Page 1

QUICK START GUIDE

Cisco 7201 Router

1 Documentation and Resources

2 Prepare for Installation

3 Rack-Mount the Router

4 Connect the Router to the Network

5 Start the System

6 Configure the Router

7 After Installation

Page 2

1 Documentation and Resources

Documentation for the Cisco 7201 router is online. For detailed hardware installation instructions, refer to the online Cisco

7201 Installation and Configuration Guide. Refer to the following online documents for titles and links to related

documentation for installation and replacement of parts (including port adapters), and for troubleshooting information and

tools.

• All Cisco 7201 documentation—See the Cisco 7201 Router Documentation Roadmap at

http://www.cisco.com/en/US/docs/routers/7200/roadmaps/7201_doc_roadmap/11365r.html

• Port adapter documentation—See the Cisco 7201 Router Port Adapter Documentation Roadmap at

http://www.cisco.com/en/US/docs/routers/7200/roadmaps/7201_port_adaper_doc_roadmap/11366pr.html

• Troubleshooting documentation and tools—See the Cisco 7201 Router Troubleshooting Documentation Roadmap at

http://www.cisco.com/en/US/docs/routers/7200/roadmaps/7201_trblshoot_doc_roadmap/11367tr.html

Documentation Survey

Is Cisco documentation helpful? Click here or go to http://www.cisco.com/warp/public/732/docsurvey/rtg/ to give us your

feedback.

Obtaining Documentation, Obtaining Support, and Security Guidelines

For information on obtaining documentation, obtaining support, providing documentation feedback, security guidelines, and

also recommended aliases and general Cisco documents, see the monthly What’s New in Cisco Product Documentation, which

also lists all new and revised technical documentation at: http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html.

Document Revision History

The Document Revision History table below records technical changes to this document.

Document Version Date Change Summary

OL-11363-02 November, 2008 Revised rack-mount bracket installation instructions.

OL-11363-01 April, 2007 This is the first version of this document.

2

Page 3

2 Prepare for Installation

This section contains information about tools and parts, warnings, site preparation information, and information for

workbench or tabletop installation and rack-mount installation.

Warning

Warning

Before beginning this router installation, read the Regulatory Compliance and Safety Information for Cisco 7200 Series Routers

document.

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

1030

The ports labeled “Ethernet,” “10BaseT,” “Token Ring,” “Console,” and “AUX” are safety extra-low voltage (SELV)

circuits. SELV circuits should only be connected to other SELV circuits. Because the BRI circuits are treated like

telephone-network voltage, avoid connecting the SELV circuit to the telephone network voltage (TNV) circuits.

Statement 22

Statement

Site Preparation and Unpacking

• Lift the router safely out of the packing container.

• Ensure the power service at the site is suitable for the router you are installing.

• Check the packing slip to ensure that all the proper components are present.

• Locate and have accessible the Site Log for recording information about this installation.

Tools and Parts

Use the following list of tools and parts as a checklist for preparing to install the Cisco 7201 router:

• ESD-preventative wrist strap

• Power cord

• Appropriate cables to connect the router to the network, console port, and auxiliary port

• Tape measure and level (optional)

• Screwdrivers: Number 2 Phillips screwdriver and 3/16-inch flat-blade screwdriver

• Wire stripper

• Chassis grounding lug and wires:

–

A grounding lug with two number-10 screw holes with a 0.63-inch (16.002-mm) spacing between them

–

A wire receptacle large enough to accept a 6-AWG multistrand, copper wire

–

Two Phillips machine screws with locking washers—M5 (metric), 0.031-inch (.08-mm) pitch, 0.315-inch (8-mm) length

–

A crimping tool to fit the grounding lug wire receptacle

–

One grounding wire—6-AWG, 0.162-inch (4.115-mm) diameter, with approximately 0.108-inch (2.743-mm)

insulation, for a total wire diameter of approximately 0.27 inches (6.858 mm). The wire length depends on your router

location and site environment.

• The rack-mount and cable-management kit:

–

Two rack-mount brackets and one cable-management bracket

–

Screws: Four 6-32 x 0.25-inch screws, two M3 x 8-mm screws, four 10-32 or 12-24 screws, and one M4 x 20-mm screw

3

Page 4

• (Optional) Any modules or disks not ordered with the chassis:

–

Cisco USB Flash memory module or Aladdin USB eToken Pro key

–

SFP module

–

CompactFlash Disk

Prepare for Workbench or Tabletop Installation

For a workbench or tabletop installation, verify the following before installing the router:

• The router is off the floor and has adequate ventilation.

• An adequate chassis ground (earth) connection exists for the router.

• The router has at last 3 inches (7.62 cm) of clearance at the inlet and exhaust vents (front and back of router).

• The router has 19 inches (48.26 cm) of clearance at the front and rear to allow for CompactFlash Disk, SFP module, USB

module and port adapter replacement or installation, or to access cables or equipment.

• The port adapter blank panel is installed if a port adapter is not installed. The slot must not be empty.

Prepare for Rack-Mount Installation

Before you begin the rack-mounting tasks, decide whether or not you want to front- or rear-mount the chassis, decide whether

or not you want to attach the cable-management bracket, and determine the type of rack—four-post or two-post—that you will

be using. Also determine if you have any optional field-replaceable units to install, particularly if you are using SFP modules,

port adapters, or CompactFlash Disks that are at your site and have not been ordered with the router. See the “After

Installation” section on page 42 for instructions on installing these units.

If you ordered a port adapter, CompactFlash Disk, or SFP module with the router, they ship installed. If you ordered a USB Flash

memory module or Aladdin USB eToken Pro key, go to the “After Installation” section on page 42 for installation information.

4

Page 5

3 Rack-Mount the Router

This section provides information for rack-mounting the router.

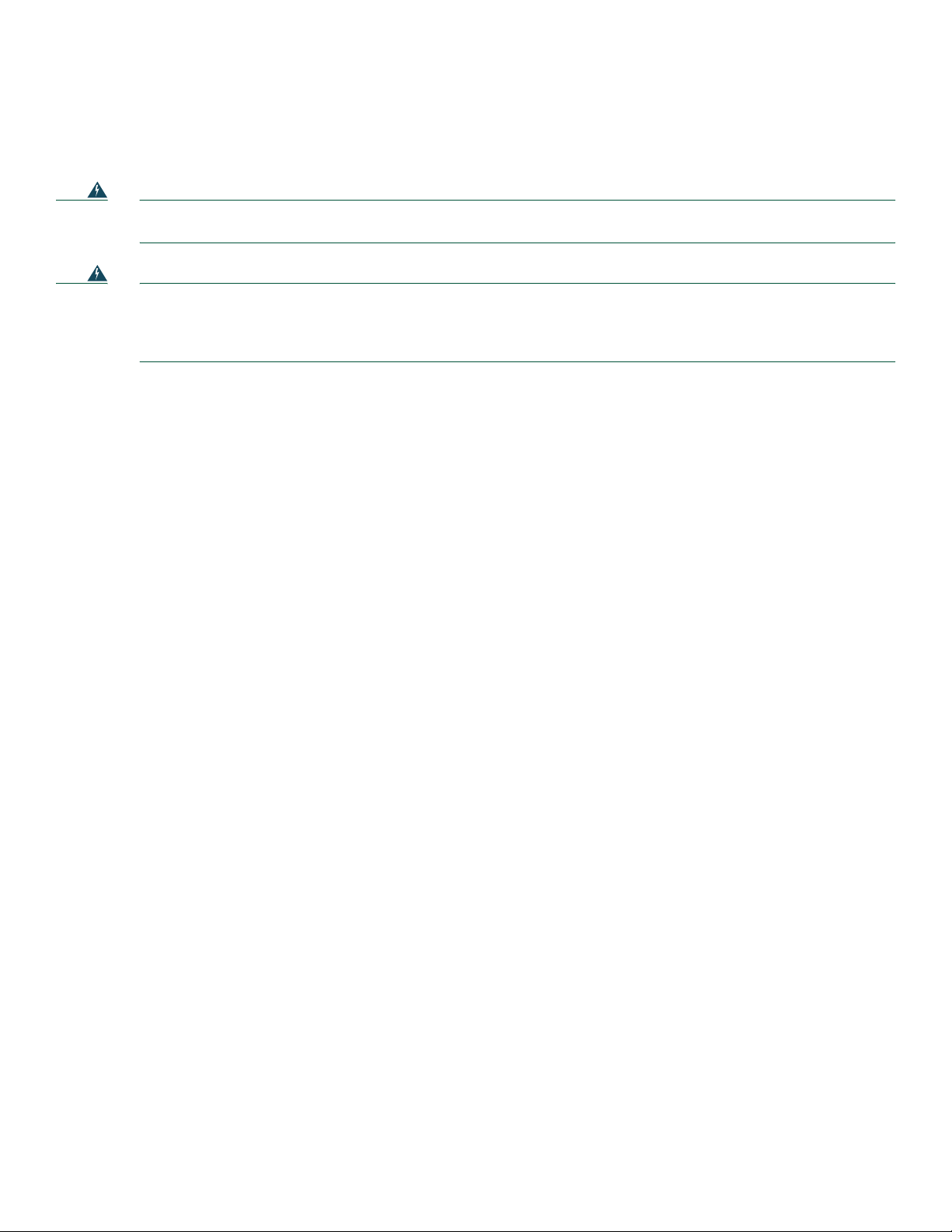

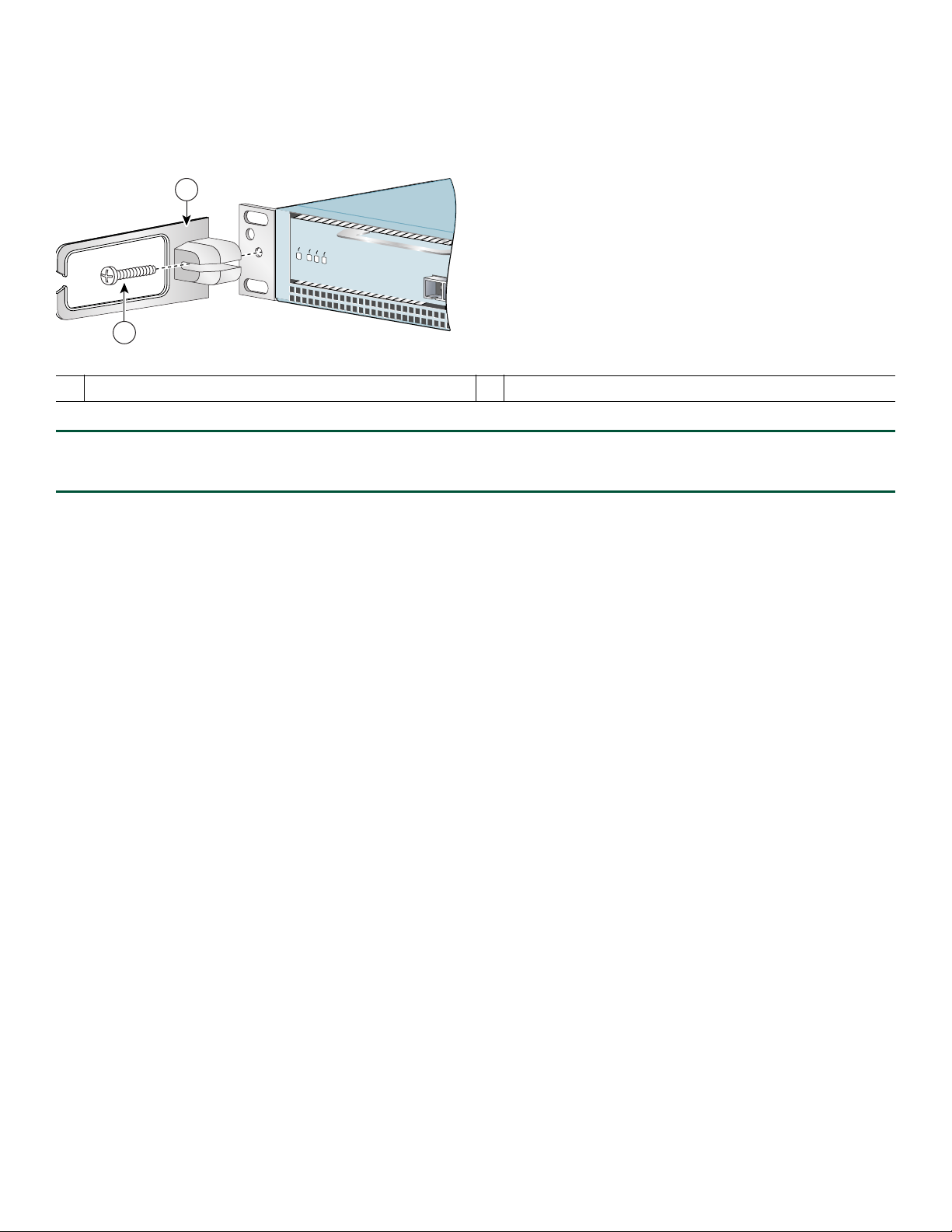

Attach the Rack-Mount Brackets—Chassis Front-Mounted

Figure 1 Attaching the Rack-Mount Brackets to the Front of the Chassis

LED

B

A

N

E

RX CELLS

RX CARRIER

RX ALARM

ATM

C

is

c

o

72

0

1

R

J45

EN

LINK

/ACTV

SFP

RJ45

EN

PA

SLOT 1

TX

GE 0/0

GE

0/1

CO

NSO

LINK/ACTV

SFP

LE

LINK

/ACTV

RX

LINK/ACTV

SFP

TX

SFP

RX

MNGM

NT USE ONL

G

E 0/2

Y

GE 0/3

AU

X

FE 0/0

0

FE

LINK

A

LARM

PW

R O

K

STATUS

CO

MPA

CT FLASH

CF

A

CT

V

2 31

281124

Rack-mount bracket

1

Four 6-32 x 0.25-in. screws

2

Two M3 x 8-mm screws

3

To install the rack-mount brackets on a Cisco 7201 router for a front rack-mount configuration, complete the following steps:

Step 1 Locate the threaded holes in the front sides of the chassis.

Step 2

Step 3

Align the rack-mount bracket to the rack-mount bracket holes on the side of the router.

Remove any existing cover screws from the front sides of the chassis that align with the rack-mount bracket holes and

then realign the bracket. (You should have to remove one cover screw from each side of the chassis.)

Step 4 Insert and tighten two 6-32 x 0.25-in. screws in the two holes nearest the front of the chassis.

Step 5 Insert and tighten the longer M3 x 8-mm screw in the hole nearest the rear of the chassis. (This screw replaces the cover

screw that you removed in Step 3.)

Step 6 Repeat Step 1 through Step 5 on the other side of the router.

To install the cable-management bracket, see page 7. If you are not installing the cable-management bracket, skip to the

“Two-Post Rack Installation” section on page 8 or the “Four-Post Rack Installation” section on page 9 for rack-mount

instructions.

5

Page 6

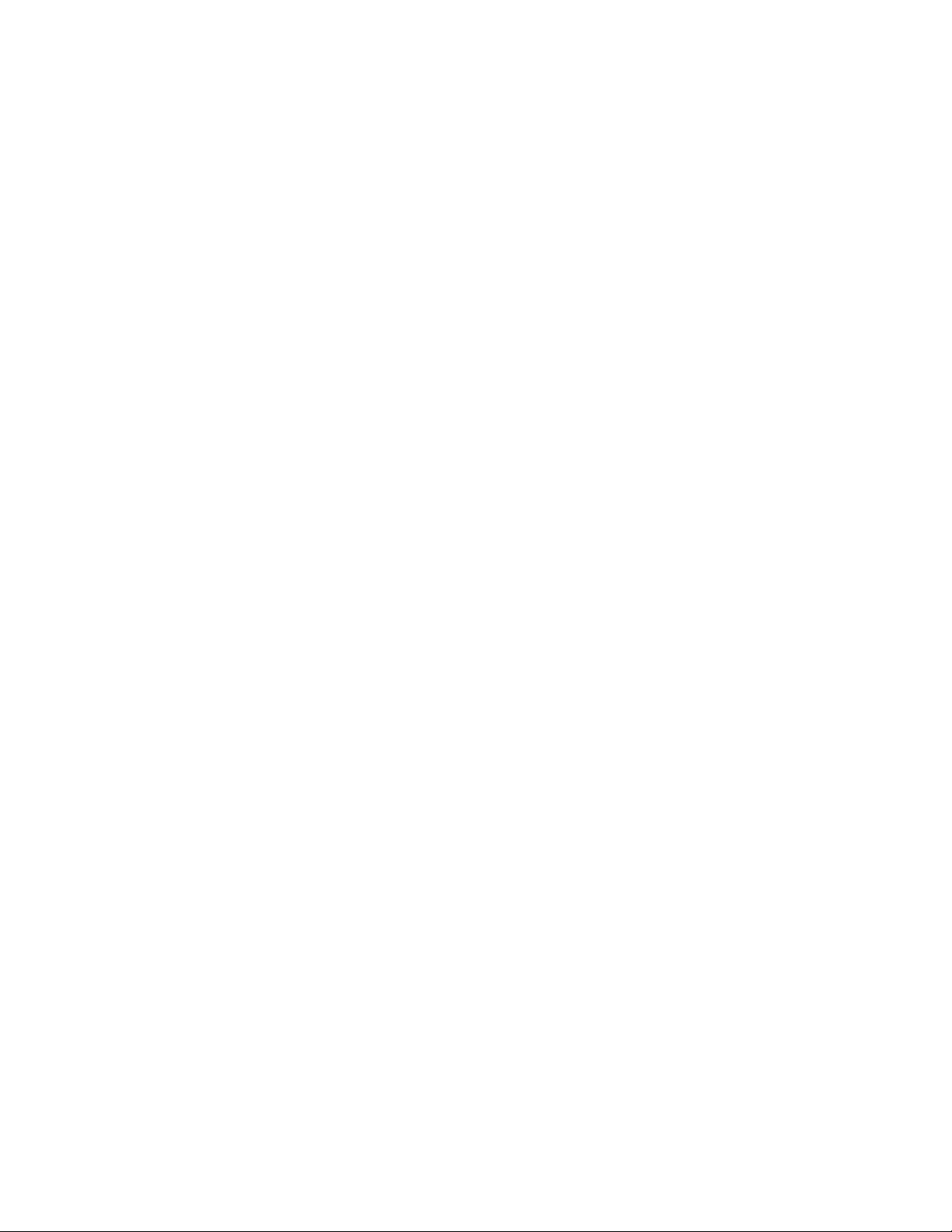

Attach the Rack-Mount Brackets—Chassis Rear-Mounted

Figure 2 Attaching the Rack-Mount Brackets to the Rear of the Chassis

3

R

S

IE

L

M

R

L

R

R

E

A

A

L

C

C

X

ENABLED

A

X

R

X

R

R

Rack-mount bracket

1

Four 6-32 x 0.25-in. screws

2

A

TM

R

P

A

S

L

O

T

1

Cisco 7201

J

4

5

E

N

L

IN

K

/A

C

T

V

S

F

P

R

J

4

5

E

N

T

G

E

0

/0

G

E

0

/1

C

O

N

S

O

L

L

IN

K

/A

C

X

S

F

P

E

T

V

L

IN

K

/A

C

T

V

R

X

L

IN

S

K

F

/A

P

C

T

V

T

X

S

F

P

R

X

M

N

G

M

N

T

U

S

E

O

N

L

G

E

0

/2

Y

G

E

0

/3

A

U

X

F

E

0

0

/0

F

E

L

IN

K

A

L

A

R

M

P

W

R

O

K

S

T

A

T

U

S

C

O

M

P

A

C

T

FL

A

SH

C

F

A

C

T

V

Two M3 x 8-mm screws

3

2

1

281125

To install the rack-mount brackets on a Cisco 7201 router for a rear rack-mount configuration, complete the following steps:

Step 1 Locate the threaded holes in the rear sides of the chassis.

Step 2

Step 3

Align the rack-mount bracket to the rack-mount bracket holes on the side of the router.

Remove any existing cover screws from the sides of the chassis that align with the rack-mount bracket holes and then

realign the bracket. (You should have to remove one cover screw from each side of the chassis.)

Step 4 Insert and tighten two 6-32 x 0.25-in. screws in the two holes nearest the rear of the chassis.

Step 5 Insert and tighten the longer M3 x 8-mm screw in the hole nearest the front of the chassis. (This screw replaces the cover

screw that you removed in Step 3.)

Step 6 Repeat Step 1 through Step 5 on the other side of the router.

To install the cable-management bracket, see page 7. If you are not installing the cable-management bracket, skip to the

“Two-Post Rack Installation” section on page 8 or the “Four-Post Rack Installation” section on page 9 for rack-mount

instructions.

