Page 1

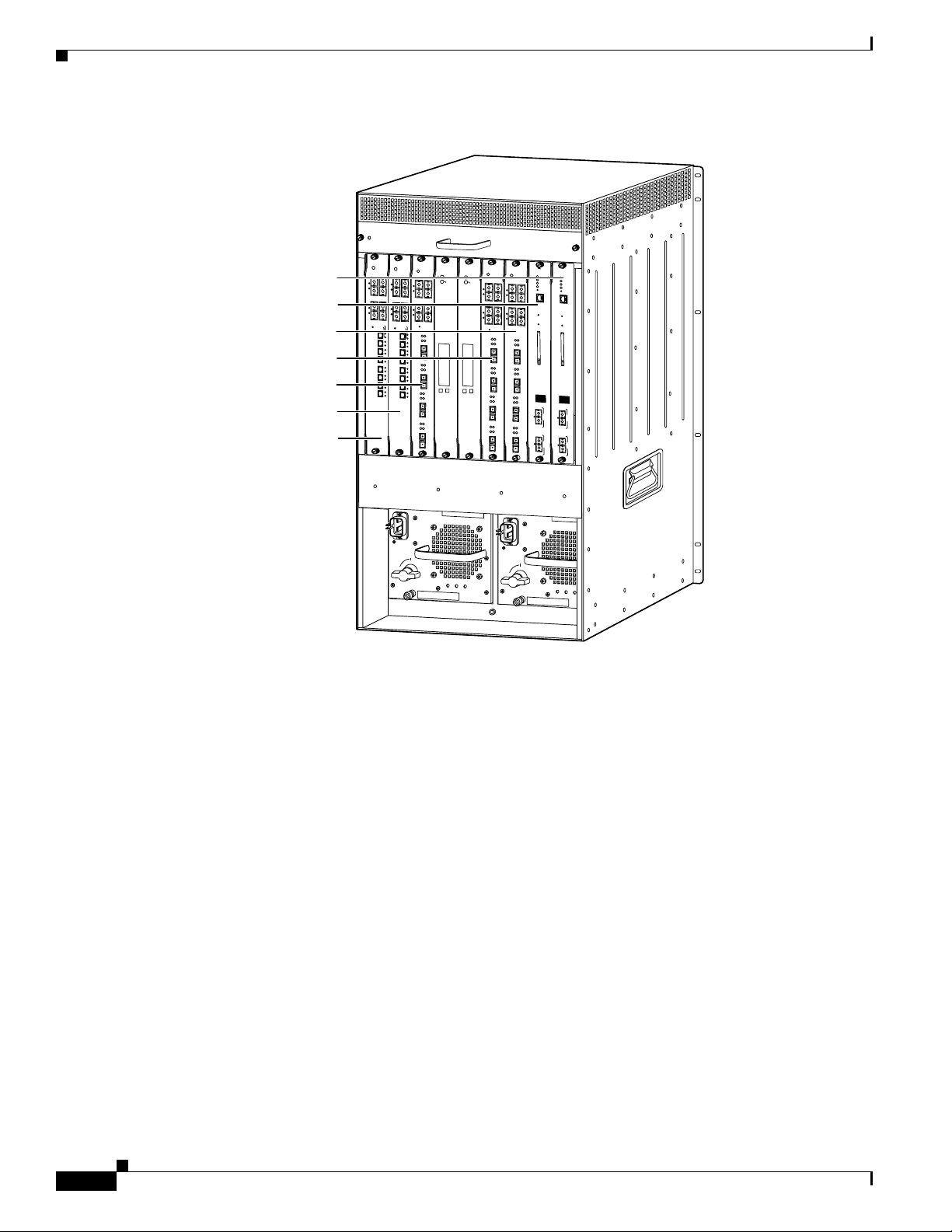

Cisco 760 0 Series Router

Supervisor

Route

January 2008

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

Fax: 408 527-0883

Text Part Number: OL-10100-04

Switch Processor Guide

800 553-NETS (6387)

Engine and

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following inform ation is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IMPLIED, INCLUDING, WITHOUT

CCVP, the Cisco logo, and the Cisco Square Bridge logo are trademarks of Cisco Systems, Inc.; Changing the Way We Work, Live, Play, and Learn is a service mark of Cisco Systems,

Inc.; and Access Registrar, Aironet, BPX, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, CCSP, Cisco, the Cisco Certified Internetwork Expert logo, Cisco IOS, Cisco

Press,

Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Enterprise/Solver, EtherChannel, EtherFast, EtherSwitch, Fast Step, Follow Me Browsing,

FormShare, GigaDrive, HomeLink, Internet Quotient, IOS, iPhone, IP/TV, iQ Expertise, the iQ logo, iQ Net Readiness Scorecard, iQuick Study, LightStream, Linksys,

MeetingPlace, MGX, Networking Academy, Network Registrar, Pack e t , PIX, ProConnect, ScriptShare, SMARTnet, StackWise, The Fastest Way to Increase Your Internet

Quotient, and TransPath are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the United States and certain other countries.

All other trademarks mentioned in this document or Website are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company. (0705R)

Any Internet Protocol (IP) addresses used in this document are not intended to be actual addresses. Any examples, command display output, and figures included in the

document are shown for illustrative purposes only. Any use of actual IP addresses in illustrative content is unintentional and coincidental.

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

Copyright © 2007-2008 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface vii

Contents vii

Document History vii

Document Organization viii

Document Conventions viii

Warning Definition ix

Related Documentation ix

Obtaining Documentation, Obtaining Support, and Security Guidelines x

CHAPTER

CHAPTER

1 Cisco 7600 Product Overview 1-1

Cisco 7600 Series Routers 1-1

Supported Hardware 1-2

Features 1-3

Port Addresses 1-5

Physical Interface Addresses 1-5

MAC Addresses 1-6

2 Route Switch Processors and Supervisor Engines 2-1

Overview 2-2

Route Switch Processor 720 2-6

RSP720 Features 2-7

Supported Chassis, Line Cards, and Modules 2-7

Unsupported Hardware and Features 2-7

RSP720 with 10GE Uplink Ports 2-8

RSP720-10GE Features 2-8

Supported Chassis, Line Cards, and Modules 2-9

RSP720-10GE Usage Guidelines and Limitations 2-10

QoS on the RSP720-10GE 2-10

OL-10100-04

Supervisor Engine 720 and Supervisor Engine 32 2-12

Front-Panel Controls (RSP720, RSP720-10GE, Sup720, Sup32) 2-12

Front-Panel LEDs (RSP720, RSP720-10GE, Sup720, Sup32) 2-13

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

iii

Page 4

Contents

Supervisor Engine 2 2-14

CHAPTER

3 Installing and Configuring Route Switch Processors and Supervisor Engines 3-1

Preparing for Installation or Removal 3-1

Safety Precautions for Module Installation and Removal 3-2

Preventing Electrostatic Discharge Damage 3-2

Tools Required for Module Installation 3-3

Determining Module Location 3-3

Installing a Supervisor Engine or Route Switch Processor 3-4

Removing a Supervisor Engine or Route Switch Processor 3-7

Hot Swapping (OIR) Modules 3-8

Removing and Replacing Memory 3-8

Connecting to the Console Port 3-9

Connecting a Terminal 3-9

Connecting a Modem 3-10

Connecting to the Uplink Ports 3-10

Using Flash Memory Cards 3-12

Installing a Flash Memory Card 3-13

Removing a Flash Memory Card 3-14

APPENDIX

APPENDIX

Power Management and Environmental Monitoring 3-14

Determining Software Feature Support 3-14

Configuring a Supervisor Engine or Route Switch Processor 3-14

A Technical Specifications A-1

Module Specifications A-1

Regulatory Standards Compliance A-1

B Cable and Connector Specifications B-1

Limiting Connection Distances B-1

Uplink Port Transceiver Modules B-2

1GE Uplink Ports and Cabling Specifications B-3

10GE Uplink Ports and Cabling Specifications B-5

GBIC Module Cabling Specifications B-6

Console Port Cabling Specifications and Pinouts B-6

Console Port Cabling Specifications B-6

Console Port Signals and Pinouts B-7

iv

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 5

Identifying a Rollover Cable B-7

DB-9 Adapter (for Connecting to a PC) B-8

DB-25 Adapter (for Connecting to a Terminal) B-9

Modem Adapter B-9

Console Port Mode 2 Signaling and Pinouts (Sup2 Only) B-10

RJ-45 Connector B-10

Fiber-Optic Connectors B-12

SC Connectors B-12

MT-RJ Connectors B-13

LC Connectors B-14

Cleaning the Fiber-Optic Connectors B-15

LX/LH GBIC and MMF Cable Considerations B-16

Patch Cord B-16

Patch Cord Configuration Example B-16

Patch Cord Installation B-17

Contents

I

NDEX

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

v

Page 6

Contents

vi

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 7

Caution Only trained and qualified service personnel (as defined in IEC 60950 and AS/NZS3260) should install,

Contents

Preface

This guide describes the route switch processors and supervisor engines supported by Cisco 7600 series

routers. It also provides technical specifications for these modules and describes cable and connector

specifications.

replace, or service the equipment described in this document.

This preface contains the following sections:

• Document History, page vii

• Document Organization, page viii

• Document Conventions, page viii

• Related Documentation, page ix

• Obtaining Documentation, Obtaining Support, and Security Guidelines, page x

Document History

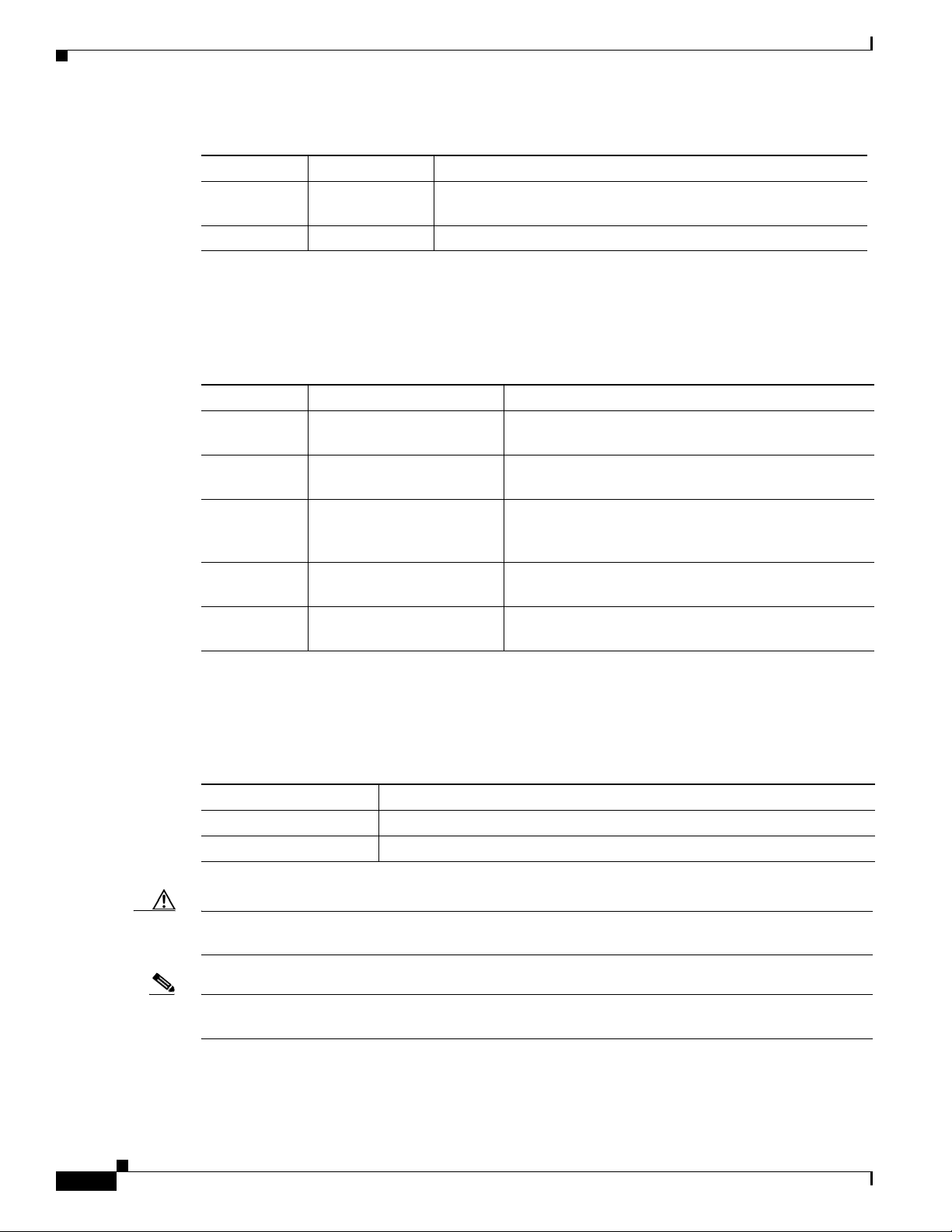

Table 1 lists the technical changes made to this document since it was first printed.

