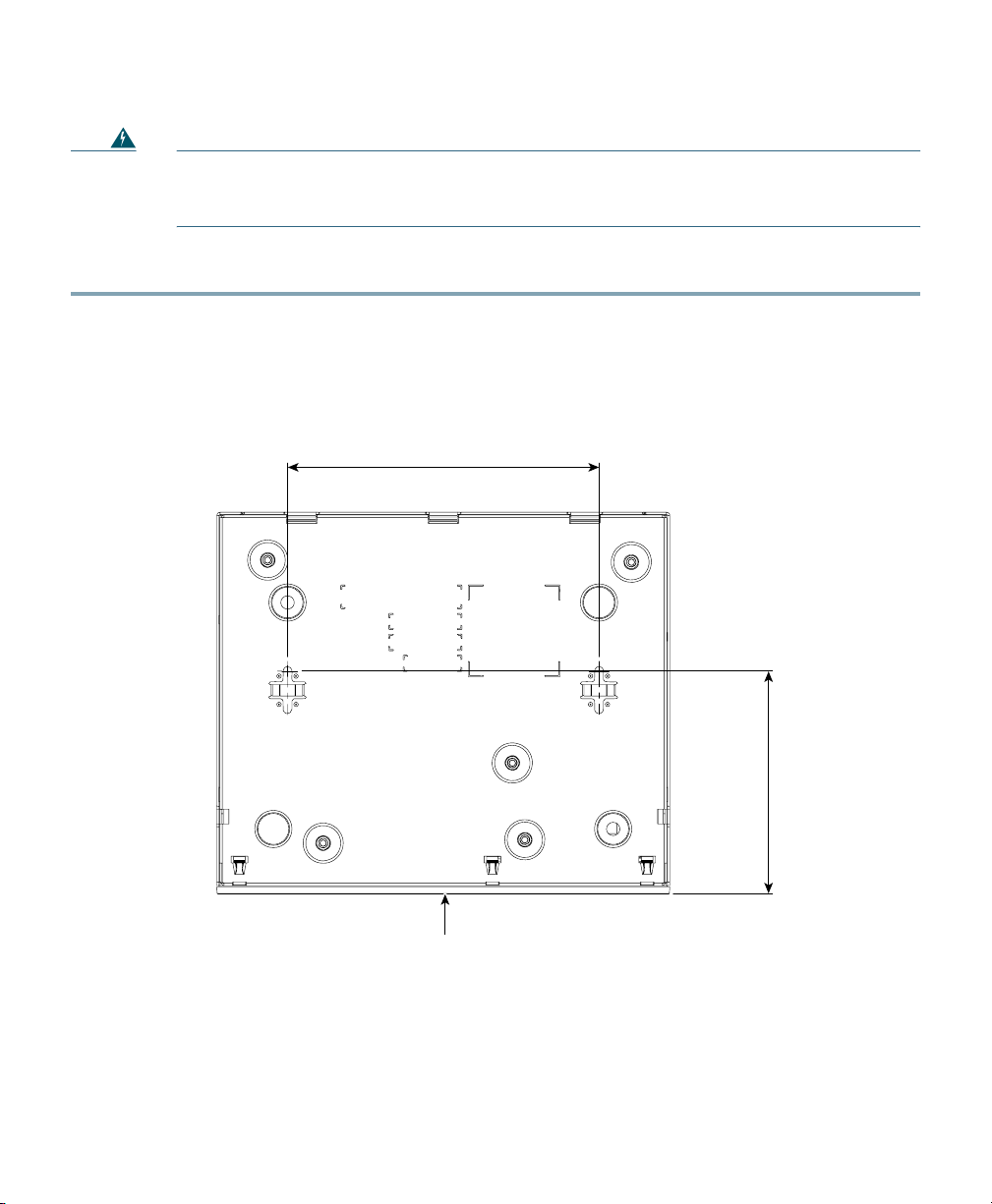

Warning

282087

5.5

Read the wall-mounting carefully before beginning installation. Failure to use the

correct hardware or to follow the correct procedures could result in a hazardous

situation to people and damage to the system.

Statement 378

To mount the controller on a wall using mounting screws, follow these steps:

Step 1 Mark the location of the mounting screws on the wall. Use the mount hole locations on the

back of the controller for placement of the mounting screws (

Figure 7). (The mount holes are

shown in Figure 7 with a cross-hatch mark.)

Figure 7 Mounting Screw Holes on the Back of the Controller

3.9

FRONT PANEL

Step 2 Use a 0.107-inch (2.7mm) or #32 drill bit to drill a 3/4 inch (19mm) hole for the two mounting

screws.

Step 3 Insert two screws into the screw holes and tighten until the top of the screws are 1/8 inch from

the wall (leaving enough room for the back panel to slide onto the screws firmly).

