Page 1

CHAPTER

3

Installing the Chassis

This chapter describes how to install and test the Cisco Metro 1500 series system

chassis. The equipment is installed during normal working hours. It is usually

connected to active CPU channels or control units after working hours.

This chapter includes the following sections:

• Before Installing, page 3-1

• Installing the System, page 3-4

• Connecting Power, page 3-8

• Cleaning the System, page 3-18

• Removing the Power Supply Module, page 3-21

• Running Online Tests, page 3-25

• Troubleshooting, page 3-28

Before Installing

Before you install the system, you must complete the following tasks:

• Unpacking and Inspecting the System

• Maintaining a Network Record

• Mounting the System

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-1

Page 2

Before Installing

Caution Use extreme care when removing or installing connectors so you do

not damage the connector housing or scratch the end-face surfaceof

the fiber. Alwaysinstall protective covers on unused or disconnected

components to prevent contamination. Always clean fiber

connectors before installing them.

Unpacking and Inspecting the System

The Cisco Metro 1500 series system comes with the following standard items:

• Cisco Metro 1500 series hardware

• Substitute power-on key (AC powered version only)

• Mounting set

–

19-in. adapter

–

rack screw

–

washers

• Two power cords for each chassis delivered

• Acrylic cover

• Cisco Metro 1500 Series Hardware Installation Guide

• Cisco Metro 1500 Series Software Configuration Guide

• Release Notes for the Cisco Metro 1500 Series

Chapter 3 Installing the Chassis

3-2

Note The systems are used in pairs. Depending on your order, a total

system package can consist of multiple boxes. All boxes are labeled

with a summary of contents, and they are signed and verified by a

packager.If an order includes more than one box, this summary will

show the number of boxes shipped.

The Cisco Metro 1500 series system is thoroughly inspected before shipment. If

any damage has occurred during transportation or if any item is missing, notify

your Cisco customer service representative immediately.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 3

Chapter 3 Installing the Chassis

Upon receipt, inspect the equipment as follows:

Step 1 Take inventory.

Compare the equipment inside with the packing slip and the equipment list

provided by customer service. If there are any discrepancies, notify the Customer

Service Center.

Step 2 Check for external damage.

Visually check all components and immediately report any shipping damage to

your customer service representative. Have the following information ready:

• Invoice number of shipper (see packing slip)

• Model and serial number of the damaged unit

• Description of damage

• Effect of damage on the installation

Before Installing

Maintaining a Network Record

Fill out all the required information in Appendix E, “Unit Maintenance and

Network Record,”so you will have a record of all of your hardware, configuration

options, and network settings.

Mounting the System

The unit is designed for rack-mounting in a cabinet. We recommend mounting up

to four units in one vertical rack and using chassis runners or telescopic slides.

Use star-type lock washers on the rack screws to ensure a good conductive

connection between the unit and the rack. For further information about installing

the units in a customer cabinet, see the instructions from the

cabinet manufacturer.

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-3

Page 4

Installing the System

Caution Because of rack mounting, the plugs of the power cables on the rear

side of the unit might not be accessible. Please provide a power

circuit breaker to allow front power access. If you do not use a power

circuit breaker, ensure quick access to the plug-socket combinations

on the rear side of the unit at all times. In this case they serve as the

main means of disconnecting.

Installing the System

Chapter 3 Installing the Chassis

Warning

Only trained and qualifiedpersonnel should be allowed to install,

replace, or service this equipment.

To install, connect, and test the system, follow these steps:

Step 1 Unpack and inspect each unit. Verify completeness against the packing list.

Step 2 Fill out the form in Appendix E, “Unit Maintenance and Network Record.”

Step 3 Mount each unit in a cabinet or a rack.

Step 4 Power up each unit.

Step 5 Run online tests as described in the “Running Online Tests” section on page 3-25.

Step 6 Connect the fiber-optic link between sites using the remote channel.

Step 7 Connect applications using the local channels.

Step 8 Test the system online to verify operation.

Note If a network element management interface (NEMI) is not installed,

you have completed this portion of the installation tasks. If a NEMI

is installed, refer to the Cisco Metro 1500 Series Software

Configuration Guide and continue with Step 9.

Step 9 Connect to the serial port.

3-4

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 5

Chapter 3 Installing the Chassis

Step 10 Change default passwords. See Appendix E, “Unit Maintenance and Network

Record.”

Step 11 Log in as root and define network settings. See Appendix E, “Unit Maintenance

and Network Record.”

Step 12 Change the SNMP configuration.

Step 13 Reboot the unit.

