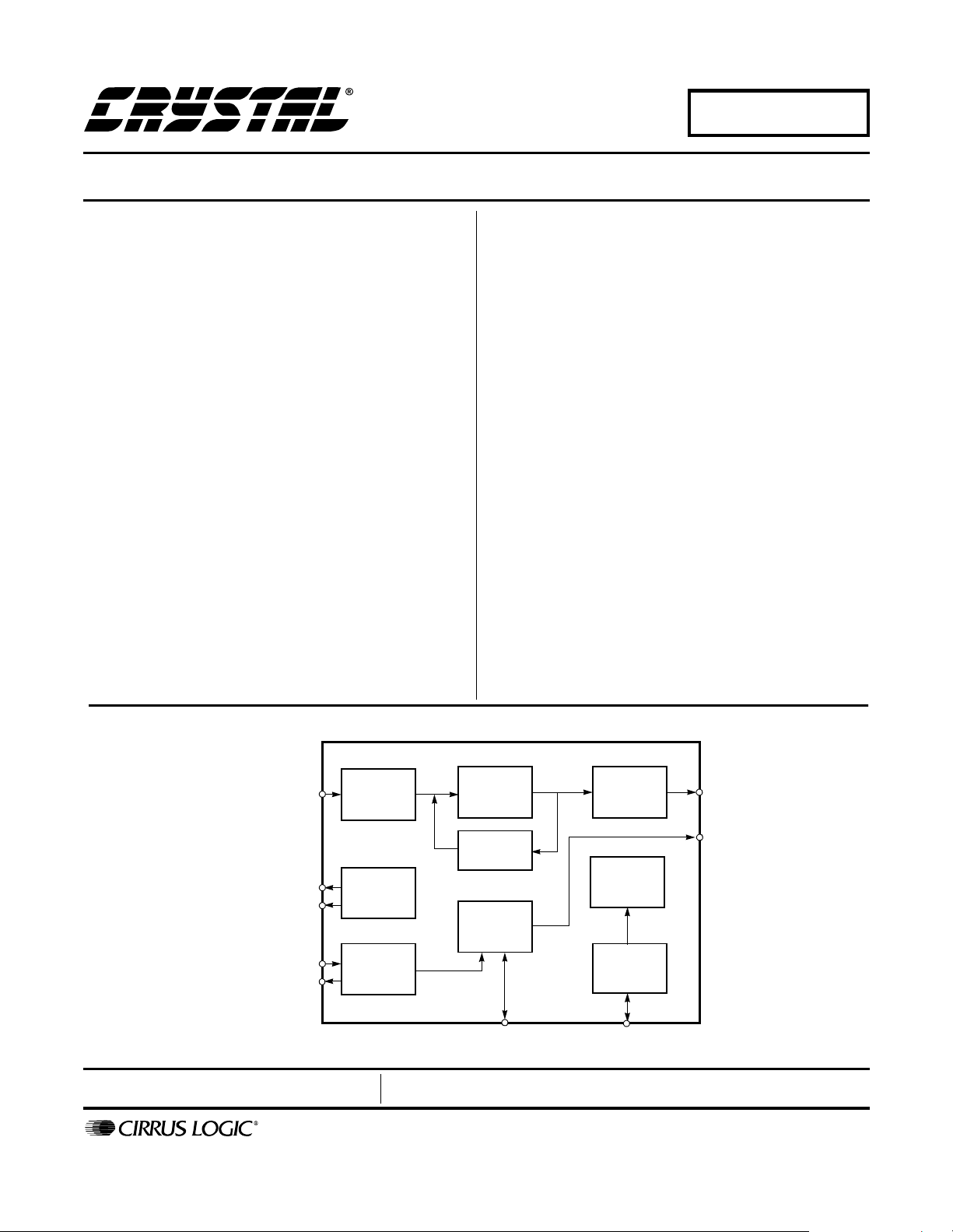

CCD Imager Analog Processor

CS7620

Features

l13-Bit A/D Conversion Using DRX™

Technology

lBacklight Compensation

lSupports three Input Ranges of 0.53V,

1.07V, and 1.60V

lMulti-Sync CCD Timing Generator

lHigh Resolution Output Mode

lLow Resolution (Preview) Output Mode for

LCD Driver

lIntegrated Correlated Double Sampler

lDigital Black Level Clamp

lDigital Outputs Selectable for 13, 12, or 10 Bits

lTwo Integrated General Purpose DACs

lLow Power Consumption

lPower Down Mode

lHigh Speed Serial Inte rface

lSupports a Large Variety of Clock Input

Frequencies

lLow power mode option

Description

The CS7620 is a low-power analog front-end processor

for interline or frame transfer CCD imager s. Main appl ications include digital still image cameras with up to

8k×8k pixels.

The architecture inc ludes a correlated double sampler,

black level clamp and a 13-bi t A/D conversion module

using patented DRX technology. In addition, the chip

contains a timing generator, which supports common

CCDs from IBM, and Polaroid. For CCDs using different

timing signals, the internal timing generator can be

bypassed.

There are 2 general purpose DACs availabl e which can

be used to drive motors for iris and shutter control.

Chip parameters can be programmed using a high

speed 4-wire asynchronous digital interface.

The chip outputs digitized CCD data in either 13-bit, 12bit or 10-bit format. 10-bit outputs are generated from the

13-bit A/D output by a programmable companding curve.

ORDERING INFORMATION

CS7620-IQ -40 to +85 °C 64-pin TQFP

10x10x1.4mm

CCD OUTPUT

DAC

OUTPUTS

MASTER

CLOCK

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

CDS/DRX

GAIN

2 DACS

PLL

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

A/D

CONVERTER

BLACK

LEVEL

TIMING

GENERATOR

CCD TIMING SIGNALS

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

OUTPUT

COMPANDER

CLOCK

REGISTER

BLOCK

SERIAL

INTERFACE

SERIAL BUS

DATA OUT

CLOCK OUT

JUL ‘99

DS301PP2

1

TABLE OF CONTENTS

1 CHARACTERISTICS/SPECIFICATIONS .................................................................................. 5

DIGITAL CHARACTERISTICS.................................................................................................5

POWER CONSUMPTION .. ...... ............................................. .............................................. ..... 5

RECOMMENDED OPERATING CHARACTERISTICS............................................................ 5

ABSOLUTE MAXIMUM RATINGS ........................................................................................... 6

ADC (ANALOG-TO-DIGITAL CONVERTER)........................................................................... 6

CDS/VGA PARAMETERS........................................................................................................6

FREQUENCY SYNTHESIZER PARAMETERS .......................................................................6

SERIAL INTERFACE TIMING SPECIFICATIONS................................................................... 7

2 GENERAL DESCRIPTION ........................................................................................................8

3 OPERATION .............................................................................................................................. 9

3.1 Black Level Adjustment .................................................................................................... 10

3.2 Gain Adjust Block ............................................................................................................. 12

3.3 13-to-10 Bit Compander ...................................................................................................13

3.4 Timing Generator .............................................................................................................15

3.4.1 Vertical and Horizontal Timing Mode ..................................................................15

3.4.2 Horizontal Only Timing Mode ..............................................................................16

3.4.3 Slave mode .........................................................................................................17

3.4.4 Horizontal Timing Generator ...............................................................................17

3.4.5 Vertical Timing Generator ...................................................................................19

3.4.6 Frame Timing ......................................................................................................19

3.5 Frequency Synthesizer ....................................................................................................19

3.6 8-Bit General Purpose DACs ...........................................................................................20

3.7 Stand By Mode ................................................................................................................ 20

3.8 Preview Mode ..................................................................................................................21

3.9 Serial Interface .................................................................................................................21

3.10 Recommended Register Settings ..................................................................................21

4 REGISTER DESCRIPTIONS ................................................................................................... 25

4.1 Reset ................................................................................................................................28

4.2 Power Down Control 1......................................................................................................28

4.3 Power Down Control 2......................................................................................................29

4.4 Operation Control 1........................................................................................................... 29

4.5 Operation Control 2........................................................................................................... 31

4.6 Black Level Control - Accumulator (LSB).......................................................................... 32

4.7 Black Level Control - Accumulator (MSB)......................................................................... 32

4.8 General Black Level.......................................................................................................... 33

4.9 Black Level Control - Loop Gain, Clamp Length............................................................... 33

4.10 Gain Calibration - Offset 1 .............................................................................................. 34

4.11 Gain Calibration - Offset 2 .............................................................................................. 34

4.12 Gain Calibration - Offset 3 .............................................................................................. 35

CS7620

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Preliminary product info rmation describes products which are i n production, but for whi ch f ull characterization data is not yet available. Advance produ ct i nfor mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document is accurate and reli able. However , the i nformati on is sub ject to change with out no tice and i s provi ded “AS IS” withou t warranty of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rig ht s

of third parties. This document i s the propert y of Cirru s Logic, Inc. and implie s no licen se under patent s, copyri ghts, trademarks, or tr ade secrets. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the pri or wri tt en consen t of Ci rrus Logic, Inc. Items from any Cirrus Logi c websi te or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 DS301PP2

CS7620

4.13 Timing Control - Number of Lines (MSBs)...................................................................... 36

4.14 Timing Control - Number of Lines (LSBs)....................................................................... 38

4.15 Timing Control - Number of Columns (MSBs)................................................................ 38

4.16 Timing Control - Number of Columns (LSBs)................................................................. 39

4.17 Timing Control - Number of Dark Rows.......................................................................... 39

4.18 Timing Control - Start of Black Pixels............................................................................. 40

4.19 Timing Control - End of Black Pixels .............................................................................. 40

4.20 Timing Control - Number of Rows until Active................................................................ 41

4.21 Timing Control - Start of Active Pixels............................................................................ 42

4.22 Timing Control - Vertical Time Division .......................................................................... 42

4.23 Timing Control - Lines in Storage Buffer (MSBs) ........................................................... 43

4.24 Timing Control - Lines in Storage Buffer (LSBs) ............................................................ 43

4.25 Timing Control - Extra Lines of Exposure in Low Resolution Mode (MSBs) .................. 43

4.26 Timing Control - Extra Lines of Exposure in Low Resolution Mode (LSBs) ................... 44

4.27 Timing Control - Vsync Mode, Lines of Exposure in Low Resolution Mode (MSBs)...... 44

4.28 Timing Control - Lines of Exposure in Low Resolution Mode (MSBs)............................ 47

4.29 Timing Control - Polarity of Vertical Shift Outputs .......................................................... 47

4.30 Horizontal Timing Control - H1 ....................................................................................... 48

4.31 Horizontal Timing Control - H2 ....................................................................................... 49

4.32 Horizontal Timing Control - H3 ....................................................................................... 50

4.33 Horizontal Timing Control - H4 ....................................................................................... 51

4.34 Horizontal Timing Control - Analog Delays..................................................................... 52

4.35 Compander - Black Slope, Slopes (MSBs)..................................................................... 53

4.36 Compander - Slope 1 (LSBs) ......................................................................................... 53

4.37 Compander - Slope 2 (LSBs) ......................................................................................... 54

4.38 Compander - Slope 3 (LSBs) ......................................................................................... 54

4.39 Compander - Slope 4 (LSBs) ......................................................................................... 55

4.40 Compander - Offset 1..................................................................................................... 55

4.41 Compander - Offsets (MSBs) ......................................................................................... 56

4.42 Compander - Offset 2 (LSBs)......................................................................................... 56

4.43 Compander - Offset 3 (LSBs)......................................................................................... 57

4.44 Compander - Offset 4 (LSBs)......................................................................................... 57

4.45 Compander - X1 (MSBs)................................................................................................ 58

4.46 Compander - X1 (LSBs)................................................................................................. 58

4.47 Compander - X2 (MSBs)................................................................................................ 59

4.48 Compander - X2 (LSBs)................................................................................................. 59

4.49 Compander - X3 (MSBs)................................................................................................ 60

4.50 Compander - X3 (LSBs)................................................................................................. 60

4.51 Power_up Counter.......................................................................................................... 61

4.52 Valid_data/Dout Edge/Clock_in Divider.......................................................................... 61

4.53 DAC #1 Control .............................................................................................................. 62

4.54 DAC #2 Control .............................................................................................................. 62

4.55 Device ID........................................................................................................................ 63

4.56 Rev Code........................................................................................................................ 63

5 PIN DESCRIPTIONS ............................................................................................................... 64

5.1 Supply .............................................................................................................................. 65

5.2 Ground ............................................................................................................................. 65

5.3 CMOS Input ..................................................................................................................... 65

5.4 CMOS Analog Input ......................................................................................................... 66

5.5 CMOS Analog Output ...................................................................................................... 66

5.6 CMOS 4 mA Output ......................................................................................................... 66

5.7 CMOS 28 mA Output ....................................................................................................... 67

5.8 Misc ................................................................................................................................. 67

6 PACKAGE DIMENSIONS ....................................................................................................... 68

DS301PP2 3

LIST OF FIGURES

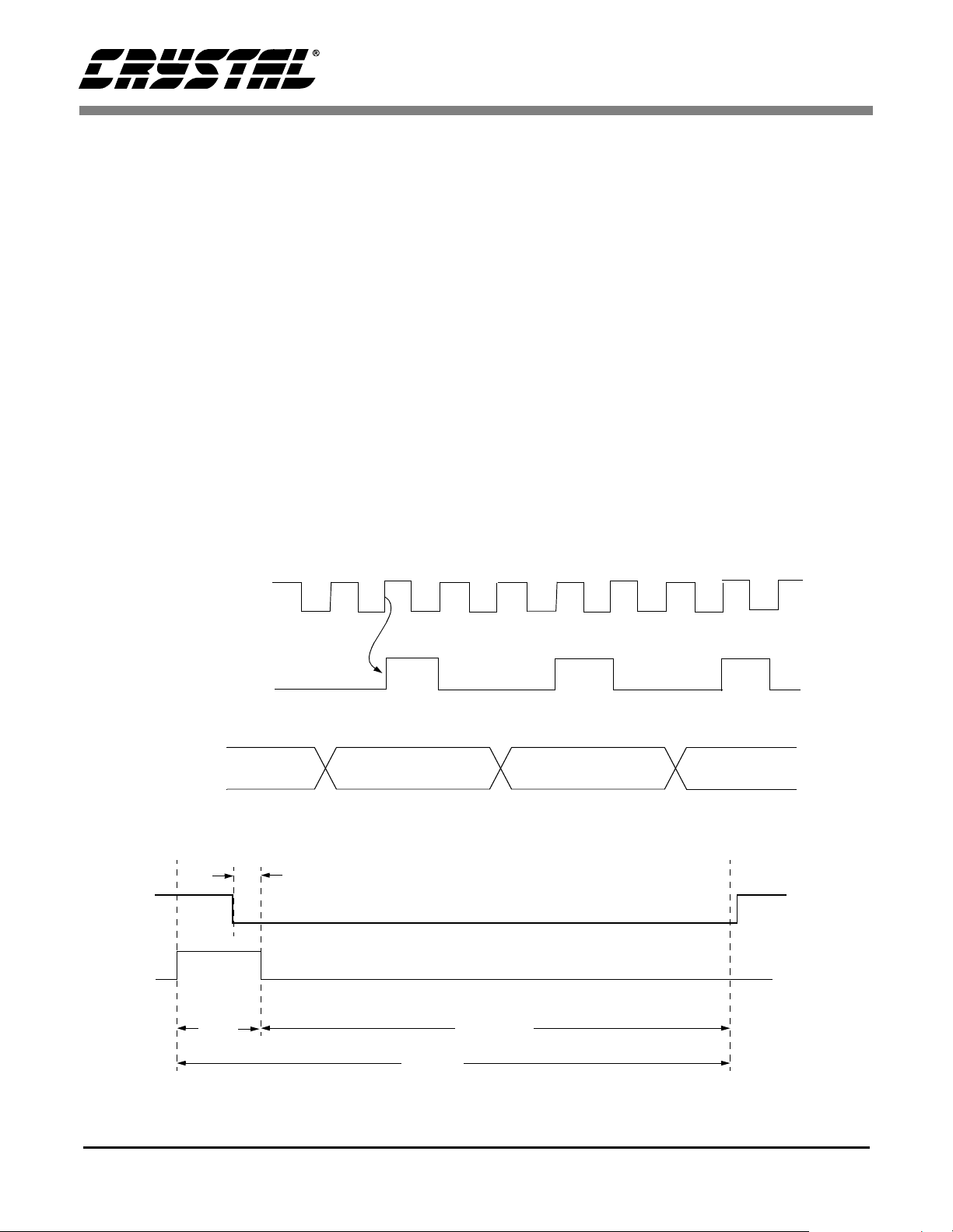

Figure 1. SEN Timing......................................................................................................................... 7

Figure 2. Serial Write Timing........... ....... ...... ....... ...... ....... ...... ............................................. ............. .. 7

Figure 3. Read Data Timing ............................................................................................................... 7

