Page 1

Doc. No.

78-1230-02

Cisco 7010 and Cisco 7505

Chassis Replacement Instructions

Cisco 7010 Product Numbers: CHAS-7010-DC=, CHAS-7010-AC=

Cisco 7505 Product Numbers: CHAS-7505-DC=, CHAS-7505-AC=

Customer Order Number: DOC-781230=

This document provides instructions for replacing Cisco 7010 and Cisco 7505 chassis as spare parts.

Note When referring to both the Cisco 7010 and Cisco 7505 chassis, the term the chassis will be

used.

Chassis are available as spare parts, and include all of the components required for operation except

the processor modules. After you replace the chassis, you must move the processor modules from

your old chassis into your new chassis.

The replacement chassis do not include the cable management or rack-mounting hardware kits. You

can move the rack-mounting hardware and cable management brackets from the existing chassis, or

order either kit as a spare part, which will ship with installation instructions.

The sections in this document include the following:

• Product Overview, page 2

• Prerequisites, page 4

• Replacing the Chassis, page 8

— Replacing a Rack-Mounted Chassis, page 9

— Installing the Cable Management Brackets, page 12

— Moving Processor Modules, page 14

— Checking the Installation, page 18

— show Command Descriptions and Examples, page 20

Copyright © 1995

Cisco Systems, Inc.

All rights reserved.

• Cisco Information Online, page 22

1

Page 2

Product Overview

Product Overview

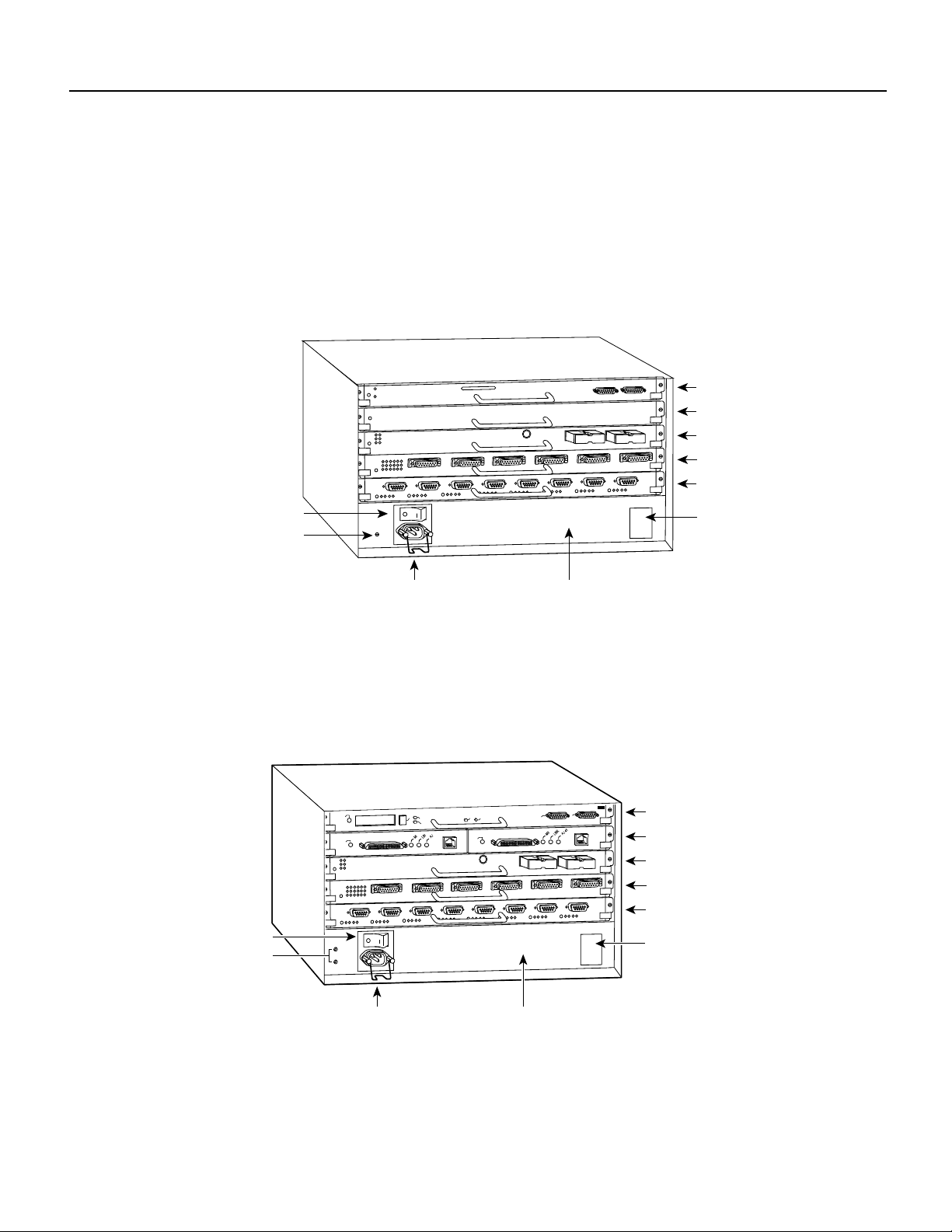

The Cisco 7010 is the five-slot model in the Cisco 7000 series. The Cisco 7010 provides three

interface processor slots. Figure 1 shows the interface processor end of the Cisco 7010. The Route

Processor (RP) and Switch Processor (SP) (or Silicon Switch Processor [SSP]), which are required

system components in all Cisco 7000 Series routers, occupy the two top slots. The remaining three

slots support any combination of interface types: Ethernet, Token Ring, FDDI, and so forth.

Figure 1 Cisco 7010—Interface Processor End

RP slot

SP or SSP slot

Interface processor slot 2

Interface processor slot 1

Interface processor slot 0

Power switch

DC OK LED

Chassis ground

screw

Power receptacle

AC-input power supply

H2359

The Cisco 7505 is a five-slot model that provides four interface processor slots. Figure 2 shows the

interface processor end of the Cisco 7505. The Route Switch Processor (RSP1), which is a required

system component in the Cisco 7505 router, occupies the top slot. The remaining four slots support

any combination of interface types: Ethernet, Token Ring, FDDI, and so forth.

Figure 2 Cisco 7505—Interface Processor End

wer switch

Chassis

grounding

receptacles

NORMAL

EJECT

SLOT 1

SLOT 0

ENABLE

CPU HALT

ENABLE

RESET

AUX.