16

Page 17

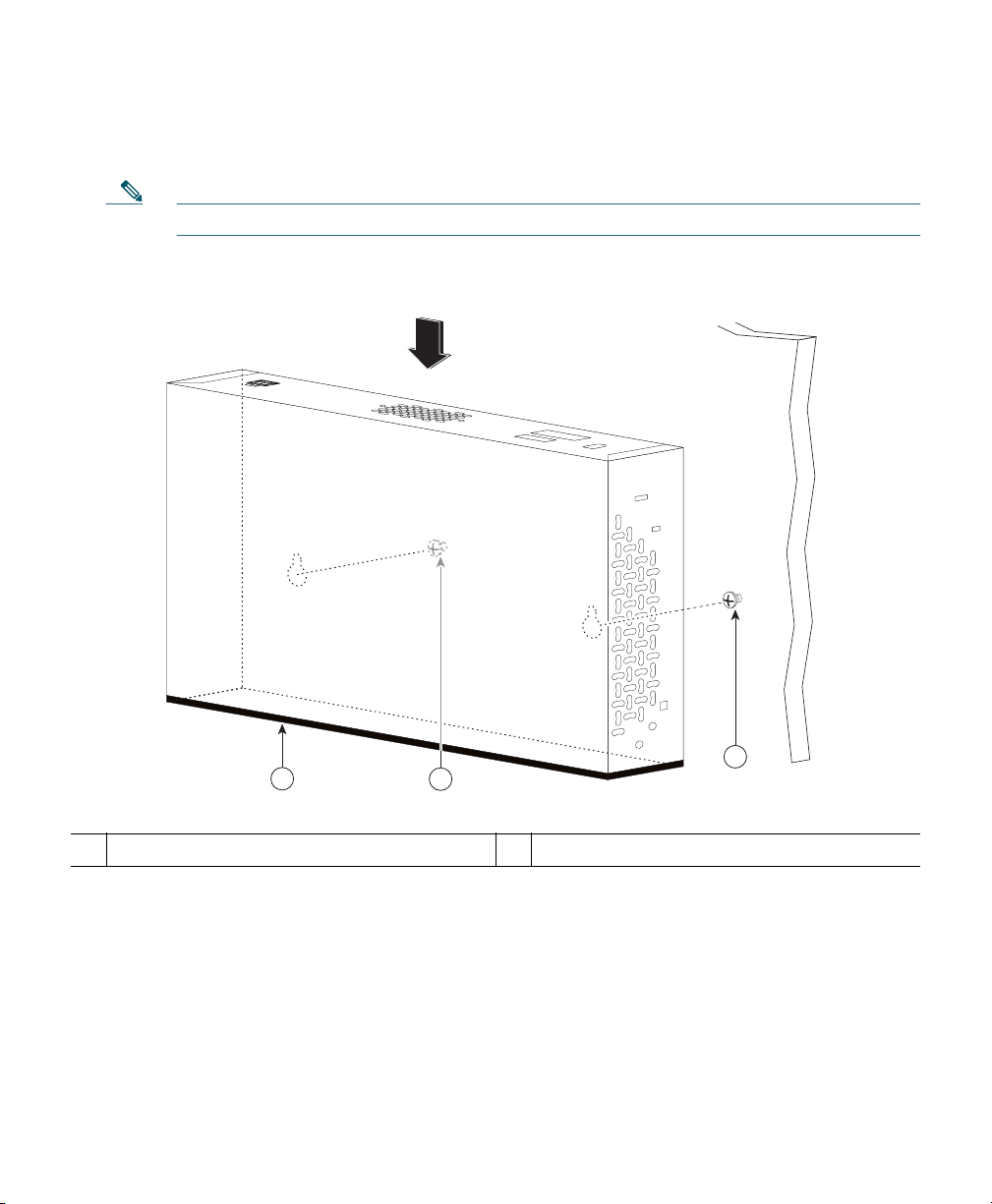

Step 4 Place the controller onto the mounting screws and slide it down until it lock into place, as

282085

shown in

Figure 8.

Note The front panel of the controller should be facing down.

Figure 8 Place the Controller on the Mounting Screws

2

Front panel (facing down)

1

1

2

Mounting screws

2

Step 5 After the controller is mounted ion the wall, perform the following tasks to complete the

installation:

• Connecting the Controller Console Port

• Securing the Power Adapter Cable

• Connecting to the Network

17

Page 18

Step 6 For configuration instructions about using the CLI setup program, see the “Running the

Bootup Script and Power-On Self Test” section on page 23.

Mounting the Controller in a Rack

To mount the 2504 controller in a 19-inch equipment rack, you can order an optional Optional Rack

Mount kit (AIR-CT2504-RMNT).

Warning

To install the controller in a rack, follow these steps.

Step 1 Attach the 19-inch brackets to each side of the controller as shown in Figure 9 with #10-32

To prevent bodily injury when mounting or servicing this unit in a rack, you must take

special precautions to ensure that the system remains stable. The following guidelines

are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the

top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the unit in the rack.

flat head screws provided in the kit.

Statement 1006

18

Page 19

Figure 9 Attaching the 19-Inch Brackets to the Side of the Controller.

1

RACK MOUNT

#10-32 flat head screws (mounting screws for each side of the controller)

1

282082

1

Step 2 After the brackets are attached to the sides of the controller, insert the controller into the

19-inch rack. Use either the 10-32 pan-head screws or the 12-24 slotted head screws to secure

the controller in the rack, as shown in

Figure 10.

19

Page 20

Figure 10 Mounting the Controller in a 19-Inch Rack

2

1

82086

#10-32 pan-head screws or #12-24 slotted head screws

1

Step 3 After the controller is mounted in the rack, perform the following tasks to complete the

installation:

• Connecting the Controller Console Port

• Securing the Power Adapter Cable

• Connecting to the Network

Step 4 For configuration instructions about using the CLI setup program, see the “Running the

Bootup Script and Power-On Self Test” section on page 23.

20

Page 21

Connecting the Controller Console Port

Caution Do not connect a Power over Ethernet (PoE) cable to the console port. Doing so will

damage the controller.

Before you can configure the 2504 controller for basic operations, you need to connect it to a PC that

uses a VT-100 terminal emulator (such as HyperTerminal, ProComm, Minicom, or Tip). To connect

the PC to the controller console port, follow these steps:

Step 1 Plug the RJ-45 connector on a null-modem serial cable into the controller console port and

the other end of the cable into the serial port of the PC.