Figure 4. Digital Camera Block Diagram............................................................................................ 8

Figure 5. CS7620 Block Diagram....................................................................................................... 8

Figure 6. Idealized CCD output waveform .........................................................................................9

Figure 7. Transfer function of VGA circuit (assuming full scale level of 1.07V)................................ 10

Figure 8. Block diagram of CDS/VGA circuit.................................................................................... 10

Figure 9. Idealized timing diagram of VGA/CDS circuit.................................................................... 11

Figure 10. Black level adjustment loop............................................................................................. 11

Figure 11. Transfer function of Vin to Gain Adjust output Block (assuming full scale level of 1.07V)13

Figure 12. Gain Adjust output Block................................................................................................. 13

Figure 13. 13-to-10 bit compander................................................................................................... 15

Figure 14. CS7620 output data and clocks ...................................................................................... 15

Figure 15. CS7620 output data and clocks ...................................................................................... 16

Figure 16. Picture Signal Timing...................................................................................................... 16

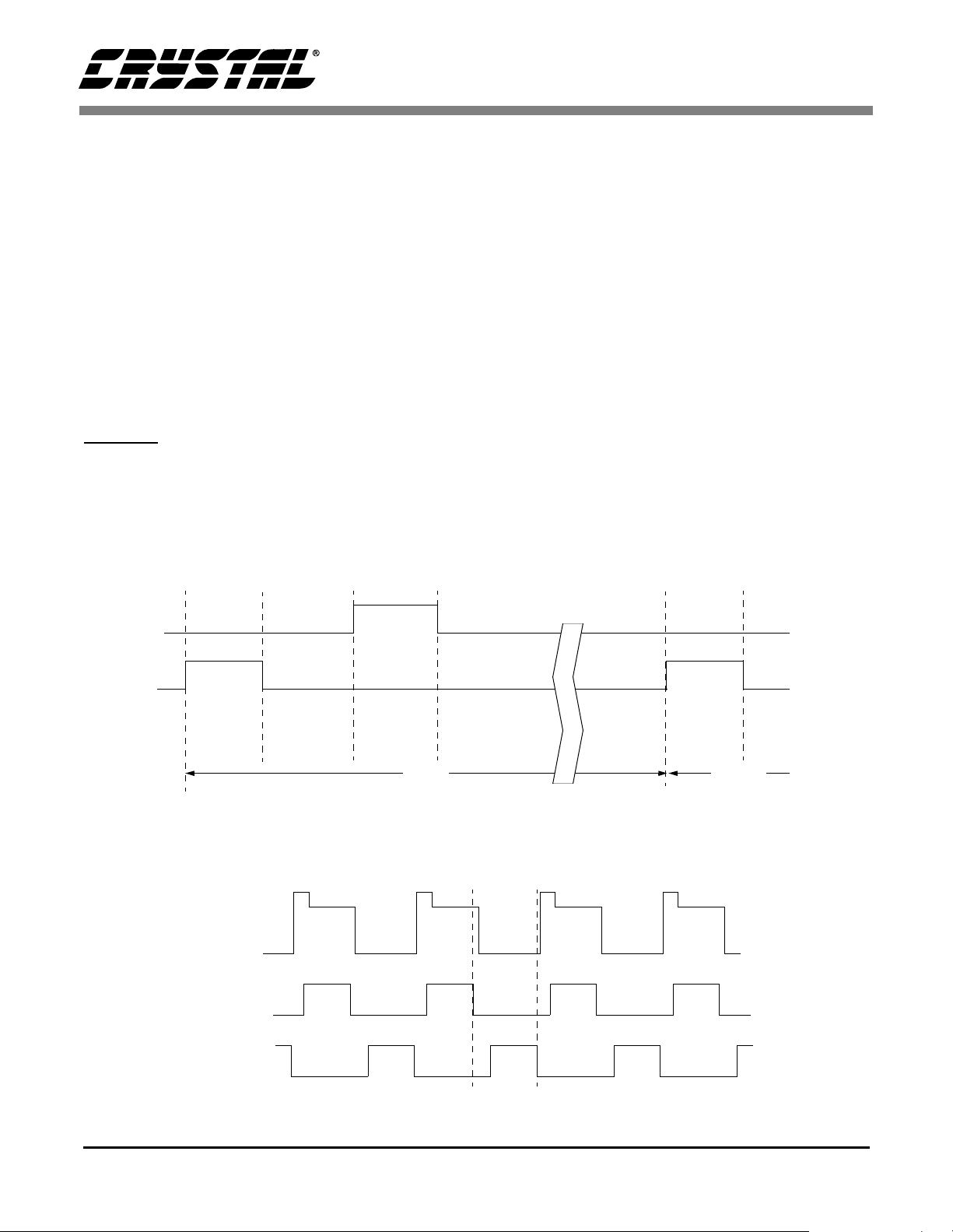

Figure 17. Signal Timing for Horizontal Only Mode.......................................................................... 17

Figure 18. Signal Timing for Slave Mode .........................................................................................17

Figure 19. Detailed Signal Timing Showing Internal Clock Phases ................................................. 18

Figure 20. Default Timing of Horizontal Signals to the CCD ............................................................ 18

Figure 21. High Resolution Mode..................................................................................................... 20

Figure 22. Low Resolution Mode...................................................................................................... 20

Figure 23. Typical Connection Diagram Using Vertical and Horizontal Timing Mode...................... 22

Figure 24. Typical Connection Diagram Using Horizontal Only Timing Mode ................................. 23

Figure 25. Typical Connection Diagram Using Slave Mode............................................................. 24

Figure 26. Transfer Function of Analog Input to Digital Output (assuming full scale level of 1.07V)36

Figure 27. Transfer Function of ADC with Fixed Gain Settings (assuming full scale level of 1.07V)37

Figure 28. Typical CCD Pixel Arrangement ..................................................................................... 41

Figure 29. 2 million pixel IBM CCD (5:1 reduction) .......................................................................... 46

Figure 30. 2 million pixel IBM CCD (5:1 reduction) RGB pattern ..................................................... 46

Figure 31. 1.3 million pixel IBM CCD (8:2 reduction) ....................................................................... 46

Figure 32. 1.3 million pixel IBM CCD (4:1 reduction) RGB pattern.................................................. 46

Figure 33. Vertical Timing Division for Low Resolution Mode.......................................................... 46

CS7620

LIST OF TABLES

Table 1. Companding Operational Control....................................................................................... 14

Table 2. Default Phases for Horizontal Signal Edges ...................................................................... 18

Table 3. Different Resolution Operating Modes ............................................................................... 19

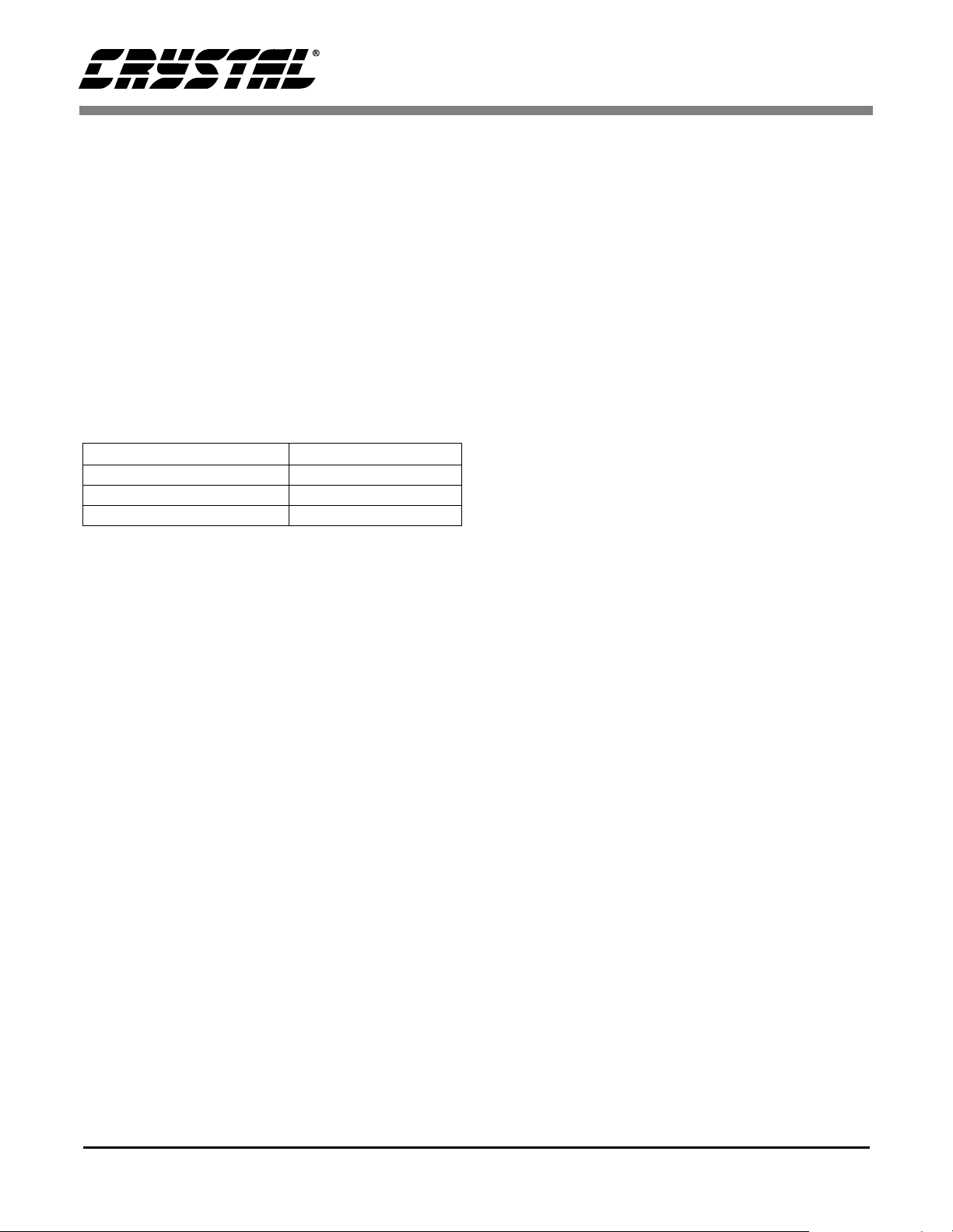

Table 4. General Purpose DAC specifications................................................................................. 20

Table 5. IBM35CCD2PIX1 ............................................................................................................... 25

Table 6. IBM35CCD13PIX ............................................................................................................... 25

Table 7. Register Description........................................................................................................... 25

Table 8. Different Resolution Operating Modes ............................................................................... 30

Table 9. Full Scale Level Choices.................................................................................................... 32

Table 10. Offset Range .................................................................................................................... 32

Table 11. Black Loop Time Constant............................................................................................... 33

4 DS301PP2

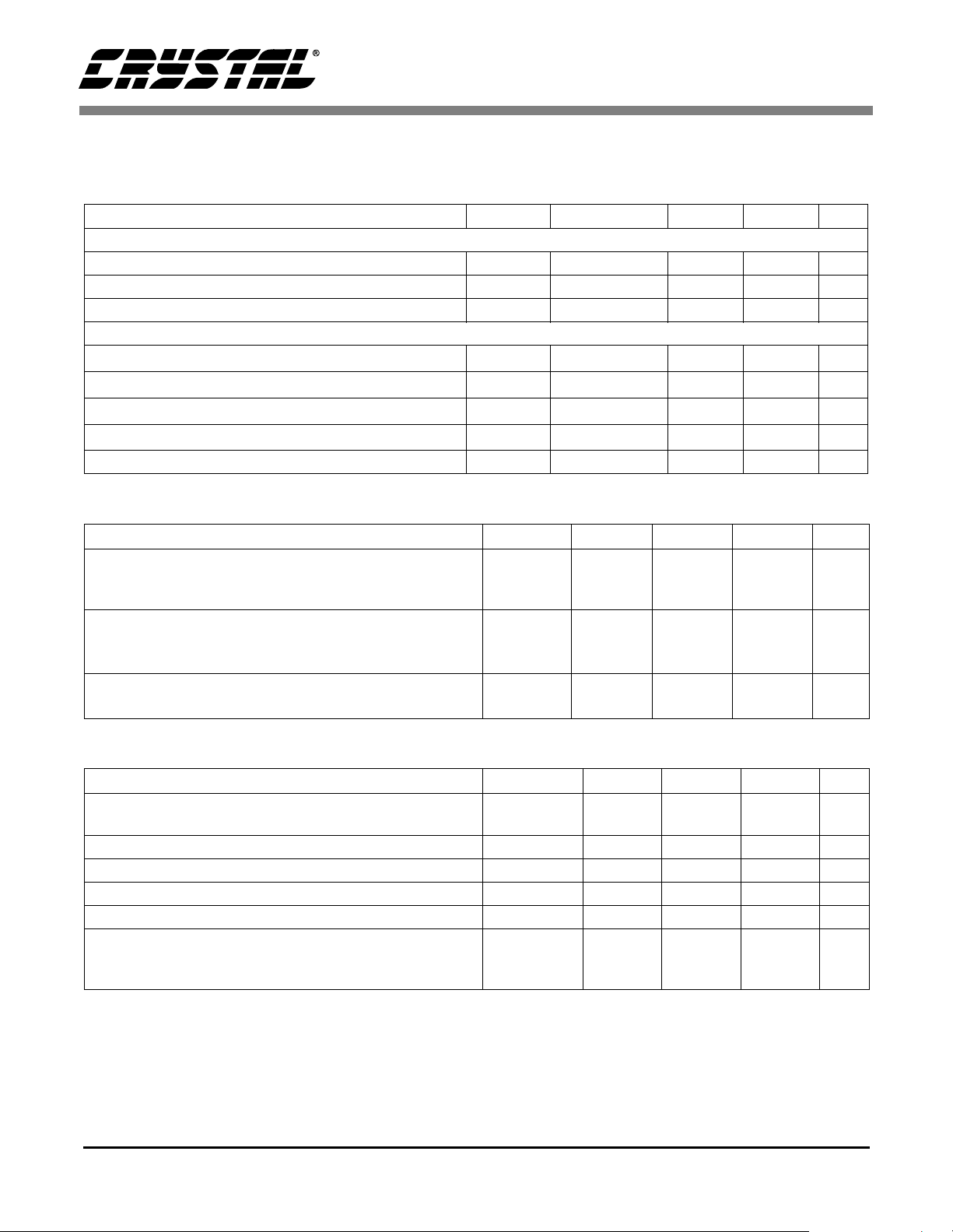

1 CHARACTERISTICS/SPECIFICATIONS

CS7620

DIGITAL CHARACTERISTICS (T

= 25 °C; VDD_Ring = 5 V)

A

Parameter Symbol Min Typ Max Units

Logic Inputs

High-Level Input Voltage V

Low-Level Input Voltage V

Input Leakage Current I

Logic Outputs

High-Level Output Source Current @ IOH = 4mA V

Low-Level Output Sink Current @ I

(H1-H4) Output Source Current @ I

(H1-H4) Output Sink Current @ I

= 4mA V

OL

OH = 24mA

OL = 24 mA

V

OH_HCLK

V

OL_HCLK

3-State Leakage Current I

POWER CONSUMPTION (T

= 25 °C; VAA = VDD = 5 V; Output Load = 30 pF)

A

Parameter Symbol Min Typ Max Units

Power Dissipation Peak Mode

Preview Mode

Stand By Down

Analog Power Supply Current Peak Mode

Preview Mode

Stand By Down

Digital Power Supply Current Peak/Preview Mode

Stand By Mode

IN

OH

OL

OZ

IH

IL

P

P

P

DLR

DPD

I

AN

I

ALR

I

APD

I

DN

I

DPD

VDD_Ring-0.8 - - V

--0.8V

--10

VDD-0.4 - V

--0.4V

VDD-0.4 V

--10

D

-

-

-

-

-

-

-

-

375

275

0.125

60

40

0.025

15

0

µ

0.4 V

µ

-

-

-

-

-

-

-

-

mW

mW

mW

mA

mA

mA

mA

mA

A

A

RECOMMENDED OPERATING CHARACTERISTICS

Parameter Symbol Min Typ Max Units

Power Supply Voltage V

Power Supply Voltage for Digital Pads V

Power Supply Voltage for Horizontal CCD Signal Outputs V

GNDA to GNDD Voltage Differential 10 mV

Clock Frequency Range 8 160 MHz

Analog Full Scale Input Voltage Range (w/ fs_lvl = 10)

(w/ fs_lvl = 01)

(w/ fs_lvl = 00)