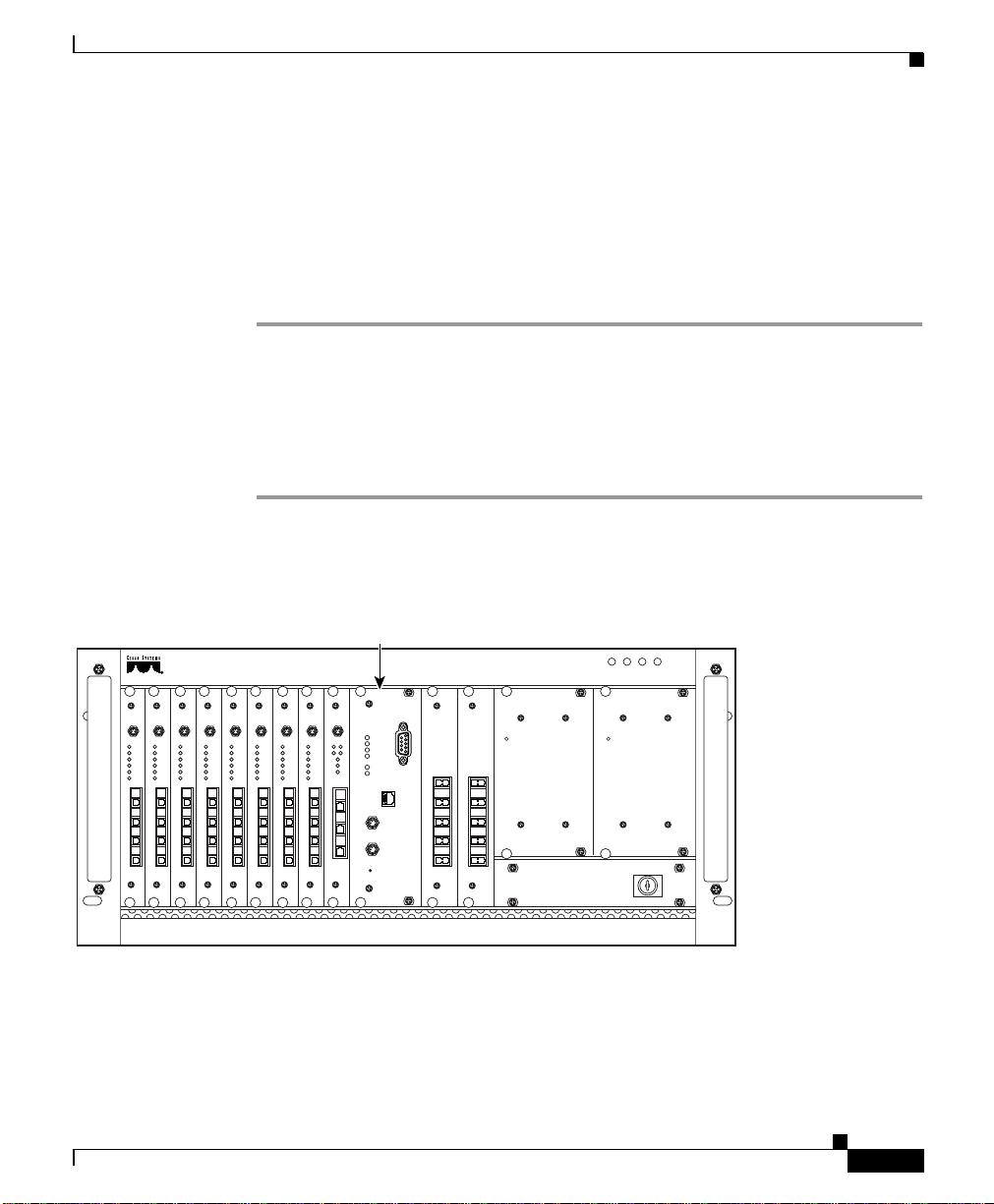

Installing the NEMI Module

To install a NEMI module (master and slave, as applicable), follow these steps:

Step 1 Remove the acrylic front cover from the unit in which the module should be

added. (See Figure 3-1.)

Figure 3-1 NEMI Placement in the Primary Chassis and Extension Chassis B.

Installing the System

On/Err

Loop

L/R

L/T

R/R

R/T

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

78-10588-03

NEMI master

OK FAIL

METRO 1500 SERIES

Serial

Power

On/Err

On/Err

On/Err

On/Err

On/Err

On/Err

Loop

Loop

Loop

L/R

L/T

R/R

R/T

L/R

L/T

R/R

R/T

Loop

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

On/Err

Loop

Loop

Loop

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

OnAL

A/T

A/R

B/T

B/R

T

R

Error

K

Err.Int.BUS

B

Err.Ext.BUS

LKA

LKB

Receive

Auto

Link

MUX

Ch.1-8

Ch.1-8

T/E

Net

BUS 1

BUS 2

2/E

7/8

7/8

5/6

5/6

3/4

3/4

1/2

1/2

110/220V AC

DMX

Power Power

POWER FAN

110/220V AC

OK FAIL

32262

Step 2 Remove the two screws from the blank filler module. Remove the blank filler

panels.

Step 3 Take the new module from the shipping container and use canned, dry, oil-free,

compressed air to blow off any possible dust particles.

Cisco Metro 1500 Series Hardware Installation Guide

3-5

Page 6

Installing the System

Step 4 Insert the NEMI module carefully into the chassis slot while guiding the upper

Caution It is critical to insert the module gently. If you need a force greater

Step 5 Hold the module in position after making full contact and use the two screws on

Step 6 Reset the NEMI modules (both master and slave, if applicable) by inserting a

Step 7 Save the blank filler panels with the packaging material.

Chapter 3 Installing the Chassis

and lower edges of the module in the tracks until its connectors come into contact

with the backplane connectors.

than 1 lb (4.5 newton) to push in the module, stop immediately.

Inspect the electrical connector. If the connector is not damaged,

repeat Step 4.

the front panel of the module to secure it in the housing. When the module is in

contact with the backplane, the green power LED is on.

pointed tool into the small hole on the front panel within the first 30 seconds of

installation. The green power LED comes on and the NEMI module starts up.