ROUTE SWITCH PROCESSOR

CONSOLE

RSP slot

Interface processor slot 3

Interface processor slot 2

Interface processor slot 1

Interface processor slot 0

DC OK LED

H2761

Power receptacle AC-input power supply

The interface processor end of the chassis also contains the AC powerreceptacle(aDC-input power

supply is also available, but not shown), the system power on/off switch, and the DC OK power

status LED, all of which are part of the power supply but accessible through cutouts in the chassis

frame. (See Figure 1 or Figure 2.) To the left of the powerswitchandreceptaclecutoutisthechassis

ground screw that provides a chassis ground connection for ESD equipment or a grounding wire.

2 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 3

Product Overview

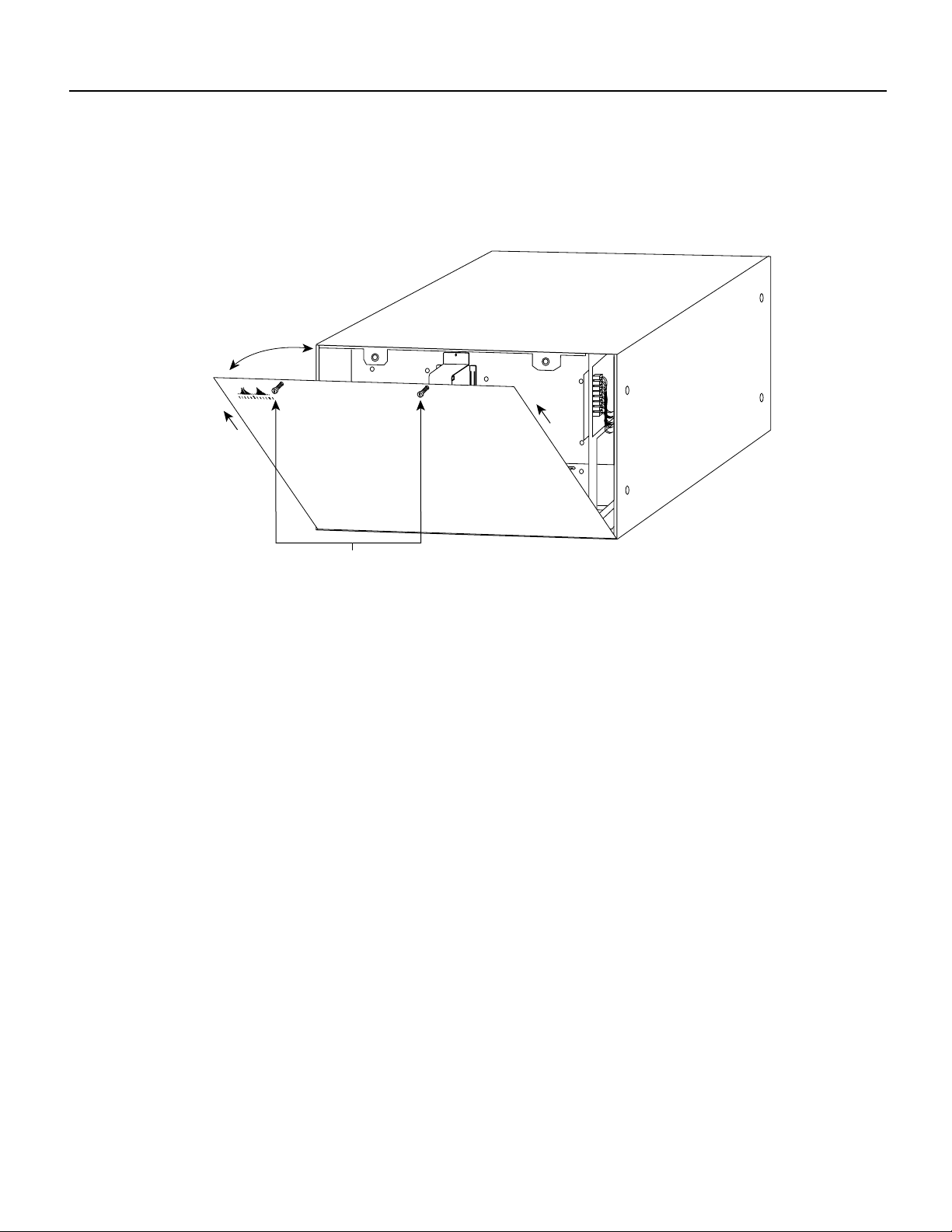

The removable chassis cover panel at the noninterface processor end of the router provides access

to the internal components. (See Figure 3.)

Figure 3 Chassis Cover Panel

H2920

Captive screws

Two captive slotted screws secure the chassis cover panel to the noninterface processor end of the

chassis. The cover shields against electromagnetic interference (EMI) and helps direct the flow of

cooling air through the chassis. Therefore, never operate the router with the cover removed.

For detailed descriptions of the system components, refer to the Cisco 7010 Hardware Installation

and Maintenance or Cisco 7505 Hardware Installation and Maintenance publications.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 3

Page 4

Prerequisites

Prerequisites

Before you begin this installation, review the safety guidelines in this section to avoid injuring

yourself or damaging the equipment. This section also provides a list of the tools that you need to

perform this replacement.

Safety Guidelines

The followingguidelineswill help to ensure your safetyand protect the equipment.These guidelines

are not inclusive of all potentially hazardous situations, so be alert.

General Safety Precautions

The following are general precautions for any workplace:

• Do not perform any action that creates a potential hazard to people or makes the equipment

unsafe.

• Do not work alone when potentially hazardous conditions exist.

• Do not wear loose clothing, jewelry (including rings and chains), or other items that could get

caught in the chassis. Fasten your tie or scarf and sleeves.

Safety with Electricity

• Never install equipment that appears damaged.

• Keep tools and chassis components away from walk areas.

• Practice good housekeeping; keep tools and parts clean, accessible, and in good working order.

Follow these guidelines when working with any electrical equipment:

• Before beginning any procedures requiring access to the chassis interior, locate the emergency

power-off switch for the room in which you are working.

• Disconnect all power and external cables before moving a chassis.

• Never assume that power has been disconnected from a circuit; always check.

• Carefully examine your work area for possible hazards such as moist floors, ungrounded power

extension cables, and missing safety grounds.

In addition, use the guidelines that follow when working with any equipment that is connected to

telephone wiring or other network cabling:

• Never install telephone wiring during a lightning storm.

• Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

• Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

• Use caution when installing or modifying telephone lines.

4 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 5

Lifting Safely

A fully configured chassis weighs approximately 70 pounds. Before installing the new

(replacement) chassis, ensure that your site is properly prepared, so you can avoid having to move

the chassis later to accommodate power sources and network connections.