DS301PP2 5

, V

AA1

V

DDD

DD_Ring

AA3

A

IN

AA2

,

4.5 5.0 5.5 V

3.0 3.3/5.0 5.5 V

3.0 3.3/5.0 5.5 V

-1.60

1.07

0.53

-V

p-p

CS7620

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

Power Supply Voltage V

Digital Input Voltage GNDD-0.3 V

Analog Input Voltage A

Input Current (except supply pins) 10 mA

Ambient Temperature Range 70 +70 °C

Lead Solder Temperature (10sec duration) +260 °C

Storage Temperature Range -65 +150 °C

WARNING: WARNING:Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

ADC (ANALOG-TO-DIGITAL CONVERTER)

Parameter Symbol Min Typ Max Unit

Input Voltage Range (w/ fs_lvl = 10)

(w/ fs_lvl = 01)

(w/ fs_lvl = 00)

ADC resolution - 10 - bits

Conversion Rate Maximum 16 - - MHz

Total Differential Non-Linearity - ±1 - LSB

Total Integral Non-Linearity - ±1 - LSB

, V

AA1

V

AA3

V

DD_Ring

V

DDD

IN

AA2

,

,

-0.3 7.0 V

,

GNDA-0.3 V

-1.60

1.07

.53

+0.3 V

DDD

+0.3 V

AAI

-V

0-p

CDS/VGA PARAMETERS

Parameter Symbol Min Typ Max Unit

Input Voltage Range (w/ fs_lvl = 10)

(w/ fs_lvl = 01)

(w/ fs_lvl = 00)

Total Gain Range A

Input Referred Noise (rms) Maximum Gain Setting Vn

VGA

VGA

-1.60

-V

0-p

1.07

.53

- 18 - dB

--0.2 mV

FREQUENCY SYNTHESIZER PARAMETERS

Parameter Symbol Min Typ Max Unit

CLKIN Frequency F

PLL Output Frequency F

CLKIN Duty Cycle D

clock_in

PLL_OUT

clock_in

Output Jitter - 200 - ps

Duty Cycle - 50 - %

PLL Acquisition Time - 200 - µs

6 DS301PP2

8 - 160 MHz

8 - 16 MHz

20 - 80 %

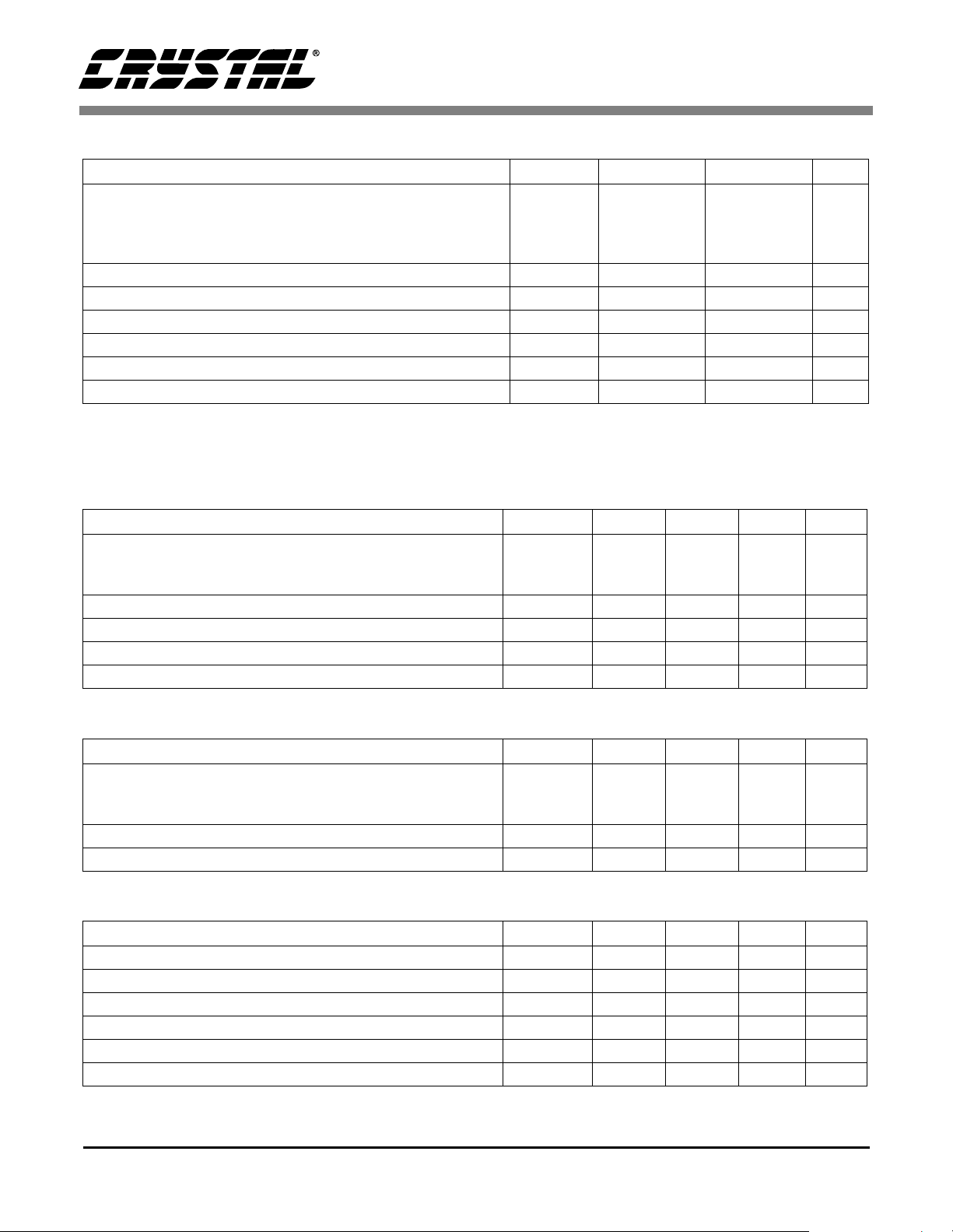

CS7620

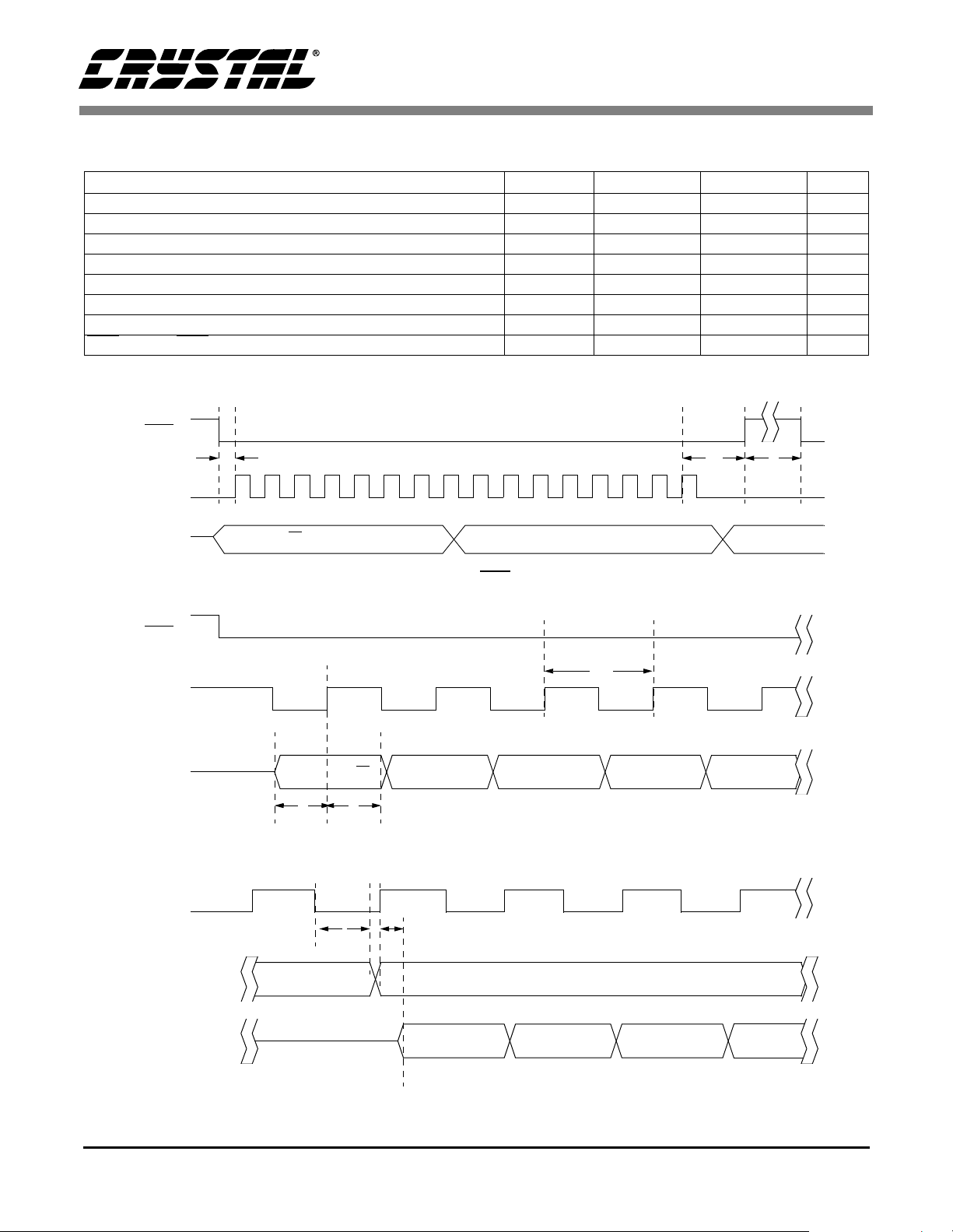

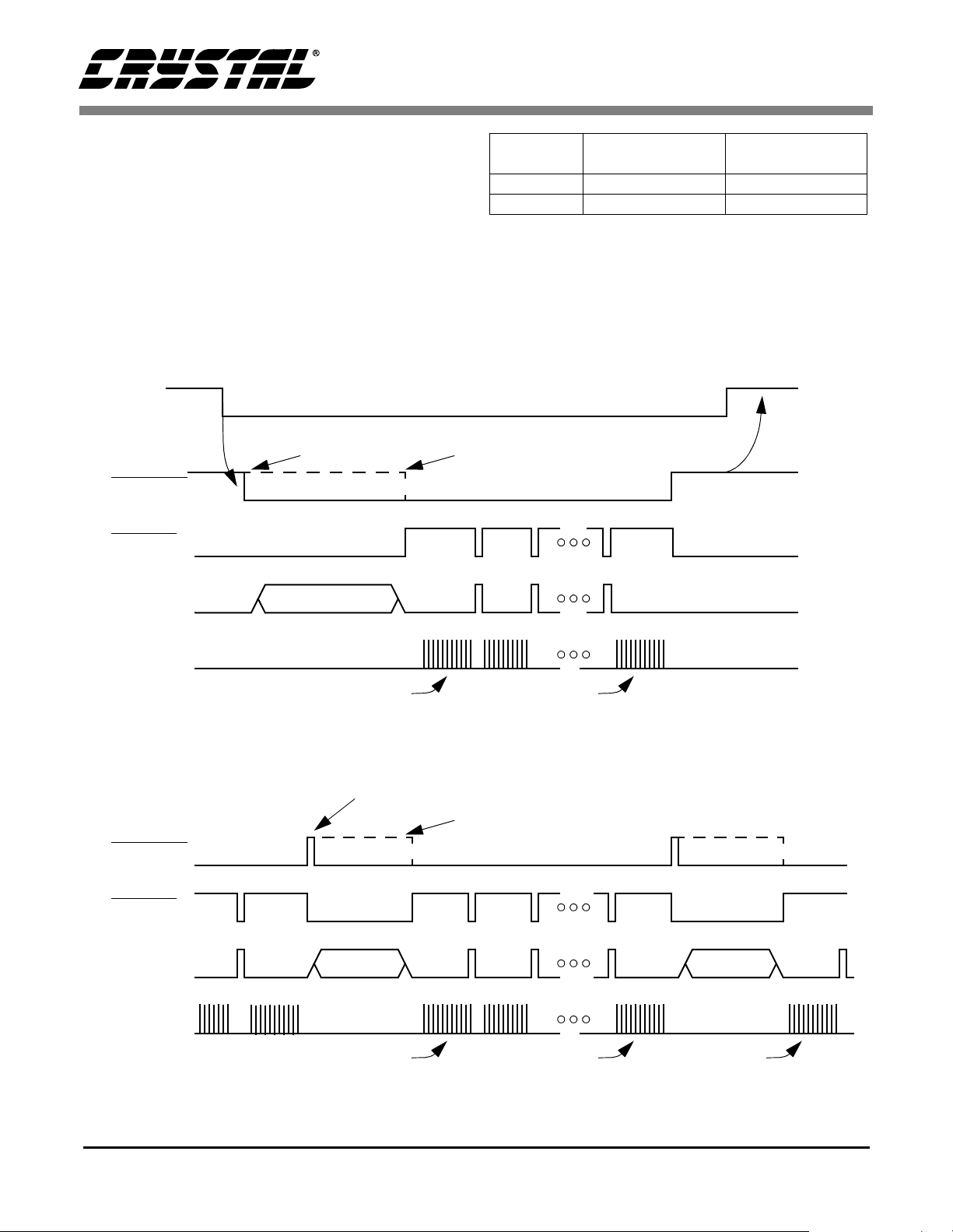

SERIAL INTERFACE TIMING SPECIFICATIONS

Description Symbol Minimum Maximum Unit

Enable Setup t1 10 - ns

SDAT Setup t2 10 - ns

SDAT Hold t3 10 - ns

Serial Clock Period (Note 1) t4 143 - ns

Write Data Invalid t5 0 10 ns

Read Data Valid t6 0 10 ns

Clock to Disable t7 143 - ns

Rise to SEN Fall t8 200 - ns

SEN

Notes: 1. the minimum serial clock period must be longer than two pixel clock periods.

SEN

t1

SCLK

t7 t8

SDATI

SEN

SCLK

SDATI

SCLK

SDATI

R/W, ADDR <6.0> DATA <7.0>

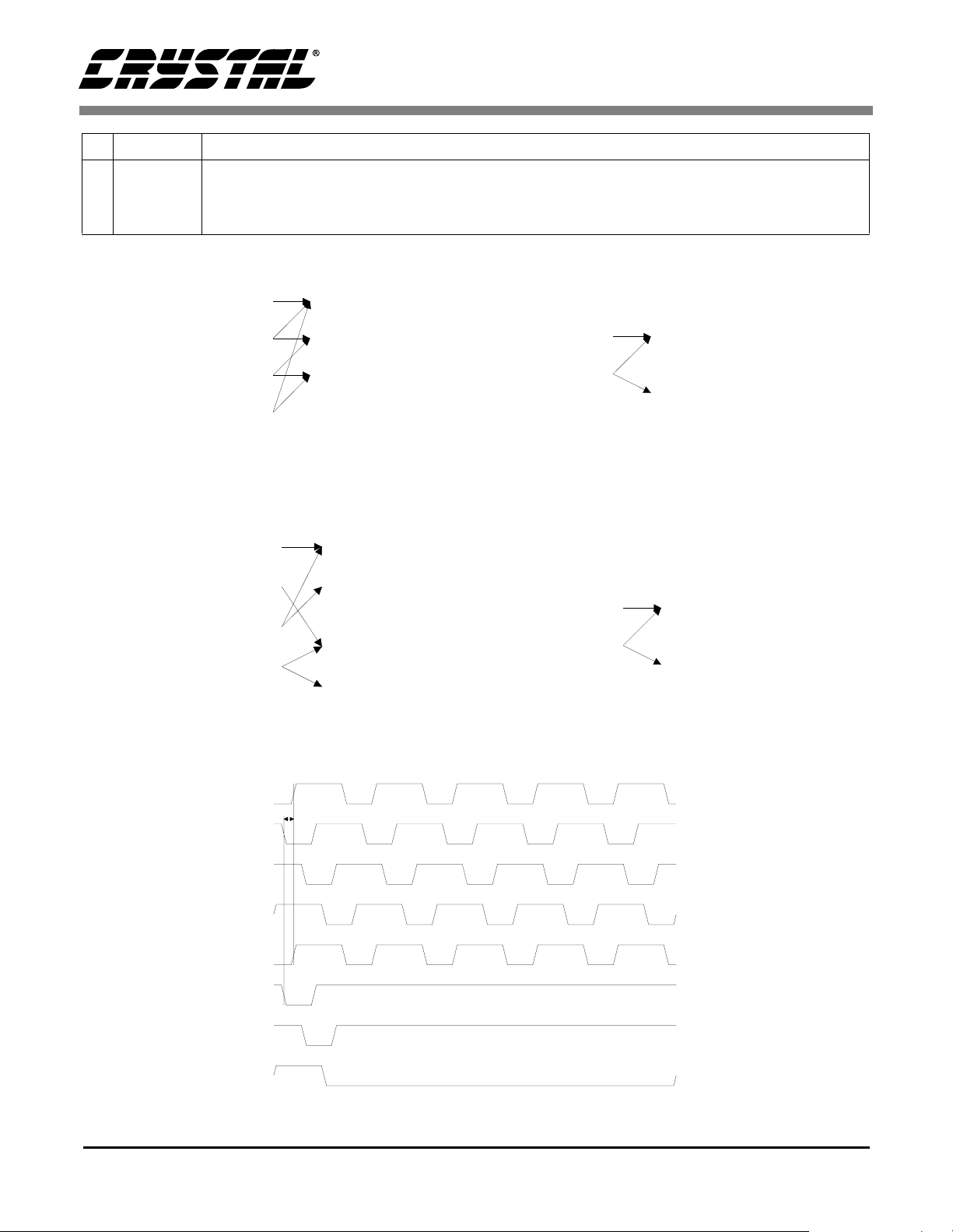

Figure 1. SEN Timing

t4

R/W A6 A5 A6 A3

t2 t3

Figure 2. Serial Write Timing

t5 t6

A0 XX (DON’T CARE)