6

Page 7

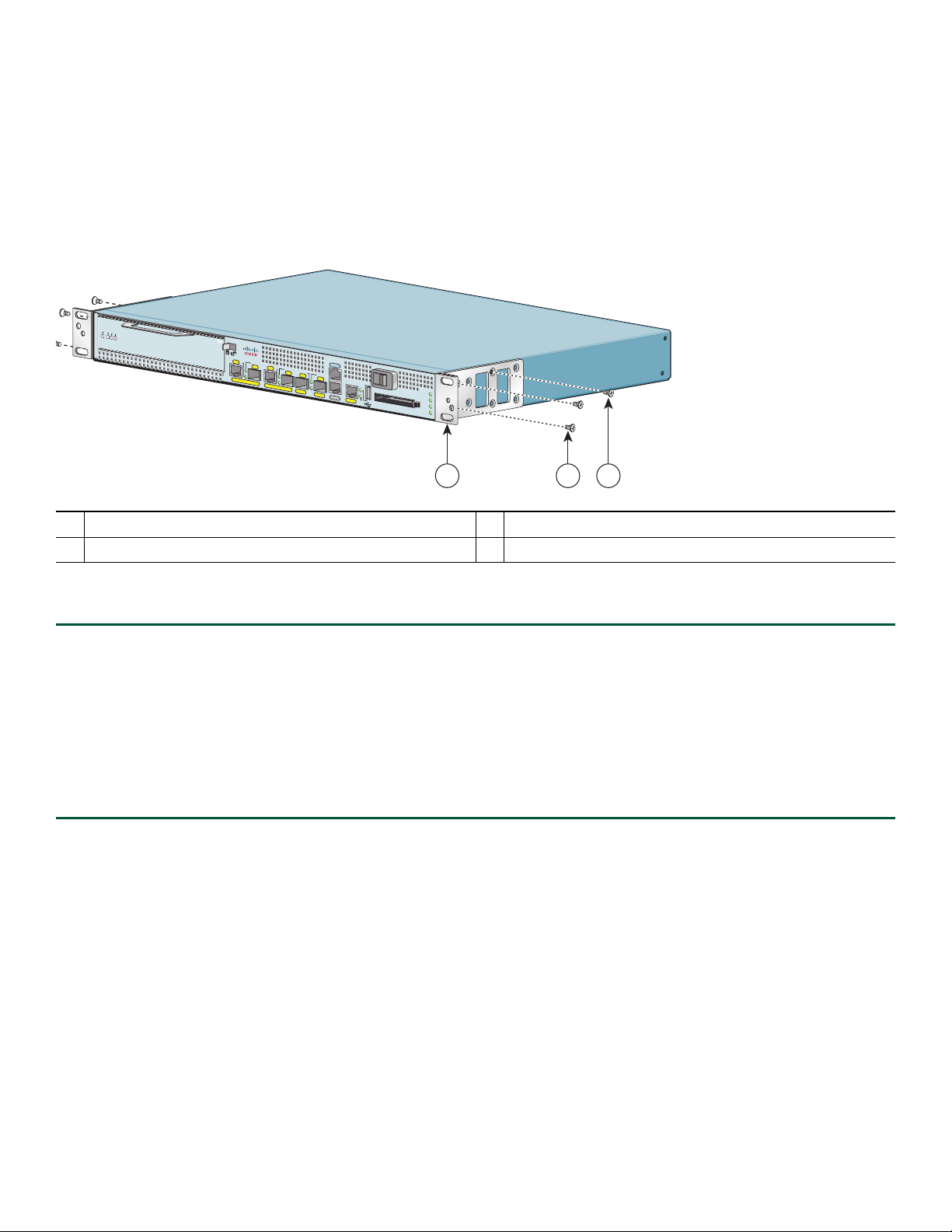

Attach the Cable-Management Bracket

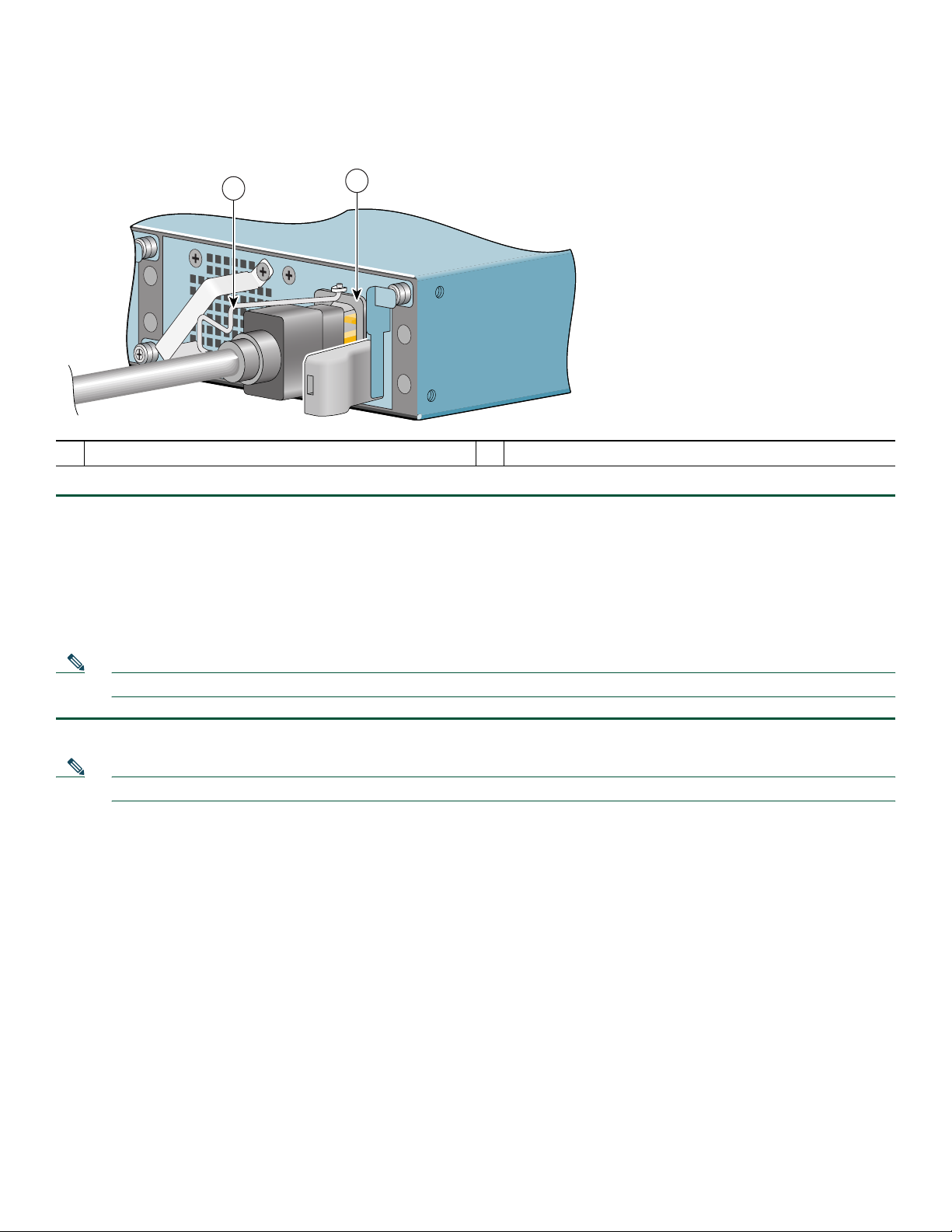

Figure 3 Installing the Cable-Management Bracket

1

ENABLED

RX CELLS

RX CARRIER

RX ALARM

2

170862

1 Cable-management bracket 2 M4 x 20-mm screw

Step 1 Align the cable-management bracket to the rack-mount bracket on the left side of the Cisco 7201 router.

Step 2 Using a Phillips screwdriver and the

M4 x 20-mm screw, thread and tighten the screw to the cable-management bracket.

This completes the procedure for installing the cable-management bracket on a Cisco 7201 router. Go to the “Two-Post Rack

Installation” section on page 8 or the “Four-Post Rack Installation” section on page 9.

7

Page 8

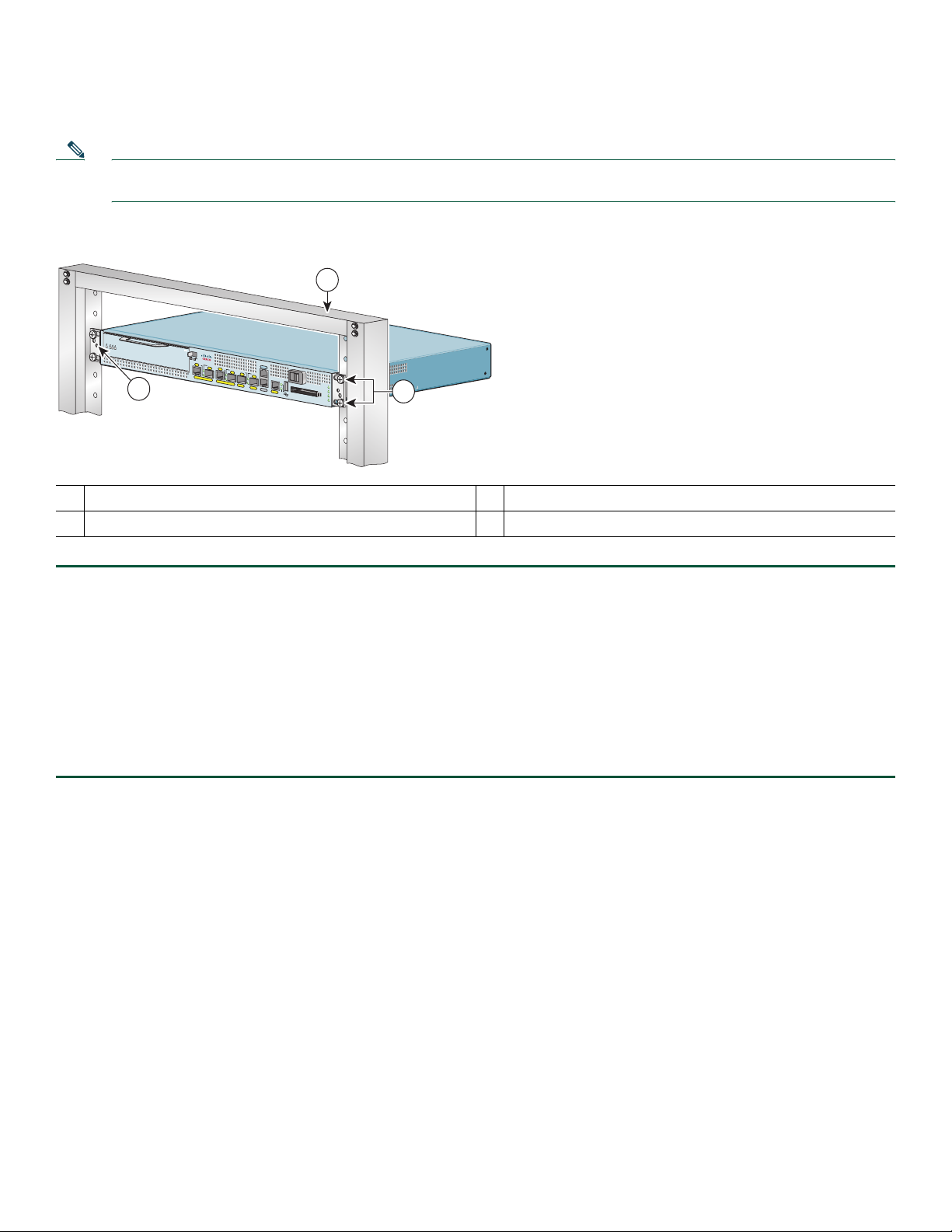

Two-Post Rack Installation

Note Inner clearance (the width between the inner sides of the two posts or rails) must be at least 19 inches (48.26 cm). The

height of the chassis is 1.73 inches (4.39 cm). Airflow through the chassis is from front to back.

Figure 4 Installing the Cisco 7201 Router in a Two-Post Rack

1

IER

M

CELLS

ENABLED

X CARR

RX

X ALAR

R

R

ATM

C

is

c

o

7

2

0

1

R

J

4

5

E

N

L

I

N

K

/A

C

T

V

S

F

P

P

A

S

LO

T

1

G

E

0

/0

2

C

O

N

S

O

L

R

E

J

4

5

E

N

L

I

N

K

/A

C

T

V

L

IN

K

T

/A

X

C

S

F

T

P

V

R

X

L

I

N

S

K

F

/A

P

C

T

V

T

X

S

F

P

R

X

M

N

G

M

N

T

U

S

E

O

N

L

G

E

0

/1

Y

G

E

0

/2

G

E

0

/3

A

U

X

F

E

0

A

L

A

R

M

P

W

R

O

K

0

/0

F

E

L

IN

K

S

T

A

T

U

S

C

O

M

P

A

C

T

F

L

A

S

H

C

F

A

C

T

V

3

281126

Two-post rack

1

Screw hole for the cable-management bracket

2

Four 10-32 or 12-24 screws

3

Step 1 Make sure that the port adapter lever is in the locked position.

Step 2 Make sure the rack brakes are locked or the rack is stabilized.

Step 3 Position the router so the front is closest to you and lift it carefully into the rack. To prevent injury, avoid any sudden

twists or moves.

Step 4 Slide the chassis into the rack, pushing it back until the brackets meet the mounting strips or posts on both sides of the

rack.

Step 5 Keeping the brackets flush against the posts or mounting strips, align the holes in the brackets with the holes on the

rack or mounting strip.

Step 6 For each bracket, insert and tighten two 10-32 or 12-24 screws to the rack.

This completes the procedure for installing the chassis in the rack. Proceed to the “Chassis Ground Connection Installation”

section on page 10 to continue the installation.

8

Page 9

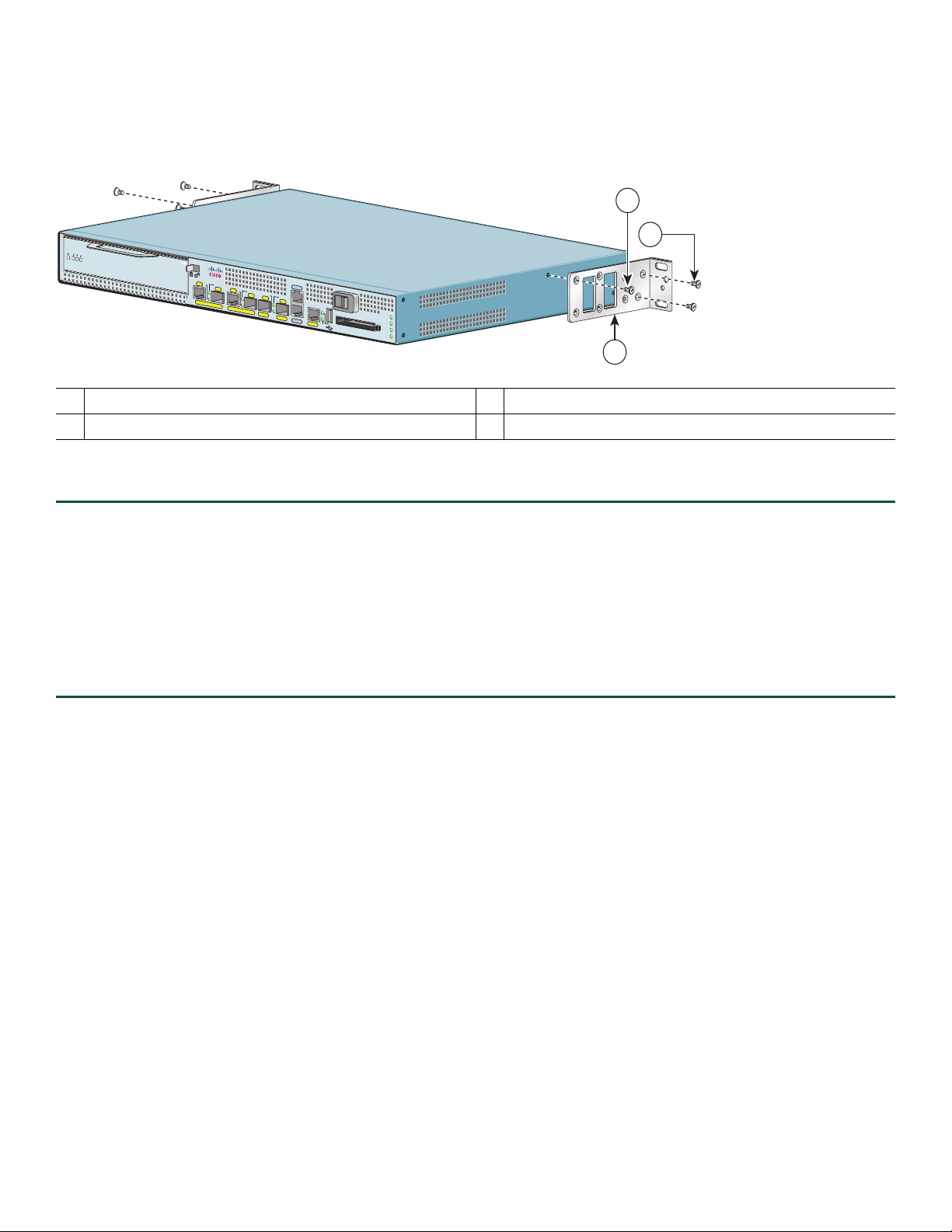

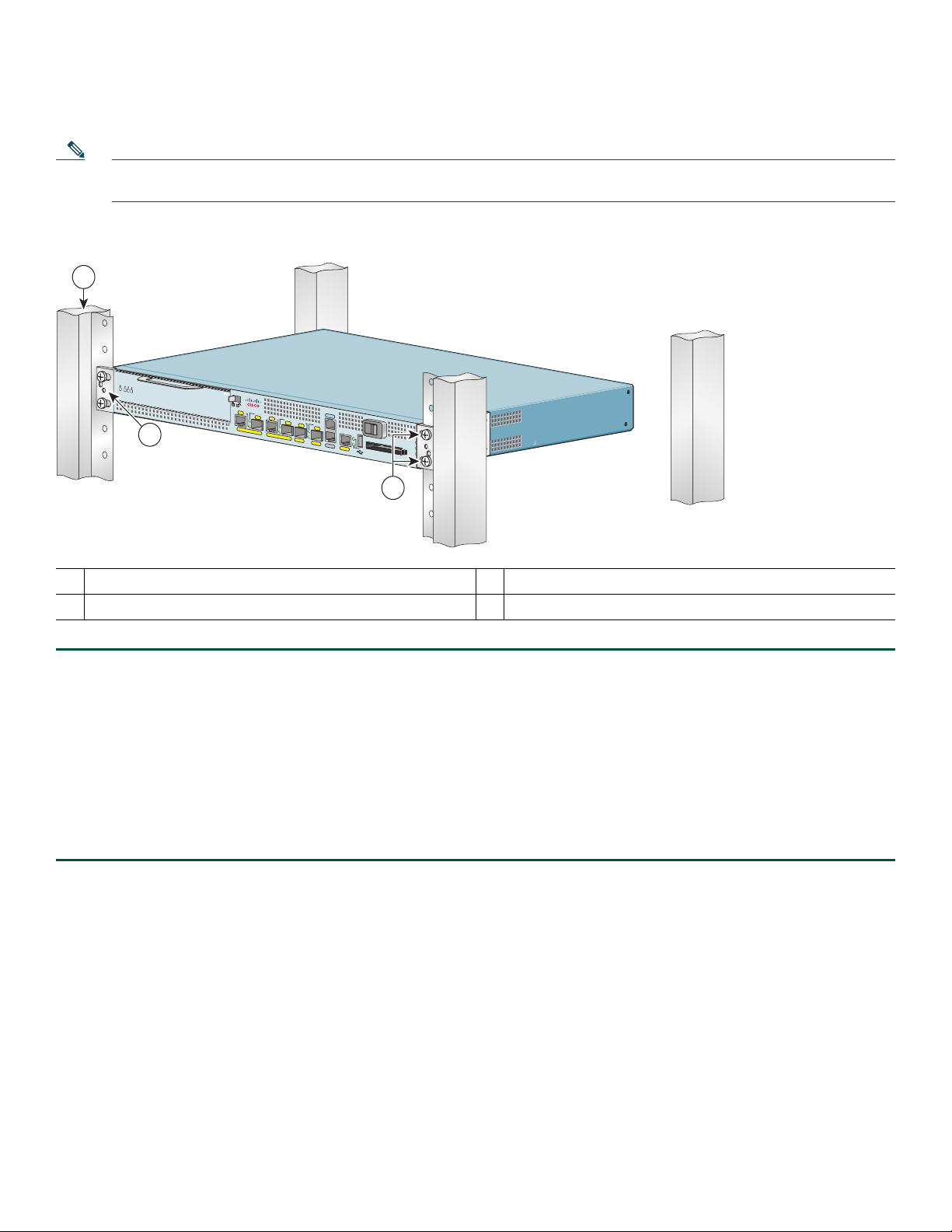

Four-Post Rack Installation

Note Inner clearance (the width between the inner sides of the two posts or rails) must be at least 19 inches (48.26 cm). The

height of the chassis is 1.73 inches (4.39 cm). Airflow through the chassis is from front to back.