Ta b l e 1 Document History

Revision Date Change Summary

OL-10100-04 January 2008 Added information about the Route Switch Processor 720 with

OL-10100-03 May 2007 Removed eFSU from the list of unsupported features for the Route

OL-10100-04

10-GE uplink ports, introduced in Cisco IOS Release 12.2SRC.

Switch Processor

eFSU and ISSU are supported on the RSP720, Sup720, and Sup32.

Added a note that Cisco IOS Release 12.2SXF is the last release in

which the Supervisor Engine 720 (with PFC3A) is supported.

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

720. Beginning in Cisco IOS Release 12.2SRB1,

vii

Page 8

Document Organization

Table 1 Document History (continued)

Revision Date Change Summary

OL-10100-02 February 2007 Added information about the Route Switch Processor 720 (a new

OL-10100-01 May 2006 Initial release of the document.

Document Organization

This document is organized as follows:

Chapter Title Description

Chapter 1 Cisco 7600 Product

Overview

Chapter 2 Route Switch Processors

and Supervisor Engines

Chapter 3 Installing and Configuring

Route Switch Processors

and Supervisor Engines

Appendix A Technical Specifications Lists the technical specifications for the RSP and

Appendix B Cable and Connector

Specifications

supervisor engine) introduced in Cisco

Provides an overview of Cisco 7600 series routers, and

interface and port addresses.

Describes the route switch processors (RSPs) and

supervisor engines supported on Cisco

Provides instructions for installing and removing RSPs

and supervisor engines and connecting to the console

and uplink ports.

supervisor engines.

Lists the cable and connector specifications for the

RSPs and supervisor engines.

Preface

IOS Release 12.2SRB.

7600 series routers.

Document Conventions

This document uses the following conventions:

Convention Description

boldface font Commands, command options, and keywords are in boldface.

italic font Command arguments for which you supply values are in italics.

Caution Means reader be careful. You are capable of doing something that might result in equipment damage or

loss of data.

Note Means reader take note. Notes contain helpful suggestions or references to materials not contained in

this document.

viii

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 9

Preface

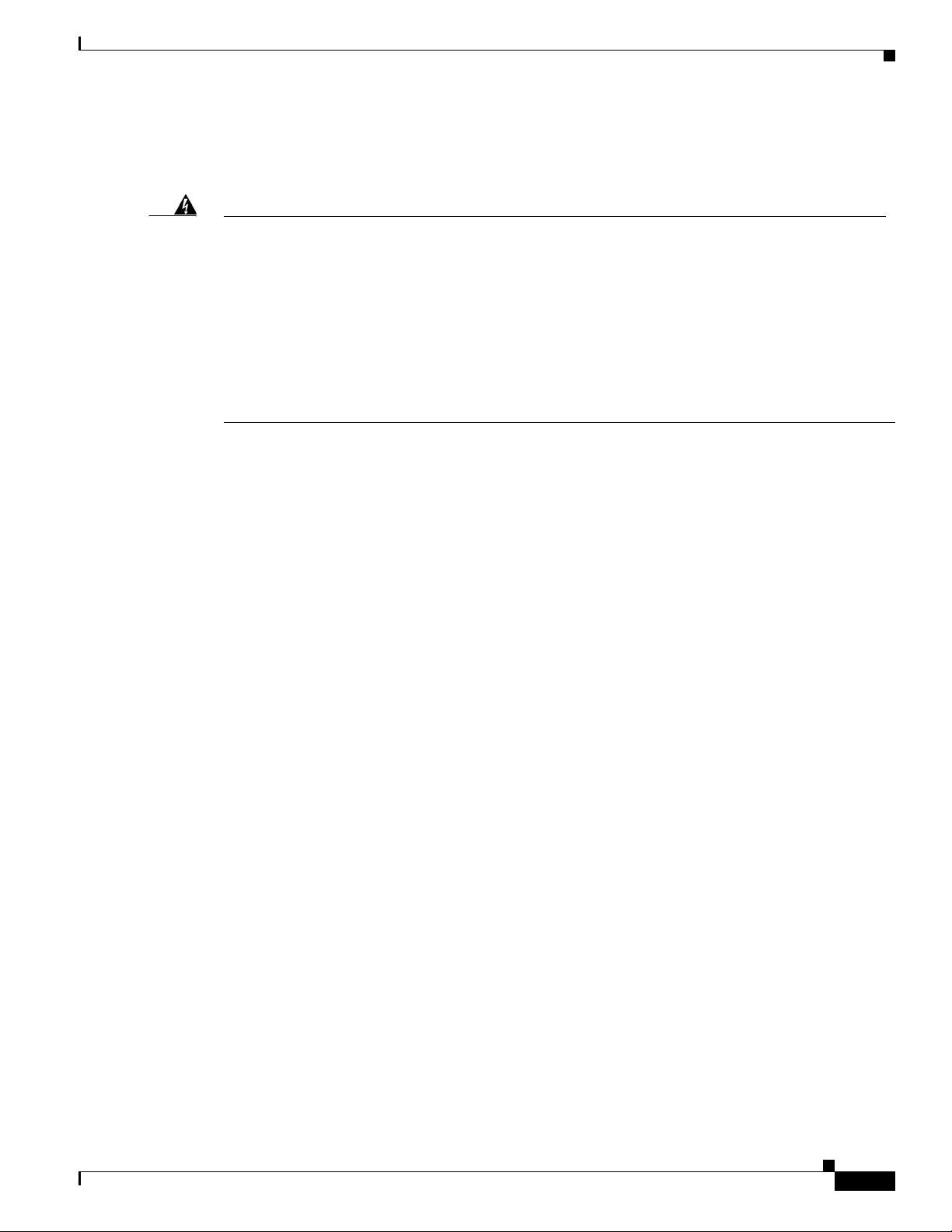

Warning Definition

Related Documentation

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar

with standard practices for preventing accidents. Use the statement number provided at the end of

each warning to locate its translation in the translated safety warnings that accompanied this

device.

SAVE THESE INSTRUCTIONS

Statement 1071

See Regulatory Compliance and Safety Information for the Cisco 7600 Series Routers for translations of

warnings and information about the compliance and safety standards with which Cisco

routers conform.

Related Documentation

The following documents provide additional information about Cisco 7600 series routers:

• Cisco 7600 Series Routers Documentation Roadmap

• Supported Hardware for Cisco 7600 Series Routers

7600 series

• Regulatory Compliance and Safety Information for the Cisco 7600 Series Routers

• Cisco 7600 Series Router Installation Guide

• Cisco 7609 Router Installation Guide (OSR-7609)

• Cisco 7600 Series Router Module Installation Guide

• Cisco 7600 Series Router Cisco IOS Command Reference

• Cisco 7600 Series Router Cisco IOS System Message Guide

• Cisco 7600 Series Router Cisco IOS Software Configuration Guide

Documentation for the Cisco 7600 series router is available online at the folowing URL:

http://www.cisco.com/en/US/products/hw/routers/ps368/tsd_products_support_series_home.html

For information about MIBs, refer to this URL:

http://www.cisco.com/public/sw-center/netmgmt/cmtk/mibs.shtml

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

ix

Page 10

Obtaining Documentation, Obtaining Support, and Security Guidelines

Obtaining Documentation, Obtaining Support, and Security

Guidelines

For information on obtaining documentation, obtaining support, providing documentation feedback,

security guidelines, and also recommended aliases and general Cisco

What’s

New in Cisco Product Documentation, which also lists all new and revised Cisco technical

documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

documents, see the monthly

Preface

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

x

OL-10100-04

Page 11

Cisco 7600 Product Overview

This chapter provides an overview of the Cisco 7600 series routers and describes interface and port

addresses on the routers. It contains the following sections:

• Cisco 7600 Series Routers, page 1-1

• Port Addresses, page 1-5

Note This document does not contain instructions for installing the router. For instructions on how to install

the router, see the Cisco 7600 Series Router Installation Guide.

Cisco 7600 Series Routers

The Cisco 7600 series routers consist of these routers:

CHA PTER

1

• Cisco 7603 router (3 slots)

• Cisco 7604 router (4 slots)

• Cisco 7606 router (6 slots)

• Cisco 7609 router (9 vertical slots)

• Cisco 7613 router (13 slots)

Note In addition, Cisco IOS Release 12.2SRB and later releases introduced enhanced versions of the 3-slot, 6-slot,

and 9-slot chassis (CISCO7603-S, CISCO7606-S, and CISCO7609-S). These enhanced chassis provide

increased power and cooling capabilities and an enhanced switch fabric to support high-power processors and

future line cards, which will provide 80-Gbps connections.

Cisco 7600 series routers provide optical wide area network (WAN) and metropolitan-area network

(MAN) networking with a focus on line-rate delivery of high-touch IP services at the edge of service

provider networks.

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

1-1

Page 12

Cisco 7600 Series Routers

Supported Hardware

Cisco 7600 series routers support the following hardware:

• A supervisor engine (such as the Sup720, Sup32, or Sup2) or Route Switch Processor (RSP720) with

modular Gigabit Ethernet uplink ports. Each supervisor engine or RSP has two integrated daughter

cards: a policy

section on page 2-2 for details.

Note You can install a redundant supervisor engine or RSP in the router to provide a backup in

• Optical Services Modules (OSMs), FlexWAN and Enhanced FlexWAN modules, recommended

Catalyst

–

Two additional modules for the Cisco 7603 router

Chapter 1 Cisco 7600 Product Overview

feature card (PFC) and a multilayer switch feature card (MSFC). See the “Overview”

case the active module fails. Both supervisor engines or RSPs must be identical. If the

system does not include a redundant supervisor engine or RSP, you can install another type

of module (fo r ex ample , FlexWAN, OSM, o r SIP a nd SPA) in the s lot that is reser ved for the

redundant processor card.

6000 family modules, and SPA interface processors (SIPs) in any combination.

–

Three additional modules for the Cisco 7604 router

–

Five additional modules for the Cisco 7606 router

–

Eight additional modules for the Cisco 7609 router

–

Twelve additional modules for the Cisco 7613 router

Note Specific combinations of supervisor engines or RSPs and modules may not be supported in

your chassis. See the Supported Hardware for Cisco 7600 Series Routers guide for

information about which combinations are not supported.

• Hot-swappable fan assembly

• Redundant AC-input or DC-input power supplies

• Redundant AC-input or DC-input power entry modules (PEMs) (Cisco 7603 and Cisco 7606 routers

only)

• An optional Switch Fabric Module (WS-X6500-SFM2) that is available with the Supervisor

Engine

2. For redundancy, you can install a redundant SFM2 module. The module that is installed

first functions as the primary module.