SDATO

D7 D6 D5

Figure 3. Read Data Timing

DS301PP2 7

CS7620

2 GENERAL DESCRIPTION

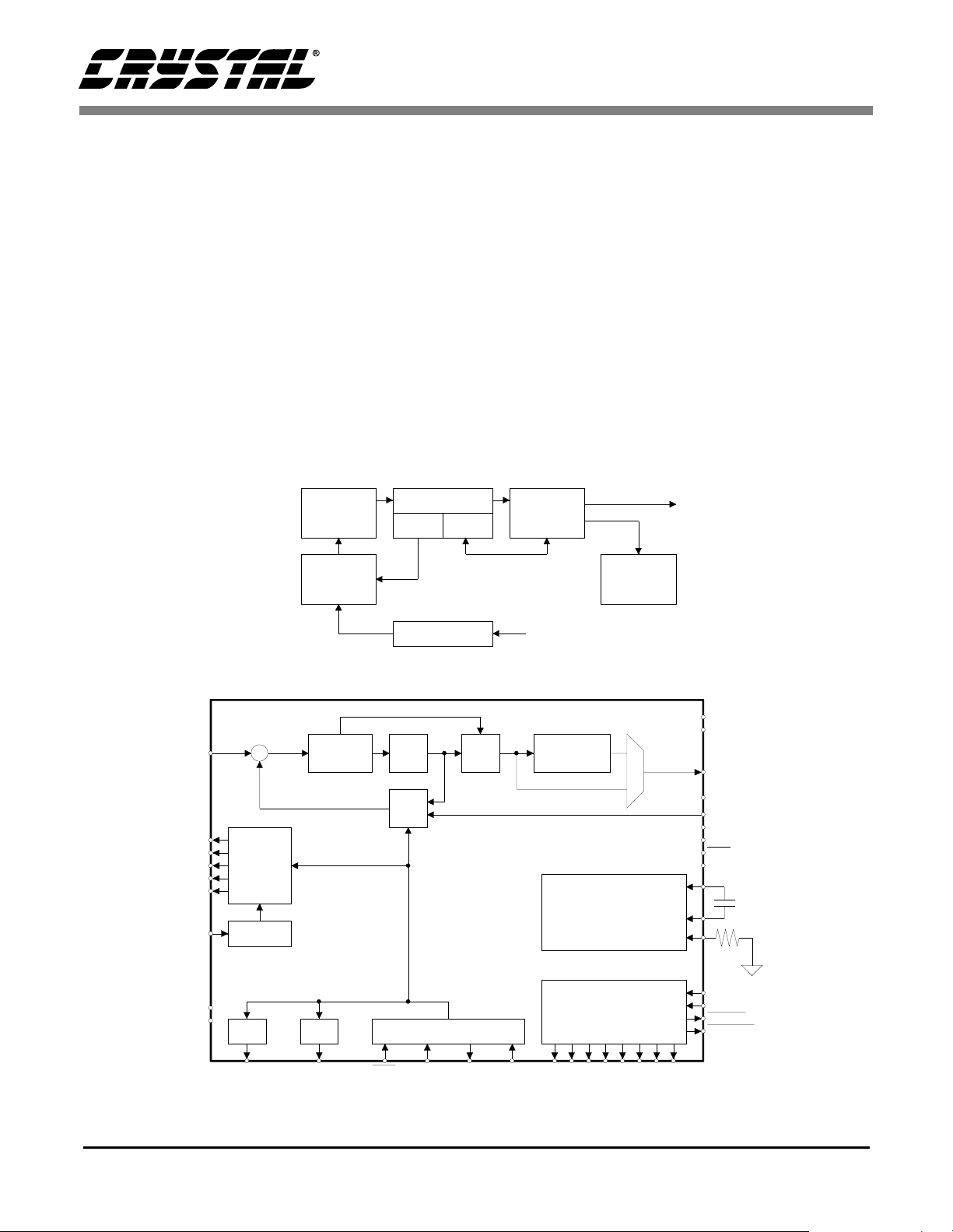

The CS7620 forms the heart of a four chip digital

CCD Camera. The four chips include the CCD imager, the CS7620 CCD digitizer, a vertical drive interface chip and a backend DSP chip to further

process the digital data (see Figure 4.) The CS7620

has a built-in timing generator which works with

imagers from IBM and Polaroid. If other CCDs are

used, the internal timing generator can be bypassed

and replaced by an external device, which outputs

the appropriate timing signals.

The patented DRX technology allows the CS7620

to output data with 13-bit dynamic range, and at the

CS7620

CDS/ADC

CCD

Timing Control

Vertical Drive

same time reducing the power consu mption to a 10bit equivalent A/D converter.

The digitized output is either available in 13-bits,

12-bits or 10-bits. The 10-bit output is created by

companding the 13-bit A/D output to 10-bits. The

companding curve consists of 4 linear segments,

where each slope and each start point is user programmable. Two output control signals and one

output clock provide synchronization with the output data.

A block diagram of the CS7620 chip is shown in

Figure 5.

Backend

DSP

Video Output

LCD Panel

AIN

RG

H1

H2

H3

H4

CLOCK_IN

BYPASS_PLL

DIAG[1:0]

+5 V to -5 V

DC-DC converter

Figure 4. Digital Camera Block Diagram

Σ

Analog

Clock

Generator

PLL

DAC1 DAC2 Serial Interface

DAC_OUT1

CDS/VGA A/D

DAC_OUT2

Black

Level

SEN

SDATI SDATO SCLK

Gain

Adjust

+5 V

13 to 10-bit

Compander

V1 V2 V3V4S1 S2 S3 S4

Reference

Timing

Generator

VDD[5]

GND[5]

M

U

X

DOUT[12:0]

(up to 3 may be unused)

CLKO

CLAMP

SCAN_MODE

PWR_DN

RST

TEST

REF_CAPP

1 µF

REF_CAPN

BG_RES

10 k

Ω

LINE_ENA

EXPOSE

HSYNC

RD_OUT

Figure 5. CS7620 Block Diagram

8 DS301PP2

CS7620

3OPERATION

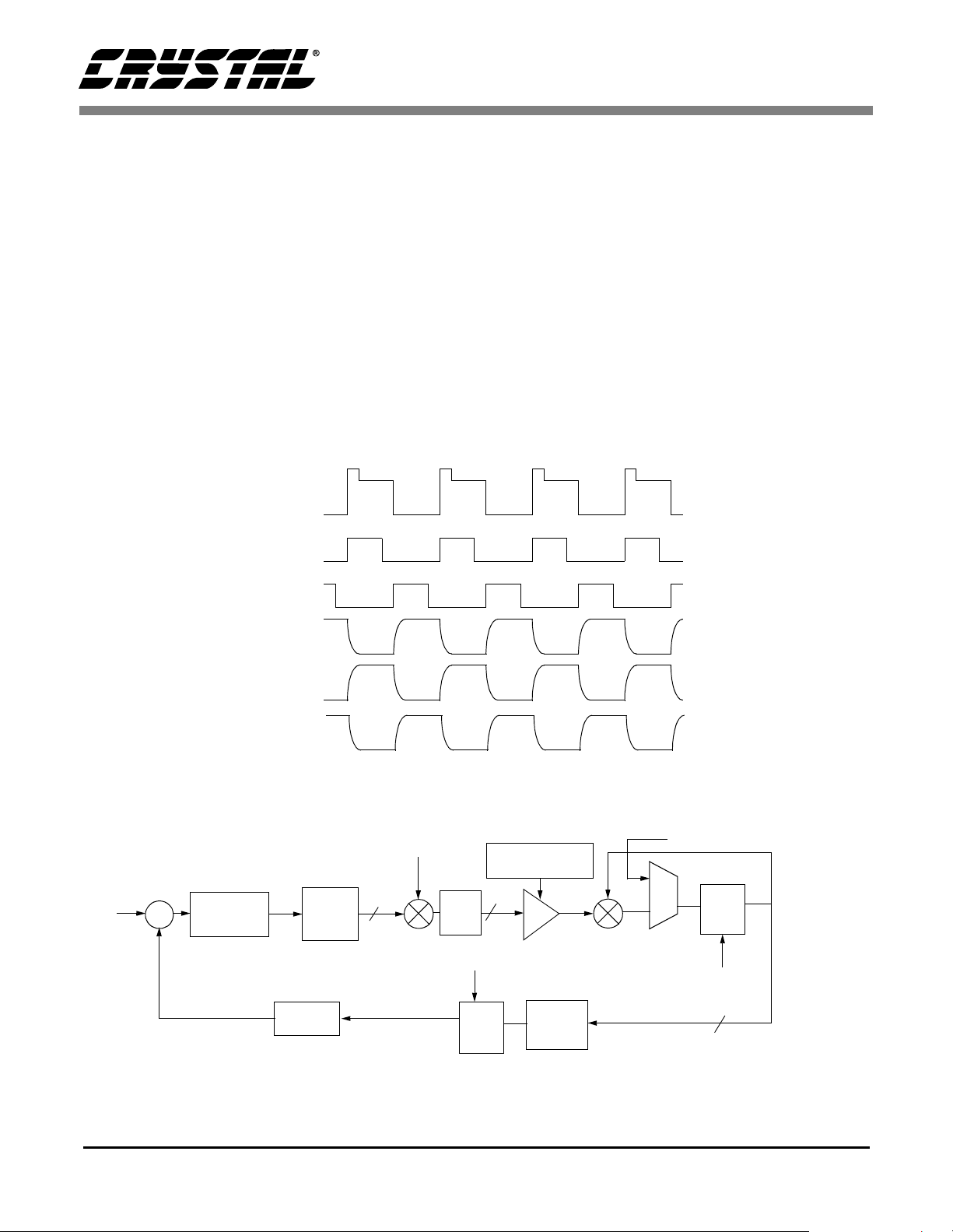

CDS/VGA (correlated double sampling/variable gain amplification)

An idealized waveform of the CCD output is

shown in Figure 6.

The CCD output contains reset noise, thermal

noise, and 1/f noise generated in the CCD output

circuit. This degrades the S/N ratio and must be

cancelled. Since the noise during the active video

portion of the CCD signal is assumed to be correlated with the noise during the feed through portion

of the signal, this noise can be cancelled by subtracting the feed through level from the video level.

This operation is called correlated double sampling. The active video signal is the difference between the feed through and video levels. The active

video signal varies according to light conditions. In

order to insure that the full dynamic range of the

ADC is utilized even under low light conditions,

the CCD output is amplified using a VGA. The

gain control is provided by a 2 bit control word

generated by an ADC after stage 1, which has a

gain of 1. Based on the input voltage, a gain of 1x,

2x, 4x, or 8x is subsequently applied to the signal.

The amount of gain is later adjusted in the digital

section. After the VGA, the signal gets digitized by

a 10 bit ADC. The 2 bit ADC output is used in

combination with the 10 bit ADC output to produce

a 13 bit output.

Adding more gain before the ADC does not offer

performance improvement because the noise of the

CCD (after gain is applied to it) begins to dominate

over the quantization noise. Any additional gain

should be done in digital since the performance is

the same as when the ADC output has the additional gain applied.

In order to add more flexibility, the full scale input

range is programmable through register 07h. This

setting will determine what input level maps to the

highest ADC output code. Thus depending on the

saturation level of the particular CCD used in the

system, an appropriate full scale input level can be

chosen in the CS7620. The choices of full scale input level are 1.6V, 1.07V, 0.53V with 1.07V the

default. In the remainder of this document, all the

figures and discussions assume a full scale level of

1.07 is used. If a different full scale level is used,

all the voltages scale up or down by x1.5 or x0.5 for

1.6V and 0.53V full scale levels respectively.

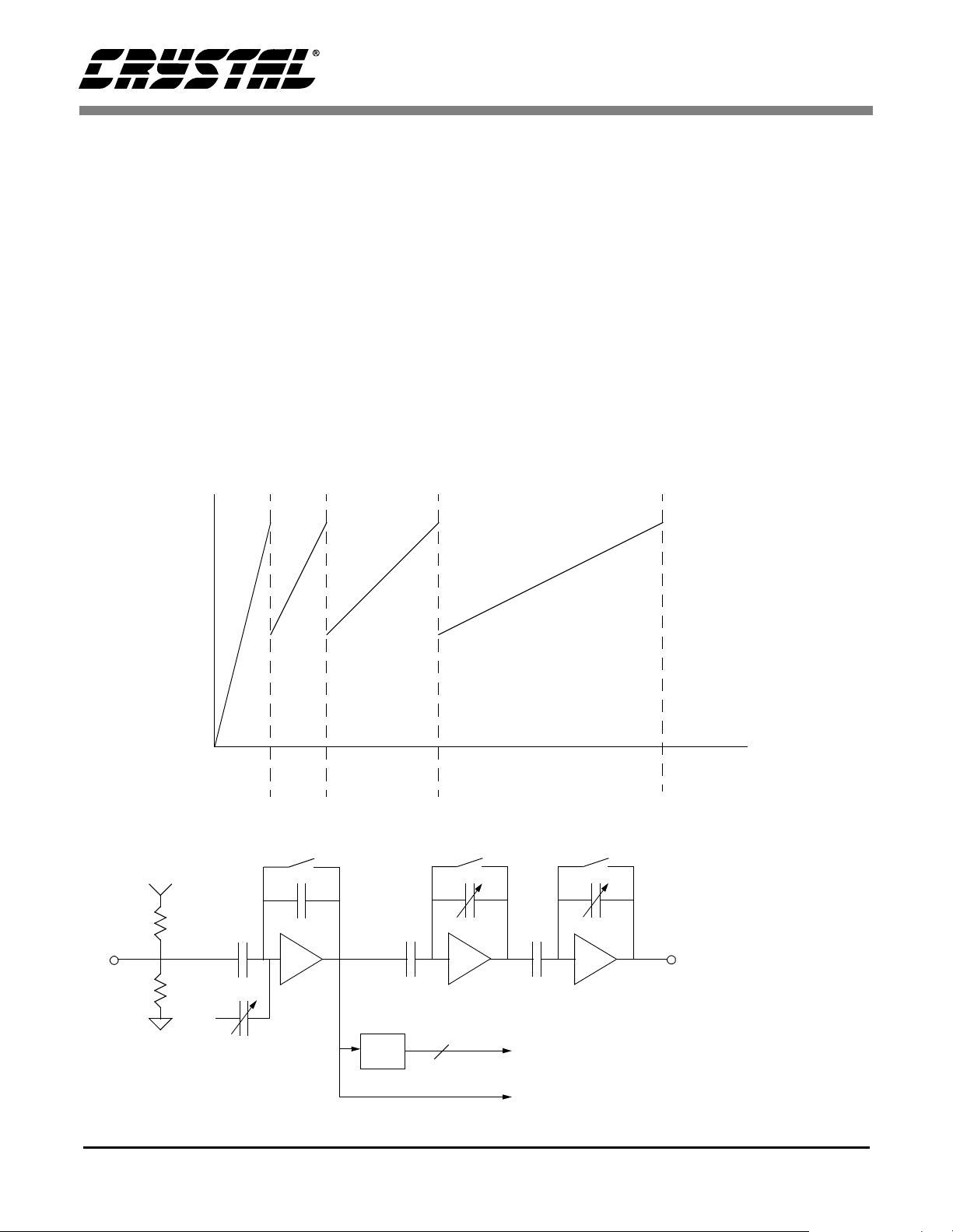

The transfer function of the VGA portion of the cir-

cuit is shown in Figure 7 with full scale level =

1.07. It is assumed that the CDS has already been

performed. If desired, the gain switching functionality can be disabled and forced to a fixed gain of

8x, 4x, 2x, or 1x. This way any dynamic range enhancement is lost and the digital output is only 10

bits. If a fixed gain of 1x is selected, DOUT[12:3]

is used as the output, a fixed gain of 2x will use

DOUT[11:2], etc. In order to use this mode, the

PIXEL PERIOD

RESET LEVEL

VIDEO

RANGE

FEED THROUGH

LEVEL

VIDEO LEVEL

Figure 6. Idealized CCD output waveform

DS301PP2 9

SIGNAL

DARK

MAX. BRIGHTNESS

CS7620

fixed gain register (16h) should be set and the calibration offset registers (10h - 12h) should be set to

0.