3-6

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 7

Chapter 3 Installing the Chassis

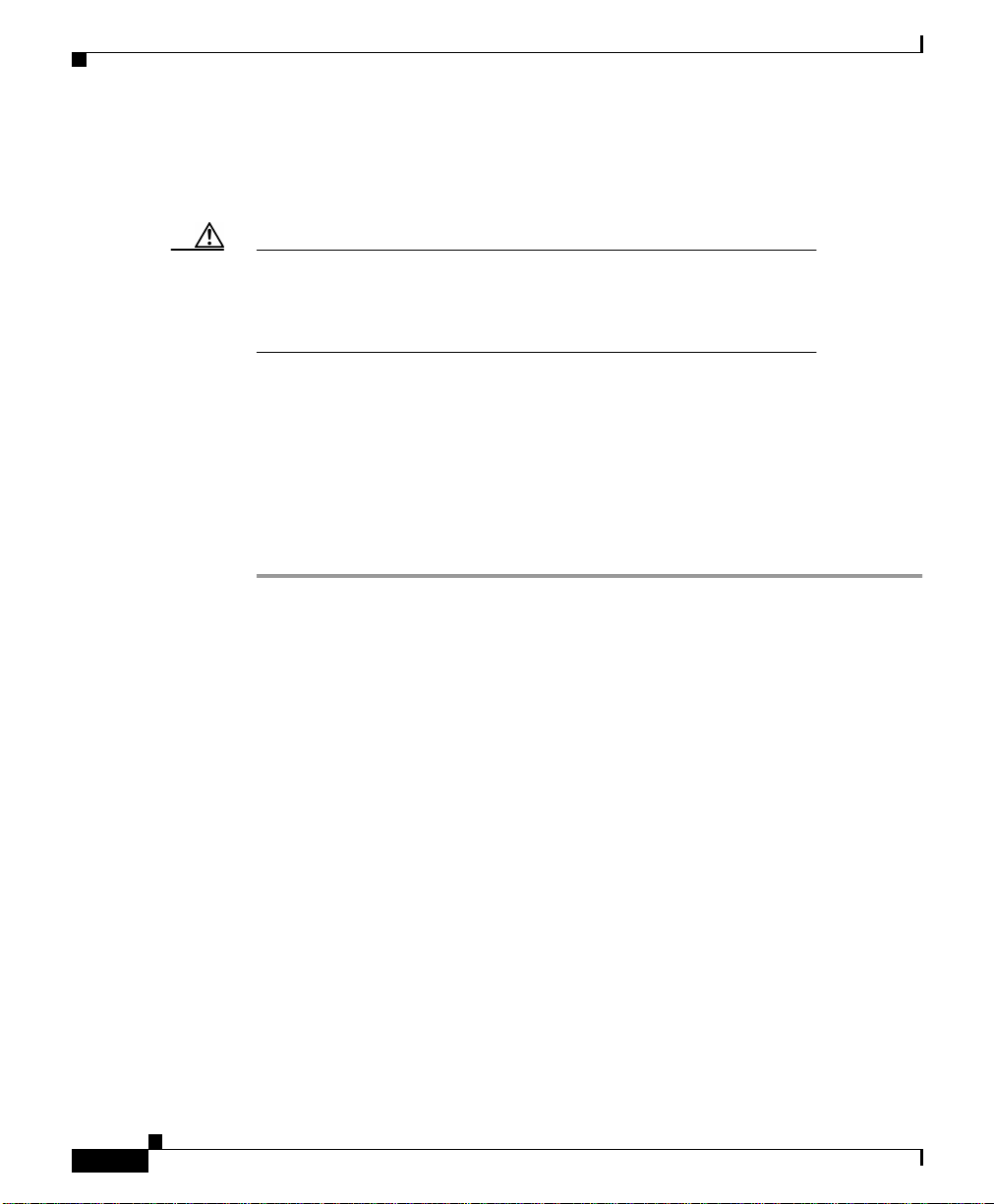

Installing the DEMI Module

To install a DEMI module, follow these steps:

Step 1 Remove the acrylic front cover from the unit in which the module should be

added. (See Figure 3-2.)

Figure 3-2 DEMI Placement in Extension Chassis A and C

DEMI location

METRO 1500 SERIES

OK FAIL

POWER FAN

Installing the System

OK FAIL

110/220V AC

MUX

DMX

On/Err

On/Err

On/Err

On/Err

On/Err

On/Err

On/Err

Loop

Loop

Loop

Loop

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

Loop

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

On/Err

Loop

Loop

Loop

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

Ch.9-16

E

15/16

13/14

11/12

9/10

Power Power

Ch.9-16

E

15/16

13/14

11/12

9/10

110/220V AC

32264

Step 2 Remove the two screws from the blank filler module. Remove the blank filler

panel.

Step 3 Take the new module from the shipping container and use canned, dry, oil-free,

compressed air to blow off any possible dust particles.

Step 4 Insert the DEMI module carefully into the chassis slot while guiding the upper

and lower edges of the module in the tracks until its connectors come into contact

with the backplane connectors.

Caution It is critical to insert the module gently. If you need a force greater

than 1 lb (4.5 newton) to push in the module, stop immediately.

Inspect the electrical connector. If the connector is not damaged,

repeat Step 4.

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-7

Page 8

Connecting Power

Step 5 Hold the module in position after making full contact and use the two screws on

the front panel of the module to secure it in the housing. When the module is in

contact with the backplane, the green power LED is on.

Step 6 Save the blank filler panels with the packaging material.

Connecting Power

The system is equipped with two power supplies and two power cords. The power

must be turned on by the power keyswitch on the AC-powered version only. The

keyswitch is secured against rotation and the key can be removed in either the on

or off position. A key for powering up the system is provided with each system.

When the power is on, all of the green power supply LEDs should be on for each

power supply module (PSM) and wavelength channel module (WCM). The

display panel provides important system information.

Chapter 3 Installing the Chassis

3-8

Warning

Warning

Caution Please use approved extension cords or a power circuit breaker to

The plug-socket combination must be accessible at all times

because it serves as the main disconnecting device.

This unit might have more than one power cord. To reduce the risk

of electric shock, disconnect the two power supply cords before

servicing the unit.