Figure 5 Installing the Cisco 7201 Router in a Four-Post Rack

1

D

E

L

B

ARRIER

CELLS

LARM

NA

C

X

E

R

X A

RX

R

2

A

T

M

Cisco 7201

R

J4

5

E

N

L

IN

K

/A

C

TV

S

FP

R

J4

5

P

A

S

LO

EN

T 1

G

E

0

/0

G

E

0/1

C

O

N

SO

LE

L

IN

K

/A

C

TV

LIN

K

T

/A

X

C

S

FP

TV

R

X

LIN

S

K

F

/AC

P

TV

TX

S

F

P

R

X

M

N

GM

N

T U

S

E

ON

L

G

E

0/2

Y

G

E 0

/3

A

U

X

FE

0/0

0

F

E

LIN

K

COMPACT FLASH

A

LA

R

M

P

W

R

O

K

ST

A

TU

S

C

F

A

C

T

V

3

281127

Four-post rack

1

Screw hole for the cable-management bracket

2

Four 10-32 or 12-24 screws

3

Step 1 Make sure that the port adapter lever is in the locked position.

Step 2 Make sure the rack brakes are locked or the rack is stabilized.

Step 3 Position the router so the front is closest to you and lift it carefully into the rack. To prevent injury, avoid any sudden

twists or moves.

Step 4 Slide the chassis into the rack, pushing it back until the brackets meet the mounting strips or posts on both sides of the

rack.

Step 5 Keeping the brackets flush against the posts or mounting strips, align the holes in the brackets with the holes on the

rack or mounting strip.

Step 6 For each bracket, insert and tighten two 10-32 or 12-24 screws to the rack.

This completes the procedure for installing the chassis in the rack. Proceed to the “Chassis Ground Connection Installation”

section on page 10 to continue the installation.

9

Page 10

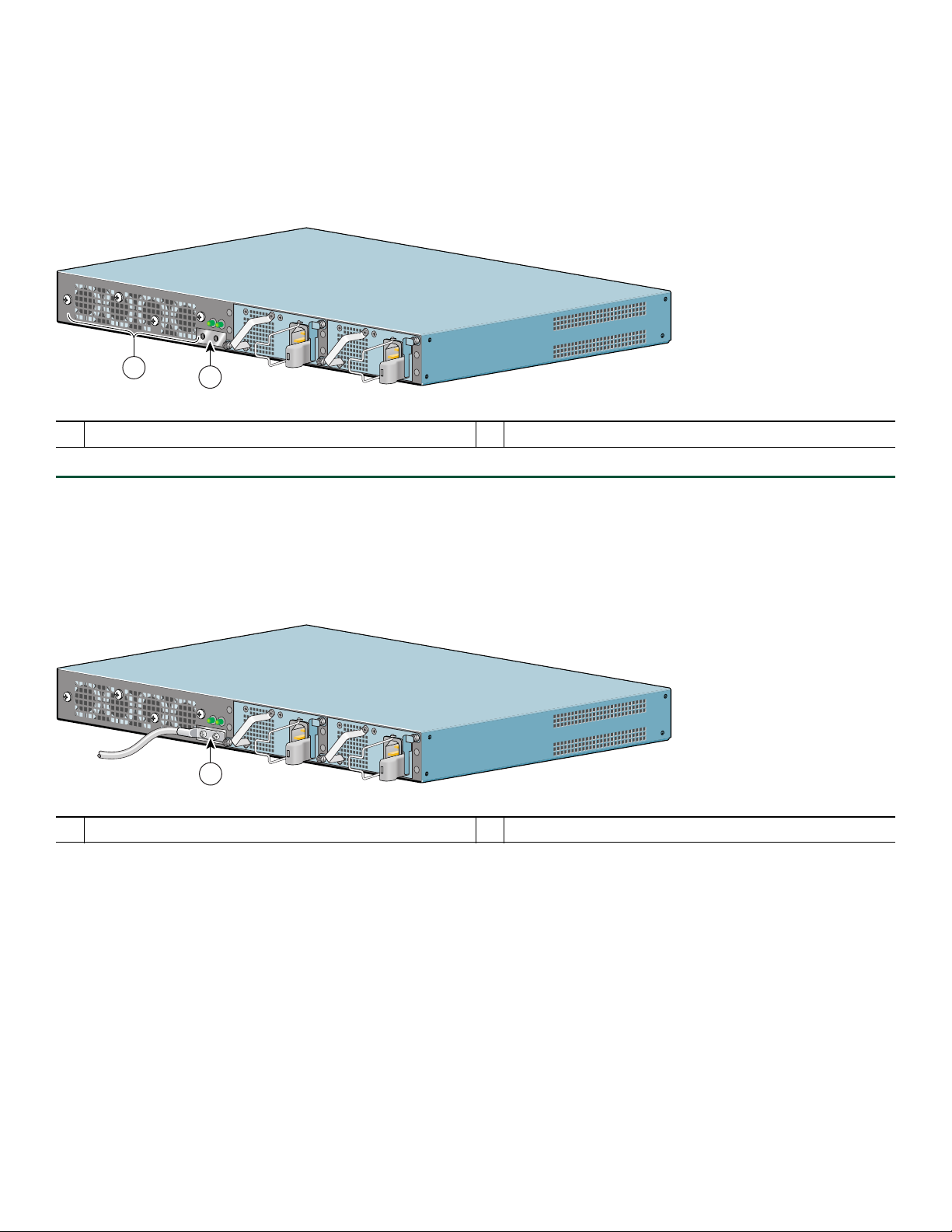

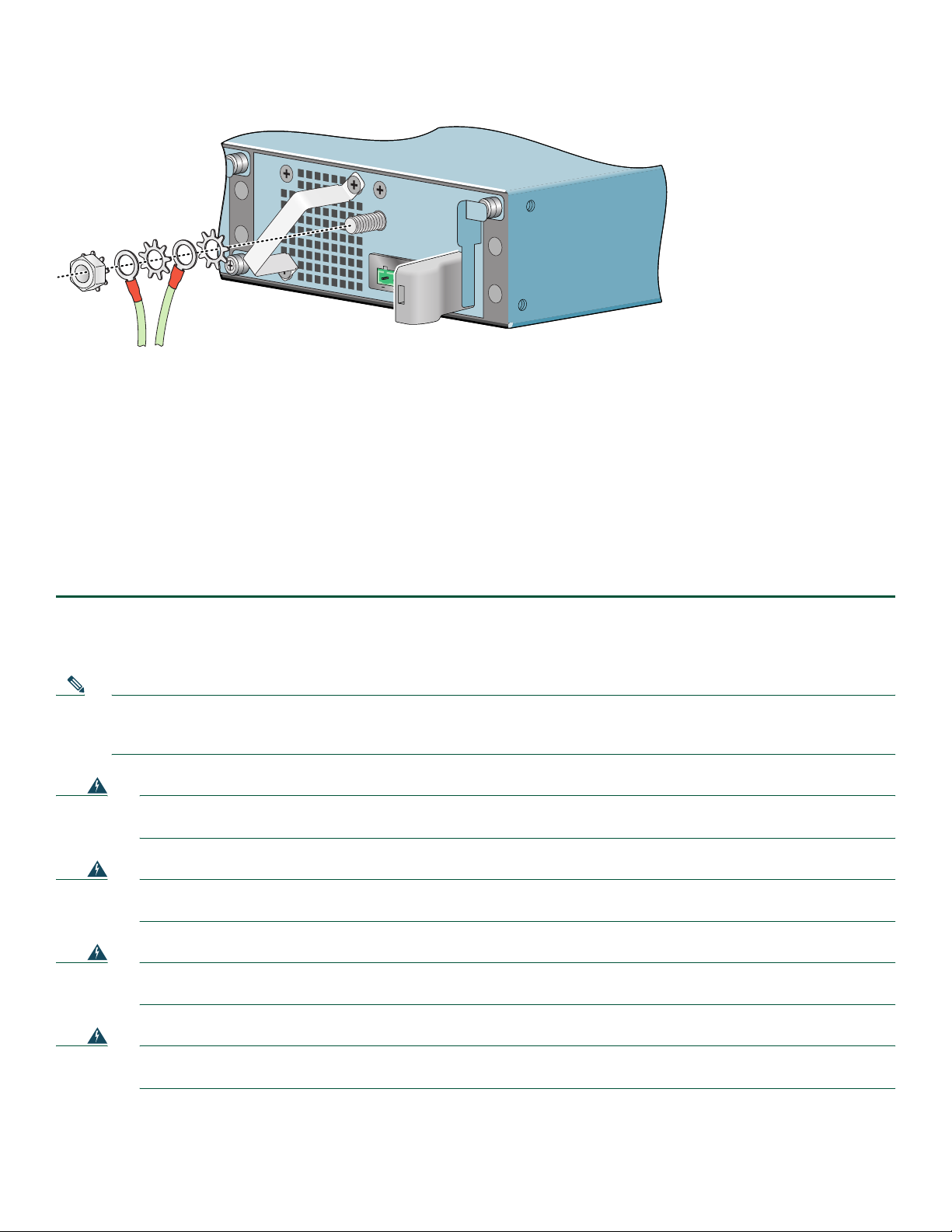

Chassis Ground Connection Installation

Before you connect power or turn on power to your router, you must provide an adequate chassis ground (earth) connection

for the router chassis. A chassis ground connector is provided on each Cisco 7201 router chassis.

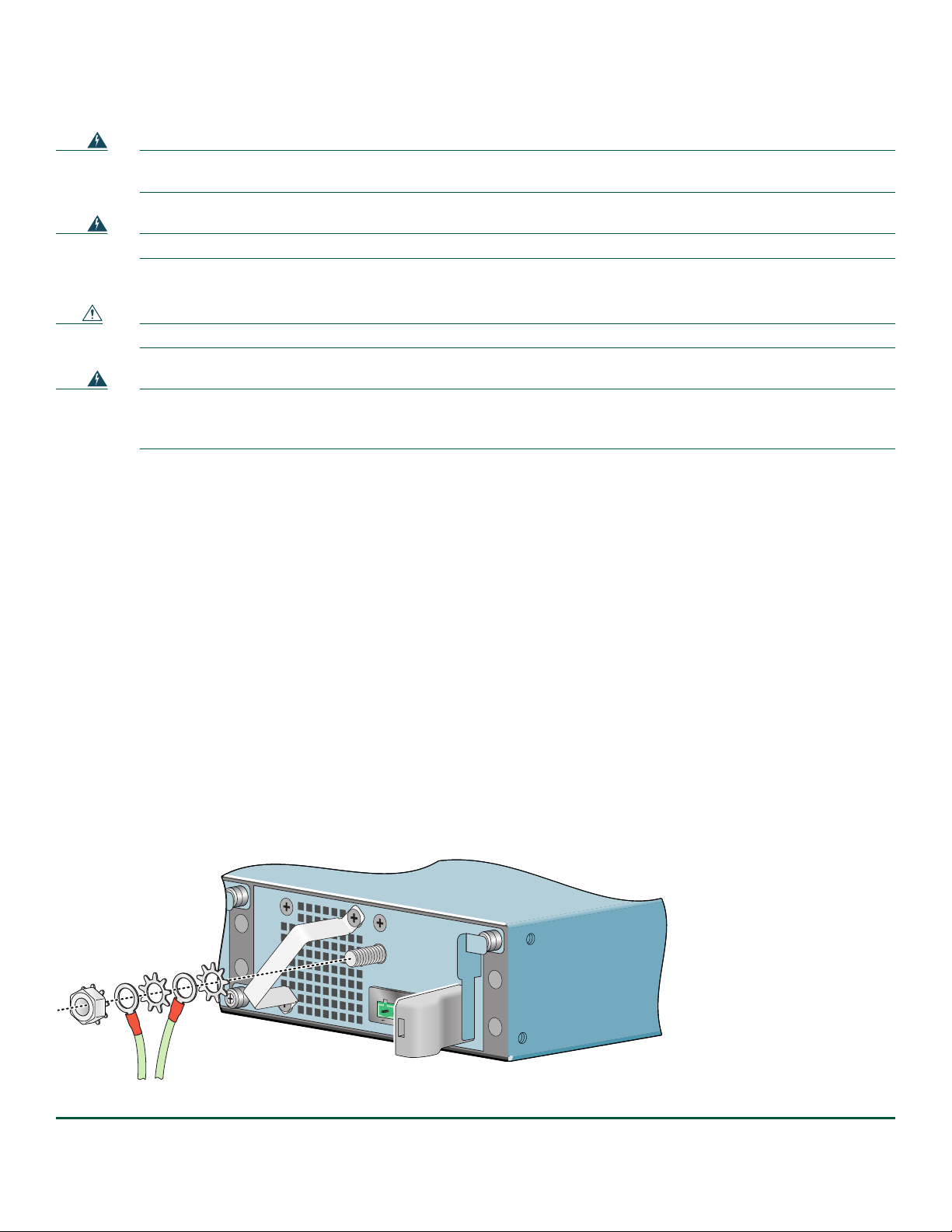

Figure 6 Locating the Chassis Ground Connector

T

H

IS

U

N

IT

M

A

Y

H

A

V

E

M

O

R

E

T

H

A

N

O

N

E

P

O

W

E

R

S

U

P

P

L

Y

C

O

N

N

E

C

T

IO

N

. A

L

L

C

O

N

N

E

C

T

IO

N

S

M

U

S

T

B

E

R

E

M

O

V

E

D

T

O

D

E

-E

N

E

R

G

IZ

E

T

H

E

U

N

IT

PWR

SLOT 1 OK

PWR

SLOT 2 OK

PWR

SLOT 1

PWR

1

2

1 Fan vents 2 Chassis ground connector

Step 1 Use the wire stripper to strip one end of the 6-AWG wire approximately 0.75 inches (19.05 mm).

Step 2 Insert the 6-AWG wire into the wire receptacle on the grounding lug.

Step 3 Use the crimping tool to carefully crimp the wire receptacle around the wire; this step is required to ensure a proper

mechanical connection.

SLOT 2

170934

Figure 7 Attaching the Grounding Lug

T

H

IS

U

N

IT

M

A

Y

H

A

V

E

M

O

R

E

T

H

A

N

O

N

E

P

O

W

E

R

S

U

P

P

L

Y

C

O

N

N

E

C

T

IO

N

. A

L

L

C

O

N

N

E

C

T

I

O

N

S

M

U

S

T

B

E

R

E

M

O

V

E

D

T

O

D

E

-E

N

E

R

G

I

Z

E

T

H

E

U

N

IT

PWR

SLOT 1 OK

PWR

SLOT 2 OK

PWR

SLOT 1

PWR

1

SLOT 2

230031

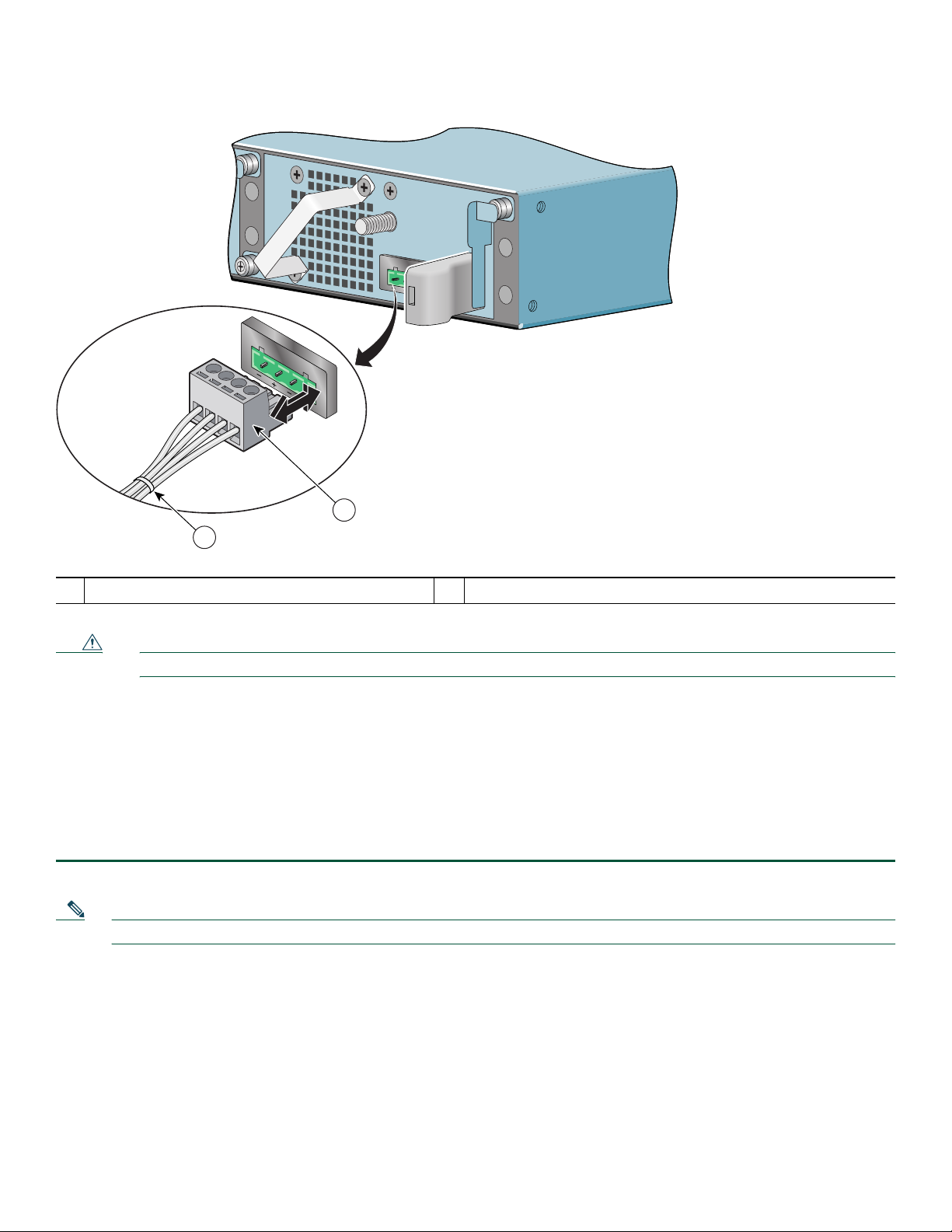

1 Grounding lug

Step 4 Attach the grounding lug with the wire on the left so the grounding wire does not overlap the power supply.