• Never try to lift an object that is too heavy for you to lift safely by yourself.

• Ensure that your footing is solid and balance the weight of the object between your feet.

• Lift the object slowly; never move suddenly or twist your body as you lift.

• Keep your back straight and lift with your legs, not your back. If you must bend down to lift the

chassis, bend at the knees, not at the waist, to reduce the strain on your lower back muscles.

• When lifting the chassis, grasp the underside of the chassis exterior with both hands. Do not

attempt to lift the end of the chassis with the handles on the interface processor carriers; these

handles are not designed to support the weight of the chassis.

• Always disconnect all external cables before lifting or moving the chassis.

Preventing Electrostatic Discharge (ESD) Damage

Electrostatic discharge (ESD) damage, which can occur when electronic boards or components are

handled improperly, can result in complete or intermittent failures. The processor modules each

comprise a printed circuit board that is fixed in a metal carrier. EMI shielding, connectors, and a

handle are integral components of the carrier. Handle processor modules by the metal frame or

carrier only; avoid touching the board (particularly avoid touching anycomponents, connector pins,

or the metal fingers on the edge connector).

Prerequisites

Following are guidelines for preventing ESD damage:

• Always use an ESD wrist strap or ankle strap and ensure that it makes good skin contact.

• When removingor installing interface processors, connect the equipment end of the ground strap

to the chassis ground screw on the interface processor end of the chassis.

• Place removed processor modules board-side-up on an antistatic mat or in a static shielding bag.

• If you are returning a replaced part to the factory, immediately place it in a static shielding bag

to avoid ESD damage to the board.

• Avoid contact between the board and clothing. The ESD strap only protects the board from ESD

voltages on the body; ESD voltages on clothing can still cause damage.

Note For safety, periodically check the resistance value of the antistatic strap. The measurement

should be between 1 and 10 megohms.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 5

Page 6

Prerequisites

Cable Strain Relief

If possible, position the newreplacement chassis close enough to the existing system so that you can

avoidhaving to disconnect power and interfacecables. Be sure to disengage any strain relief devices

before attempting to pull the cables from the port. Following are descriptions of the different

methods of strain relief that are used on the AC-input and DC-input power cables and the various

types of network interface cables:

• On the AC power input receptacle (on the interface processor end of the AC-input powered

• On the DC-input power supply, a nylon cable tie is used to fasten the power cable to a bracket

• Serial interface cables (all types) use thumbscrewson the cable connectors that secure the cable

• Ethernet interface cables use either slide-type locks or thumbscrews. Although all Ethernet

chassis), a cable retention clip (see Figure 1 or Figure 2) snaps up around the plug on the power

cord to prevent it from being inadvertently pulled out of the receptacle. Before attempting to

disconnect the power cable, be sure to push the retention clip down away from the plug.

located just below the input terminal block. Carefully cut this cable tie before you disconnect the

power cable leads from the terminal block, and replace the cable tie after you install the new

chassis and wire the power cable leads to the terminal block.

to the Fast-Serial Interface Processor (FSIP) port.

Interface Processors (EIPs) ship from the factory with slide-type locks on each port, all EIPs also

include conversion kits for replacing the slide-type locks with jackscrews to accommodate

Ethernet interface cables with thumbscrews.

• Multimode, Fiber Distributed Data Interface (FDDI) connectors use small plastic arms on two

sides ofthe connector that act like springs andare constrained by the inside of theconnector port.

To remove a multimode cable from a FDDI Interface Processor (FIP) port, pinch the two plastic

arms inward while pulling the connector out of the port.

When removing any cable, pull the cable out at the connector; never pull or tug on the cable itself.

For detailed descriptions of the system components, refer to the Cisco 7010 Hardware Installation

and Maintenance or Cisco 7505 Hardware Installation and Maintenance publications.

Preparing the Work Area

Although some network downtime is unavoidable while you remove the RP and SP (or SSP) or

RSP1 from their respective chassis, and replace them in the new chassis, you can minimize the

downtime by placing the old and new chassis close together. If your existing chassis is mounted in

a rack and there is space in the same rack or another rack close by, we recommend that you install

the new, empty chassis in the rack before moving the components. (A fully configured chassis

weighs approximately 70 pounds.)

Before installing the chassis in a new rack location, ensure that routing the interface cables to the

new positions will not strain or tangle them.

You can further minimize downtime by leaving interface cables attached when you move interface

processors to the new chassis, provided that doing so will not strain the cables.

Leave network interface cables connected to the interface ports only if the following conditions are

true:

• You are able to place the new chassis close to the existing chassis, and moving the processor

modules to the new chassis will not strain the interface cables.

• The new chassis is already located in its permanent location, or you will need to move it only a

few feet into the space vacated by the old chassis when it is removed.

6 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 7

Prerequisites

Note If these conditions are not true, for instance, if you must remove a rack-mounted chassis

before you can install the new chassis, you must disconnect all power and network interface cables.

Also, ensure that your new chassis allows sufficient clearance for maintenance: to remove and

replace processor modules and interface cables at the interface processor end, and to access the