Step 2 Start the PC terminal emulation program.

Step 3 Configure the terminal emulation program for the following parameters:

• 9600 baud

• 8 data bits

• No flow control

• 1 stop bit

• No parity

Securing the Power Adapter Cable

To secure the power adapter cable to the 2504 controller, use the plastic relief clip shipped with the

cable. The clip relieves the cable in the event it falls and prevents the connector from being sheared off

at the plug pins.

Caution If the relief clip is not installed, the power connector can be damaged if the power cable

is pulled or if the power adapter falls.

Note The Cisco 2106 power adapter is not compatible with a 2504 controller.

To secure the power adapter cable and plug, follow these steps:

21

Page 22

Step 1 Wrap the power adapter cable through the plastic security clip as shown in Figure 11.

Figure 11 Plastic Relief Clip

281917

Step 2 Fasten the security clip with a screw to the existing hole on the back panel on the 2504

controller (see

Figure 12).

Figure 12 Securing the Power Adapter Cable

281918

1

3

22

2

Page 23

Security clip secured with screw

1

AC/DC power adapter cable

2

Power plugged into the POWER 48VDC

3

port.

Installing a Security Lock

The controller has a security slot on the back panel. You can install an optional customer-supplied

cable lock, such as the type that is used to secure a laptop computer, to secure the controller. Refer to

Figure 3 for the location of the security lock.

4 Running the Bootup Script and Power-On Self Test

When you plug the controller into an AC power source, the bootup script initializes the system, verifies

the hardware configuration, loads its microcode into memory, verifies its operating system software

load, and initializes itself with its stored configurations. Before performing this test, you should have

connected your PC to the CLI console on the controller as described in the

Console Port” section on page 21.

To run the bootup script and conduct the power-on self test (POST), follow these steps:

“Connecting the Controller

Step 1 Plug the external power supply into the power jack on the back of the controller.

Step 2 Plug a country-specific power cord into the external power supply, then plug the other end

into a grounded 100 to 240 VAC, 50–60 Hz electrical outlet.

Note If you wish to run a previous release of the controller code, press Esc when the boot

loader prompt appears. The Bootloader Options menu appears.

Note When the controller receives power, the green front panel Power LED lights. If the

Power LED does not light, make sure that the electrical outlet is supplying power and

that the power connections to the controller are correct.

23

Page 24

Step 3 Observe the bootup using the CLI screen.

The bootup script displays operating system software initialization (code download and POST

verification) and basic configuration as shown in the following bootup display example:

CISCO SYSTEMS

WLCNG Boot Loader Version 1.0.15 (Built on Nov 23 2010 at 07:51:36 by cisco)

Board Revision 0.0 (SN: PSJ143302MT, Type: AIR-CT2504-K9) (P)

Verifying boot loader integrity... OK.

OCTEON CN5230C-SCP pass 2.0, Core clock: 750 MHz, DDR clock: 330 MHz (660 Mhz data

rate)

CPU Cores: 4

DRAM: 1024 MB

Flash: 32 MB

Clearing DRAM........ done

Network: octeth0', octeth1, octeth2, octeth3

' - Active interface

E - Environment MAC address override

CF Bus 0 (IDE): OK

IDE device 0:

- Model: 1GB CompactFlash Card Firm: CF B612J Ser#: C181101244A1Yb3A5QNU

- Type: Hard Disk

- Capacity: 977.4 MB = 0.9 GB (2001888 x 512)

Press <ESC> now to access the Boot Menu...

Continue booting the controller or press Esc to access the following menu:

============================================================

Boot Loader Menu

============================================================

1. Run primary image (7.0.114.76) - Active

2. Run backup image (7.0.114.75)

3. Change active boot image

4. Clear configuration

5. Format FLASH Drive

6. Manually update images

-----------------------------------------------------------Enter selection:

If you did not press Esc, the boot process continues and takes two to three

minutes. Do not reboot the controller until the user login prompt appears.

Loading primary image (7.0.114.76)

100%

31427987 bytes read

Launching images...

init started: BusyBox v1.6.0 (2010-05-13 17:50:10 EDT) multi-call binary

starting pid 672, tty '': '/etc/init.d/rcS'

type = block

dump-device = 254:4

disrupt

level = header

24

Page 25

compress = none

ifconfig: SIOCGIFFLAGS: No such device

Detecting Hardware ...

Installing ether-pow driver - 0x6008

starting pid 805, tty '/dev/ttyS0': '/usr/bin/gettyOrMwar'

Cryptographic library self-test....passed!

XML config selected

Validating XML configuration

octeon_device_init: found 1 DPs

/dev/fpga: No such device or address

readCPUConfigData: cardid 0x6060001

Cisco is a trademark of Cisco Systems, Inc.

Software Copyright Cisco Systems, Inc. All rights reserved.

Cisco AireOS Version 7.0.114.76

Firmware Version PIC 14.0

Initializing OS Services: ok

Initializing Serial Services: ok

Initializing Network Services: ok

Initializing Licensing Services: ok

Starting ARP Services: ok

Starting Trap Manager: ok

Starting Network Interface Management Services: ok

Starting System Services: ok

Starting Fastpath Hardware Acceleration: ok

Starting Fastpath Console redirect : ok

Starting Fastpath DP Heartbeat : ok

Fastpath CPU00: Starting Fastpath Application. SDK-1.8.0, build 269. Flags-[DUTY

CYCLE] : ok

Fastpath CPU00: Initializing last packet received queue. Num of cores(2)

Fastpath CPU00: Init MBUF size: 1856, Subsequent MBUF size: 2040

Fastpath CPU00: Core 0 Initialization: ok

Fastpath CPU00: Initializing Timer...