The CDS/VGA circuit is composed of three stages.

The first stage has a fixed gain of 1, and the second

and third stages have variable gain with a combined

gain range of 1 to 8 (0-18 dB). Figure 8 shows a

block diagram of the CDS/VGA circuit. The total

gain is A = (C2/C3)(C4/C5) which is adjusted by

varying C3 and C5. The capacitor Cb on the front

of stage 1 is for black level adjustment and will be

discussed in detail later.

This circuit utilizes a two phase non-overlapping

clock to perform the desired CDS function. The

VOUT (V)

1.07

two phase clock also allows the video signal to be

passed to the output while retaining a positive polarity signal. Figure 9 shows a timing diagram of

the two phase clock along with the CCD signal and

output signals of stages one, two and three.

There is an internal mid-scale DC bias level circuit

at the input pin. This allows AC coupling into the

CS7620 with a capacitor and having the input automatically biased to mid-supply without worrying

about external circuitry to perform this task.

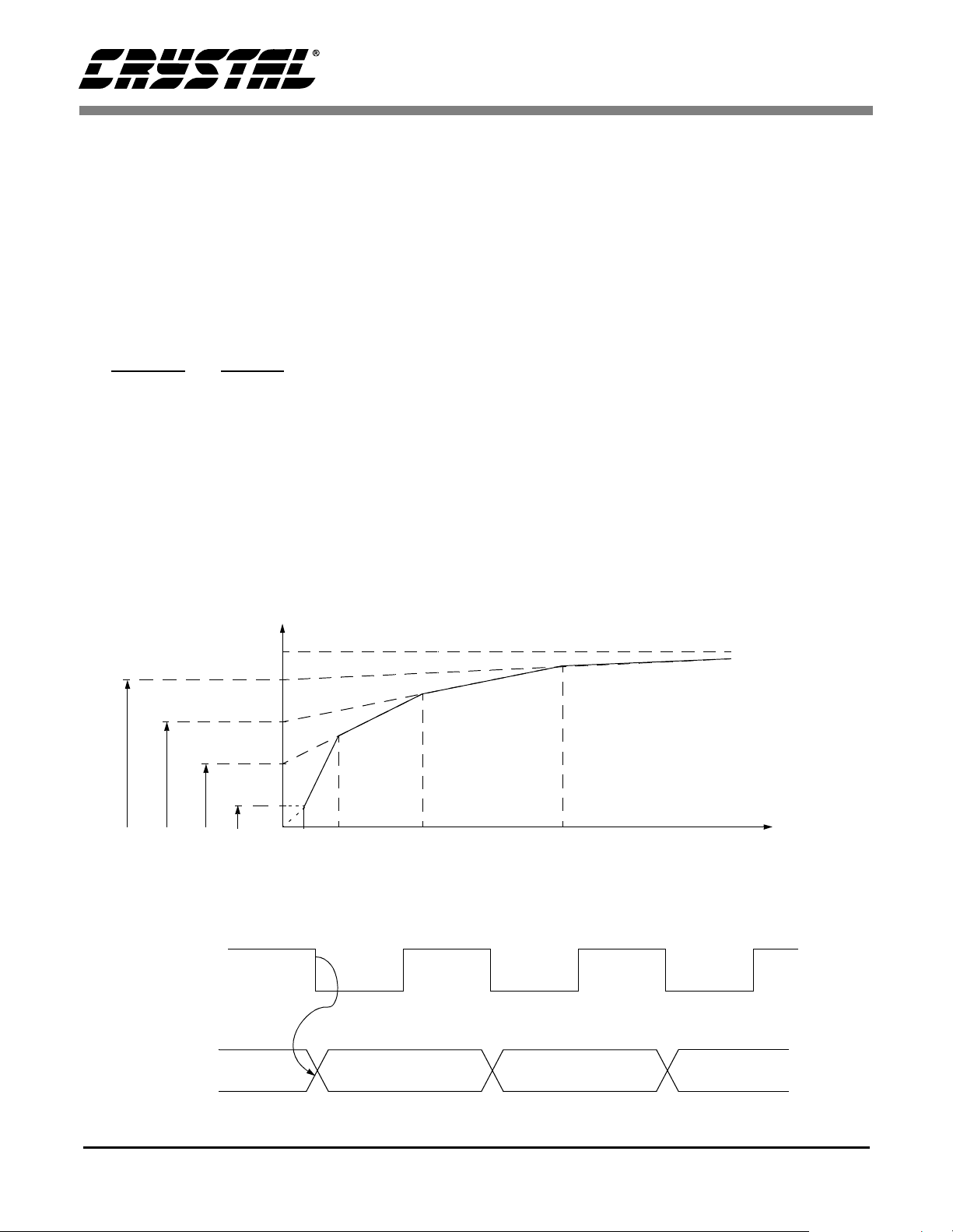

3.1 Black Level Adjustment

In order to maintain a constant reference level for

black pixels, a feedback loop is implemented that

VIN

0.5

100 KΩ

100 KΩ

VREF

1X2X4X8X

0.530.270.13

00 01 10 11

Figure 7. Transfer function of VGA circuit (assuming full scale level of 1.07V)

Φ2

C3

C4

-A2

Vo2

STAGE 2 STAGE 3

2

CONTROLS C3, C5

CONTROLS GAIN ADJUST BLOCK IN DIGITAL

Φ1

-A3

C1

Cb

Φ1

C1

-A1

STAGE 1

C2

Vo1

ADC

1.07

ADC OUTPUT

C5

VOUT

VIN (V)

TO AOUT CIRCUITRY

Figure 8. Block diagram of CDS/VGA circuit

10 DS301PP2

CS7620

sets the black level value at the output of the ADC

to 64 in the 13 bit digital code. This loop is active

during the optically black pixels which are output

at the beginning and end of a frame as well as during a portion of the horizontal blanking period. The

presence of black pixels in the CCD output is indicated by the CLAMP pulse, which can either be

supplied externally or generated internally if the

timing for the CCD is generated by the CS7620.

CCD

INPUT

SIGNAL

Φ1

V(1)

The black level can also be written to through the

serial port.

In order to acquire a starting value for the black level, the loop will run over the several lines of black

pixels at the beginning of the frame. The block diagram of the loop is shown in Figure 10. The update rate is once per line during active pixel lines,

and once every (n + 10) pixels during the optical

black lines.

V(2) V(3)

VIN

CDS/VGA

Σ

FU = UPDATE FREQUENCY

= PIXEL FREQUENCY

F

P

Φ2

OUT OF

STAGE 1

OUT OF

STAGE 2

OUT OF

STAGE 3

V(1) V(2) V(3)

V(1) V(2) V(3)

V(1) V(2)

Figure 9. Idealized timing diagram of VGA/CDS circuit

DAC

ADC

10

‘64’

+

-

CLIP

7

F

U

-1

Z

BLK LVL LOOP

GAIN REG

K

BINARY

TO

THERM

+

+

Figure 10. Black level adjustment loop

FROM SERIAL INTERFACE

MUX

-1

Z

F

P

9

DS301PP2 11

The open-loop transfer function of the black level

K

1

256

-------- -

blk_gain=

τ

1

1nK–()ln

-------------------------- -–

1

fu

-----

=

τ

1

1

nK

2

-------–

ln

--------------------------- -–

1

fu

-----

=

τ

1

1

nK

8

-------–

ln

--------------------------- -–

1

fu

-----

=

τ

1

1

nK

4

-------–

ln

--------------------------- -–

1

fu

-----

=

adjustment loop is

Hz()

Kn×

-------------=

z1–

blk_gain = 1, 2, 4, or 8

For a fixed gain of 4:

CS7620

1

τ

--------------------------- -–

=

1

ln

nK

-------–

2

-----

fu

1

where blk_gain is programmable through a register

and n = # of black pixels during clamp time, which

is also programmable. The value of Kxn will determine the open-loop gain of the system. The settling

time for the loop can be calculated using the following formula:

For offset range=1 (reg 06h, bit 0)

For offset range =0

During fixed gain mode the time constant is a little

different.

For a fixed gain of 1:

For a fixed gain of 2:

12 DS301PP2

For a fixed gain of 8:

1

τ

-------------------------- -–

=

1nK–()ln

1

-----

fu

In order to achieve no ringing in the settling use,

n

----

for offset range = 1, and for offset

1≤

K

n

------2K

1≤

range = 0.

The 9 MSBs of the black level accumulator can be

read or written through a register. If written, the

LSBs are set to zero. The black level is set to “8 ” in

a 10-bit digital output representation. In a 13-bit

representation, it is set to “64.” The power-up default value in the accumulator is at mid level.

Also note that the black level adjust loop can be

disabled. In addition, the black level can be programmed through the serial port.

3.2 Gain Adjust Block

In order to increase the dynamic range of the ADC,

a variable gain, whose value is determined by the

signal level, is applied to each pixel. This allows

for 13 bits of dynamic range and 10 bits of resolution after accounting for the significance of the

ADC output bits. The gain applied in the analog is

illustrated in the transfer curve in Figure 7. Once

the signal is digitized, the gain adjust block uses the

gain information for a given pixel word and shifts

its bits accordingly. For example, using the default

full scale level of 1.07V, if Vin = 0.3 V, the VGA

would choose a gain of 2X so the ADC input is 0.6

V. The 10-bit output of the ADC (with no black

level) is (0.6/1.07) × 1024 = 574, or “1000111110.”

in binary. The gain adjust block will take this value

CS7620

plus the bits representing the 2x gain and divide the

output by two (shift right by 1). The output of the

gain adjust block is then “0100011111.000.” Note

that the decimal point is virtual, having no existence in silicon. It is representing the fact that we

keep 3 extra bits of lower significance in the output.

In the same manner, if Vin = 0.75 V, a gain of 1X

would be chosen and the output of the gain adjust

block would be “1011001101000.” The transfer

function of the Vin/gain adjust out is shown in

Figure 11.

A block diagram of the gain adjust block is shown

in Figure 12.

DIG ADJUST OUT (13 BITS)

8192

Since the analog gain changes do not match the

digital shifts exactly, there is a potential to have

non-monotonic digital output. In order to remove

this problem, calibration is performed. During calibration, offset values are found that will be used to

counteract the errors caused by the analog gain

mismatch. Using these offset values, the final output is a monotonic continuous 13-bit value.

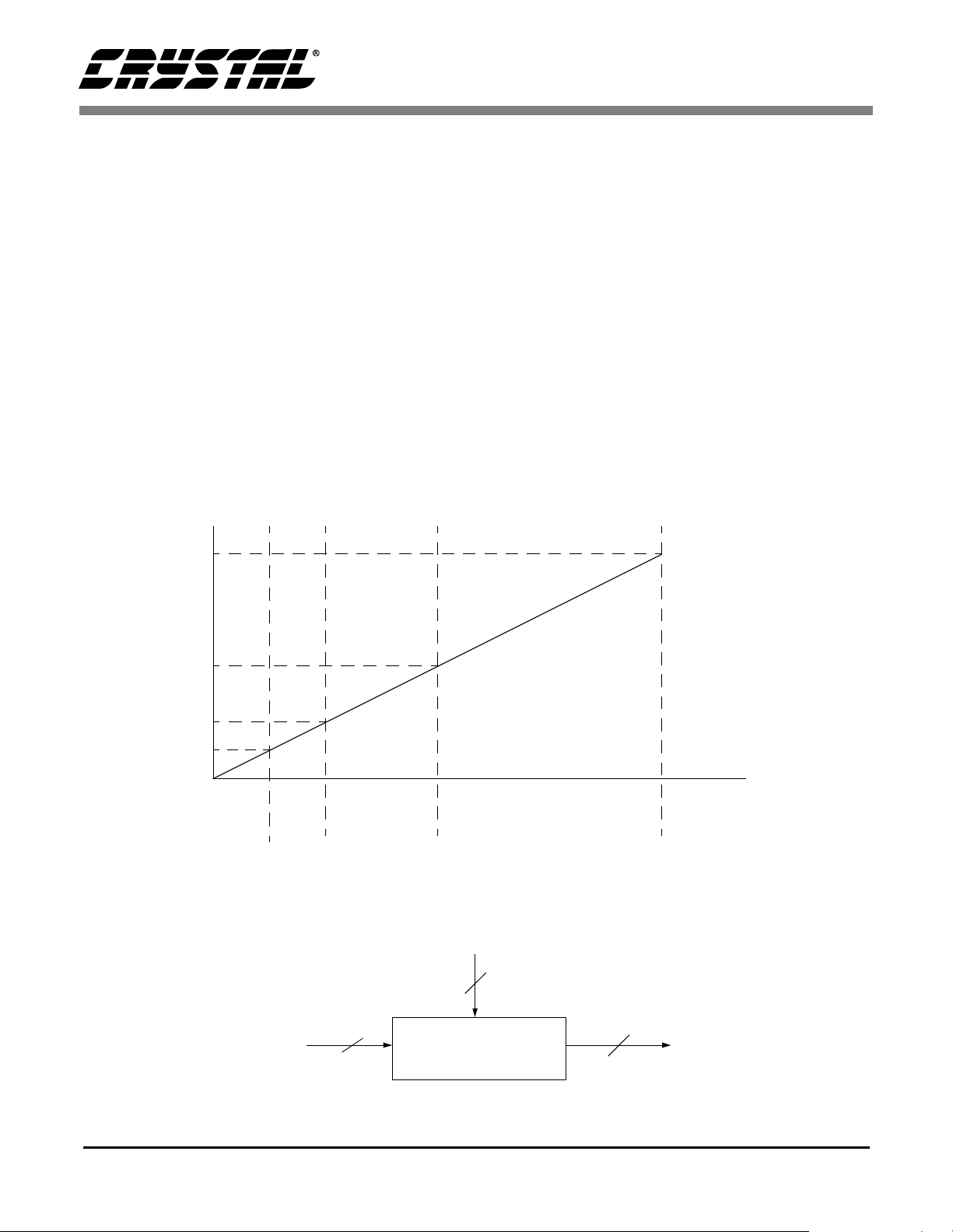

3.3 13-to-10 Bit Compander

While a 13 bit output may be useful in some applications, others may require the standard 10 bit output. To accommodate this and yet still retain the

advantages of the increased dynamic range, a 13to-10 (or 13-to-12) bit compander is included. By

4096

2048

1024

0

0.13

00 01 10 11

Figure 11. Transfer function of Vin to Gain Adjust output Block (assuming full scale level of 1.07V)

VGA_ADC OUTPUT

2

Figure 12. Gain Adjust output Block

0.530.27

ADC OUTPUT

10

GAIN ADJUST

SHIFT BY 0,1,2, OR 3

1X2X4X8X

13

1.07

TO DIGITAL GAIN

VIN (V)

ADC OUTPUT

DS301PP2 13

CS7620

using the picture content as a guide, the user can select which curve will lead to the best overall dynamic range in the picture. The Companding

module takes 13-bit data as input, and outputs either 10-bit companded data, 12-bit MSB-clipped

data or it lets the original 13-bit data pass through.

By programming the compander in the way that is

shown in Figure 13, it is possible to compensate for

backlighting conditions. Details in dark areas stay

visible, even in very complex lighting conditions.

These three modes can be selected through 2 register bits in operational control.

Bits_out register bits Output mode

0x 10 bits companded

10 13 bits

11 12 bits (clipped)

Table 1. Companding Operational Control

In the 12-bit clipped mode, any input above 4095

gets clipped to 4095. In the 10-bit companded

mode, the input gets companded through a four

segment, three knees, fully programmable curve.

The second option clips all pixel values less than

black (code 64 in the 13 bit data) to a programmable offset value, offset1. This may be set to 0 if desired. This option will lose the “blacker-thanblack” pixel information, but allow for slightly

more dynamic range. Note: If using the linear mode

(option 1), offset1 must be set to 8.

Registers x1 through x3 should be programmed

with the x coordinates of each one of the three

knees.

Registers slope1 through slope4 should be programmed with 256 multiplied by the calculated

slopes.

Finally, the offsets can be programmed following

the formulas below:

y1 = slope1/256 × (x1-64) + offset1

y2 = slope2/256 × (x2-x1) + y1

y3 = slope3/256 × (x3-x2) + y2

offset2 = y1 - (x1 × slope2 / 256)

offset3 = y2 - (x2 × slope3 / 256)

To program the curve, the placement of the t hree

knees in the companding curve must be determined. The next step is to determine the slope of

the four segments created by the three knees (slope

for each segment is defined as delta y / delta x). Finally, offsets must be calculated to keep the companding curve continuous.