10

Page 11

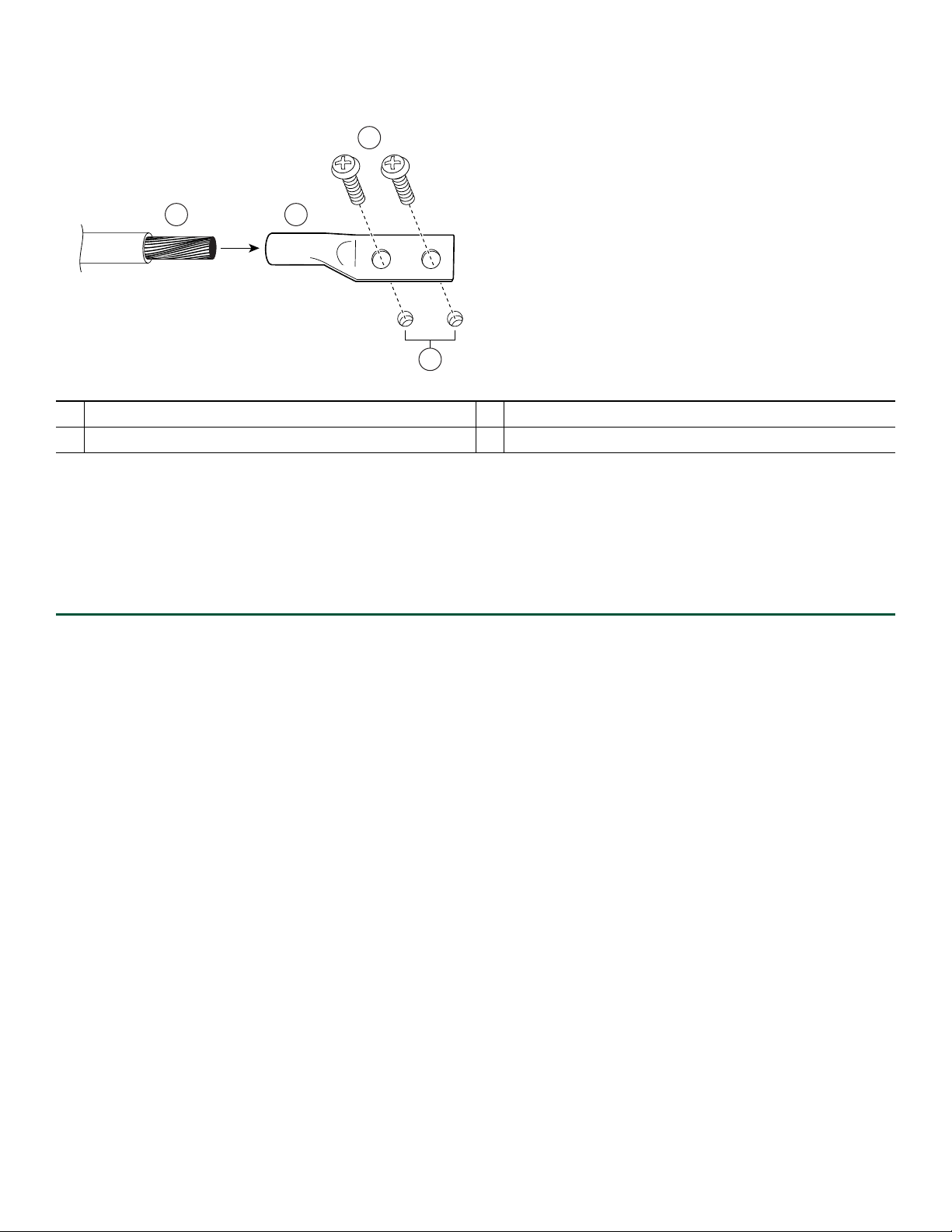

Figure 8 Attaching a Grounding Lug to the Chassis Ground Connector

3

4

2

50536

1

1 Chassis ground connector 3 Screws

2 Grounding lug 4 Wire

Step 5 Locate the chassis ground connector on the rear of your router chassis.

Step 6 Insert the two screws through the holes in the grounding lug.

Step 7 Use the Number 2 Phillips screwdriver to carefully tighten the screws until the grounding lug is held firmly to the

chassis. Do not overtighten the screws.

Step 8 Connect the opposite end of the grounding wire to the appropriate grounding point at your site to ensure an adequate

chassis ground.

This completes the procedure for attaching a chassis ground connection. Go to the “Connect the Router to the Network” section

on page 12 for information on attaching cables.

11

Page 12

4 Connect the Router to the Network

This section provides information about cables and ports and attaching the router to the network.

• Console and Auxiliary Port Cable Connections, page 12

• Connect the Fast Ethernet Management Port Cable, page 14

• Connect Native Gigabit Ethernet Cables, page 14

• Connect the Port Adapter Cables, page 18

• Install the Cables in the Cable-Management Bracket, page 19

Warning

The ports labeled “Ethernet,” “10BaseT,” “Token Ring,” “Console,” and “AUX” are safety extra-low voltage (SELV)

circuits. SELV circuits should only be connected to other SELV circuits. Because the BRI circuits are treated like

telephone-network voltage, avoid connecting the SELV circuit to the telephone network voltage (TNV) circuits.

Statement 22

Console and Auxiliary Port Cable Connections

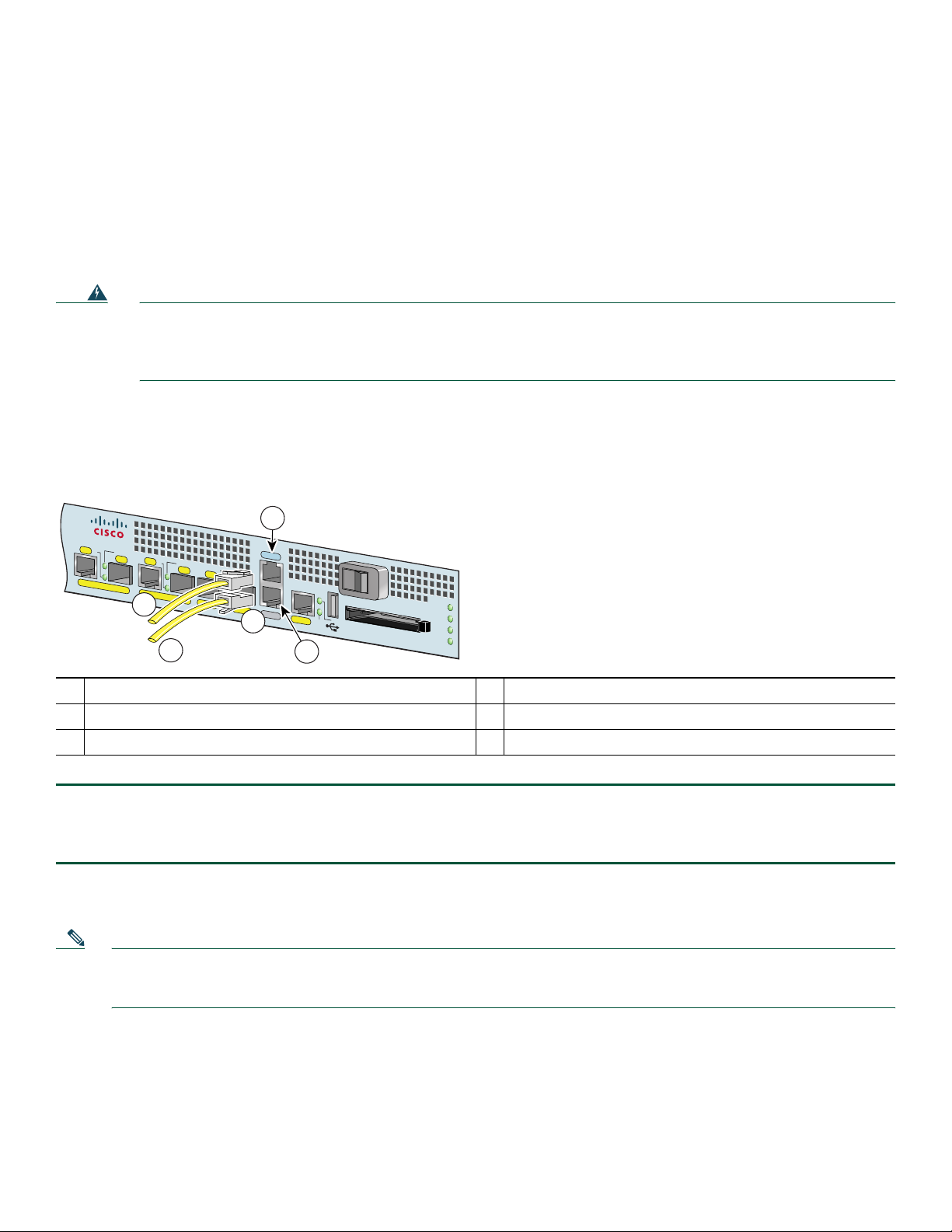

Figure 9 Console and Auxiliary Port RJ-45 Connectors

2

Cisco

7201

RJ45

EN

LINK/A

CTV

SFP

G

E 0/0

Auxiliary port

1

Console port

2

RJ-45 connector

3

RJ45

EN

LIN

K/ACTV

LINK/A

TX

CTV

SFP

RX

SFP

G

E 0/1

G

4

E 0/2

5

CO

NSO

LE

LINK/A

CTV

TX

SFP

RX

M

N

G

M

NT U

SE O

N

LY

GE

0/3

AU

X

FE 0/0

0

3

FE

LIN

K

COMPACT FLASH

1

A

PW

STATUS

LARM

AC

R O

K

CF

TV

170866

4

5

Cable to console terminal or DTE

Cable to modem or DCE

Step 1 Before connecting a terminal to the console port, configure the terminal to match the router console port as follows:

9600 baud, 8 data bits, no parity, 1 stop bits (9600 8N1).

Step 2 After you establish normal router operation, you can disconnect the terminal.

The Cisco 7201 router uses RJ-45 ports for both the auxiliary port and the console port.

Note You must supply your own interface cable between the auxiliary port and the equipment you are connecting. For

console and auxiliary port pinouts, see Appendix A, “Specifications,” of the online Cisco 7201 Installation and

Configuration Guide.

12

Page 13

Table 1 Pinouts for the RJ-45-to-DB-25 Adapters

Adapter DTE M/F Pins

1

DCE M/F Pins MMOD Pins

2

1455

22068

3233

4777

5777

6322

762020

8544

1. The female data terminal equipment (FDTE) adapter that is available from Cisco is labeled “Terminal”.

2. The MMOD adapter that is available from Cisco is labeled “Modem”.

Refer to Table 1 for a list of the pins used on the RJ-45-to-DB-25 adapters, used with an RJ-45 cable, to connect terminals and

modems to the Cisco 7201 router. The cable you use may be a roll-over cable or a straight-through cable.

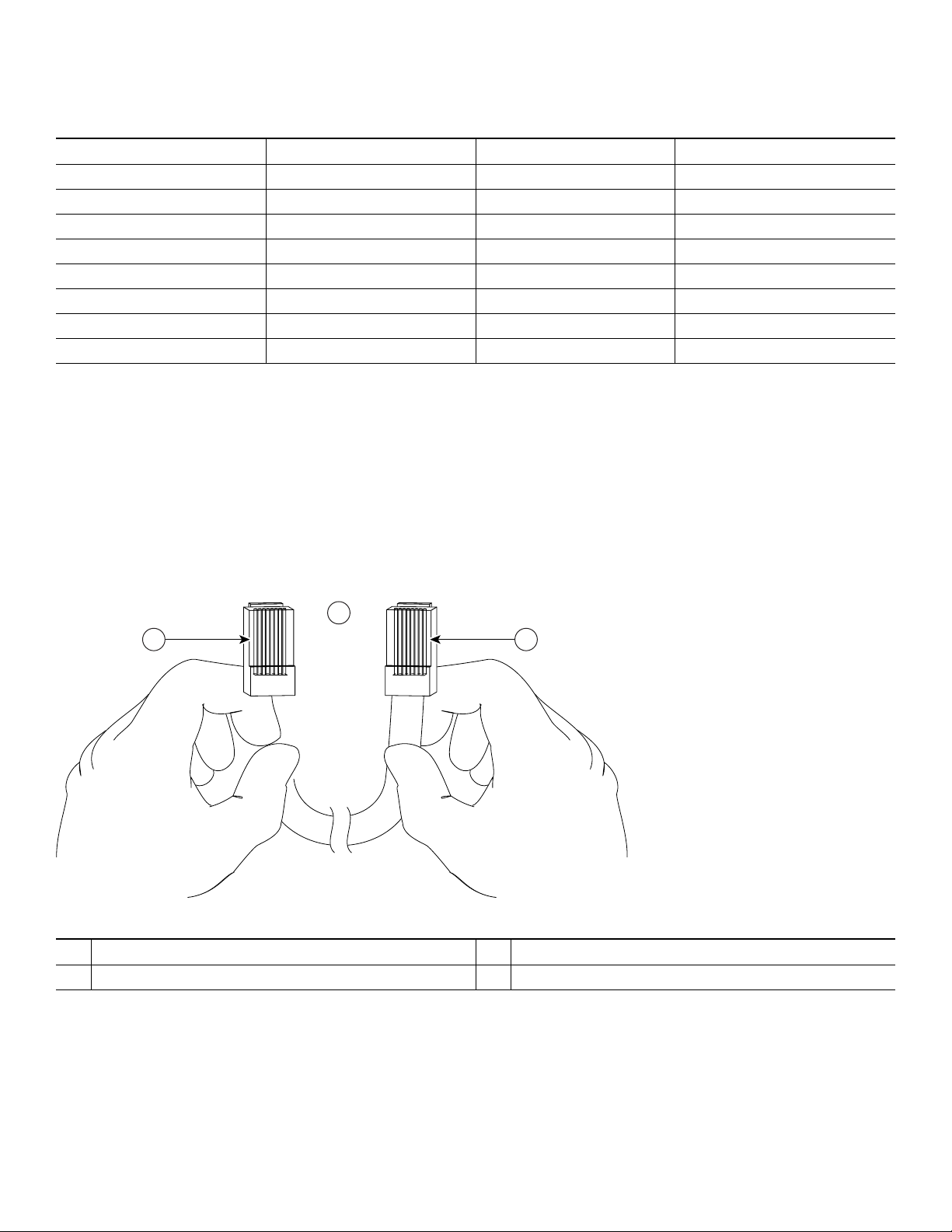

A roll-over cable can be detected by comparing the two modular ends of the cable. Holding the cables in your hand, side-by-side,

with the tab at the back, the wire connected to the pin on the outside of the left plug should be the same color as the pin on the

outside of the right plug. If your cable was purchased from Cisco, pin 1 will be white on one connector, and pin 8 will be white

on the other (a roll-over cable reverses pins 1 and 8, 2 and 7, 3 and 6, and 4 and 5). (See Figure 10.)

Figure 10 Identifying a Roll-Over Cable

2

1 3

84532

Pin 1

1

Pin 1 and pin 8 should be the same color

2

Pin 8

3

The Cisco 7201 router ships with a roll-over cable. Connection to a terminal or a modem will require an RJ-45-to-DB-25

adapter, and possibly a DB-25-to-DB9 adapter. Refer to Table 2 for the cable and adapter configurations that can be used to

connect terminals and modems to the Cisco 7201 router.

13

Page 14

Table 2 Asynchronous Device Cabling Options

Access Server Port RJ-45 Cable Type DB-25 Adapter End Device

Console or auxiliary Roll-over FDTE

1

Termina l

Console or auxiliary Straight-through FDCE Terminal

Auxiliary or console Roll-over MMOD

1. The FDTE RJ-45-to-DB-25 adapter is labeled “Terminal”.

2. The MMOD RJ-45-to-DB-25 adapter is labeled “Modem”.

2

Modem

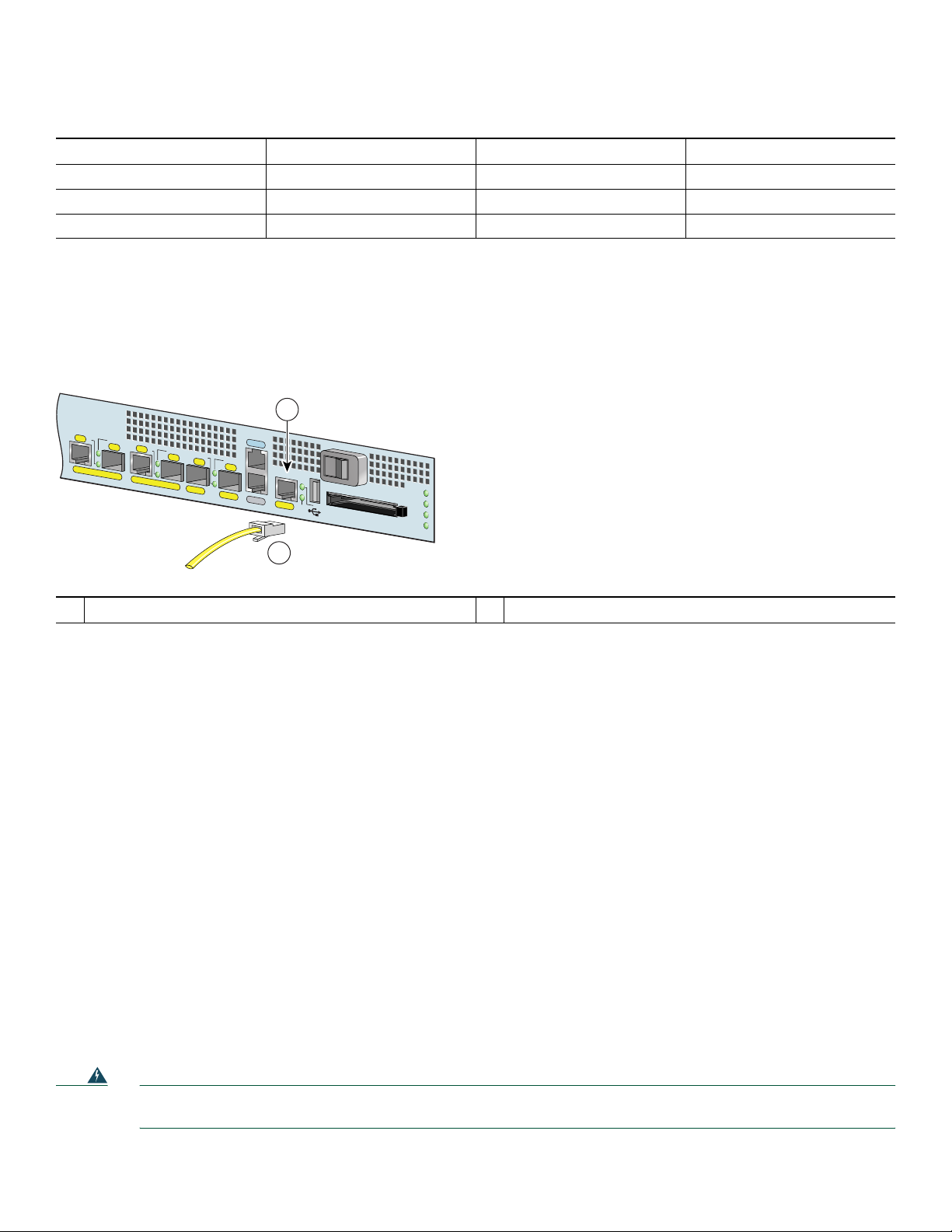

Connect the Fast Ethernet Management Port Cable

Figure 11 Installing the Fast Ethernet Management Port Cable

1

R

J4

5

E

N

L

IN

K

/A

C

T

V

S

F

P

R

J45

E

N

L

IN

K

/A

C

T

V

L

IN

K

/A

T

X

C

S

F

P

R

X

S

G

E

0/0

G

FP

E

0/1

G

E

0/2

C

O

N

S

O

L

T

V

E

L

IN

K

/A

C

T

V

T

X

S

F

P

R

X

M

N

G

M

N

T

U

S

E

O

N

L

Y

G

E

0/3

A

U

X

F

E

0/0

0

F

E

LIN

K

COMPACT FLASH

A

L

A

R

M

P

W

R

O

K

S

T

A

T

U

S

C

F

A

C

T

V

170868

2

Fast Ethernet Management port

1

RJ-45 Fast Ethernet cable

2

When using the Fast Ethernet Management port in the default mode (speed-auto and duplex-auto) the port operates in

auto-MDI/MDI-X mode. The port automatically provides the correct signal connectivity through the Auto-MDI/MDI-X feature.

The port automatically senses a crossover or straight-through cable and adapts to it.

However, when the Fast Ethernet Management port is configured to a fixed speed (10 or 100 Mbps) through command-line

interface (CLI) commands, the port is forced to MDI mode.

When in a fixed-speed configuration and MDI mode:

• Use a crossover cable to connect to an MDI port

• Use a straight-through cable to connect to an MDI-X port

Connect Native Gigabit Ethernet Cables

The Cisco 7201 router native Gigabit Ethernet ports use either optical fiber or RJ-45 Ethernet cables. For installation

information see:

• Install the SFP Module Optical Fiber Cables, page 15

• Install the Native Gigabit RJ-45 Ethernet Cables, page 18

The SFP port is a 1000-Mbps optical interface in the form of an LC-type duplex port that supports IEEE 802.3z interfaces

compliant with the 1000BASEX standard. (See Figure 13.)

Appendix A, “Specifications” of the online Cisco 7201 Installation and Configuration Guide, provides cabling specifications

and configuration information for the SFP modules that you install in the Gigabit Ethernet SFP ports.

Warning

14

Because invisible laser radiation may be emitted from the aperture of the port when no cable is connected, avoid

exposure to laser radiation and do not stare into open apertures.

Statement 70

Page 15

Figure 13 shows the duplex LC-type connectors on your multimode or single-mode optical fiber cables. For simplex connectors,

two cables are required, one cable for transmit (TX) and a second cable for receive (RX). For duplex connectors, only one cable

that has both TX and RX connectors is required. You can use either simplex or duplex connectors to the SFP ports on the

Cisco 7201 router.

Install the SFP Module Optical Fiber Cables

The SFP module ports support IEEE 802.3z (optical Gigabit Ethernet) interfaces compliant with 1000BASESX and

1000BASELX specifications.

SFP modules ordered with the Cisco 7201 router come installed in the system. Optical fiber cables are commercially available;

they are not available from Cisco.