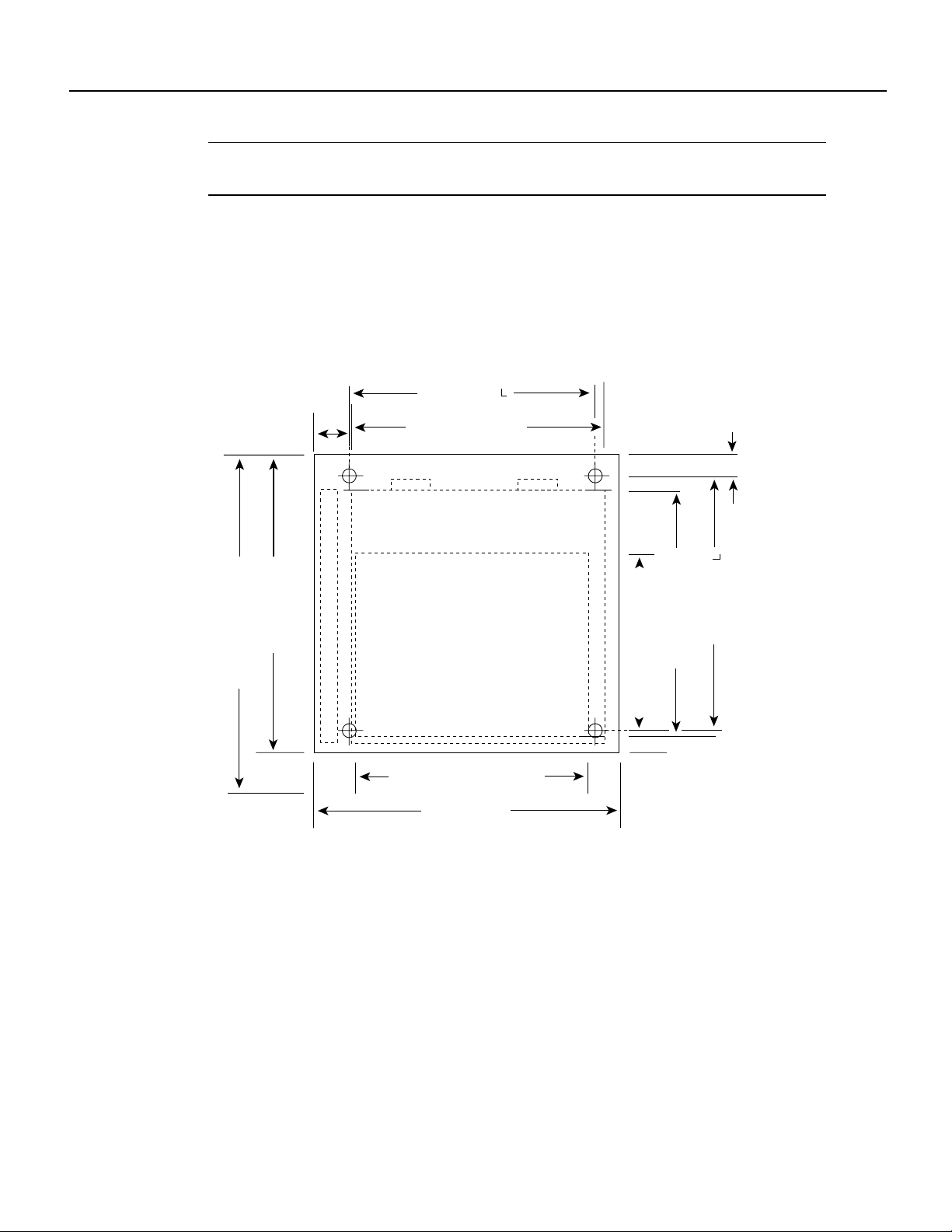

internal components at the noninterface processor end. Figure 4 shows the chassis footprint and the

clearance required to remove or install each of the major components.

Figure 4 Chassis Footprint and Clearance Requirements for Maintenance

Chassis foot C

2 in.

(5.08 cm)

14.25 in. (36.20 cm)

Power supply width

14.60 in. to ears (37.08 cm)

Noninterface processor end

1.25 in. (3.18 cm)

Chassis depth

19.0 in. (48.26 cm)

management bracket

Chassis depth with power cord and cable

Fan tray

17.0 in. (43.18 cm)

Interface processor end

Interface processor width

14.55 in. (36.96 cm)

Chassis width

17.50 in. (44.45 cm)

Chassis foot C

Power supply depth

11.25 in. (28.58 cm)

Interface processor depth

H2818

13.32 in. (33.83 cm)

12.00 in. (30.48 cm)

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 7

Page 8

Replacing the Chassis

Tools and Parts Required

This section lists the tools and parts you will need to complete these replacement procedures. Have

the necessary tools on hand so that you can complete the replacement without interruption:

• To replace the chassis cover, you need a 3/16-inch, flat-blade screwdriver to loosen the captive

screws on the chassis cover panel

• To install a replacement chassis, you need a number 1 Phillips and a 3/16-inch, flat-blade

screwdriverfor the captive installation screwson the processor modules(most of the carriers use

slotted screws, but some use Phillips screws)

• To install new cable management brackets or to move brackets from the existing chassis, you

need the following tools and parts (panhead screws are included with the brackets):

— Number 1 Phillips screwdriver

— Two cable management brackets

— Six M3 x 8-mm, Phillips panhead screws

• If you will mount or replace the chassis in an equipment rack, you also need the followingtools:

— Number 2 Phillips screwdriver

— 1/4-inch and 3/16-inch, flat-blade screwdrivers

— Two chassis ears

— Four M4 x 10-mm, Phillips flathead screws to secure the ears to the chassis

— Eight 10-32 x 3/8-inch, slotted binderhead screws to secure the chassis ears to the rack

• Whenever you remove or install processor modules, have the following equipment on hand to

help prevent ESD damage:

— Antistatic mat or antistatic foam pad in case you need to put one of the processor modules

down

— Your own ESD-preventive strap or the disposable ESD strap that is included with all spares

Replacing the Chassis

The RP,SP (orSSP), and RSP1 are requiredsystem components in theirrespective chassis; you must

shut downthe system power beforeremoving or installing any oneof these three processor modules.

All interface processors support online insertion and removal (OIR); however, after installing an

interface processor on line, you must wait at least 15 seconds for the system to reinitialize the

interfaces before installing the next interface processor. Therefore, it is more efficient to leave the

power off until all components are moved into the new chassis, then start up the system and check

the entire installation.

If you are installing the new chassis in an equipment rack, proceed to the next section. Otherwise,

proceed to the section “Installing the Cable Management Brackets” on page 12.

8 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 9

Replacing a Rack-Mounted Chassis

This section describes how to replace a chassis that is installed in an equipment rack. The order in

which you removethe existing system, install the newchassis, and replace the components will vary

depending upon the space available in the rack and in the work area.

Some rack configurations, such as an enclosed rack or a rack with a power strip that limits access,

prohibit the normal installation sequence of first installing the chassis in the rack and then installing

the cable management brackets before installing the processor modules. In these situations, you can

move all the components into the new chassis before installing it in the rack, but ensure that you

follow the safety guidelines for lifting and working with electrical equipment that are provided in

the section “Safety Guidelines” beginning on page 4.

If thereis sufficient space availablein the same rack (oran adjacent rack) and you havea rack-mount

kit available, you can install the new (replacement) chassis before you remove the existing system.

You can minimize downtime and avoidhaving to disconnect network interface cables by leaving the

existing system operating while you install the empty replacement chassis in the rack. Also, an

empty chassis is significantly lighter and easier to handle than one that is fully configured. Just

ensure that both chassis, when installed, will be close enough to avoid straining the interface cables

connected to the interface processors.

If you must removethe existing system to make room for the replacement chassis, or if you needthe

existing rack mounting hardware to mount the new chassis, you will have to disconnect all network

interface cables before removing the existing system from the rack. You can leave the system

components in the old chassis until after you install the new, empty chassis in the rack.