Fastpath CPU01: Core 1 Initialization: ok

Fastpath CPU00: Initializing Timer...done.

Starting Switching Services: ok

Starting QoS Services: ok

Starting Policy Manager: ok

Starting Data Transport Link Layer: ok

Starting Access Control List Services: ok

Starting System Interfaces: ok

Starting Client Troubleshooting Service: ok

Starting Management Frame Protection: ok

Starting Certificate Database: ok

Starting VPN Services: ok

Starting Licensing Services: ok

Starting LWAPP: ok

Starting CAPWAP: ok

Starting LOCP: ok

Starting Security Services: ok

25

Page 26

Starting Policy Manager: ok

Starting Authentication Engine: ok

Starting Mobility Management: ok

Starting Virtual AP Services: ok

Starting AireWave Director: ok

Starting Network Time Services: ok

Starting Cisco Discovery Protocol: ok

Starting Broadcast Services: ok

Starting Logging Services: ok

Starting DHCP Server: ok

Starting IDS Signature Manager: ok

Starting RFID Tag Tracking: ok

Starting Power Supply and Fan Status Monitoring Service: ok

Starting Mesh Services: ok

Starting TSM: ok

Starting CIDS Services: ok

Starting Ethernet-over-IP: ok

Starting DTLS server: enabled in CAPWAP

Starting CleanAir: ok

Starting WIPS: ok

Starting SSHPM LSC PROV LIST: ok

Starting RRC Services: ok

Starting FMC HS: ok

Starting Management Services:

Web Server: ok

CLI: ok

Secure Web: Web Authentication Certificate not found (error). If you cannot

access management interface via HTTPS please reconfigure Virtual Interface.

License Agent: ok

(Cisco Controller)>

Step 4 If desired, press Esc key to interrupt the boot process and access the Boot menu.

26

Page 27

Step 5 Continue booting the controller or press Esc to access the following menu:

1. Run primary image (7.0.114.76) - Active

2. Run backup image (7.0.114.75)

3. Change active boot image

4. Clear configuration

5. Format FLASH Drive

6. Manually update images

-----------------------------------------------------------Enter selection:

If you did not press Esc, the boot process continues and takes two to three minutes. Do not

reboot the controller until the user login prompt appears.

Loading primary image (7.0.114.76)

100%

31427987 bytes read

Launching images...

init started: BusyBox v1.6.0 (2010-05-13 17:50:10 EDT) multi-call binary

starting pid 672, tty '': '/etc/init.d/rcS'

type = block

dump-device = 254:4

disrupt

level = header

compress = none

ifconfig: SIOCGIFFLAGS: No such device

Detecting Hardware ...

Installing ether-pow driver - 0x6008

starting pid 805, tty '/dev/ttyS0': '/usr/bin/gettyOrMwar'

Cryptographic library self-test....passed!

XML config selected

Validating XML configuration

octeon_device_init: found 1 DPs

/dev/fpga: No such device or address

readCPUConfigData: cardid 0x6060001

Cisco is a trademark of Cisco Systems, Inc.

Software Copyright Cisco Systems, Inc. All rights reserved.

Cisco AireOS Version 7.0.114.76

Firmware Version PIC 14.0

Initializing OS Services: ok

Initializing Serial Services: ok

Initializing Network Services: ok

Initializing Licensing Services: ok

Starting ARP Services: ok

Starting Trap Manager: ok

Starting Network Interface Management Services: ok

Starting System Services: ok

Starting Fastpath Hardware Acceleration: ok

Starting Fastpath Console redirect : ok

27

Page 28

Starting Fastpath DP Heartbeat : ok

Fastpath CPU00: Starting Fastpath Application. SDK-1.8.0, build 269. Flags-[DUTY

CYCLE] : ok

Fastpath CPU00: Initializing last packet received queue. Num of cores(2)

Fastpath CPU00: Init MBUF size: 1856, Subsequent MBUF size: 2040

Fastpath CPU00: Core 0 Initialization: ok

Fastpath CPU00: Initializing Timer...

Fastpath CPU01: Core 1 Initialization: ok

Fastpath CPU00: Initializing Timer...done.

Starting Switching Services: ok

Starting QoS Services: ok

Starting Policy Manager: ok

Starting Data Transport Link Layer: ok

Starting Access Control List Services: ok

Starting System Interfaces: ok

Starting Client Troubleshooting Service: ok

Starting Management Frame Protection: ok

Starting Certificate Database: ok

Starting VPN Services: ok

Starting Licensing Services: ok

Starting LWAPP: ok

Starting CAPWAP: ok

Starting LOCP: ok

Starting Security Services: ok

Starting Policy Manager: ok

Starting Authentication Engine: ok

Starting Mobility Management: ok

Starting Virtual AP Services: ok

Starting AireWave Director: ok

Starting Network Time Services: ok

Starting Cisco Discovery Protocol: ok

Starting Broadcast Services: ok

Starting Logging Services: ok

Starting DHCP Server: ok

Starting IDS Signature Manager: ok

Starting RFID Tag Tracking: ok

Starting Power Supply and Fan Status Monitoring Service: ok

Starting Mesh Services: ok

Starting TSM: ok

Starting CIDS Services: ok

Starting Ethernet-over-IP: ok

Starting DTLS server: enabled in CAPWAP

Starting CleanAir: ok

Starting WIPS: ok

Starting SSHPM LSC PROV LIST: ok

Starting RRC Services: ok

Starting FMC HS: ok

Starting Management Services:

Web Server: ok

28

Page 29

CLI: ok

Secure Web: Web Authentication Certificate not found (error). If you cannot

access management interface via HTTPS please reconfigure Virtual Interface.