1-2

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 13

Chapter 1 Cisco 7600 Product Overview

Features

Table 1-1 lists some key features of the Cisco 7600 series routers.

Ta b l e 1-1 Cisco 7600 Series Routers Key Features

Feature Description

Performance and

configuration

Supervisor engine or

route switch

processor

Cisco 7600 Series Routers

For detailed information about the features supported on Cisco 7600 series

routers, see the Cisco 7600 Series Router Cisco IOS Software Configuration

Guide for the version of software being used on the router.

• Modular, upgradable feature modules for core switching logic

• Modular Gigabit Ethernet ports that you can configure with Gigabit

Interface Converter (GBIC), small form-factor pluggable (SFP), XENPAK,

and X2 optics modules

• Several combinations of multilayer switch feature cards (MSFCs) and

policy feature cards (PFCs) supported (see

–

MSFC4 and PFC3C or PFC3CXL (for the RSP720, see note below)

Table 2-1):

Fault tolerance and

redundancy

–

MSFC3 and PFC3B, PFC3BXL, or PFC3A (see note below)

–

MSFC2 and PFC or PFC2

• The MSFC contains the switch processor and route processor (SP/RP) for

the router.

• PCMCIA slot

• Console port for terminal and modem access

Note The Route Switch Processor 720 (RSP720) is the newest supervisor

engine for the Cisco

7600 series routers. It is available in Cisco IOS

Release 12.2SRB and later releases.

Note Cisco IOS Release 12.2SRC introduces support for the RSP720-10GE

(an RSP with 10 Gigabit Ethernet uplink ports).

Note Cisco IOS Release 12.2SXF is the last release in which the PFC3A is

supported. Later releases do not support this PFC.

• Support for two hot-swappable (redundant) supervisor engines or route

switch processors, including fast switchover to the redundant (standby)

module

• Support for two redundant AC- or DC-input, load-sharing power supplies

• Support for two redundant AC- or DC-input PEMs (Cisco 7603 and

Cisco

7606 routers only)

OL-10100-04

• Power management for modules and power supplies

• Environmental monitoring of critical system components

• Hot-swappable fan assembly

• Redundant clock modules

• LACP 1-1 redundancy with fast switchover

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

1-3

Page 14

Cisco 7600 Series Routers

Table 1-1 Cisco 7600 Series Routers Key Features (continued)

Feature Description

Memory

components

• Electrically erasable programmable read-only memory (EEPROM) on the

supervisor engine or route switch processor stores module-specific

information, such as the serial number, part number, controller type,

hardware revision, configuration information, and other details unique to

each module.

• NVRAM for storing configuration information.

• DRAM for default system software.

• Internal flash memory—To store the boot image. The defaults are:

• The RSP720 SP/RP and the Sup32 SP contain a CompactFlash (CF)

adapter that provides 512 MB of internal flash memory.

• The Sup720 SP/RP, Sup32 RP, and Sup2 SP/RP contain 32-MB or

64-MB of internal flash memory. Cisco IOS Release 12.2(18)SXF and

later releases support the CF

adapter as an orderable option (Cisco part

number CF-ADAPTER=) for these Sups. 1

Chapter 1 Cisco 7600 Product Overview

Note In the command-line-interface (CLI), you access internal flash memory

as bootdisk (CF adapter) or bootflash (non-CF adatper). When you

install a CF adapter on the Sup720, Sup32, or Sup2, bootflash becomes

an alias to bootdisk.

• External flash memory—To store and run software images and configuration

files or to serve as an input/output (I/O) device. You can install 64-MB,

128-MB, 256-MB, or 512-MB flash memory cards, or 1-GB MicroDrive card,

in slots on the supervisor engine or RSP front panel.

The Sup2 supports PCMCIA flash memory cards only. It does not support

CompactFlash or MicroDrive cards.

• Flash file system—Flash memory contains a file system. You can use a

variety of commands to manage the file system (such as cd, pwd, dir, and

delete). The file system includes the following devices:

–

Onboard bootflash/bootdisk

–

Flash memory slot

Component hot

swapping

All components (including optional redundant modules and fans) support hot

swapping, which allows you to add, replace, or remove components without

interrupting the system power or causing other software or interfaces to shut down.

Management • CLI through the console port or Telnet

• Simple Network Management Protocol (SNMP)

1. For information on how to install a CF adapter, see the instructions at:

http://www.cisco.com/en/US/products/hw/switches/ps708/products_installation_and_configuration_guide09186a0080537ae3.

html

1-4

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 15

Chapter 1 Cisco 7600 Product Overview

Port Addresses

Each port (or interface) in the Cisco 7600 series router has several different types of addresses. The

physical interface address is the actual physical location (slot and port) of the interface connector within

the chassis. The system software uses the physical addresses to control activity within the router and to

display status information. These physical slot and port addresses are not used by other devices in the

network; they are specific to the individual router and its internal components and software. For more

information, see the

The Media Access Control (MAC) address is a standardized data link layer address that is required for

every port or device that connects to a network. Other devices in the network use MAC addresses to

locate specific ports in the network and to create and update routing tables and data structures. Routers

use a unique method, described in the

MAC addresses of their interfaces.

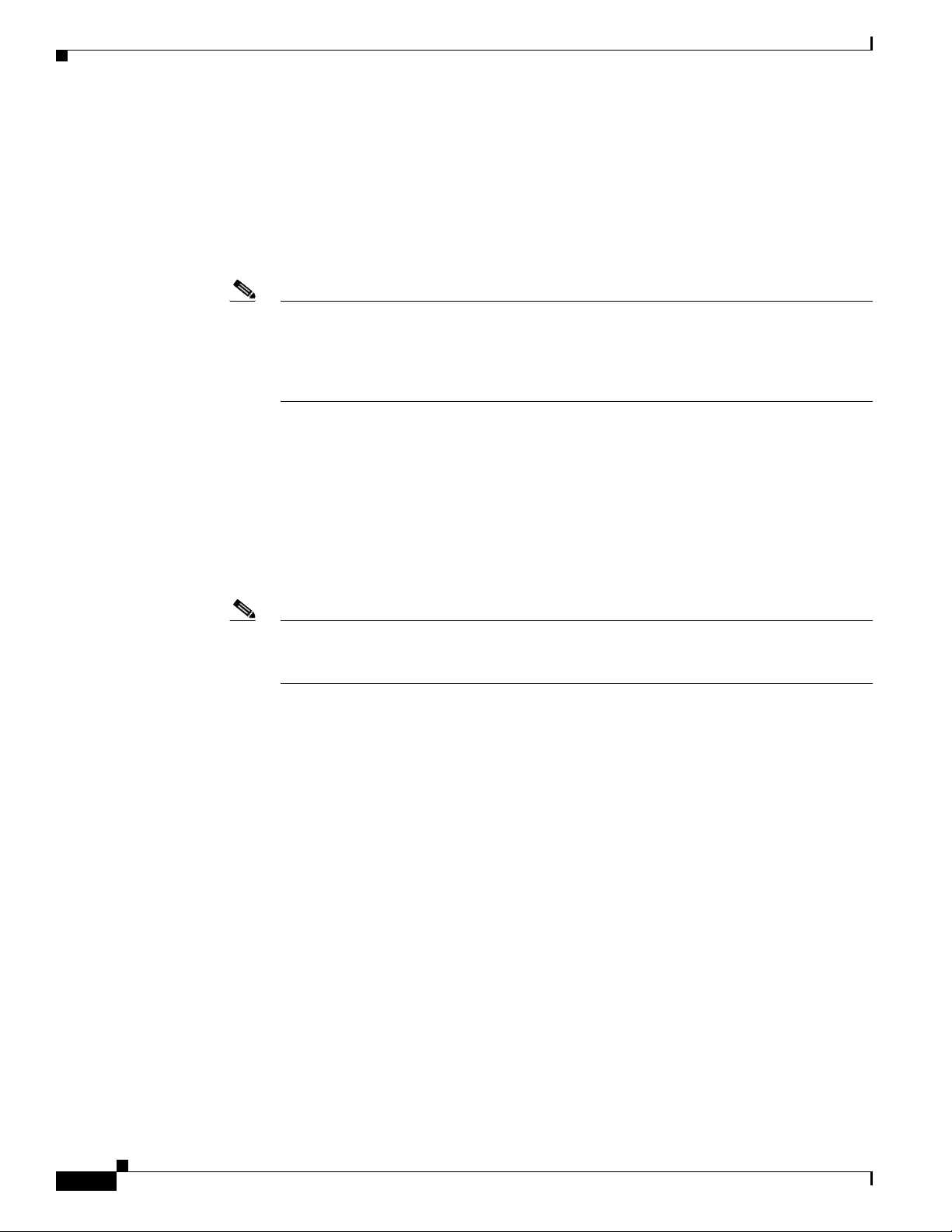

Physical Interface Addresses

Physical port addresses specify the actual physical location of each port on every module in the router,

as shown in

example, 1/1, 1/2, 2/1, 2/2, and so on):

• Slot—Identifies the slot in which the module is installed. Depending on the router layout, the slots

are numbered from top to bottom or right to left starting with

Figure 1-1. The port address is a two-part number in the format slot/port number (for

“Physical Interface Addresses” section on page 1-5.

Port Addresses

“MAC Addresses” section on page 1-6, to assign and control the

1 (1/n, 2/n, and so on).

–

On horizontal-oriented chassis (such as the Cisco 7606 and Cisco 7613 routers), slots are

numbered from top to bottom.

–

On vertical-oriented chassis (such as the Cisco 7609 router), slots are numbered from right to left.

• Port nu m b e r—Identifies the physical port number on the module. Port numbers always begin at 1

(n/1, n/2, and so on).

–

On horizontal-oriented modules, ports are numbered from left to right.

–

On vertical-oriented modules, ports are numbered from top to bottom.