allow front power access.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 9

Chapter 3 Installing the Chassis

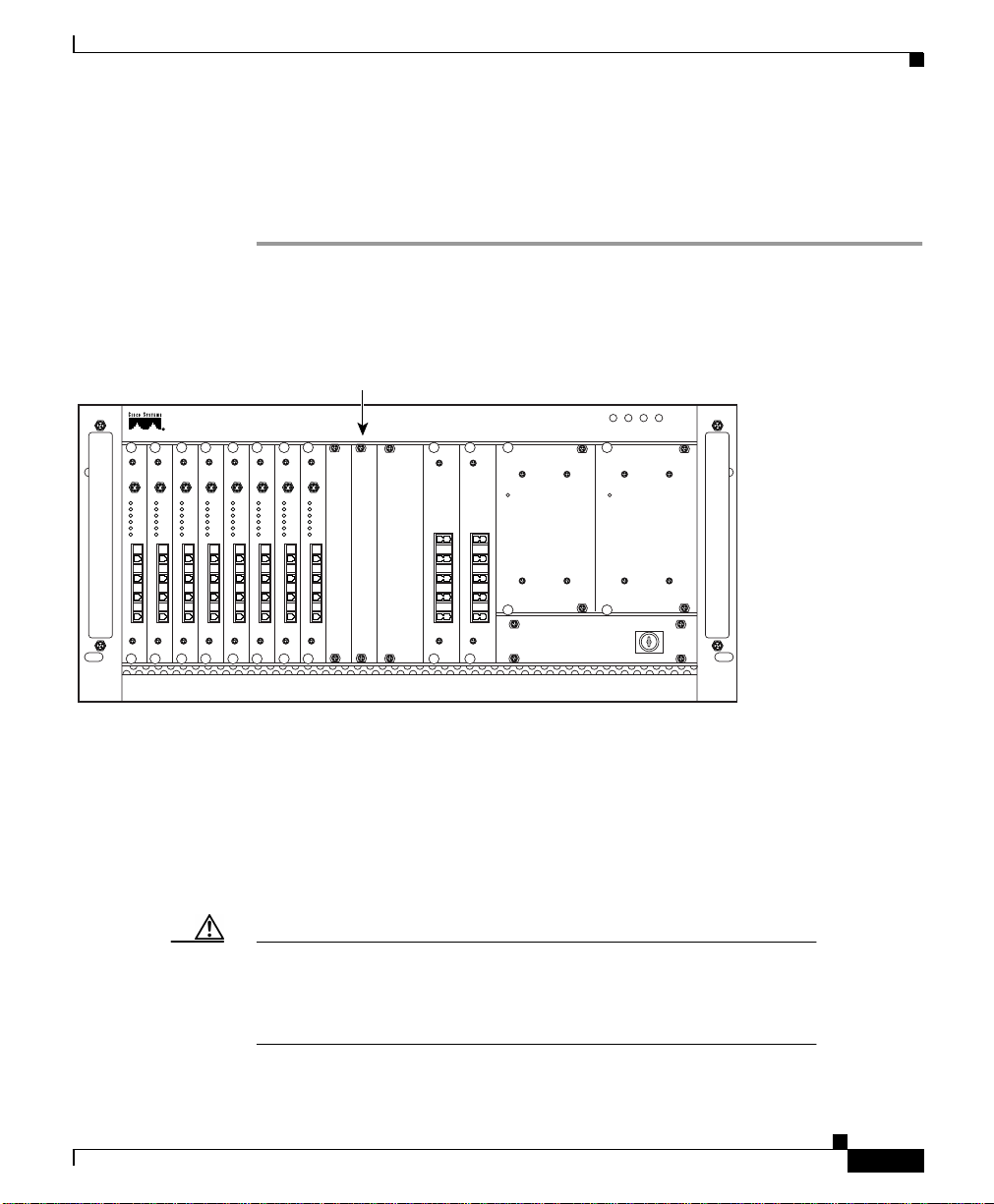

Connecting AC Power

To connect AC power, follow these steps:

Step 1 Connect the power supply cords to power 1 and power 2 on the rear panel of the

unit. (See Figure 3-3.)

Figure 3-3 Rear Panel of the Cisco Metro 1500 (AC Version)

Connecting Power

Fan module

78-10588-03

115/230 V 50/60 Hz

Voltage:

Max. Current: 2.5 A

Power Consumption

max. 100 W

Fuse: 2

Power 2

Fuse 2 Fuse 1

Power 1

x T 2,5 A / 250 V

For continued protection against risk of fire replace

only with same type and ratings of fuse.

For proper selection of power supply cord refer to

Always remove both

instruction manual.

power cords when dis-

Made in Germany

connecting from power

March 1999

!

source !

Always remove both poewr cords when

disconnecting from a power source.

Instructions for

power supply

50323

AC Power

connectors

Fuse

holders

Step 2 Connect the ends of the power supply cords to the main power supply source.

Step 3 Turn the power on with the keyswitch at the front panel of the unit. (See

Figure 3-4.)

Cisco Metro 1500 Series Hardware Installation Guide

3-9

Page 10

Connecting Power

Figure 3-4 Front Panel of the Cisco Metro 1500

Power

LEDs

Fan

FAIL

OK FAILOK

POWER

LEDs

FAN

PSM1

METRO 1500 SERIES

PSM2

Chapter 3 Installing the Chassis

Serial

Net

MUXM

1-8(32) 1-8(32)

nc

M1

8

8

7

7

6

5

4

3

2

1

D1

7

5

3

1

DMXM

nc

8

6

4

2

Power

on

Power

on

0

I

50322

Keyswitch

(AC version only)

The keyswitch is secured against rotation. The key can be removed in either the

( 0 ) or ( | ) position. A pair of keysfor powering up is supplied with each system.

Warm up the unit for 30 minutes before testing the laser power or connecting

applications.

3-10

Caution If powered down, wait at least 10 seconds before you switch the unit

on again.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 11

Chapter 3 Installing the Chassis

Connecting DC Power

The system is equipped with two PSMs and two DC power cables. There are two

DC powered versions of the Cisco Metro 1500 Series. The European DC version

uses the DC plug-socket conbination. The US version uses terminal blocks.

Depending on the type of connectors on the power distribution unit (PDU), you

have to use the power cables for SELV applications or the power cables for all

other centralized 48-VDC applications.

Installing Terminal Blocks (US Version)

The Cisco Metro 1500 series system is equipped with two PSMs. To connect the

system to the PDU, you need two approved three-core interconnection cables.

To connect the power cables for the US version, follow these steps:

Step 1 Remove the insulation of each wire on both ends of the interconnection cables at

a length of about 5 mm.

Step 2 Connect the wires of the cables to the terminal blocks in the rear panel of the unit.

(See Figure 3-5.)

Connecting Power

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-11

Page 12

Connecting Power

Figure 3-5 Rear Panel of the PSM (US Version)

Fan module

Voltage:

115/230 V 50/60 Hz

Max. Current: 2.5 A

Power Consumption

max. 100 W

Fuse: 2

Power 2

Fuse 2 Fuse 1

Power 1

x T 2,5 A / 250 V

For continued protection against risk of fire replace

only with same type and ratings of fuse.

For proper selection of power supply cord refer to

Always remove both

instruction manual.

power cords when dis-

Made in Germany

connecting from power

March 1999

!

source !

Always remove both poewr cords when

disconnecting from a power source.