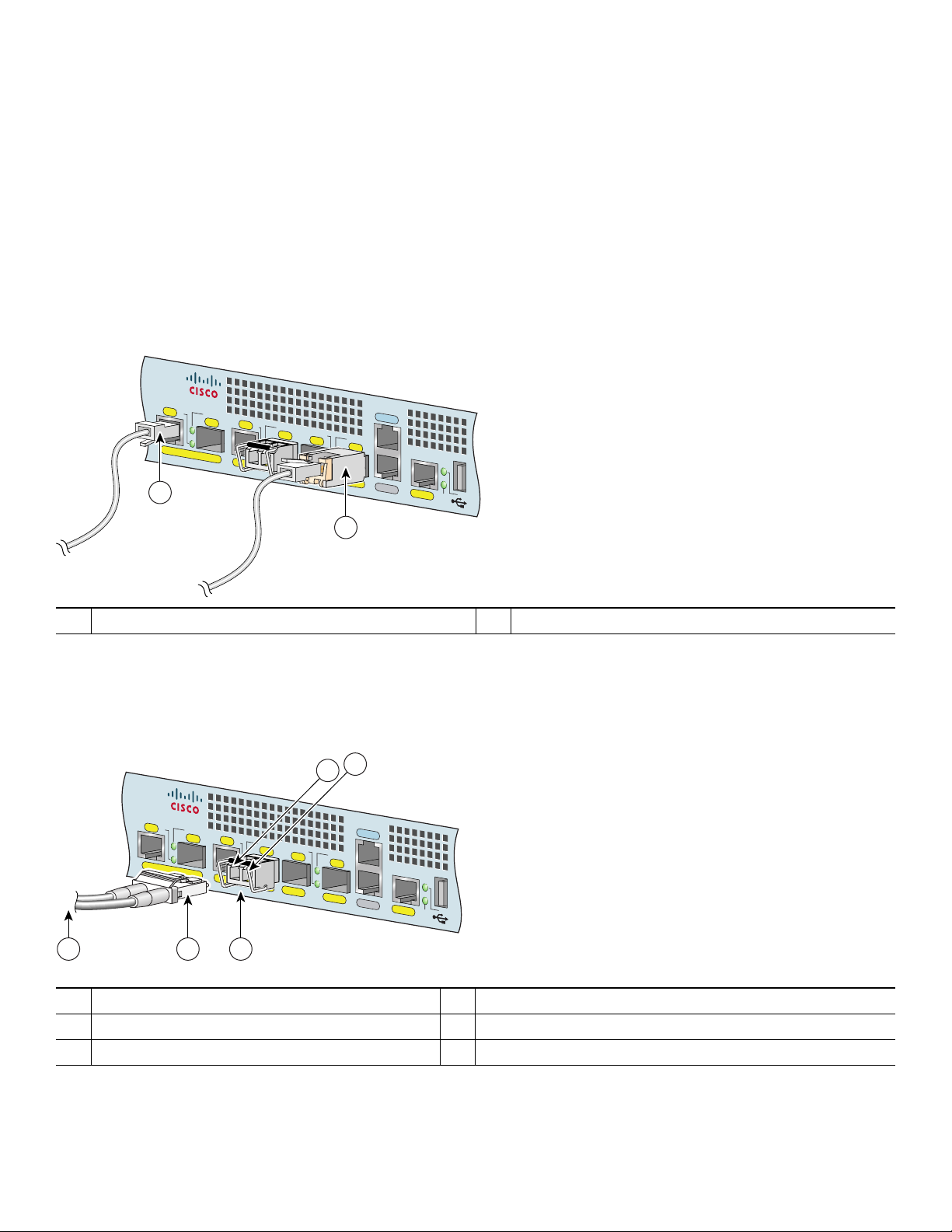

Figure 12 Optical SFP Modules and Copper SFP Modules

Cisco

7201

RJ45

EN

LINK/ACTV

SFP

RJ45

EN

LINK/ACTV

LINK/ACTV

TX

SFP

RX

GE 0/0

GE 0/1

SFP

GE 0/2

1

TX

2

LINK/ACTV

SFP

GE 0/3

RX

CONSOLE

AUX

MNGMNT USE ONLY

FE 0/0

LINK

0

FE

230316

1 RJ-45 cable 2 Copper SFP module RJ-45 connector

The optical SFP modules can occupy any of the four optical Gigabit Ethernet ports, 0/0 through 0/3. However, the copper SFP

modules can occupy only optical Gigabit Ethernet ports 0/2 and 0/3.

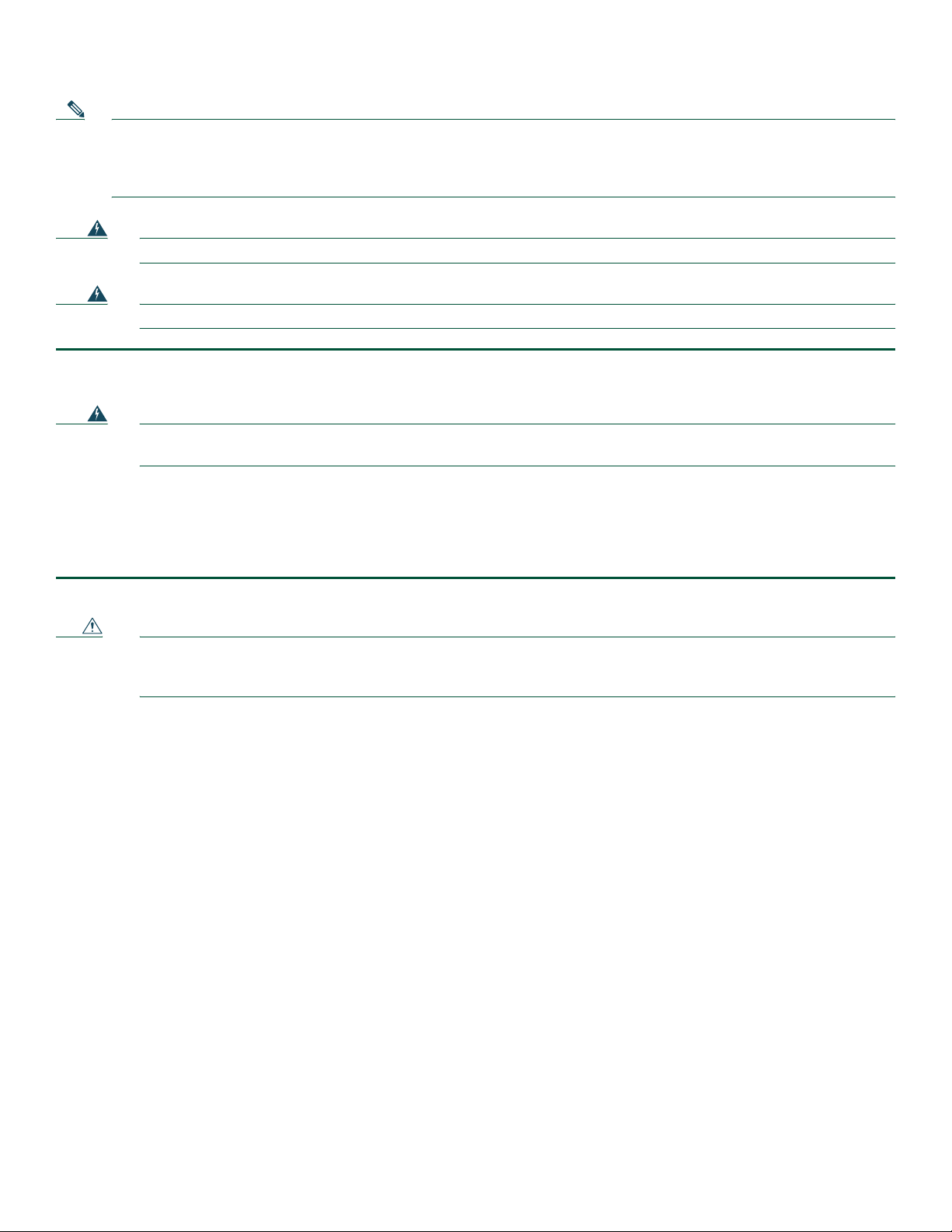

Figure 13 SFP Port Connections

5

4

Cisco

7201

RJ45

EN

GE 0/0

LINK/ACTV

SFP

RJ45

EN

GE 0/1

TX

LINK/ACTV

SFP

LINK/ACTV

RX

SFP

GE 0/2

TX

LINK/ACTV

SFP

GE 0/3

CONSOLE

RX

MNGMNT USE ONLY

AUX

FE 0/0

0

FE

LINK

170869

1 32

To external 1000BASEX network

1

Duplex connector (TX and RX)

2

SFP module

3

TX (SFP port 0/1)

4

RX (SFP port 0/1)

5

15

Page 16

Note We strongly recommend cleaning optical fiber connections before attaching cables to equipment. For information about

cleaning fiber-optic cable connectors and receptacles, see the Inspection and Cleaning Procedures for Fiber-Optic

Connections document. It provides detailed illustrations and photos of procedures and equipment required to properly clean

fiber-optic connections. Also see the Compressed Air Cleaning Issues for Fiber-Optic Connections document.

Warning

Warning

Step 1 Remove the plug from the SFP module so that you can insert the optical fiber cables. Keep the plug for use should you

Warning

Step 2 Attach the appropriate optical fiber cable directly to the SFP module. You can use either simplex or duplex connectors

Caution If you plan to use a SFP-GE-L at distances greater than 984.25 feet (300 meters) over 50/125-micron or

Class 1 laser product.

Class 1 LED product.

ever disconnect the optical fiber cables.

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view

directly with optical instruments.

for most devices. (Figure 13 shows an SFP module with a duplex connector being installed in SFP port 0/1.)

• For simplex connectors, two cables are required, one cable for transmit (TX) and a second cable for receive (RX).

• For duplex connectors, only one cable that has both TX and RX connectors is required.

62.5/125-micron multimode fiber, you must use the mode-conditioning patch cord to prevent data transmission

problems.

Statement 1008

Statement 1027

Statement 1051

Mode-Conditioning Patch Cord Description

A mode-conditioning patch cord can be used with the SFP-GE-L= (SFP module) to allow reliable laser transmission between the

single-mode laser source on the SFP module and a multimode optical fiber cable.

When an unconditioned laser source designed for operation on single-mode optical fiber is directly coupled to a multimode

optical fiber cable, an effect known as differential mode delay (DMD) might result in a degradation of the modal bandwidth of

the optical fiber cable.

This degradation results in a decrease in the link span (the distance between a transmitter and a receiver) that can be supported

reliably. The effect of DMD can be overcome by conditioning the launch characteristics of a laser source. A practical means of

performing this conditioning is to use a device called a mode-conditioning patch cord.

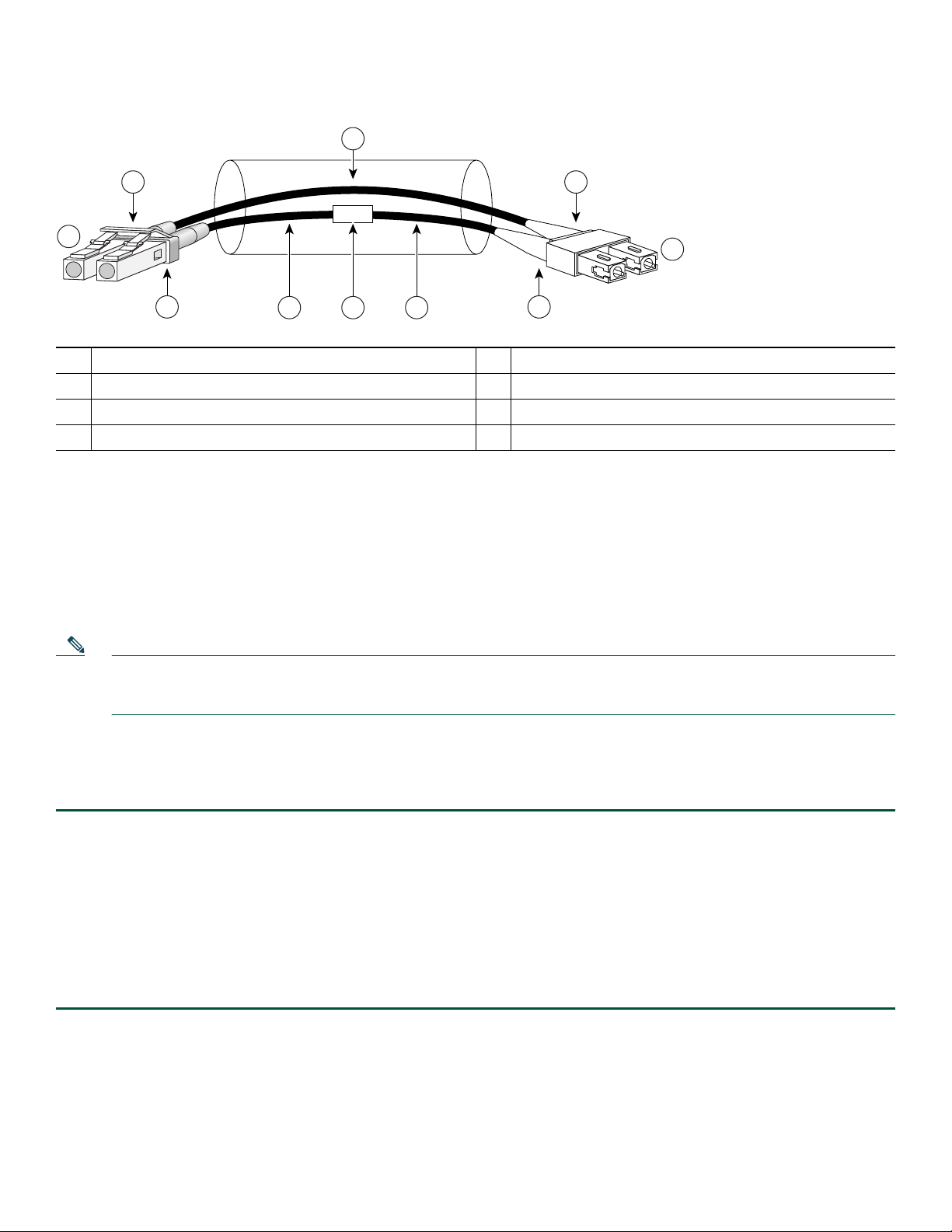

A mode-conditioning patch cord is an optical fiber cable assembly that consists of a pair of optical fibers terminated with

connector hardware. Specifically, the mode-conditioning patch cord is composed of a single-mode optical fiber permanently

coupled off-center (see Offset in Figure 14) to a graded-index multimode optical fiber. Figure 14 shows a diagram of the

mode-conditioning patch cord assembly.

16

Page 17

Figure 14 Mode-Conditioning Patch Cord Assembly for an SFP Module

4

1 7

/ /

/ / / /

2

TX

RX

3 7

Gray color identifier

1

To Gigabit Ethernet interface

2

Blue color identifier

3

Multimode bar

4

The mode-conditioning patch cord assembly is composed of duplex optical fibers, including a single-mode-to-multimode offset

launch fiber connected to the transmitter, and a second conventional graded-index multimode optical fiber connected to the

receiver. The use of a plug-to-plug patch cord maximizes the power budget of multimode 1000BASE-LX and 1000BASE-LH

links.

The mode-conditioning patch cord is required to comply with IEEE standards. The IEEE found that link distances could not be

met with certain types of fiber-optic cable cores. The solution is to launch light from the laser at a precise offset from the center,

which is accomplished by using the mode-conditioning patch cord. At the output of the patch cord, the SFP-GE-L= is compliant

with the IEEE 802.3z standard for 1000BASE-LX.

Offset

65 4

Single-mode bar

5

Offset

6

Beige color identifier

7

To cable plant

8

8

84159

Note We strongly recommend cleaning optical fiber connections before attaching cables to equipment. See the Inspection and

Cleaning Procedures for Fiber-Optic Connections document and the Compressed Air Cleaning Issues for Fiber-Optic

Connections document. Figure 14 shows one type of mode-conditioning patch cord.

Attach the Mode-Conditioning Patch Cord

To use a mode-conditioning patch cord, follow these steps:

Step 1 If you have not already done so, and the mode-conditioning patch cord has been in use, we strongly recommend

cleaning optical fiber connections before attaching cables to equipment. For information about cleaning fiber-optic cable

connectors and receptacles, see the Inspection and Cleaning Procedures for Fiber-Optic Connections document and the

Compressed Air Cleaning Issues for Fiber-Optic Connections document.

Step 2 Attach a mode-conditioning patch cord to the SFP module. (See Figure 14.)

Step 3 Attach the network ends of your mode-conditioning patch cord to the appropriate 1000BASEX equipment in your

building cable plant.

Ensure that you connect the TX and RX ports on one end of the patch cord to the RX and TX ports (respectively) on

the other end. Connect TX to RX and RX to TX.

17

Page 18

Install the Native Gigabit RJ-45 Ethernet Cables

This section provides information about installing the native Gigabit Ethernet RJ-45 cables.

Intra-Building Lightning Protection

Shielded cables, which are grounded at both ends, are required to be used on the 10/100/1000 Gigabit Ethernet RJ-45 ports in

order to be in compliance with requirement R4-11 in GR-1089-Core for a Central Office environment. This is not a requirement

for customer premises installations.

Warning

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network voltage

(TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some LAN and WAN ports

both use RJ-45 connectors. Use caution when connecting cables.

Statement 1021

Connect the Cables

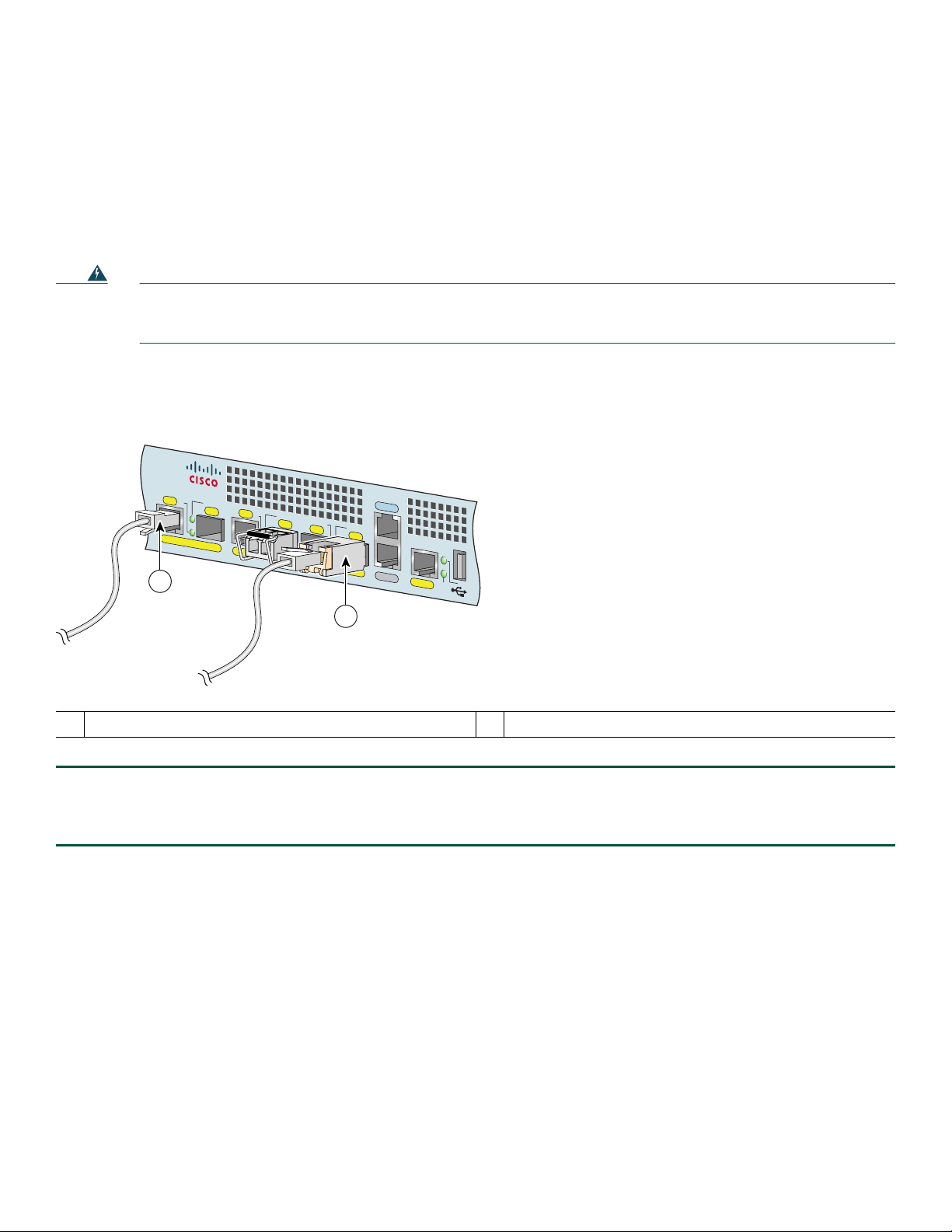

Figure 15 RJ-45 Port and Copper SFP RJ-45 Gigabit Ethernet Port Cabling

Cisco

7201

RJ45

EN

LINK/ACTV

SFP

RJ45

EN

LINK/ACTV

LINK/ACTV

TX

SFP

RX

GE 0/0

GE 0/1

SFP

GE 0/2

1

LINK/ACTV

TX

GE 0/3

CONSOLE

SFP

RX

MNGMNT USE ONLY

AUX

FE 0/0

0

FE

LINK

230316

2

1 RJ-45 connector 2 Copper SFP module

Step 1 Insert an Gigabit Ethernet RJ-45 cable into Gigabit Ethernet RJ-45 ports 0/0 and 0/1 if you are not using Gigabit

Ethernet SFP optical ports 0/0 and 0/1.