Replacing the Chassis

Assess your rack and lab configuration and the equipment you have available, then choose the

appropriate replacement procedure from the following:

• If you have a spare rack-mount kit available and you are able to install the new, empty chassis

before you shut down and remove the existing one, followthe installation instructions provided

with the rack mount kit, Cisco 7010 and Cisco 7505 Rack-Mount and Cable Management Kits

Installation Instructions (Document Number 78-1231-xx).

• After you install the new chassis in the rack and install the cable management brackets, proceed

to the section “Moving Processor Modules” on page 14 to move the components. (After you

complete the replacement and check the installation, you will be directed to the following

section, “Removing the Existing Chassis from the Rack,” to remove the empty chassis.)

• If you must remove the existing chassis before you can install the new one, proceed to the

following section, “Removing the Existing Chassis from the Rack.”

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 9

Page 10

Replacing the Chassis

Removing the Existing Chassis from the Rack

Before removing the existing chassis from the rack, you must shut down the system power and

disconnect the power cord and all interface cables. To help avoidproblems when you installthe new

chassis, label all interface cables with their slot/port address and mark the positions of the chassis

ears (with tape, chalk, or a marker) so that you can install the new chassis in the same position.

Two chassis ears support the chassis in the rack. The ears are secured to the chassis sides and to the

rack posts, so that the chassis is cantilevered off the ears. We recommend that two people perform

this procedure: one person to support the chassis while the other person removes the screws that

secure the ears to the rack.

Follow these steps to remove the existing chassis from the rack:

Step 1 Turn off the system power and disconnect the power cord and all interface cables from the

chassis.

Step 2 Have a second person support the chassis while you perform this step. From the front of

the rack, use a 1/4-inch flat-blade screwdriver to loosen and remove each of the eight

10-32 x 3/8-inch, slotted screws (four on each side) that secure the chassis ears to the rack.

Step 3 Pull the chassis out of the rack and place it on the floor or a table.

Step 4 Use a number 2 Phillips screwdriver to loosen and remove the two M4 x 10-mm, Phillips

flathead screws that secure the ears to the chassis sides.

Step 5 Pull the ears off the chassis, and place the ears and all fasteners aside.

This completes the chassis removal procedure. If you have not yet installed the new chassis in the

rack, proceed to the next section.

Installing the New Chassis in the Rack

Mount the chassis in the rack before connecting any interface or powercables. If possible, install the

new, empty chassis in the rack first, then install the system components from the old chassis. The

chassis is supported in the rack by two chassis ears, which attach to the sides of the chassis and to

the mounting strips on the rack. Each chassis ear has two studs that fit into holes in either the

interface processor end or the noninterface processor end of the chassis, whichever will be in the

front of the rack. Tomount thechassis, installthe earson thechassis first,then securethe earsto the

rack mounting posts or strips. We recommend that two people perform this procedure: one person

to support the chassis in the rack while the other person secures the ears to the rack. Before lifting

the chassis, ensure that your path to the rack is unobstructed.

Follow these steps to install the new chassis in the rack:

Step 1 Position the chassis so that the end that will be in the front of the rack is closest to you.

Figure 5 shows the correct orientation if the noninterface processor end of the chassis will

be installed at the front of the rack.

Step 2 Attach the right chassis ear to the chassis first. Hold the ear in the orientation shown in

Figure 5, with the studs pointing toward the chassis and the mounting strip facing you.

Step 3 Insert the two studs through the holes on the side of the chassis. The ear should be flush

against the chassis side.

Step 4 Insert twoM4 x 10-mm, Phillips flatheadscrews through the earsand into the chassis sides.

Use a number 2 Phillips screwdriver to tighten the screws.

10 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 11

Replacing the Chassis

Step 5 Repeat Steps 2 through 4 for the left ear. The strip of mounting holes on the front of each

ear should be approximately flush with the end of the chassis. (See Figure 5.)

Figure 5 Installing the Ears on the Chassis

H2917

Step 6

Step 7 Insert the rear of the chassis into the rack, pushing it back until the ears meet the front

Lift the chassis and move it to the rack. Avoid sudden twists or moves to prevent injury.

mounting strips or posts on both sides of the equipment rack. Slide the chassis vertically

along the rails to align the mounting holes in the ears with those in the rack.

Step 8 From the front of the rack, insert all eight 10-32 x 3/8-inch, slotted screws (four on each

side) through the chassis ears and into the mounting strip. (See Figure 6.)

Step 9 When all screws are inserted, use a 1/4-inch, flat-blade screwdriver to tighten each one.

This completes the rack installation. Proceed to the next section to install the cable management

brackets.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 11

Page 12

Replacing the Chassis

Figure 6 Installing the Chassis in a Standard Four-Post, 19-Inch Equipment Rack

H2919

Installing the Cable Management Brackets

The cable management brackets help to keep network interface cables untangled and orderly, and

prevent cables from hindering access to interface processors in the lower interface processor slots.

The brackets attach to the inner sides of the chassis at the interface processor end. Six M3 x 8-mm,

Phillips panhead screws, which are included with the brackets, secure the brackets to the chassis

(three per bracket). Figure 7 shows the interface processor end of the chassis with the brackets

installed.

Note For this procedure, the Cisco 7010 andCisco 7505 chassis are functionally the same, and are

referred to as the chassis.

Install the brackets on the new chassis first, before you begin moving system components from the

old chassis. If you install the brackets after you move the interface processors and connect the

interface cables, you might have to disconnect the cables to install the screws that secure the

brackets. Route interface cables through the cable management brackets as you connect them to the

interface processor ports (or as you install interface processors that still have interface cables

connected to them). Wrap cable ties through the holes provided to secure small-gauge cables.

Chassis front

12 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 13

Figure 7 Cable Management Brackets—Cisco 7010 Shown

H2045

Follow these steps to install the two cable management brackets on the new chassis:

Replacing the Chassis

Step 1 If you have new brackets to install on the new chassis, proceed to Step 4. If you are

removing the brackets from the old chassis, proceed to the next step.

Step 2 At the interface processor end of the existing chassis, push the cables out of the cutouts in

the brackets. The brackets are flexible and allow cables to pass through the access slots;

however, bending them at extreme angles can cause them to break.

Step 3 Use a number 1 Phillips screwdriver to remove the six panhead screws (three per bracket)

that secure brackets to the inner side of the chassis. You might need to disconnect some of

the interface cables to access the screws. If so, label the cables withtheir slot/portlocation,

or reconnect them immediately after removing the bracket.

Step 4 At the interface processor end of the new chassis, place a bracket on one of the inner sides

of the chassis and align the three holes in the bracket with the holes in the chassis.