Instructions for

power supply

Terminal blocks

Fuse

holders

Chapter 3 Installing the Chassis

50327

3-12

Caution Do not use damaged terminal blocks. Immediately replace damaged

or defective terminal blocks

Step 3 Take a medium screwdriver and push it into the rectangular hole of the terminal

block. (See Figure 3-6.)At the same time, slide the insulation-free end of the wire

into the respective rectangular hole at the bottom of the power clamp. Repeat this

step for the other wires.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 13

Chapter 3 Installing the Chassis

Figure 3-6 Connecting Wires

Green/yellow wire (ground)

Blue wire (negative)

Brown wire (positive)

Connecting Power

78-10588-03

50328

Step 4 Connect the three wires on the other end to the corresponding high current

connectors of the power distribution unit. Attach the wires to their respective

points in the connectors.

Caution Make sure that the three wires of the power cables are correctly fixed

at the clamps of the PDU connectors.

Caution Never connect blue (negative) or brown (positive) wires to the

ground pin.

Step 5 Turn the power on using the corresponding power switch of the PDU.

Cisco Metro 1500 Series Hardware Installation Guide

3-13

Page 14

Chapter 3 Installing the Chassis

Connecting Power

The chassis powers up as soon as the corresponding power switch of the PDU is

turned on.

Installing the DC Plug-Socket Combination (European Version)

To connect the power cables for the European version, follow these steps:

Step 1 Connect the desired power cables to power 1 and power 2 on the rear panel of the

Cisco Metro 1500 series system and attach the plugs with the screws to the

sockets. (See Figure 3-7.)

Figure 3-7 Rear Panel of the Cisco Metro 1500 (DC Version)

Fan module

3-14

Fuse

holders

Fuse 1 Fuse 2

Power 1 Power 2

DC Power

connectors

Cisco Metro 1500 Series Hardware Installation Guide

115/230 V 50/60 Hz

Voltage:

2.5 A

Max. Current:

max. 100W

Power Consumption:

2x T2.5A / 250V

Fuse:

For continued protection against risk of fire replace

only with same type and ratings of fuse.

For proper selection of power supply cord refer to

instruction manual.

Always remove both

power cords when dis-

Made in Germany

connecting from power

March 1998

!

source 1.

32268

78-10588-03

Page 15

Chapter 3 Installing the Chassis

Caution Tighten the screw of the plug to avoid loss of connection.

Step 2 Choose the appropriate power cable.

Step 3 Connect the plug (the power cable for the SELVapplication is fitted with a special

plug) to the corresponding connector of the PDU. (See Figure 3-8.)

Figure 3-8 SELV Application Power Cable

Connecting Power

78-10588-03

50325

Step 4 Attach the three wires to their respective points in the corresponding connectors

of the PDU as described as follows:

Brown wire life +

Blue wire neutral Green/ Yellow wire ground PE

The power cable for the 48 VDC application has wire ferrules on the other end.

(See Figure 3-9.)

Cisco Metro 1500 Series Hardware Installation Guide

3-15

Page 16

Connecting Power

Figure 3-9 48 VDC Application Power Cable

Blue

Brown

Green/yellow

Ferrules

Chapter 3 Installing the Chassis

3-16

50326

Caution Make sure that the three wires on the power cables are correctly

fixed at the terminal clamps of the unit and at the connectors of the

PDU.

Warning

This warning applies only to units equipped with DC input power

supplies. Wire the DC power supply using the appropriate lugs at

the wiring end. The proper wiring sequence is ground to ground,

positive to positive (line to L), and negative to negative (neutral to

N).Note that the groundwire should alwaysbe connected firstand

disconnected last.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 17

Chapter 3 Installing the Chassis

Step 5 Turn the power on using the corresponding power switch of the PDU.

The chassis powers up as soon as the corresponding power switch of the PDU is

turned on. If the DC power cables are not connected to the PDU, the plug socket

combinations on the rear end of the unit serve as switches.

Power Consumption and Power Supply Fuses

The system power consumption is less than 150 W.

Use the following fuses:

Power Type Fuse Type No. of Fuses

AC version 2.5A at 250V, slow blow, 5 x 20 mm 2

DC version 6.3A at 250V, slow blow, 5 x 20 mm 2

Connecting Power

78-10588-03

Caution Always replace blown fuses with fuses of the same type and size.

Caution Do not use damaged terminal blocks. Immediately replace damaged

or defective terminal blocks.

Note The 115/230V version automatically detects the input voltage. No

further adjustment is necessary.

The Cisco Metro 1500 series system supports the following power sources:

AC 110 to 240V, 50 or 60 Hz

DC -48 to -60V

Cisco Metro 1500 Series Hardware Installation Guide

3-17

Page 18

Cleaning the System

Table 3-1 lists the power requirements in different countries.

Table 3-1 Power Requirements

Region Power Requirements

North America 110 to 120 VAC, 60 Hz or

Europe 210 to 240 VAC, 50 Hz or

Grounding the Chassis

Connecting the power cords to the chassis provides basic grounding. You should

also connect a separate grounding cable for each chassis to the rack. Use the

ground contact on the right side of the chassis to make the grounding connection.

To ground the chassis, follow these steps:

Chapter 3 Installing the Chassis

-48 to -60 VDC

-48 to -60 VDC

Step 1 Connect a wire to the earth contact on the right side of the chassis.

Step 2 Connect the other end of the wire to the rack.

Cleaning the System

This section describes how to clean the chassis and the connectors and includes

the following sections:

• Cleaning the Chassis

• Cleaning the Connectors

Cisco Metro 1500 Series Hardware Installation Guide

3-18

78-10588-03

Page 19

Chapter 3 Installing the Chassis

Cleaning the Chassis

Be very careful with the air flow system when you clean the chassis. If the

cleaning process has to be done while the system is on, be aware that the airflow

system is in operation. Clean the chassis with a damp cloth only and be careful of

the following:

• Do not touch the safety lattice of the airflow system while fans are operating.

• Do not use wet tissues for cleaning the product's outer housing.

• Do not use any harsh or abrasive cleaning agents.

Cleaning the Connectors

Fiber optic connectors are used to connect two fibers together. When these

connectors are used in a communication system, proper connection becomes a

critical factor.