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

1-5

Page 16

Port Addresses

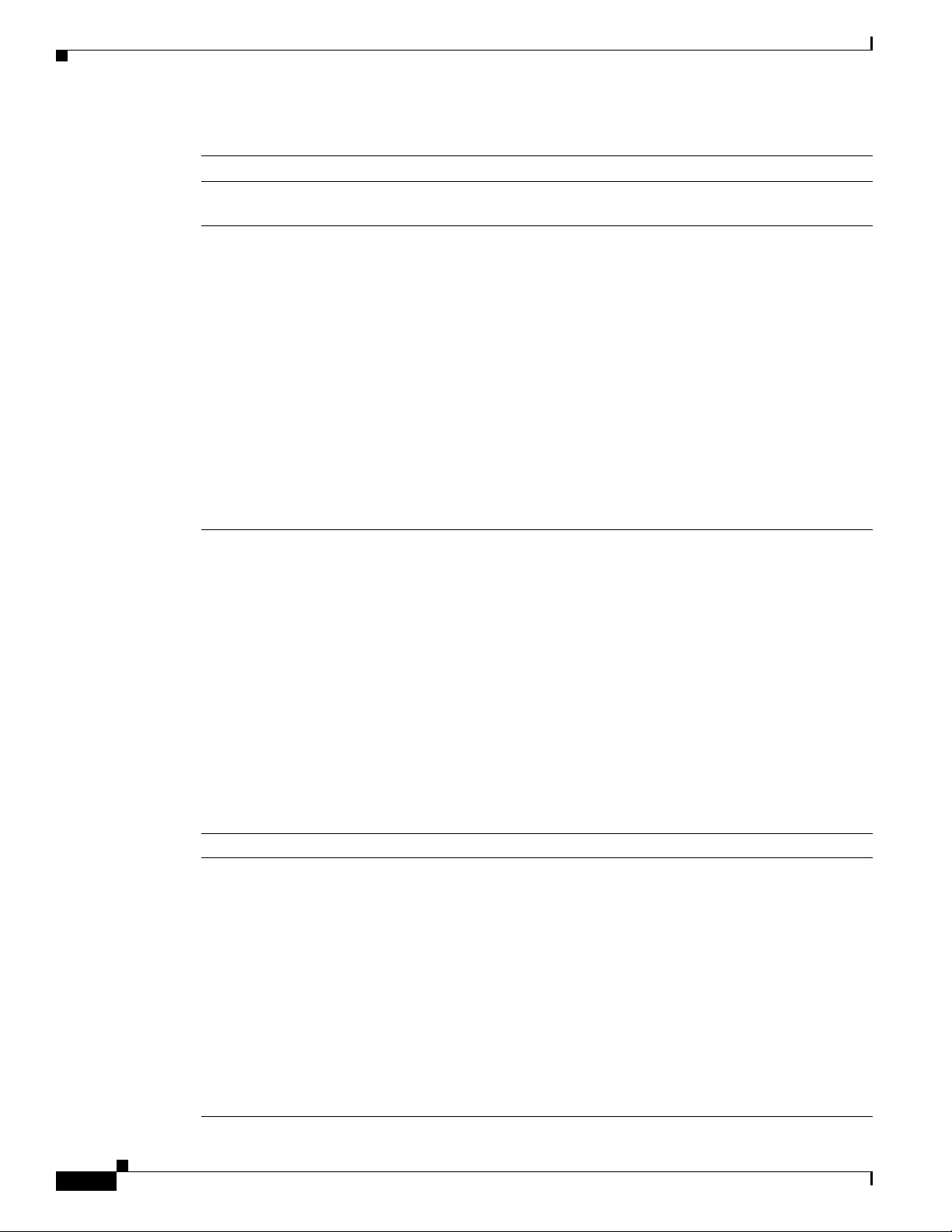

Figure 1-1 Cisco 7609 Router Port Address Examples

FAN

STATUS

8 PORT OC3 POS MM

OSM-8OC3-POS MM

8 PORT OC3 POS MM

OSM-8OC3-POS MM

O

O

C

S

1

M

2

W

O

W

S

Port numbers 1/1 to 1/2

Port numbers 2/1 to 2/2

Port numbers 3/1 to 3/4

Port numbers 4/1 to 4/4

Port numbers 7/1 to 7/4

Port numbers 8/1 to 8/8

Port numbers 9/1 to 9/8

S

T

A

T

U

S

2

1

L

I

N

K

1

2

L

I

N

K

4

3

L

I

N

K

3

4

L

I

N

K

C

A

L

A

R

I

R

N

L

R

E

K

A

I

S

E

R

E

R

M

T

1

2

3

4

5

6

7

8

-

P

4

S

W

O

0

S

T

A

T

U

S

2

1

L

I

N

K

1

2

L

I

N

K

4

3

L

I

N

K

3

4

L

I

N

K

C

A

L

A

R

I

R

N

L

R

E

K

A

I

S

E

R

E

R

M

T

1

2

3

4

5

6

7

8

C

C

IT

S

6

1

C

M

S

5

2

T

0

-

H

M

A

P

0

T

O

F

-

U

S

A

S

S

F

-

B

M

M

R

M

I

C

M

D

2

1

S

L

T

ATUS

L

I

N

AC

K

TIVE

1

L

I

N

K

2

4

3

L

I

N

K

3

L

I

N

K

4

R

E

S

E

T

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

P

O

R

T

1

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

IV

E

R

T

X

X

R

X

P

O

R

T

2

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

SEL

N

C

EXT

T

EC

IV

E

T

R

T

X

X

R

X

P

O

R

T

3

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

T

X

O

S

O

C

O

S

S

W

1

C

M

C

I

T

6

C

5

0

H

0

F

S

A

F

B

M

R

IC

M

D

ST

L

AT

U

S

AC

TIV

E

S

N

ELE

EX

T

CT

S

SUPERVISOR2

2

1

M

WS-X6K-SUP2-2GE

2

P

4

O

0

P

C

O

S

1

S

M

S

2

T

M

M

A

P

T

M

O

U

S

S

-

M

M

2

1

L

I

N

L

I

K

N

K

1

1

L

I

N

L

I

K

N

K

2

2

4

3

L

I

N

L

I

K

N

K

3

3

L

I

N

L

I

K

N

K

4

4

R

E

S

E

T

C

A

A

R

L

R

A

IE

R

M

R

A

C

T

IV

E

R

T

X

X

R

X

P

O

R

T

1

T

X

C

A

A

R

L

R

A

I

R

E

M

R

C

A

A

A

R

L

C

R

A

T

L

I

R

I

E

IV

N

M

R

K

E

R

T

X

X

R

X

P

O

R

T

2

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

IV

E

R

T

X

X

R

X

P

O

R

T

3

T

X

C

A

A

R

L

R

A

L

I

R

I

E

N

M

R

K

A

C

T

I

V

E

R

T

X

X

R

X

T

X

SUPERVISOR2

4

0

C

1

S

2

T

-

A

P

T

O

U

S

S

-

M

M

2

1

4

3

R

E

S

E

T

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

P

O

R

T

1

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

P

O

R

T

2

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

P

O

R

T

3

T

X

C

A

A

R

L

R

A

I

R

E

M

R

A

C

T

I

V

E

R

T

X

X

R

X

T

X

WS-X6K-SUP2-2GE

S

T

A

S

T

T

U

A

S

T

U

S

Y

S

S

S

T

Y

E

S

M

T

C

E

M

O

C

N

O

S

N

O

S

L

P

E

O

W

L

P

R

E

W

M

R

G

R

M

M

E

G

T

R

S

M

E

E

T

T

S

E

T

C

O

C

N

O

S

N

O

S

L

O

E

L

E

C

O

C

N

O

M

P

S

N

O

M

O

O

P

S

D

O

R

O

L

O

E

T

D

E

R

L

E

T

E

L

I

N

K

P

C

P

M

C

C

M

I

C

A

I

A

E

J

E

E

J

C

E

T

C

T

1

0

1

1

0

%

0

%

1

0

%

%

S

w

S

i

w

t

c

i

h

t

c

h

L

o

L

a

o

d

a

d

P

O

P

R

O

T

R

L

IN

T

1

L

K

I

N

1

K

P

O

P

R

O

L

T

R

I

N

T

K

2

2

Chapter 1 Cisco 7600 Product Overview

The supervisor engine and route switch processor have two or more uplink ports (numbered n/1, n/2, and

so on). The Supervisor Engine 32 (WS-SUP32-GE-3B) has nine uplink ports, numbered n/1 to n/9.

In some cases, a single port supports two different types of connectors (for example, Port 2 on the

Supervisor Engine 720 supports a Gigabit Ethernet SFP module or a 10/100/1000-Mbps RJ-45

connector). However, only one of the two options can be active at a time.

MAC Addresses

All network interface connections (ports) require a unique MAC address. The MAC address of an

interface is stored in electrically erasable programmable read-only memory (EEPROM) on a component

that resides directly on the interface circuitry. The router system code reads the EEPROM for each

interface in the system, learns the MAC addresses, and then initializes appropriate hardware and data

structures. Each VLAN in the spanning tree has one unique MAC address. This addressing scheme

enables the router to identify the state (connected or not connected) of each interface. When you hot

swap a module, the MAC address changes with the module.

o

INPUT

FAN

OUTPUT

OK

OK

o

FAIL

INPUT

FAN

OUTPUT

OK

OK

FAIL

55748

1-6

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 17

CHA PTER

2

Route Switch Processors and Supervisor Engines

This chapter describes the route switch processors and supervisor engines supported on Cisco 7600

series routers and provides instructions for performing basic tasks on the modules. It contains the

following sections:

• Overview, page 2-2

• Route Switch Processor 720, page 2-6

• RSP720 with 10GE Uplink Ports, page 2-8

• Supervisor Engine 720 and Supervisor Engine 32, page 2-12

• Supervisor Engine 2, page 2-14

Note The route switch processor is the newest version of supervisor engine. See Table 2-1 for a list of the route

switch processor and supervisor engine configurations supported on Cisco 7600 series routers. Be sure

to review the release notes for the software version running on your router for information about any

restrictions and limitations that might apply.

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-1

Page 18

Overview

Overview

Chapter 2 Route Switch Processors and Supervisor Engines

The supervisor engine or route switch processor (RSP) is a module that is installed in one of the card

slots in the router. The supervisor engine or RSP provides switching and local and remote management

for the router and also contains the uplink ports for the router. Both types of modules (supervisor engine

and RSP) perform the same functions in the router.

Cisco 7600 series routers support the following types of RSPs and supervisor engines:

• Route Switch Processor 720—Supported on all chassis (including enhanced) except the Cisco 7603

router and the Cisco OSR-7609. Available in Cisco

• RSP720-10GE (with 10GE uplink ports)—Supported on the Cisco 7604 and 7609 routers and

the

Cisco 7603-S, 7606-S, and 7609-S routers (enhanced chassis). Available in Cisco IOS

Release

• Supervisor Engine 720—Supported on all Cisco 7600 series routers.

• Supervisor Engine 32—Supported on all but the Cisco 7603 router.

• Supervisor Engine 2—Supported on all but the Cisco 7613 router. The Supervisor Engine 2 is no

longer supported in Cisco

12.2SRC and later releases.

IOS Release 12.2SRA and later releases.

IOS Release 12.2SRB and later releases.

Although the router can operate with a single supervisor engine or RSP, you can also install a second

redundant module (of the same type) in the chassis. Only one module is active at a time. The second

module acts as a “standby,” serving as a backup if the active module fails.

Note If the system does not include a redundant supervisor engine or RSP, you can install another type of

module in the slot reserved for the redundant supervisor engine or RSP.

The supervisor engine or RSP contains the following integrated daughter cards that perform forwarding and

routing and provide the protocols supported on the router. Several configurations of daughter cards are

supported (as shown in

• Policy Feature Card (PFC) is the forwarding plane and does the following:

–

Performs Layer 2 and Layer 3 forwarding.

–

Enforces access control list (ACL) functions.

–

Performs policing and marking for quality of service (QoS) traffic.

–

Collects Netflow statistics.

Note A high-capacity (XL) PFC is also available. The XL version (PFC3BXL or PFC3CXL)

Tabl e 2-1).

provides more memory for more routing table and netflow cache capacity than a PFC.

It

allows routing and forwarding processes to be offloaded from the supervisor engine or

RSP to the PFC, thus increasing the performance of the supervisor engine or RSP.

2-2

• Multilayer Switch Feature Card (MSFC) is the control plane and does the following:

–

Performs routing for the chassis. The MSFC contains the route processor (RP) and

switch

processor (SP) for the router.

–

Runs Layer 2 and Layer 3 protocols, such as the Spanning Tree Protocol (STP) and others.

For

information about supported protocols, see the Cisco 7600 Series Router Cisco IOS Software

Configuration Guide and the release notes for the software version running on the router.