A fourth knee exists in the curve, which represents

the black level value. There are two options for the

10-bit black value. In case one, a linear mapping is

employed such that “blacker-than-black” pixel information is kept, with black (code 64 in the 13 bit

data) being defined as code 8 in the 10 bit domain.

offset4 = y3 - (x3 × slope4 / 256)

(use integer division and discard the remainder)

When using the 10 bit companded output, be aware

of the non-linearity of the output data. If linear output is needed to perform AWB or AGC, a linear

curve can be implemented to gather statistics. This

can be achieved by writing 8191 to x1 (set register

38h to 1fh and set register 39h to ffh) and setting

slope1 to 32 (set register 2eh to 00010xxxb and set

register 2fh to 20h). Once the statistics have been

gathered, all four registers should be returned to

their previous values before taking the actual picture.

14 DS301PP2

CS7620

The output of the compander is available at the pins

DOUT<9:0> and it makes transitions either at the

falling or rising edges of the pixel rate clock CLKO, controlled by a register bit. The Falling edge

option is shown in Figure 14.

Two options exist for outputting data. The first option will output the pixel rate clock on the CLKO

pin. The polarity of the pixel clock out of the pin is

programmable so that the user may choose the appropriate clock edge to latch in the data. Based on

the RD_OUT and HSYNC signals, the user will be

able to determine when he is over active pixels. The

second option will output a data_valid signal on the

CLKO pin that is synchronous with the input clock

(Figure 15). The data_valid signal will only toggle

over active pixels. The user may then latch the data

during this valid time. Note: DATA_VALID mode

cannot be used if the system clock runs at the pixel

rate.

3.4 Timing Generator

There are three timing options available with the

CS7620. The chip may produce all the vertical and

horizontal timing for the imager, only the horizontal timing, or the chip may be used in a complete

slave mode and not produce any of the CCD timing

at all. Each will be discussed in detail in this section.

3.4.1 Vertical and Horizontal Timing Mode

To select this option, the user must tie the

BYPASS_PLL pin low and select the proper internal timing mode in the timing mode register. The

CS7620 is the master of the clocking. It will provide vertical outputs and horizontal outputs. In this

mode, the user must control two signals. The first is

the master PWR_DN signal. When this signal is

high, all of the CS7620 powers down except for the

OFFSET4

OFFSET3

OFFSET2

CLKO

CODE_OUT

1023

OFFSET1

(x2,y2)

SLOPE3

(x1,y1)

64

SLOPE2

SLOPE1

X1 X2 X3

Figure 13. 13-to-10 bit compander

(x3,y3)

SLOPE4

8191

CODE_IN

DOUT<9:0>

Figure 14. CS7620 output data and clocks

DS301PP2 15

CS7620

DAC outputs (these may be powered down through

register control if they are not being used). The second signal is the EXPOSE signal. This signal

should go high at the beginning of exposure and

low at the beginning of readout. The suggested timing of these signals is shown in Figure 16. Note that

the chip must power up at least 500 µs before readout begins. The LINE_ENA and CLAMP pins are

not used in this mode.

3.4.2 Horizontal Only Timing Mode

To select this mode, the user must set the

BYPASS_PLL pin low and select external timing

mode in the timing mode register. The CS7620 is

the master of the pixel rate timing, but the line and

frame timing is controlled externall y. In this mode,

the user must control four signals- PWR_DN, EX-

POSE, LINE_ENA, and CLAMP. The master

PWR_DN signal may be used to conserve power

during non-readout time. The EXPOSE pin is redefined as the non-readout signal. When high, the

H1-H4 and RG signals are set in their idle state

(low for H1-H4, high for RG). The LINE-ENA pin

should be high during the vertical shift and load periods. This will hold the H1-H4 signals in their

user-programmable default states. The CLAMP

pin should be high when over dark reference

(black) pixels. The suggested timing for these signals is shown in Figure 17. Note that the chip

should power up at least 500 µ s before the beginning of readout. The CLAMP signal may also be

high during the dark pixel lines at the beginning of

the frame.

SYSTEM_CLK

CLKO (DATA_VALID)

DOUT<9:0>

T

EXP

>500 µs

Figure 15. CS7620 output data and clocks

POWERDOWN SIGNAL

EXPOSE SIGNAL

T

READOUT

T

FRAME

Figure 16. Picture Signal Timing

WARNING: NOTE: It is reco mmended to keep the par t in power down mode while not in use to reduce power

16 DS301PP2

CS7620

3.4.3 Slave mode

To select this mode, the user must set the

BYPASS_PLL pin high and select external timing

mode in the timing register. The CS7620 timing is

now slaved off of an external source and supplied

with sampling clocks for feedthrough and data. In

this mode, the user must control five signalsPWR_DN, EXPOSE, CLAMP, CK_FT

(CLOCK_IN), and CK_DT (LINE_ENA). The

master PWR_DN signal may be used to conserve

power during non-readout time. The EXPOSE pin

is redefined as the non-readout signal. Using the

falling edge of this signal, the chip will delay its

RD_OUT pin output by the appropriate amount as

determined by the chip latency so that it will go active at the correct point in the data stream. CLAMP

should be high when over the dark reference pixels.

The CLOCK_IN and LINE_ENA pins are rede-

fined as the CK_FT and CK_DT signals, which

sample the feedthrough and data levels, respectively. The suggested timing for PWR_DN, EXPOSE,

and CLAMP is the same as shown previously in

Figures 16 and 17. The timing for CK_FT

(CLOCK-IN) and CK_DT (LINE-ENA) is shown

in Figure 18.

3.4.4 Horizontal Timing Generator

During every horizontal line period the data from

the horizontal shift register is shifted out on the

CCD output pin one pixel at a t ime. The analog timing generator creates the required driving signals to

control the CCD horizontal timing as well as the

analog sampling signals. The timing signals involved in this operation are H1, H2, H3, H4 and

RG. The exact timing of these signals can be con-

V SHIFT

& LOAD

CCD

INPUT

SIGNAL

CK_FT

CK_DT

CLAMP

LINE_ENA SIGNAL

EXTENDED

PIXELS

Figure 17. Signal Timing for Horizontal Only Mode

DARK

PIXELS

T

LINE

SIGNAL

ACTIVE

PIXELS

ACTIVE

PIXELS

V SHIFT

& LOAD

T

LINE+1

Figure 18. Signal Timing for Slave Mode

DS301PP2 17

Ideal

CCD Signal

CS7620

internal

sampling

clocks

Figure 19. Detailed Signal Timing Showing Internal Clock Phases

CK_FT

CK_DT

Ideal

CCD Signal

H1

H2

default

settings

H3

H4

RG

t0t4 t5 t6 t7 t0t3 t4 t5 t6 t7t1 t2 t3t1 t2

Figure 20. Default Timing of Horizontal Signals to the CCD

trolled through the serial interface as described below.

The pixel period is broken down into 8 equal time

periods. By delaying the clock a given number of

these time periods, different phases are created.

This is shown in Figure 19. These clock phases are

labeled t0-t7 and are shown relative to an idealized

CCD signal and the internal sampling signals.

Using these eight clock phases, the user may set the

rising and falling edges of each horizontal pixel

clock at 1/8 of a pixel clock period. In addition, t he

18 DS301PP2

user may set each horizontal signal to a default

state when the output lines are to be held constant

during blanking. The default timing for the horizontal signals is shown in Figure 20 and Table 2.

See the register listing for more details.

Signal Rising edge Falling edge Hold level

H1 t0 t5 high (‘1’)

H2 t2 t7 high (‘1’)

H3 t4 t1 high (‘1’)

H4 t6 t3 low (‘0’)

Table 2. Default Phases for Horizontal Signal Edges

CS7620

3.4.5 Vertical Timing Generator

The signals involved in the vertical timing generator are the vertical shift clocks V1 through V4 and

the storage clocks S1 through S4. The vertical timing generator generates the signals needed by the

CCD to shift charge vertically down into the horizontal shift register. The chip is the timing master,

and it generates the signals needed by the horizontal timing generator and other modules to operate.

The timing generator is controlled externally by

various signals; the falling edge of the input signal

EXPOSE sets the part into readout mode, and after

this edge, it generates the timing signals to output a

full frame, provided that RST and PWR_DN are

not active.

The mode register selects the CCD timing, and the

resolution mode to be generated. Please refer to

IBM-CCD datasheet for more info.

Mode value Mode

000 IBM35CCD2PIX1 and IBM35CCDPIX13

CCD high resolution mode

001 IBM35CCD2PIX1 CCD low resolution

(viewfinder) mode

010-100 reserved

101 IBM35CCD13PIX CCD (2x2) low resolu-

tion (viewfinder) mode

110 IBM35CCD13PIX CCD (3x4) low resolu-

tion (viewfinder) mode

111 external timing used

Table 3. Different Resolution Operating Modes

The timing module’s functionality can be configured through the use of registers. Note that before

entering a preview mode, all of the programmable

parameters must be set prior to this.

Shiftl_num is the number of lines in the shift buffer.

Tdv is the length of the minimum vertical timing

interval measured in pixel clocks.

Num_pixels is the number of pixels per line

V_polarity allows to switch the polarity of all the

vertical timing signals going to the CCD.

Blk_begin is the first black pixel in a line

Blk_end is the last black pixel in a line

Drk_rws_fst is the number of black lines to be

readout at the beginning of the frame

Drk_rws_lst is the number of black lines to be

readout at the end of the frame

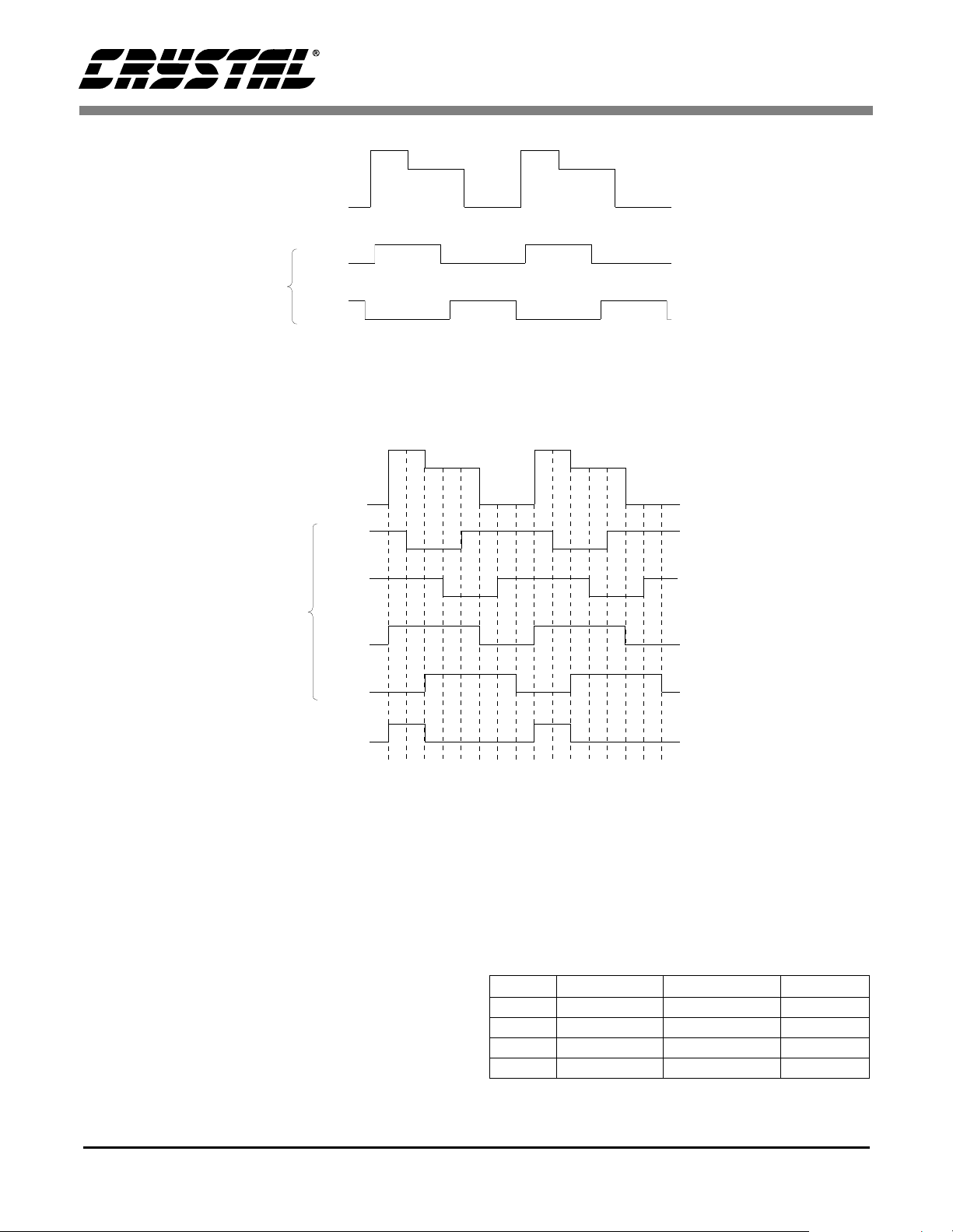

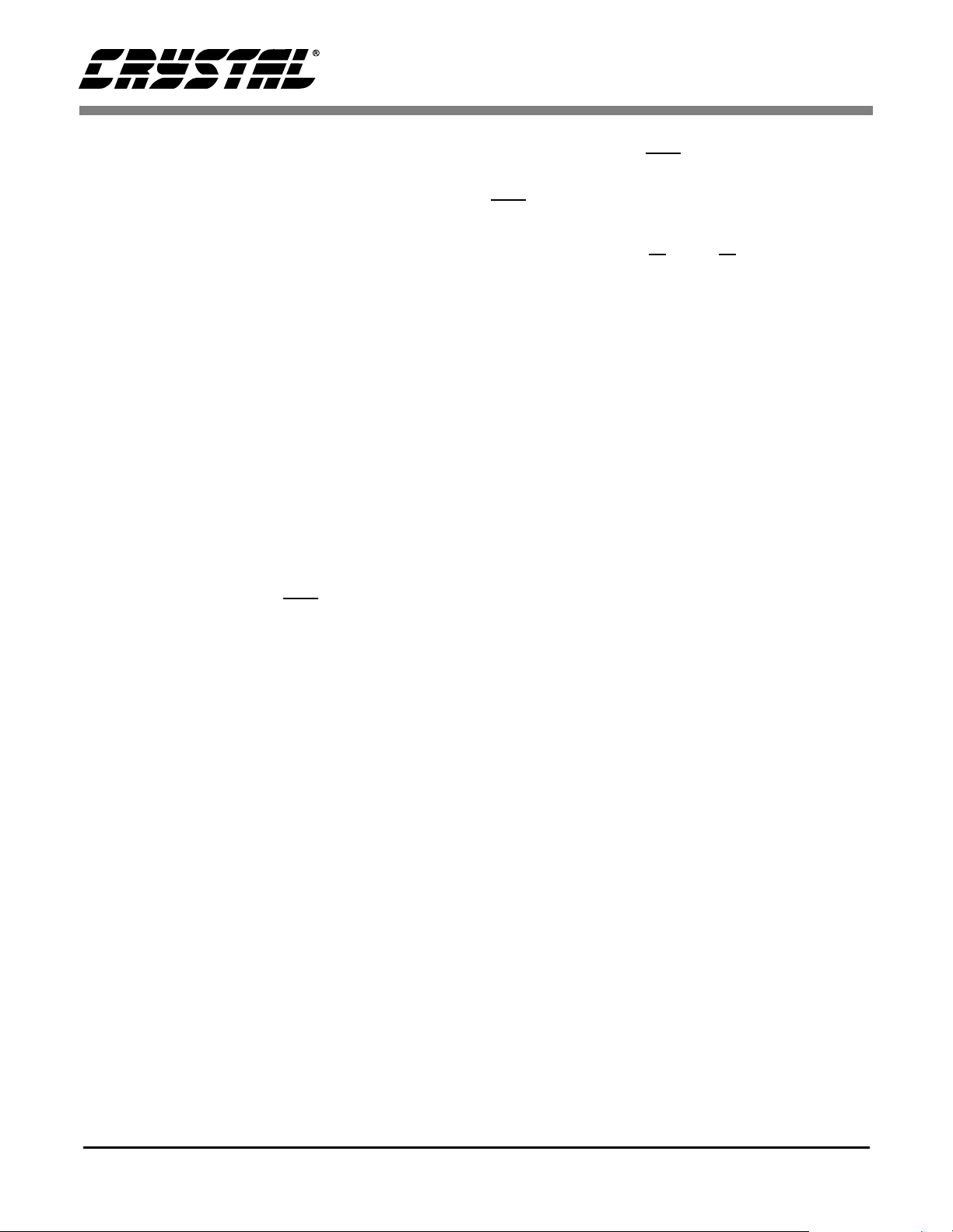

3.4.6 Frame Timing

Figures 21 and 22 illustrates the frame timing for

the low and high resolution modes.