Fiber optic cable connectors can be damaged by improper cleaning and

connection procedures. Dirty or damaged fiber optic connectors can result in not

repeatable or inaccurate communication.

Fiber optic connectors differ from electrical or microwave connectors. In a fiber

optic system, light is transmitted through an extremely small fiber core. Because

fiber cores are often 62.5 microns or less in diameter, and dust particles range

from a tenth of a micron to several microns in diameter, dust and any

contamination at the end of the fiber core can degrade the performance of the

connector interface where the two cores meet. Therefore, the connector must be

precisely aligned and the connector interface must be absolutely free of trapped

foreign material.

Connector,or insertion, loss is a critical performance characteristic of a fiber optic

connector. Return loss is also an important factor. It specifies the amount of

reflectedlight;the lower the reflectionthe better the connection. The best physical

contact connectors have return losses better than -40 dB, although -20 to -30 dB

is more common.

The connection quality depends on two factors; the type of connector and the

proper cleaning and connection techniques.Dirty fiber connectors are a common

source of light loss. Keep the connectors clean at all times and keep the dust cover

installed when not in use.

Cleaning the System

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-19

Page 20

Cleaning the System

Caution Use extreme care when removing or installing connectors so you do

Step 1 Gently wipe the ferrules and end-face surfaces of the connector with an alcohol

Step 2 Blow dry the connectors with canned, dry, oil-free, compressed air.

Step 3 Use a magnifying glass to inspect the ferrule.

Chapter 3 Installing the Chassis

Before installing any type of cable or connector, use a lint-free alcohol pad from

a cleaning kit to clean the ferrule, the protective white tube around the fiber, and

the end-face surface of the fiber.

As a general rule, whenever there is a significant, unexplained loss of light, clean

the connectors.

not damage the connector housing or scratch the end-face surface of

the fiber.Always install protective covers on unused or disconnected

components to prevent contamination. Always clean fiber

connectors before installing them.

Use a swab saturated with isopropyl alcohol to clean the end-surfaces. Use dry,

oil-free compressed air after applying the isopropyl alcohol.

To clean the optical connectors, follow these steps:

pad from the cleaning kit. Be sure that the pad makes full contact with the

end-face surfaces. Wait five seconds for the surfaces to dry and repeat.

3-20

The connectors used inside the system havebeen cleaned by the manufacturer and

connected to the adapters in the proper manner. The operation of the system

should be error free if the customer provides clean connectors on the application

side, follows the previous directions and ensures the following:

• Clean the connectors using lens tissues before connecting to the adapters. Use

pure alcohol to remove soil.

• Do not clean the inside of the connector adapters.

• Do not use force or quick movements when connecting the fiber optic

connectors in the adapters.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 21

Chapter 3 Installing the Chassis

• Cover the connector adapters to avoid soiling or contaminating the inside of

the adapters while cleaning the chassis.

• Cover the connectors and adapters to avoid the inside of the adapters or the

surface of the connectors from getting dirty when not using the connectors.

Note If the surface is not clean or does not have a uniform shine, repeat

the process using a fresh surface of the alcohol pad.