Step 5 Insert and finger-tighten three M3 Phillips screws from the inner side of the chassis,

through the bracket and into the chassis. (See Figure 7.)

Step 6 When all three screws are inserted, use the number 1 Phillips screwdriver to tighten the

screws.

Step 7 Repeat Steps 4 through 6 for the second bracket.

Step 8 When connecting the network interface cables or installing processor modules with the

interfacecables attached, route the cables through thecable management brackets as shown

in Figure 7. If you are using very thin cables that slip through the bracket openings, insert

cable ties through the holes in the bracket and wrap them around the cables to secure them.

This completes the cable management bracket installation. Proceed to the next section to move the

processor modules to the new chassis.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 13

Page 14

Replacing the Chassis

Moving Processor Modules

At the interface processor end of the chassis, slots contain the processor modules. (See Figure 1 or

Figure 2.) In the Cisco 7010, the RP occupies the top slot (the RP slot or slot 4) and the SP (or SSP)

occupies the second slot from the top (the SP slot or slot 3), directly below the RP slot. The

remaining three slots, which are numbered 0 through 2 beginning at the bottom slot, support any

combination of interface processors.

In the Cisco 7505, the RSP1 occupies the top slot (slot 4). The remaining four slots, numbered 0

through 3 beginning at the bottom, support any combination of interface processors.

The processor modules are all keyed with guides on the backplane to preventthem from being fully

inserted in the wrong slot. Empty interface processor slots contain an interface processor filler (an

empty carrier) to help keep dust out of the chassis, provide EMI shielding, and maintain proper air

flow through the chassis interior.

Processor modules slide into the processor slots and connect directly to the backplane. The

spring-loaded ejector levers (see Figure 8) help to ensure that the bus connector on the back of the

processor module is fully seated in the backplane or fully dislodged from it. Captive installation

screws at both ends of each processor module faceplate prevent the processor from pulling away

from the backplane and support the EMI integrity of the system. Failure to use the ejector levers and

captiveinstallation screwscould result in a partial backplane connection, which can hang the system.

To retainyour existing configuration, moveinterface processors to the same slot positions in the new

chassis. The lithium battery backup on the RP and RSP1 retains the system configuration and

MAC-layer addresses in nonvolatile random-access memory (NVRAM). Therefore, if you install

interface processors in the same slot positions in the new chassis that they occupied in the old

chassis, the system and the individual interfaces should come up in their previous configuration. If

you install interface processors in different slots in the new chassis, the system will recognize the

interfaces, but will leave them in a shutdown state until you reconfigure and enable them.

Although interface processors support OIR, you must wait at least 15 seconds after inserting an

interface processor before inserting the next one. To help avoid errors with the installation, leavethe

power off until all components are moved into the new chassis and you have verified that all are

installed properly.

In the chassis, move the interface processors first, one at a time, then, in the Cisco 7010, move the

SP (or SSP) and finally the RP; in the Cisco 7505, move the RSP1 last. Before you remove an

interface processor from the existing chassis, remove the interface processor filler from the

corresponding slot in the new chassis. Then immediately install the interface processor in the new

chassis and secure it in the slot before removing the nextinterface processor filler or module. If you

leave the interface cables attached to the interface processors, route the cables through the cable

management brackets immediately after you secure the interface processor in the slot to help keep

the other slots clear during the installation.

If there is sufficient slack in the interface cables, and if you can easily move the processor modules

between the chassis without straining the cables, leave the interface cables connected. If you must

disconnect the cables, label each cable with its slot and port number before you disconnect it. Do not

reconnect the interface cables until you haveinstalled all of the components in the new chassis (it is

easier to install interface processors when the slots are not impeded by cables that drop from other

slots). Use the optional cable management bracketsto keepthe interface cablesuntangled and away

from other interface processor slots and ports.

Caution You must turn off the system power before removing or installing the RP, SP (or SSP), or

RSP1, all of which are required system components. Removing one while the system is operating

will cause the system to shut down or crash and might damage or destroy memory files.

14 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 15

Figure 8 Ejector Levers and Captive Installation Screws

Interface processor

card slot

Ejector

lever

Interface processor card

carrier guide (black)

Replacing the Chassis

a

Captive

installation

screw

c

b

H1984

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 15

Page 16

Replacing the Chassis

Follow these steps to move the processor modules to the new chassis:

Step 1 Before moving any processor modules, ensure that you have met the following

prerequisites (refer to the section “Prerequisites” on page 4 for details):

• On both chassis, ensure that the poweris turned off and the power cable is disconnected

from the AC power receptacle or the DC terminal block.

• To prevent ESD damage, wear a grounding strap or other ESD-prevention device and

attach the equipment end to the chassis ground screwon the interface processor end of

the chassis. (See Figure 1 or Figure 2.)

• If you will leave the interface cables connected to the processor modules, ensure that

there is sufficient slack to avoid straining the cables when moving the processor

between chassis. Otherwise, label each cable with its slot and port number position.

(This will help avoid mixing up cables when you reconnect them.)

• Optional: Install the cable management brackets on the new chassis before moving the

components. Either move the brackets from the old chassis or install a new set.

Step 2 Note the slot location of the interface processor you will move. Before removing the

interface processor,remove the interface processor filler from the corresponding slot in the

new chassis. When installing interface processors in the new chassis, place them in the

same slot position that they occupied in the old chassis; this will retain your existing

configuration and will help avoid confusion when reconnecting cables and checking the

installation.

Step 3 If necessary, disconnect any interface cables that are connected to the processor module.

Step 4 Use a screwdriver to loosen both of the captive installation screws. (See Figure 8a.)

Step 5 Place your thumbs on the end of each ejector and simultaneously pull them both outward,

away from the carrier handle (in the opposite direction from that show in Figure 8c) to

release the processor module from the backplane.

Caution In the Cisco 7010, you must install the RP in the slot labeled RP (the top slot) and the SP

(or SSP) in the slot labeled SP (the slot directly below the RP slot). In the Cisco 7505, you must

install the RSP1 in the slot labeled slot 4. For both chassis models, you can install interface

processors in any of the interface processor slots (the lowest slots), but we recommend that you

install them in the same slot positions that they occupied in the old chassis. The slots are keyed for

correct installation. Forcing a processor module into the wrong slot can damage the backplane and

board connectors.

Step 6 Grasp the carrier handle with one hand and pull the processor module straight out of the

slot, keeping your other hand under the carrier to guide it. (See Figure 9.) Keep the carrier

at a90-degree orientation to the backplane. Avoid touching the board orany connector pins.