Step 2 Insert an Gigabit Ethernet RJ-45 cable into a copper SFP module in Gigabit Ethernet ports 0/2 and 0/3.

.

Connect the Port Adapter Cables

The instructions for connecting the cables for the port adapter installed in the Cisco 7201 router are contained in the respective

configuration notes for each port adapter. For example, if you are connecting the optical fiber cables for the PA-GE port adapter,

refer to the PA-GE Gigabit Ethernet Port Adapter Installation and Configuration document at

http://www.cisco.com/en/US/docs/interfaces_modules/port_adapters/install_upgrade/ethernet/pa-ge_gigabit_ethernet_install_c

onfig/pa_ge.html.

Port adapter documents are also available on the Cisco Documentation DVD.

18

Page 19

Install the Cables in the Cable-Management Bracket

Figure 16 Securing Interface Cables Through the Cable-Management Bracket

2

R

IE

LS

M

R

L

R

R

E

A

A

L

C

C

X

ENABLED

A

X

R

X

R

R

1 Input/output cables 2 Cable-management bracket

Secure port adapter interface cables and I/O cables by placing them through the cable-management bracket.

Proceed to the “Start the System” section on page 20 to complete the installation.

A

TM

Cisco

7201

RJ45

EN

LINK/ACTV

SFP

RJ45

PA

SLOT 1

EN

GE 0/0

GE 0/1

CONSOLE

LINK/ACTV

LINK/ACTV

TX

SFP

RX

LINK/ACTV

SFP

TX

SFP

RX

MNGMNT USE ONLY

GE 0/2

GE 0/3

AUX

FE 0/0

0

FE

LINK

ALARM

PWR OK

STATUS

C

O

M

PACT

F

LAS

H

CF

ACTV

170870

1

19

Page 20

5 Start the System

Before you start the system, you must connect power to it.

Connect Power to the Router

• If you have AC power supplies, go to the “Connect AC-Input Power” section on page 20.

• If you have DC power supplies, go to the “Connect DC-Input Power” section on page 22.

Warning

Warning

Warning

Warning

Installation of the equipment must comply with local and national electrical codes.

Never install an AC power module and a DC power module in the same chassis.

Statement 1074

Statement 1050

This unit might have more than one power supply connection. All connections must be removed to de-energize the

unit.

Statement 1028

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than: 120 VAC, 20A U.S. (240 VAC, 10A international).

Statement 1005

Connect AC-Input Power

This section provides instructions for installing the AC power supply.

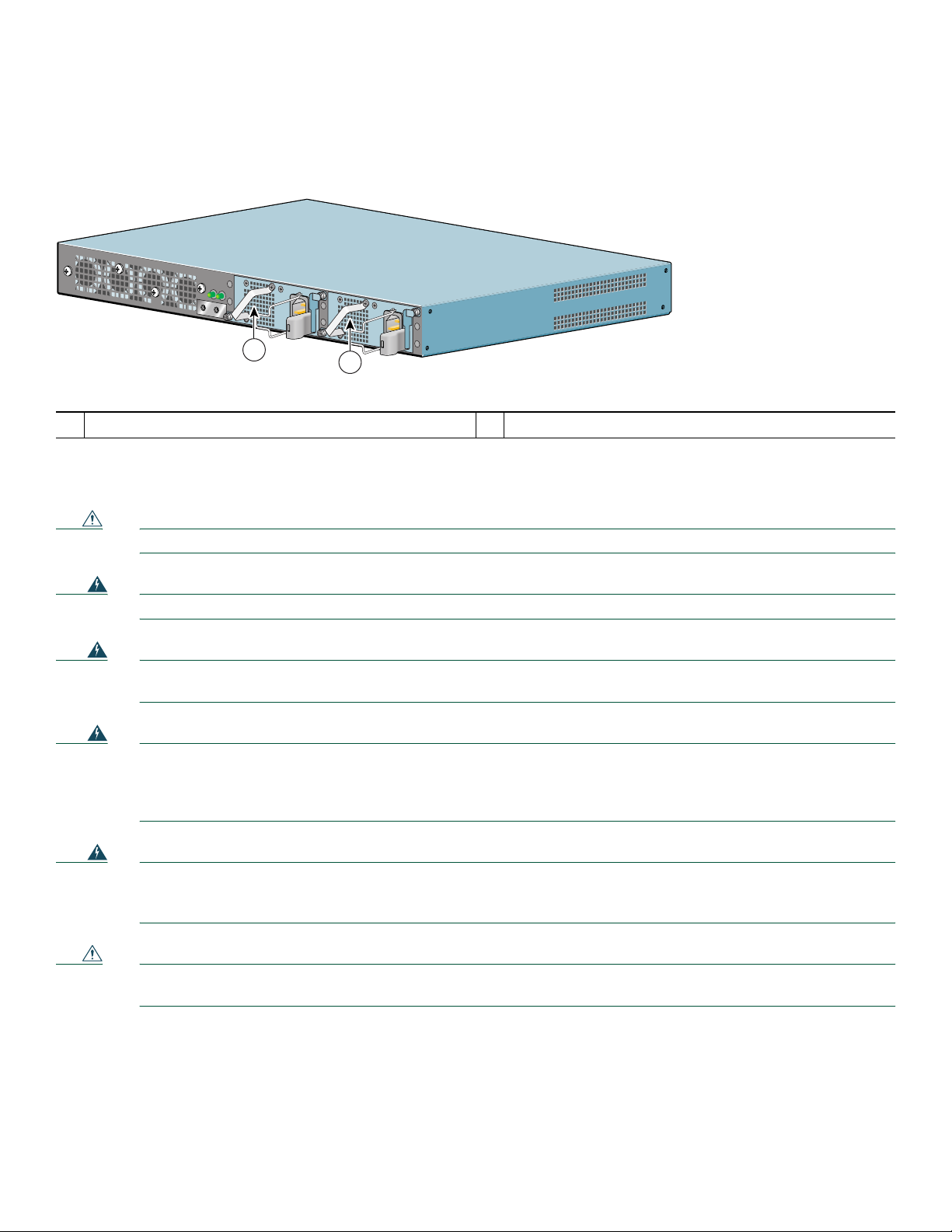

The Cisco 7201 router has two of the same type of power supplies in power supply slot 1 and power supply slot 2. (See

Figure 17.) The power supply slot numbers are on the chassis to the left of the left power supply, and to the right of the right

power supply.

Figure 17 Power Supply Slot 1 and Slot 2

T

H

IS

U

N

IT

M

A

Y

H

A

V

E

M

O

R

E

T

H

A

N

O

N

E

P

O

W

E

R

S

U

P

P

L

Y

C

O

N

N

E

C

T

I

O

N

. A

L

L

C

Power supply slot 1

1

20

O

N

N

E

C

T

I

O

N

S

M

U

S

T

B

E

R

E

M

O

V

E

D

T

O

D

E

E

N

E

R

G

IZ

E

T

H

E

U

N

IT

PWR

SLOT 1 OK

PWR

SLOT 2 OK

PWR

SLOT 1

PWR

1

SLOT 2

230086

2

Power supply slot 2

2

Page 21

Connect an AC-input power supply as follows:

Figure 18 Connecting AC-Input Power

1

PWR

SLOT 2

Adjustable AC power cable-retention clip

2

158677

AC power receptacle

1

2

Step 1 At the front of the router, check that the power switch is in the standby (|) position.

Step 2 Swing the wire cable-retention clip to the left.

Step 3 Plug the power cable into the AC connector of the power supply.

Step 4 Slide the cable-retention clip to the right, so that the power cable is held by the cable-retention clip.

Step 5 Plug the AC power supply cable into the AC power source. Repeat these steps if you have a dual-AC power supply.

Step 6 On the front of the router, place the power switch in on (O) the router to turn on the router.

Note After powering off the router, wait a minimum of 30 seconds before powering it on again.

Note If required, use Sinewave Output UPS (uninterruptable power supply), not Ferro-resonant type UPS.

This completes the procedure for connecting AC-input power. Your installation is complete. Proceed to the “Start the Router”

section on page 29 to start the router and to perform a basic configuration.

21

Page 22

Connect DC-Input Power

This section provides instructions for installing the DC power supply ground leads and installing the DC-input power leads.

Figure 19 Power Supply Slot 1 and Slot 2

T

H

IS

U

N

IT

M

A

Y

H

A

V

E

M

O

R

E

T

H

A

N

O

N

E

P

O

W

E

R

S

U

P

P

L

Y

C

O

N

N

E

C

T

I

O

N

.

A

L

L

C

O

N

N

E

C

T

IO

N

S

M

U

S

T

B

E

R

E

M

O

V

E

D

T

O

D

E

E

N

E

R

G

IZ

E

T

H

E

U

N

I

T

PWR

SLOT 1 OK

PWR

SLOT 2 OK

PWR

SLOT 1

PWR

1

SLOT 2

2

1 Power supply slot 1 2 Power supply slot 2

The Cisco 7201 has two of the same type of power supplies in power supply slot 1 and power supply slot 2. (See Figure 19.)

The power supply slot numbers are on the chassis to the left of the left power supply, and to the right of the right power supply.

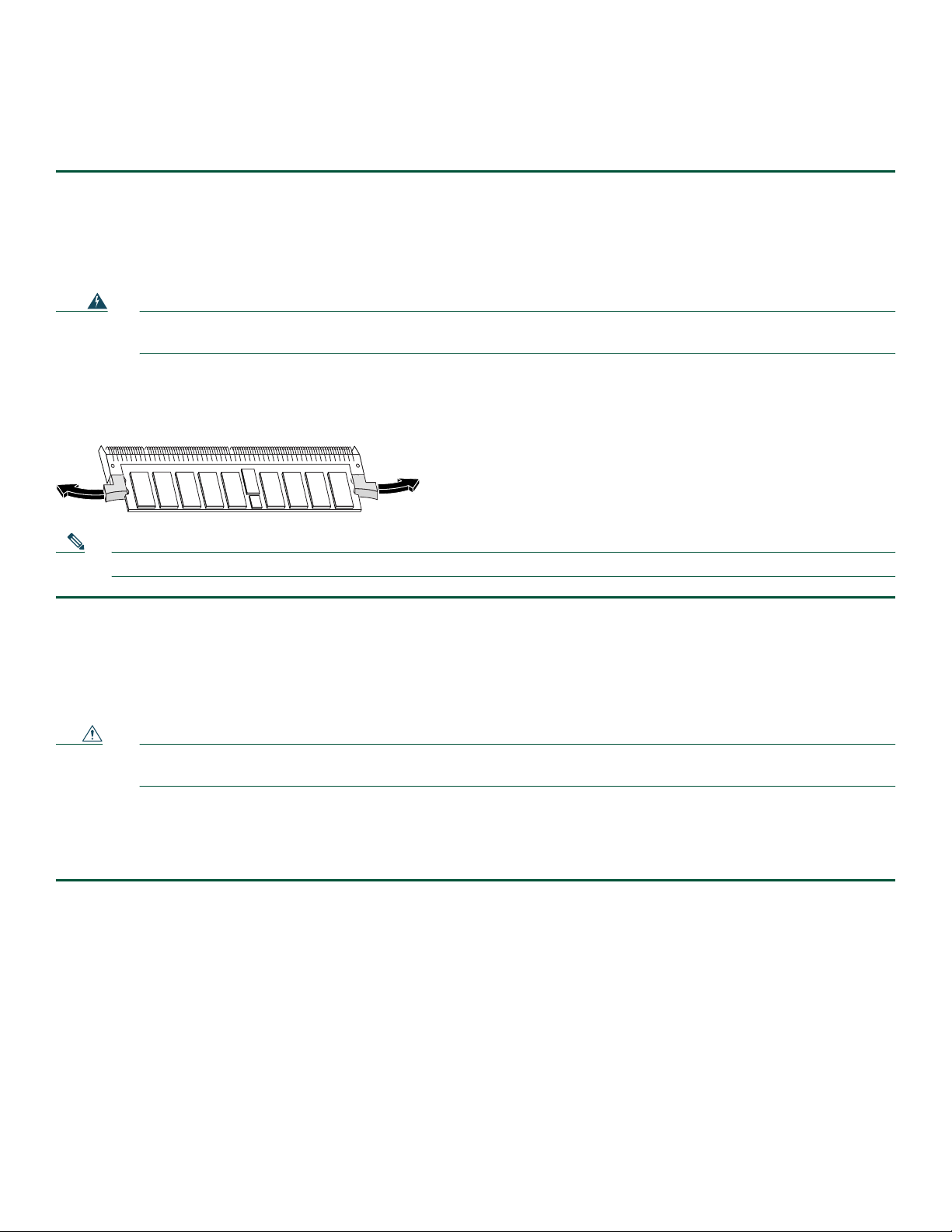

Caution Before you connect DC-input power, you must install the DC power ground leads to the DC power supply.

230086

Warning

Warning

Never install an AC power module and a DC power module in the same chassis.

Statement 1050

When installing or replacing the unit, the ground connection must always be made first and disconnected last.

Statement 1046

Warning

Before connecting or disconnecting ground or power wires to the chassis, ensure that power is removed from the

DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC

circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF

Warning

position.

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of

Statement 140

a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if

you are uncertain that suitable grounding is available.

Statement 1024

Caution To make sure that the equipment is reliably connected to earth ground, follow the grounding procedure

instructions, and use a UL-listed lug suitable for 6-AWG wire and M5 screws.

Obtain these necessary tools and equipment:

• Ratcheting torque screwdriver with a Phillips head that exerts up to 15 pound force-inches (lbf in.) or 240 ounce

force-inches (ozf in.) of pressure

• Panduit crimping tool with optional controlled cycle mechanism

• 18-gauge copper ground wire (insulated or noninsulated)

22

Page 23

• Four leads of 18-gauge copper wire

• Wire-stripping tool for stripping 18-gauge wire

Install the DC Grounding Leads

To install the DC grounding leads on the DC power supply, follow these instructions.

The DC power supply ships with the DC power supply ground lugs, star washers, and nut attached to the grounding stud on

the DC power supply.

Figure 20 Locating the DC Grounding Stud and Grounding Materials

A

B

PWR

SLOT 2

170976

Step 1 Locate the grounding stud on the DC power supply.

Step 2 Remove the nut, ground lug, star washer, and second ground lug and star washer from the grounding stud.

Figure 21 Stripping the DC-Input Power Ground Wire

1

57019

1 0.5 inch (12.7 mm) + 0.02 inch (0.5 mm)

Step 3 If your ground wire is insulated, use a wire stripping tool to strip the 18-gauge (or 16-gauge, but not smaller than the

supply conductor) ground wire to 0.5 inch (12.7 mm)+ 0.02 inch (0.5 mm) as shown in Figure 21.

Step 4 Slide the open end of the ground lug over the exposed area of the 18-gauge wire.

Step 5 Use a crimping tool to crimp the ground wire to a ground lug.

23

Page 24

Figure 22 Placing the Ground Lugs, Star Washers, and Nut

A

B

PWR

SLOT 2

170970

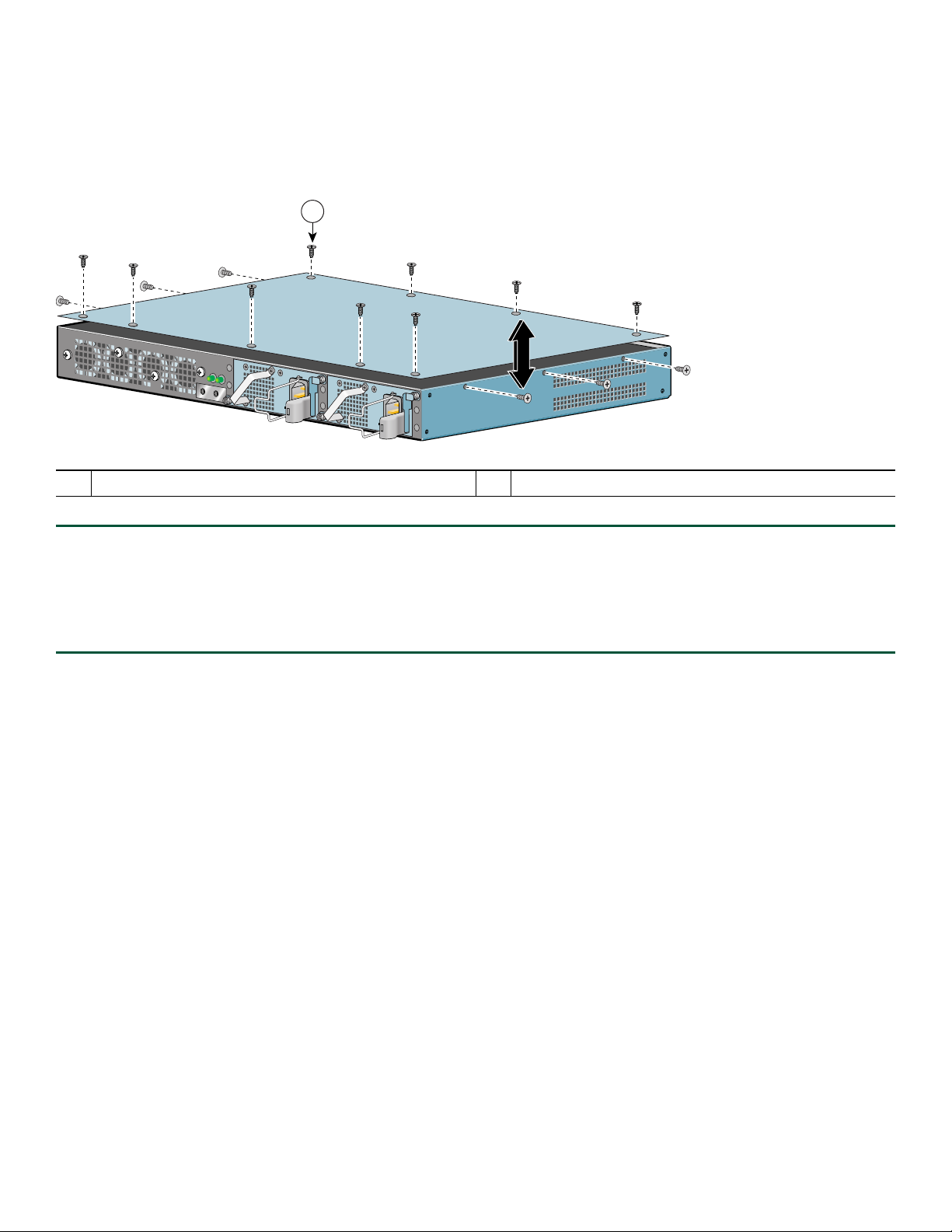

Step 6 Place the ground lugs, star washers, and nut on the grounding stud in this order:

a. Star washer

b. Ground lug

c. Star washer

d. Ground lug

e. Nut

Step 7 Tighten the nut to complete the installation.

Step 8 Attach the other end of the ground wires to an appropriate grounding point at your site.

Step 9 Repeat Step 1 through Step 8 on the second DC power supply.

Wire the DC-Input Power Source

Note The color coding of the DC-input power supply leads depends on the color coding of the DC power source at your site.

Make certain the lead color coding you choose for the DC-input power supply matches lead color coding used at the

DC power source.

Warning

Warning

Warning

Warning

When installing or replacing the unit, the ground connection must always be made first and disconnected last.

Statement 1046

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than: 120 VAC, 20A U.S. (240 VAC, 10A international).

Statement 1005

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1003

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

24

Page 25

Use these instructions to wire the DC-input power source:

Step 1 At the front of the router, make sure the power switch is in the standby (|) position.

Step 2 Move the circuit-breaker switch handle to the off position, and apply tape to hold it in the off position.