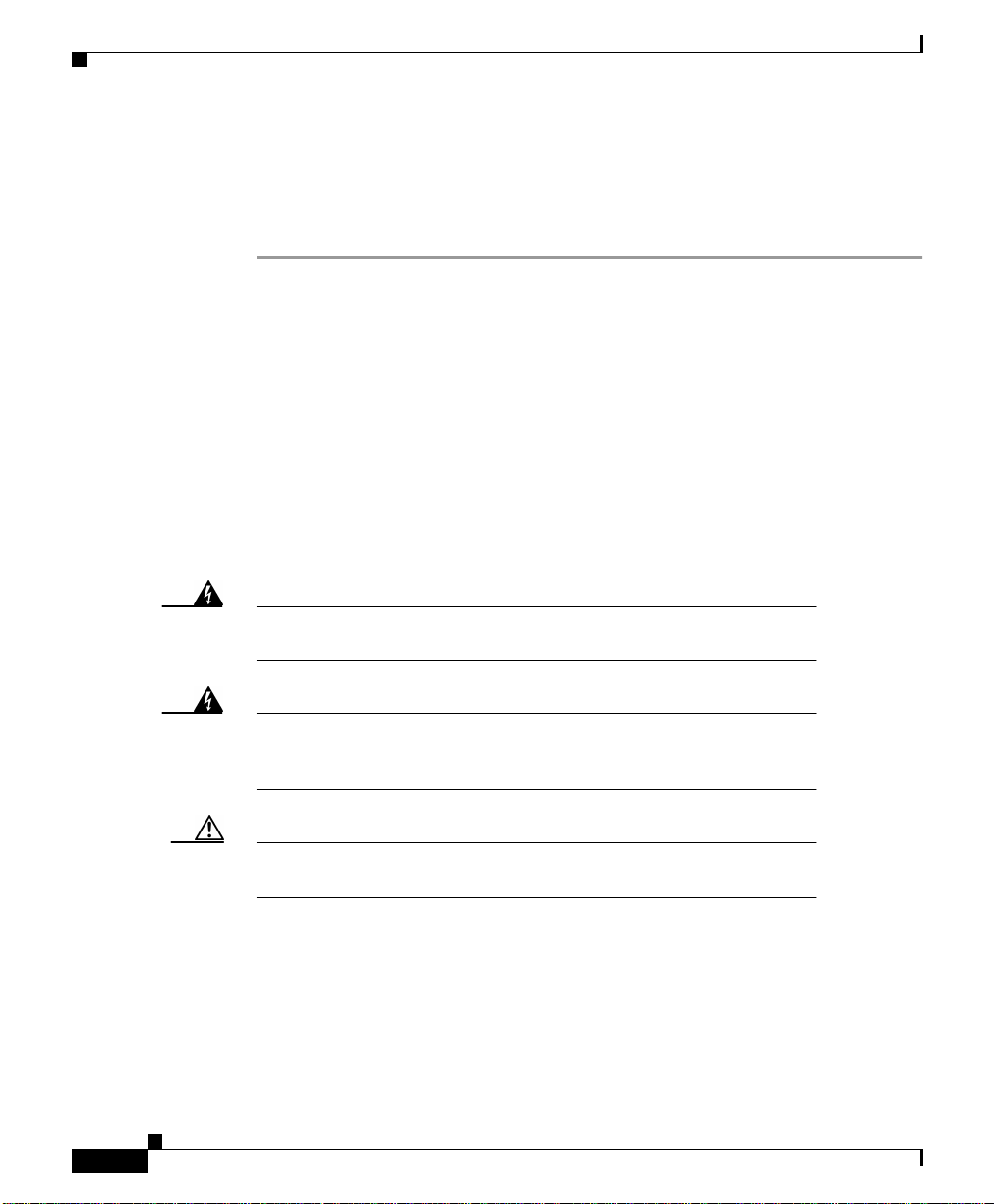

Removing the Power Supply Module

This section describes how to power on the system, determine whether a power

supply module (PSM) is faulty, and how to replace a PSM, if necessary.

Removing the Power Supply Module

Warning

Power On/Off

Caution If powered off, wait at least 10 seconds before you switch the unit

Only trained and qualifiedpersonnel should be allowed to install,

replace, or service this equipment.

The Cisco Metro 1500 series system has two identical, fully redundant PSMs.

Each PSM can cover the power needs of the entire system. These PSMs provide

5V and 30A to the system. The PSM provides full input-to-output, input-to-case,

and output-to-output isolation.

on again.

Turn the power on or off using the keyswitch on the AC-powered version only.

(See Figure 3-10.) This switch supplies power to the redundant power supplies.

You can only move the switch to the on ( | ) or off ( 0 ) position. Two keys are

shipped with each unit and all units use the same key. You can remove the key in

either the on or off position.

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-21

Page 22

Removing the Power Supply Module

The display on the front panel of the chassis indicates whether the power is on or

off. You can also monitor power status from the NEMI. For more information

about monitoring the power supply from the NEMI, refer to the

Cisco Metro 1500 series Software Configuration Guide.

Figure 3-10 Power Supply Modules

Chapter 3 Installing the Chassis

MUX

WCM

On/Err

On/Err

On/Err

On/Err

Loop

Loop

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

On/Err

Loop

Loop

Loop

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

L/R

L/R

L/R

L/T

L/T

L/T

R/R

R/R

R/R

R/T

R/T

R/T

RSM

On/Err

On/Err

Loop

Loop

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

L/R

L/R

L/T

L/T

R/R

R/R

R/T

R/T

NEMI

Serial

L

Power

On/Err

On

k

Error

B

Loop

A

Err.Int.BUS

LA

L/R

k

Err.Ext.BUS

L/T

LB

k

Auto

R/R

Receive

R/T

Link

A/T

A/R

BUS 1

B/T

B/R

BUS 2

M

D

Net

MUX DMX

1-8(32) 1-8(32)

nc

M1

8

8

7

7

6

5

4

3

2

1

DMX

METRO 1500 SERIES

on

nc

D1

8

7

6

5

4

3

2

1

Power 1

Power

Power 2

OK FAILOK

POWER

on

FAIL

FAN

Power

0

I

39943

3-22

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 23

Chapter 3 Installing the Chassis

Determining Power Supply Status

If the LED on a power supply is off while the unit is powered on, and the power

cable is plugged in the corresponding power socket, then either the cable is faulty,

a fuse has blown, or the power supply itself has failed. To determine the possible

cause of the failure, follow these steps:

Step 1 Check the power cable to make sure that it is securely plugged into the unit. If the

cable is correctly attached, go to Step 2.

Step 2 Check the fuses by disconnecting the power cord and opening the fuse holder. If

the fuses are okay, swap out the failed power supply module.

Note Check and replace the failed unit as soon as possible.While you

replace the faulty power supply, the redundant power supply

continues to provide uninterrupted service.

Removing the Power Supply Module

78-10588-03

Note The power socket labeled Power 1 supplies current to the left power

supply (Power 1). See Figure 3-11. The power socket labeled

Power 2 supplies current to the right power supply (Power 2).

Cisco Metro 1500 Series Hardware Installation Guide

3-23

Page 24

Removing the Power Supply Module

Figure 3-11 Rear View of Power Supply Module

Fuse

holders

Fuse 1 Fuse 2

Power 1 Power 2

Fan module

Voltage:

Max. Current:

Power Consumption:

Fuse:

For continued protection against risk of fire replace

only with same type and ratings of fuse.

For proper selection of power supply cord refer to

instruction manual.

Made in Germany

March 1998

Chapter 3 Installing the Chassis

115/230 V 50/60 Hz

2.5 A

max. 100W

2x T2.5A / 250V

Always remove both

power cords when disconnecting from power

!

source 1.

32268

3-24

DC Power

connectors

All PSMs are hot-swappable and can be replaced while the system is in service.

To replace a PSM, follow these steps:

Step 1 Remove the power cord associated with the failed power supply and loosen the

four panel screws.

Step 2 Pull out the malfunctioning module.

Step 3 Slide in the spare module.

Step 4 Check that the green LED is on.

Step 5 Reconnect the power cord.

Step 6 Tighten the four panel screws.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 25

Chapter 3 Installing the Chassis

Running Online Tests

Note The power levels cannot be checked without special measurement

equipment because of the automatic laser shutdown (ALS). All

power measurements must be done in-line because of ALS.

System checkout and online testing are usually performed during working hours.

Be sure to coordinate these tasks with the Cisco authorized representative.

Online testing varies from site to site depending on the CPU, operating systems

in use, and the local channels being connected.

Be sure to set up and run your test jobs before installing the unit. Test jobs must

be set up and verifiedby the customer prior to the actual installation of the system.

Fortest purposes, you can force the laser on by means of the network management

system as described in the Cisco Metro 1500 Series Software Configuration

Guide.

Running Online Tests

Note If your test results of the remote link deviate from the results

described in these steps and you cannot correct the problem, contact

your service representative.