Step 7 Place the processor module in the same slot position in the new chassis and align the

notches along the edge of the carrier with the grooves in the slot. (See Figure 8a.)

Step 8 While keeping the carrier at a 90-degree orientation to the backplane, carefully slide the

carrierinto the slot untilthe back of thefaceplate makes contactwith the ejector levers,then

stop. (See Figure 8b.)

Do not use unnecessary force when installing processormodules. Always guide the carrier

into the slot only until the carrier faceplate makes contact with the ejector levers, then use

the ejector levers to complete the insertion.

16 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 17

Replacing the Chassis

Step 9 Using the thumb and forefinger of each hand to pinch each ejector, simultaneously push

both ejectors inward (toward the carrier handle) until they snap into place and are at a full

90-degree orientation to the faceplate. (See Figure 8c.) The carrier ears (the ends of the

faceplate) should be flush against the chassis.

Step 10 Use a screwdriver to tighten the two captive screws to prevent the processor module from

becoming partially dislodged from the backplane and to ensure proper EMI shielding.

Step 11 Repeat Steps 2 through 10 for the remaining interface processors.

Step 12 Repeat Steps 3 through 10 for the SP (or SSP) and RP in the Cisco 7010, and the RSP1 in

the Cisco 7505.

Figure 9 Handling a Processor Module

H1985

Captive installation

screws

Note Leave the interface processor filler installed in any unfilled interface processor slots.

This completes the processor module removal andreplacement procedure. If you now need toinstall

the new chassis in an equipment rack, proceed to the section “Installing the New Chassis in the

Rack” on page 10. Otherwise, proceed to the next section to check the installation.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 17

Page 18

Replacing the Chassis

Checking the Installation

To complete the replacement procedure, perform the following steps to verify that the system is

functioning properly. These steps will also help you verify that all the processormodules you moved

arereturned to their previousstate. Foradditional first-time startup troubleshootingprocedures, refer

tothe Cisco 7010HardwareInstallation and Maintenanceor Cisco 7505HardwareInstallation and

Maintenance publications.

Because the lithium battery backup on the RP and RSP1 retains the system configuration in

NVRAM, the system and the individual interfaces should come up in their previous configuration,

providedthat you installed the interface processors in the sameslots they occupied inthe old chassis.

If you installed interface processors in different slot positions in the new chassis, the system will

recognize the interfaces butleave them in a down state until you reconfigure and enable them. If you

need assistance, refer to the section “Cisco Information Online” at the end of this document.

Step 1 Ensure that the system power switch is in the off position, then reconnect the power cable

Step 2 Connect all interface cables to the appropriate interface processor ports. Ensure that all

Step 3 Ensure that you have either a console terminal connected to the system console port or a

to the AC receptacle or DC terminal block, as required. For the AC-input power supply,

snap thecable retention clip up around theplug to secure the cable. Forthe DC-input power

supply, reattach a new nylon cable tie to support the weight of the cable.

cables are fully seated in the ports and that all strain relief systems are engaged.

port available for a Telnet session to the router.

Step 4 Turn on the system power. The DC OK LED should go on and stay on. If if does, proceed

to the next step. If it does not, do the following:

• First, check the source power. Ensure that the power switch is completely in the on (|)

position and that the power (input) cord is properly connected at both ends.

• Listen forthe fans; you should hear them operating immediately after turnon the power.

If the DC OK LED is off and the fans are not operating, there is most likely a problem

with the AC or DC input power or with one of the internal DC lines. If so, there are no

installation adjustments that you should make; contact a service representative for

further instructions.

Step 5 While the system initializes, the yellow boot error LED on the RP should go on for about

ten seconds, then go off. Verify that the normal LED on the RP or RSP1 goes on and stays

on, which indicates that the system software booted successfully. If it does, proceed to the

next step. If it does not go on, do the following:

• Check the ejector leversand captiveinstallation screws onthe processor modules. Ifany

appear loose, use the ejector levers to reseat the module, then tighten the captive

installation screws to secure it. Toggle the power off and back on again.

• If the RP or RSP1 normal LED still remains off, note whether the boot fail LED (onthe

RP) or the CPU halt LED (on the RSP1) goes on, and contact a service representative.

18 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 19

Replacing the Chassis

Step 6 When the system boot is complete, the RP or RSP1 begins to initialize the interface

processors. During this initialization, the LEDs on each interface processor behave

differently (most flash on and off). The enabled LED on each interface processor goes on

when initialization has been completed.

• If the enabled LED on the SP (or SSP) and all interface processors go on, the system

has booted successfully and is now functional.

• If the RP or RSP1 LEDs previously indicated a successful system boot, but none of the

enabled LEDs on the SP (or SSP) or the interface processors go on, suspect that one of

them has shifted out of its backplane connector and hung the bus. Turn off the power,

then use the ejector levers to release the SP (or SSP) and each interface processor and

reseat themin their slots. (Refer to thesection “Moving Processor Modules” onpage 14

for removal and insertion steps.) Tighten all captive installation screws, then return to

Step 1.

Step 7 If the enabled LED on a single interface processor remains off, suspect that the interface

processor has shifted out of its slot. Usethe ejectorlevers to release the interface processor

and reseat it in the backplane. (Refer to the section “Moving Processor Modules” on

page 14, for removal and insertion steps.) Tighten both captive installation screws, then

return to Step 1.

Step 8 If an enabled LED still fails to go on after performing these steps, suspect that the specific

SP (or SSP) or interface processor has failed. Contact a service representative.

Step 9 Verify that the console terminal displays a script and system banner similar to the

following:

GS Software (GS7), Version 10.3(3), SOFTWARE

Copyright (c) 1986-1995 by cisco Systems, Inc.

Compiled Wed 10-May-95 14:46 by mpo

System Bootstrap, Version 4.6(1) [fc2], SOFTWARE

Step 10 After the system initializes, use the various show commands to display the status of the

system and individual interfaces, and ensure that they are operating according to their

previous configuration. (For descriptions and examples of these commands, refer to the

following section, “show Command Descriptions and Examples.”)

When thesystem starts up and operates successfully, the replacementprocedure is complete and you

can resume normal operation.

If the system still fails to start up or operate properly, or if you isolate the cause of the problem to a

failed component, contact a service representative for further assistance.

Note After you verify a successful installation, gather the old chassisand any remaining spares and

parts. If the old chassis is still mounted in a rack, follow the steps in the section “Removing the

Existing Chassis from the Rack” on page 10 to remove it. Place spare interface processors or

interface processor fillers in the chassis slots, and move the chassis to the appropriate location for

storage or shipment.