HSYNC is high during the active pixel area, and it

is low during vertical shift (horizontal and vertical

blanking periods).

RD_OUT is triggered by the falling edge of expose, it is delayed by the chip latency, and it

switches back high once the last pixel has been read

out of the CS7620. RD_OUT is low during the active pixel areas and during the horizontal blanking

periods (vertical line shifts) and it goes high during

the vertical blanking period, between frames.

The dotted lines in Figures 21 and 22 correspond to

the vsync option which can be enabled by writing a

one to register vsync_md (register 25h bit 5). This

causes the RD_OUT signal to behave like a verti cal

sync signal. It makes the signals HSYNC and

RD_OUT the same length at the beginning of a

new frame (see Figures 21 and 22).

3.5 Frequency Synthesizer

Since multiple clock phases and timing are required for the pixel rate clocks controlling the CCD

imager, the clock generator contains a PLL circuit

to generate the proper timing. “Frequency Synthesizer Parameters” on page 6 shows the requirements for this PLL. The frequency of the input

clock may be set from 1 to 20X the pixel clk frequency, in integer mult iples. The freq uency us ed is

Num_lines is the number of lines per frame.

DS301PP2 19

CS7620

register programmable in terms of multiples of the

pixel clock rate.

3.6 8-Bit General Purpose DACs

Two 8-bit current-output DACs are available for

external use. Table 4 shows the output specifications of these DACs.

3.7 Stand By Mode

Stand-by mode can be entered using the PWR_DN

pin. All circuitry on chip including the DACs can

Expose

vsync_md = 1vsync_md = 0

RD_OUT

HSYNC

Parameter High impedance

mode

Iout 2.155 mA 8.7 mA

loading 464

Table 4. General Purpose DAC specifications

Ω

Low impedance

mode

Ω

115

be powered down. Various functional blocks can

be powered down individually, and are controlled

through registers. Note that the DACs can be powered down in that way if not in use. During Stand

By mode, the register contents are maintained and

V1 ... V4

S1 ... S4

H1 ... H4

Expose

RD_OUT

HSYNC

V1 ... V4

S1 ... S4

H1 ... H4

262 lines

don’t care

first read-out line last read-out line

Figure 21. High Resolution Mode

vsync_md = 0

vsync_md = 1

262 lines

262 lines

first read-out line last read-out line

first read-out line

picture n picture n picture (n+1)

Figure 22. Low Resolution Mode

20 DS301PP2

CS7620

do not have to be reprogrammed at the next power

up.

3.8 Preview Mode

It is strongly recommend that the chip should be

kept in Stand By mode when not in use in order to

save power. When in preview mode, a user may

wish to cut down the resolution of the ADC output

to 6 bits in order to reduce the power consumption

of the CS7620. In this mode, the current is reduced

by 20 mA. With the DRX (Dynamic Range eXtension) circuitry, 3 bits of dynamic range are added to

the 6-bit ADC output producing a 9-bit output. The

pins DOUT[12:4] are used to output the digitized

data in preview or Stand By mode.

3.9 Serial Interface

The serial interface is designed to allow high speed

input to control the chip’s registers. The specifications on this interface are as follows:

Asserting the enable pin, SEN, enables the serial

interface to perform data transfers. Data present on

the SDATI pin is latched into the CS7620 on each

rising edge of the serial clock, SCLK. Data output

on SDATO from the CS7620 is clocked out on the

rising edge of SCLK.

The CS7620 receives only the first 16 rising edges

of the SC LK while SEN is low and then ignores

any remaining SCLK and SDATI information. If

SEN goes high before 16 SCLK pulses have been

received, the CS7620 aborts the serial transfer.

The first bit is the R/W bit. R/W = 1 identifies the

transfer as a read. If (0), the transfer is a write. The

next seven bits define the address. For write transfers, the second byte of the 16-bit packet contains

the data byte. For read transfers, the CS7620 outputs the read data on SDATO after accepting the

address. Address and data are transferred MSB

first. When not reading out data, the SDATO pin is

not driven by the chip (Hi-Z state).

The timing diagrams and specifications are shown

in “Serial Interface Timing Specifications” on

page 7 and Figures “SEN Timing”, “Read Data

Timing”, and “Serial Write Timing” on page 7.

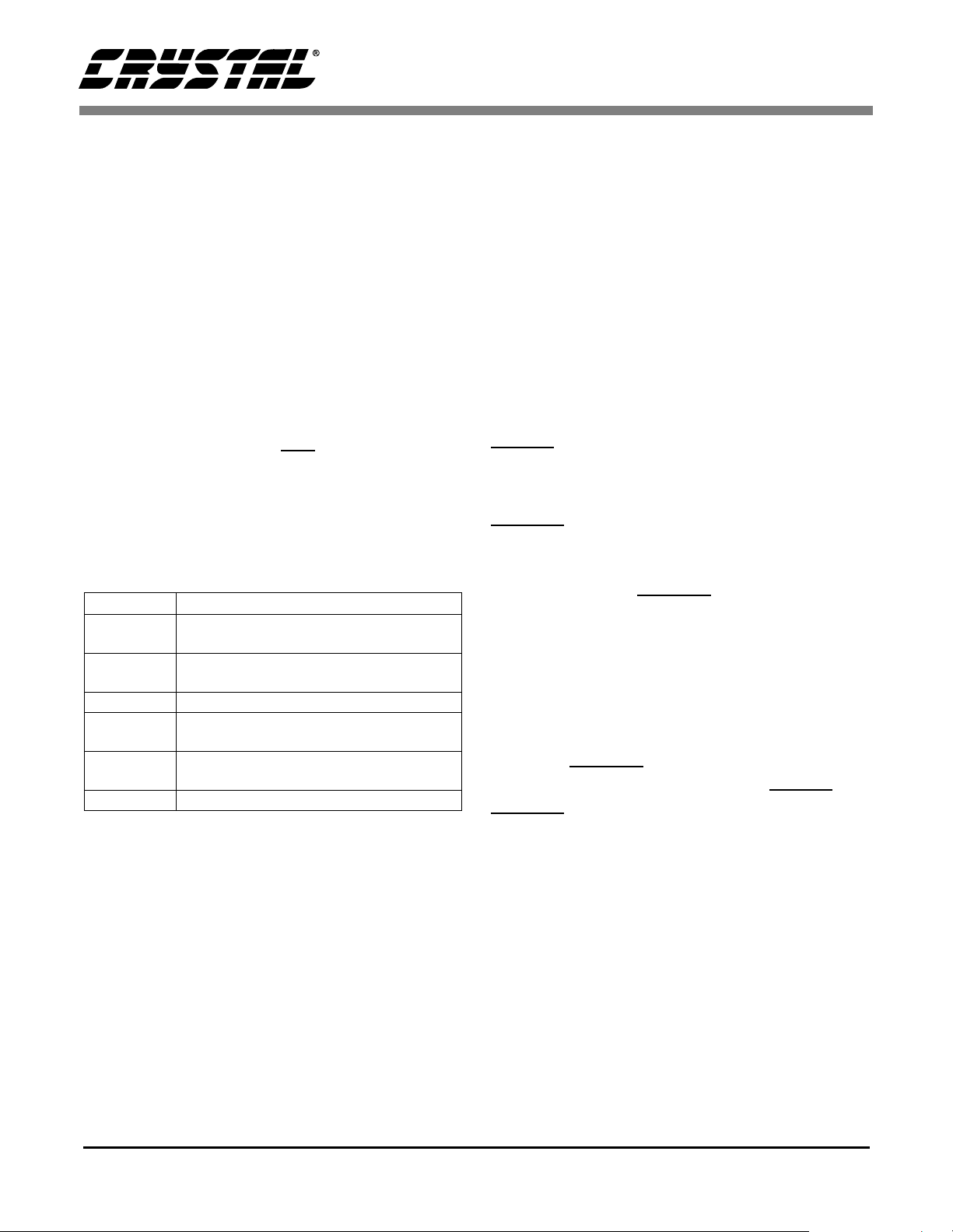

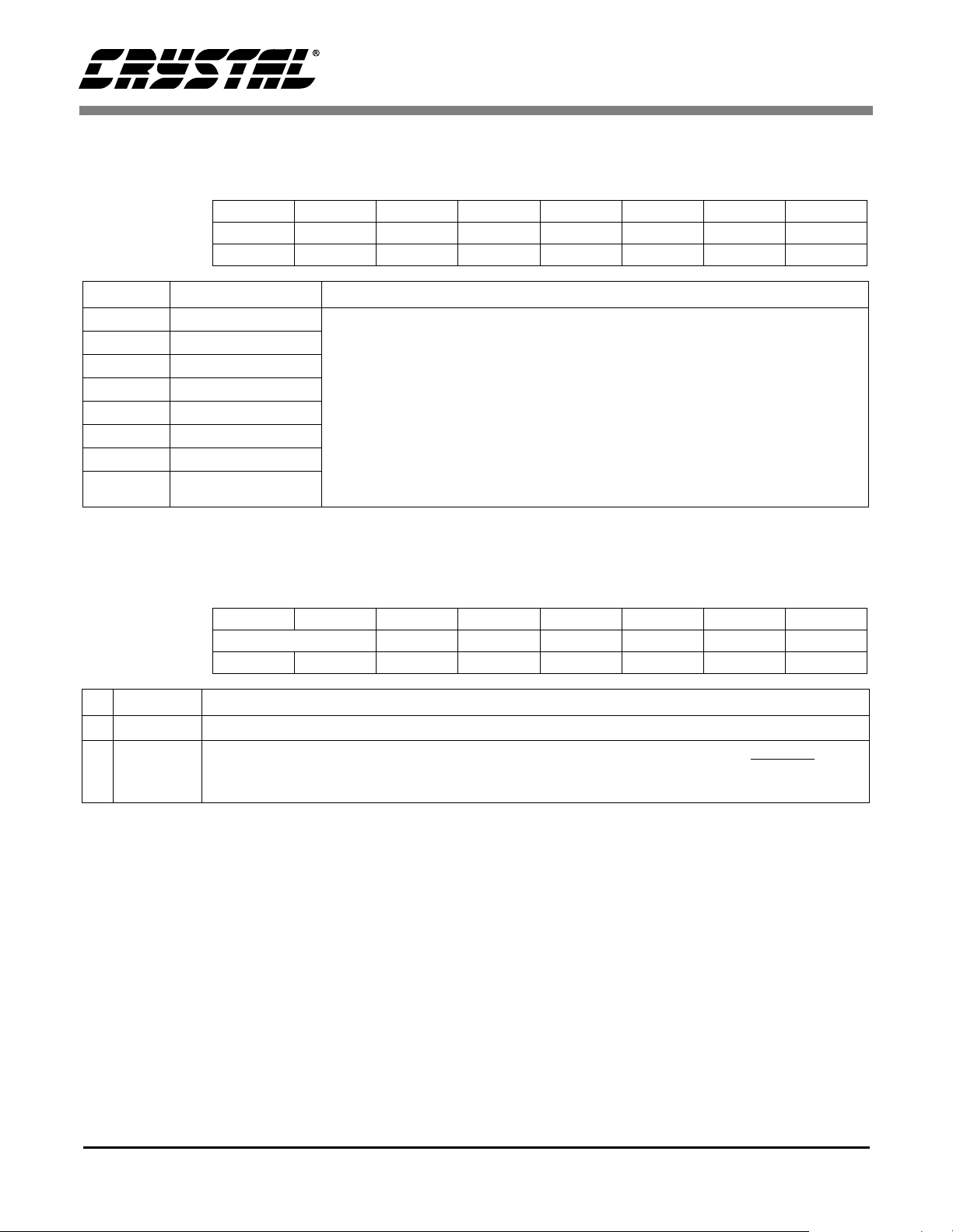

3.10 Recommended Register Settings

These are the values that need to be written to the

registers to change the configuration of the CS7620

to work with each CCD in either low resolution or

high resolution mode. (2 × 2) refers to a RGRGRG

pattern and (3 × 4) refers to a RGBRGB pattern

CCD.

DS301PP2 21

CS7620

2.0M pixel (default)

high resolution

tim_modes(06h) 000b 001b 001b

num_lines[12:8](17 h ) 05h 05h 05h

num_lines[7:0](18h ) 1Ch 1Ch 1Ch

num_pixels[12: 8]( 19h ) 06h 06h 06h

num_pixels[7:0](1Ah) 93h 93h 93h

drk_rws (frst/lst)(1Bh) A4h 20h 20h

blk_begin(1Ch) 04h 04h 04h

blk_end(1Dh) 3Fh 3Fh 3Fh

act_rws (frst/lst)(1Eh) B6h 32h 32h

act_begin(1Fh) 4Bh 4Bh 4Bh

tdv(20h) 01h 01h 01h

shiftl_num[8](21h) 01h 01h 01h

shiftl_num[7:0](22h) 06h 06h 06h

lowres_sen[3:0](25h) XXXXb 0000b

Table 5. IBM35CCD2PIX1

1.3M pixel

high resolution

tim_modes(06h) 000b 101b 110b

num_lines[12:8](17 h ) 04h 04h 04h

num_lines[7:0](18h ) 1Ch 1Ch 1Ch

num_pixels[12: 8]( 19h ) 05h 05h 05h

num_pixels[7:0](1Ah) 50h 50h 50h

drk_rws (frst/lst)(1Bh) A4h 20h 20h

blk_begin(1Ch) 04h 04h 04h

blk_end(1Dh) 3Fh 3Fh 3Fh

act_rws (frst/lst)(1Eh) B6h 42h 42h

act_begin(1Fh) 4Bh 4Bh 4Bh

tdv(20h) 01h 01h 01h

shiftl_num[8](21h) 01h 01h 01h

shiftl_num[7:0](22h) 06h 06h 06h

lowres_sen[3:0](25h) XXXXb 0000b

Table 6. IBM35CCD13PIX

2.0M pixel (2x2)

low resolution

0100b 2x sens

0001b 2x sens

0101b 3x sens

1.3M pixel (2x2)

low resolution

0100b 2x sens

2.0M pixel (3x4)

low resolution

0000b

0010b 2x sens

1.3M pixel (3x4)

low resolution

0000b

0010b 2x sens

22 DS301PP2

Microcontroller

VCC

CLK_IN

RESET

from

NC

NC

43

XTAL_IN

39

BYPASS_PLL

38

RST

29

DIAG0

30

DIAG1

17

SCAN_MODE

16

TEST

3

LINE_ENA

2

CLAMP

15

POWER_DOWN

14

EXPOSE

6

SCLK

7

SDATI

8

SDATO

9

SEN

5 11253240

VAA

DOUT[0:12]

RD_OUT

REF_CAPP

REF_CAPN

BG_RES

DAC_OUT1

CS7620

CLKO

HSYNC

V[1:4]

S[1:4]

H[1:4]

RG

13

52

12

13

37

28

27

21

18

4

4

4

464

Vertical

Drivers

1 µF

10 kΩ ±1%

Ω

10 k

1000 pF

Ω

to Microcontroller

to CCD

to CCD

Ω

60.4 k

CS7620

to CCD

Ω

100 k

from

CCD

23

AIN

DAC_OUT2

GND

4 10243141

19

464

10 k

Ω

Ω

60.4 k

Substrate

Voltage

to CCD

Ω

Figure 23. Typical Connection Diagram Using Vertical and Horizontal Timing Mode

DS301PP2 23

VCC

CLK_IN

RESET

from

Microcontroller

NC

NC

43

XTAL_IN

39

BYPASS_PLL

38

RST

29

DIAG0

30

DIAG1

17

SCAN_MODE

16

TEST

3

LINE_ENA

2

CLAMP

15

POWER_DOWN

14

EXPOSE

6

SCLK

7

SDATI

8

SDATO

9

SEN

5 11253240

VAA

DOUT[0:12]

RD_OUT

REF_CAPP

REF_CAPN

BG_RES

DAC_OUT1

CS7620

CLKO

HSYNC

V[1:4]

S[1:4]

H[1:4]

RG

13

52

13

12

4

4

4

37

28

27

21

18

NC

NC

NC

1 µF

10 kΩ ±1%

Ω

464

10 k

1000 pF

Ω

to Microcontroller

to CCD

Ω

60.4 k

CS7620

to CCD

Ω

100 k

from

CCD

23

AIN

DAC_OUT2

GND

4 10243141

19

464

10 k

Ω

Ω

60.4 k

Substrate

Voltage

to CCD

Ω

Figure 24. Typical Connection Diagram Using Horizontal Only Timing Mode

24 DS301PP2

VCC

Sampling

Signals

VDD

RESET

from

Microcontroller

CK_FT

CK_DT

NC

NC

43

XTAL_IN

3

LINE_ENA

39

BYPASS_PLL

38

RST

29

DIAG0

30

DIAG1

17

SCAN_MODE

16

TEST

2

CLAMP

15

POWER_DOWN

14

EXPOSE

6

SCLK

7

SDATI

8

SDATO

9

SEN

5 11253240

VAA

DOUT[0:12]