Verifying Connections

Although the optical side of the Cisco Metro 1500 series system is designed to be

plug and play, it is common practice to verify input and output levels for the

optical interfaces existing in a typical connection because optical connections are

susceptible to dust and optical cables can be ruined by physical abuse.

Budget measurements should be carried out at points A and F to check whether

the user equipment is correctly interfaced. The budget measurement at point A

should be within the range specified on the Cisco Metro 1500 series label.

Measurement at point E is required to check whether the attenuation over the long

distance is within the power budget. Budget measurements at point C and point

D, measured at the remote side, can be used to calculate loss-levels of the

connecting fiber line. All channel modules leaving the factory are accompanied

by a test report.

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-25

Page 26

Chapter 3 Installing the Chassis

Running Online Tests

Measuring Channel Outputs and Channel Budgets

Channel module outputs, measured at entry to the MUX, point B, or exit of the

DMX, point E, are practically constant for all channel cards, whereas

measurements at the exit of the BSM (point C) or entry to the BSM (point D) can

exhibit a variation of 0 to 2 dB.

Note All power measurements must be done in-line because of ALS.

All measurements concerning budgets need modulated light. We recommend

using an external modulated light source. Practically any low powered light

source with roughly 100 MHz modulation can be used. If a need for an approved

light source exists, contact your Cisco representative.

You need:

• A Cisco Metro 1500 series system

• Access to two Cisco Metro 1500 series systems under test already connected

through optical fibers and RSMs (or fiber spools) depending on system

configuration

• A short fiber jumper

• Access to ocmstate

• An optical power meter connected in-line through an optical coupler or an

optical in-line power meter

If you have an external 100-MHz modulated light source, follow Steps 1 to 3 to

measure channel output at point F:

3-26

Step 1 Pick a pair of channel modules preferably without clock (or with a clock that can

be disabled with the ocmstate command, since none of the currently delivered

clocks will match).

Step 2 Connect the light source output to the connector labeled L/R (local receiver) of

the local channel module. As a result, the green LED of the local receiver of the

channel module is on and the ALS starts working (every 10 seconds the LED for

remote transmitting blinks shortly). However, the signal does not get looped

back yet.

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 27

Chapter 3 Installing the Chassis

Step 3 Use the ocmstate command to switch on the local loop. Now you can measure the

output power at point F. Afterwards, switch off the local loop. To measure at

points B or C, follow Steps 1 and 2 and then Step 4:

Step 4 Use the ocmstate command to switch the remote laser to “forced ON” to overcome

ALS. Then measure at points B and C. If you want to measure the input at points

D or E, follow Steps 1, 2, and 3 and then Step 5.

Step 5 Use ocmstate to activate the remote loopback on the remote side of the link.

The link comes up. All lasers and receivers at the channel module are on and the

remote receiver and the remote transmitter at the channel module on the remote

side of the link are on. The local transmitter at the channel module at the remote

side of the link is also on to allow measurements.

In case you do not have an adequate external modulated light source, you can use

the modulated light (100 MHz) of the pilot laser of the Cisco Metro 1500 series

system’sRSM (only an option if your Cisco Metro 1500 series system is equipped

with an RSM). In this case, in Step 2 you connect the local RSMs B/R (output of

the pilot laser) to the connector labeled L/R (local receiver) of the channel

module. The output of the pilot laser is sent against traffic.

Running Online Tests

78-10588-03

Note Do not forget to set or enable clocks, disable loopback and enable

automatic mode for the RSM before putting the Cisco Metro 1500

series units into service.

Cisco Metro 1500 Series Hardware Installation Guide

3-27

Page 28

Troubleshooting

Troubleshooting

If trouble occurs during installation, check Table 3-2 for a list of troubleshooting

tips. If the solution is not in the table, contact your Cisco service representative.

Table 3-2 Troubleshooting Tips

Problem Probable Cause Solution

No power No power is coming from the

outlet.

Power cables are loose. Check and reseat cables.

Power supply modules are not

engaged.

Power alarm No power is coming from one

outlet.

One power cable is loose. Check and reseat cables.

Power supply fuse is blown. Check and replace fuse.

Not

receiving

local data

Local channel is not online. Place local channel online.

Fiber-optic connectors are loose. Check and reseat connectors.

Tx-Rx connectors are not matched. Switch Tx-Rx connectors.

Connectors are dirty or blown. Clean or replace connectors.

Local cables are not properly

seated.

Local link power exceeds budget. Troubleshoot and retest local link.

Channel card is not connected. Connect all required optical fiber cables to the

Fiber links are dirty or blown. Clean or replace fiber cables.

Turn on power.

Fully engage modules.

Turn on power.

Trace and properly connect cables.

channel card.

Chapter 3 Installing the Chassis

3-28

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Page 29

Chapter 3 Installing the Chassis

Table 3-2 Troubleshooting Tips (continued)

Problem Probable Cause Solution

Not

receiving

remote data

Fiber-optic connectors are loose. Check and reseat connectors.

Tx-Rx connectors are not matched. Switch Tx-Rx connectors.

Remote cables are not properly

Trace and properly connect cable.

seated.

Remote link power exceeds

Troubleshoot and retest remote link.

budget.

Channel card is not connected. Connect all required optical fiber cables to the

channel card.

Fiber links are dirty or blown. Clean or replace fiber cables.

Inactive line

is not in

standby

mode

Link is not connected. Connect all required optical fibercables of the line

to the channel card.

Remote link power exceeds

Troubleshoot and retest remote link.

budget.

Fiber links are dirty or blown. Clean or replace fiber cables.

No password

prompt after

entering a

A non-supported adapter is being

used to connect to the Cisco Metro

1500 series serial port.

Use the supplied DB-9 to RJ-45 adapter or an

adapter that includes DCD/DTR1flow control and

RTS/CTS2 flow control.

proper login

name

1. DCD/DTR = data carrier detect/data terminal ready

2. RTS/CTS = request to send/clear to send

Troubleshooting

78-10588-03

Cisco Metro 1500 Series Hardware Installation Guide

3-29

Page 30

Troubleshooting

Chapter 3 Installing the Chassis

3-30

Cisco Metro 1500 Series Hardware Installation Guide

78-10588-03

Loading...

Loading...