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 19

Chapter 2 Route Switch Processors and Supervisor Engines

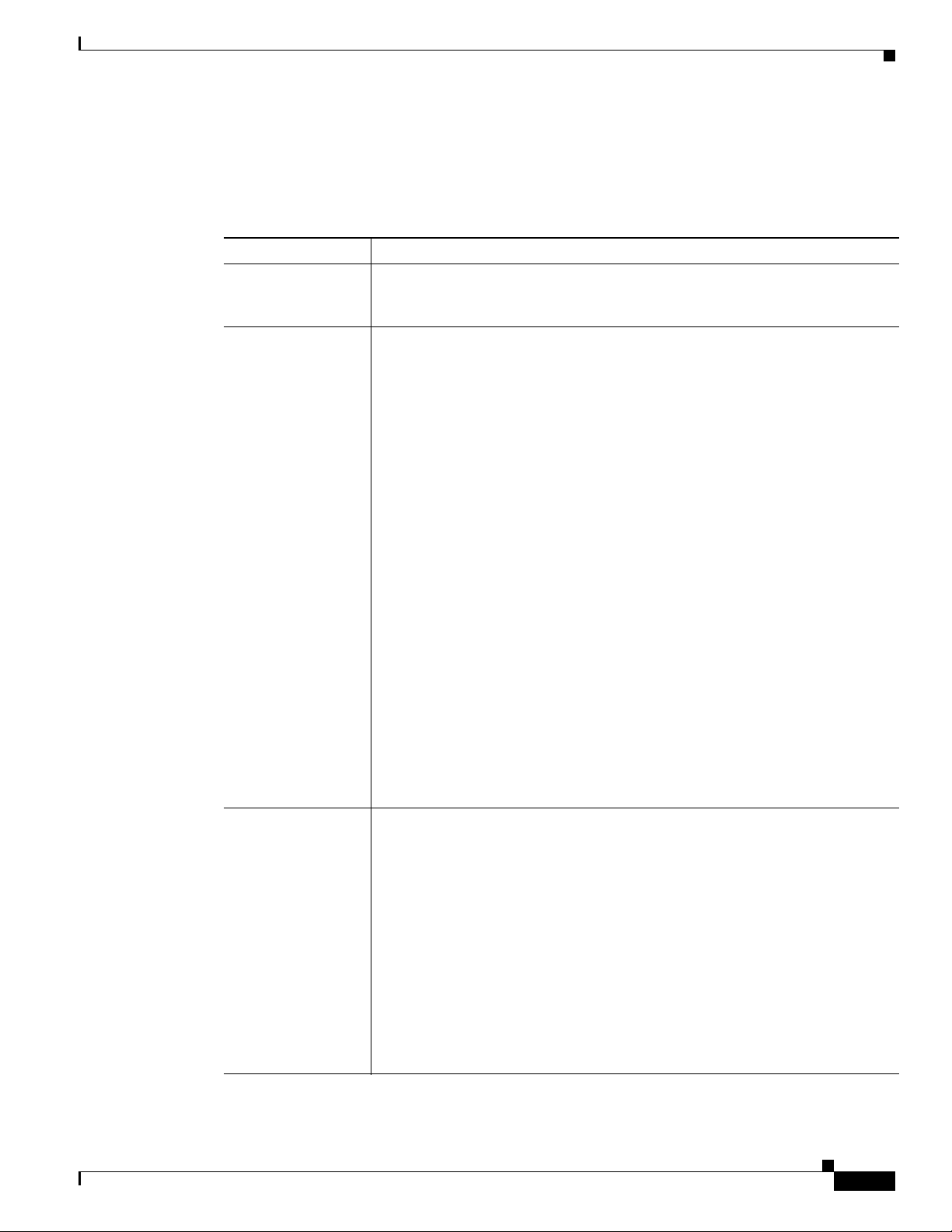

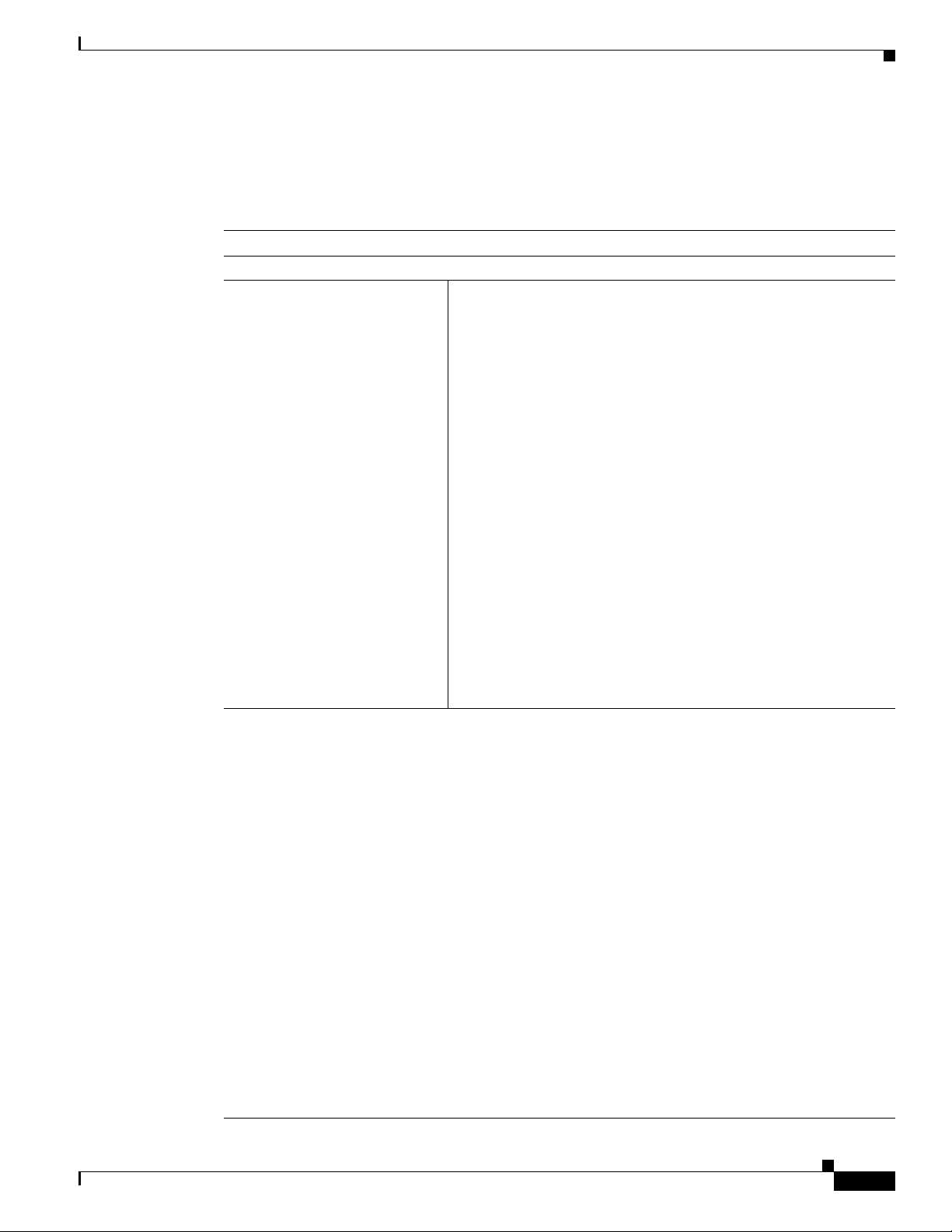

Table 2-1 lists the RSP and supervisor engine configurations supported on Cisco 7600 series routers.

Specific combinations of processors and modules may not be supported in your chassis. See the release

notes for your software version for information about supported combinations.

Ta b l e 2-1 Route Switch Processor and Supervisor Engine Configurations

Product Number Description

Route Switch Processor 720

RSP720-3C-10GE • Two 10 Gigabit Ethernet (10GE) uplink ports support 10-Gbps X2

Overview

modules

• Three Gigabit Ethernet (1GE) uplink ports: two ports support

1-Gbps small form-factor pluggable (SFP) module; one port

supports 10/100/1000-Mbps RJ-45 connector

Note Use Category 5 Shielded Twisted Pair cable at the port that

supports the10/100/1000-Mbps RJ-45 connector.

• Integrated 720-Gbps switch fabric

• PFC3C and MSFC4 with 512-MB bootflash, 4-MB NVRAM,

4-MB ROMmon, and several DRAM options:

–

Route processor (RP): 1- to 4-GB DRAM (default 1 GB)

–

Switch processor (SP): 1- to 2-GB DRAM (default 1 GB)

• One CompactFlash Type II slot (512 KB) on front panel and two

internal CompactFlash (512 KB each for RP and SP; you can

optionally increase each internal CompactFlash to 1 GB)

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture, 10GE ports (Rx/Tx): 8q8t/1p7q8t (CoS)

• QoS port architecture, 1GE ports (Rx/Tx): 2q8t/1p3q8t

RSP720-3CXL-10GE • Two 10GE) uplink ports support 10-Gbps X2 modules

• Three 1GE)uplink ports: two ports support 1-Gbps small

form-factor pluggable (SFP) module; one port supports

10/100/1000-Mbps RJ-45 connector

Note Use Category 5 Shielded Twisted Pair cable at the port that

supports the10/100/1000-Mbps RJ-45 connector.

• Integrated 720-Gbps switch fabric

• PFC3CXL (high-capacity) and MSFC4 with 512-MB bootflash,

4-MB NVRAM, 4-MB ROMmon, and several DRAM options:

–

Route processor (RP): 1- to 4-GB DRAM (default 2 GB)

–

Switch processor (SP): 1- to 2-GB DRAM (default 1 GB)

OL-10100-04

• One CompactFlash Type II slot (512 KB) on front panel and two

internal CompactFlash (512 KB each for RP and SP; you can

optionally increase each internal CompactFlash to 1 GB)

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture, 10GE ports (Rx/Tx): 8q8t/1p7q8t (CoS)

• QoS port architecture, 1GE ports (Rx/Tx): 2q8t/1p3q8t

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-3

Page 20

Overview

Chapter 2 Route Switch Processors and Supervisor Engines

Table 2-1 Route Switch Processor and Supervisor Engine Configurations (continued)

Product Number Description

Note See the “QoS on the RSP720-10GE” section on page 2-10 for more information about the

QoS port architecture on the uplink ports.

RSP720-3C-GE • Two Gigabit Ethernet uplink ports: port 1 supports a 1-Gbps SFP

module; port 2 is configurable with either a 1-Gbps SFP module

or a 10/100/1000-Mbps RJ-45 connector

• Integrated 720-Gbps switch fabric

• PFC3C and MSFC4 with 512-MB bootflash, 4-MB NVRAM,

4-MB ROMmon, and several DRAM options:

–

RP: 1- to 4-GB DRAM (default 1 GB)

–

SP: 1- to 2-GB DRAM (default 1 GB)

• Two CompactFlash Type II slots on front panel (512 KB default)

and two internal CompactFlash slots (one each for RP and SP,

512 KB default for each)

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

RSP720-3CXL-GE • Two Gigabit Ethernet uplink ports: port 1 supports a 1-Gbps SFP

module; port 2 is configurable with either a 1-Gbps SFP module

or a 10/100/1000-Mbps RJ-45 connector

• Integrated 720-Gbps switch fabric

• PFC3CXL (high-capacity) and MSFC4 with 512-MB bootflash,

4-MB NVRAM, 4-MB ROMmon, and several DRAM options:

–

Route processor (RP): 1- to 4-GB DRAM (default 2 GB)

–

Switch processor (SP): 1- to 2-GB DRAM (default 1 GB)

• Two CompactFlash Type II slots on front panel (512 KB default)

and two internal CompactFlash slots (one each for RP and SP,

512 KB default for each)

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

Supervisor Engine 720

WS-SUP720 • Two Gigabit Ethernet uplink ports: port 1 supports a 1-Gbps SFP

module; port 2 is configurable with either a 1-Gbps SFP module

or a 10/100/1000-Mbps RJ-45 connector

• Integrated 720-Gbps switch fabric

• PFC3A and MSFC3 with 2-MB NVRAM, 512-MB DRAM, and

64-MB bootflash (see note below)

2-4

• Two CompactFlash Type II slots

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

Note Cisco IOS Release 12.2SXF is the last release in which the

Sup720 with PFC3A is supported.