License Agent: ok

(Cisco Controller)>

Step 6 If the controller passes the POST, the bootup script runs the Startup Wizard, which prompts

you for basic configuration information.

Welcome to the Cisco Wizard Configuration Tool

Use the '-' character to backup

System Name [Cisco_d9:16:24]:

Note The startup wizard runs the first time that you power on the controller. The second

time you power it on, the controller prompts you for a login ID and password.

Using the Startup Wizard

Before you can use the startup wizard, you must obtain the information discussed in the “Required

Tools and Information” section on page 9. Ta b le 3 contains startup wizard information you can use

to configure your controller for basic operation.

Note The available options appear in brackets after each configuration parameter. The default value

appears in all uppercase letters.

Note If you enter an incorrect response, the controller provides you with an appropriate error

message such as invalid response, and returns to the wizard prompt.

29

Page 30

Note Press the hyphen key if you need to return to the previous command line.

Ta b l e 3 Startup Wizard Information

Wizard Setting Action

System Name Enter the system name, which is the name you

want to assign to the controller. You can enter up

ASCII characters.

to 31

Administrative user name Enter the administrative user name to be assigned

to this controller. You can enter up to 24 ASCII

characters for each.

The default administrative username is admin.

Administrative password Enter the administrative password to be assigned

to this controller. You can enter from 3 to 24

ASCII characters for each.

Note There is no default administrative

password, you must enter a password.

Management Interface IP Address Enter the IP address of the management interface.

The management interface is the default interface

for in-band management of the controller and

connectivity to enterprise services such as AAA

servers.

You can access the controller GUI interface using

the management interface IP address.

Management Interface Netmask Enter the IP address of the management interface

netmask.

Management Interface Default Router Enter the IP address of the default router.

Management Interface VLAN Identifier Enter the VLAN identifier of the management

interface (a valid VLAN identifier or 0 for an

untagged VLAN).

The VLAN identifier should be set to match the

switch interface configuration.

Management Interface Port Num [1 to 4] Enter the port number of the access point

manager interface. Ports values are 1 to 4.

30

Page 31

Table 3 Startup Wizard Information (continued)

Wizard Setting Action

Management Interface DHCP Server IP Address Enter the management interface DHCP server IP

address.

Virtual Gateway IP Address Enter the IP address of the controller virtual

interface. You should enter a fictitious,

unassigned IP

address, such as 1.1.1.1.

The virtual interface is used to support mobility

management, DHCP relay, and embedded Layer

3 security such as guest web authentication and

VPN termination. All controllers within a

mobility group must be configured with the same

virtual interface IP address.

Mobility/RF Group Name If desired, enter the name of the mobility

group/RF group to which you want the controller

to belong.

Although the name that you enter here is assigned

to both the mobility group and the RF group,

these groups are not identical. Both groups define

clusters of controllers, but they have different

purposes. All of the controllers in an RF group

are usually also in the same mobility group and

vice versa. However, a mobility group facilitates

scalable, system-wide mobility and controller

redundancy while an RF group facilitates

scalable, system-wide dynamic RF management.

Network Name (SSID) Enter the network name, or service set identifier

(SSID). This is the default SSID that the access

points use when they join a controller.

Configure DHCP Bridging Mode Enter yes to configure DHCP Bridging Mode.

Values are yes or no. The following message

appears:

Warning! The default WLAN security policy

requires a RADIUS server. Please see

documentation for more details.

31

Page 32

Table 3 Startup Wizard Information (continued)

Wizard Setting Action

Allow Static IP Addresses Enter YES to allow clients to assign their own IP

address or no to make clients request an IP

address from a DHCP server. Values are YES or

no. The default setting is YES.

Configure a RADIUS Server Now? If you select YES, you are prompted to enter the

following:

• RADIUS server IP address

• RADIUS server port (default port is 1812)

• RADIUS server secret

If you select no, the following message appears:

Warning! The default WLAN security policy

requires a RADIUS server. Please see

documentation for more details.

Enter Country Code List Enter the two letter country code. The default

country code is the United States (US). Enter

‘help’ to see a list of countries.

Enable 802.11b Network Choose YES to enable or no to disable the

802.11b radio network. The default is YES.

Enable 802.11a Network Choose YES to enable or no to disable the

802.11a radio network. The default is YES.

Enable 802.11g Network Choose YES to enable or no disable the 802.11g

radio network. The default is YES.

Enable Auto-RF Choose YES to enable or no to disable radio

resource management. The default is YES.

Configure a NTP server now? Enter YES to configure an NTP server. The values

are YES or no. The default value is YES.

Enter the NTP server IP address Enter the NTP server IP address.

Note This prompt only displays if YES was

entered in the “Configure a NTP Server

Now?” prompt.

32

Page 33

Table 3 Startup Wizard Information (continued)

Wizard Setting Action

Enter a polling interval between 3600 and

604800 secs

Configuration correct? Enter yes if the configuration entered is correct.

Enter the polling interval between 3600 and

604800 seconds.

Note This prompt only displays if YES was

entered in the “Configure a NTP Server

Now?” prompt.

Values are yes and no. If yes is entered. the

controller saves your configuration, reboots, and

prompts you to log in.

5 Logging into the Controller

To log into the 2504 controller, follow these steps:

Step 1 Enter a valid username and password to log into the controller CLI.

Note The administrative username and password you created in the startup wizard are case

sensitive.