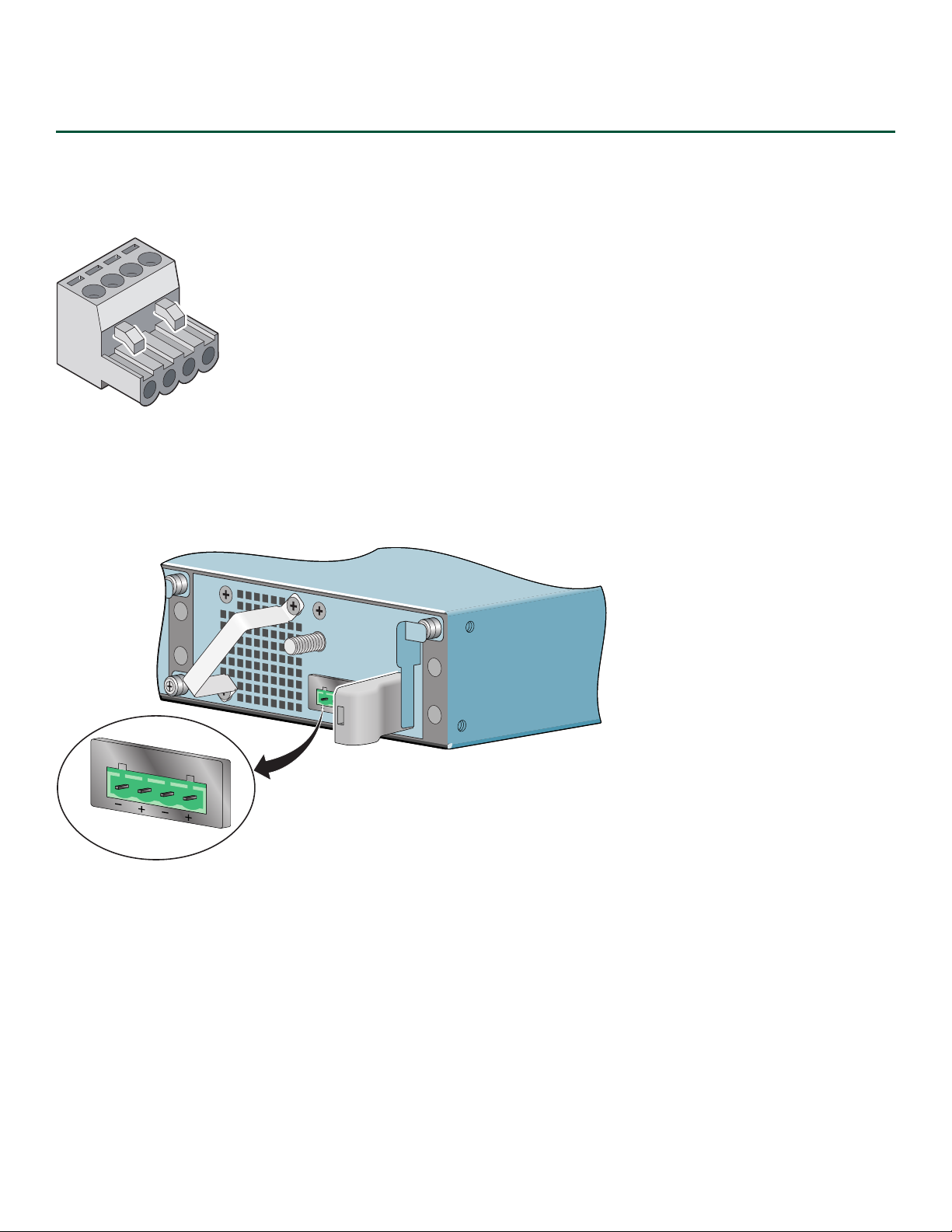

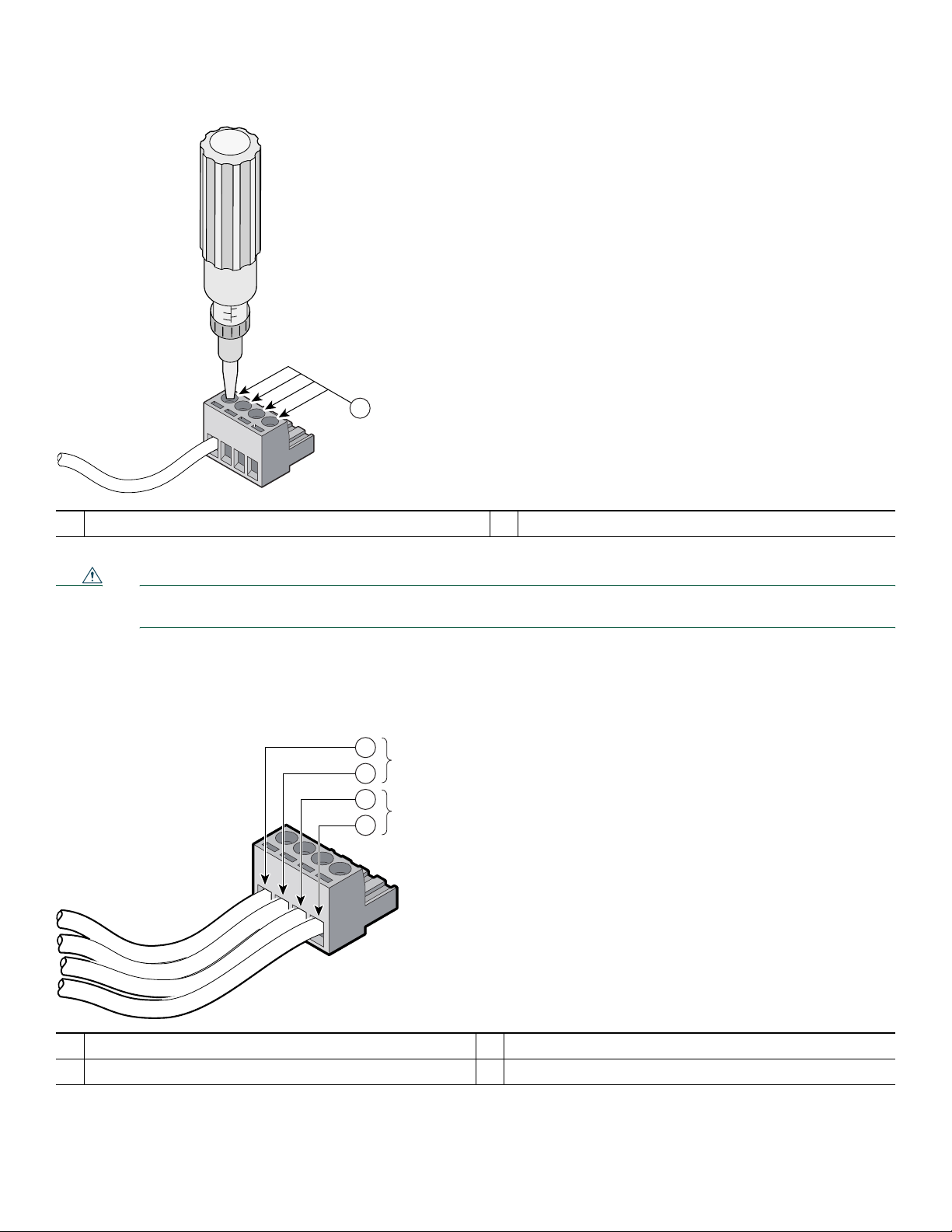

Figure 23 Terminal Block Plug

60530

Step 3 Locate and remove the terminal block plug.

Step 4 Identify the positive and negative feed positions for the terminal block connection. The wiring sequence is positive to

positive and negative to negative for both the A and B feed wires.

Figure 24 Positive and Negative Positions

A

B

A

B

PWR

SLOT 2

170971

The rear panel of the power supply unit identifies the positive and negative positions for both the A and B feed wires.

See Figure 24.

25

Page 26

Figure 25 Stripping the DC-Input Power Source Wire

1

57019

1 0.25 inch (6.3 mm) + 0.02 inch (0.5 mm)

Step 5 Using an 18-gauge wire-stripping tool, strip each of the four wires coming from the DC-input power source to

0.25 inch (6.3 mm) +

0.02 inch (0.5 mm). Do not strip more than 0.29 inch (7.4 mm) of insulation from the wire.

Stripping more than the recommended amount of wire can leave exposed wire from the terminal block plug after

installation.

Warning

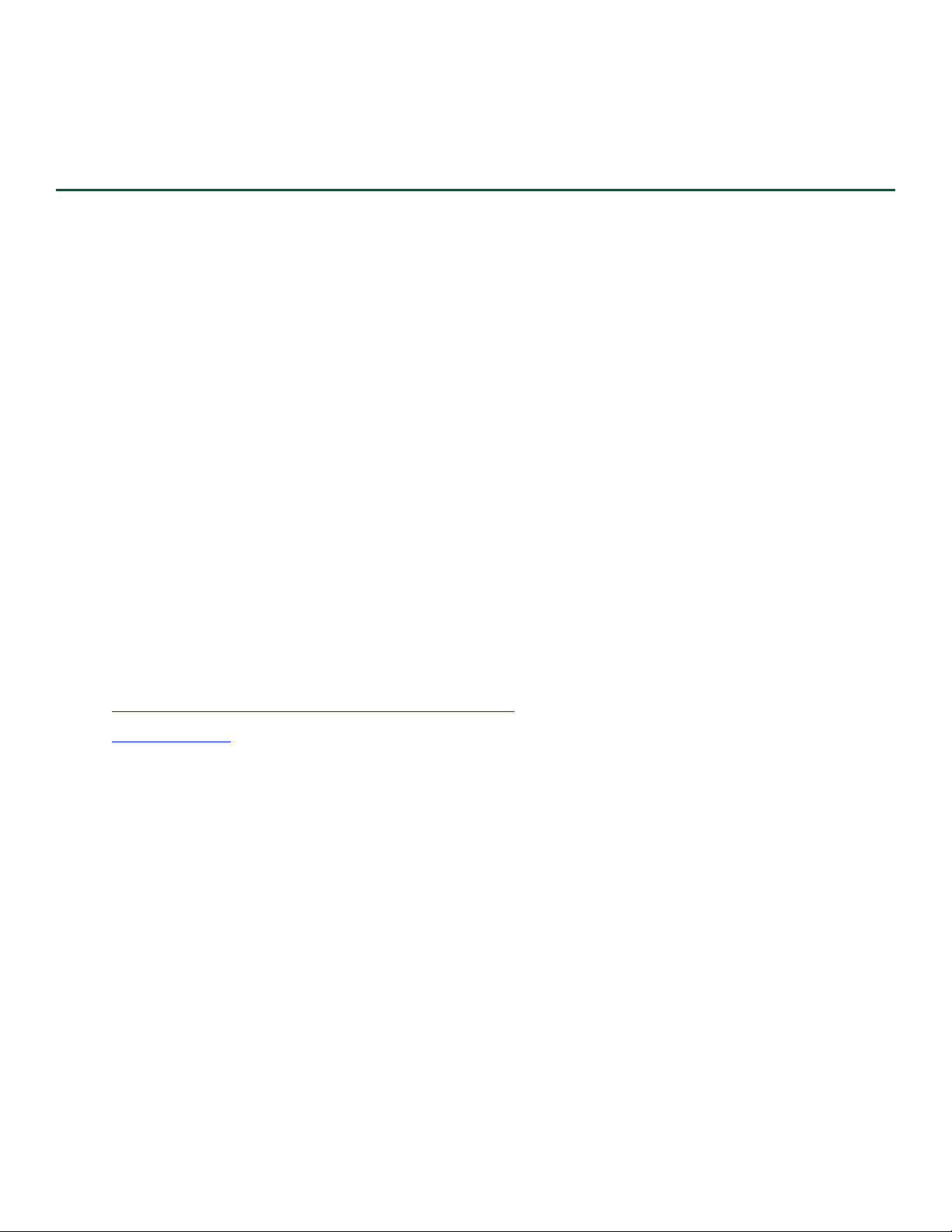

Figure 26 Inserting Wires into the Terminal Block Plug

An exposed wire lead from a DC-input power source can conduct harmful levels of electricity. Be sure that no

exposed portion of the DC-input power source wire extends from the terminal block plug.

1

A

2

3

B

4

170975

Statement 122

1 Negative( –) 3 Negative (–)

2 Return (+) 4 Return (+)

Step 6 Insert the exposed wire of one of the four DC-input power source wires into the terminal block plug, as shown in

Figure 26. Make sure that you cannot see any wire lead. Only wire with insulation should extend from the terminal

block.

26

Page 27

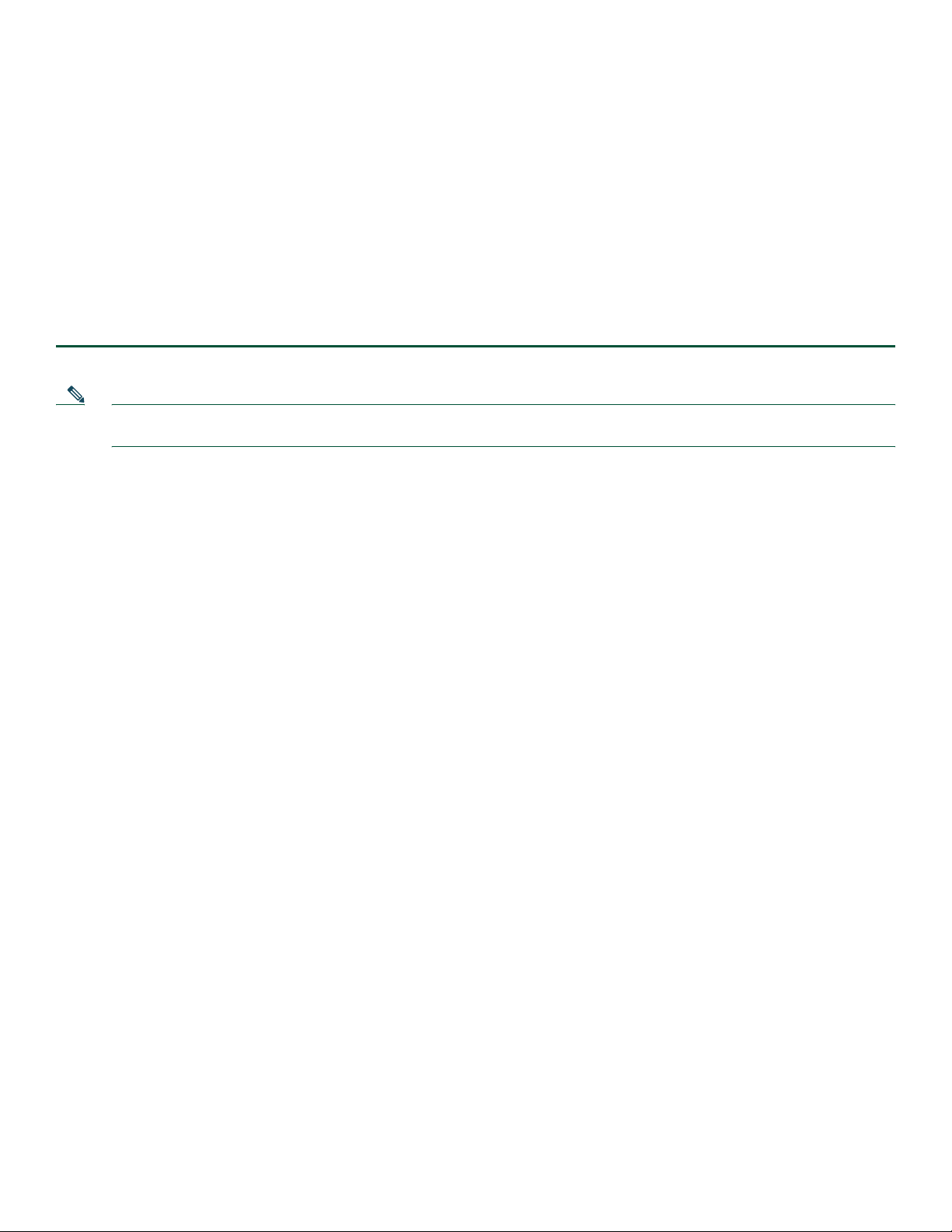

Figure 27 Torquing the Terminal Block Plug Captive Screws

1

170974

1 Torque is from 0.5 Nm (4.425 lbf in.) to 0.6 Nm (5.310 lbf in.)

Caution Do not overtorque the terminal block plug captive screws. The recommended maximum torque is from 0.5 Nm

(4.425 lbf in.) to 0.6 Nm (5.310 lbf in.).

Step 7 Use a ratcheting torque screwdriver to torque the terminal block plug captive screw (above the installed wire lead) to

from 0.5 Nm (4.425 lbf in.) to 0.6 Nm (5.310 lbf in.), as shown in Figure 27.

Figure 28 Completed Wiring of Terminal Block Plug

1

A

2

3

B

4

170972

1 Negative (–) 3 Negative (–)

2 Return (+) 4 Return (+)

Step 8 Repeat Step 6 and Step 7 for the remaining three DC-input power source wires. Figure 28 shows the completed wiring

of a terminal block plug.

27

Page 28

Note Each DC power supply accepts two power feeds, but works with only one. You may choose to install only one power

B

A

feed per power supply. For example, DC power feed A to the power supply in power supply slot 1 and DC power feed

B to the power supply in power supply slot 2.

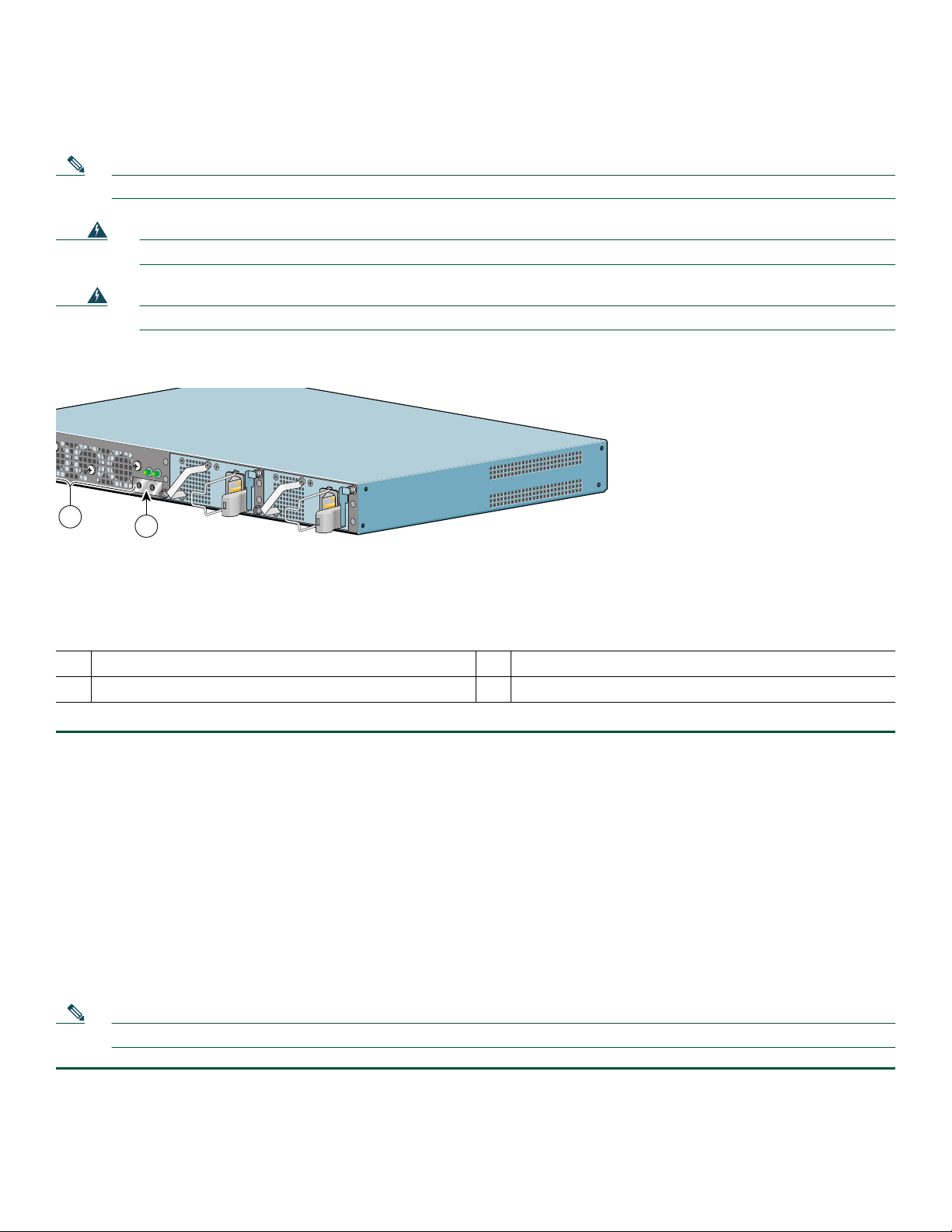

Figure 29 Inserting the Terminal Block Plug in the Block Header

A

B

PWR

SLOT 2

170973

2

1

1

Tie wrap

Terminal block plug

2

Caution Secure the wires coming in from the terminal block plug so that they cannot be disturbed by casual contact.