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 21

Chapter 2 Route Switch Processors and Supervisor Engines

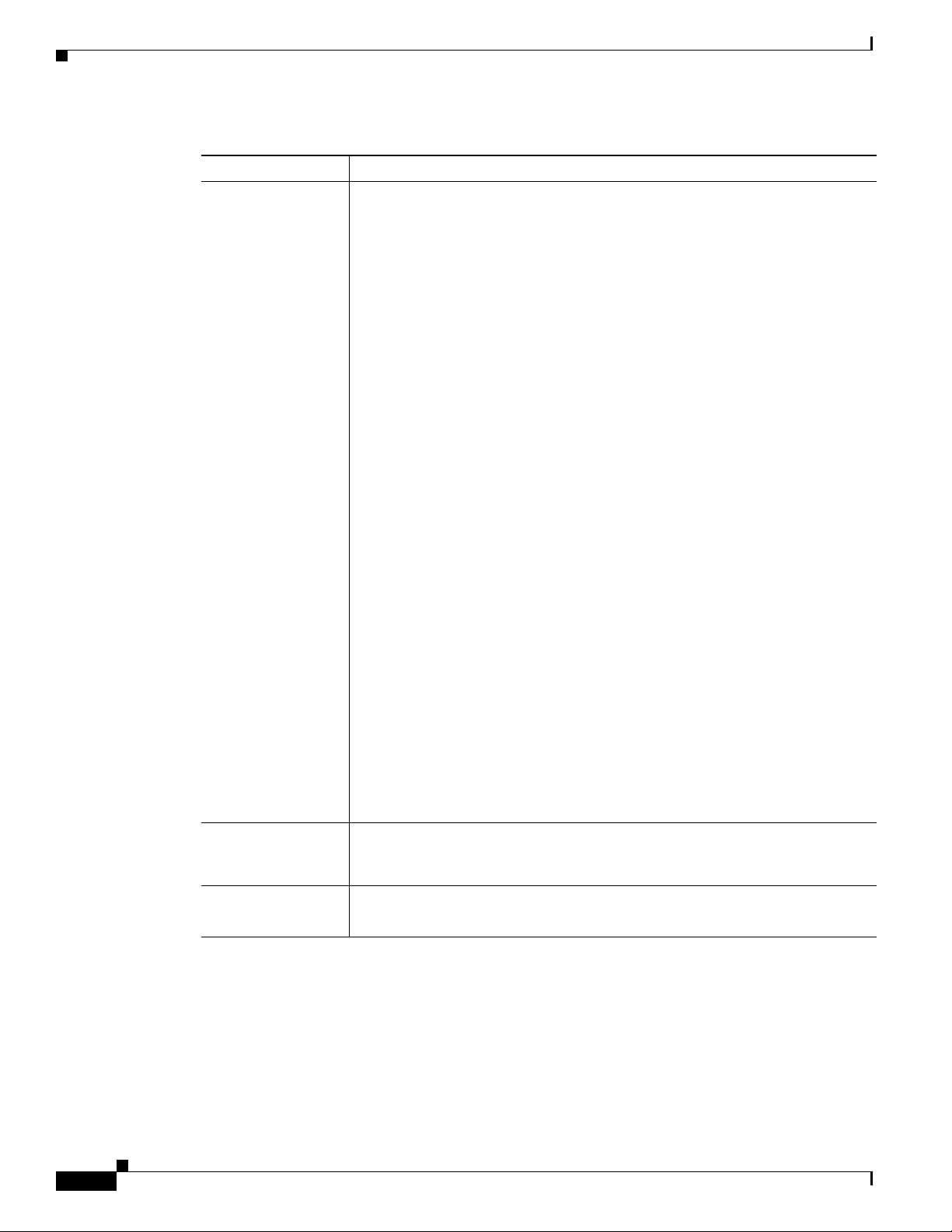

Table 2-1 Route Switch Processor and Supervisor Engine Configurations (continued)

Product Number Description

WS-SUP720-3B • Two Gigabit Ethernet uplink ports: port 1 supports a 1-Gbps SFP

WS-SUP720-3BXL • Two Ethernet uplink ports: port 1 supports a 1-Gbps SFP

Overview

module; port 2 is configurable with either a 1-Gbps SFP module

or a 10/100/1000-Mbps RJ-45 connector

• Integrated 720-Gbps switch fabric

• PFC3B and MSFC3 with 2-MB NVRAM, 512-MB DRAM, and

64-MB bootflash (see note below)

• Two CompactFlash Type II slots

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

module; port 2 is configurable with either a 1-Gbps SFP module

or a 10/100/1000-Mbps RJ-45 connector

• Integrated 720-Gbps switch fabric

• PFC3BXL and MSFC3 with 2-MB NVRAM, 1-GB DRAM, and

64-MB bootflash; high-capacity PFC3BXL allows routing and

forwarding processes to be offloaded from the supervisor engine

to the PFC (see note below)

• Two CompactFlash Type II slots

• Requires larger power supplies and a high-speed fan tray

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

Note A CompactFlash (CF) adapter with 512-MB bootflash is available for Sup720 modules in

Release 12.2(18)SXF and later releases. Use the Cisco part number CF-ADAPTER= for

ordering.

Supervisor Engine 32

WS-SUP32-GE-3B • Nine Gigabit Ethernet uplink ports: eight SFP modules and one

RJ-45 10/100/1000-Mbps connector

• Integrated 32-Gbps switch fabric

• PFC3B and MSFC2 daughter cards (see notes below)

• QoS port architecture (Rx/Tx): 1p3q8t/1p3q8t

WS-SUP32-10GE-3B • Two 10-Gigabit Ethernet ports (XENPAKs) and one

10/100/1000-Mbps connector

• Integrated 32-Gbps switch fabric

• PFC3B and MSFC2 daughter cards (see notes below)

OL-10100-04

• QoS port architecture (Rx/Tx): 1p3q8t/1p3q8t

Note To run Release 12.2SRB, the Sup32 requires a minimum of 512-MB DRAM.

Note A CF adapter with 512-MB bootflash is available for Sup32 modules in Release 12.2(18)SXF

and later releases. Use the Cisco part number CF-ADAPTER= for ordering.

Supervisor Engine 2

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-5

Page 22

Route Switch Processor 720

Table 2-1 Route Switch Processor and Supervisor Engine Configurations (continued)

Product Number Description

WS-X6K-S2-MSFC2 • Two dual-port 1000BASE-X GBIC uplinks, 16-MB bootflash,

WS-X6K-S2U-MSFC2 • Two dual-port 1000BASE-X GBIC uplinks, 32-MB bootflash,

WS-X6K-S2-PFC2 • Two dual-port 1000BASE-X GBIC uplinks

Chapter 2 Route Switch Processors and Supervisor Engines

128-MB DRAM on supervisor engine and 128

• PFC2 and MSFC2

• Fabric enabled to support optional switch fabric module (SFM2)

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

256-MB DRAM on supervisor engine and 256

• PFC2 and MSFC2

• Fabric enabled to support optional SFM2

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

• PFC2; fabric enabled, supports optional SFM2

MB on MSFC2

MB on MSFC2

WS-X6500-SFM2 • (Optional) SFM2

Note The Sup2 is not supported in Cisco IOS Release 12.2SRA and later releases.

Route Switch Processor 720

This section describes the Route Switch Processor 720 (RSP720). The Cisco 7600 RSP720 consists of a

full-size board and two integrated daughter cards: the MSFC4 and a PFC3C or PFC3CXL. The RSP720

has an integrated switch fabric that interconnects all of the line cards in the Cisco

point-to-point 20-Gbps full-duplex serial channels.

Note • Cisco IOS Release 12.2SRB and later releases support the RSP720; earlier releases do not.

The RSP720 is supported on all Cisco 7600 routers (including enhanced chassis) except the Cisco

7603 and the Cisco OSR-7609.

• Cisco IOS Release 12.2SRC and later releases support an RSP720 that has 10GE uplinks

(RSP720-3C-10GE and RSP720-3CXL-10GE). See the

on page 2-8 for more information.

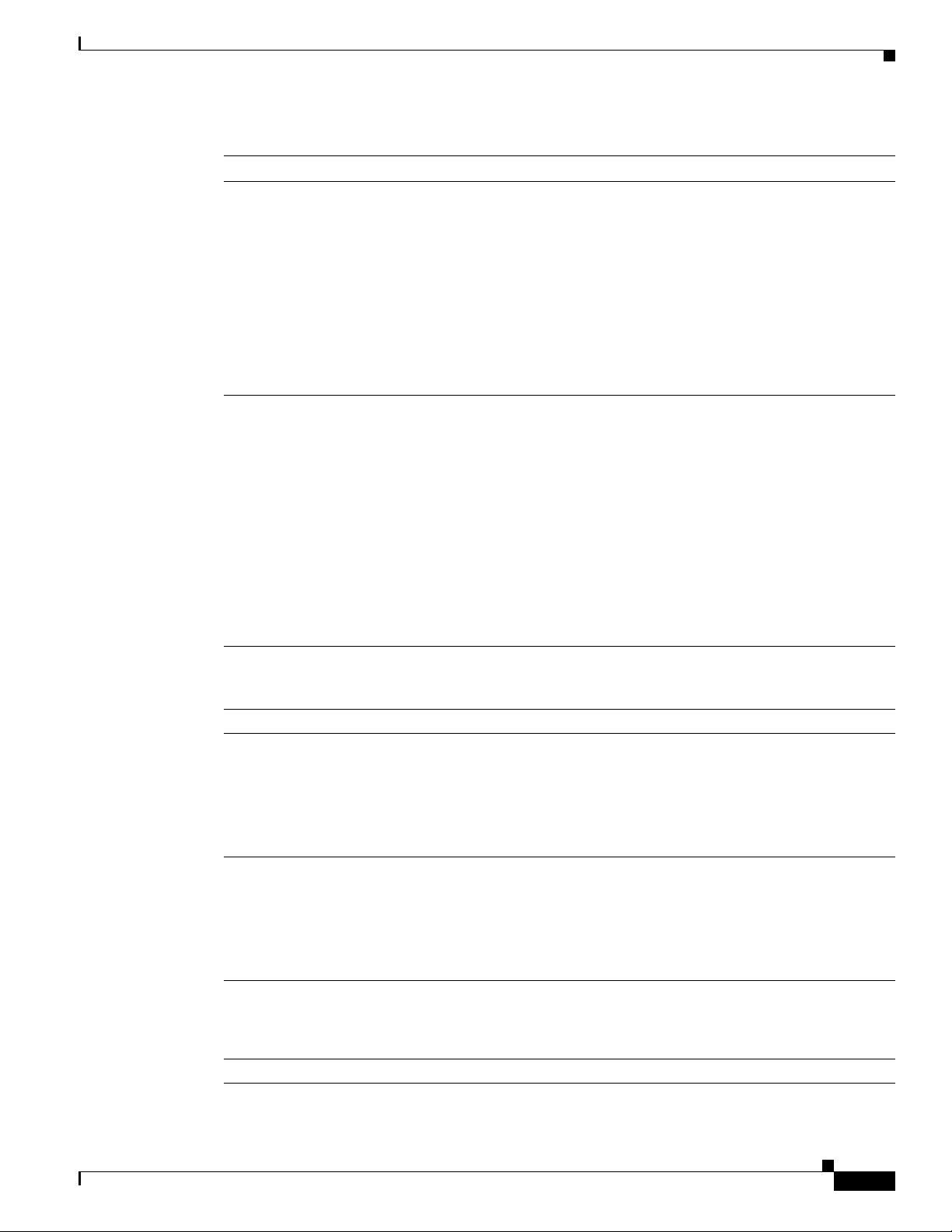

Figure 2-1 shows the RSP720-3C-GE front panel, which is the same as the RSP720-3CXL-GE front

panel. See Table 2-2 and Table 2-3 for information about the front-panel controls and LEDs.