33

Page 34

Step 2 The CLI displays the root level system prompt:

C

Cisco

ts

#(system prompt)>

The system prompt can be any alphanumeric string up to 31 characters. You can change it by

entering the config prompt command. For example, to change the system prompt to

CISCO2504, enter config prompt "CISCO2504" and press Enter. Make sure you enter the

new prompt using double quotation marks.

Note The CLI automatically logs out without saving any changes after 5 minutes of

inactivity. You can set the automatic logout from 0 (never log out) to 160 minutes

using the config serial timeout command.

6 Connecting to the Network

Figure 13 shows the connection from the network (802.11 distribution system) to the controller. The

connection uses 10/100/1000BASE-T Ethernet (RJ-45 physical port, UTP, Category-5 or higher cable).

Always use Category-5, Category-5e, Category-6, or Category-7 Ethernet cables to connect the office

network equipment to the controller.

Figure 13 External Network Equipment Connection to the Controller

Access Poin

10/100/1000BASE-T

MDI cable

CLI console

Firewall

Network

onnection to

main office

34

Office

network

10/100/1000BASE-T

MDI cable

282298

Page 35

Note If the link does not activate, check the cable. When you are connecting to a hub or a switch,

use a straight-through cable.

Connecting Access Points

After you have configured the controller, use Category-5, Category-5e, Category-6, or Category-7

Ethernet cables to connect up to 50 Cisco lightweight access points to the controller Ethernet ports or

to the network (distribution system) as shown in

so you can use an MDI-X or MDI cable (crossover or straight-through) to make the connections.

As soon as the controller is operational, the controller is available to connect access that are scanning

for a controller. When it detects an access point, it records the access point MAC address in its

database. The controller Radio Resource Management (RRM) feature automatically configures the

access point to start transmitting and allowing clients to associate.

Note Direct connection of access points to Cisco 2500 Series Wireless Controllers are not currently

supported.

You have prepared the controller for basic operation. Refer to the Cisco Wireless LAN Controller

Configuration Guide for information on configuring the controller to meet the specific needs of your

wireless network.

Figure 14. The controller has an auto MDI feature,

35

Page 36

Figure 14 Access Points Connected to a Controller

C

Network

isco 2504 Wireless

Controller

Network

10/100/1000BASE-T

MDI cable

10/100/1000BASE-T

MDI cables

Cisco Access Points

282081

Checking the Controller LEDs

If your 2504 controller is not working properly, check the LEDs on the front panel of the unit. You

can use the LED indications to quickly assess the status of the unit. See

Table 1 on page 5 for a

description of the front panel LEDs.

The installation is complete. Refer to the Cisco Wireless Controller Configuration Guide for more

information about configuring your controller. The guide is available on cisco.com.

Using the Reset Button

The Reset button on the front panel of the controller becomes active after the controller boots. To reset

the controller using the Reset button, follow these steps:

Step 1 Connect a PC to the controller console point.

36

Page 37

Step 2 Press and hold the Reset button for at least 3 seconds using a pointed object, such as a ball

point pen, pencil, or paper clip.

Step 3 After the controller reboots, enter your username and password at the prompts.

If you have configured the controller, it reboots and loads the configuration. If you have not configured

the controller, the configuration wizard appears.

7 What’s New in Cisco Product Documentation

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new

and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS)

feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds

are a free service and Cisco currently supports RSS Version 2.0.

37

Page 38

8 Translated Safety Warnings

Statement 1071—Warning Definition

Warning

Waarschuwing

Varoitus

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, be aware of the hazards

involved with electrical circuitry and be familiar with standard practices for

preventing accidents. Use the statement number provided at the end of each

warning to locate its translation in the translated safety warnings that

accompanied this device.

SAVE THESE INSTRUCTIONS

BELANGRIJKE VEILIGHEIDSINSTRUCTIES

Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat

werken, dient u zich bewust te zijn van de bij elektrische schakelingen

betrokken risico's en dient u op de hoogte te zijn van de standaard praktijken

om ongelukken te voorkomen. Gebruik het nummer van de verklaring

onderaan de waarschuwing als u een vertaling van de waarschuwing die bij

het apparaat wordt geleverd, wilt raadplegen.

BEWAAR DEZE INSTRUCTIES

TÄRKEITÄ TURVALLISUUSOHJEITA

Tämä varoitusmerkki merkitsee vaaraa. Tilanne voi aiheuttaa ruumiillisia

vammoja. Ennen kuin käsittelet laitteistoa, huomioi sähköpiirien

käsittelemiseen liittyvät riskit ja tutustu onnettomuuksien yleisiin

ehkäisytapoihin. Turvallisuusvaroitusten käännökset löytyvät laitteen

mukana toimitettujen käännettyjen turvallisuusvaroitusten joukosta

varoitusten lopussa näkyvien lausuntonumeroiden avulla.

Statement 1071

SÄILYTÄ NÄMÄ OHJEET

38

Page 39

Attention

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant entraîner des blessures ou des dommages corporels. Avant

de travailler sur un équipement, soyez conscient des dangers liés aux circuits

électriques et familiarisez-vous avec les procédures couramment utilisées

pour éviter les accidents. Pour prendre connaissance des traductions des

avertissements figurant dans les consignes de sécurité traduites qui

accompagnent cet appareil, référez-vous au numéro de l'instruction situé à la

fin de chaque avertissement.

CONSERVEZ CES INFORMATIONS

Warnung

Avvertenza

WICHTIGE SICHERHEITSHINWEISE

Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die

zu Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit

den Gefahren elektrischer Schaltungen und den üblichen Verfahren zur

Vorbeugung vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung

angegebenen Anweisungsnummer nach der jeweiligen Übersetzung in den

übersetzten Sicherheitshinweisen, die zusammen mit diesem Gerät

ausgeliefert wurden.