Step 9 Use a tie wrap to secure the wires to the rack, so that the wires are not pulled from the terminal block plug by casual

contact. Make sure the tie wrap allows for some slack in the ground wire.

Step 10 Insert the terminal block plug in the terminal block header on the DC power supply panel, as shown in Figure 29.

Step 11 Repeat Step 1 through Step 10 on the second DC power supply.

Step 12 Remove the tape from the circuit-breaker switch handle, and move the circuit-breaker switch handle to the on position.

Step 13 Switch the circuit breaker to the on position.

Step 14 On the front of the router, place the power switch in on (O) the router to turn on the router.

Note After powering off the router, wait a minimum of 30 seconds before powering it on again.

This completes the procedure for connecting DC-input power. Your installation is complete. Proceed to the “Start the Router”

section on page 29 to start the router.

28

Page 29

Start the Router

Check the following conditions before you start your router:

• The port adapter is inserted in its slot and the port adapter lever is in the locked position.

• The network interface cable is connected to the port adapter.

• A CompactFlash Disk is installed.

• SFP modules and their optical-fiber or copper cables are installed.

• The optional USB Flash memory module or Aladdin eToken Pro key is installed.

• The optional Fast Ethernet Management port cable is installed.

• The console terminal is turned on.

Step 1 Place the power switch in the on (O) position.

Step 2 Listen for the fans; they should be operating as soon as power is turned on. The following table provides information

about the LEDs as the system starts.

Figure 30 Cisco 7201 Router—Faceplate LEDs

Cisco

7201

RJ45

EN

LINK/ACTV

SFP

RJ45

EN

LINK/ACTV

LINK/ACTV

TX

SFP

RX

GE 0/0

1

2

GE 0/1

1

2

SFP

GE 0/2

1

1

TX

LINK/ACTV

SFP

GE 0/3

RX

CONSOLE

AUX

MNGMNT USE ONLY

3

FE 0/0

0

FE

LINK

COMPACT FLASH

4

ALARM

PW

STATUS

ACTV

R OK

5

6

CF

7

8

170859

In the Power Up State

No. LED Label LED

1

LINK/ACTV

SFP and RJ-45 ports Solid green Link with no activity

(Link/Active) (0/0, 0/1,

0/2, 0/3)

Color-Activityr Behavior Description

Flashing green Link with activity

Off No link

EN (Enable) (0/0, 0/1) RJ-45 ports only Solid green RJ-45 port is selected.

2

Off SFP port is selected.

USB USB port Flashing green Activity

3

Off No activity

FE 0/0 Fast Ethernet Management

4

port

Solid green Link with no activity

Flashing green Link with activity

Off No link

ALARM Alarm port Solid red

5

On if Cisco IOS has crashed, and a reset

has happened, and remains on until Cisco

IOS is reloaded.

Off Off, the system is normal.

29

Page 30

In the Power Up State

No. LED Label LED

PWR OK Power Solid green The power-on is successful and the system

6

STATUS System status Solid green Cisco IOS has successfully booted.

7

CF ACTV CompactFlash Disk Flashing green Activity

8

Step 3 During the boot process, observe the system LEDs. The STATUS LED comes on immediately as amber, then turns to

green when the Cisco IOS is booted. Port adapter LEDs go on and off irregularly.

Step 4 Observe the initialization process. The port adapter ENABLED LEDs go on when initialization is completed and the

console screen displays a script and system banner.

Proceed to the “Configure the Router” section on page 31 to configure the router.

Color-Activityr Behavior Description

is attempting to boot software, or has

booted software.

Off Off, the router is in standby mode.

Blinking amber ROMmon is loading.

Blinking green Cisco IOS is loading.

Off No activity

30

Page 31

6 Configure the Router

Use this section for information on configuring the Cisco 7201 router.

Perform a Basic Configuration Using AutoInstall

The AutoInstall process is designed to configure the Cisco 7201 router automatically after connection to your WAN. For

AutoInstall to work properly, a TCP/IP host on your network must be preconfigured to provide the required configuration files.

The TCP/IP host may exist anywhere on the network as long as the following two conditions are maintained:

1. The host must be on the remote side of the router synchronous serial connection to the WAN.

2. User Datagram Protocol (UDP) broadcasts to and from the router and the TCP/IP host are enabled.

This functionality is coordinated by your system administrator at the site where the TCP/IP host is located. You should not use

AutoInstall unless the required files are available on the TCP/IP host. Refer to the Cisco IOS Configuration Fundamentals

Configuration Guide and Cisco IOS Configuration Fundamentals Command Reference publications for information about how

AutoInstall works.

Complete the following steps to prepare your Cisco 7201 router for the AutoInstall process:

Step 1 Attach the appropriate synchronous serial cable to synchronous serial interface 0 on the router.

Step 2 Turn the power switch on the power supply to the on (O) position. (This action turns on AC power to the router.)

The router loads the operating system image from flash memory. If the remote end of the WAN connection is connected

and properly configured, the AutoInstall process begins.

Step 3 Once the AutoInstall process is completed, use the copy running-config startup-config command to write the

configuration data to the router’s nonvolatile random-access memory (NVRAM). Perform the following step to

complete this task.

Step 4 At the # prompt, enter the following command:

Hostname# copy running-config startup-config

Note Completing Step 3 saves the configuration settings that the AutoInstall process created to NVRAM. If you fail to do

this, your configuration will be lost the next time you reload the router.

Perform a Basic Configuration Using the Setup Facility

If you do not plan to use AutoInstall, do not connect the router’s serial (WAN) cable to the channel service unit/data service unit

(CSU/DSU). If the WAN cable is not connected, the router boots from flash memory and goes automatically into the setup

facility.

Note You can run the setup facility any time you are at the enable prompt (#) by entering the setup command.

If the serial (WAN) cable is connected to the CSU/DSU and the router does not have a configuration stored in NVRAM, the

router attempts to run AutoInstall at startup. The router may take several minutes to determine that AutoInstall is not set up

to a remote TCP/IP host. Once the router determines that AutoInstall is not configured, it defaults to the setup facility.

31

Page 32

Configure Global Parameters

When you first start the setup program, you must configure the global parameters. These parameters are used for controlling

system-wide settings. Complete the following steps to enter the global parameters:

Step 1 Connect a console terminal to the console port, and then boot the router.

The system boots from flash memory. The following information appears after about 30 seconds. When you see this

information, you have successfully booted your router:

Restricted Rights Legend

Use, duplication, or disclosure by the Government is

subject to restrictions as set forth in subparagraph

(c) of the Commercial Computer Software - Restricted

Rights clause at FAR sec. 52.227-19 and subparagraph

(c) (1) (ii) of the Rights in Technical Data and Computer

Software clause at DFARS sec. 252.227-7013.

cisco Systems, Inc.

170 West Tasman Drive

San Jose, California 95134-1706

Cisco IOS Software, 7200 Software (C7200P-ADVENTERPRISEK9-M), Version 12.4(TAZ3XD.2006-12-03), INTERIM

SOFTWARE

Copyright (c) 1986-2006 by Cisco Systems, Inc.

Compiled Sun 03-Dec-06 00:44 by

Image text-base: 0x0000A3F8, data-base: 0x0327A000

This product contains cryptographic features and is subject to United

States and local country laws governing import, export, transfer and

use. Delivery of Cisco cryptographic products does not imply

third-party authority to import, export, distribute or use encryption.

Importers, exporters, distributors and users are responsible for

compliance with U.S. and local country laws. By using this product you

agree to comply with applicable laws and regulations. If you are unable

to comply with U.S. and local laws, return this product immediately.

A summary of U.S. laws governing Cisco cryptographic products may be found at:

http://www.cisco.com/wwl/export/crypto/tool/stqrg.html

If you require further assistance please contact us by sending email to

export@cisco.com

Cisco 7201 (c7201) processor (revision A) with 917504K/65536K bytes of memory.

Processor board ID 4294967295

MPC7448 CPU at 1666Mhz, Implementation 0, Rev 2.1

1 slot midplane, Version 2.255

Last reset from power-on

1 FastEthernet interface

4 Gigabit Ethernet interfaces

4 Channelized T1/PRI ports

2045K bytes of NVRAM.

250200K bytes of ATA PCMCIA card at slot 0 (Sector size 512 bytes).

65536K bytes of Flash internal SIMM (Sector size 512K).

Press RETURN to get started!

.

The first two sections of the configuration script (the banner and the installed hardware) appear only at initial system

startup. On subsequent uses of the setup facility, the script begins with a System Configuration Dialog as shown in the

following example.

--- System Configuration Dialog ---

Step 2 When asked if you would like to enter the initial configuration dialog, enter yes.

32

Would you like to enter the initial configuration dialog? [yes/no] yes

Page 33

At any point you may enter a question mark '?' for help.

Use ctrl-c to abort configuration dialog at any prompt.

Default settings are in square brackets '[]'.

Basic management setup configures only enough connectivity for management of the system, extended setup

will ask you to configure each interface on the system.

Step 3 When asked if you want to enter the basic management setup, enter no.

Would you like to enter the basic management setup [yes/no]: no

Step 4 When asked if you want to enter the initial configuration dialog and see the current interface summary, enter yes or

press Return:

First, would you like to see the current interface summary? [yes]:

In the following example, the summary shows a Cisco 7201 router at first-time startup; that is, nothing is configured.

Interface IP-Address OK? Method Status Protocol

FastEthernet0/0 unassigned NO unset up up

GigabitEthernet0/0 unassigned NO unset up up

GigabitEthernet0/1 unassigned NO unset up up

GigabitEthernet0/2 unassigned NO unset up up

GigabitEthernet0/3 unassigned NO unset up up

Step 5 Choose which protocols to support on your interfaces. For Internet Protocol (IP)-only installations, you can accept the

default values for most of the questions. A typical configuration using IP,

IPX, and AppleTalk follows and continues

through Step 10:

Configuring global parameters:

Enter host name [Router]:

Step 6 Enter enable secret, enable, and virtual terminal passwords:

The enable secret is a password used to protect access to privileged EXEC and configuration modes. This

password, after entered, becomes encrypted in the configuration.

Enter enable secret: barney

The enable password is used when you do not specify an

enable secret password, with some older software versions, and

some boot images.

Enter enable password: betty

The virtual terminal password is used to protect access to the router over a network interface.

Enter virtual terminal password: fred

Step 7 When asked whether you want to configure System Management, enter no.

Configure System Management? [yes/no]: no

Step 8 The Simple Network Management Protocol (SNMP) is the most widely supported open standard for network

management. It provides a means to access and set configuration and run-time parameters of routers and

communication servers. SNMP defines a set of functions that can be used to monitor and control network elements.

Enter yes or press Return to accept SNMP management; enter no to refuse it:

Configure SNMP Network Management? [yes]: no

Community string [public]:

33

Page 34

Step 9 For the following queries, do not enable LAT, IP, RIP routing, bridging, AppleTalk, DECnet, CLNS, or IPX:

Configure LAT? [no]:

Configure IP? [yes]:

Configure RIP routing? [no]:

Configure bridging? [no]:

Configure AppleTalk? [no]:

Configure DECnet? [no]:

Configure CLNS? [no]:

Configure IPX? [no]:

Step 10 In most cases, you use IP routing. If you are using IP routing, you must also select an interior routing protocol. You can

specify only one of two interior routing protocols to operate on your system using the setup facility: Interior Gateway

Routing Protocol (IGRP) or Routing Information Protocol (RIP).

To configure IP routing, enter yes (the default) or press Return, and then select an interior routing protocol:

Do you want to configure FastEthernet0/0 interface? [yes]:

Use the 100 Base-TX (RJ-45) connector? [yes]:

Operate in full-duplex mode? [no]: yes

Configure IP on this interface? [yes]:

IP address for this interface: 10.2.2.1

Subnet mask for this interface [255.0.0.0] : 255.255.255.0

Class A network is 10.0.0.0, 24 subnet bits; mask is /24

Do you want to configure GigabitEthernet0/0 interface? [yes]:

Configure IP on this interface? [yes]:

IP address for this interface: 25.2.4.10

Subnet mask for this interface [255.0.0.0] : 255.255.0.0

Class A network is 25.0.0.0, 16 subnet bits; mask is /16

Do you want to configure GigabitEthernet0/1 interface? [yes]:

Configure IP on this interface? [yes]:

IP address for this interface: 70.1.1.2

Subnet mask for this interface [255.0.0.0] : 255.255.255.0

Class A network is 70.0.0.0, 24 subnet bits; mask is /24

Do you want to configure GigabitEthernet0/2 interface? [yes]: no

Do you want to configure GigabitEthernet0/3 interface? [yes]: no

Would you like to go through AutoSecure configuration? [yes]: no

AutoSecure dialog can be started later using "auto secure" CLI

The following sample display includes a continuous listing of all configuration parameters selected in Step 5 through

Step 10. Only IP is the selected protocol for this example.

Configuring global parameters:

Enter host name [Router]: router

The enable secret is a one-way cryptographic secret used instead of the enable password when it exists.

Enter enable secret: barney

The enable password is used when there is no enable secret and when using older software and some boot

images.

Enter enable password: betty

line vty 0 4

password cisco

no snmp-server

!

ip routing

no bridge 1

no appletalk routing

no decnet routing

no clns routing

34

Page 35

no ipx routing

!

interface FastEthernet0/0

media-type 100BaseX

full-duplex

ip address 10.2.2.1 255.255.255.0

no mop enabled

!

interface GigabitEthernet0/0

ip address 25.2.4.10 255.255.0.0

no mop enabled

!

interface GigabitEthernet0/1

ip address 70.1.1.2 255.255.255.0

no mop enabled

!

interface GigabitEthernet0/2

shutdown

no ip address

!

interface GigabitEthernet0/3

shutdown

no ip address

!

end

Step 11 If you choose not to save your configuration, go directly into the router command structure by choosing 0, or choose

1 from the menu to go back to the start of the setup menu. See the following output for options 0, 1, and 2. Choose

option 2 to save your settings to NVRAM. (See the “Check the Running Configuration Settings” section on page 40,

and then the “Save the Running Configuration to NVRAM” section on page 40.) If you do not save the configuration

settings that you created in the router using configuration mode and the setup facility, your configuration will be lost

the next time you reload the router.

[0] Go to the IOS command prompt without saving this config.

[1] Return back to the setup without saving this config.

[2] Save this configuration to nvram and exit.

Enter your selection [2]: 2

media-type 100BaseX

Building configuration...

Use the enabled mode 'configure' command to modify this configuration.

Press RETURN to get started!

Configure the Native Gigabit Ethernet Interfaces

The Cisco 7201 router reports the Gigabit Ethernet SFP ports as GigabitEthernet 0/0, GigabitEthernet 0/1, GigabitEthernet 0/2,

and GigabitEthernet 0/3. The Cisco 7201 router reports the RJ-45 ports as GigabitEthernet 0/0 and Gigabit Ethernet 0/1. Before

configuring either the GigabitEthernet 0/0 or Gigabit Ethernet 0/1 interfaces, you must first use the media-type interface

command to select the media type, sfp or rj45.

Changing the Media Type

To be able to use a particular media type, use Cisco IOS to select the media type. This is done by using the media-type interface

command:

media-type { sfp | rj45 }

Example:

interface GigabitEthernet 0/0

media-type rj45

end

35

Page 36

Configuring the Interface Transmission and Speed Modes

After changing the media type, configure the speed and duplex transmission modes to appropriately match the new interface

characteristics. Changing the speed and duplex of a Cisco 7201 router Gigabit Ethernet interface is done using the speed and

duplex interface commands.

Table 3 Supported Speed and Duplex Settings

Media Type Speed Duplex

SFP 1000, auto full, half, auto

1

RJ-45 10, 100, 1000, auto full, half, auto

1. GE 0/3 only supports full duplex mode.

When using the sfp media type, there is also the additional negotiation auto command that is used to enable the IEEE 802.1z

Gigabit Ethernet (1000 Mbps) autonegotiation protocol.

To turn this negotiation auto feature off (it is on by default), issue the interface command

no negotiation auto. This is useful for connecting to other Gigabit Ethernet equipment that does not support IEEE 802.1z

autonegotiation. We recommended that a fixed speed and duplex setting should be used.

When the interface is configured for negotiation auto, the interface advertises all modes of which it is capable. The link only

comes up if the negotiation process succeeds in finding a common mode between the Cisco 7201 SFP media type and its link

partner.

The sfp media type always defaults to 1000-Mbps, full-duplex operation. The only available speed in this mode is 1000 Mbps;

there is no difference whether 1000 or auto is selected. GE 0/0, GE 0/1 and GE 0/2 support half and full duplex mode; GE 0/3

only supports full duplex mode.

Note Copper SFP modules are considered to be SFP media types, not RJ-45 media types. GE 0/2 and GE 0/3 are optical ports,

whether or not a copper SFP module with an RJ-45 connector, or a standard SFP module is installed.

Note The negotiation auto feature is not supported when using the rj-45 media type and will be ignored if implementation

is attempted. (Auto negotiation is always on in RJ-45 mode.)

When an RJ-45 interface is enabled, it advertises all modes of which it is capable. The link only comes up if the negotiation

process succeeds in finding a common mode between the Cisco 7201 RJ-45 media type and its link partner.

If you change from the sfp to the rj-45 media type, you must set speed and duplex after you have executed the media type

command to ensure the interface operates in the correct mode.

For information on flow control, see the Cisco 7201 Installation and Configuration Guide, Appendix A, “Gigabit Ethernet Flow

Control Information” section.

Debug Information

Cisco IOS provides two commands to provide information on your interfaces: show interface GigabitEthernet 0/X (where X is

0, 1, 2, or 3) and show controllers GigabitEthernet 0/X (where X is 0, 1, 2, or 3).

The output of the show interface command is useful for determining the current operating mode of the interface

(speed/duplex/media type) and the current interface statistics.

The output of the show controllers command displays more information specific to the Cisco 7201 router Gigabit Ethernet

interface. For example, it shows the detected link status, speed, and duplex, and also determines the current status of

autonegotiation and the link partners’ abilities (if it is an autonegotiation-capable interface).

The show controllers command also displays the current operating state of the driver and the Ethernet controller hardware. The

show controllers command is a very powerful debugging aid, especially for Cisco engineers should you need help in debugging

a problem. If you have any problems with your Gigabit Ethernet interfaces, you will need to provide this information to Cisco

for analysis.

36

Page 37

Reset the Interface

Should you have a problem with your interface and you want to try and reset it, use the command:

clear interface GigabitEthernet 0/X (where X is 0, 1, 2, or 3)

Clear Counters

Interface counters may be cleared (reset) by using the command:

clear counters GigabitEthernet 0/X (where X is 0, 1, 2, or 3)

Note Using this command will not reset the interface.

Configure Port Adapter Interfaces

Following are the steps for configuring interfaces to allow communication over a LAN or WAN. To configure the interface

parameters, you need your interface network addresses and subnet mask information. Consult with your network administrator

for this information.

Note Only one port adapter can be installed in the Cisco 7201 router. Following are three examples of three different

interfaces that might be used.

Configure ATM Interfaces

In the following example, an ATM interface in slot 1 is configured for an ATM LAN using IP. Follow these steps to configure

an ATM interface:

Step 1 Using your own addresses and mask at the setup prompts, respond to the prompts as follows:

Configuring interface parameters:

Configuring interface ATM1/0:

I this interface in use? [yes]:

Configure IP on this interface? [yes]:

IP address for this interface: 1.1.1.10

Number of bits in subnet field [0]:

Class C network is 1.1.1.0, 0 subnet bits; mask is /24

Step 2 Determine if you are going to enable IPX on this interface; if you are, enter the unique IPX network number:

Configure IPX on this interface? [no]: yes

IPX network number [2]:

Step 3 If you are using AppleTalk on the interface, enter yes. Enter yes to configure for extended AppleTalk networks, and

then enter the cable range number. Enter the zone name and any other additional zones that are associated with your

local zone:

Configure AppleTalk on this interface? [no]: yes

Extended AppleTalk network? [no]: yes

AppleTalk starting cable range [0]:

Step 4 Save your settings to NVRAM. (See the “Check the Running Configuration Settings” section on page 40, and then the

“Save the Running Configuration to NVRAM” section on page 40.) If you do not save the configuration settings that

you created in the router using configuration mode and the setup facility, your configuration will be lost the next time

you reload the router.

37

Page 38