• QoS port architecture (Rx/Tx): 1p1q4t/1p2q2t

7600 router with

“RSP720 with 10GE Uplink Ports” section

2-6

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 23

Chapter 2 Route Switch Processors and Supervisor Engines

Figure 2-1 Route Switch Processor 720 (RSP720-3C-GE) Front Panel

Route Switch Processor 720

CompactFlash

STATUS LEDs

RSP720-3C-GE

RSP 720 WITH INTEGRATED SWITCH FABRIC/3C-GE

Type II slots

Disk LEDs

CONSOLE port

RSP720 Features

The RSP720 provides several new features and enhancements, which are summarized here. For details,

see the Cisco

• 720 gigabits per second (Gbps) bandwidth (320 Gbps ingress and 320 Gbps egress)

• A faster CPU and additional memory to support larger configurations and more subscribers

• Performance and scalability improvements

• Quality of service (QoS) enhancements

7600 Series Router Cisco IOS Software Configuration Guide, Release 12.2SR.

Supported Chassis, Line Cards, and Modules

LINK LEDs

191402

Gigabit Ethernet

uplink port

10/100/1000 uplink port

The RSP720 supports the following Cisco 7600 chassis, line cards and modules:

• Supported on all Cisco 7600 routers (including enhanced chassis) except the Cisco 7603 and the

Cisco OSR-7609

• SPA interface processors (SIPs) and their shared port adapters (SPAs): 7600-SIP-600,

7600-SIP-400, and 7600-SIP-200

• Enhanced FlexWAN module (WS-X6582-2PA)

• Ethernet services modules: 2-port 10 GE line card (7600-ESM-2X10GE) and 20-port 1 GE line card

(7600-ESM-20X1GE)

• Distributed Forwarding Cards: DFC3C, DFC3CXL, DFC3B, DFC3BXL

• LAN cards (which require DFC): WS-X6704-10GE, WS-X6724-SFP, WS-X6748-SFP,

WS-X6748-GE-TX, WS-X6708A-10GE, WS-X67xxA series, WS-X6148-FE-SFP,

WS-X6148A-GE-TX

Unsupported Hardware and Features

The following hardware and features are not supported by the RSP720:

• Unsupported chassis: Cisco 7603, Cisco OSR-7609.

• Unsupported modules: Services modules, Optical Service Modules (OSMs), FlexWAN module.

• Server load balancing (SLB) is not supported, although it is supported on the Supervisor Engine 720.

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-7

Page 24

RSP720 with 10GE Uplink Ports

RSP720 with 10GE Uplink Ports

Cisco IOS Release 12.2SRC introduces a new RSP720 with 10 Gigabit Ethernet (GE) uplink ports

(RSP720-10GE). The Cisco

daughter cards: an MSFC4 and a PFC. The RSP720-10GE has an integrated switch fabric that

interconnects all of the line cards in the router with point-to-point 20-Gbps full-duplex serial channels.

Two versions of the RSP720-10GE module are available:

• RSP720-3C-10GE

• RSP720-3CXL-10GE

Because of physical differences between the RSP720 and RSP720-10GE (such as the CPU memory map

and ASIC operation), there are several configuration guidelines and restrictions you should be aware of.

See the

“RSP720-10GE Usage Guidelines and Limitations” section on page 2-10 for details.

Following are the total power requirements for the RSP720-10GE:

• RSP720-3C-10GE = 355 watts (total power)

• RSP720-3CXL-10GE = 378 watts (total power)

Figure 2-2 shows the RSP720-3C-10GE front panel. The RSP720-3CXL-10GE front panel is similar.

See Ta bl e 2-2 and Table 2-3 for information about the front-panel controls and LEDs.

7600 RSP720-10GE consists of a full-size board and two integrated

Chapter 2 Route Switch Processors and Supervisor Engines

Figure 2-2 RSP720-3C-10GE Front Panel

Disk LEDs

RSP720-3C-10GE

ACTIVE

STATUS SYSTEM

RSP720 WITH INTERATED SWITCH FABRIC/PFC3C-10GE

PWR MGMT

STATUS

LEDs

Note Use Category 5 Shielded Twisted Pair cable at the port that supports the10/100/1000-Mbps RJ-45

connector.

RSP720-10GE Features

The RSP720-10GE provides all of the features of the RSP720 and also provides the following benefits:

• The RSP720-10GE has two 10GE uplink ports and three 1GE uplink ports. You can use the 10GE

ports as high-bandwidth uplinks and save chassis slots for high-density interfaces, such as a

SIP/SPA. This is especially useful in smaller chassis and in redundant configurations. For the three

1GE uplink ports, two ports support 1-Gbps SFP modules and one port supports a 10/100/1000-Mbps

RJ-45 connector.

1-GE uplink

DISK 0

EJECT

RESET

CompactFlash

Type II slots

ports

SFP

1

LINK LINKLINK

LINK

LEDs

UPLINK

10-GE uplink

CONSOLE

ports

port

10GE UPLINK

10/100/100

3

3

CONSOLE

4

LINK

10/100/1000

uplink port

LEDs

LINK

5

LINK

250253

2-8

Note Use CAT5 Shielded Twisted Pair cable at the port that supports the10/100/1000-Mbps RJ-45 connector.

• The RSP720-10GE supports the following line rates for uplink traffic and backplane forwarding:

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 25

Chapter 2 Route Switch Processors and Supervisor Engines

–

10 gigabits per second (Gbps) on both 10GE ports

–

1 Gbps on all three 1GE ports

–

16 Gbps backplane forwarding

When all five uplink ports are operational, the total bandwidth for uplink traffic is 20 Gbps (20 GE).

• The RSP720-10GE provides flexible memory options like the RSP720. The RSP720-10GE ships

with 2-GB memory on the route processor (RP) and 1-GB memory on the switch processor (SP).

Memory options are available to upgrade to 4-GB memory on the RP and 2-GB memory on the SP.

• The RSP720-10GE supports Route Processor Redundancy (RPR) mode. However, uplink ports on

the standby supervisor will be unusable.

See the “RSP720-10GE Usage Guidelines and Limitations” section on page 2-10 for information about

things to consider when you use the RSP720-10GE.

Supported Chassis, Line Cards, and Modules

The RSP720-10GE supports the following chassis and modules:

• Supported on the Cisco 7604 and 7609 chassis and the Cisco 7603-S, 7606-S, and 7609-S chassis

RSP720 with 10GE Uplink Ports

Note If you insert an RSP720-10GE into an unsupported chassis, the RSP720-10GE drops to

ROMmon and only the console is accessible.

• SPA interface processors (SIPs) and their shared port adapters (SPAs): 7600-SIP-600,

7600-SIP-400, and 7600-SIP-200

• Enhanced FlexWAN module (WS-X6582-2PA)

• Ethernet services modules: 2-port 10 GE line card (7600-ESM-2X10GE) and 20-port 1 GE line card

(7600-ESM-20X1GE)

• Distributed Forwarding Cards: DFC3C, DFC3CXL, DFC3B, DFC3BXL

• LAN cards (which require CFC or DFC): WS-X6704-10GE, WS-X6724-SFP, WS-X6748-SFP,

WS-X6748-GE-TX, WS-X6708A-10GE, WS-X67xxA series, WS-X6148-FE-SFP,

WS-X6148A-GE-TX

• Uplink port transceiver modules: see Appendix B, “Cable and Connector Specifications”

Note The RSP720-10GE also supports two new 8-port 10GE line cards (WS-X6708-10G-3C and

WS-X6708-10G-3CXL). The line cards, which provide 2-to-1 oversubscription, are

available in Cisco IOS Release 12.2SRC and later.

Unsupported Chassis and Modules

The RSP720-10GE does not support the following chassis and modules:

OL-10100-04

• Unsupported chassis: Cisco 7603, 7606, and 7613 chassis

• Unsupported modules: Services modules, Optical Service Modules (OSMs), FlexWAN module

Unsupported Features

In Cisco IOS Release 12.2SRC, the RSP720-10GE does not support the following features, which are

supported on the RSP720:

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-9

Page 26

RSP720 with 10GE Uplink Ports

• High-availability features such as NonStop Forwarding with Stateful Switchover (NSF/SSO) and

In-Service Software Upgrade (ISSU) are not supported. Only Route Processor Redundancy (RPR)

mode is supported.

• The uplinks on the standby RSP720-10GE are not active. This restriction exists because the uplink

ports must perform lookups on the active RSP, which is not possible in RPR mode.

• Intelligent Service Gateway is not supported.

• Device authentication to prevent counterfeiting

• Keystore controller for key authentication

• Virtual switch functionality

RSP720-10GE Usage Guidelines and Limitations

Observe the following guidelines when using the RSP720-10GE:

• The RSP720-10GE runs the same Cisco IOS software images as the RSP720. The following

software image feature sets are available for the RSP720-10GE: ipservices, ipservicesk9,

advipservices, advipservicesk9, and adventerprisek9.

• Line cards require new firmware to operate with the RSP720-10GE. If a line card does not have the

correct firmware, an error message is displayed on boot-up and the line card is powered off.

Chapter 2 Route Switch Processors and Supervisor Engines

• The RSP720-10GE uses new ROMMON software for both the SP and RP. Because the

RSP720-10GE and RSP720 use a different IO memory map, the RSPs cannot share the same

ROMMON software.

–

–

• You can configure the RSP720-10GE to run QoS features on all uplink ports (10GE and 1GE) or on

10GE ports only. A new CLI command (mls qos supervisor 10g-only) is available to configure the

module to run QoS features on 10GE ports only. QoS operates differently in each mode. See the

“QoS on the RSP720-10GE” section on page 2-10 for more information.

QoS on the RSP720-10GE

The RSP720-10GE has both 10GE and 1GE uplink ports. You can configure the RSP720-10GE to run

QoS features on all uplink ports (mixed mode) or on 10GE ports only. The number of queues available

for QoS depends on which mode is used:

• In mixed mode (10GE and 1GE ports), the default, only four queues are available for QoS.

The QoS port architecture for 1GE ports is (Rx/Tx): 2q8t/1p3q8t.

If you attempt to load RSP720 ROMMON software onto the RSP720-10GE, the RSP720-10GE

does not power up and the ROMMON banner is not displayed.

If you load RSP720-10GE ROMMON software onto the RSP720, Cisco IOS software boots up

but the software detects a mismatch and enters ROMMON mode.

2-10

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 27

Chapter 2 Route Switch Processors and Supervisor Engines

• In 10GE only mode, eight queues are available for QoS. Use the mls qos supervisor 10g-only

command to enable 10GE only mode.

The QoS port architecture for 10GE only mode is as follows (Rx/Tx):

–

8q8t/1p7q8t (CoS)

–

16q8t/1p15q8t (DSCP)

–

16q1t/1p15q1t (VLAN)

QoS Configuration Guidelines

As you configure QoS on the RSP720-10GE, consider the following:

• When you switch between mixed-mode QoS and 10GE only mode, any existing QoS configuration

on the uplinks is lost. You must reconfigure QoS.

• While transitioning between modes, service will be temporarily lost on the uplinks.

• You can manually shut down all three 1GE ports before issuing the mls qos supervisor 10g-only

command to switch to 10GE only mode. If you do not shut down the ports first, the mls qos

supervisor 10g-only command shuts down the ports.

RSP720 with 10GE Uplink Ports

• When you switch from 10GE10GE only to mixed-mode QoS, you must issue the no shutdown

• In 10GE only mode, the 1GE ports are visible but they remain in an administratively down state.

Configuring 10GE Only QoS

Cisco IOS Release 12.2SRC introduces a new command to enable QoS features on 10GE uplink ports

only. By default, the router runs in mixed mode, which means that QoS is enabled on both the 10GE

uplink ports and the 1GE uplink ports.