BEWAHREN SIE DIESE HINWEISE GUT AUF.

IMPORTANTI ISTRUZIONI SULLA SICUREZZA

Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe

causare infortuni alle persone. Prima di intervenire su qualsiasi

apparecchiatura, occorre essere al corrente dei pericoli relativi ai circuiti

elettrici e conoscere le procedure standard per la prevenzione di incidenti.

Utilizzare il numero di istruzione presente alla fine di ciascuna avvertenza per

individuare le traduzioni delle avvertenze riportate in questo documento.

CONSERVARE QUESTE ISTRUZIONI

39

Page 40

Advarsel

VIKTIGE SIKKERHETSINSTRUKSJONER

Dette advarselssymbolet betyr fare. Du er i en situasjon som kan føre til skade

på person. Før du begynner å arbeide med noe av utstyret, må du være

oppmerksom på farene forbundet med elektriske kretser, og kjenne til

standardprosedyrer for å forhindre ulykker. Bruk nummeret i slutten av hver

advarsel for å finne oversettelsen i de oversatte sikkerhetsadvarslene som

fulgte med denne enheten.

TA VARE PÅ DISSE INSTRUKSJONENE

Aviso

¡Advertencia!

INSTRUÇÕES IMPORTANTES DE SEGURANÇA

Este símbolo de aviso significa perigo. Você está em uma situação que poderá

ser causadora de lesões corporais. Antes de iniciar a utilização de qualquer

equipamento, tenha conhecimento dos perigos envolvidos no manuseio de

circuitos elétricos e familiarize-se com as práticas habituais de prevenção de

acidentes. Utilize o número da instrução fornecido ao final de cada aviso para

localizar sua tradução nos avisos de segurança traduzidos que acompanham

este dispositivo.

GUARDE ESTAS INSTRUÇÕES

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este símbolo de aviso indica peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considere los riesgos de la corriente

eléctrica y familiarícese con los procedimientos estándar de prevención de

accidentes. Al final de cada advertencia encontrará el número que le ayudará

a encontrar el texto traducido en el apartado de traducciones que acompaña

a este dispositivo.

GUARDE ESTAS INSTRUCCIONES

40

Page 41

Varning!

VIKTIGA SÄKERHETSANVISNINGAR

Denna varningssignal signalerar fara. Du befinner dig i en situation som kan

leda till personskada. Innan du utför arbete på någon utrustning måste du vara

medveten om farorna med elkretsar och känna till vanliga förfaranden för att

förebygga olyckor. Använd det nummer som finns i slutet av varje varning för

att hitta dess översättning i de översatta säkerhetsvarningar som medföljer

denna anordning.

SPARA DESSA ANVISNINGAR

41

Page 42

4243444546

Page 43

Page 44

Page 45

Page 46

Page 47

Statement 1015—Battery Handling

Warning

Waarschuwing

Varoitus

Attention

Warnung

Avvertenza

There is the danger of explosion if the battery is replaced incorrectly. Replace

the battery only with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the manufacturer’s

instructions.

Er is ontploffingsgevaar als de batterij verkeerd vervangen wordt. Vervang de

batterij slechts met hetzelfde of een equivalent type dat door de fabrikant

aanbevolen is. Gebruikte batterijen dienen overeenkomstig

fabrieksvoorschriften weggeworpen te worden.

Räjähdyksen vaara, jos akku on vaihdettu väärään akkuun. Käytä

vaihtamiseen ainoastaan saman- tai vastaavantyyppistä akkua, joka on

valmistajan suosittelema. Hävitä käytetyt akut valmistajan ohjeiden mukaan.

Danger d'explosion si la pile n'est pas remplacée correctement. Ne la

remplacer que par une pile de type semblable ou équivalent, recommandée

par le fabricant. Jeter les piles usagées conformément aux instructions du

fabricant.

Bei Einsetzen einer falschen Batterie besteht Explosionsgefahr. Ersetzen Sie

die Batterie nur durch den gleichen oder vom Hersteller empfohlenen

Batterietyp. Entsorgen Sie die benutzten Batterien nach den Anweisungen des

Herstellers.

Pericolo di esplosione se la batteria non è installata correttamente. Sostituire

solo con una di tipo uguale o equivalente, consigliata dal produttore.

Eliminare le batterie usate secondo le istruzioni del produttore.

Statement 1015

Advarsel

Aviso

Det kan være fare for eksplosjon hvis batteriet skiftes på feil måte. Skift kun

med samme eller tilsvarende type som er anbefalt av produsenten. Kasser

brukte batterier i henhold til produsentens instruksjoner.

Existe perigo de explosão se a bateria for substituída incorrectamente.

Substitua a bateria por uma bateria igual ou de um tipo equivalente

recomendado pelo fabricante. Destrua as baterias usadas conforme as

instruções do fabricante.

47

Page 48

¡Advertencia!

Existe peligro de explosión si la batería se reemplaza de manera incorrecta.

Reemplazar la batería exclusivamente con el mismo tipo o el equivalente

recomendado por el fabricante. Desechar las baterías gastadas según las

instrucciones del fabricante.

Varning!

Explosionsfara vid felaktigt batteribyte. Ersätt endast batteriet med samma

batterityp som rekommenderas av tillverkaren eller motsvarande. Följ

tillverkarens anvisningar vid kassering av använda batterier.

Page 49

Statement 1024—Ground Conductor

Warning

Waarschuwing

Varoitus

Attention

Warnung

This equipment must be grounded. Never defeat the ground conductor or

operate the equipment in the absence of a suitably installed ground conductor.