RD_OUT

REF_CAPP

REF_CAPN

BG_RES

DAC_OUT1

CS7620

CLKO

HSYNC

V[1:4]

S[1:4]

H[1:4]

RG

13

52

13

12

37

28

27

21

18

NC

4

NC

NC

4

NC

4

NC

1 µF

464

10 kΩ ±1%

10 k

Ω

CS7620

to Microcontroller

Ω

Ω

60.4 k

to RG bias

circuitry

from

CCD

23

AIN

DAC_OUT2

GND

4 10243141

19

464

10 k

Ω

Ω

60.4 k

Substrate

Voltage

to CCD

Ω

Figure 25. Typical Connection Diagram Using Slave Mode

DS301PP2 25

CS7620

4 REGISTER DESCRIPTIONS

Register (hex) Register Function Access Default value (hex)

00h Software Reset W 00

01h Power Down Control 1 R/W 00h

02h Power Down Control 2 R/W 00

03h-05h Reserved

06h Operation Control 1 R/W 09h

07h Operation Control 2 R/W 04h

08h-0Ch Reserved

0Dh Black Level Control - Accumulator (LSB) R/W 00h

0Eh Black Level Control - Accumulator (MSB) R/W 01h

0Fh Black Level Control - Loop Gain, Clamp Length R/W 0Ah

10h Gain Calibration - Offset 1 R/W 00h

11h Gain Calibration - Offset 2 R/W 00h

12h Gain Calibration - Offset 3 R/W 00h

13h-15h Reserved

16h Gain Calibration - Fixed Gains R/W 00h

17h Timing Control - Number of Lines (MSB’s) R/W 05h

18h Timing Control - Number of Lines (LSB’s) R/W 1Ch

19h Timing Control - Number of Columns (MSB’s) R/W 06h

1Ah Timing Control - Number of Columns (LSB’s) R/W 93h

1Bh Timing Control - Number of Dark Rows R/W A4h

1Ch Timing Control - Start of Black Pixel s R/W 04h

1Dh Timing Control - End of Black Pixels R/W 3Fh

1Eh Timing Control - Number of Rows Until Active R/W C6h

1Fh Timing Control - Start of Active Pixels R/W 4Bh

20h Timing Control - Vertical Time Division R/W 01h

21h Timing Control - Lines in Storage Buffer (MSB) R/W 01h

22h Timing Control - Lines in Storage Buffer (LSB’s) R/W 06h

23h Timing Control - Extra Lines of Exposure in Low Resolution

Mode (MSB’s)

24h Timing Control - Extra Lines of Exposure in Low Resolution

Mode (LSB’s)

25h Timing Control - Vsync Mode, Low Res Sensitivity, Lines of

Exposure in Low Res Mode (MSB)

26h Timing Control - Lines of Exposu re in Low Res Mode (LSB) R/W 06h

27h Reserved

28h Timing Control - Polarity of vertical shift outputs R/W FFh

29h Horizontal Timing Control - H1 R/W 68h

2Ah Horiz ontal Timing Control - H2 R/W 7Ah

2Bh Horiz ontal Timing Control - H3 R/W 4Ch

2Ch Horizontal Timing Control - H4 R/W 1Eh

2Dh Horizontal Timing Control - Analog Delays R/W 00h

2Eh Compander - Black slope, Slopes (MSBs) R/W 00h

2Fh Compander - Slope1 (LSBs) R/W A8h

30h Compande - Slope2 (LSBs) R/W 60h

31h Compander - Slope3 (LSBs) R/W 20h

Table 7. Register Description

R/W 00h

R/W 00h

R/W 01h

26 DS301PP2

CS7620

Register (hex) Register Function Access Default value (hex)

32h Compander - Slope4 (LSBs) R/W 07h

33h Compander - Offs et1 R/W 08h

34h Compander - Offsets (MSBs) R/W 0Bh

35h Compander - Offset2 (LSBs) R/W BFh

36h Compander - Offset3 (LSBs) R/W 05h

37h Compander - Offset4 (LSBs) R/W 20h

38h Compander - X1 (MSBs) R/W 03h

39h Compander - X1 (LSBs) R/W 20h

3Ah Compander - X2 (MSBs) R/W 05h

3Bh Compander - X2 (LSBs) R/W 18h

3Ch Compander - X3 (MSBs) R/W 0Bh

3Dh Compander - X3 (LSBs) R/W 58h

3Eh Power_up Counter R/W 7Dh

3Fh Valid_data/Dout edge/Clock_in divider R/W 01h

40h DAC #1 Control R/W 00h

41h DAC #2 Control R/W 00h

42h-7Dh Reserved

7Eh Device ID R ECh

7Fh Rev Code R 02h

Table 7. Register Description (Continued)

DS301PP2 27

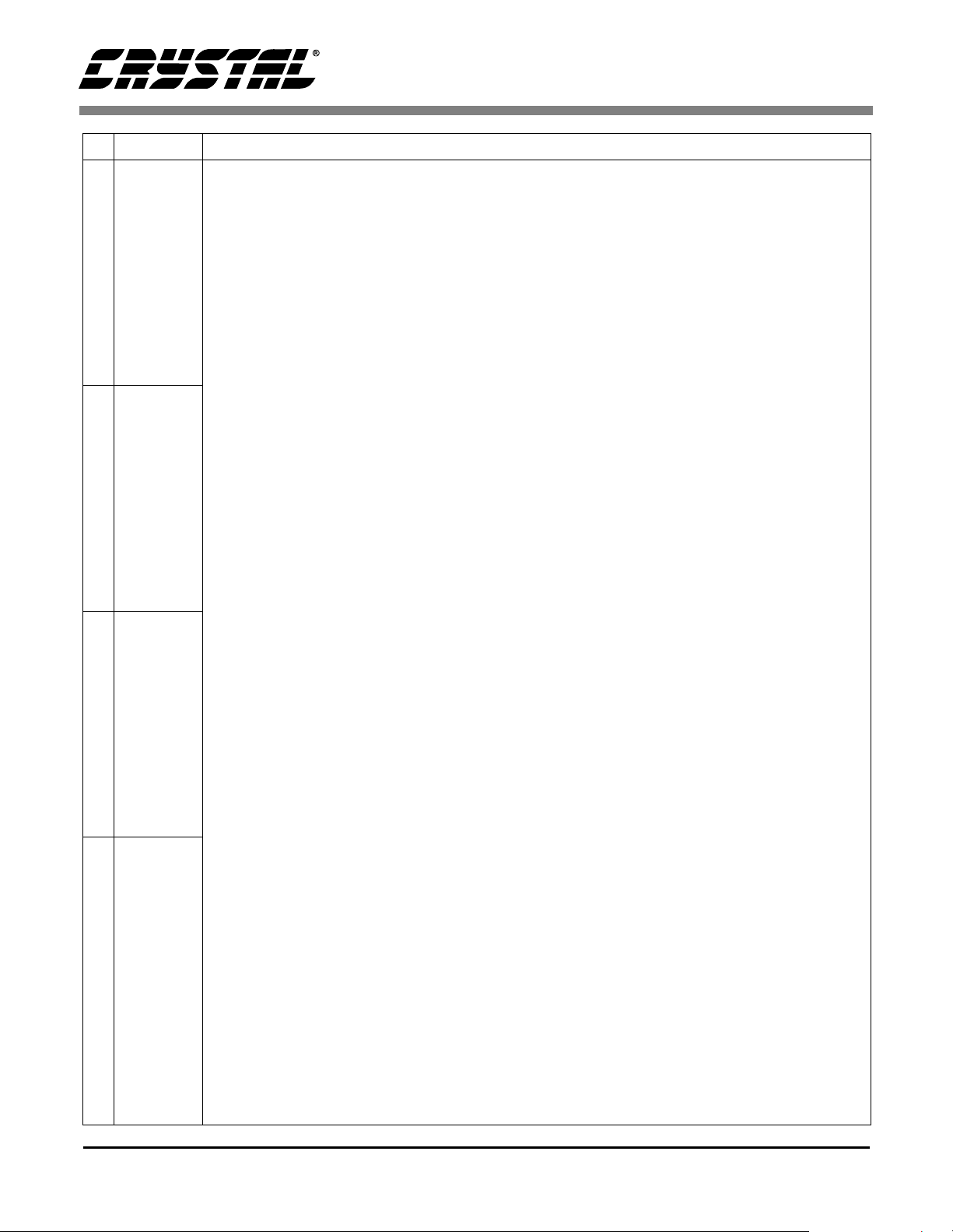

4.1 Reset

Default = 00; Write (address 00h)

CS7620

Bit Number

Bit Name

Default

76543210

Reserved sft_rst

-------00

Bit Mnemonic Function

7:1 -

Reserved

Software Reset: When this bit is written with a ‘1’, all of the digital circuitry

0sft_rst

and the registers will reset to their default values. It automatically clears after

4 pixel clock periods. The clocks remain running during the reset period.

4.2 Power Down Control 1

Default = 00h; Read/Write (address 01h)

Bit Number

Bit Name

Default

Bit Mnemonic Function

7 pd_vga

6 pd_adc

5pd_ref

4:3 -

2 pd_dac1

1 pd_dac2

0-

76543210

pd_vga pd_adc pd_ref Reserved pd_dac1 pd_dac2 Reserved

000- -00-

DRX Front End Power Down: When written with a ‘1’, the DRX front end

circuitry powers down. Used for test purposes only.

ADC Power Down: When written with a ‘1’, the Analog-to-Digital converter

circuitry powers down. Used for test purposes only.

Voltage Reference Power Down: When written with a ‘1’, the voltage reference generator powers down. Used for test purposes only.

Reserved

DAC #1 Power Down: When written with a ‘1’, DAC #1 powers down. Should

be powered down when DAC#1 is not being used by the system.

DAC #2 Power Down: When written with a ‘1’, DAC #2 powers down. Should

be powered down when DAC#2 is not being used by the system.

Reserved

28 DS301PP2

4.3 Power Down Control 2

Default = 00; Read/Write (address 02h)

CS7620

Bit Number

Bit Name

Default

76543210

Reserved pd_htim Reserved

------0-

Bit Mnemonic Function

7:2 -

Reserved

Horizontal Timing Power Down: When written with a ‘1’, the horizontal tim-

1 pd_htim

ing generator powers down. Should be powered down when horizontal timing

is not being used by the system. In this mode the chip is a “timing slave.”

0-

Reserved

4.4 Operation Control 1

Default = 09h; Read/Write (address 06h).

Bit Number

Bit Name

Default

Bit Mnemonic Function

7 low_res

6 tim_modes2

5 tim_modes1

4 tim_modes0

76 5 4 3210

low_res tim_modes2 tim_modes1 tim_modes0 bits_out1 bits_out1 blk_dis of f_range

00 0 0 1001

Low Resolution Mode: This mode can be used to cut the current consumption of the chip by 20 mA. The output of the ADC will have 6 bits of resolution

in this mode, and the output of the chip will have 9 bits after using the DRX

circuitry. It is intended to be used when driving an LCD display or any other

time when a lower resolution picture is acceptable.

Timing Generator Select: The type of timing signals output by the chip can

be selected using these control bits. IBM35CCDPIX13 2x2 and

IBM35CCDPIX13 3x4 modes, support type IBM CCDs with different color filter

patterns. Note that register 1Bh needs to be rewritten with correct low resolution values for black rows if low resolution mode is used (see Table 3).

The chip’s default power up setting is hardcoded to be IBM35CCD2PIX1. So

that the registers that hold the number of lines, the number of pixels per line,

the number of black lines, and the number of active lines are all set up to their

proper values. If IBM35CCDPIX13 is to be used, the values on all those registers has to be changed appropriately (see Tables 5 and 6).

DS301PP2 29

Bit Mnemonic Function

Number of Data Bits Out: The range of the output data can be determined

by these bits. The data internal to the chip has a 13-bit range. The output can

3 bits_out1

be this full range, half this range (12 bits), or an eighth of this range (10 bits).

If 12-bit data is selected, the top half of the 13-bit range is saturated to the

maximum 12-bit code. If 10-bit data is selected, the compander curve which

is user programmable is employed to map the 13-bit data to the 10-bit output.

CS7620

2 bits_ou t1

Black Level Loop Disabled: If the user chooses to adjust the black level him-

self through register access, he may disable the internal black level loop. This

loop usually updates the black level to what it calculates to be the correct level.

1 blk_dis

0 off_range

Mode value Mode

000 IBM35CCD2PIX1 and IBM35CCDPIX13 CCD high resolution mode

001 IBM35CCD2PIX1 CCD low resolution (viewfinder) mode

010 reserved

100 reserved

101 IBM35CCD13PIX CCD (2x2) low resolution (viewfinder) mode

110 IBM35CCD13PIX CCD (3x4) low resolution (viewfinder) mode

111 external timing used

If disabled, the offset used will be determined from the value written in the

black level accumulator register.

0 - internal black level loop is enabled

1 - black level loop is disabled

Offset Range: The black level loop is used to cancel any offsets from the

CCD and chip circuitry. If the offsets are small, the user has the option to decrease the offset cancellation range for the added advantage of increasing the

resolution of the offset cancellation.

0 - smaller offset cancellation range used (~50 mV)

1 - larger offset cancellation range used (~100 mV)

Table 8. Different Resolution Operating Modes

0 - 10 bits output

1 - 10 bits output

2 - 13 bits output

3 - 12 bits output

30 DS301PP2

4.5 Operation Control 2

Default = 04h; Read/Write (address 07h).

CS7620

Bit Number

Bit Name

76543210

pol_hsyncb pol_rd_outb dac2_mode dac1_mode fs_lvl1 fs_lvl0 gain_cal1 gain_cal2

Default 0 0 0 0 0 1 0 0

Bit Mnemonic Function

Hsync Polarity: The HSYNC signal output from the chip defaults to be high

when data is being shifted out of the CCD and low during all other times (the

vertical shift time of each line and idle times). This polarity may be swapped

7 pol_hsyncb

with this bit so that HSYNC

is low when data is being shifted out and high all

other times.

0 - HSYNC

1 - HSYNC

is high during horizontal data read out

is low during horizontal data read out

Rd_Out Polarity: The RD_OUT signal output from the chip defau lts to b e low

when the CCD data readout is being performed and high when not reading out

6 pol_rd_outb

data from the CCD. The polarity of this signal may be swapped with this bit so

that RD_OUT

is high during readout and low when not reading data out. Note

that when this bit is redefined in order to function as a vertical sync signal, this

bit will serve to swap its polarity as well.

Dac #2 Current Mode: There are two modes for the output current of DAC2.

Default mode provides a current range of 2.2 mA for the 8-bit input word. This

5 dac2_mode

will increment the current by ~8.6 µA per LSB code change. The high current

mode can be selected using this bit to change the current range to 8.7 mA for

the 8-bit input word. This will increment the current by ~34 µA per LSB code

change.

Dac #1 Current Mode: There are two modes for the output current of DAC1.

Default mode provides a current range of 2.2 mA for the 8-bit input word. This

4 dac1_mode

will increment the current by ~8.6 µA per LSB code change. The high current

mode can be selected using this bit to change the current range to 8.7 mA for

the 8-bit input word. This will increment the current by ~34 µA per LSB code

change.

3 fs_lvl1

2 fs_lvl0

Full Scale Level: This is used to set the full scale input range of the CS7620.

Since CCDs have various saturation levels, it is advantageous to set the full

scale input range of the CS7620 to match the saturation level of the CCD

used. Table 9 shows the full scale level choices

Gain Calibration #1: A calibration of the gain stages is required to insure a

monotonic digital output. In default (‘0’), this calibration is automatically done

1 gain_cal1

after a chip reset and after coming up from power down mode. If the recalibration after power down is not desired, this bit can be written with a ‘1’ to force

a calibration only after a chip reset.

Gain Calibration #2: A calibration of the gain stages is required to insure a

monotonic digital output. This calibration is transparent to the user. However,

0 gain_cal2

if the user wishes to force a calibration to occur, he may do so by setting this

bit to ‘1’, which will invoke a gain calibration sequence immediately. This bit

automatically clears itself after a calibration has been initiated.

DS301PP2 31

fs_lvl Full Scale Voltage

00 0.53 V

01 1.07 V

1X 1.60 V

Table 9. Full Scale Level Choices

4.6 Black Level Control - Accumulator (LSB)

Default = 00h; Read/Write (address 0Dh)

CS7620

Bit Number

Bit Name

76543210

accumulator7 accumulator6 accumulator5 accumulator4 accumulator3 accumulator2 accumulator1 accumulator0

Default 00000000

Bit Mnemonic Function

7 accumulator7

6 accumulator6

5 accumulator5

4 accumulator4

3 accumulator3

2 accumulator2

1 accumulator1

0 accumulator0

Black Level Accumulator: See Description of register 0Eh.

4.7 Black Level Control - Accumulator (MSB)