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 19

Page 20

Replacing the Chassis

show Command Descriptions and Examples

This section describes the various show commands that you can use to display system status and

configuration. If you installed the interface processors in the same slot locations that they occupied

in the old chassis, the interfaces should retain the same configuration. If you installed the interface

processors in different slot locations, the system will recognize the interfaces, but you will have to

use the configure command to reconfigure and enable them.

The showversioncommand displays the current hardware configuration of the router,including the

systemsoftware version thatis currently loaded and running. The showcontrollers cxbuscommand

lists all CxBus interfaces and includes the currently loaded and running microcode versionfor each.

You can check the version of the default ROM image either by removing the board and checking the

ROM labels or by configuring the interface or system software to boot from ROM, restarting the

system, and using these same commands to check the running version.

Use the show version command to display the current system software version, and use the show

controllers cxbus command to display the microcode version of the SP and each interface

processor.In the following example of the show version command, the running system software is

Release 10.3(1)).

Router> show version

GS Software (GS7), Version 10.3(3), SOFTWARE

Copyright (c) 1986-1995 by cisco Systems, Inc.

Compiled Wed 10-May-95 14:46 by mpo

System Bootstrap, Version 4.6(1) [fc2], SOFTWARE

Current date and time is Sat 1-22-1994 21:38:35

Boot date and time is Tue 12-28-1993 15:32:28

Router uptime is 3 weeks, 4 days, 6 hours, 7 minutes

System restarted by reload

System image file is “gs7-k.103-1”, booted via tftp from 1.1.1.12

(example text omitted

X.25 software, Version 2.0, NET2 and BFE compliant.

Bridging software.

1 EIP controller (6 Ethernet).

1 TRIP controller (4 Token Ring).

6 Ethernet/IEEE 802.3 interfaces.

4 Token Ring/IEEE 802.5 interfaces.

(remainder of example text omitted)

Following is an example of the show controller cxbus command display. (In this example, ROM

Version 1.0 is assumed because you cannot determine the ROM version with screen displays unless

it is the running version.)

Router# show controllers cxbus

(text omitted from example)

FSIP 1, hardware version 1.0, microcode version 1.0

Interface 8 - Serial1/0, electrical interface is V.35 DTE

(text omitted from example)

Interface 9 - Serial1/1, electrical interface is V.35 DTE

(remainder of displayed text omitted from example)

20 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Page 21

Replacing the Chassis

The command show interfaces serial slot/port displays statistics for the specificserial interface you

specify by its slot/port address. If you use this command without the type and slot/port arguments,

the system will display statistics for all interfaces in the system.

Router> show int hssi 1/0

Hssi 1/0 is up, line protocol is up

Hardware is cxBus HIP

Internet address is 1.1.1.9, subnet mask is 255.255.255.0

(display text omitted)

The command show configuration displays the contents of the system configuration file stored in

NVRAM.

Router# show config

Using 1652 out of 130048 bytes

version 10.3(3)

!

hostname Router

!

enable-password guessagain

!

microcode TRIP flash trip1-0

microcode reload

!

interface hssi1/0

ip address 1.1.1.67

ip route-cache cbus

no keepalive

!

interface serial2/1

ip address 1.1.1.12

(display text omitted)

The commandshow protocolsdisplaysthe global (system-wide) and interface-specificstatus of any

configured Level 3 protocol.

Router> show protocols

Global values:

Internet Protocol routing is enabled

Hssi1/0 is up, line protocol is up

(display text omitted)

Cisco 7010 and Cisco 7505 Chassis Replacement Instructions 21

Page 22

Cisco Information Online

Cisco Information Online

Cisco Information Online (CIO) is Cisco Systems’ primary,real-time support channel. Maintenance

customers and partners can self-register on CIO to obtain additional content and services.

Available24 hours a day,7 daysa week, CIO providesa wealth of standard andvalue-added services

to Cisco’s customers and business partners. CIO services include product information, software

updates, release notes, technical tips, the Bug Navigator, configuration notes, brochures,

descriptions of service offerings, and download access to public and authorized files.

CIO serves a wide variety of users through two interfaces that are updated and enhanced

simultaneously—a character-basedversion and amultimedia version that resideson the WorldWide

Web (WWW). The character-based CIO (called “CIO Classic”) supports Zmodem, Kermit,

Xmodem, FTP, Internet e-mail, and fax download options, and is excellent for quick access to

information over lower bandwidths. The WWW version of CIO provides richly formatted

documents with photographs, figures, graphics, and video, as well as hyperlinks to related

information.

You can access CIO in the following ways:

• WWW: http://www.cisco.com

• Telnet: cio.cisco.com

• Modem: From North America, 408 526-8070; from Europe, 33 1 64 46 40 82. Use the

following terminal settings: VT100 emulation; data bits: 8; parity: none; stop bits: 1; and baud

rates up to 14.4 kbps.

For a copy of CIO’s Frequently Asked Questions (FAQ), contact cio-help@cisco.com. For

additional information, contact cio-team@cisco.com.

Note If you are a network administrator and need personal technical assistance with a Cisco

product that is under warranty or covered by a maintenance contract, contact Cisco’s Technical

Assistance Center (TAC) at 800 553-2447, 408 526-7209, or tac@cisco.com. To obtain general

information about Cisco Systems, Cisco products, or upgrades, contact 800 553-6387,

408 526-7208, or cs-rep@cisco.com.

This document is to be used in conjunction with the Cisco 7010 Hardware Installation and Maintenance or Cisco 7505 Hardware Installation and Maintenance publications.

(1230chas.fm)

2

Access Without Compromise, Catalyst, CD-PAC, CiscoFusion, Cisco Internetwork Operating System, Cisco IOS, CiscoView, CiscoWorks, HyperSwitch, LAN

Enterprise, LAN

UniverCD, WNIC, Workgroup Director, WorkgroupStack, and XCI are trademarks;Access by Cisco and Bringingthe power of internetworking toeveryone are service marks; andCisco,

Cisco Systems, the Cisco logo, EtherSwitch, and Kalpanaare registered trademarks ofCisco Systems, Inc. All other trademarks, service marks, registered trademarks, or registered service

marks mentioned in this document are the property of their respective owners.

Copyright © 1995, Cisco Systems, Inc.

All rights reserved. Printed in USA

954R

2

LAN Remote Office, LAN2PC, LightStream, Newport Systems Solutions, PC2LAN/X.25, Point and Click Internetworking, SMARTnet, SynchroniCD, The Packet,

LAN, LAN2LAN

22 Cisco 7010 and Cisco 7505 Chassis Replacement Instructions

Loading...

Loading...