Note You can shut down all three 1GE uplink ports before entering the mls qos supervisor 10g-only

command. If you do not shut down the ports first, the mls qos supervisor 10g-only command shuts down

the ports.

command on each of the three 1GE ports to resume QoS service on those ports.

mls qos supervisor 10g-only

no mls qos supervisor 10g-only

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-11

Page 28

Chapter 2 Route Switch Processors and Supervisor Engines

Supervisor Engine 720 and Supervisor Engine 32

Supervisor Engine 720 and Supervisor Engine 32

The following figures (Figure 2-3, Figure 2-4, and Figure 2-5) show the front panel on the Supervisor

Engine 720 (Sup720) and Supervisor Engine 32 (Sup32). The tables that follow describe the controls and

LEDs on the RSP720, Sup720, and Sup32. For information on the Supervisor Engine 2 controls and LEDs,

see the

“Supervisor Engine 2” section on page 2-14.

Figure 2-3 Supervisor Engine 720 (WS-SUP720) Front Panel

CompactFlash

STATUS LEDs

Figure 2-4 Supervisor Engine 32 (WS-SUP32-GE-3B) Front Panel

Status LEDs

RESET button

Disk LED

Figure 2-5 Supervisor Engine 32 (WS-SUP32-10GE-3B) Front Panel

Type II slots

Disk LEDs

CONSOLE port

CompactFlash

Type II slot

CONSOLE port

Uplink ports

Link Status LEDs

LINK LEDs

Gigabit Ethernet

uplink port

10/100/1000 uplink port

Uplink port

USB ports

87890

120690

Status LEDs

Disk LED

CONSOLE port

CompactFlash

Type II slot

Uplink ports

Link Status LEDs

Uplink port

USB ports

Front-Panel Controls (RSP720, RSP720-10GE, Sup720, Sup32)

Tabl e 2-2 describes the front-panel controls on the Route Switch Processor 720 and RSP720-10GE, the

Supervisor Engine 720, and the Supervisor Engine 32.

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-12

120691

OL-10100-04

Page 29

Chapter 2 Route Switch Processors and Supervisor Engines

Ta b l e 2-2 RSP720, RSP720-10GE, Sup720, and Sup32 Front-Panel Controls

Component Description

Status LEDs

Reset Button

Indicate the status of various functions on the module (see Tab l e 2-3).

Restarts the router. Use a ballpoint pen tip or other small, pointed object to

access the Reset button. Not all modules have a Reset button.

CompactFlash

Disk Slots

One or two slots for flash memory cards. Do not remove the card from

the slot while the disk LED is on. See the

section on page 3-12 for information about working with flash memory.

Console Port

Provides access to the router. The port is an EIA/TIA-232 asynchronous,

serial connection with hardware flow control and an RJ-45 connector.

See the

instructions on connecting to the console port.

On the RSP720, the console port allows you to access either the switch

processor (SP) or the route processor (RP).

Uplink Ports

Used to connect the router to other network devices. The uplink ports are

configurable with SFP, XENPAK, or X2 optics modules. See the

“Connecting to the Uplink Ports” section on page 3-10 for more

information.

USB Ports (Sup32 only)

Each USB port can function as a console port or security key.

Supervisor Engine 720 and Supervisor Engine 32

“Using Flash Memory Cards”

“Connecting to the Console Port” section on page 3-9 for

Front-Panel LEDs (RSP720, RSP720-10GE, Sup720, Sup32)

LEDs on the front panel of the supervisor engine or route switch processor show the status of the

processor and other components installed in the router.

Switch Processor 720 and RSP720-10GE, the Supervisor Engine 720, and the Supervisor Engine 32.

See

Ta bl e 2-5 for a list of LED functions on the Supervisor Engine 2.

Ta b l e 2-3 RSP720, Sup720, and Sup32 LEDs

LED Color Description

STATUS

Green All diagnostics pass; the module is operational (normal initialization

sequence).

Orange The module is booting or running diagnostics (normal initialization

sequence).

Yell ow Minor hardware problems.

Red An overtemperature condition occurred. (A major threshold has been

exceeded during environmental monitoring.)

SYSTEM

1

Green All chassis environmental monitors are reporting OK.

Orange The module is powering up or a minor hardware fault has occurred.

Red Major hardware problem.

The temperature of the supervisor engine or RSP has exceeded the major

temperature threshold.

Blinking

Continuous backplane stall.

Red

Table 2-3 lists the LED functions on the Route

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-13

Page 30

Supervisor Engine 2

Chapter 2 Route Switch Processors and Supervisor Engines

Table 2-3 RSP720, Sup720, and Sup32 LEDs (continued)

LED Color Description

ACTIVE

Green The supervisor engine or RSP is operational and active.

Orange The supervisor engine or RSP is powering up or is in standby mode.

PWR MGMT

1

Green Sufficient power is available for all modules installed in the router.

Orange The supervisor engine or RSP is powering up or has minor hardware

problems.

Red Major hardware problem.

DISK

Green The disk is active. Do not remove the disk while the light is on or the file

may be corrupted.

LINK

Green The port is operational.

Orange The port is disabled.

Flashing

The port is bad.

orange

Off The supervisor engine or RSP is powering up or the port is enabled and

there is no link.

1. The SYSTEM and PWR MGMT LEDs on a redundant supervisor engine or RSP are synchronized to the active module.

Supervisor Engine 2

This section describes the Supervisor Engine 2 (see Figure 2-6), which has slightly different controls and

features than the Supervisor Engine 720 and Supervisor Engine 32. Tab l e 2-4 describes the controls and

features on the front panel and Tabl e 2-5 describes the LEDs.

Note In Cisco IOS Release 12.2SR and later releases, the Supervisor Engine 2 is no longer supported on

Cisco 7600 series routers.

Figure 2-6 Supervisor Engine 2 Front Panel

CONSOLE port

WS-X6K-SUP2-2GE

STATUS

SYSTEM

CONSOLE

PWR MGMT

RESET

SUPERVISOR2

Status

LEDs

CONSOLE

CONSOLE PORT

MODE switch

RESET button

PCMCIA LED

CONSOLE

PORT

MODE

PCMCIA EJECT

PCMCIA slot

Switch load

display

Switch Load

100%

1%

1000BASE-X GBIC

Uplink Ports

PORT 1 PORT 2

LINK

LINK

LINK LEDs

44312

2-14

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 31

Chapter 2 Route Switch Processors and Supervisor Engines

Ta b l e 2-4 Supervisor Engine 2 Front-Panel Controls

Component Description

Status LEDs

Reset Button

Console Port

Console Port Mode Switch

PCMCIA Slot and LED

Switch Load Meter

Uplink Ports

Supervisor Engine 2

Indicate the status of various functions on the module (see Tab l e 2-5).

Restarts the router. Use a ballpoint pen tip or other small, pointed object

to access the Reset button.

Provides access to the router either locally (with a console terminal) or

remotely (with a modem). The port is an EIA/TIA-232 asynchronous,

serial connection with hardware flow control and an RJ-45 connector. See

the

“Connecting to the Console Port” section on page 3-9 for instructions

on connecting to the console port.

Enables you to connect a terminal to the console port using either the

cable and adapters provided with the router (switch in the in position,

factory default) or a Catalyst 5000 Supervisor Engine III console cable

and adapter, not provided (switch in the out position).

PCMCIA flash memory card slot. Do not remove the card from the slot

while the disk LED is on. See the

“Using Flash Memory Cards” section

on page 3-12 for information about working with flash memory.

A visual approximation of the current traffic load across the backplane.

Used to connect the router to another network device. Two dual-port

Gigabit Ethernet uplink ports operate in full-duplex mode only. You can

configure the ports with any combination of copper, short-wave (SX),

long-wave/long-haul (LX/LH), extended-reach (ZX), and coarse

wavelength division multiplexing (CWDM) 1000BASE-X Gigabit

Interface Converters (GBICs). See the

“Connecting to the Uplink Ports”

section on page 3-10 for more information.

Table 2-5 lists the LED functions on the Supervisor Engine 2.

Ta b l e 2-5 Supervisor Engine 2 LEDs

LED Color Description

STATUS

Green All diagnostics pass; the module is operational (normal initialization

sequence).

Orange The module is booting or running diagnostics (normal initialization

sequence).

An overtemperature condition has occurred. (A minor threshold has

been exceeded during environmental monitoring.)

Red Diagnostic test failed; the module is not operational. (The fault occurred

during the initialization sequence.)

An overtemperature condition has occurred. (A major threshold has

been exceeded during environmental monitoring.)

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

2-15

Page 32

Supervisor Engine 2

Chapter 2 Route Switch Processors and Supervisor Engines

Table 2-5 Supervisor Engine 2 LEDs (continued)

LED Color Description

SYSTEM

1

Green All chassis environmental monitors are reporting OK.

Orange The power supply or power supply fan failed.

Incompatible power supplies are installed.

The redundant clock failed.

One VTT2 module has failed or the VTT module temperature minor

threshold has been exceeded.

Red Two VTT modules failed or the VTT module temperature major

threshold has been exceeded.

3

3

The temperature of the supervisor engine major threshold has been

exceeded.

CONSOLE

Green The supervisor engine is operational and active.

Orange The supervisor engine is in standby mode.

PWR MGMT

1

Green Sufficient power is available for all modules.

Orange Sufficient power is not available for all modules.

SWITCH LOAD

- If the system is operational, the switch load meter indicates (as an

approximate percentage) the current traffic load over the backplane.

PCMCIA

- The PCMCIA LED is lit when no PCMCIA card is in the slot and goes

off when you insert a card.

LINK

Green The port is operational.

Orange The link has been disabled by software.

Flashing

The link is bad and has been disabled due to a hardware failure.

orange

Off No signal is detected.

1. The SYSTEM and PWR MGMT LED indications on a redundant supervisor engine are synchronized to the active engine.

2. VTT = voltage termination. The VTT module terminates signals on the system switching bus.

3. If no redundant supervisor engine is installed and there is a VTT module minor or major overtemperature condition, the

system shuts down.

2-16

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

OL-10100-04

Page 33

CHA PTER

3

Installing and Configuring Route Switch Processors and Supervisor Engines

This chapter describes how to install and configure a route switch processor or supervisor engine. It also

provides instructions for connecting to the console and uplink ports on the module.

This chapter contains the following sections:

• Preparing for Installation or Removal, page 3-1

• Determining Module Location, page 3-3

• Installing a Supervisor Engine or Route Switch Processor, page 3-4

• Removing a Supervisor Engine or Route Switch Processor, page 3-7

• Hot Swapping (OIR) Modules, page 3-8

• Connecting to the Console Port, page 3-9

• Connecting to the Uplink Ports, page 3-10

• Using Flash Memory Cards, page 3-12

• Power Management and Environmental Monitoring, page 3-14

• Determining Software Feature Support, page 3-14

• Configuring a Supervisor Engine or Route Switch Processor, page 3-14

Preparing for Installation or Removal

Before you attempt to install a supervisor engine or route switch processor in the router, be sure to:

• Review the safety precautions and electrostatic discharge guidelines in the “Safety Precautions for

Module Installation and Removal” section on page 3-2 and the “Preventing Electrostatic Discharge

Damage” section on page 3-2.

• Make sure you have on hand the tools required for the installation. (See the “Tools Required for

Module Installation” section on page 3-3.)

• Determine which chassis slot to install the module in. (See the “Determining Module Location”

section on page 3-3.)

• Consider cabling for the console and uplink ports. (See Appendix B, “Cable and Connector

Specifications.”)

OL-10100-04

Cisco 7600 Series Router Supervisor Engine and Route Switch Processor Guide

3-1