Contact the appropriate electrical inspection authority or an electrician if you

are uncertain that suitable grounding is available.

Deze apparatuur dient geaard te zijn. De aardingsleiding mag nooit buiten

werking worden gesteld en de apparatuur mag nooit bediend worden zonder

dat er een op de juiste wijze geïnstalleerde aardingsleiding aanwezig is.

Neem contact op met de bevoegde instantie voor elektrische inspecties of met

een elektricien als u er niet zeker van bent dat er voor passende aarding

gezorgd

Laitteiden on oltava maadoitettuja. Älä koskaan ohita maajohdinta tai käytä

laitteita ilman oikein asennettua maajohdinta. Ota yhteys

sähkötarkastusviranomaiseen tai sähköasentajaan, jos olet epävarma

maadoituksen sopivuudesta.

Cet équipement doit être mis à la masse. Ne jamais rendre inopérant le

conducteur de masse ni utiliser l'équipement sans un conducteur de masse

adéquatement installé. En cas de doute sur la mise à la masse appropriée

disponible, s'adresser à l'organisme responsable de la sécurité électrique ou

à un électricien.

Dieses Gerät muss geerdet sein. Auf keinen Fall den Erdungsleiter unwirksam

machen oder das Gerät ohne einen sachgerecht installierten Erdungsleiter

verwenden. Wenn Sie sich nicht sicher sind, ob eine sachgerechte Erdung

vorhanden ist, wenden Sie sich an die zuständige Inspektionsbehörde oder

einen Elektriker.

is.

Statement 1024

Avvertenza

Questa apparecchiatura deve essere dotata di messa a terra. Non escludere

mai il conduttore di protezione né usare l'apparecchiatura in assenza di un

conduttore di protezione installato in modo corretto. Se non si è certi della

disponibilità di un adeguato collegamento di messa a terra, richiedere un

controllo elettrico presso le autorità competenti o rivolgersi a un elettricista.

49

Page 50

Advarsel

Dette utstyret må jordes. Omgå aldri jordingslederen og bruk aldri utstyret

uten riktig montert jordingsleder. Ta kontakt med fagfolk innen elektrisk

inspeksjon eller med en elektriker hvis du er usikker på om det finnes

velegnet jordning.

Aviso

¡Advertencia!

Varning!

Este equipamento deve ser aterrado. Nunca anule o fio terra nem opere o

equipamento sem um aterramento adequadamente instalado. Em caso de

dúvida com relação ao sistema de aterramento disponível, entre em contato

com os serviços locais de inspeção elétrica ou um eletricista qualificado.

Este equipo debe estar conectado a tierra. No inhabilite el conductor de tierra

ni haga funcionar el equipo si no hay un conductor de tierra instalado

correctamente. Póngase en contacto con la autoridad correspondiente de

inspección eléctrica o con un electricista si no está seguro de que haya una

conexión a tierra adecuada.

Denna utrustning måste jordas. Koppla aldrig från jordledningen och använd

aldrig utrustningen utan en på lämpligt sätt installerad jordledning. Om det

föreligger osäkerhet huruvida lämplig jordning finns skall elektrisk

besiktningsauktoritet eller elektriker kontaktas.

50

Page 51

51

Page 52

Statement 1040—Product Disposal

Waarschuwing

52

Warning

Varoitus

Attention

Warnung

Ultimate disposal of this product should be handled according to all national

laws and regulations.

Het uiteindelijke wegruimen van dit product dient te geschieden in

overeenstemming met alle nationale wetten en reglementen.

Tämä tuote on hävitettävä kansallisten lakien ja määräysten mukaisesti.

La mise au rebut ou le recyclage de ce produit sont généralement soumis à des

lois et/ou directives de respect de l'environnement. Renseignez-vous auprès

de l'organisme compétent.

Die Entsorgung dieses Produkts sollte gemäß allen Bestimmungen und

Gesetzen des Landes erfolgen.

Statement 1040

Page 53

Avvertenza

Lo smaltimento di questo prodotto deve essere eseguito secondo le leggi e

regolazioni locali.

Advarsel

Aviso

¡Advertencia!

Varning!

Endelig kassering av dette produktet skal være i henhold til alle relevante

nasjonale lover og bestemmelser.

Deitar fora este produto em conformidade com todas as leis e regulamentos

nacionais.

Al deshacerse por completo de este producto debe seguir todas las leyes y

reglamentos nacionales.

Vid deponering hanteras produkten enligt gällande lagar och bestämmelser.

53

Page 54

54

Page 55

Statement 371—Power Cable and AC Adapter

When installing the product, please use the provided or designated connection cables/power cables/AC

adaptors/batteries. Using any other cables/adaptors could cause a malfunction or a fire. Electrical

Appliance and Material Safety Law prohibits the use of UL-certified cables (that have the “UL” or

“CSA” shown on the cord), not regulated with the subject law by showing “PSE” on the cord, for any

other electrical devices than products designated by Cisco.

Statement 157—VCCI Compliance for Class B Equipment

Warning

This is a Class B product based on the standard of the Voluntary Control

Council for Interference from Information Technology Equipment (VCCI). If this

is used near a radio or television receiver in a domestic environment, it may

cause radio interference. Install and use the equipment according to the

instruction manual.

55

Page 56

Cisco and the Cisco Logo ar e tr ademarks of Cisco Systems, In c. and/ or its affiliates in the U.S. and o ther countries. A listing of Cisco's trademar ks

can be found at

partner does not imply a partnership relat ionship bet ween Cisco and any oth er company . (1005R).

www.cisco.com/go/trademarks. Third party trademarks mentioned are the property of their respective owners . The use of the word

56

Loading...

Loading...